Friedrich SH15M30A, SH20M30A, SH20M50A Product Profile

Product Profile

Features

Larger, commercial grade, enclosed fan motor

UL LISTED for CLASS 1, DIV 2, GROUPS A, B, C and D

KSA REGISTERED and TESTED in accordance with SASO

50 60

H E R T Z

Hazardous Location Room Air Conditioners

Hazardgard®

Engineered to perform in the harshest environments

Permanent split capacitor motor

Hermetically sealed refrigeration system

Environmentally sealed on/off switch and gold

plated contacts in thermostat for corrosion

resistance

Solid-state control relays for compressor and

fan operation

Hot gas bypass allows the air conditioner to

operate at low ambient conditions without

freezing at outdoor temperatures as low as

45° F (7°C)

Hermetically sealed reciprocating compressor

is cooled during the refrigeration cycle, which

allows the unit to tolerate higher outdoor

temperatures up to 130˚ F (55°C)

with hermetically sealed overload for arc-free

operation.

Field supplied, direct-wired, 15-amp circuit

with time-delay fuse that will tolerate current

surge without tripping the breaker

22-gauge, G60 steel air conditioner cabinet is

powder coated for corrosion protection and to

withstand years of hard use

High density EPS foam insulation for thermal

resistance and sound control

Heavy duty hexacomb packaging resists

damage during shipment and is

environmentally friendly

Coils coated for corrosion resistance

T4 / T4A Temperature Classification

CERTIFIED in accordance with ISA 12.12.01 and NFPA 70

(NATIONAL ELECTRIC CODE), ANSI/UL 484 Room Air

Conditioners

Hazardgard® Product Profile_2014

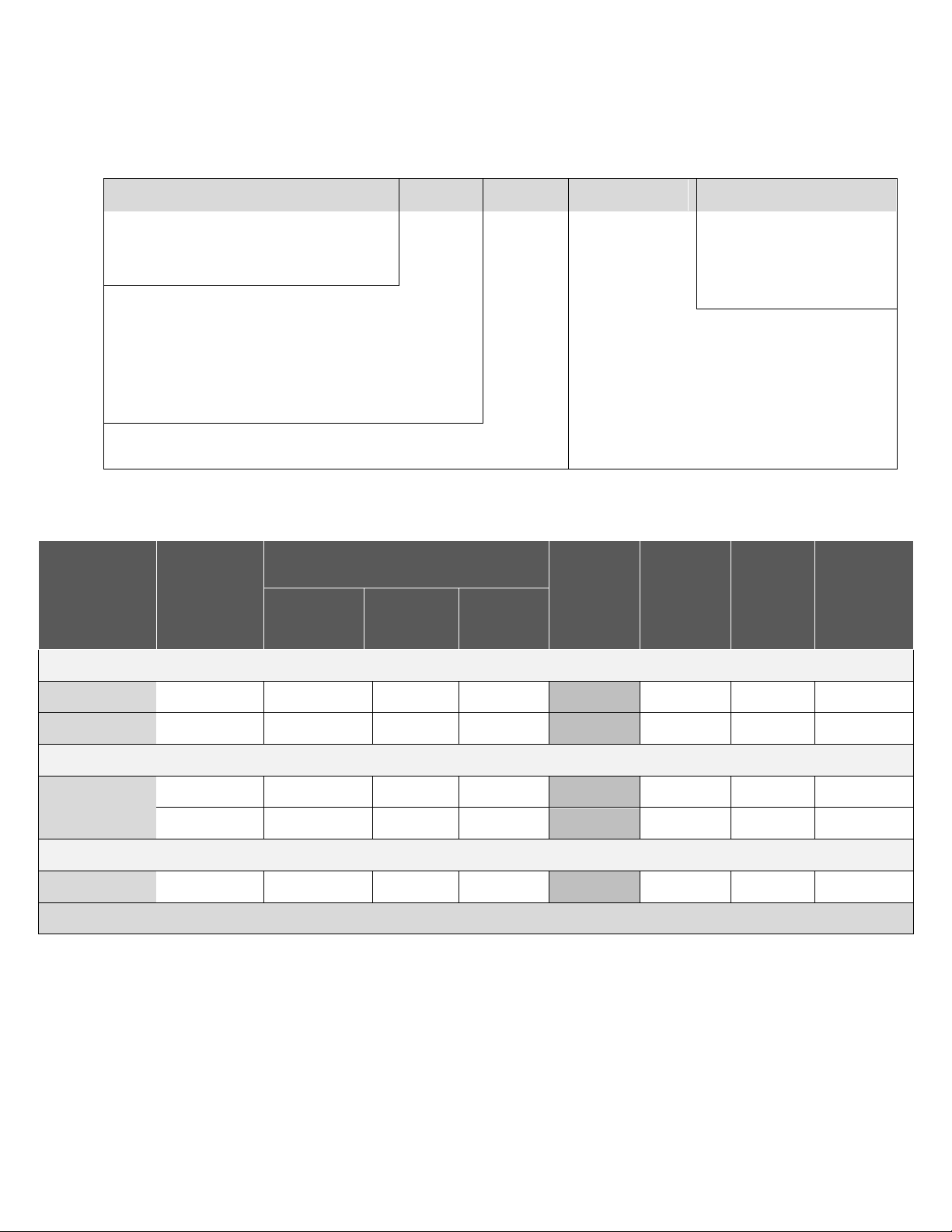

Model Identification & Specifications

SH

15 M 20

A

Series

Marketing Code

SH = Hazardgard® Series

Nominal Capacity

(BTU)

Voltage & Frequency

15 =15000

20 = 230/208V - 60Hz / 240/220V – 50 Hz

20 = 20000

30 = 230/208V - 60Hz

24 = 24000

50 = 240/220V - 50 Hz

M = Hazardgard® Engineering Series

Model

Cooling

Capacity

Btu / Hr.

Electrical Characteristics (60 Hertz)

Energy

Efficiency

Ratio

( EER)

Moisture

Removal

(Pints/Hr.)

Air

Direction

Controls

Air

Circulation

(CFM)

Volts -

Frequency

Rated

Cooling

Amps

Cooling

Watts

60 Hz North America

SH15M30A

14500/14000

230/208 - 60

6.9/7.5

1495/1443

9.7/9.7

4.0

8-way

375

SH20M30A

20000/19000

230/208 - 60

8.7/9.6

2125/2021

9.4/9.4

5.5

8-way

375

50 Hz / 60 Hz International / North America

SH24M20 *

24000/23700

230/208 -60

12.6/13.5

2727/2788

8.8/8.5

8.0/7.5

8-way

385

21000/20500

240/220 - 50

15.0 /13.2

2600/2412

8.1/8.5

7.0 /7.0

8-way

360

50 Hz International

SH20M50A

19500/19100

240/220 - 50

9.8/10.3

2167/2156

9.0/9.0

5.6/5.5

8-way

425

Refrigerant: R – 410A (all Models)

Due to continuing engineering research and technology, specifications are subject to change without notice. Manufactured

from ISO Standard 5151 for testing and rating for performance of non-ducted air conditioners and heat pumps.

under U.S. Design Patent DES 368, 306 decorative front; Utility Patent 5, 622, 058. MAXIMUM outdoor ambient operating

temperature is 130°F. (55°C) MAXIMUM TEMPERATURE RATING FOR CLASS I, DIVISION 2, GROUPS A,B,C,D.

For global applications, Hazardgard cooling capacities are tested in a certified laboratory at moderate (T1*) and hot (T3*) climate

conditions in accordance with SASO (Saudi Arabian Standards Organization) Standard 2681. SASO Standard 2681 is adopted

Hazardgard® Product Profile_2014

COILS COATED FOR CORROSION RESISTANCE

deterioration and extends the life of the unit especially in coastal or corrosive environments

Features

Operates at low ambient conditions without freezing at outdoor ambient temperatures as low as 7° C/45° F

ARTICLE 501

Class I, Div. 2, Group D

ARTICLE 505

Class I, Zone 2, Group IIA

Hazardgard® meets T4 temperature classification which means unit surface temperatures will not rise

above 135° C/275° F. (note: 50/60Hz model listed as T4A for surface temperatures to 120° C/248° F).

Tolerates higher outdoor temperatures up to 55° C /130° F

Equipment is certified in accordance with ISA 12.12.01 and NFPA 70

(National Electric Code)

Class I, Div. 2, Group A and Group B

Class I, Div. 2, Group B

Class I, Div. 2, Group C

MODEL SH24M20

ElectroFin® 5-stage, immersion ecoat process on 100% of metallic surfaces on the outdoor coil

Class I, Zone 2, Group IIC

Class I, Zone 2, Group IIB plus hydrogen, or “+H2”

Class I, Zone 2, Group IIB

ELECTROFIN BENEFITS:

ELECTROFIN MEETS THE FOLLOWING:

provides outstanding corrosion resistance protection in coastal or corrosive environments

Excellent adhesion characteristics

Less than 1% thermal degradation

Outstanding chemical resistance

Passed 6048 hrs.ASTM B-117 Salt Spray Test

MIL-C-46168 Chemical Agent Resistance - DS2, HCI Gas

CID A-A-52474A (GSA)

MIL-STD 810F, Method 509.4 (Sand and Dust)

MIL-P-53084 (ME)-TACOM Approval

MIL-DTL-12468 Decontamination Agent (STB)

DPG (Douglas Proving Grounds) Soil & Water Exposure Tests

GM9540P-97 Accelerated Corrosion Test (120 cycles)

ASTM B117-G85 Modified Salt Spray (Fog) Testing-2,000 hours

ASTM B117 Salt Spray Test (tested by ARL for Lockheed Martin)

MODELS SH15M30A, SH20M30A, SH20M50A

Diamonblue Advanced Corrosion Protection® on the outdoor coil protects the coil against

Hazardgard® Product Profile_2014

Loading...

Loading...