Friedrich WallMaster PX Series, WallMaster PE Series, WallMaster PH Series, WallMaster PH07K3SA1 Installation & Operation Manual

Page 1

WallMaster®PTAC

PackagedTerminalAirConditioners& Heat Pumps

• Standard

• RemoteThermostat

• SeacoastProtected

Installation& OperationManual

920-087-02 (9-03)

Page 2

920-087-02(9-03)

Tableof Contents

UnitComponents......................................................................................................................................................................................... 2

P-SeriesAnnouncement/ModelNumberCode............................................................................................................................................ 3

InstallationRecommendations.................................................................................................................................................................... 4

DrainKit Installation ................................................................................................................................................................................ 5-6

Wall SleeveInstallation............................................................................................................................................................................ 7-8

DeepWall Installation .................................................................................................................................................................................. 9

Standard GrilleInstallation ........................................................................................................................................................................ 10

InstallationChecklist................................................................................................................................................................................. 11

Electrical RatingTables.............................................................................................................................................................................. 11

ChassisInstallation............................................................................................................................................................................. 12-13

Standard UnitOperations.......................................................................................................................................................................... 14

TemperatureLimitingThermostat .............................................................................................................................................................. 14

HeatingControl(Heat Pumps& Emergency Heat)..................................................................................................................................... 15

FanCycleSwitch....................................................................................................................................................................................... 15

FreshAirVentControl................................................................................................................................................................................ 15

AirDischargeGrille.................................................................................................................................................................................... 16

Start-up Checklist...................................................................................................................................................................................... 16

AppendixA: RemoteThermostatWiring............................................................................................................................................... 17-18

AppendixB: ElectricalWiringfor 265 V Models........................................................................................................................................ 19

RoutineMaintenance................................................................................................................................................................................ 20

BasicTroubleshootingTechniques............................................................................................................................................................. 21

Accessories......................................................................................................................................................................................... 22-23

Warranty................................................................................................................................................................................................... 24

TypicalUnit Components

Chassis

tcover

2

Page 3

920-087-02 (9-03)

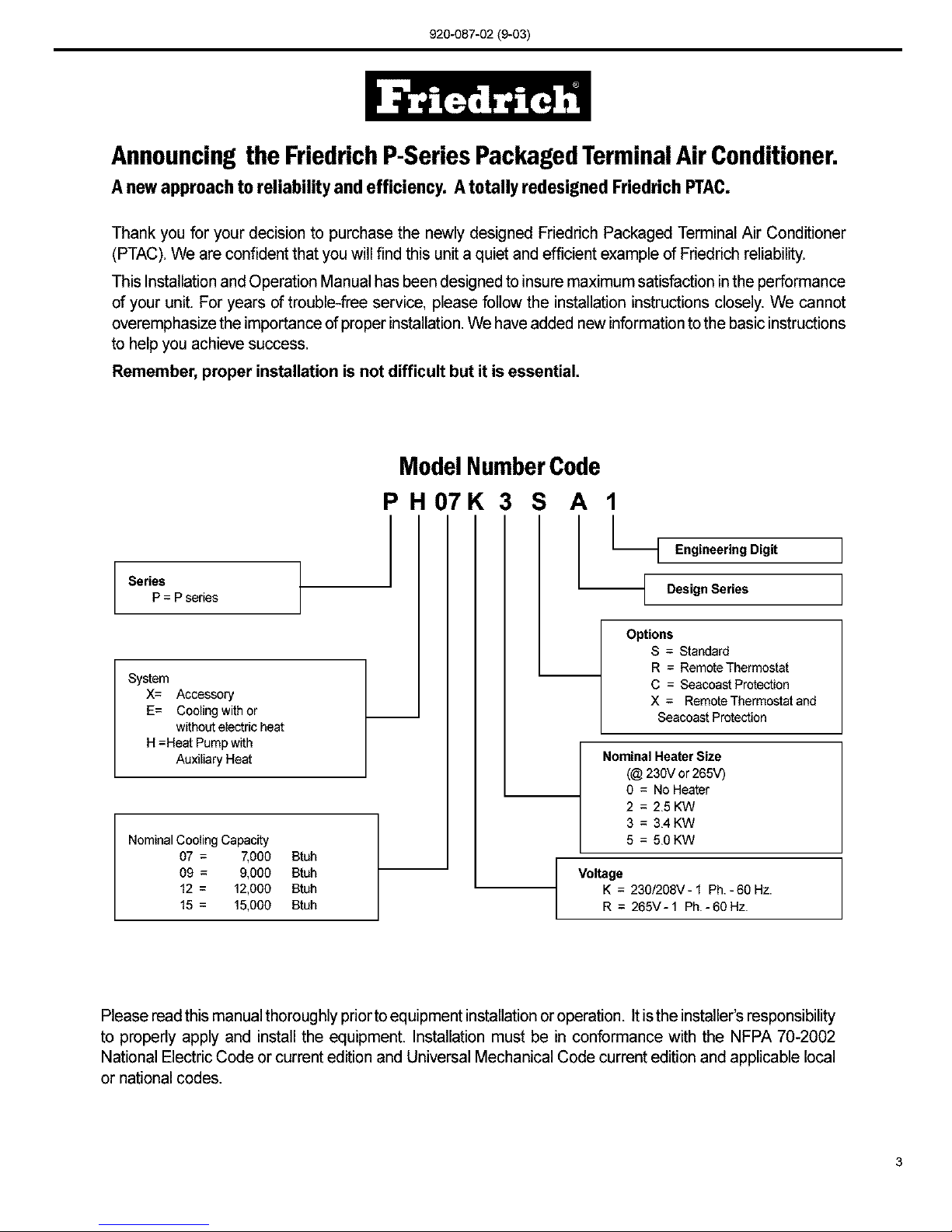

Announcing the FriedrichP-Series PackagedTerminalAir Conditioner.

A new approach to reliability and efficiency. A totally redesigned Friedrich PTAC.

Thank you for your decision to purchase the newly designed Friedrich Packaged Terminal Air Conditioner

(PTAC). We are confident that you will find this unit a quiet and efficient example of Friedrich reliability.

This Installation and Operation Manual has been designed to insure maximum satisfaction in the performance

of your unit. For years of trouble-free service, please follow the installation instructions closely. We cannot

overemphasize the importance of proper installation. We have added new information to the basic instructions

to help you achieve success.

Remember, proper installation is not difficult but it is essential.

Series

P= Pseries

System

X= Accessory

E= Coolingwith or

withoutelectric heat

H =Heat Pumpwith

Auxiliary Heat

NominalCoolingCapac_y

07 = _000 Btuh

09 = 9,000 Btuh

12 = 12,000 Btuh

15 = 15,000 Btuh

ModelNumberCode

PH07K 3 S A 1

L

I Engineering Digit I

I Designsedes I

Options

S = Standard

R = RemoteThermostat

C = SeacoastProtection

X = RemoteThermostatand

SeacoastProtection

NominalHeater Size

(@230Vor 265V)

0 = NoHeater

2 = 2.5 KW

3 = 3.4 KW

5 = 5.0 KW

Voltage

K = 230/208V-1Ph.-60 Hz.

R = 265V-1Ph.-60 Hz.

Please read this manual thoroughly prior to equipment installation or operation. It isthe installer's responsibility

to properly apply and install the equipment. Installation must be in conformance with the NFPA 70-2002

National Electric Code or current edition and Universal Mechanical Code current edition and applicable local

or national codes.

3

Page 4

920-087-02 (9-03)

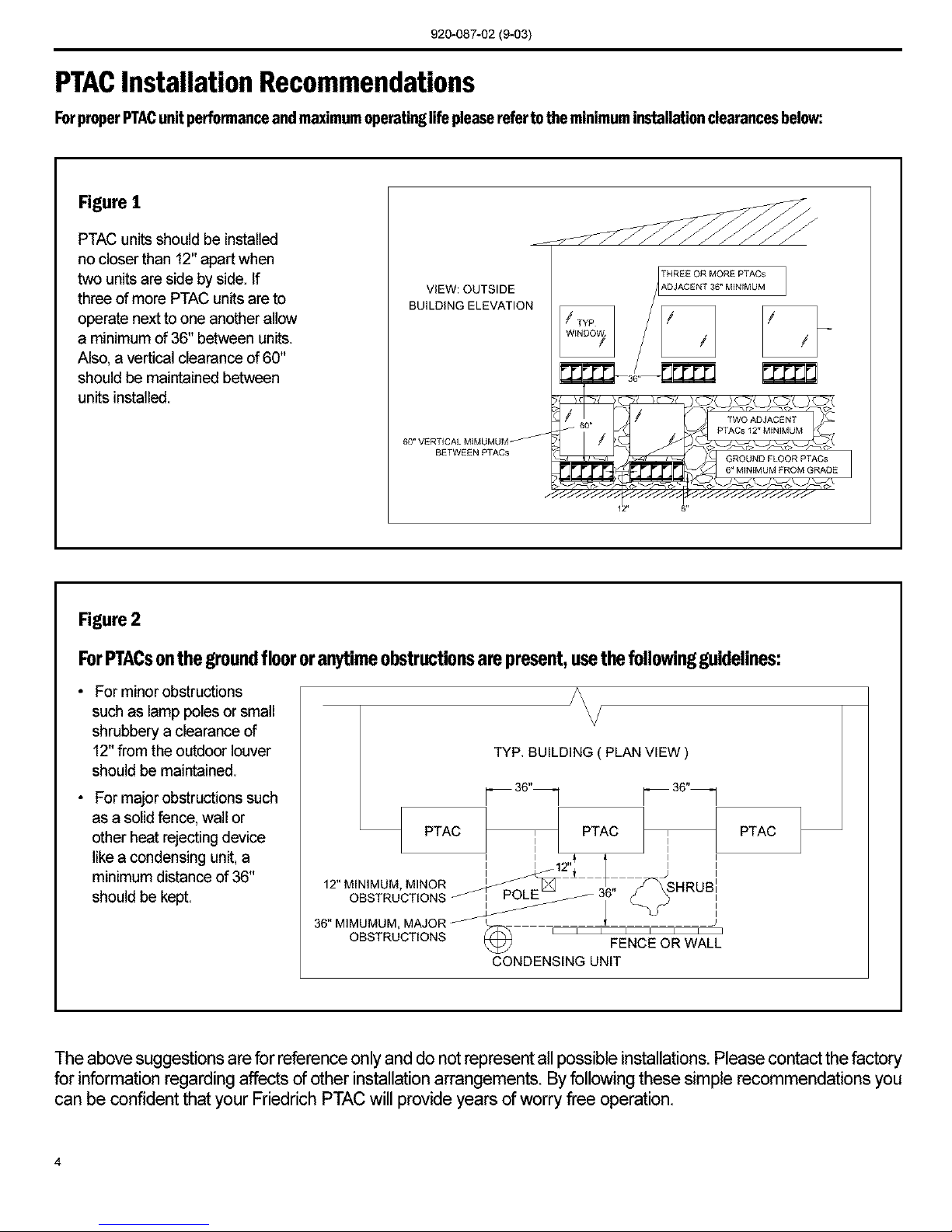

PTACInstallation Recommendations

ForproperPTACunit performanceandmaximumoperatinglifepleaserefertothe minimuminstallationclearancesbelow:

Figure I

PTAC units should be installed

no closer than 12" apart when

two units are side by side. If

three of more PTAC units are to

operate next to one another allow

a minimum of 36" between units.

Also, a vertical clearance of 60"

should be maintained between

units installed.

VIEW: OUTSIDE

BUILDING ELEVATION

60" VERTICAL M]MUMUM

BETWEEN PTACs

THREE OR MORE PTACs

#,DJACENT 36" MINIMUM

GROUND FLOOR PTACs

6" MINIMUM FROM GRADE

Figure 2

ForPTACsonthegroundfloororanytimeobstructionsarepresent,usethefollowingguidelines:

• For minor obstructions

such as lamp poles or small

shrubbery a clearance of

12"from the outdoor louver

should be maintained.

• For major obstructions such

as a solid fence, wall or

other heat rejecting device

like a condensing unit, a

minimum distance of 36"

should be kept.

TYP. BUILDING ( PLAN VIEW )

-- 36"_] [_ 36"--

PTAC 7 PTAC r

I I

I I

I I

I I

12" MINIMUM, MINOR

OBSTRUCTIONS _ 36"

36" MIMUMUM, MAJOR _

OBSTRUCTIONS _) ' ' ' FENCE OR WALL'

CONDENSING UNIT

PTAC

The above suggestions are for reference only and do not represent allpossible installations. Please contact the factory

for information regarding affects of other installation arrangements. By following these simple recommendations you

can be confident that your Friedrich PTAC will provide years of worry free operation.

4

Page 5

920-087-02(9-03)

Installation Instructions PXDRIODrain Kit

NOTE: Determine whetherdrain willbe located within the wall, on the indoor side, or will drain to the exterior of the building. Follow

appropriate instructionsbelow depending on your particular type of installation.

Internal Drain (optional for new construction)

NOTE: Ifinstalling an internaldrain, you MUST install a drain kit on

the wall sleeve before the wall sleeve is installed.

1,

Refer to Figure 3 below and locate the drain within the

"Primary" area for best drainage. Maintain at least a 1/2"

clearance from the embossed area.

2.

Using the mounting plate with the 1/2" hole as a template,

mark and drill two, 3/16" mounting holes and a 1/2" drain

hole.

,

Removethe backingfrom the gasket and mount it on the flat

side of the mounting plate. (See Figure 4.) Insert the drain

tube through the hole in the gasket and mounting plate so

the tube flange will be against the wall sleeve.

4. Position the assembly beneath the drilledholes and secure

itwith #10-24 x 1/2" machine screws and lock nuts provided.

Seal the tops of the screws with silicone caulking.

5. Use 1/2" I.D.copper tube, PVC pipe, or vinyl hose (obtained

locally) to connect the internaldrain tube tothe drainsystem

in the building.

6. Referring to Detail A on page 6, locate and assemble the

(2) two cover plates and gaskets over the drain holes at the

rear of the wall sleeve.Attach them withthe #10 sheetmetal

screws provided. Makecertain that the four overflow slots at

the rear of the wall sleeve are not blocked (See drawing of

the back of the sleeve on page 6).

7. If a deep wall extension (PXWE) is used, after installing the

field supplied flashing, caulk as required. Be sure to caulk

around the flashingand thewall sleeve where the hole was

drilled for the drain tube.

Figure 3

DrainKitLocationandInstallation

Secondary area

Primary area _ no foam insulation --

If the drain must be located in the

secondary area, the foam insulation

must be cut away and removed to

allow access to the drain,

76 cm

Screw [_

Wail sleeve

Gasket t t

i

Mounting plateNut _ j _ I \\

)

5

Page 6

920-087-02 (9-03)

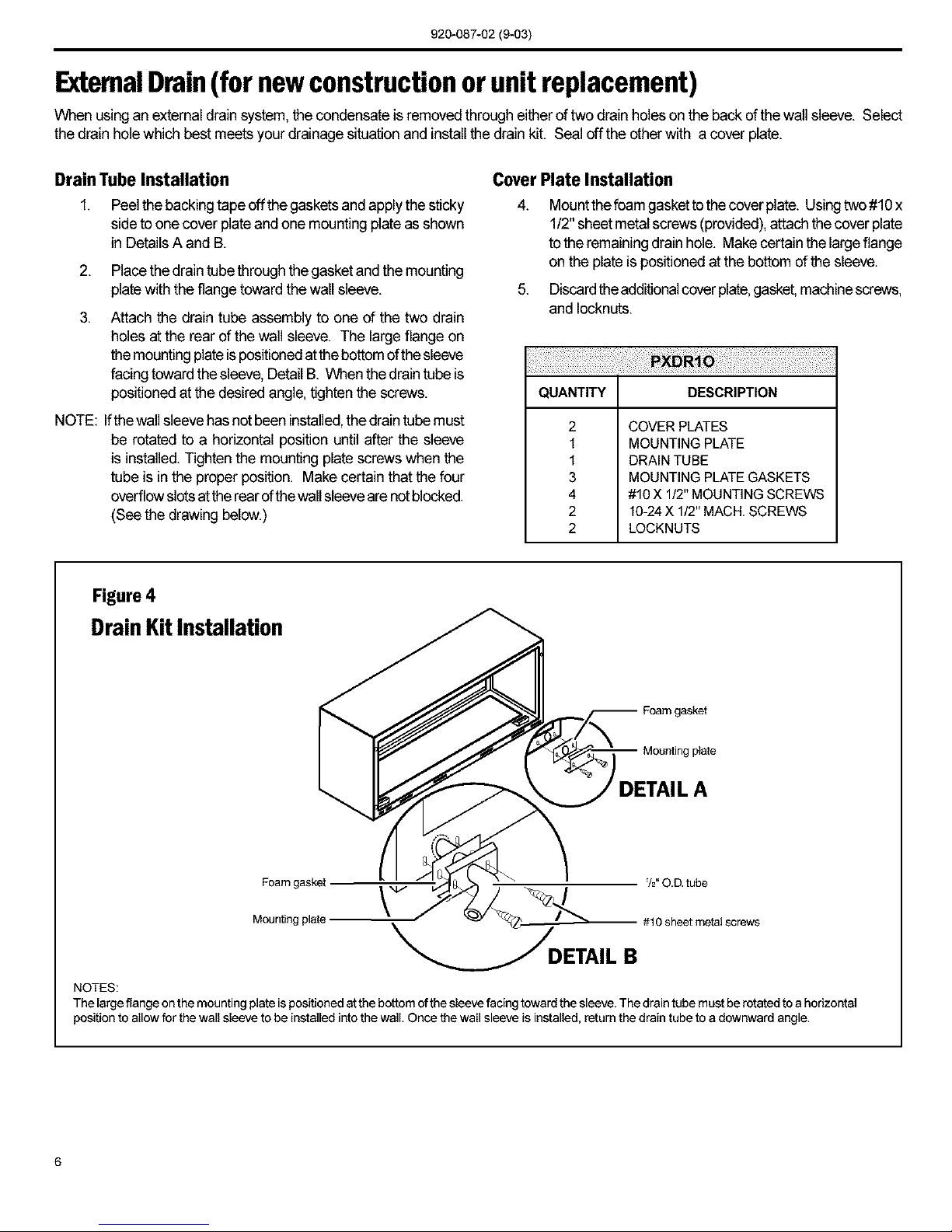

ExtemalDrain(for newconstructionorunit replacement)

When usingan external drain system, the condensate is removed through eitherof two drain holes on the back of thewall sleeve. Select

the drain hole which best meets your drainage situation and install the drain kit. Seal off the other with a cover plate.

Drain Tube Installation

1. Peelthe backing tape off thegaskets and apply the sticky

side toone cover plateand one mounting plateas shown

in Details A and B,

2. Placethe drain tube throughthe gasketand the mounting

plate with the flange toward the wall sleeve.

3. Attach the drain tube assembly to one of the two drain

holes at the rear of the wall sleeve. The large flange on

themounting plateispositionedatthe bottomofthesleeve

facing toward thesleeve, Detail B. When the drain tube is

positioned at the desired angle, tighten the screws.

NOTE: Ifthewallsleeve has not been installed,the draintube must

be rotated to a horizontal position until after the sleeve

is installed. Tighten the mounting plate screws when the

tube is in the proper position. Make certain that the four

overflow slotsat the rearof the wallsleeveare notblocked.

(See the drawing below.)

Cover Plate Installation

4. Mountthefoamgaskettothecoverplate. Usingtwo#10x

1/2"sheet metal screws (provided),attachthe cover plate

tothe remaining drainhole. Make certain the largeflange

on the plate is positioned at the bottom of the sleeve.

5. Discardtheadditionalcoverplate,gasket,machinescrews,

and Iocknuts.

QUANTITY DESCRIPTION

2

1

1

3

4

2

2

COVER PLATES

MOUNTING PLATE

DRAIN TUBE

MOUNTING PLATE GASKETS

#10 X 1/2" MOUNTING SCREWS

10-24 X 1/2" MACH, SCREWS

LOCKNUTS

Figure 4

DrainKitInstallation

gasket

plate

DETAIL A

Foam gasket _ _/2"O.D.tube

Mounting plate #10 sheet metal screws

_DETAIL B

NOTES:

The large flange on the mounting plate ispositioned at the bottom of the sleeve facing toward the sleeve. The drain tube must be rotated to a horizontal

position to allow for the wall sleeve to be installed into the wall. Once the wall sleeve is installed, return the drain tube to a downward angle.

6

Page 7

920-087-02(9-03)

WallSleeveInstallation Instructions(PXWS)

NOTE: Insurethat theunit isonlyinstalled inawall structurallyadequateto support the unitincludingthe sleeve,chassis and accessories.

Ifthe sleeve projects more than 8" intothe room, a subbase or other means of support MUST be used. Please read these instructions

completely before attempting installation.

Figure 5

TypicalWall Sleeve Installation

Lintel to support masonry walls .--_.b_//_

10"

(25.4 cm

Electrical receptacle -

Wall opening Wall sleeve

/

1 1_ _ /]

41._m) _\_'[_ -- -- Electrical receptacle

Insulation --

Smoothsideof screw

slip facing into room

ForDeep Wall Installation See Section II

The following instructions apply ONLY to walls less than

13 1/4" in depth.

1. Frominsidethebuilding,positionthewall sleevein the opening

and push it through the wall so it protrudes atleast 1/4"on the

outside, note Figure 5.

2. Position thewall sleeve with a slight tilt towards the outside to

facilitate condensate drainage. It should be level side-to-side

and the front should be 1/4 bubble higherthan the back. DO

NOT allow any pitch toward the inside.

Electricalshock hazard.

Turnelectric power OFF at the fuse box or service panel

before making any electrical connections and ensure a

proper ground connectionis made before connecting line

voltage. Failureto do so can result in property damage,

personalinjury and/ordeath.

Page 8

920-087-02 (9-03)

Figure 6

Dimensions

A

S

_ ...........Wall

'_7€/////_ _ 6.4 cm

in.

13¾ _

Dimension*

A B

Allow Allow for floor finishing

for wall

finishing

(Minimum) Min. Max

No Accessories ¼" ¼"

(6.4 ram)* (6.4 mm) ---

With Subbase 1¾" 3½" 5"

(4.5 cm) (8.9cm) (12.7cm)

With Lateral Duct ¾" ¼"

(1.9 cm) (6.4 mm) ---

* If mere than one accessory [sto be used, use the maximum

dimension. Ifthe wail thickness is more than 13¾" (35cm) -

(A + ¼" [6.4 mm]), a sleeve extension must be used.

,

Drill two 3/16" holes through each side of the sleeve

approximately4"from top and4"from bottom of sleeve. Screw

four#10x 1"screws(included)orappropriatefastenersfor your

installation, through the holes inthe sides of the wall sleeve.

4. Apply sealant aroundthewall sleevewhere itprojectsthrough

the insideand outside wall surfaces. Apply the sealant to the

screw headsor thetops of the fasteners used in Step #3.

NOTE: When sealing the sleeve on the outside of the building,

be careful NOT to let the sealant block the two condensate

drain holes or the four overflow slots at the bottom flange of

the sleeve.

5. Ifthe chassisandexteriorgrilleareto beinstanedlater,leavethe

weatherboard and center support in place, otherwise remove

and dispose of them.

6. Providea supportlintelifthewallsleeve isinstalledina concrete

or masonry wall. (See Figure 7.)

Rgure 7

Main studs

LintelInstallation Jack studs

Jack stud

Untel

Mounting screw holes

No holes in bottom of wall

sleeve unless drain kit is used

NOTE: Construct wall opening to comply with all applicable

building codes.

8

Page 9

920-087-02 (9-03)

Section II - DeepWall Installation(PXWE)

If the wail is thicker than allowed in the notes in Figure 6, a sheet

metal wall sleeve extension and flashing MUST beused.

Installation Instructions for the PXWE - 4" Wall Sleeve

Extension

The following points MUST be considered when installing a wall

sleeve extension:

Provision must be made to direct excess condensate from

the back of the wall sleeve into the extension then outside

the building or to a drainage system.

2. Air baffles mustbe mounted to properly direct airflow to and

from the condenser.

3. The wail sleeve extension design must allow for the proper

mounting of the grille.

4. Caulking is required atansites where condensate or external

water could potentially infiltrate intothe building.

6. Condensate notches and overflow slots must be kept clear

ofsealant and gaskets so condensate canflow freely intothe

wall sleeve extension.

NOTE: Improperfabricationor installationofa wallsleeveextension

will impair PTAC performance.

Extension Installation

Secure thewall sleeveextensionto the wail sleeve beforeinstalling

it in the wall. Refer to Figure 8 for a guide for fabrication of a

condensate drip panel. The panel MUST extend the full depth of

the wail sleeve and the wail sleeve extension.

Payparticular carein sealingand caulkingthe panelwhere itmakes

contact with the wall sleeve (see Figure 8).After installation in the

wall, secure with fasteners through the sides. Use a good grade

of silicone sealant around the sleeve extension. Seal all exposed

screw heads. When the installation is complete, the outside grille

should be attached to the wall sleeve extension.

5. Fabricate and install metal flashing in wall to serve as a drip

panel. Refer to drawing for more information.

Figure8

WallSleeveExtensionSealant Locations

®

IMPORTANT NOTE: The silicone bead MUST extend 3"

up the side of the two flanges to prevent condensate

from leaking.

Wall Sleeve

Outside Edge

Insulation

Wall Sleeve

Wall Sleeve Extension

Rear Flange Flange

| Wall SLoe %_j_) |

Silicone Bead T-_ "%'

Wall Sleeve

Extension

Sealant

I Drip Panel L

Sealant around perimeter

2 n

Sealant inside (4) bottom corners

Drip

Width of Wall Edge Notches (4)

Wall Sleeve Extension, 42" X 16" Frame, 20 gauge minimum, painted or aluminium

9

Page 10

920-087-02(9-03)

Installation InstructionsModelPXGAStandardGrille

1. Remove the center support and weatherboardifstininstalled

in the sleeve.

2. Insert six plastic grommets into the grille openings from the

outside of the grille as shown in Figure 9.

3. Insert two #8 x 3/8" sheet metal screws (provided) in the top

two outside edge plasticgrommets, and tightenthem halfway

intothe grommets.

4. CAUTION: Bodily injury can be caused by grillesfalling from

a building during installation. It is recommended that a safety

line be attached to the grille and an anchor point inside the

building durinq installation.

5. Graspthe grille bythe attached plastic handles. Positionitwith

thecondensate drain knockoutsfacing down. From insidethe

building, maneuver the grille through the wall sleeve and pull

toward you untilthe screw headsare inserted intothe keyhole

slots at the top of the wall sleeve. Tighten the two screws

completely.

6. Insert the remaining screws into the remaining holes and

tighten securely.

Figure 9

Quantity Description

1 Stamped Aluminum Grille

6 Plastic Grommets

6 #8 x 3/8"Sheet Metal Screws

Figure 9

StandardGrille

Waft sleeve

-- Weatherboard

-- Center support

Plastic handles

\

\

Plastic

grommets

10

Page 11

920-087-02(9-03)

A. Installation Checklist

[]

[]

[]

[]

[]

Inspect all components and accessories for damage

before and after installation.

[] Installthe recommended Condensate Drain Kits for

complete condensate removal.

Removethe cardboard wall sleeve support and grille []

weatherboard.

Check for proper wall sleeve installation in accordance

with the wall sleeve installation instructions.

Check installationof the wall sleeve foamgasket.

Check for a subbase kit or other means of structural

support which is required for ALL installations projecting

more than 8" into room.

Ensurethat the chassis is installed in a 16" high x 42" wide

wall sleeve that isno deeper than

13 3/4". A baffle kit is required if the sleeve exceeds that

depth.

[] Ensure that drapes, bed, bedspread,furniture, etc. DO

NOT block either returnor discharge air grilles.

[] Inspect the condenser air inlet and outlet for any

obstructions (shrubbery,etc,)

B. ElectricalRatingTables

All230/208 voltunitsare equippedwithpowercords.SeeAppendixBonpage19 forwiringinstructionson 265V units.

NOTE: Use Copper Conductors ONLY. Wire sizesare per NEC,check local codes for overseas applications.

Table 1 250 V Receptacles and Fuse Types

AMPS 15 20 * 30

RECEPTACLE (_ (_ (_

MANUFACTURER PART NUMBERS

Hubbell 5661 5461 9330

P & S 5661 5871 5930

GE GE4069-1 GE4182-1 GE4139-3

Arrow-Hart 5661 5861 5700

TiME-DELAY TYPE FUSE 15 20 30

(or HACR circuit breaker)

HACR- Heating, Air Conditioning, Refrigeration

* May be used for 15 Amp applications if fused for 15Amp

NOTE: 265 volt units are hard wired.

Table 2 Recommended branch circuit wire sizes*

Nameplate

maximum circuit breaker size AWG Wire size**

15 14

20 12

30 10

AWG -American Wire Gauge

* Single circuit from main box

** Based on copper wire, single insulated conductor at 60°C

Electric shock hazard.

Turnoffelectricpowerbeforeserviceorinstallation

A_IelectricalconnectionsandwiringMUSTbe instaUedbya qualifiedelectricianand

confon'nto the NationalElectricalCodeandalllocalcodeswhichhavejurisdiction

Failureto dosocanrescttinpropertydamage,personalinjuryand/ordeath.

Wire Size UseONLY wiringsize recommendedfor single outlet branch circuit.

Fuse/Circuit Use ONLY type and size fuse or HACR circuit breaker indicated on unit's rating plate. Proper current protection to the unit is the responsibility of the

Breaker owner. NOTE: A time delay fuse is provided with 265V units.

Unit MUST be grounded from branch circuit through service cord to unit, or through separate ground wire providedon permanentlyconnected units.

Grounding Besure that branch circuit or general purpose outlet is grounded. The field supplied outlet must match plugon service cord and be within reach of

service cord. Refer to Table I for proper receptacle and fuse type. Do NOT alter the service cord or plug. Do NOT use an extension cord.

The field supplied outlet must match plug on service cord and be within reach ofservice cord. Refer to Table 1 for proper receptacle and fuse type.

Receptacle Do NOT alter the service cord or plug. Do NOT use an extension cord.

Use recommended wire size given in Table 2 and install a single branch circuit. All wiring must comply with local and national codes. NOTE: Use

Wire Sizing copper conductors only.

11

Page 12

920-087-02(9-03)

Section III - ChassisInstallation

* Check to be surethe wall sleeve, extension (if used), grille, and drain kit are installed properly before

chassis installation

1. Remove the weatherboard and center support from

the sleeve (if still in place). Be sure an outdoor grille is

attached.

NOTE: To avoid breaking the door or hinge pins, donot apply

excessive force when installing

_ Pins

Wall sleeve / Control

Door

-- Weatherboard

Center support

Front Panel

3. Remove the two chassis shipping brackets from the ends of

the shipping pallet.

IMPORTANT:Useawa]]sleeveadapterkit(PXSE)if

installingaP-Series chassis in a T-Seriessleeve.

Suffocation hazard

Keep bag away from babies and children.

Do NOT use in cribs, beds or playpens. Destroy

immediately after opening. This oag is NOT a toy.

Failure to do so can result in personal injury end/or death

2. Remove the front cover contained ina protective plasticbag

from chassis. Remove the bag and dispose ofit properly.

If the control door is not installed,follow these steps:

Fromthe front of the cover, slidethe rightcontrol doorpin into

thehole onthe right side of thefront cover. Slidethe left door

pin intothehole on the leftside ofthefront cover opening and

snap it intoplace.

@

Compressor

Chassis

shippingbracket

Shipping pallet

IMPORTANT: When installinga Friedrich P-Series PTAC intoan

existing sleeve, it is important to ensure that the unit is installed

completely. Inspection of the air seal between the condenser air

baffles and aroundthe indoormountingflange isrecommended. In

some cases additional gaskets or baffling may be required.

12

Page 13

920-087-02(9-03)

4. Center the chassis in the pre-instanedsleeve and carefully

push the chassis until the chassis flange and gasket contact

the sleeve flange.

®

....... Wall sleeve

Wallsleeveflange

Chassisflange

and gasket

at the bottom back corners of the cover. Tighten them into

the quick nuts located on the chassis to secure the cover. If

the unit has been placed such that there is no room to insert

the thumbscrews from the bottom, request a Side Mounting

kit (Part No.PXSM)from Friedrich. Locate the service cord

or conduit in the notch at the bottom rightof the front cover.

®

NOTE: If the unit is mounted flush to the floor, the service cord

MUSTbereroutedat thebottomofthefrontcoveron the sideclosest

to the receptacle. A notch MUST be made inthe front cover side

where the cord exitsthe unit. Itis the responsibility ofthe installer

to create an exit notch. See diagram 8 for suggested opening size

and placement.

®

mounting screw

Chassis

flange

5. Locate the four #10 x 1"chassis mounting screws. Tighten

the screws into the clips - adjacent to the alignment dimples

on the mounting brackets onthe wall sleeve flange (two per

side).

6. lnstanthefrontcover assembly (includingthe dischargegrine)

by placing the top of the cover onto the 90° angle bracket

along the top of the chassis. Rotate the bottom into place

and insert the included thumb screws into the slots located

7. If the filters are not already installed in tracks in the plastic

cover,slide them into place.

8. Plug the cord (if applicable) into the appropriate receptacle.

Extra cord may be coiled inside the front cover behind the

return air grille. Restore power tothe unit.

®

To remove the front cover, remove the thumbscrews at

the bottom back comers of the cover (or sides). Pull the

bottom end forward and lift it up to clear the L bracket

across the top of the chassis.

®

Not to scale

If a remotethermostat isto beinstalled,proceedtoAppendixA,Step 1. Fora 265 Vunit, proceedtoAppendixB,Step 1. 13

Page 14

C.Standard UnitOperation

920-087-02 (9-03)

Rotatethe temperature dial in small increments in the

warmer or cooler direction.Moving the dial more than

1/4" at a time may overcompensate and result in an

extreme hotor cold situation.

Ifa remotethermostat is installed,see AppendixA,

page 18-20.

Control Operation

The full-range thermostat maintains room

temperature at the desired setting in both

Temperature the heating and cooling modes. Turnthe dial

counterclockwise forwarmer and clockwise

for a cooler temperature.

Operates the unit on cooling. Cooling will not

Low and High Cool begin ifthe room temperature isbelow60°F.

Operates the unit on heating. Some models

Low and High Heat do not provide this selection.

Circulates air within the room at high fan

Fan Only speed only. No heatingor cooling functions

are active.

Standard Unit ControlPanel

_#ALLMAST E R ®

COOLING ONLY MODEL HEAT/COOL MODEL

D.TemperatureLimitingThermostat

1,

2.

,

4,

5,

6,

Set the thermostat knob to center of dial.

Removethe four screws holding thecontrol panel.Pull up on

thethermostat knob and remove it.

Locate the two temperature limiting screws. These screws

arefactory installedfor a maximumtemperature rangeof60°-

90°E Each hole in the dial plate represents approximately a

4°change from the adjacenthole.

To adjust the temperature range, move the temperature

limiting screws to the desired location.

Replace the knob when the desired range has been set.

Replace the control panel.

Remo_

knobs

Control panel

limiting

SCreWS

EXAMPLE: To set a maximum temperature range of approximately 64° to 86°F, move the screws to the locations shown inthe diagram at right,

14

Page 15

920-087-02 (9-03)

E.HeatingControl (heat pumpsandemergencyheat operation)

NOTE: Heat pumpmodels only. Heatpumpequipped models use

backup electric resistance heating coils. At extremely low,outdoor

ambient temperatures,theheat pumpisautomaticallydisabled and

the unit operates solely on electric resistance heat.

This control islocated behindthe decorativefrontcover and isfound

on the right side panel ofthe chassis. Itsfunction isto allow youto

set the temperature range inwhich the heat pump operates. This

control switches the unit heat operation between heat pump and

electric resistanceheatbasedon theoutdoorambient temperature.

These change-over temperatures are basedon the settings of the

control. Thefactory setting is at theone o'clockposition. Ifyouwish

to changethe factory set point, insert a flat-bladed screwdriver into

the slot and turn counterclockwise to increase the changeover set

point, or clockwise to decrease it.

HEATING CONTROL

COMMANDE DE CHAUFFAGE

CONTROL DEL CALOR

\OAD O_"

EMERGeNCy HEAT

CHAUFFAG£o URGENCE

CALOR D_ [ME_G_NCIA

250454-00

NOTE: The factory set point is recommended for optimum

performance.

NOTE: Emergency heatoperation only. Inthe event ofa compressor malfunction inthe heat pump mode, turnthe screw to the extreme

counterclockwise emergency heat position. The heater will then cycle using electric resistance heat only. Note that in the emergency

heat position,the compressor is locked out, disabling both heat pump and cooling operations. CALL A SERVICE PERSON. DO NOT

FORGET TO RETURN THE CONTROL TO ITS ORIGINAL POSITION AFTER REPAIRSARE MADE OR THE COMPRESSOR WILL

NOT COME ON IN COOLING MODE.

F.FanCycleSwitch

The fan cycle switch is located behind the decorative front cover

below the control panel. It is designed to operate the fan either

continuously or intermittently with the compressor or heating

elements. When the switch is in the CONTINUOUS position, the

fan will run continuously at the selected speed when the unit is

turned on, With the fan cycleswitch in the CYCLE position,thefan

will run only when the compressor or heating elements cycle on.

I I

CONTINUOUS CYCLE

GONTINU CICLO

250-458-02

CYCLE DU I

FAN VENTILATEUR I

CYCLE CICLO DEL

VENTILADOR

NOTE: It is recommended that this switch be set in the continuous position for maximum comfort and temperature control.

G.FreshAirVentControl

The vent control lever is located behind the front cover on the left

side of the unit. The unit is shipped in the closed position with a

locking screw in place. Thescrew must be removedto operatethe

lever. When the lever is back, (OPEN), outside air is mixedwith

indoor air. When the lever isforward, (CLOSED), no outside air is

admitted into the room and room air is recycled through the unit.

NOTE: The vent should remain closed for peak operating efficiency.

OPEN CLOSED

OUVERT FERME

ABIERTA CERRADA

VENT

AERATION

SALIDA (ESCAPE)

DEL AIRE

FRESH AIR DOOR IS FACTORY

SHIPPED IN CLOSED POSITION.

REMOVE TOP SCREW ON LEVER

TO OPEN DOOR.

250_453_01

15

Page 16

920-087-02 (9-03)

H.Air DischargeGrille

Moving parts hazard

Turn oft electric power before

servicing this component.

Failure to do so can result in property

damage, personal injury and/or death.

I

I

I

®

The air discharge grillecan be redirectedto blowair either straightup or atan angle intothe room. To changethe airflow direction,remove

the front cover, locate and remove the six grill retaining screws. Reverse the ends ofthe grille and refasten the grille to the cover.

I. Start-up Checklist

[] Inspect all components and accessories for

damage before and after installation.

[] Check installation for compliance with all national

and local codes and ordinances.

[] Read and follow all manufacturer's installation

instructions.

[] Check that circuit breaker(s) and electrical wire

sizes are correct. If the unit is supplied with a

power supply cord, insure that it is stored properly.

[] Check the condensate water drain outlet(s) to

make sure they are in compliance with all national

and local codes, that they are adequate for the

removal of condensate water, and that they meet

the approval of the end user.

[] Strictly follow installation instructions concerning

clearances around the unit.

] Secure components and accessories, such as the

control door and front cover.

[] Check the unit air filter, condenser coil and

evaporator coil for any obstructions

[] Check for proper operation of all components.

[] Instruct the owner or operator of the units operation,

and the manufacturer's

recommended routine maintenance schedule.

NOTE: It is highly recommended that a maintenance

schedule log book be prepared for recording

the dates and times of service.

[] Operatethe unit for twenty minutes Record

the unit's indoor/outdoor intake and discharge

temperatures, amperage draw, and power voltage.

[] Assemble the Warranty Certificate, the Operation

and Installation Manual, all accessory installation

instructions and the name, address and telephone

number of the Authorized Friedrich Warranty Service

Company in the area for the owner or operator.

NOTE: Unitsare to be installed, inspected, and checked byqualified service personnelonly.

16

Page 17

920-087-02(9-03)

AppendixA:RemoteThermostatUnitInstallation

RemoteThermostatSelection& WiringGuidelinesfor

PackagedTerminalAirConditioners

Follow the instructions and recommendations of the thermostat

manufacturer for installation and wiring. Do notuse a conventional

heat pump thermostat with emergency electric heat selection for

our heat pump units. Our units make an automatic decision about

turning on electric heat ifthe heatingdemand cannot bemet by the

heat pumpdue to low outdoor temperatures.

Manual Changeover Thermostat

For Heat Pump equipped units: A single stage, heat/cool

thermostatwith aterminalfora reversingvalve operationisrequired.

Terminal "B" should be continuously energized in the heat mode

and terminal "G" should be energized whenever there is a call for

heating or cooling. Typically,a heat/cool thermostat designed for

use with electric heat systems will meet the above requirements.

NOTE: This unit is designed for use with a single stage thermostat only. Improper application of the thermostat may result in property

damage, personal injury or death.

Honeywell Thermostat Terminal Designation:

TERMINAL LETTER OPERATION CONTACT MADE

Y Cooling During call for cooling.

W Heating During call forheating.

G Fan Continuous if the slider is inthe "Fan" position,otherwise, intermittent.

C Common Terminal Forthermostats requiring a common terminal

R 24 V to the thermostat Directly from the transformer

B (Heat Pump units Only) Reversing Valve Made continuously during call for heating.

For Non-Heat Pump equipped units: A single stage cooling and heating thermostat is required. Terminal "G" should be

energized whenever a call for heating or cooling is made. Typically a heat/cool thermostat designed for use with electric heat

systems will meet this requirement.

SimplifiedWiringExample

Unit Terminal Board

* A-Suffix models do not have a "C" terminal

I

0 @ _ v _ ® B 01

--T.plca,PTAO,PT.P..lti

[_ -- Wall thermostat

Thermostat Terminals

NOTE: It isthe installer'sresponsibilitytoensurethatall control wiringconnectionsare made inaccordance with theinstallationinstructions.

Improper connectionof the thermostat control wiring and/or tampering with the unit's internalwiring can void the equipment warranty and

may result in property damage, personal injuryor death. Other manufacturer'sPTACsand evenolder Fdedrich models may havedifferent

control wire connections. Questionsconcerning proper connectionsto the unit should be directedto thefactory.

17

Page 18

920-087-02(9-03)

AppendixA(continued)

Remote Thermostat 208V Operation

Connection208V60HZDiagram/

-t;t

SMOOTHG RIBBED

i z

I

I

I

COM

The simplified connection diagram at left shows the factory

configured wiring set for 240V operation. If you are going to use

208V exclusively, switch the two (2) black wires on the 240V post

of the primary side of the transformer to the 208V post. This will

ensure correct secondary (low)voltages for the unit. This is only

required on remote thermostat units.

CAUTION

If the supply voltage is 208V, the low

voltage transformer MUST be wired for

208V operation Failure to do so will result

in lower contro_ voltages to the unit and can

damage _ow voltage components

Remote Thermostat Unit Operation

Theseunitsare controlledby the use ofa remotethermostatthatwill

cyclethe unitto maintaindesiredroomtemperature.Seethermostat

operating instruction sheet for details.

Thefan speed switch controlshighand lowspeed fan operation. Itis

located on the control panel and is independent of the thermostat.

Auto Changeover Thermostat

A singlestage heat/coolthermostatwithauto changeoveris needed.

Thewiring scheme isthesame as the manualthermostat.

Remote Thermostat Installation

Follow Steps 1through 5 (pages 12and 13),then:

6. Locate the terminal strip on the front of the control box (See

Figure9). Attach thethermostatsubbasewires(fieldsupplied)

tothe appropriately labeled terminals in accordance with the

wiring diagram on the side of the chassis.

7. Carefullyroute the wiresalongside theconduitor servicecord.

Attach the otherend of the wires to the appropriateterminals

on thethermostat subbase. Seethe thermostatdirections for

proper wiring and mounting ofthe thermostat.

Figure 10

TerminalStripLocation

WALLMASTER _

REMOTE CONTROL UNIT

SEE WALL

THERMOSTAT

FOR UNIT

OPERATION

HI

Fan

Speed

-t-

LOW

18

Page 19

920-087-02(9-03)

AppendixB: ElectricalWiringfor 265 VoltModels

NOTE: Itis recommended that the PXSBsubbase assembly, the PXCJ conduit kit and the PXDS disconnect switch be installed on all

hardwired units. If installing a flush-floor mounted unit, make provisions for allthe linevoltage power leads and conduit to be removed for

ease of maintenance and service to the chassis.

Toinstall the linevoltage power leads and conduit to the chassis, follow the instructions below.

1. Remove the four control box retaining screws (A) and open

the control box.

2. Punthechassis power lead wires (B) (locatedon the bottom-

right side of the control box) through the plastic bushing so

they are located inside the control box.

3. Remove the plastic bushing.

4. Route the line voltage power leads through the hole where

theplastic bushing was located,and secure itsconduit (use a

1/2" straightconduit connector,with the Iocknuton the inside

ofthe control box.)

5. Makethe appropriateelectricalconnections within thecontrol

box,thensecure the boxonthechassis. Detailed instructions

are included with the installation instructions for the conduit

kit (PXCJ).

6. Route the line voltage power conduit from the control

box straight down the right front to the bottom side of the

chassis. This will allowthe front cover to be installedwithout

interference with the electrical conduit.

Figure 11

LineVoltageConnections

Fuse holder

SCOWS

Inside back of co_rol

panelcove_

19

Page 20

920-087-02(9-03)

J.RoutineMaintenance

NOTE: Units are to be inspected and serviced by qualified service personnel only.

1. Clean the unitair intakefilter at leastevery 300 to 350 hours

of operation. Clean the filters with a mild detergent in warm

water and allowto dry thoroughly before reinstalling.

2. The indoor coil (evaporatorcoil), the outdoor coil (condenser

coil) and base pan should be inspectedperiodically (yearly

or bi-yearly) and cleaned ofall debris (lint, dirt, leaves,paper,

etc.). Clean the coils and base pan with a soft brush and

compressed air or vacuum. If using a pressure washer, be

careful not to bend the aluminium fin pack. Use a sweeping

up and down motion in the direction of the vertical aluminum

fin pack when pressure cleaning coils. Cover all electrical

componentstoprotectthem fromwateror spray. Allow theunit

todry thoroughly,inspect allgasket materialfor deterioration

(replace as necessary), and then reinstall the chassis in the

sleeve.

NOTE: Do not use a caustic coil cleaning agent on coils or base pan. Use a biodegradable cleaning agent and degreaser.

Before reinstalling the chassis in the sleeve, inspect the

indoorblower housing, blower wheel, condenser fan blade,

and condenser shroud periodically (yearly or bi-yeafly) and

clean of all debris (lint, dirt, mold, fungus, etc.) Clean the

blower housingarea and blowerwheel with an antibacterial/

antifungal cleaner. Use a biodegradable cleaning agent and

degreaser on condenser fan and condenser shroud. Use

warm or cold water when rinsing these items.Allow allitems

to dry thoroughly before reinstallingthem.

3. Periodically (at leastyearly or bi-yearly): inspectall control

components, both electrical and mechanical, as well as the

power supply. Use proper testing instruments(voltmeter,

ohmmeter, ammeter, wattmeter, etc.) to perform electrical

tests. Usean air conditioning or refrigeration thermometer to

check room, outdoor and coil operatingtemperatures. Use a

slingpsychrometertomeasurewet bulbtemperatures indoors

and outdoors.

4,

,

6,

Inspect the surrounding area (inside and outside) to ensure

that the units' clearances have not been compromised or

altered.

Inspectthesleeveanddrainsystemperiodically(atleastyearly

or bi-yearly) and dean of all obstructions anddebris. Clean

bothareaswith an antibacterialand antifungalcleaner. Rinse

both itemsthoroughly with water and ensure that the drain

outletsare operatingcorrectly. Check the sealant aroundthe

sleeve and resealareas as needed.

Clean the front cover when needed. Use a mild detergent.

Washand rinsewith warmwater. Allow themto dry thoroughly

before reinstallingthem in the chassis.

Filters

Return Air

Grille

CondenserFanBlade

\

DischargeAir Grille IndoorBlower_

Condenser Gasket

Condenser Shroud

8asepan

Control Panel

Evaporator Coil

Wall Sleeve

2O

Page 21

920-087-02(9-03)

K.BasicTroubleshootingTechniques

Beingfamiliarwith the sequence ofoperation on StandardControlled OperatingUnitsor theoperationof the RemoteThermostat Controlled

Unitsis important, The following questions and answers may help to identify performance problems,

EnvironmentalEffects- CoolingMode

Is unit sized to room size area and heat load demand?

RoomWidthx Lengthx 3.5 (x-factor)equal a "guesstimate" ofthe

numberofBTU'srequiredfor the area. The numberofpeopleinthe

room, number of electrical devices, solar gains, etc.are allvariable

itemsthatcan affect propersizingoftheunit. Friedrichrecommends

that you consultwith an applications engineer for proper sizing.

Is the outdoor temperature 60°F or below?

The unitis designed for outdoor temperatures above60°E

Is the indoor temperature 80°F or above?

Ambient indoor temperatures of 80°F or above will take a longer

period of run time to cool down the area. Long run times may

indicate that the unit isundersized.

Is indoor humidity high?

This condition will cause the unit to operate longer to remove

humidity before noticing any cooling effect.

Hasthe heat loadbeen increased byadditional devices such

as computer equipment, or hasthe room areabeen increased

where the unit is located?

If conditions have changed, the unit may not be able to cool and

condition as effectively as previously planned.

Environmental Effects - Heating Mode

Is unit properly sized to room area and heat load demand?

Multiplying the Width x Length x 3.5 ("x-factor") provides a

"guesstimate" of the number of BTU's required for the area. The

number of people inthe room, number ofelectrical devices, solar

gains,etc. are all variable itemsthat can affect propersizingofthe

unit. Ffieddchrecommends that you consult with an applications

engineer for propersizing.

Is the outdoortemperature 70oForabove?- Theunit isdesigned

for outdoor temperatures below 70°E

Is the indoor temperature 60°F or below? Ambient indoor

temperatures of 6O°F or below will take a longer period of run

time to heat the area. Long run times may indicate that the unit is

undersized.

Hasthe roomarea been increased where the unit is located?

If the area where the unit is located has been increased, the unit

may not provideadequateheat.

Insufficient Maintenance and Inspection

Installationerrorsare themost common cause ofpoorperformance.

Pleasefollowinstallationinstructionscarefully.Ifotherproblemsexist,

see Maintenanceand InspectionTroubleshootingGuide below.

Maintenance and Inspection Troubleshooting Guide

CAUSE RESULT

System is not serviced or inspected Can result inpremature component failures, poor performance and

regularly (semiannuallyor annually), increased operating costs.

Air filters are not cleaned regularly and May result in poor cooling, icing and water problems as well as

become blockedwith particles, component failures and increased operating costs.

Condenser coil not maintained properly May result in poor cooling, component failures and increased costs.

(blocked with particles).

Evaporator coil not maintained properly Mayresult in poor cooling, icing and water problems, and increased

(blocked with particles), operating costs.

Components that show signs of fatigue May result in multiple service calls, poor performance and increased

- not replaced, operating costs.

Condensate drains and drain lines not May result in water and odor problems.

maintained.

21

Page 22

FriedrichPTACAccessories

920-087-02 (9-03)

MODELNUMBER

PXWS

PXGA

PXAA

PXDB

PXSC

PXDR10

PXWE

PXSB

PXCJ

PXDC

DESCRIPTION

WALL SLEEVE G-90 zinc coatedsteelisprepared in aneleven-

step process, thenelectrostaticanycoated witha polyesterfinish

and cured in an oven for exceptional durability. The wall sleeve

is insulated for thermal efficiency. 16" Highx 42" Wide x 13¾"

Deep.

GRILLE, standard, stamped aluminium, anodized to resist

chalking and oxidation.

ARCHITECTURAL GRILLS that consist of heavy-gauge

6063-i5 aluminium alloy:

Clear, extruded aluminium or dark bronze acrylic enamel

Also available in custom colors.

CONDENSATE DRAIN KIT Attaches to the bottom of the wall

sleevefor internaldrainingofcondensateortotherearwallsleeve

fiangefor externaldraining. Recommendedon allunitstoremove

excess condensate. Packaged in quantitiesoften.

DEEPWALL SLEEVE EXTENSION A four inchdeep anodized

aluminiumextensionthatattachestothe outsideof thewallsleeve

when the wall is greater than eleven inches thick (9½"when a

subbase is used, 10 inches when a lateral duct is used).

DECORATIVESUBBASE Providesunitsupportforwansless

than six inches thick. Includes levelinglegs, side filler panels

and mounting brackets for electrical accessories. Accepts

circuitbreaker, power disconnect switch, or conduit kit.

CONDUIT KIT WITH JUNCTION BOX Hard wire conduit kit

with junction boxfor 208/230V and 256V units (subbase not

required). Kit includesa means of quick disconnect for easy

removal of the chassis. *Required for 265V installations.

DESK CONTROL KIT A field installed kit which allows the

unit to be turned on or off from a remote central station via

a 24V interface.

PHOTO

PXWS_ /

PXDB

PXDR1O

PXCJ

PXDC

RT2

DIGITAL REMOTE THERMOSTAT A Honeywell wall

mounted remote thermostat. Requires proper P-Series

chassis.

RT2

22

Page 23

920-087-02(9-03)

FriedrichPTACAccessories (continued)

MODEL NUMBER

PXSE

PXDA

PXDE

PXFT

DESCRIPTION

SLEEVE EXTENSION RETROFIT KIT G-90 zinc coated

steel, 2.4" sleeve extension attached to the room side of

the sleeve to allow for the installation of a P-Series Friedrich

PTACin a T-Series sleeve.

LATERAL DUCT ADAPTER Attaches tothe PTAC/PTHP

unit and provides a transition to directup to 35% of the total

CFM to a secondary room, eitherleft or right ofthe unit. Kit

includes duct plenum with discharge grille and internal baffle,

adapter and end cap.

LATERAL DUCT EXTENSION A three foot insulated plenum

that attaches to the left or right side of the duct adapter. The

extension can be cut to length by the installer. Maximum

allowable straight extension isfifteen feet.

REPLACEMENT FILTER PACK These are original

equipment return air filters. They are reusable and can be

cleaned by vacuuming, washing, or blowing out, and are sold

in convenient ten packs. (Two filters per chassis)

PHOTO

PXSE _ /

PXDA

PXFT

[_]:r:T,-_'_ [o]',,;lll[o]_r[,-"]

DESIGNATOR DESCRIPTION

S STANDARD UNIT Standard PTAC/PTHP chassis. Can be230/208V or 265V,electric or heat pump.

R REMOTE THERMOSTAT Chassisoption necessary for wall mounted thermostat control of the unit.

SEACOAST PROTECTION AdditionalprotectionforPTAC/PTHPunitsina coastalorcorrosiveenvironment.

C The entire outdoorcoil is submerged ina spedelly formulatedenamel coating,thenoven-cured for a tough,

corrosion-resistantfinish.

23

Page 24

FRIEDRICHWALLMASTER®P-SERIESPACKAGEDTERMINALAIRCONDITIONERS[

I

I

LIMITEDWARRANTY

FRIEDRICH AIR CONDITIONING CO.

Post Office Box 1540. San Antonio, Texas 78295-1540

(210) 357-4400. FAX (210) 357-4480

SAVE THIS CERTIFICATE. Itgives you specific dghts, you may also have other rights which may vary from state to state and provinceto province.

Inthe event that your unit needs servicing, contact your nearest authorized service center. If you do not know the nearest service center, ask the company that installed

your unit or contact us - see address and telephone number below.

When requesting service: please have the model and _ from your unit readily available.

Unless specified otherwise herein, the following applies:

PACKAGED TERMINAL AIR CONDITIONERS AND HEAT PUMPS

LIMITED WARRANTY - FIRST YEAR (Eighteen (18) Months from the original date of purchase or twelve (12) months from installation). Any defect in the

unit's material or workmanshipwillbe repaired or replaced free of charge by our authorized service center duringthe normal working hours; and

LIMITED WARRANTY- SECOND THROUGH FIFTH YEAR (Sixty-six (66) months from the date of purchase) ON THE SEALED REFRIGERATION SYSTEM.

Any part of the sealed refrigeration system on the P-sedse that is defective in material or workmanshipwill be repaired or replaced free of charge (excludingfreight

charges) by our authorized service center during normal working hours. The sealed refrigeration system consists of the compressor, metering device, evaporator,

condenser, reversing valve, check valve, and the interconnecting tubing.

These warranties apply only while the unit remains at the original site and only to units installed inside the continental United States, Alaska, Hawaii,

Puerto Rico and Canada. The warranty applies only if the unit is installed and operated in accordance with the printed instructions and in compliance

with applicable local installation and building codes and good trade practices.

For international warranty information, contact the Friedrich Air Conditioning Company - International Division.

Reasonable proofmust be presentedto establish the originalpurchasedate, otherwise the beginningdate ofthis certificatewillbe consideredtobe our shipmentdate

plus sixtydays. Replacement parts can be newor remanufectured. Replacement partsand labor are only warranted for any unused portionof the unit'swarranty.

We will notbe responsible for and the user will payfor:

1. Service calls to:

A) Instruct on unit operation. B) Replace house fuses or correct house wiring. C) Clean or replace air filters. D) Remove

the unit from inaccessiblelocations. E) Correct improper installations.

2. Parts or labor provided by anyone other than an authorized service center.

3. Damage caused by:

A) Accident, abuse, negligence, misuse, dot, fire, flood, or acts of God. B) Operating the unit where there is a corrosive atmosphere containing chlorine,

fluorine, or any damaging chemicals (other than in a normal residential environment). C) Unauthorized alteration or repair of the unit, which in turn

affects its stability or performance. D) Failing to provide proper maintenance and service. E) Using other than a"Seacoast Protected" unit ina coastal

environment. F) Using an incorrect power source. G) Faulty installation or application of the unit.

We shall not be liable for any incidental, consequential, or special damages or expenses in connection with any use or failure of this unit. We have not

made and do not make any representation or warranty of fitness for a particular use or purpose and there is no implied condition of fitness for aparticular

use or purpose. We make no expressed warranties except as stated in this certificate. No one is authorized to change this certificate or to create for us

any other obligation or liability in connection with this unit. Any implied warranties shall last for one year after the original purchase date. Some states

and provincesdo not allow limitations on how longan implied warranty or condition lasts,so the above limitations or exclusions may not apply to you. The provisions

of this warranty are in addition to and not a modification of or subtraction from the statutory warranties and other rights and remedies provided by law.

In case of any questions regarding the provisions of this warranty, the English version will govern.

Revised 8/01

Model No. Serial No.

Date Purchased: Installation Location:

Date Installed:

Installed by:

Printedinthe U,S.A, 920-087-02 (9-03)

Loading...

Loading...