2 0 1 1

Service Manual

PTAC - R410A Models

Packaged Terminal Air Conditioners

Packaged Terminal Heat Pumps

PD-ServMan-E (2-11)

CUSTOMER SATISFACTION and QUALITY ASSURANCE

Friedrich is a conscientious manufacturer, concerned about customer satisfaction, product quality, and

controlling warranty costs. As an Authorized Service Provider you play a vital role in these areas. By adhering

to the policies and procedures you provide us with vital information on each warranty repair you complete.

This information is used to identify product failure trends, initiate corrective action, and improve product

quality, thereby further reducing warranty expenses while increasing customer satisfaction levels.

CHARGES TO CUSTOMER

The customer/end user is not to be charged for any warranty repairs to correct defects in materials or

workmanship in accordance with the specifi c warranty provisions outlined in the product’s warranty

certifi cate.

FRIEDRICH AUTHORIZED PARTS DEPOTS

AAA Refrigeration Service

1322 24th Street, Suite B

Kenner, Louisiana 70062

504-464-7444

877-813-7444

Alamo Service Company

1450 North Flores Street

San Antonio, Texas 78212

210-227-2450

800-328-2450

TECHNICAL SUPPORT

CONTACT INFORMATION

The Gabbert Company

6868 Ardmore

Houston, Texas 77054

713-747-4110

800-458-4110

Johnstone Supply of Woodside

27-01 Brooklyn Queens Expway

Woodside, New York 11377

718-545-5464

800-431-1143

Reeve Air Conditioning, Inc.

2501 South Park Road

Hallandale, Florida 33009

954-962-0252

800-962-3383

FRIEDRICH AIR CONDITIONING CO.

10001 Reunion Place, Ste. 500, San Antonio, TX 78216

(210) 546-0500 877-599-5665 x 261 FAX (210) 546-0630

Email: tac@friedrich.com

www.friedrich.com

Printed in the U.S.A.

Table of Contents

Important Safety Information ...........................................2-4

Introduction .........................................................................4

General Product Features ..................................................5

HVAC Engineering Specifi cations ......................................6

Component identifi cation ....................................................7

Accessories .....................................................................8-9

Unit Identifi cation ..............................................................10

Chassis Specifi cations ......................................................11

Cooling and Heating Performance ..............................12-13

Electric Heat Data ............................................................14

Electrical Rating Tables ....................................................15

Power Cord Information ..............................................15-17

Remote Wall Thermostat / Low Voltage

Wire Connections ........................................................18-19

Digital Control Features ....................................................20

Digital Control Operation ..................................................21

Capillary Tube Systems/Check Valve ..........................33

Reversing Valve — Description/Operation ...................34

Testing Coil ...................................................................34

Checking Reversing Valves .....................................34-35

Reversing Valve

Touch Testing Heating/Cooling Cycle ..........................35

Procedure For Changing Reversing Valve ..............35-36

Compressor Checks .....................................................36

Locked Rotor Voltage Test ............................................36

Single Phase Connections ............................................36

Determine Locked Rotor Voltage ..................................36

Locked Rotor Amperage Test ........................................36

Single Phase Running & Locked Rotor Amperage ........36

Checking the Overload ..................................................36

External Overload ..........................................................37

Compressor Single Phase Resistance Test ...................37

Digital Control User Input Confi guration ...........................22

Digital Control Diagnostics ................................................23

Malfunction Analysis ....................................................24-26

Components Testing ....................................................27-28

Refrigeration System Sequence of Operation ...................29

Sealed Refrigeration System Repairs ...............................30

Refrigerant Charging .........................................................31

Method Of Charging ..........................................................31

Undercharged Refrigerant Systems .............................31-32

Overcharged Refrigerant Systems ....................................32

Restricted Refrigerant Systems .........................................32

Compressor Replacement ........................................38-39

Routine Maintenance .....................................................39

Troubleshooting Charts .............................................40-41

Wiring Diagrams for Wall Mounted Thermostats .......42-43

Wiring Diagram .........................................................42-44

RT6 Installation, Operation and Application Guide ...45-46

Thermistors Resistance Values ................................47-48

Warranty ..........

2011 PTAC Exploded View ..........

2011 PTAC Parts List - PDE Models ...

2011 PTAC Parts List - PDH Models ...

.....................................................................49

.....................................50

.............................51

.............................52

1

IMPORTANT SAFETY INFORMATION

The information contained in this manual is intended for use by a qualifi ed service technician who is familiar

with the safety procedures required for installation and repair, and who is equipped with the proper tools and

test instruments required to service this product.

Installation or repairs made by unqualifi ed persons can result in subjecting the unqualifi ed person making

such repairs as well as the persons being served by the equipment to hazards resulting in injury or electrical

shock which can be serious or even fatal.

Safety warnings have been placed throughout this manual to alert you to potential hazards that may be

encountered. If you install or perform service on equipment, it is your responsibility to read and obey these

warnings to guard against any bodily injury or property damage which may result to you or others.

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read

and obey all safety messages.

This is a safety Alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol with the word “WARNING”

or “CAUTION”. These words mean:

WARNING

CAUTION

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury,

and tell you what will happen if the instructions are not followed.

NOTICE

You can be killed or seriously injured if you do not follow instructions.

You can receive minor or moderate injury if you do not follow instructions.

A message to alert you of potential property damage will have the

word “NOTICE”. Potential property damage can occur if instructions

are not followed.

2

PERSONAL INJURY OR DEATH HAZARDS

ELECTRICAL HAZARDS:

Unplug and/or disconnect all electrical power to the unit before performing inspections, maintenance, •

or service.

Make sure to follow proper lockout/tag out procedures.•

Always work in the company of a qualifi ed assistant if possible. •

Capacitors, even when disconnected from the electrical power source, retain an electrical charge •

potential capable of causing electric shock or electrocution.

Handle, discharge, and test capacitors according to safe, established, standards, and approved •

procedures.

Extreme care, proper judgment, and safety procedures must be exercised if it becomes necessary to •

test or troubleshoot equipment with the power on to the unit.

Do not spray or pour water on the return air grille, discharge air grille, evaporator coil, control panel, •

and sleeve on the room side of the air conditioning unit while cleaning.

Electrical component malfunction caused by water could result in electric shock or other electrically •

unsafe conditions when the power is restored and the unit is turned on, even after the exterior is dry.

Never operate the A/C unit with wet hands.•

Use air conditioner on a single dedicated circuit within the specifi ed amperage rating. •

Use on a properly grounded outlet only.•

Do not remove ground prong of plug.•

Do not cut or modify the power supply cord.•

Do not use extension cords with the unit.•

Follow all safety precautions and use proper and adequate protective safety aids such as: gloves, •

goggles, clothing, adequately insulated tools, and testing equipment etc.

Failure to follow proper safety procedures and/or these warnings can result in serious injury or death.•

REFRIGERATION SYSTEM HAZARDS:

Use approved standard refrigerant recovering procedures and equipment to relieve pressure before •

opening system for repair.

Do not allow liquid refrigerant to contact skin. Direct contact with liquid refrigerant can result in minor •

to moderate injury.

Be extremely careful when using an oxy-acetylene torch. Direct contact with the torch’s fl ame or hot •

surfaces can cause serious burns.

Make sure to protect personal and surrounding property with fi re proof materials.•

Have a fi re extinguisher at hand while using a torch.•

Provide adequate ventilation to vent off toxic fumes, and work with a qualifi ed assistant whenever •

possible.

Always use a pressure regulator when using dry nitrogen to test the sealed refrigeration system for •

leaks, fl ushing etc.

3

Make sure to follow all safety precautions and to use proper protective safety aids such as: gloves, •

safety glasses, clothing etc.

Failure to follow proper safety procedures and/or these warnings can result in serious injury or death.•

MECHANICAL HAZARDS:

Extreme care, proper judgment and all safety procedures must be followed when testing, •

troubleshooting, handling, or working around unit with moving and/or rotating parts.

Be careful when, handling and working around exposed edges and corners of sleeve, chassis, and •

other unit components especially the sharp fi ns of the indoor and outdoor coils.

Use proper and adequate protective aids such as: gloves, clothing, safety glasses etc.•

Failure to follow proper safety procedures and/or these warnings can result in serious injury or death.•

PROPERTY DAMAGE HAZARDS

FIRE DAMAGE HAZARDS:

Read the Installation/Operation Manual for this air conditioning unit prior to operating.•

Use air conditioner on a single dedicated circuit within the specifi ed amperage rating. •

Connect to a properly grounded outlet only.•

Do not remove ground prong of plug.•

Do not cut or modify the power supply cord.•

Do not use extension cords with the unit.•

Failure to follow these instructions can result in fi re and minor to serious property damage.•

WATER DAMAGE HAZARDS:

Improper installation maintenance, or servicing of the air conditioner unit, or not following the above •

Safety Warnings can result in water damage to personal items or property.

Insure that the unit has a suffi cient pitch to the outside to allow water to drain from the unit. •

Do not drill holes in the bottom of the drain pan or the underside of the unit. •

Failure to follow these instructions can result in result in damage to the unit and/or minor to serious •

property damage.

INTRODUCTION

This service manual is designed to be used in conjunction with the installation manuals provided with each unit.

This service manual was written to assist the professional HVAC service technician to quickly and accurately

diagnose and repair any malfunctions of this product.

This manual, therefore, will deal with all subjects in a general nature. (i.e. All text will pertain to all models).

IMPORTANT:

4

It will be necessary for you to accurately identify the unit you are

servicing, so you can be certain of a proper diagnosis and repair.

(See Unit Identifi cation.)

DIAMONBLUE

TECHNOLOGY

Diamonblue seacoast protection protects the outdoor coil from harsh environments. Comes standard

on all models.

DIGITAL DEFROST

THERMOSTAT

The new Friedrich PTAC uses a digital thermostat to accurately monitor the outdoor coil conditions to al-

low the heat pump to run whenever conditions are correct. Running the PTAC in heat pump mode saves

energy and reduces operating costs. The digital thermostat allows maximization

of heat pump run time.

INSTANT HEAT

HEAT PUMP MODE

Heat pump models will automatically run the electric heater to quickly bring the room up to temperature

when initially energized, then return to heat pump mode. This ensures that the room is brought up to

temperature quickly without the usual delay associated with heat pump units.

EVEN HEAT MONITORING

of the setpoint. If necessary, the unit will cycle the electric heat to maintain the temperature. This feature

-

SEPARATE HEAT/COOL

FAN CYCLE

CONTROL

The owner may choose between fan cycling or fan continuous mode based on property preference. (Note:

Even heat monitoring and quiet start/stop fan delay only operate in fan cycle mode) Fan continuous mode is

energy by only operating the fan while the compressor or electric heater is operating.

The ability to set the

fan cycling condition independently between heating and cooling mode will increase user comfort by

allowing the choice of only constantly circulating air in the summer or winter time. Unlike other PTAC

brands that only allow one selection.

EMERGENCY

HEAT OVERRIDE

In the event of a compressor failure in heat pump mode, the compressor may be locked out to provide

heat through the resistance heater. This feature ensures that even in the unlikely event of a compressor

failure, the room temperature can be maintained until the compressor can be serviced.

DESK CONTROL

READY

All Friedrich digital PTACs have low voltage terminals ready to connect a desk control energy manage-

ment system. Controlling the unit from a remote location like the front desk ca

n reduce energy usage and

requires no additional accessories on the PTAC unit.

INDOOR COIL

FROST SENSOR

temperatures cause the indoor coil to freeze. When the indoor coil reaches 30°F, the compressor is

disabled and the fan continues to operate based on demand. Once the coil temperature returns to 45°F,

the compressor returns to operation.

ULTRA QUIET

AIR SYSTEM

The new Friedrich PD series units feature an indoor fan system design that reduces sound levels without

HIGH EFFICIENCY

The Friedrich PTAC has been engineered so that all functional systems are optimized so that they work

together to deliver the highest possible performance.

DUAL MOTOR

With Friedrich’s new dual-motor design the indoor motor can run at slower speeds which reduces sound

levels indoors.

ROTARY COMPRESSOR

-

ciency.

STAINLESS STEEL

ENDPLATES

Outdoor coil endplates made from stainless steel reduce corrosion on the outdoor coil common with other

coil designs.

TOP -MOUNTED

ANTIMICROBIAL

AIR FILTERS

front cover.

FILTERED FRESH

AIR INTAKE

Friedrich PTAC units are capable of introducing up to 75 CFM of outside air into the conditioned space.

The outdoor air passes through a washable mesh screen to prevent debris from entering the airstream.

R-410A REFRIGER ANT

Friedrich PTAC units use environmentally-friendly refrigerant.

General Product Features

5

Digital Packaged Terminal Air Conditioners & Heat Pumps

All units shall be factory assembled, piped, wired and fully charged with

310 for air conditioners and ARI standard 380 for heat pumps. Units

shall be UL listed and carry a UL label. All units shall be factory runtested to check operation and be Friedrich or equivalent.

The basic unit shall not exceed 16” high x 42” wide. Overall depth

of the unit from the rear of the Friedrich wall sleeve to the front of

the decorative front cover shall not exceed 21 ¼”. The unit shall be

designed so that room int

rusion may be as little as 7 ½”. Installations

in walls deeper than 13 ¼” may be accomplished with the use of a

deep wall sleeve (PDXWSEXT). Unit shall draw in ambient air through

both sides of an outdoor architectural louver or grille measuring 42”

.revuol eht fo noitrop elddim tuo ria tsuahxe llahs dna hgih ”61 x ediw

The architectural louver and wall sleeve shall be designed so that the

louver may be installed f

rom the inside of the building.

REFRIGERATION SYSTEM – The refrigeration system shall be hermetically sealed and consist of a rotary compressor that is externally

mounted on vibration isolators no smaller than 1 3/8” dia. x 1 ½” high;

condenser and evaporator coils constructed of copper tubes and

.etasnednoc fo snollag ½ 1 gniniater fo elbapac nap niard a evah dna

A tertiary condensate removal system shall also be incorporated for

of the building as a safeguard against damage to the interior room.

INDOOR AIR HANDLING SECTION – The indoor air handling section shall consist of a tangential blower wheel direct driven by a totally

enclosed motor. The air handling system shall be designed to minimize

fan must have three fan speeds that may be selected by the user.

throughout the room. The grille shall be reversible to allow a change

personal injury or damage to the unit.

and reusable by cleaning with water or by vacuuming.

The chassis shall have a built-in damper capable of providing at least

damper closed to ensure a proper seal.

OUTDOOR AIR HANDLING SECTION – The outdoor air section

shall consist of a single injection molded fan shroud that incorporates

the outdoor motor mount into a single piece for ease of service and

assembly. The outdoor motor shall be totally enclosed, ball-bearing,

permanently lubricated and directly drive the outdoor fan/slinger ring.

CONTROLS – Covered controls shall be accessible in a compartment

at least 7½” wide with the controls no deeper than 1 ¼” in the opening

to facilitate easy operation of the unit.

The unit controls shall feature a soft blue LED readout that can display

either room temperature or setpoint temperature. The unit shall receive input from the digital control panel through push buttons labeled:

‘Cool’, ‘Heat’, ‘High Fan’, ‘Med Fan’, ‘Low Fan’,

’, ‘’ and ‘Power’.

When ‘Off’, the unit may be put directly into cooling or heating mode

by pressing the ‘Cool’ or ‘Heat’ button.

The unit must have the following energy saving and convenience

features built-in:

• Quiet start/stop fan delay

• Fan cycle control for cooling and heating independently

• Room freeze protection

• Random compressor restart

• Electronic temperature limiting

The PTAC must also offer the ability to be controlled by a remote wallmounted thermostat wit

hout additional accessories. Low voltage inputs

will include: C (common), R (24V power), Y (cooling), GL (fan low), GH

(fan high), W (heat) and O (reversing valve on PDH heat pumps only).

PTAC models shall use a single stage cool / single stage heat thermostat. PTHP models shall use a single stage cool / two-stage heat

thermostat. An accessory thermostat must be available from the

manufacturer, RT6 or equivalent. The RT6

thermostat will provide

.sedom naf dna taeh ,looc morf noitceles edom ,tnioptes erutarepmet

The thermostat must also allow the selection of fan speed between

high and low speed.

Other controls accessible without removal of the chassis shall include

fan cycle switch, fresh air vent control and emergency heat override

switch (heat pump only).

ELECTRICAL CONNECTION – All PTAC/PTHP units shall come from

the factory with a power cord installed. All 230/208V power cords shall

feature a leakage current detection device on the plug head. All units

shall feature a 6-pin connector for removal of the power cord. The

power cord shall be interchangeable to allow changes to the heater

output based on the property/electrical requirements.

GENERAL CONSTRUCTION – The wall sleeve shall be constructed

of 18-gauge Galvanized zinc-coated steel. It shall be prepared by

a process where it is zinc phosphate pretreated and sealed with a

cured for durability. The sleeve shall be shipped with a protective

weatherboard and a structural center support, and be insulated for

shipped separately and made from stamped or extruded anodized

aluminum. All louvers shall be in the horizontal plane.

clips. As an option the cover may be attached by two screws to prevent tampering. The front panel will feature a contoured discharge

with no sharp corners.

CORROSION PROTECTION – The unit shall have corrosion-resistant

fans, fan shroud and drain pan for corrosion protection and to prevent

rust on the side of the building below the outdoor louver. The unit shall

-

rioration. The outdoor coil shall have Diamonblue corrosion protection

applications including seacoast environments. All outdoor coils shall

also have stainless steel endplates to eliminate rusting of the endplates.

WARRANTY – The warranty is one year on all parts and 5 years on

the sealed system including compressor, indoor and outdoor coils and

refrigerant tubing.

Cooling: 7600 – 15,000 Btuh

Heating: 7600 – 14500 Btuh (Heat Pump)

6824 – 17060 Btuh (Electric Heat)

Friedrich Models: PDE – Coo

ling with or without electric heat

PDH – Heat Pump with electric heat

6

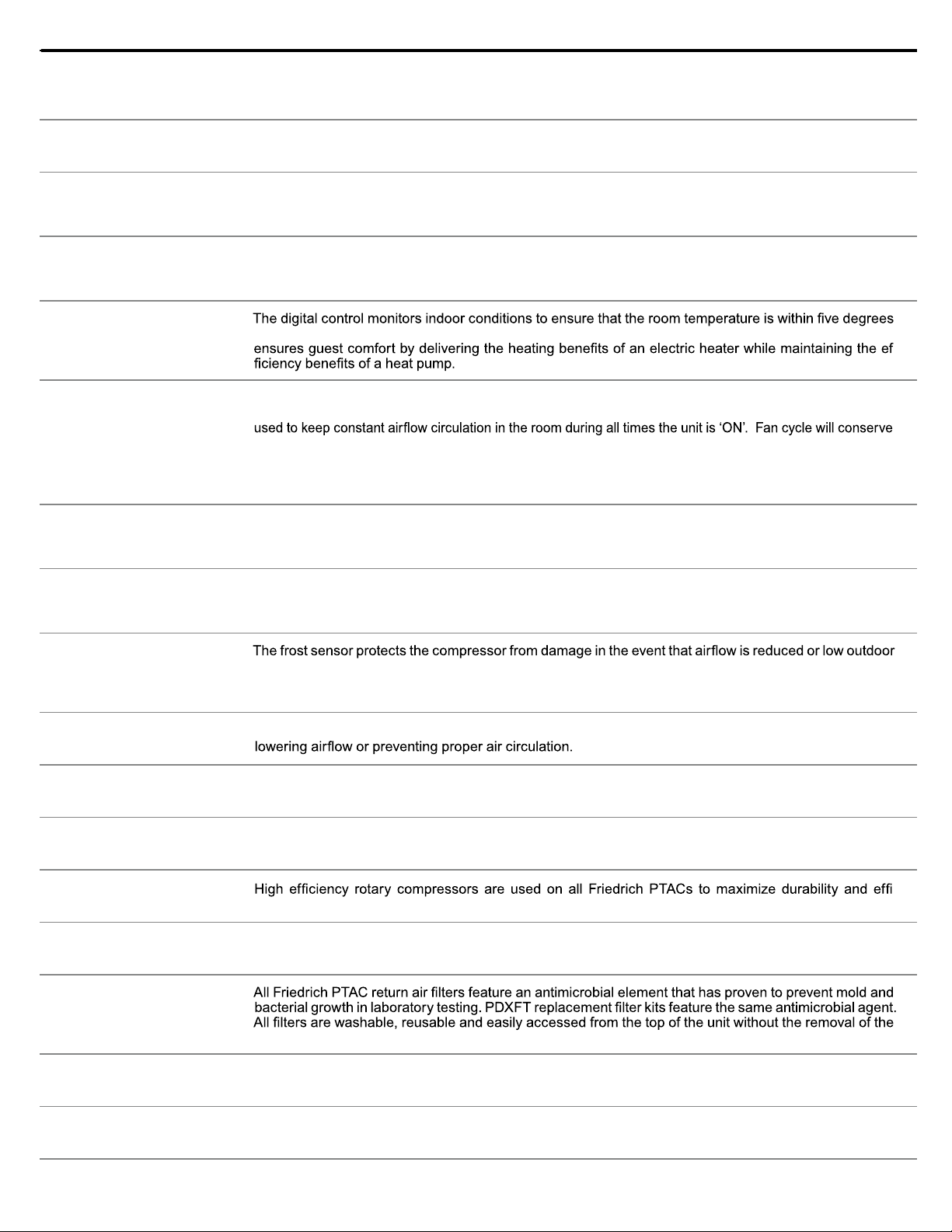

Component Identification

Typical Unit Components and Dimensions

FILTERS

RETURN AIR GRILLE

FRONT COVER

CHASSIS

OUTDOOR GRILLE

WALL SLEEVE

DISCHARGE

GRILLE

PDXWS Wall Sleeve Dimensions:

16" H x 42" W x 13-¾" D

Front Cover Dimensions:

16" H x 42" W x 7-¾" D

Cut-Out Dimensions:

16-¼" x 42-¼"

7

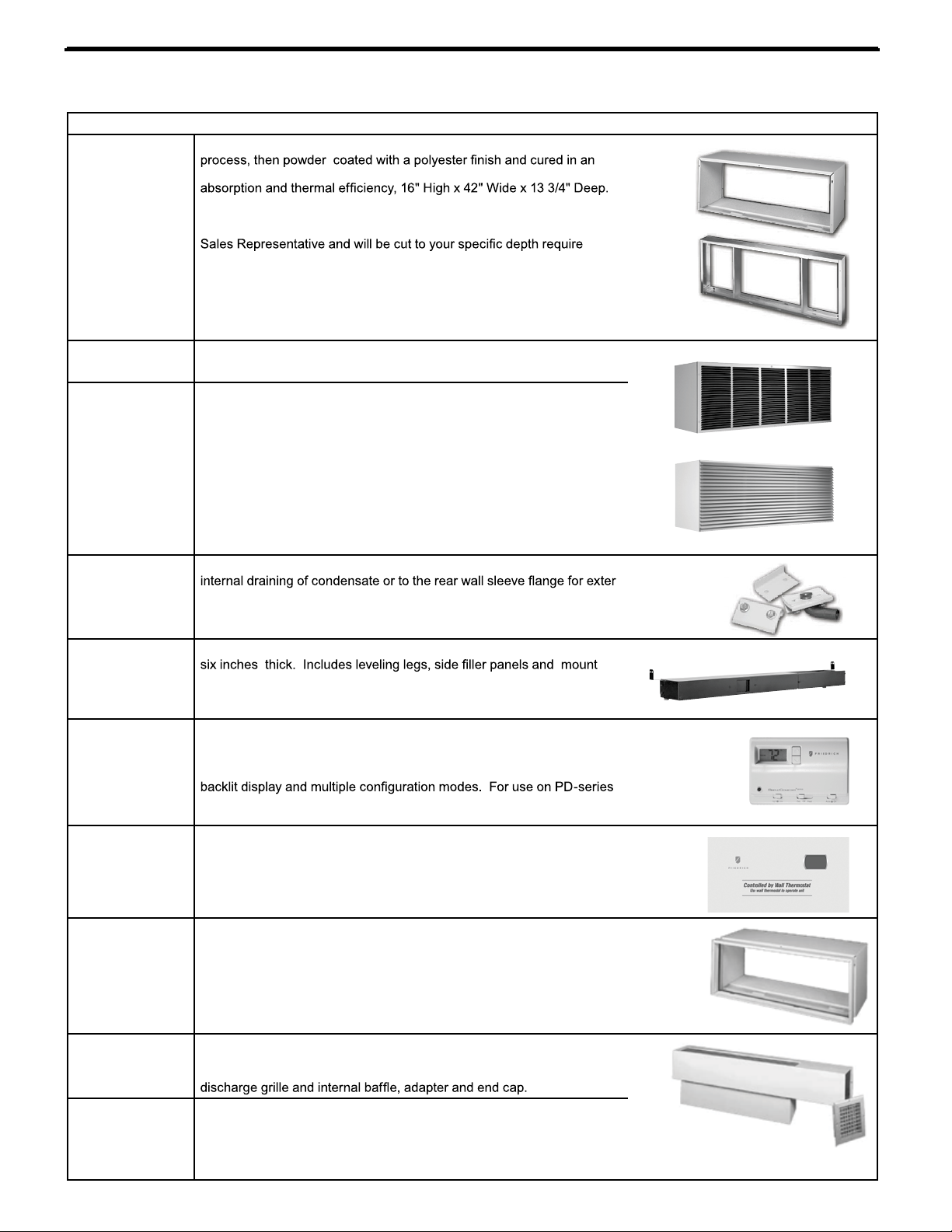

Accessories

PXAA

New Construction Accessories

PDXWS

PDXWSEXT

WALL SLEEVE Galvanized zinc coated steel is prepared in an 11-step

oven for exceptional durability. The wall sleeve is insulated for sound

DEEP WALL SLEEVE EXTENSION For use when the wall is thicker

than 13 1/4”deep. The wall sleeve may be special ordered through your

-

ments..

PXGA

GRILLE Standard, stamped aluminium, anodized to resist chalking and

oxidation.

PXAA

PXBG

PXSC

ARCHITECTURAL GRILLES Consist of heavy-gauge 6063-T5 alumi-

num alloy:

PXAA – Clear, extruded aluminum

PXBG – Beige acrylic enamel

PXSC – Also available in custom colors.

PXDR10

CONDENSATE DRAIN KIT Attaches to the bottom of the wall sleeve for

nal draining. Recommended on all units to remove excess condensate.

Packaged in quantities of ten.

PXSB

DECORATIVE SUBBASE Provides unit support for walls less than

ing brackets for electrical accessories. Accepts circuit breaker, power

disconnect switch, or conduit kit.

RT6

DIGITAL REMOTE WALL THERMOSTAT Single stage cool, single

stage heat for PDE models or single stage cool, dual stage heat for

PDH model thermostat features high/low fan speed switch. Thermostat

is hard wired and can be battery powered or unit powered. Features

Friedrich PTACs and Vert-I-Paks.

PDXRTA

REMOTE THERMOSTAT ESCUTCHEON KIT This kit contains ten

escutcheons that can be placed over the factory control buttons when

a remote wall mounted thermostat is used. The escutcheon directs the

guest to the wall thermostat for operation and retains the LED window to

display error codes and diagnostic information.

PXSE

SLEEVE EXTENSION RETROFIT KIT Galvanized zinc coated steel,

2.4" sleeve extension attached to the room side of the sleeve to allow for

the installation of a PD-Series Friedrich PTAC in a T-Series sleeve.

PDXDAA

LATERAL DUCT ADAPTER Attaches to the PTAC/PTHP unit and

provides a transition to direct up to 35% of the total CFM to a secondary room, either left or right of the unit. Kit includes duct plenum with

PDXDEA

LATERAL DUCT EXTENSION A three-foot insulated plenum that attaches to the left or right side of the duct adapter. The extension can be

cut to length by the installer. Maximum allowable straight extension is 15

feet.

PXGA

PDXWSE XT

PDXWS

8

Accessories

New Construction Accessories

PXCJA

CONDUIT KIT WITH JUNCTION BOX Hard wire conduit kit with

junction box for 208/230V and 265V units (subbase not required). Kit

includes a means of quick disconnect for easy removal of the chassis.

*Required for 265V installations.

PXFTA

REPLACEMENT FILTER PACK These are original equipment return air

chassis).

9

A A A M 00001

LJ = 2009 AE = 2015

AK = 2010 AF = 2016

AA = 2011 AG = 2017

AB = 2012 AH = 2018

AC = 2013 AJ = 2019

AD = 2014

A = Jan D = Apr G = Jul K = Oct

B = Feb E = May H = Aug L = Nov

C = Mar F = Jun J = Sep M = Dec

PRODUCT LINE

M = PTAC

MONTH MANUFACTURED

PTAC Serial Number Identification Guide

SERIAL NUMBER

REBMUN NUR NOITCUDORPDERUTCAFUNAM RAEY

UNIT IDENTIFICATION

Model Number Code

PD H 07 K 3 S F A

Series

PD = P Series Digital PTAC

System

E = Cooling with or

without electric heat

H = Heat Pump with

Auxiliary Heat

Nominal Cooling Capacity

07 = 7000 BTUh

09 = 9000 BTUh

12 = 12000 BTUh

15 = 15000 BTUh

Engineering Digit

Design Series

Options

S = Standard

Nominal Heater Size

(@ 230V or 265V)

0 = No Heater

2 = 2KW

3 = 3KW

5 = 5.0KW

Voltage

K = 208/230V - 1Ph. - 60Hz.

R = 265V - 1Ph. - 60Hz.

10

250 V Receptacles and Fuse Types

AMPS 15 20 30

HEATER SIZE 0, 2.0 kW 3.0 kW 5.0 kW

RECEPTACLE

PDE Series

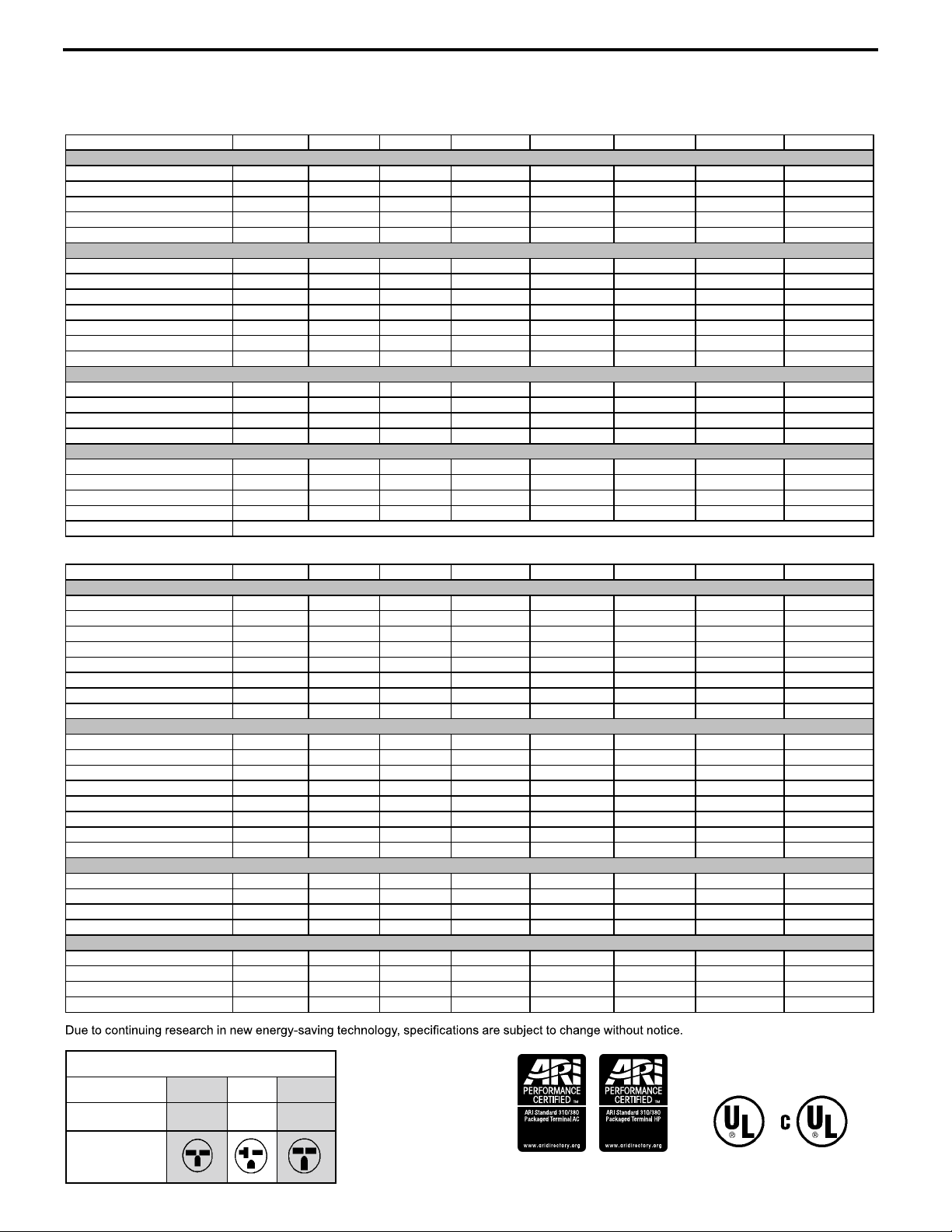

PDE07K PDE07R PDE09K PDE09R PDE12K PDE12R PDE15K PDE15R

PERFORMANCE DATA:

COOLING BTUh 7700/7600 7700 9000/8800 9000 12000/11800 12000 15000/14600 15000

POWER (WATTS) 640/620 640 800/770 800 1120/1120 1120 1530/1510 1530

EER 12.0/12.2 12.0 11.3/11.4 11.3 10.7/10.5 10.7 9.8/9.7 9.8

DEHUMIDIFICATION (pints/hr) 1.7 1.7 2.2 2.2 2.7 2.7 3.2 3.2

SENSIBLE HEAT RATIO 0.84 0.84 0.81 0.81 0.67 0.67 0.65 0.65

ELECTRICAL DATA:

VOLTAGE (1 PHASE, 60 Hz) 230/208 265 230/208 265 230/208 265 230/208 265

VOLT RANGE 253-187 292-239 253-187 292-239 253-187 292-239 253-187 292-239

CURRENT (AMPS) 2.8/3.0 2.4 3.7/3.9 3.7 5.1/5.3 4.8 6.7/7.5 5.9

POWER FACTOR 0.97 0.99 0.99 0.99 0.99 0.99 0.99 0.99

Compressor LRA 19.0 12.0 17.0 18.0 27.00 23.0 32.6 27.8

Compressor RLA 2.8 2.4 3.7 2.9 5.0 4.3 6.6 5.6

Fan motor horsepower 0.024 0.024 0.029 0.029 0.031 0.031 0.031 0.031

AIRFLOW DATA:

INDOOR CFM, HIGH 345/315 345 360/345 360 360/350 360 385/375 385

INDOOR CFM, MED 320/290 320 330/305 330 330/310 330 360/330 360

INDOOR CFM, LOW 295/265 295 300/270 300 310/280 310 320/290 320

VENT CFM 75 75 75 75 75 75 75 75

PHYSICAL DATA:

DIMENSIONS 16x42x13 3/4 16x42x13 3/4 16x42x13 3/4 16x42x13 3/4 16x42x13 3/4 16x42x13 3/4 16x42x13 3/4 16x42x13 3/4

NET WEIGHT 106 106 111 111 116 116 119 119

SHIPPING WEIGHT 126 126 131 131 136 136 139 139

R-410A CHARGE (oz) 23.63 24.69 33.51 33.51 35.27 35.98 38.1 40.21

Dim.s w/ Pkg. 19.75x23x 43.5 (all models)

PDH Series

PDH07K PDH07R PDH09K PDH09R PDH12K PDH12R PDH15K PDH15R

PERFORMANCE DATA:

COOLING BTUh 7700/7600 7700 9000/8800 9000 12000/11800 12000 14500/14200 14500

POWER (WATTS) cool 640/620 640 800/770 800 1120/1120 1120 1480/1460 1480

EER 12.0/12.2 12 11.3/11.4 11.3 10.7/10.5 10.7 9.8/9.7 9.8

REVERSE HEATING BTUh 6300/6100 6300 8100/7900 8100 10700/10500 10700 13300/13000 13300

POWER (WATTS) HEAT 540/530 540 720/770 720 1010/990 1010 1300/1270 1300

COP 3.4/3.4 3.4 3.3/3.3 3.3 3.1/3.1 3.1 3.0/3.0 3

DEHUMIDIFICATION (pints/hr) 1.7 1.7 2.2 2.2 2.7 2.7 3.2 3.2

SENSIBLE HEAT RATIO 0.84 0.84 0.81 0.81 0.67 0.67 0.65 0.65

ELECTRICAL DATA:

VOLTAGE (1 PHASE, 60 Hz) 230/208 265 230/208 265 230/208 265 230/208 265

VOLT RANGE 253-187 292-239 253-187 292-239 253-187 292-239 253-187 292-239

CURRENT (AMPS) 2.8/3.0 2.4 3.7/3.9 3.7 5.1/5.3 4.8 6.7/7.5 5.7

REVERSE HEAT. Amps 2.4/2.5 2.1 3.4/3.8 3.4 4.5/4.7 4.5 5.8/6.2 5.0

POWER FACTOR 0.97 0.99 0.99 0.99 0.99 0.99 0.98 0.98

Compressor LRA 19.0 12.0 18.5 19.0 27.00 23.0 36.0 26.0

Compressor RLA 2.8 2.4 3.6 3.2 5.0 4.3 6.5 5.3

Fan motor horsepower 0.024 0.024 0.029 0.029 0.031 0.031 0.031 0.031

AIRFLOW DATA:

INDOOR CFM, HIGH 345/315 345 360/345 360 360/350 360 420/390 385

INDOOR CFM, MED 320/290 320 330/305 330 330/310 330 410/380 360

INDOOR CFM, LOW 295/265 295 300/270 300 310/280 310 380/350 320

VENT CFM 75 75 75 75 75 75 75 75

PHYSICAL DATA:

DIMENSIONS 16x42x13.5 16x42x13.5 16x42x13.5 16x42x13.5 16x42x13.5 16x42x13.5 16x42x13.5 16x42x13.5

NET WEIGHT 108 108

113 113 118 118 121 123

SHIPPING WEIGHT 128 128 133 133 138 138 141 143

R-410A CHARGE (oz) 23.63 24.69 33.51 35.27 35.27 35.98 39.86 36.33

Chassis Specifications

11

Cooling & Heating Performance

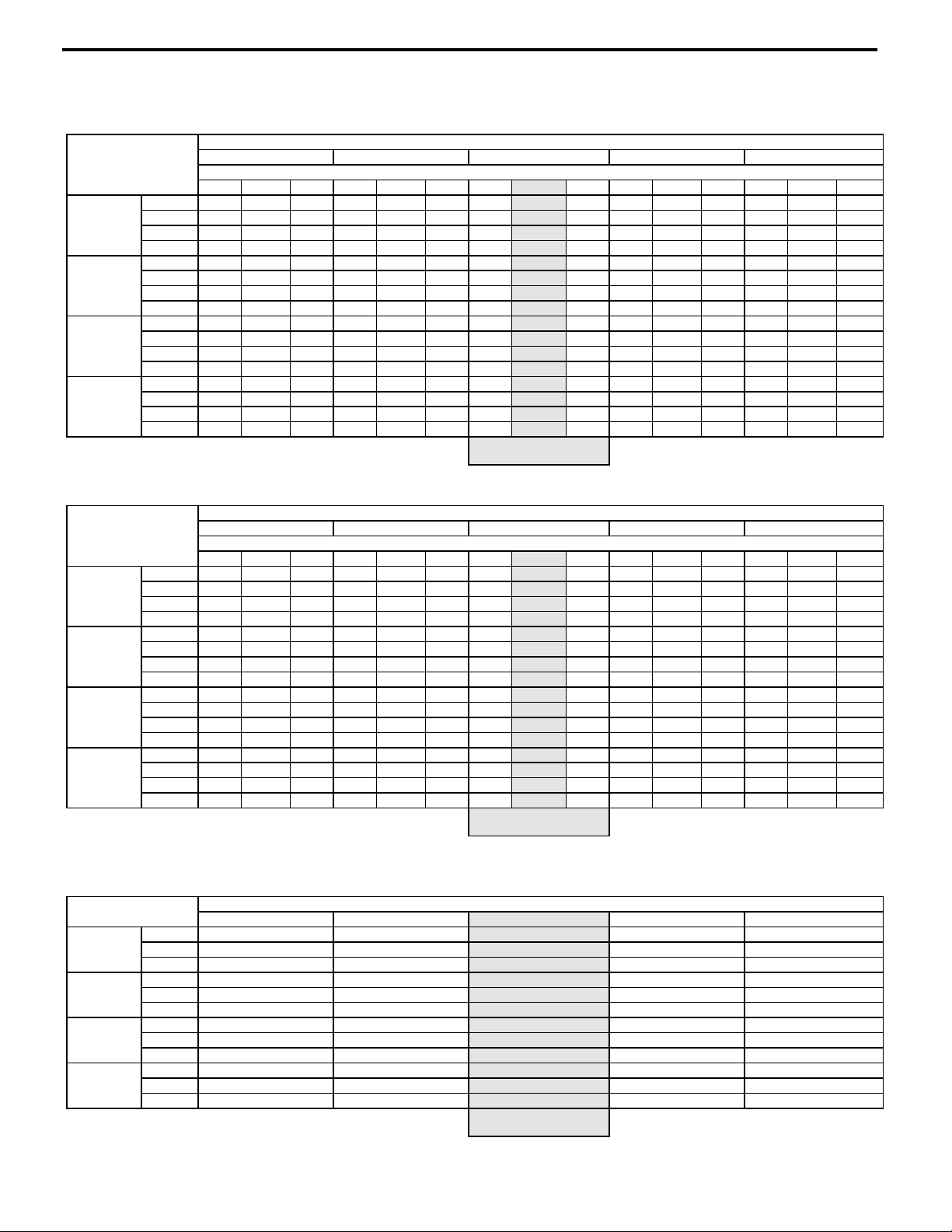

PDE 230V - Extended Cooling Performance

OUTDOOR DRY BULB TEMP. (DEGREES F AT 40% R.H.)

75 85 95 105 110

INDOOR WET BULB TEMP. (DEGREES F AT 80 F D.B.)

72 67 62 72 67 62 72 67 62 72 67 62 72 67 62

PDE07

BTUh 9055 8709 8062 8624 8131 7500 8285

7700

6815 7762 6892 6075 6907 5944 5251

WATTS 522 531 536 569 575 582 640

640

640 692 691 693 755 755 758

AMPS 2.3 2.3 2.4 2.5 2.5 2.5 2.8

2.80

2.8 3 3 3 3.3 3.3 3.3

SHR 0.53 0.72 0.96 0.54 0.74 0.98 0.54

0.77

0.99 0.55 0.81 0.99 0.58 0.87 0.99

PDE09

BTUh 10584 10179 9423 10080 9504 8766 9684

9000

7965 9072 8055 7101 8073 6948 6138

WATTS 653 663 670 711 718 727 800

800

800 865 864 866 943 943 947

AMPS 3.1 3.1 3.1 3.3 3.3 3.3 3.7

3.70

3.7 4 4 4 4.3 4.3 4.4

SHR 0.49 0.66 0.89 0.5 0.69 0.91 0.5

0.71

0.91 0.51 0.75 0.92 0.54 0.8 0.91

PDE12

BTUh 14112 13572 12564 13440 12672 11688 12912

12000

10620 12096 10740 9468 10764 9264 8184

WATTS 914 928 939 996 1006 1018 1120

1120

1120 1211 1210 1213 1320 1320 1326

AMPS 4.2 4.2 4.3 4.5 4.6 4.6 5.1

5.10

5.1 5.5 5.5 5.5 6 6 6

SHR 0.49 0.66 0.89 0.5 0.69 0.91 0.5

0.71

0.91 0.51 0.75 0.92 0.54 0.8 0.91

PDE15

BTUh 17640 16965 15705 16800 15840 14610 16140

15000

13275 15120 13425 11835 13455 11580 10230

WATTS 1248 1268 1282 1360 1374 1391 1530

1530

1530 1654 1652 1657 1804 1804 1812

AMPS 5.5 5.6 5.6 6 6 6 6.7

6.70

6.7 7.2 7.2 7.2 7.9 7.9 7.9

SHR 0.47 0.63 0.85 0.48 0.66 0.87 0.48

0.68

0.87 0.49 0.72 0.88 0.51 0.77 0.87

RATING POINT

ARI 310/380

PDH 230V - Extended Cooling Performance

OUTDOOR DRY BULB TEMP. (DEGREES F AT 40% R.H.)

75 85 95 105 110

INDOOR WET BULB TEMP. (DEGREES F AT 80 F D.B.)

72 67 62 72 67 62 72 67 62 72 67 62 72 67 62

PDH07

BTUh 9055 8709 8062 8624 8131 7500 8285

7700

6815 7762 6892 6075 6907 5944 5251

WATTS 522 531 536 569 575 582 640

640

640 692 691 693 755 755 758

AMPS 2.3 2.3 2.4 2.5 2.5 2.5 2.8

2.80

2.8 3 3 3 3.3 3.3 3.3

SHR 0.53 0.72 0.96 0.54 0.74 0.98 0.54

0.77

0.99 0.55 0.81 0.99 0.58 0.87 0.99

PDH09

BTUh 10584 10179 9423 10080 9504 8766 9684

9000

7965 9072 8055 7101 8073 6948 6138

WATTS 653 663 670 711 718 727 800

800

800 865 864 866 943 943 947

AMPS 3.1 3.1 3.1 3.3 3.3 3.3 3.7

3.70

3.7 4 4 4 4.3 4.3 4.4

SHR 0.49 0.66 0.89 0.5 0.69 0.91 0.5

0.71

0.91 0.51 0.75 0.92 0.54 0.8 0.91

PDH12

BTUh 14112 13572 12564 13440 12672 11688 12912

12000

10620 12096 10740 9468 10764 9264 8184

WATTS 914 928 939 996 1006 1018 1120

1120

1120 1211 1210 1213 1320 1320 1326

AMPS 4.2 4.2 4.3 4.5 4.6 4.6 5.1

5.10

5.1 5.5 5.5 5.5 6 6 6

SHR 0.49 0.66 0.89 0.5 0.69 0.91 0.5

0.71

0.91 0.51 0.75 0.92 0.54 0.8 0.91

PDH15

BTUh 17052 16400 15182 16240 15312 14123 15602

14500

12833 14616 12978 11441 13007 11194 9889

WATTS 1208 1227 1240 1316 1329 1345 1480

1480

1480 1600 1598 1603 1745 1745 1752

AMPS 5.4 5.5 5.5 5.9 5.9 5.9 6.5

6.6

6.6 7.1 7.1 7.1 7.7 7.7 7.7

SHR 0.48 0.65 0.88 0.49 0.68 0.89 0.49

0.70

0.9 0.5 0.74 0.9 0.53 0.79 0.9

RATING POINT

ARI 310/380

Extended Heating Performance

OUTDOOR DRY BULB TEMP. (DEGREES F)

37 42 47 52 57

PDH07

BTUh 5250 5540

6300

6900 7620

WATTS 509 518

540

549 580

AMPS 2.3 2.4

2.4

2.5 2.6

PDH09

BTUh 6005 6399

8100

8647 9245

WATTS 647 656

720

725 735

AMPS 3.3 3.3

3.4

3.4 3.5

PDH12

BTUh 7726 8531

10700

11278 12234

WATTS 883 917

1010

1039 1073

AMPS 4 4.1

4.5

4.7 4.9

PDH15

BTUh 10530 10850

13300

14550 15940

WATTS 1197 1212

1300

1377 1439

AMPS 5.3 5.4

5.8

6.1 6.3

RATING POINT

ARI 310/380

12

Cooling & Heating Performance

PDE 265V - Extended Cooling Performance

OUTDOOR DRY BULB TEMP. (DEGREES F AT 40% R.H.)

75 85 95 105 110

INDOOR WET BULB TEMP. (DEGREES F AT 80 F D.B.)

72 67 62 72 67 62 72 67 62

72 67 62 72 67 62

PDE07

BTUh 9055 8709 8062 8624 8131 7500 8285

7700

6815

7762 6892 6075 6907 5944 5251

WATTS 522 531 536 569 575 582 640

640

640

692 691 693 755 755 758

AMPS 2 2 2 2.1 2.1 2.2 2.4

2.40

2.4

2.6 2.6 2.6 2.8 2.8 2.8

SHR 0.53 0.72 0.96 0.54 0.74 0.98 0.54

0.77

0.99

0.55 0.81 0.99 0.58 0.87 0.99

PDE09

BTUh 10584 10179 9423 10080 9504 8766 9684

9000

7965

9072 8055 7101 8073 6948 6138

WATTS 653 663 670 711 718 727 800

800

800

865 864 866 943 943 947

AMPS 3.1 3.1 3.1 3.3 3.3 3.3 3.7

3.70

3.7

4 4 4 4.3 4.3 4.4

SHR 0.49 0.66 0.89 0.5 0.69 0.91 0.5

0.71

0.91

0.51 0.75 0.92 0.54 0.8 0.91

PDE12

BTUh 14112 13572 12564 13440 12672 11688 12912

12000

10620

12096 10740 9468 10764 9264 8184

WATTS 914 928 939 996 1006 1018 1120

1120

1120

1211 1210 1213 1320 1320 1326

AMPS 4 4 4 4.3 4.3 4.3 4.8

4.80

4.8

5.2 5.2 5.2 5.6 5.6 5.7

SHR 0.49 0.66 0.89 0.5 0.69 0.91 0.5

0.71

0.91

0.51 0.75 0.92 0.54 0.8 0.91

PDE15

BTUh 17640 16965 15705 16800 15840 14610 16140

15000

13275

15120 13425 11835 13455 11580 10230

WATTS 1248 1268 1282 1360 1374 1391 1530

1530

1530

1654 1652 1657 1804 1804 1812

AMPS 4.9 4.9 5 5.3 5.3 5.3 5.9

5.90

5.9

6.3 6.3 6.4 6.9 6.9 7

SHR 0.47 0.63 0.85 0.48 0.66 0.87 0.48

0.68

0.87

0.49 0.72 0.88 0.51 0.77 0.87

RATING POINT

ARI 310/380

PDH 265V - Extended Cooling Performance

OUTDOOR DRY BULB TEMP. (DEGREES F AT 40% R.H.)

75 85 95

105 110

INDOOR WET BULB TEMP. (DEGREES F AT 80 F D.B.)

72 67 62

72 67 62 72 67 62 72 67 62 72 67 62

PDH07

BTUh 9055 8709 8062 8624 8131 7500 8285

7700

6815 7762 6892 6075 6907 5944 5251

WATTS 522 531 536 569 575 582 640

640

640 692 691 693 755 755 758

AMPS 2 2 2 2.1 2.1 2.2 2.4

2.40

2.4 2.6 2.6 2.6 2.8 2.8 2.8

SHR 0.53 0.72 0.96 0.54 0.74 0.98 0.54

0.77

0.99 0.55 0.81 0.99 0.58 0.87 0.99

PDH09

BTUh 10584 10179 9423 10080 9504 8766 9684

9000

7965 9072 8055 7101 8073 6948 6138

WATTS 653 663 670 711 718 727 800

800

800 865 864 866 943 943 947

AMPS 3.1 3.1 3.1 3.3 3.3 3.3 3.7

3.70

3.7 4 4 4 4.3 4.3 4.4

SHR 0.49 0.66 0.89 0.5 0.69 0.91 0.5

0.71

0.91 0.51 0.75 0.92 0.54 0.8 0.91

PDH12

BTUh 14112 13572 12564 13440 12672 11688 12912

12000

10620 12096 10740 9468 10764 9264 8184

WATTS 914 928 939 996 1006 1018 1120

1120

1120 1211 1210 1213 1320 1320 1326

AMPS 4 4 4 4.3 4.3 4.3 4.8

4.80

4.8 5.2 5.2 5.2 5.6 5.6 5.7

SHR 0.49 0.66 0.89 0.5 0.69 0.91 0.5

0.71

0.91 0.51 0.75 0.92 0.54 0.8 0.91

PDH15

BTUh 17052 16400 15182 16240 15312 14123 15602

14500

12833 14616 12978 11441 13007 11194 9889

WATTS 1208 1227 1240 1316 1329 1345 1480

1480

1480 1600 1598 1603 1745 1745 1752

AMPS 4.7 4.7 4.8 5.1 5.1 5.1 5.7

5.7

5.7 6.1 6.1 6.2 6.7 6.7 6.7

SHR 0.48 0.65 0.88 0.49 0.68 0.89 0.49

0.70

0.9 0.5 0.74 0.9 0.53 0.79 0.9

RATING POINT

ARI 310/380

Extended Heating Performance

OUTDOOR DRY BULB TEMP. (DEGREES F)

37 42 47 52 57

PDH07

BTUh 5250 5540

6300

6900 7620

WATTS 509 518

540

549 580

AMPS 2.3 2.4

2.4

2.5 2.6

PDH09

BTUh 6005 6399

8100

8647 9245

WATTS 647 656

720

725 735

AMPS 3.3 3.3

3.4

3.4 3.5

PDH12

BTUh 7726 8531

10700

11278 12234

WATTS 883 917

1010

1039 1073

AMPS 4 4.1

4.5

4.7 4.9

PDH15

BTUh 10530 10850

13300

14550 15940

WATTS 1197 1212

1300

1377 1439

AMPS 4.5 4.6

5

5.3 5.5

RATING POINT

ARI 310/380

13

Electric Heat Data

Electric Heat Data

PDE07K0 PDE/PDH07K PDE/PDH07R

HEATER WATTS 0 Kw 2000 1635 3000 2450 2000 3000

VOLTAGE 230/208 230 208 230 208 265

HEATING BTUh 0 6824 5580 10236 8360 6824 10236

HEATING CURRENT (AMPS) 0 8.9 7.9 13.2 12.2 7.6 11.4

MINIMUM CIRCUIT AMPACITY 4.0 11.4 10.0 16.8 15.6 9.6 14.6

BRANCH CIRCUIT FUSE (AMPS) 15 15 15 20 20 15 20

Electric Heat Data

PDE09K0 PDE/PDH09K PDE/PDH09R

HEATER WATTS 0 Kw 2000 1635 3000 2450 5000 4090 2000 3000 5000

VOLTAGE 230/208 230 208 230 208 230 208 265

HEATING BTUh 0 6824 5580 10236 8360 17060 13960 6824 10236 17060

HEATING CURRENT (AMPS) 0 8.9 7.9 13.2 12.2 21.5 20.5 7.6 11.4 19.0

MINIMUM CIRCUIT AMPACITY 5.2 11.4 10.0 16.8 15.6 27.2 26.0 9.8 14.6 24.1

BRANCH CIRCUIT FUSE (AMPS) 15 15 15 20 20 30 30 15 20 30

Electric Heat Data

PDE12K0 PDE/PDH12K PDE/PDH12R

HEATER WATTS 0 Kw 2000 1635 3000 2450 5000 4090 2000 3000 5000

VOLTAGE 230/208 230 208 230 208 230 208 265

HEATING BTUh 0 6824 5580 10236 8360 17060 13960 6824 10236 17060

HEATING CURRENT (AMPS) 0 8.9 7.9 13.2 12.2 21.5 20.5 7.6 11.4 19.0

MINIMUM CIRCUIT AMPACITY 7.1 11.4 10.0 16.8 15.6 27.2 26.0 9.8 14.6 24.1

BRANCH CIRCUIT FUSE (AMPS) 15 15 15 20 20 30 30 15 20 30

Electric Heat Data

PDE15K0 PDE/PDH15K PDE/PDH15R

HEATER WATTS 0 Kw 2000 1635 3000 2450 5000 4090 2000 3000 5000

VOLTAGE 230/208 230 208 230 208 230 208 265

HEATING BTUh 0 6824 5580 10236 8360 17060 13960 6824 10236 17060

HEATING CURRENT (AMPS) 0 8.9 7.9 13.2 12.2 21.5 20.5 7.6 11.4 19.0

MINIMUM CIRCUIT AMPACITY 9.1 11.4 10.0 16.8 15.6 27.2 26.0 9.8 14.6 24.1

BRANCH CIRCUIT FUSE (AMPS) 15 15 15 20 20 30 30 15 20 30

14

ELECTRICAL RATING TABLES

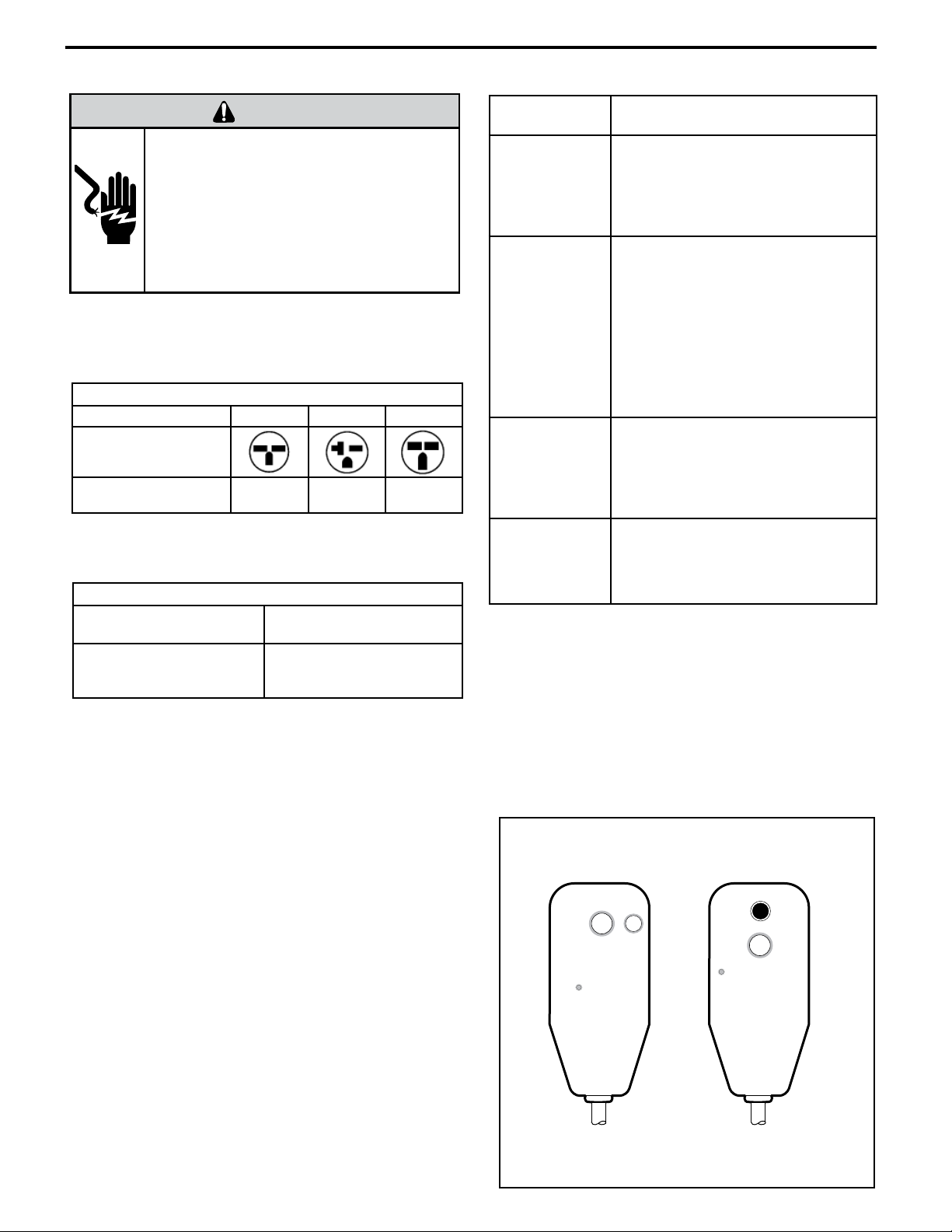

W ARNING

15/20A LCDI Device 30A LCDI Device

TEST BEFORE EACH USE

1. PRESS RESET BUTT ON

2. PLUG LCDI INT O POWER

RECEPT ACLE

3. PRESS TEST BUTT ON,

RESET BUTT ON SHOULD

POP UP

4. PRESS TEST BUTT ON,

FOR USE

DO NOT USE IF ABOVE TEST

F AILS

WHEN GREEN LIGHT IS ON

IT IS WORKING PROPERL Y

RESET

TEST

W ARNING

TEST BEFORE EACH USE

1. PRESS RESET BUTT ON

2. PLUG LCDI INT O POWER

RECEPT ACLE

3. PRESS TEST BUTT ON,

RESET BUTT ON SHOULD

POP UP

4. PRESS TEST BUTT ON,

FOR USE

DO NOT USE IF ABOVE TEST

F AILS

WHEN GREEN LIGHT IS ON

IT IS WORKING PROPERL Y

RESET

TEST

FRP014

Typical LCDI Devices

WARNING

ELECTRIC SHOCK HAZARD

Turn off electric power before service or

installation. All electrical connections and

wiring MUST be installed by a qualifi ed

electrician and conform to the National

Electrical Code and all local codes which

have jurisdiction. Failure to do so could result

in serious personal injury or death.

NOTE: Use Copper Conductors ONLY. Wire sizes

are per NEC, check local codes for overseas applications.

Table 1 250 V Receptacles and Fuse Types

AMPS 15 20* 30

RECEPTACLE

TIME-DELAY TYPE FUSE

(or HACR circuit breaker)

HACR – Heating, Air Conditioning, Refrigeration

* May be used for 15 Amp applications if fused for 15 Amp

NOTE: 265 volt units are hard wired.

Table 2 Recommended branch circuit wire sizes*

NAMEPLATE / MAXIMUM

CIRCUIT BREAKER SIZE

15

20

30

15 20 30

AWG WIRE SIZE**

14

12

10

WIRE SIZE

FUSE/CIRCUIT

BREAKER

GROUNDING

RECEPTACLE

WIRE SIZING

Use ONLY wiring size recommended for

single outlet branch circuit.

Use ONLY type and size fuse or HACR

circuit breaker indicated on unit’s rating

plate. Proper current protection to the unit

is the responsibility of the owner. NOTE:

A time delay fuse is provided with 265V

units.

Unit MUST be grounded from branch

circuit through service cord to unit, or

through separate ground wire provided

on permanently connected units. Be sure

that branch circuit or general purpose

outlet is grounded. The fi eld supplied

outlet must match plug on service cord

and be within reach of service cord. Refer

to Table 1 for proper receptacle and fuse

type. Do NOT alter the service cord or

plug. Do NOT use an extension cord.

The fi eld supplied outlet must match plug

on service cord and be within reach of

service cord. Refer to Table 1 for proper

receptacle and fuse type. Do NOT alter

the service cord or plug. Do NOT use an

extension cord.

Use recommended wire size given

in Table 2 and install a single branch

circuit. All wiring must comply with local

and national codes. NOTE: Use copper

conductors only.

AWG – American Wire Gauge

* Single circuit from main box

** Based on copper wire, single insulated conductor at 60°C

POWER CORD INFORMATION (230/208V MODELS ONLY)

All Friedrich 230/208V PTAC units are shipped from the

factory with a Leakage Current Detection Interrupter (LCDI)

equipped power cord. The LCDI device meets the UL and

NEC requirements for cord connected air conditioners

effective August 2004.

To test your power supply cord:

1. Plug power supply cord into a grounded 3 prong outlet.

2. Press RESET.

3. Press TEST (listen for click; Reset button trips and pops

out).

4. Press and release RESET (listen for click; Reset button

latches and remains in). The power supply cord is ready for

operation.

NOTE: The LCDI device is not intended to be used as a

switch.

Once plugged in the unit will operate normally without the

need to reset the LCDI device. If the LCDI device trips and

15

Loading...

Loading...