Page 1

Unifit Heat Cool Svc Parts 2010 (05/10)

Thru-the-Wall Series

230 Volts UE10C33 UE12C33

Unifit. Cool (03/07)

Thru-the-Wall Series

Service and Parts

Ma

nual

115 Volts UE08C13

R

Uni- Fit

Page 2

2 Room Air Conditioner

Air Conditioner Service Manual

TABLE OF CONTENTS

Safety Precautions ..........................................................................................................................................

3

Operating Instructions ..................................................................................................................................7

Controls.................................................................................................................................................... 7

Remote control......................................................................................................................................... 8

Disassembly instructions ............................................................................................................................. 9

Mechanical Parts...................................................................................................................................... 9

Air Handling Parts ...................................................................................................................................10

Electrical Parts ........................................................................................................................................11

Refrigeration Cycle..................................................................................................................................13

Schematic Diagram........................................................................................................................................16

Wiring Diagram........................................................................................................................................16

Troubleshooting Guide ................................................................................................................................17

Piping System .........................................................................................................................................17

Troubleshooting Guide ............................................................................................................................18

Room Air Conditioner Voltage Limits.......................................................................................................21

Product specifications............................................................................... .........................23~25

Exploded Vi ew .............................................................................................................................................26

Replacement Parts List ...............................................................................................................................27~29

........................................

Page 3

Service Manual 3

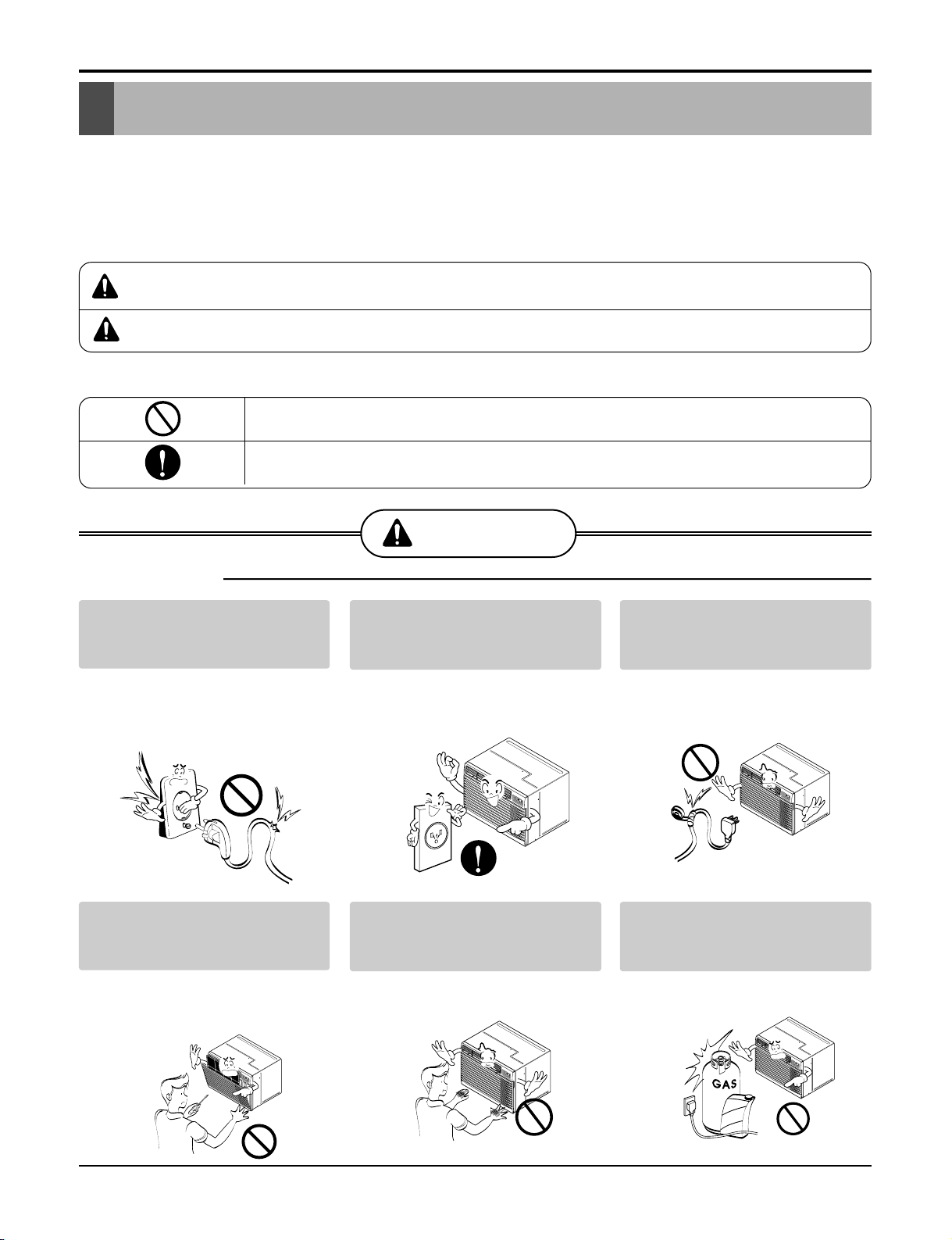

Safety Precautions

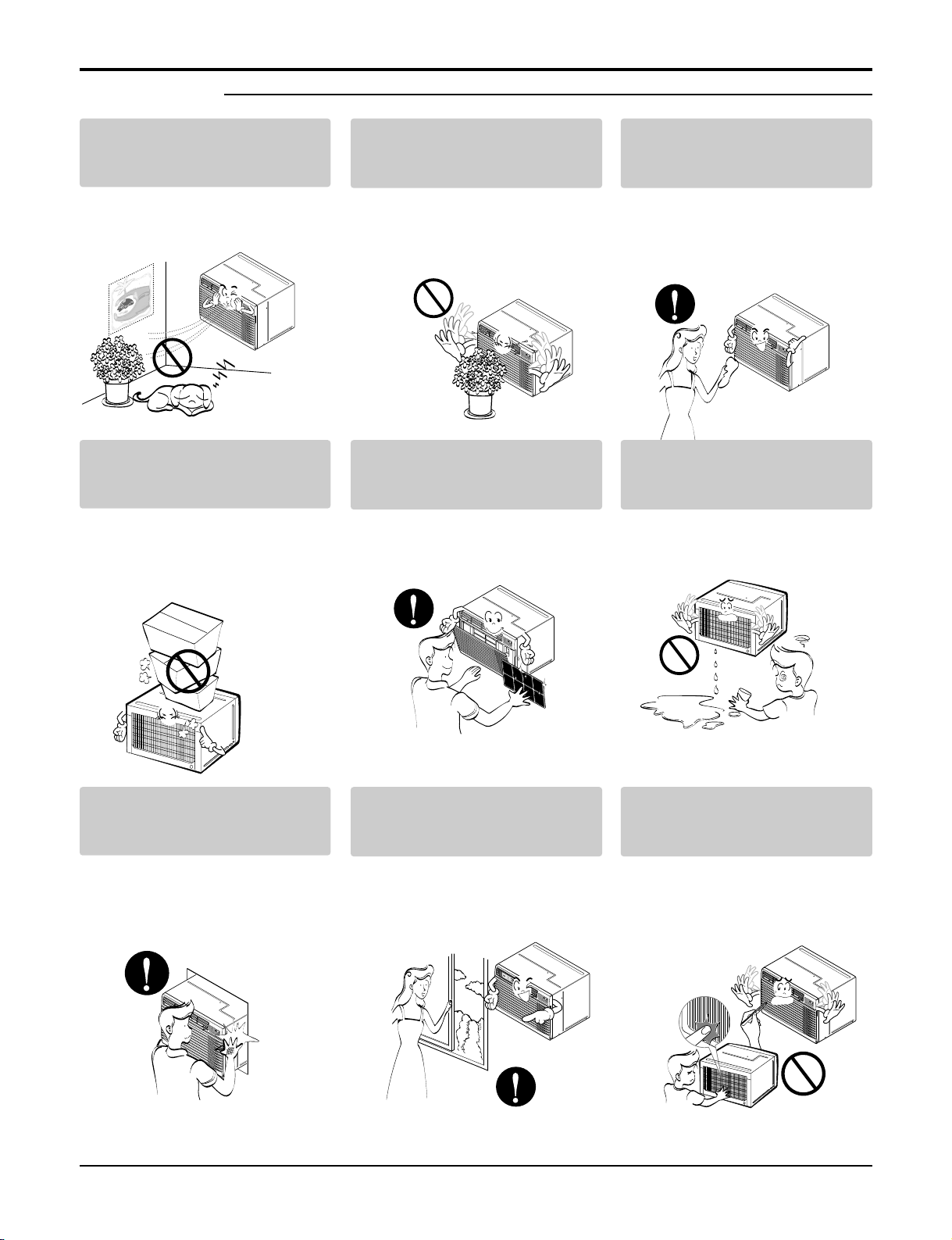

Safety Precautions

To prevent injury to the user or other people and property damage, the following instructions must

be followed.

■ Incorrect operation due to ignoring instruction will cause harm or damage. The seriousness is

classified by the following indications.

■ Meanings of symbols used in this manual are as shown below.

WARNING

CAUTION

This symbol indicates the possibility of death or serious injury.

This symbol indicates the possibility of injury or damage to property only.

WARNING

■ Installation

Don’t use a power cord, a plug

or a loose socket which is damaged.

• Otherwise, it may cause a fire or

electrical shock.

Always plug into a gr ounded

outlet.

• Otherwise, it may cause a fire or

electrical shock.

Do not modify or extend the

power cord length.

• It will cause electric shock or fire

due to heat generation.

Do not disassemble or modify

products.

• It may cause failure and electric

shock.

Be caution when unpacking and

installing.

• Sharp edges may cause injury.

Do not use the power cord near flammable gas or combustibles such as

gasoline, benzene, thinner, etc.

• It may cause explosion or fire.

Be sure not to do.

Be sure to follow the instruction.

M

O

DE

TIM

ER

POW

ER

F

A

N

S

P

E

E

D

F

a

n

H

e

a

t

E

n

e

r

g

y

S

a

v

e

r

C

o

o

l

T

i

m

e

r

TEMP

'

F

F

1

L

O

W

F

2

H

I

G

H

M

O

D

E

T

I

M

E

R

P

O

W

E

R

F

A

N

S

P

EE

D

Fan

Heat

E

n

e

r

g

y

S

a

v

e

r

Cool

Tim

er

T

E

M

P

'

F

F

1

L

O

W

F2 H

IG

H

M

O

D

E

T

I

M

E

R

P

O

W

E

R

FA

N

SP

EED

F

a

n

H

e

a

t

E

n

e

r

g

y

S

a

v

e

r

C

o

o

l

T

i

m

e

r

T

E

M

P

'

F

F

1

L

O

W

F

2

H

I

G

H

M

O

D

E

T

I

M

E

R

P

O

W

E

R

F

A

N

S

P

E

E

D

F

a

n

H

e

a

t

Energy

Saver

C

o

o

l

T

i

m

e

r

T

E

M

P

'

F

F

1

L

O

W

F2

H

IG

H

Gasolin

M

O

D

E

T

IM

E

R

P

O

W

E

R

F

A

N

S

P

E

E

D

F

a

n

H

e

a

t

E

n

e

r

g

y

S

a

v

e

r

C

o

o

l

T

i

m

e

r

T

E

M

P

'

F

F

1

L

O

W

F

2 H

IG

H

Page 4

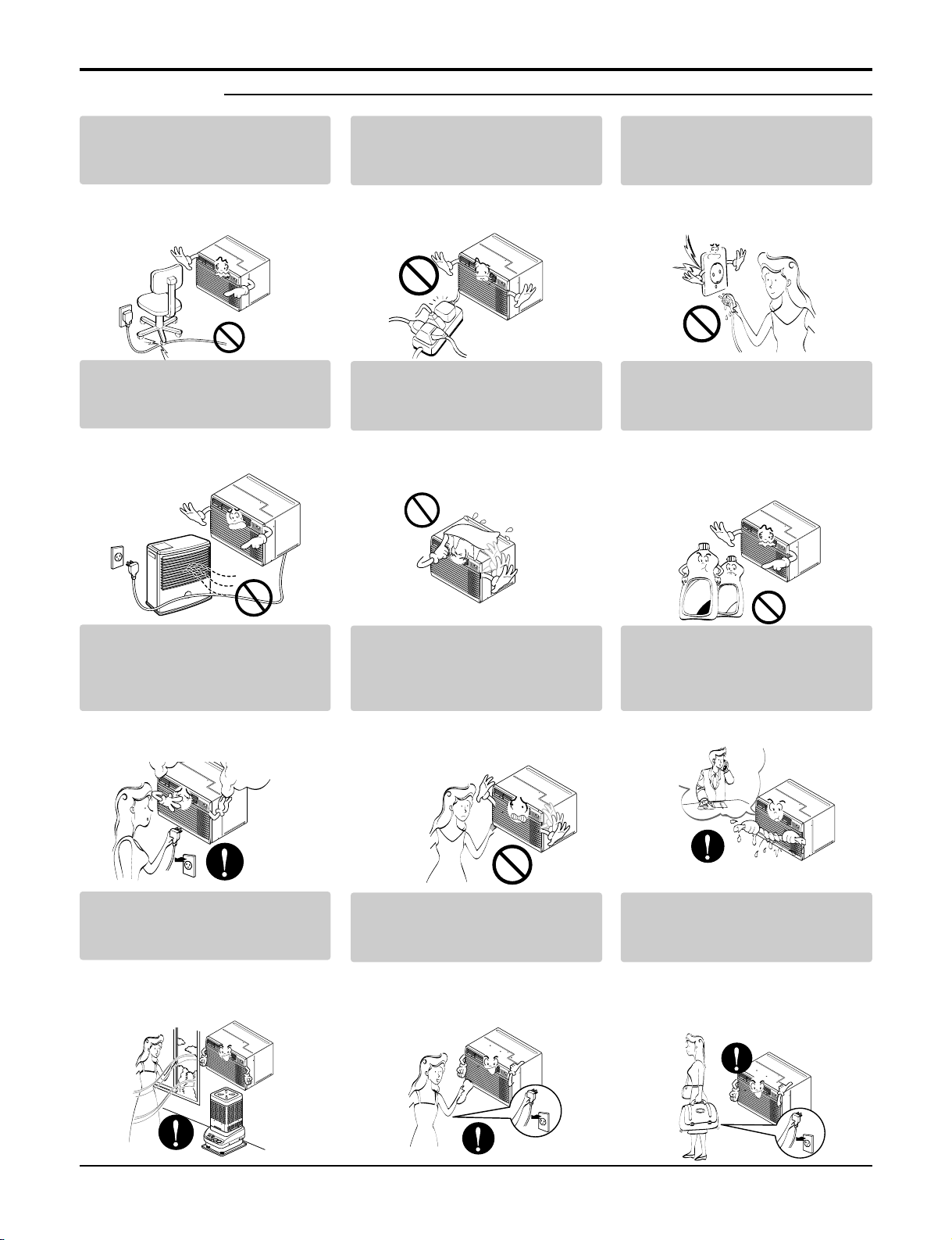

4 Room Air Conditioner

Safety Precautions

■ Operation

Do not place heavy object on the

power cord and take care so that

the cord should not be pressed.

• There is danger of fire or electric

shock.

Do not share the outlet with

other appliances.

• It will cause electric shock or fire

due to heat generation.

Take the power plug out if necessary, holding the head of the plug

and do not touch it with wet hands.

• Otherwise, it may cause a fire or

electrical shock.

Do not place the power cord

near a heater.

• It may cause fire and electric

shock.

Do not allow water to run into

electric parts.

• It will cause failure of machine or

electric shock.

Use a soft cloth to clean. Do not

use wax, thinner, or a strong

detergent.

• The appearance of the air conditioner may deteriorate, change

color, or develop surface flaws.

Unplug the unit if strange

sounds, odors, or smoke come

from it.

• Otherwise it may cause fire and

electric shock accident.

Do not open the suction inlet

grill of the product during operation.

• Otherwise, it may electrical

shock and failure.

If water enters the product, turn off the the

power switch of the main body of appliance.

Contact service center after taking the

power-plug out from the socket.

Ventilate the room well when

using this appliance together

with a stove, etc.

• An oxygen shortage may occur.

Turn off the power and breaker

firstly when cleansing the unit.

• Since the fan rotates at high speed

during operation, it may cause

injury.

Turn off the main power switch

when not using it for a long

time.

• Prevent accidental startup and the

possibility of injury.

M

OD

E

TIM

E

R

P

O

W

E

R

F

A

N

S

P

E

E

D

F

a

n

H

e

a

t

E

n

e

r

g

y

Sav

er

C

o

o

l

T

i

m

e

r

T

E

M

P

'

F

F

1

L

O

W

F

2

H

I

G

H

M

O

D

E

T

I

M

E

R

P

O

W

E

R

F

A

N

S

P

E

E

D

F

an

H

e

a

t

E

n

e

r

g

y

S

a

v

e

r

C

o

o

l

T

i

m

e

r

T

E

M

P

'

F

F

1

L

O

W

F

2

H

I

G

H

M

O

D

E

T

IM

E

R

P

O

W

E

R

F

A

N

S

P

E

E

D

F

a

n

H

e

a

t

E

n

e

rg

y

S

a

ve

r

C

o

o

l

T

i

m

e

r

T

E

M

P

'

F

F

1

L

O

W

F

2

H

I

G

H

M

O

D

E

T

I

M

E

R

P

O

W

E

R

F

A

N

S

P

E

E

D

F

an

H

e

at

E

n

e

r

g

y

S

a

v

e

r

C

o

o

l

Tim

e

r

T

E

M

P

'

F

F

1

L

O

W

F

2

H

IG

H

Wax

Thinner

MODE

TIMER

POWER

F

A

N

S

P

E

E

D

F

a

n

H

e

a

t

E

n

e

r

g

y

S

a

v

e

r

C

o

o

l

T

i

m

e

r

T

E

M

P

'

F

F

1

L

O

W

F

2

H

I

G

H

M

ODE

TIM

ER

PO

W

ER

FAN

SPEED

F

a

n

H

e

a

t

E

nerg

y

Sa

ver

C

o

o

l

T

i

m

e

r

T

E

M

P

'

F

F

1

L

O

W

F

2

H

I

G

H

MODE

TIMER

POWE

R

F

A

N

SPEED

F

a

n

H

e

a

t

E

n

e

r

g

y

S

a

v

e

r

C

o

o

l

T

i

m

e

r

T

E

M

P

'

F

F

1

L

O

W

F

2

H

I

G

H

M

O

D

E

T

IM

E

R

P

O

W

E

R

FA

N

S

PEE

D

Fan

Heat

En

er

g

y

Saver

Cool

Timer

TE

M

P

'

F

F

1

L

O

W

F

2

H

I

G

H

MODE

TIMER

POWER

F

A

N

S

P

E

E

D

F

a

n

H

e

a

t

E

n

e

r

g

y

S

a

v

e

r

C

o

o

l

T

i

m

e

r

T

E

M

P

'

F

F

1

L

O

W

F

2

H

I

G

H

M

O

D

E

T

I

M

E

R

P

O

W

E

R

F

A

N

S

P

E

E

D

F

a

n

H

ea

t

E

n

e

r

g

y

S

a

v

e

r

C

o

o

l

T

im

e

r

T

E

M

P

'

F

F

1

L

O

W

F

2

H

IG

H

M

O

D

E

T

I

M

E

R

P

O

W

E

R

F

A

N

S

P

E

E

D

F

an

He

at

Ene

rgy

Saver

Co

ol

T

ime

r

T

E

M

P

'

F

F

1

L

O

W

F

2

H

I

G

H

Page 5

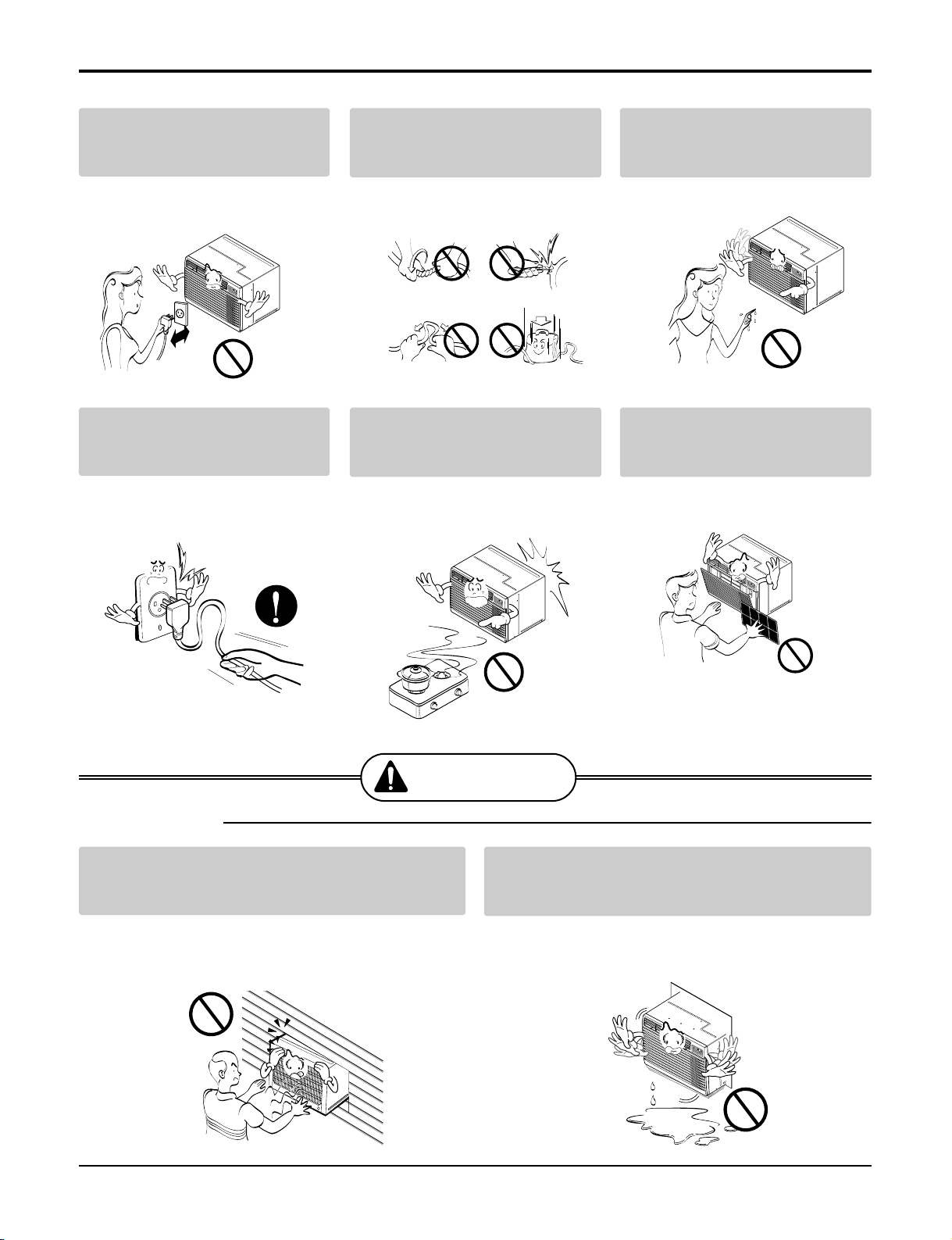

Service Manual 5

Safety Precautions

Do not operate or stop the unit

by inserting or pulling out the

power plug.

• It will cause electric shock or fire

due to heat generation.

Do not damage or use an

unspecified power cord.

• It will cause electric shock or fire.

Do not operate with wet hands

or in damp environment.

• It will cause electric shock.

Hold the plug by the head when

taking it out.

• It may cause electric shock and

damage.

When gas leaks, open the window for ventilation before operating the unit.

• Otherwise, it may cause explosion, and a fire.

Never touch the metal parts of

the unit when removing the filter.

• They are sharp and may cause

injury.

Install the product so that the noise or hot wind

from the outdoor unit may not cause any damage

to the neighbors.

• Otherwise, it may cause dispute with the neighbors.

Keep level parallel in installing the product.

• Otherwise, it may cause vibration or water leakage.

M

O

D

E

T

I

M

E

R

P

O

W

E

R

F

A

N

S

P

E

E

D

F

a

n

H

e

a

t

E

n

e

r

g

y

S

a

v

e

r

C

o

o

l

T

i

m

e

r

T

E

M

P

'

F

F

1

L

O

W

F

2

H

I

G

H

M

O

D

E

T

IM

E

R

P

O

W

E

R

FAN

SPEED

F

a

n

H

e

a

t

E

n

e

r

g

y

S

a

v

e

r

C

o

o

l

T

i

m

e

r

T

E

M

P

'

F

F1

L

OW

F2 HIGH

M

O

D

E

T

I

M

E

R

P

O

W

E

R

F

A

N

S

P

E

E

D

F

a

n

H

e

a

t

E

n

e

r

g

y

S

a

v

e

r

C

o

o

l

T

i

m

e

r

TEMP

'

F

F

1

L

O

W

F

2

H

IG

H

M

O

D

E

T

I

M

E

R

P

O

W

E

R

FA

N

SPEED

F

a

n

H

e

a

t

E

n

e

r

g

y

S

a

v

e

r

C

o

o

l

T

i

m

e

r

T

E

M

P

'

F

F

1 L

OW

F

2 HIGH

M

O

D

E

T

I

M

E

R

P

O

W

E

R

FAN

SPEED

F

a

n

H

e

a

t

E

n

e

r

g

y

S

a

v

e

r

C

o

o

l

T

i

m

e

r

T

E

M

P

'

F

F

1 L

O

W

F2 HIGH

CAUTION

■ Installation

Page 6

6 Room Air Conditioner

Safety Precautions

Do not put a pet or house plant

where it will be exposed to

direct air flow.

• It may cause injury.

Do not block the inlet or outlet

of air flow.

• It may cause product failure.

Use a soft cloth to clean. Do not

use wax, thinner, or a strong

detergent.

• The appearance of the air condi-

tioner may deteriorate, change

color, or develop surface flaws.

Do not step on the indoor/outdoor unit and do not put anything on it.

• It may cause an injury through

dropping of the unit or falling

down.

Always insert the filter securely.

Clean it every two weeks.

• Operation without filters will cause

failure.

Do not drink water drained from

air conditioner.

• It contains containments and will

make you sick.

Be cautious not to touch the

sharp edges when installing.

• It may cause injury.

Avoid excessive cooling and

perform ventilation sometimes.

• Otherwise, it may do harm to

your health.

Do not insert the hands or bars

through the air inlet or outlet

during operation.

• Otherwise, it may cause personal injury.

■ Operation

M

O

D

E

T

IM

E

R

P

O

W

E

R

FA

N

SPEED

F

a

n

H

e

a

t

E

n

e

r

g

y

S

a

v

e

r

C

o

o

l

T

i

m

e

r

T

E

M

P

'

F

F1

LOW

F2 HIGH

M

O

D

E

T

I

M

E

R

P

O

W

E

R

F

AN

SPEED

F

a

n

H

e

a

t

E

n

e

r

g

y

S

a

v

e

r

C

o

o

l

T

i

m

e

r

T

E

M

P

'

F

F1 L

O

W

F2 H

IGH

M

O

D

E

T

IM

E

R

P

O

W

E

R

FA

N

SPEED

F

a

n

H

e

a

t

E

n

e

r

g

y

S

a

v

e

r

C

o

o

l

T

i

m

e

r

T

E

M

P

'

F

F

1

L

O

W

F2 HIGH

M

O

D

E

T

I

M

E

R

P

O

W

E

R

FAN

SPEED

Fan

Heat

E

n

e

r

g

y

S

a

v

e

r

Cool

Timer

T

E

M

P

'

F

F

1

L

O

W

F

2

H

I

G

H

M

O

D

E

T

IM

E

R

P

O

W

E

R

FAN

SPEED

F

a

n

H

e

a

t

E

n

e

r

g

y

S

a

v

e

r

C

o

o

l

T

i

m

e

r

T

E

M

P

'

F

F1 LOW

F2 HIGH

M

O

D

E

T

I

M

E

R

P

O

W

E

R

F

A

N

S

P

E

E

D

F

a

n

H

e

a

t

E

n

erg

y

Save

r

C

o

o

l

T

i

m

e

r

TE

MP

'

F

F

1

L

O

W

F

2

H

I

G

H

M

O

D

E

T

IM

E

R

P

O

W

E

R

FAN

SPEED

F

a

n

H

e

a

t

E

n

e

r

g

y

S

a

v

e

r

C

o

o

l

T

i

m

e

r

T

E

M

P

'

F

F

1 L

OW

F2 HIGH

Page 7

7 Room Air Conditioner

Operating Instructions

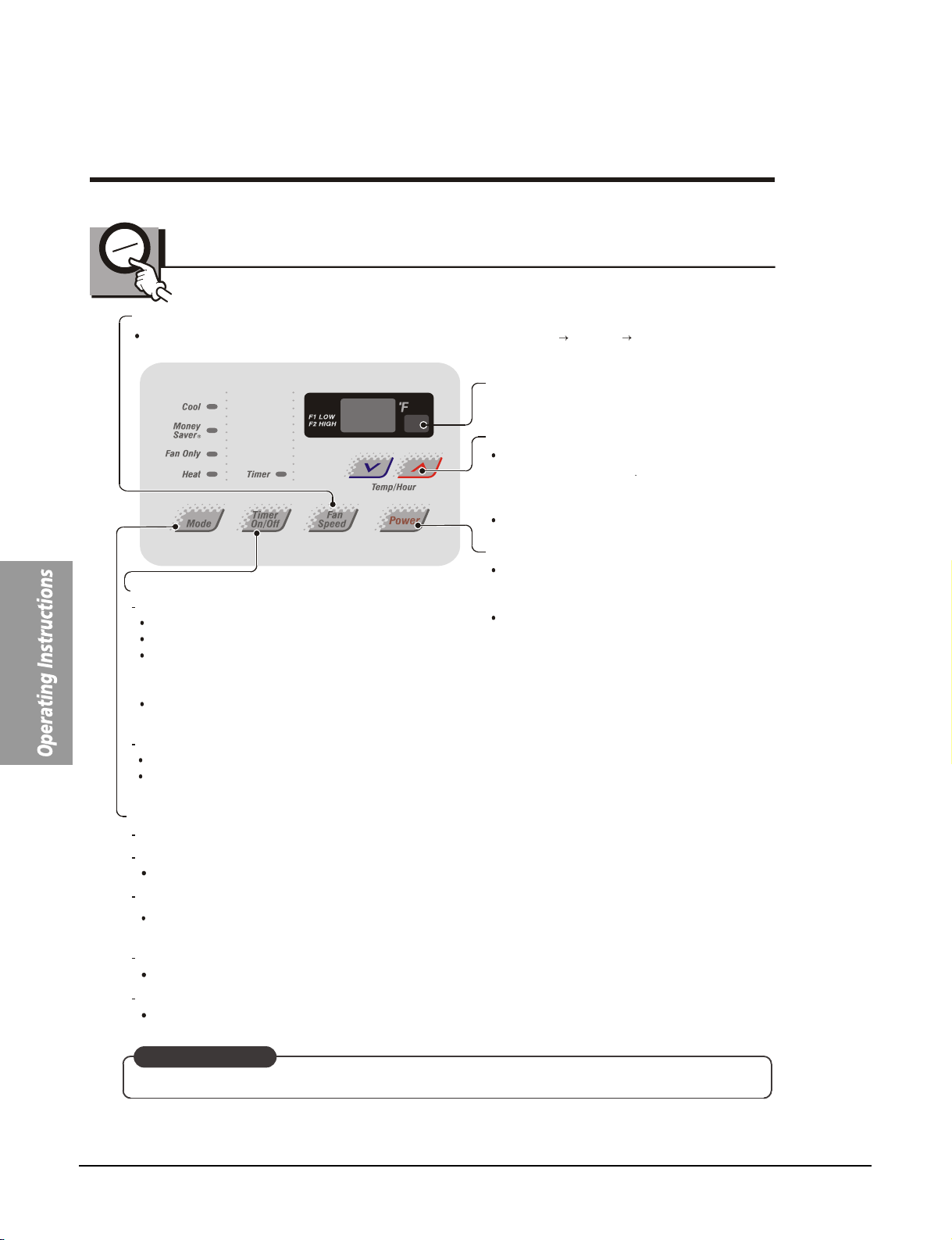

Controls

FAN SPEED

Every time you push this button,it advances the setting as follows:{High[F2] Low[F1]} High[F2]

TIMER

SHUT-OFF TIME

You will usually use shut-off time while you sleep.

If unit is running,use Timer to set number of hours until shut-off.

For your sleeping comfort,once Timer is set,the Temperature

setting will raise 2 F after 30 min,and once again after another

30 min.

Push Timer button to advance setting from 1Hour→

→12Hours maximum.

START TIME

If unit is off,use Timer to set number of hours before nuit starts.

Push Timer button to advance setting from 1Hour→

→12Hours maximum.

MODE

Push this button to shift mode of operation from COOL → MONEY SAVER→ FAN ONLY→HEAT

COOL:

Fan runs continually for normal cooling operation.

MONEY SAVER:

The fan stops when the compressor stops cooling.Approximately every 3 minutes the fan will turn on and the nuit will

check the room air temperature to determine if cooling is needed.

FAN ONLY:

Fan-only operation.

HEAT:

Fan runs continually for normal heating operation.

。

2Hour →...

2Hour →...

REMOTE CONTROL SIGNAL

RECEIVER

TEMPERATURE SETTING

Use this button to automatically control the

temperature of the room

The tmeperature can be set within a range of

60 F to 86 F by increments of 1 F.

The setting appears in the display.

。

。

。

POWER

To turn the air conditioner ON,push this button.

To turn the air conditioner OFF,push the button

again.

This button takes priority over any other button.

AUTO RESTART

When power is restored after an electrical power failure,the unit will begin to run at its last setting.

Page 8

Service Manual 8

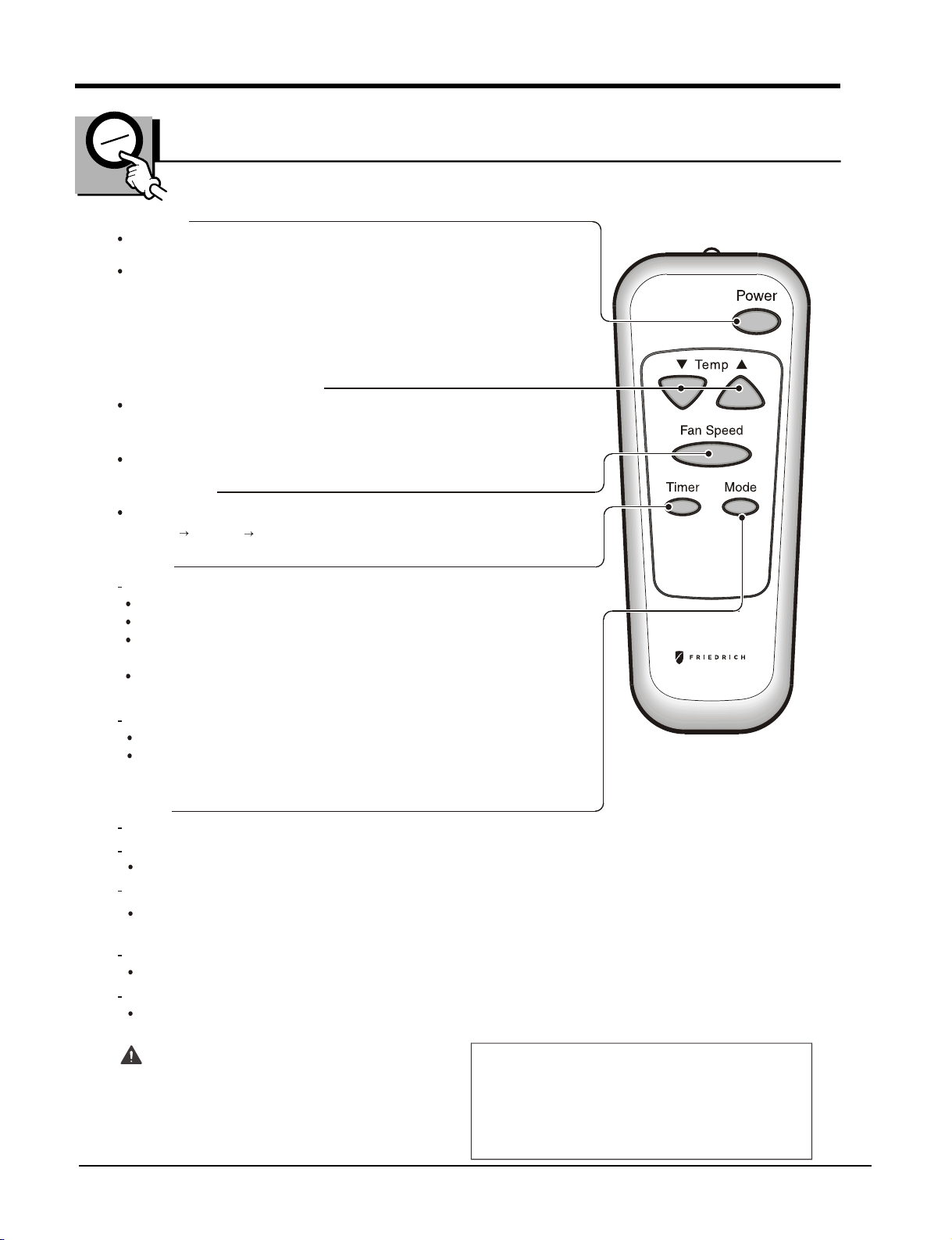

REMOTE CONTROL

POWER

To turn the air conditioner ON,push this button.

To turn the air conditioner OFF,push the button again.

This button takes priority over any other button.

TEMPERATURE SETTING

Use this button to automatically control the

The tmeperature can be set within a range of

increments of 1 F.

The setting appears in the display.

。

FAN SPEED

Every time you push this button,it advances the setting as follows:

{High[F2]

Low[F1]} High[F2]

TIMER

SHUT-OFF TIME

You will usually use shut-off time while you sleep.

If unit is running,use Timer to set number of hours until shut-off.

For your sleeping comfort,once Timer is set,the Temperature

。

raise 2 F after 30 min

Push Timer button to advance setting from 1Hour→

→12Hours maximum.

,

and once again after another

temperature of the room.

。

60 F to 86 F by

。

30 min.

2Hour →...

setting will

START TIME

If unit is off,use Timer to set number of hours before nuit starts.

Push Timer button to advance setting from 1Hour→

→12Hours maximum.

2Hour →...

MODE

Push this button to shift mode of operation from COOL → MONEY SAVER→ FAN ONLY→HEAT

COOL:

Fan runs continually for normal cooling operation.

MONEY SAVER:

The fan stops when the compressor stops cooling.Approximately every 3 minutes the fan will turn on and the nuit will

check the room air temperature to determine if cooling is needed.

FAN ONLY:

Fan-only operation.

HEAT:

Fan runs continually for normal heating operation.

CAUTION

When the air conditioner has been performed its

cooling or feating operation and is turned off or

set to the fan position,wait at 3 minutes

before resetting to the cooling operation again.

A slight heat odor may come from the nuit

when first switching to HEAT after the

cooling season is over.This odor,caused

by fine duct particles on the heater,will

disappear quickly.This is harmless.

Page 9

Service Manual 9

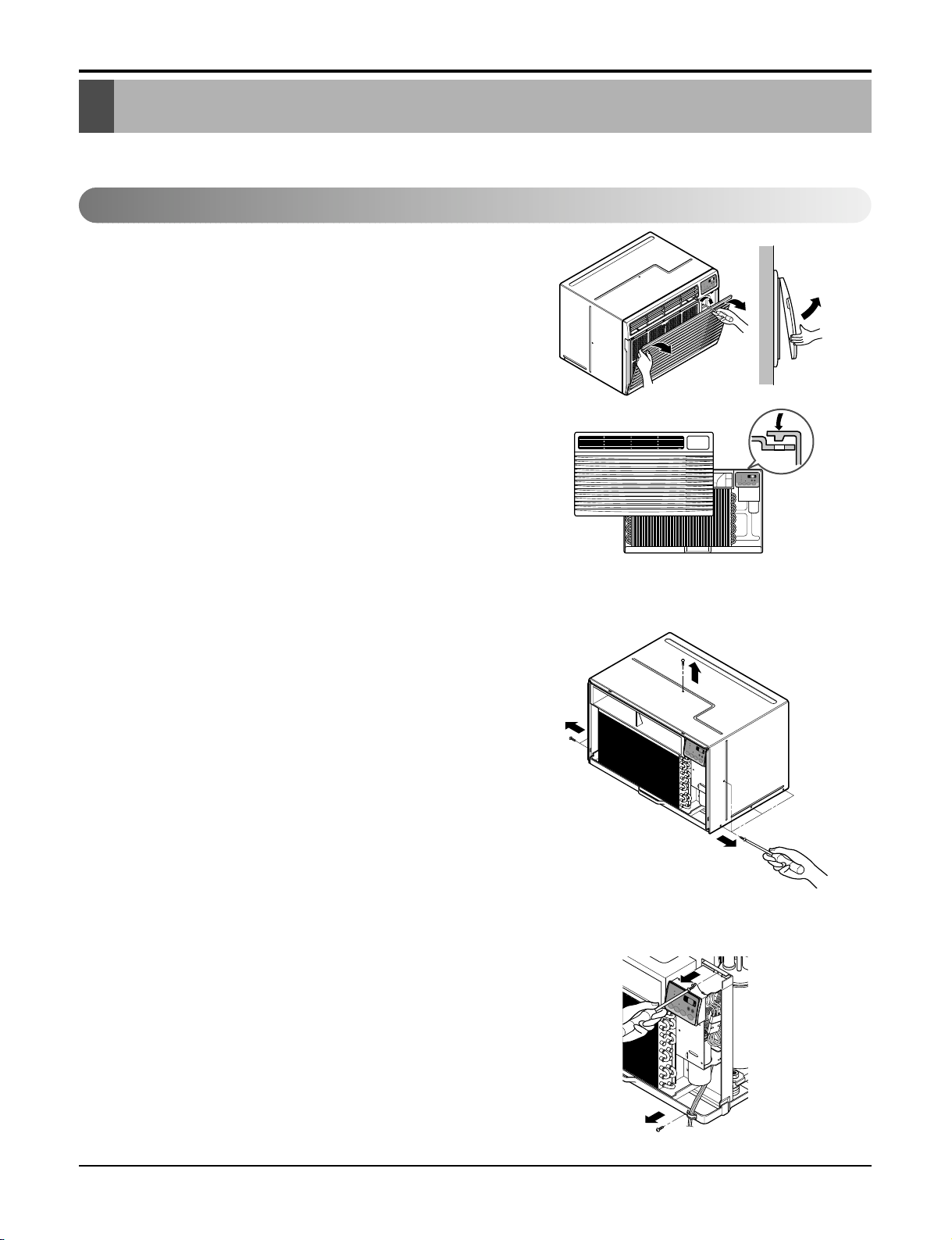

Disassembly Instructions

Disassembly Instructions

Mechanical Parts

— Before the following disassembly, POWER SWITCH is set to OFF and disconnected the power cord.

1.

FRONT GRILLE

1. Open the inlet grille upward or downward.

2. Remove the screw which fastens the front grille.

3. Pull the front grille from the right side.

4. Remove the front grille. (See Fig. 1)

5. Re-install the component by referring to the

removal procedure.

2. CABINET

1. After disassembling the FRONT GRILLE, remove the 9

screws which fasten the cabinet at the both sides and the

top. (See Fig. 2)

Keep these for later use.

3. CONTROL BOX

1. Remove the front grille. (Refer to section 1)

2. Remove the screw which fasten the control

box. (See Fig. 3)

3. Pull the control box from the barrier.(See Fig.3)

4. Discharge the capacitor by placing a 20,000 ohm resistor

across the capacitor terminals.

5. Disconnect two wire housings in the control box.

6. Pull the control box forward completely.

7. Re-install the components by referring to the removal

procedure. (See Fig. 3)

(Refer to the circuit diagram found on pages 24 in this

manual and on the control box.)

FIG. 1

FIG. 3

FIG. 2

MODE

TIMER

POWER

FAN

SPEED

Fan

Energy

Saver

Cool

Timer

TEMP

'

F

F

1

L

O

W

F2

M

E

D

F

3

H

IG

H

MODE TIMER POWER

FAN

SPEED

Fan

Heat

Energy

Saver

Cool

Timer

TEMP

'

F

F1 LOW

F2 HIGH

MODE

TIMER

POWER

F

A

N

S

P

E

E

D

F

a

n

H

e

a

t

Energy

Saver

C

o

o

l

T

i

m

e

r

TEM

P

'

F

F1 LOW

F2 HIGH

M

O

D

E

T

IM

E

R

P

O

W

E

R

FAN

SPEED

Fan

Energy

Saver

Cool

Timer

TEMP

'

F

F

1

L

O

W

F

2

M

E

D

F

3

H

IG

H

Page 10

10 Room Air Conditioner

Disassembly Instructions

4. ORIFICE, HEATER ASSY AND TURBO FAN

1. Remove the front grille. (Refer to section 1)

2. Remove the cabinet. (Refer to section 2)

3. Remove the 2 screws which fasten the evaporator

at the left side and the right side.

(See Fig. 4)

4. Move the evaporator sideward carefully.

5. Remove the 2 terminals carefully

(See Fig. 28, at Electric Heater Model only)

6. Remove the 4 screws which fasten the orifice. (See

Fig. 5)

7. Remove the orifice. (See Fig. 5)

8. Remove the clamp which secures the turbo fan with

plier. (See Fig. 6)

9. Remove the turbo fan with plier or your hand without touching blades. (See Fig. 7)

10. Re-install the components by referring to the

removal procedure, above.

5. FAN

1. Remove the cabinet. (Refer to section 2)

2. Remove the brace and shroud cover.

(Refer to section 4)

3. Remove the 6 screws which fasten the condenser.

4. Move the condenser sideways carefully.

5. Remove the clamp which secures the fan.

6. Remove the fan. (See Fig. 8)

7. Re-install the components by referring to the removal

procedure, above.

Air Handling Parts

MODE

TIMER

POW

ER

FAN

SPEED

Fan

En

e

rg

y

Saver

C

o

o

l

Timer

TE

M

P

'

F

F1 LO

W

F

2 M

ED

F3 HIGH

FIG. 4

FIG. 5

FIG. 6

FIG. 7

FIG. 8

Page 11

Service Manual 11

6. SHROUD

1. Remove the fan. (Refer to section 5)

2. Remove the screw which fasten the shroud.

3. Remove the shroud. (See Fig. 9)

4. Re-install the component by referring to the

removal procedure, above.

7. MOTOR

1. Remove the cabinet. (Refer to section 2)

2. Remove the clamp cord and disconnect a wire

housing in control box. (Refer to section 3)

3. Remove the turbo fan. (Refer to section 5)

4. Remove the fan. (Refer to section 5)

5. Remove the 4 or 2 screws which fasten the motor.

(See Fig. 10)

6. Remove the motor.

7. Re-install the components by referring to the

removal procedure, above.

8. COMPRESSOR

1. Remove the cabinet. (Refer to section 2)

2. Discharge the refrigerant system using Freon

TM

Recovery System.

If there is no valve to attach the recovery system,

install one (such as a WATCO A-1) before venting

the Freon

TM

. Leave the valve in place after

servicing the system.

3. Disconnect the 3 leads from the compressor.

4. After purging the unit completely, unbraze the suction and discharge tubes at the compressor connections.

5. Remove the 3 nuts and the 3 washers which fasten the compressor. (See Fig. 11)

6. Remove the compressor.

7. Re-instill the components by referring to the

removal procedure, above.

9. CAPACITOR

1. Remove the control box. (Refer to section 3)

2. Remove a screw which fasten the display panel.

3. Remove 2 screws and unfold the control box.

(See Fig. 12)

4. Remove the screw and the clamp which fastens

the capacitor. (See Fig. 12)

5. Disconnect all the leads of capacitor terminals.

6. Re-install the components by referring to the

removal procedure, above.

Disassembly Instructions

Electrical Parts

FIG. 9

FIG. 11

FIG. 12

MODE

TIMER

POWER

FAN

SPEED

Fan

Energy

Saver

Cool

Timer

TEMP

'

F

F1 LO

W

F2 MED

F3 HIG

H

FIG. 10

Page 12

12 Room Air Conditioner

Disassembly Instructions

10. POWER CORD

1. Remove the control box. (Refer to section 3)

2. Unfold the control box. (Refer to section 9)

3. Disconnect the grounding screw from the control

box.

4. Disconnect 2 receptacles.

5. Remove a screw which fastens the clip cord.

6. Pull the power cord. (See Fig. 13)

7. Re-install the component by referring to the

removal procedure, above.

(Use only one ground-marked hole for ground

connection.)

8. If the supply cord of this appliance is damaged, it

must be replaced by the special cord.

(The special cord means the cord which has the

same specification marked on the supply cord fitted to the unit.)

11. THERMOSTAT

1. Remove the control box. (Refer to section 3)

2. Unfold the control box. (Refer to section 9)

3. Disconnect the theristor terminals from main

P.W.B assembly.

4. Remove the thermostat. (See Fig. 14)

5. Re-install the components by referring to the

removal procedure, above.

MODE

TIMER

POWER

FAN

SPEED

Fan

Energy

Saver

Cool

Timer

TEMP

'

F

F1 LOW

F2 MED

F3 HIGH

MODE

TIMER

POWER

FAN

SPEED

Fan

Energy

Saver

Cool

Timer

TEMP

'

F

F1 LOW

F2 MED

F3 HIGH

FIG. 13

FIG. 14

Page 13

Service Manual 13

Disassembly Instructions

12. CONDENSER

1. Remove the cabinet. (Refer to section 2)

2. Remove the brace and the shroud cover.

(Refer to section 4)

3. Remove the 5 screws which fasten the condenser.

4. After discharging the refrigerant completely,

unbraze the interconnecting tube at the condenser

connections.

5. Remove the condenser.

6. Re-install the components by referring to notes.

(See Fig. 15)

13. EVAPORATOR

1. Remove the cabinet. (Refer to section 2)

2. Discharge the refrigerant completely.

3. Remove the 2 screws which fasten the evaporator

at the left side and the right side.

4. Move the evaporator sideward carefully and then

unbraze the interconnecting tube at the evaporator

connectors.

5. Remove the evaporator.

6. Re-install the components by referring to notes.

(See Fig. 16)

14. CAPILLARY TUBE

1. Remove the cabinet. (Refer to section 2)

2. After discharging the refrigerant completely,

unbraze the interconnecting tube at the capillary

tube.

3. Remove the capillary tube.

4. Re-install the components by referring to notes.

FIG. 15

FIG. 16

Refrigerating Cycle

Discharge the refrigerant system using Freon

TM

Recovery System.

If there is no valve to attach the recovery system,

install one (such as a WATCO A-1) before venting the Freon

TM

. Leave the valve in place after

servicing the system.

CAUTION

MODE

TIMER

POW

ER

FAN

SPEED

Fan

Energy

Saver

Cool

Timer

TEM

P

'

F

F1 LOW

F2 MED

F3 HIGH

Page 14

14 Room Air Conditioner

Disassembly Instructions

— Replacement of the refrigeration cycle.

1. When replacing the refrigeration cycle, be sure to

discharge the refrigerant system using a Freon

TM

recovery System.

If there is no valve to attach the recovery system,

install one (such as a WATCO A-1) before venting

the FreonTM. Leave the valve in place after

servicing the system.

2. After discharging the unit completely, remove the

desired component, and unbrace the pinch-off

tubes.

3. Solder service valves into the pinch-off tube ports,

leaving the valves open.

4. Solder the pinch-off tubes with Service valves.

5. Evacuate as follows.

1) Connect the vacuum pump, as illustrated Fig.

17A.

2) Start the vacuum pump, slowly open manifold

valves A and B with two full turns counterclockwise and leave the valves closed.

The vacuum pump is now pulling through valves

A and B up to valve C by means of the manifold

and entire system.

3) Operate the vacuum pump for 20 to 30 minutes,

until 600 microns of vacuum is obtained. Close

valves A and B, and observe vacuum gauge for

a few minutes. A rise in pressure would

indicate a possible leak or moisture remaining in

the system. With valves A and B closed, stop

the vacuum pump.

4) Remove the hose from the vacuum pump and

place it on the charging cylinder. See Fig. 17B.

Open valve C.

Discharge the line at the manifold connection.

5) The system is now ready for final charging.

6. Recharge as follows :

1) Refrigeration cycle systems are charged from the

High-side. If the total charge cannot be put

in the High-side, the balance will be put in the

suction line through the access valve which you

installed as the system was opened.

2)

Connect the charging cylinder as shown in Fig. 17B.

With valve C open, discharge the hose at the manifold connection.

3) Open valve A and allow the proper charge to

enter the system. Valve B is still closed.

4) If more charge is required, the high-side will not

take it. Close valve A.

5) With the unit running, open valve B and add the

balance of the charge.

a. Do not add the liquid refrigerant to the Low-

side.

b. Watch the Low-side gauge; allow pressure to

rise to 39 lbs.

c. Turn off valve B and allow pressure to drop.

d. Repeat steps B and C until the balance of the

charge is in the system.

6) When satisfied the unit is operating correctly,

use the pinch-off tool with the unit still running

and clamp on to the pinch-off tube. Using a tube

cutter, cut the pinch-off tube about 2 inches from

the pinch-off tool. Use sil-fos solder and solder

pinch-off tube closed. Turn off the unit, allow it to

set for a while, and then test the leakage of the

pinch-off connection.

NOTICE

If high vacuum equipment is used, just crack

valves A and B for a few minutes, then open

slowly with the two full turns counterclockwise.

This will keep oil from foaming and being

drawn into the vacuum pump.

CAUTION

Page 15

Service Manual 15

Disassembly Instructions

Equipment needed: Vacuum pump, Charging cylinder, Manifold gauge, Brazing equipment. Pinch-off tool capable of making a vapor-proof seal, Leak detector, Tubing cutter, Hand Tools to remove components, Service valve.

A

COMPOUND GAUGE

EVAPORATOR

(LOW PRESSURE SIDE)

COMPRESSOR

CAPILLARY TUBE

CONDENSER

(HIGH PRESSURE SIDE)

SEE INSETS

BELOW

MANIFOLD

GAUGE

B

FIG. 17A-Pulling Vacuum

FIG 17B-Charging

A

B

EXTERNAL

VACUUM PUMP

LOW

B

HI

A

CHARGING

CYLINDER

C

Page 16

16 Room Air Conditioner

Schematic Diagram

Schematic Diagram

Wiring Diagram

■ ELECTRIC HEATING MODEL

Page 17

Troubleshooting Guide

Troubleshooting Guide

Piping System

Following is a brief description of the important components and their functions in the refrigeration system.

Refer to Fig. 18 to follow the refrigeration cycle and the flow of the refrigerant in the cooling cycle.

MOTOR

COMPRESSOR

OIL

(LIQUID REFRIGERANT)

CAPILLARY TUBE

OUTSIDE COOLING

AIR FOR REFRIGERANT

PASS THROUGH

SUCTION LIME

COOL LOW PRESSURE VAPOR

COOLED

AIR

COMPLETE LIQUID

BOIL OFF POINT

LIQUID

PRESSURE

DROP

ROOM AIR HEAT LOAD

VAPOR INLET

HOT

DISCHARGED

AIR

LIQUID OUTLET

HIGH PRESSURE VAPOR

LIQUID PEFRIGERANT

LOW PRESSURE VAPOR

ROOM AIR CONDITIONER

EVAPORATOR COILS CONDENSER COILS

CYCLE OF REFRIGERATION

FIG. 18

Service Manual 17

CONDENSER COILS

FAN

CAPILLARY TUBE

MOTOR

COMPRESSOR

TURBO FAN

EVAPORATOR COILS

: REFRIGERANT FLOW

Page 18

18 Room Air Conditioner

Troubleshooting Guide

Troubleshooting Guide

In general, possible trouble is classified in two causes.

The one is called Starting Failure which is caused from an electrical defect, and the other is Ineffective Air

Conditioning caused by a defect in the refrigeration circuit and improper application.

Unit is running but cooling is ineffective

Ineffective Cooling

Check of outdoor coil

(heat exchanger) & the fan

operation.

Check gas leakage.

Repair gas leak.

Replacement of unit if the

unit is beyond repair.

Satisfactory operation with

temperature difference of

inlet & outlet air ; 44.6~50˚F

Check heat load increase.

Unexpected residue

Overloaded Circuit

Check of inside gas

pressure.

Adjusting of refrigerant

charge

Malfunction of compressor

Replacement of

compressor

Check of cold air circulation

for smooth flow.

Dirty indoor coil

(Heat exchanger)

Malfunction of fan

Clogged of air filter

Obstruction at air outlet

Correct above trouble

Stop of auto air-swing

Check clogging in

refrigeration circuit.

Repair clogging in

refrigeration circuit.

Page 19

Service Manual 19

Troubleshooting Guide

Fails to Start

Check of circuit breaker

and fuse.

Gas leakage of feeler bulb

of thermostat

Check of control switch.

Only fan fails to start.

Improper wiring.

Defect of fan motor

capacitor.

Irregular motor resistance

( ).

Irregular motor insulation

( ).

Replacement of fan motor

Regular but fails to start

Replacement of compressor

(locking of rotor, metal)

Improper thermostat setting

Loose terminal connection.

Improper wiring

Irregular motor resistance ( )

Irregular motor insulation ( )

Replacement of compressor

(Motor damaged)

Drop of power voltage.

Check capacitor.

Replacement.

Only compressor fails to

start.

Defect of compressor

capacitor.

Check of power source.

Check of control switch

setting.

Page 20

20 Room Air Conditioner

Troubleshooting Guide

YDEMERESUACTNIALPMOC

Check voltage at outlet. Correct if none.

Connect wire. Refer to wiring diagram for terminal

identification. Repair or replace loose terminal.

Test capacitor.

Replace if not within ±10% of manufacturer's

rating. Replace if shorted, open, or damaged.

Fan blade hitting shroud or blower wheel hitting

scroll. Realign assembly.

Units using slinger ring condenser fans must

have

1

/4to5/16inch clearance to the base. If it is

hitting the base, shim up the bottom of the fan

motor with mounting screw(s).

Check fan motor bearings; if motor shaft will not

rotate, replace the motor.

Check voltage. See limits on this page. If not within

limits, call an electrician.

Test capacitor.

Check bearings. Does the fan blade rotate freely?

If not, replace fan motor.

Pay attention to any change from high speed to

low speed. If the speed does not change, replace

the motor.

Check grommets; if worn or missing, replace them.

If cracked, out of balance, or partially missing,

replace it.

If cracked, out of balance, or partially missing,

replace it.

Tighten it.

If knocking sounds continue when running or

loose, replace the motor. If the motor hums or

noise appears to be internal while running,

replace motor.

No power

Wire disconnected or

connection loose

Capacitor (Discharge

capacitor before testing.)

Will not rotate

Revolves on overload.

Grommets

Fan

Turbo fan

Loose set screw

Worn bearings

Fan motor will not run.

Fan motor runs

intermittently

Fan motor noise.

Page 21

Service Manual 21

Troubleshooting Guide

NAME PLATE RATING MINIMUM MAXIMUM

115V 103.5V 126.5V

208/230V 187V 253V

YDEMERESUACTNIALPMOC

Check voltage. See the limits on the preceding.

page. If not within limits, call an electrician.

Check the wire connections, if loose, repair or

replace the terminal. If wires are off, refer to wiring

diagram for identification, and replace. Check wire

locations. If not per wiring diagram, correct.

Check the capacitor.

Replace if not within ±10% of manufacturers

rating. Replace if shorted, open, or damaged.

Check the compressor for open circuit or

ground. If open or grounded, replace the compressor.

Check the compressor overload, if externally

mounted. Replace if open. (If the compressor

temperature is high, remove the overload, cool it,

and retest.)

Voltage

Wiring

Capacitor (Discharge

capacitor before

servicing.)

Compressor

Overload

Compressor will not run,

but fan motor runs.

ROOM AIR CONDITIONER VOLTAGE LIMITS

Page 22

22 Room Air Conditioner

COMPLAINT CAUSE

REMEDY

Check the voltage. See the limits on the preceding page. If not within limits, call an electrician.

Check overload, if externally mounted.

Replace if open. (If the compressor temperature

is high, remove the overload, cool, and retest.)

If not running, determine the cause. Replace if

required.

Remove the cabinet. inspect the interior surface

of the condenser; if restricted, clean carefully

with a vacuum cleaner (do not damage fins) or

brush. Clean the interior base before

reassembling.

If condenser fins are closed over a large area

on the coil surface, head pressures will increase,

causing the compressor to cycle. Straighten the

fins or replace the coil.

Test capacitor.

Check the terminals. If loose, repair or replace.

Check the system for a restriction.

If restricted, clean of replace.

Close if open.

Determine if the unit is properly sized for the area to

be cooled.

Check the set screw or clamp. If loose or missing,

correct. If the blower or fan is hitting air guide,

rearrange the air handling parts.

Remove the cabinet and carefully rearrange tubing

not to contact cabinet, compressor, shroud, and barrier.

Voltage

Overload

Fan motor

Condenser air flow

restriction

Condenser fins

(damaged)

Capacitor

Wiring

Refrigerating system

Air filter

Exhaust damper door

Unit undersized

Blower or fan

Copper tubing

Compressor cycles

on overload.

Insufficient cooling or heating

Excessive noise.

Troubleshooting Guide

Page 23

Service Manual 23

Product Specifications

ITEMS

COOLING

HEATING

OPERATING

TEMPERATURE

REFRIGERANT(R410A)

EVAPORATOR

CONDENSER

FAN,INDOOR

FAN,OUTDOOR

FAN,SPEEDS

FAN,MOTOR

OPERATION CONTROL

ROOM TEMP.CONTROL

AIR DIRECTTION CONTROL

CONSTRUCTION

ELECTRIC HEATER

PROTECTOR

POWER CORD

DRAIN SYSTEM

NET WEIGHT(lbs/kg)

DIMENSION

(Wx Hx D)

SLEEVE DIMESION

(Wx Hx D)

SLEEVE DEPTH

WITH FRONT GRILLE

MODELS

COOLING

HEATING

(FAN/COOLING/HEATING)

COMPRESSOR

FAN,MOTOR

ELECTRIC HEATER

REMARK

POWER SUPPLY

CAPACITY(Btu/h)

INPUT(W)

RUNNING CURRENT(A)

E.E.R(Btu/W.h)

CAPACITY(Btu/h)

INPUT(W)

RUNNING CURRENT(A)

INDOOR(

OUTDOOR(

INDOOR(

OUTDOOR(

CHARGE(g)

(

( mm)

(

(

(

(

°F)

°F)

°F)

°F)

inch)

inch)

mm)

inch)

mm)

Ø5.0 3 ROW 18 STACKS,L-BENDED TYPE

PROPELLER TYPE FAN WITH SLINGER-RING

VERTICAL LOUVER (RIGHT&LEFT)

HORIZONTAL LOUVER (UP&DOWN)

EXTERNAL OVERLOAD PROTECTOR

INTERANL THERMAL PROTECTOR

FUSE LINK,BIMETAL THERMOSTAT

1.92m(3WIRE WITH GROUDING)

ATTACHMENT PLUG(CORD-CONNECTED TYPE)

SPLASHED BY FAN SLINGER

24 21/32 x 14 13/32 x 19 21/32

25 7/8 x 15 17/32 x 16 23/32

UE08C13

Ø,115V,60HZ

1

8,000

830

7.5

9.6

3,850

1,230

10.7

80

(DB)

(DB)

95

(DB)

70

47

320

2 ROW 12 STACKS

TURBO FAN

TOUCH PANEL

THERMISTOR

TOP - DOWN

3.5KW,230V

656 x 366 x 499

656 x 394 x 425

67

75

60

44

(DB)

(11.3OZ)

2/2/2

6 POLES

80/36

20

510

(WB)

(WB)

(

(

WB

WB

)

)

LOUVERFIN TYPE

OPTIONA PART

Page 24

Product Specifications

24 Room Air Conditioner

ITEMS

COOLING

HEATING

OPERATING

TEMPERATURE

REFRIGERANT(R410A)

EVAPORATOR

CONDENSER

FAN,INDOOR

FAN,OUTDOOR

FAN,SPEEDS

FAN,MOTOR

OPERATION CONTROL

ROOM TEMP.CONTROL

AIR DIRECTTION CONTROL

CONSTRUCTION

ELECTRIC HEATER

PROTECTOR

POWER CORD

DRAIN SYSTEM

NET WEIGHT(lbs/kg)

DIMENSION

(Wx Hx D)

SLEEVE DIMESION

(Wx Hx D)

SLEEVE DEPTH

WITH FRONT GRILLE

MODELS

COOLING

HEATING

(FAN/COOLING/HEATING)

COMPRESSOR

FAN,MOTOR

ELECTRIC HEATER

REMARK

POWER SUPPLY

CAPACITY(Btu/h)

INPUT(W)

RUNNING CURRENT(A)

E.E.R(Btu/W.h)

CAPACITY(Btu/h)

INPUT(W)

RUNNING CURRENT(A)

INDOOR(

OUTDOOR(

INDOOR(

OUTDOOR(

CHARGE(g)

(

( mm)

(

(

(

(

°F)

°F)

°F)

°F)

inch)

inch)

mm)

inch)

mm)

2 ROW 18 STACKS,L-BENDED TYPE 1 ROW

PROPELLER TYPE FAN WITH SLINGER-RING

VERTICAL LOUVER (RIGHT&LEFT)

HORIZONTAL LOUVER (UP&DOWN)

EXTERNAL OVERLOAD PROTECTOR

INTERANL THERMAL PROTECTOR

FUSE LINK,BIMETAL THERMOSTAT

1.92m(3WIRE WITH GROUDING)

ATTACHMENT PLUG(CORD-CONNECTED TYPE)

SPLASHED BY FAN SLINGER

24 21/32 x 14 13/32 x 19 21/32

25 7/8 x 15 17/32 x 16 23/32

UE10C33

Ø,230/208V,60HZ

1

000/9 800

10

1,080/1

11

3,500/2 900

80

95

70

47

440

3 ROW 12 STACKS

TURBO FAN

TOP - DOWN

656 x 366 x 499

656 x 394 x 425

040

4.7/5.2

9.4/9.4

200/9 200

15.3/14.0

67

(DB)

(DB)

(DB)

(DB)

(WB)

75

(WB)

(

60

WB

(

44

WB

(15.5OZ)

2/2/2

6 POLES

TOUCH PANEL

THERMISTOR

3.5KW,230V

80/36

20

510

)

)

LOUVERFIN TYPE

OPTIONA PART

Page 25

Product Specifications

Service Manual 25

ITEMS

COOLING

HEATING

OPERATING

TEMPERATURE

REFRIGERANT(R410A)

EVAPORATOR

CONDENSER

FAN,INDOOR

FAN,OUTDOOR

FAN,SPEEDS

FAN,MOTOR

OPERATION CONTROL

ROOM TEMP.CONTROL

AIR DIRECTTION CONTROL

CONSTRUCTION

ELECTRIC HEATER

PROTECTOR

POWER CORD

DRAIN SYSTEM

NET WEIGHT(lbs/kg)

DIMENSION

(Wx Hx D)

SLEEVE DIMESION

(Wx Hx D)

SLEEVE DEPTH

WITH FRONT GRILLE

MODELS

COOLING

HEATING

(FAN/COOLING/HEATING)

COMPRESSOR

FAN,MOTOR

ELECTRIC HEATER

REMARK

POWER SUPPLY

CAPACITY(Btu/h)

INPUT(W)

RUNNING CURRENT(A)

E.E.R(Btu/W.h)

CAPACITY(Btu/h)

INPUT(W)

RUNNING CURRENT(A)

INDOOR(

OUTDOOR(

INDOOR(

OUTDOOR(

CHARGE(g)

(

( mm)

(

(

(

(

°F)

°F)

°F)

°F)

inch)

inch)

mm)

inch)

mm)

2 ROW 18 STACKS,L-BENDED TYPE 1 ROW

PROPELLER TYPE FAN WITH SLINGER-RING

VERTICAL LOUVER (RIGHT&LEFT)

HORIZONTAL LOUVER (UP&DOWN)

EXTERNAL OVERLOAD PROTECTOR

INTERANL THERMAL PROTECTOR

FUSE LINK,BIMETAL THERMOSTAT

1.92m(3WIRE WITH GROUDING)

ATTACHMENT PLUG(CORD-CONNECTED TYPE)

SPLASHED BY FAN SLINGER

24 21/32 x 14 13/32 x 19 21/32

25 7/8 x 15 17/32 x 16 23/32

UE12C13

Ø,230/208V,60HZ

1

500/11,200

11

1,220/1

11

3,500/2 900

80

95

70

47

540

3 ROW 12 STACKS

TURBO FAN

TOP - DOWN

656 x 366 x 499

656 x 394 x 425

190

5.6/6.0

9.4/9.4

200/9 200

15.3/14.0

67

(DB)

(DB)

(DB)

(DB)

(WB)

75

(WB)

(

60

WB

(

44

WB

(19.0OZ)

2/2/2

6 POLES

TOUCH PANEL

THERMISTOR

3.5KW,230V

80/36

20

510

)

)

LOUVERFIN TYPE

OPTIONA PART

Page 26

Exploded View

Exploded View

349600

567502

W48602

550140

359012

B

249940

249950 267110

A

264110

238310

W0CZZ

237200

MODE

TIMER

POWER

FAN

SPEED

Fan

Energy

Sav

e

r

Cool

Timer

T

EM

P

'

F

F1

L

O

W

F

2M

ED

F

3

H

IGH

552206

753000

349480

W48602

559011

346811

349001

130410

148000

149980

135313

C

D

E

26 Room Air Conditioner

731273

132100

135312

352380

147581

147582-1

145200

147582-2

152302

130900

435300

435301

268711-2

567480

268711-1

Page 27

W0CZZ CAPACITOR,FILM,BOX 67301909

130410 BASE ASSEMBLY,SINGLE 67302923

130900 CABINET 67303718

132100 FRAME 67303504

135303 GRILLE,INLET 67306113

135312 GRILLE ASSEMBLY,FRONT(SINGLE) 67306020

238310 ESCUTCHEON 67304802

W48602 CLAMP,SPRING 67302500

346811 MOTOR ASSEMBLY,SINGLE 67303019

147581 LOUVER,HORIZONTAL 67306203

147582-1 LOUVER,VERTICAL 67306252

147582-2 LOUVER,VERTICAL 67306253

349600 BRACKET,MOTOR 67303607

149980 SHROUD 67303111

5

50140 DAMPER,COMPRESSOR 67305000

152302 FILTER,AIR 67304304

352380 AIR GUIDE 67302735

359012 FAN,TURBO 67302608

559011 FAN ASSEMBLY,AXIAL 67303202

567480 THERMISTOR ASSEMBLY 67307808

264110 POWER CORD ASSEMBLY 67300031

267110 REMOTE CONTROLLER ASSEMBLY 67302239

567502 OverloadProtect 67301907

268711-2 PWB(PCB) ASSEMBLY,MAIN 67307644

268711-1 PWB(PCB) ASSEMBLY,DISPLAY 67307646

435300 PLASTIC REAR AIR DEFLECTOR 67307208

237200 PANEL,CON

TROL 67305527

731273 INSTALL PART ASSEMBLY,SINGLE 67306307

249950 CASE ASSEMBLY,CONTROL 67305528

435301 GRILLE,REAR 67304801

349480 ORIFICE 67303406

753000 Heater,Electric 67310101

Description

LocNo

UE08C13

Service Manual 27

Page 28

W0CZZ CAPACITOR,FILM,BOX 67301910

130410 BASE ASSEMBLY,SINGLE 67302923

130900 CABINET 67303718

132100 FRAME 67303504

135303 GRILLE,INLET 67306104

135312 GRILLE ASSEMBLY,FRONT(SINGLE) 67306005

238310 ESCUTCHEON 67304802

W48602 CLAMP,SPRING 67302500

346811 MOTOR ASSEMBLY,SINGLE 67303008

147581 LOUVER,HORIZONTAL 67306203

147582-1 LOUVER,VERTICAL 67306252

147582-2 LOUVER,VERTICAL 67306253

349600 BRACKET,MOTOR 67303607

149980 SHROUD 67303111

5

50140 DAMPER,COMPRESSOR 67305000

152302 FILTER,AIR 67304304

352380 AIR GUIDE 67302735

359012 FAN,TURBO 67302608

559011 FAN ASSEMBLY,AXIAL 67303202

567480 THERMISTOR ASSEMBLY 67307808

264110 POWER CORD ASSEMBLY 67300029

267110 REMOTE CONTROLLER ASSEMBLY 67302239

567502 OverloadProtect 67301908

268711-2 PWB(PCB) ASSEMBLY,MAIN 67307645

268711-1 PWB(PCB) ASSEMBLY,DISPLAY 67307646

435300 PLASTIC REAR AIR DEFLECTOR 67307208

237200 PANEL,CO

NTROL 67305527

731273 INSTALL PART ASSEMBLY,SINGLE 67306307

249950 CASE ASSEMBLY,CONTROL 67305529

435301 GRILLE,REAR 67304801

349480 ORIFICE 67303406

753000 Heater,Electric 67310100

Description

LocNo

UE10C33

28 Room Air Conditioner

Page 29

Service Manual 29

W0CZZ CAPACITOR,FILM,BOX 67301911

130410 BASE ASSEMBLY,SINGLE 67302930

130900 CABINET 67303718

132100 FRAME 67303504

135303 GRILLE,INLET 67306104

135312 GRILLE ASSEMBLY,FRONT(SINGLE) 67306005

238310 ESCUTCHEON 67304802

W48602 CLAMP,SPRING 67302500

346811 MOTOR ASSEMBLY,SINGLE 67303020

147581 LOUVER,HORIZONTAL 67306203

147582-1 LOUVER,VERTICAL 67306252

147582-2 LOUVER,VERTICAL 67306253

349600 BRACKET,MOTOR 67303606

149980 SHROUD 67303111

5

50140 DAMPER,COMPRESSOR 67305000

152302 FILTER,AIR 67304304

352380 AIR GUIDE 67302735

359012 FAN,TURBO 67302608

559011 FAN ASSEMBLY,AXIAL 67303202

567480 THERMISTOR ASSEMBLY 67307808

264110 POWER CORD ASSEMBLY 67300029

267110 REMOTE CONTROLLER ASSEMBLY 67302239

567502 OverloadProtect 67301906

268711-2 PWB(PCB) ASSEMBLY,MAIN 67307645

268711-1 PWB(PCB) ASSEMBLY,DISPLAY 67307646

435300 PLASTIC REAR AIR DEFLECTOR 67307208

237200 PANEL,CO

NTROL 67305527

731273 INSTALL PART ASSEMBLY,SINGLE 67306307

249950 CASE ASSEMBLY,CONTROL 67305530

435301 GRILLE,REAR 67304801

349480 ORIFICE 67303406

753000 Heater,Electric 67310100

Description

LocNo

UE12C33

Page 30

Unifit Heat Cool Svc Parts 2010 (05/10)Printed in the U.S.A

Post Office Box 1540 • 4200 N. Pan Am Expressway • San Antonio, Texas 78295-1540

• (210) 357-4400 • FAX (210) 357-4480

FRIEDRICH AIR CONDITIONING CO.

Visit our web site at www.friedrich.com

Loading...

Loading...