Page 1

SPLIT TYPE

ROOM AIR CONDITIONER

FLOOR CONSOLE /

UNDER CEILING

DUAL

type (60Hz)

Models

Indoor unit

Outdoor unit

MS24Y3F MR24UY3F

CONTENTS

SPECIFICATIONS

OUTLINE AND DIMENSIONS

REFRIGERANT SYSTEM DIAGRAM

CIRCUIT DIAGRAM

PCB CIRCUIT DIAGRAM

ERROR CONTENTS

DISASSEMBLY ILLUSTRATION (Indoor Unit)

DISASSEMBLY ILLUSTRATION (Outdoor Unit)

PARTS LIST (Indoor Unit)

PARTS LIST (Outdoor Unit)

STANDARD ACCESSORIES

................................

.....................

..............

..............................

........................

............................

.......................

......................

.....................

.....

....

1

2

4

5

7

11

13

20

24

25

26

Page 2

SPECIFICATIONS

TYPE

INDOOR UNIT

OUTDOOR UNIT

COOLING CAPACITY

HEA TING CAPACITY

ELECTRICAL DATA

POWER SOURCE

FREQUENCY

RUNNING CURRENT (Cool)

RUNNING CURRENT (Heat)

INPUT WATTS (Cool)

INPUT WATTS (Heat)

E.E.R. (Cool)

E.E.R. (Heat)

MOISTURE REMOVAL

AIR CIRCULATION-High

COMPRESSOR

TYPE

Cool and Heat

MS24Y3F

MR24UY3F

22,200 / 22,200 BTU/h

24,200 / 24,200 BTU/h

230 V / 208 V

160Hz

9.8 A / 10.9 A

10.2 A / 11.3 A

2.25 kW / 2.25 kW

2.33 kW / 2.33 kW

2.89 / 2.89 kW/kW

3.05 / 3.05 kW/kW

3.5 l/hr

3

/hr

880 m

Hermetic type, 4 poles, Inverter, Twin Rotary

DISCRIMINA TION

REFRIGERANT

FAN MOTOR

POWER SOURCE

INDOOR UNIT

( Cool / Heat )

OUTDOOR UNIT

( Cool / Heat )

DIMENSIONS

INDOOR UNIT

OUTDOOR UNIT

WEIGHT

INDOOR UNIT

R410A

DISCRIMINATION

HIGH-SPEED

MED-SPEED

LOW-SPEED

DISCRIMINATION

HIGH- SPEED

HxWxD

HxWxD

Gross / Net

TNB220FPBM9

4 lb 3 oz (1,900 g)

230 V

MFA-24PPT

1,180 / 1,100 r.p.m.

1,000 / 1,000 r.p.m.

900 / 900 r.p.m.

MFE-45ROM

850 / 900 r.p.m.

7-7/8" x 39-1/8" x 25-7/8" inch

(199 x 990 x 655 mm)

32-3/4" x 35-1/2" x 13" inch

(830 x 900 x 330 mm)

37 kg / 28 kg

OUTDOOR UNIT

Gross / Net

REFRIGERANT CHARGE (R410A)

Pipe Length

FULL CHARGE AMOUNT

ADDITIONAL REFRIGERANT

49 ft. (15 m)

66 ft. (20 m)

98 ft. (30 m)

131 ft. (40 m)

164 ft. (50 m)

12006.05.29

70 kg / 64 kg

4 lb 3 oz (1,900 g)

4 lb 10 oz (2,100 g)

5 lb 8 oz (2,500 g)

6 lb 6 oz (2,900 g)

7 lb 5 oz (3,300 g)

0.424 oz / ft. (40g/m)

Page 3

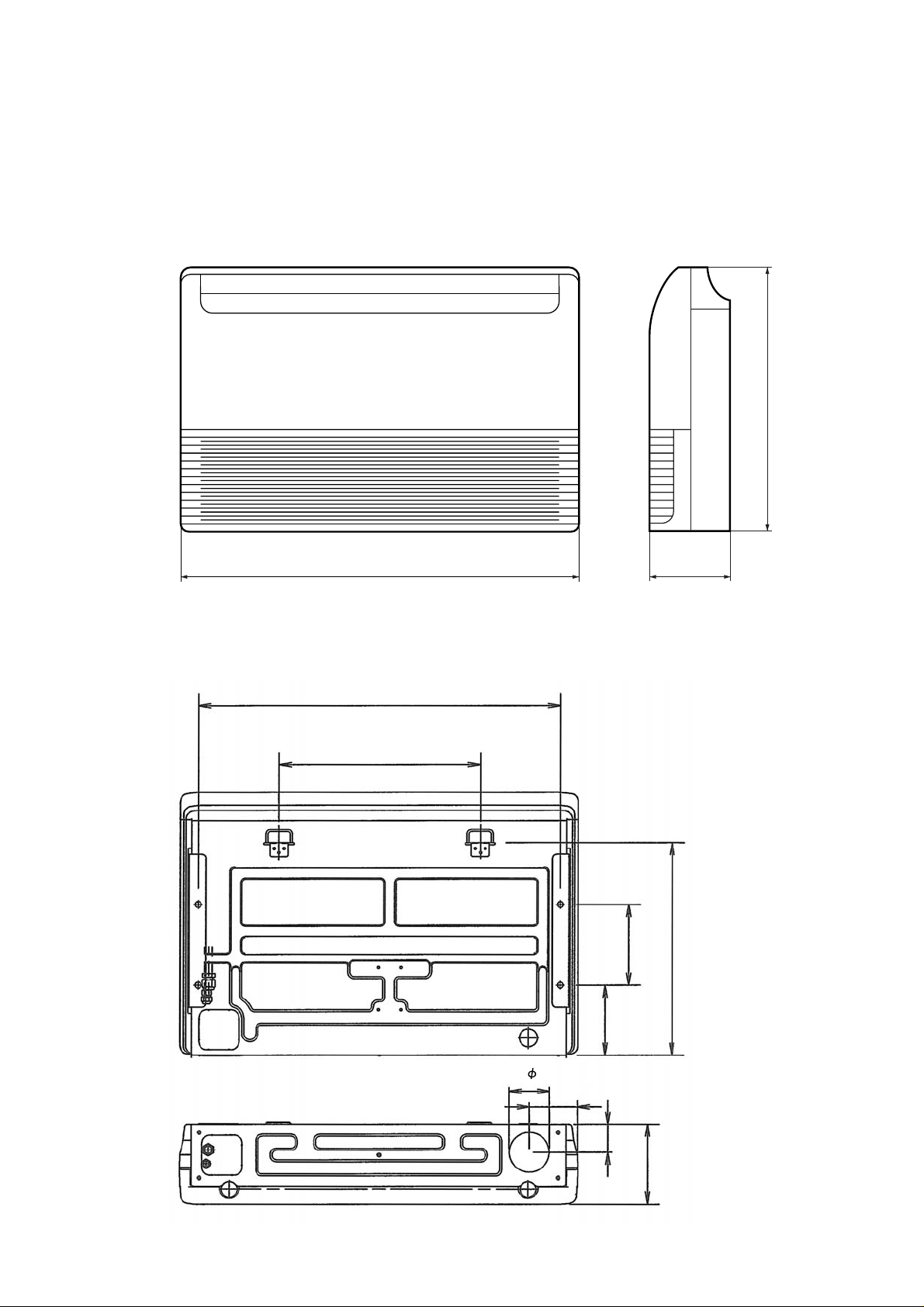

OUTLINE AND DIMENSIONS

INDOOR UNIT

Unit : inch (mm)

25-7/8" (655)

(rear view)

39-1/8" (990)

7-7/8" (199)

35" (900)

19-3/4" (500)

7-7/8" (200)

20-7/8" (530)

3-15/16" ( 100)

22006.05.25

6-7/8"

4-23/32" (120)

2-3/4" (70)

(175)

7-27/32" (199)

Page 4

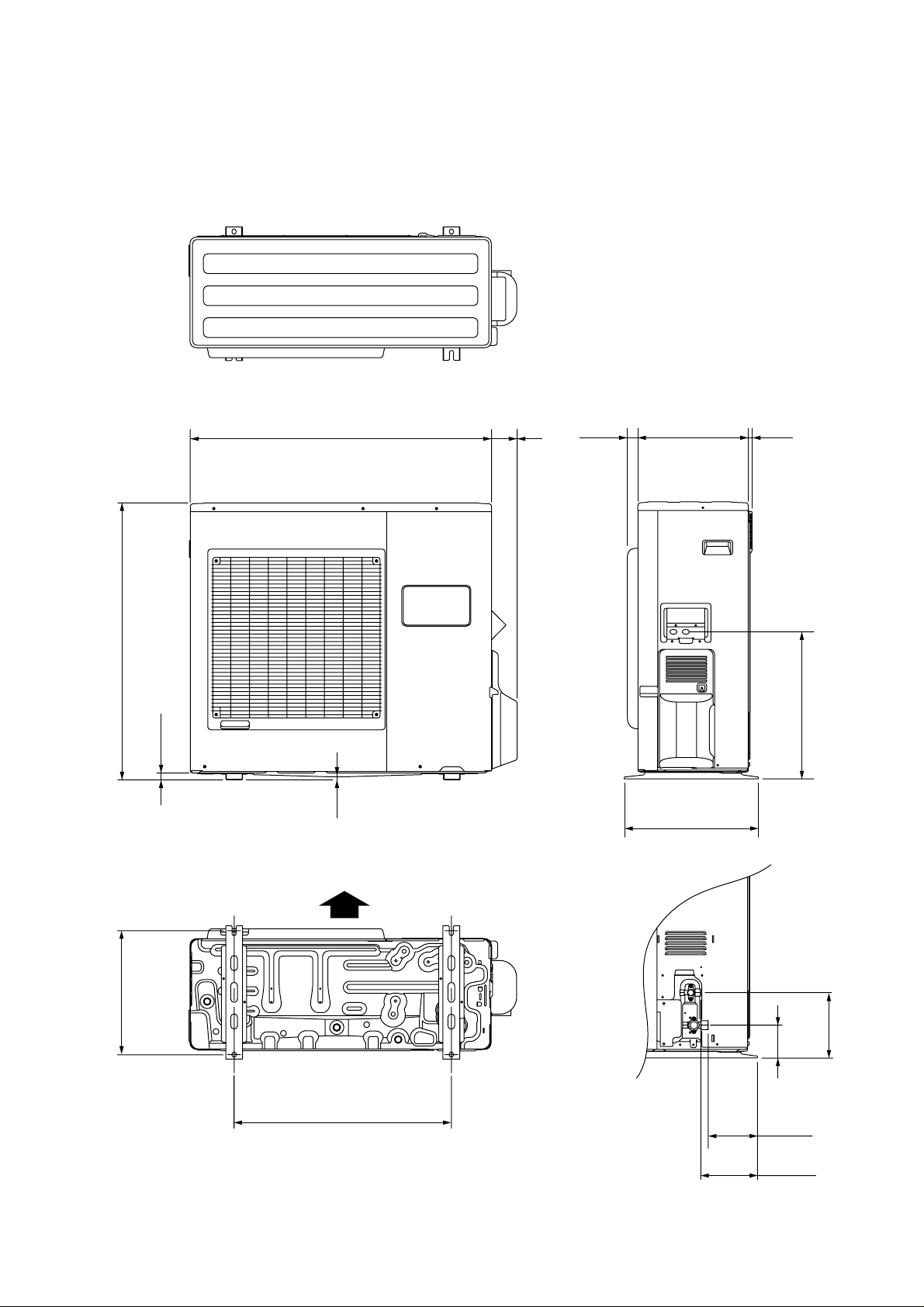

OUTDOOR UNIT

Unit : inch (mm)

32-3/4" (830)

7/8" (21)

35-1/2" (900)

3/8"

(9)

3"(77)

1-1/4"

(31)

13" (330)

15-3/4" (400)

1/2"

(12)

17-3/8" (440)

14-5/8" (370)

Air Flow

25-5/8" (650)

3-7/8"

(99)

7-3/4" (196)

5-3/4" (147)

6-3/4" (170)

32006.05.25

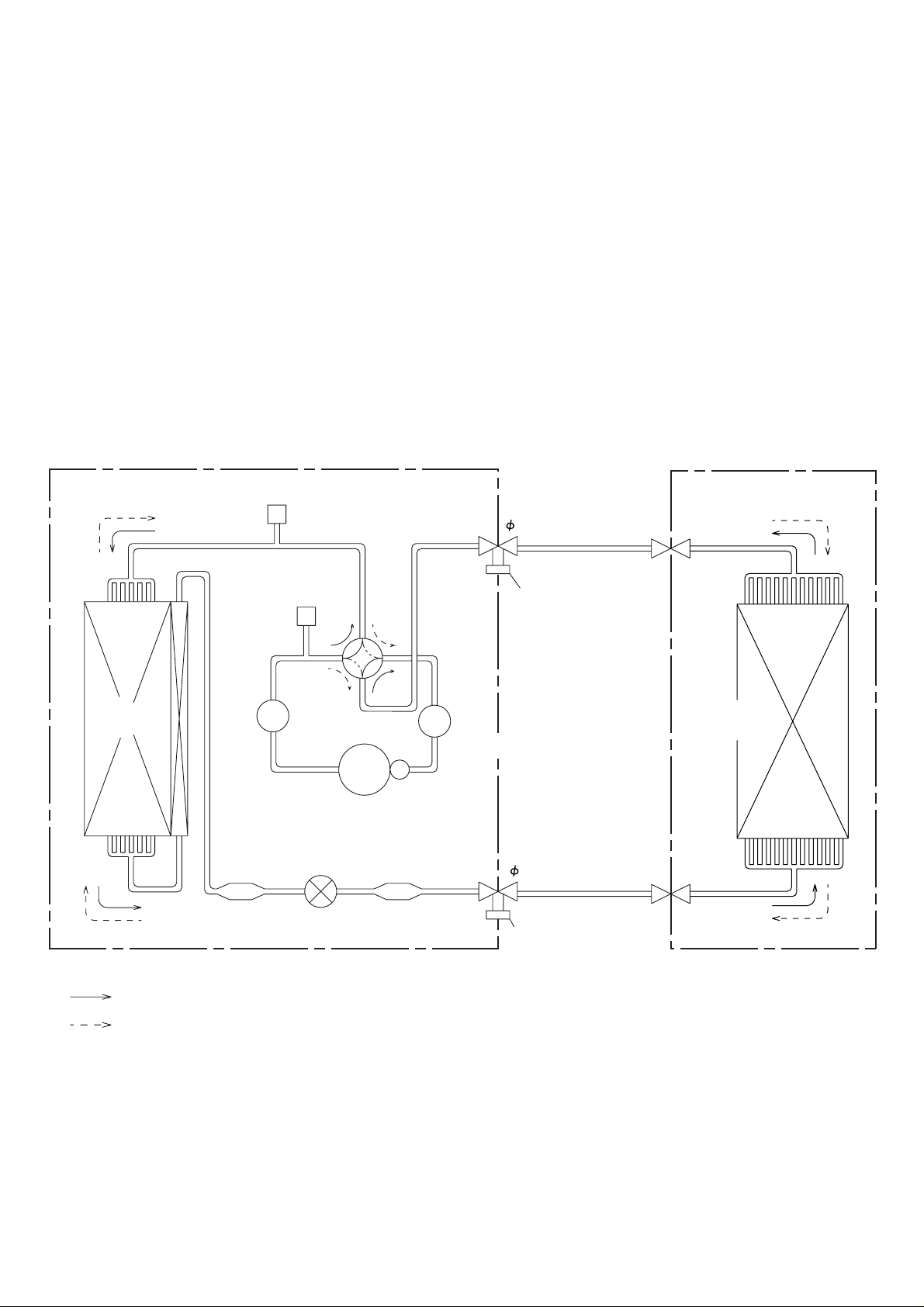

Page 5

REFRIGERANT SYSTEM DIAGRAM

OUTDOOR UNIT

Condenser

Pressure

Check Valve

High Pressure

Switch

4-way

Muffler

Valve

Expansion

Valve

INDOOR UNIT

Refrigerant Pipe

15.88mm (5/8")

Charging

Valve

Evaporator

Accumulator

Compressor

Refrigerant Pipe

9.52mm (3/8")

: COOL

: HEAT

Strainer

Strainer

Charging Valve

42006.05.25

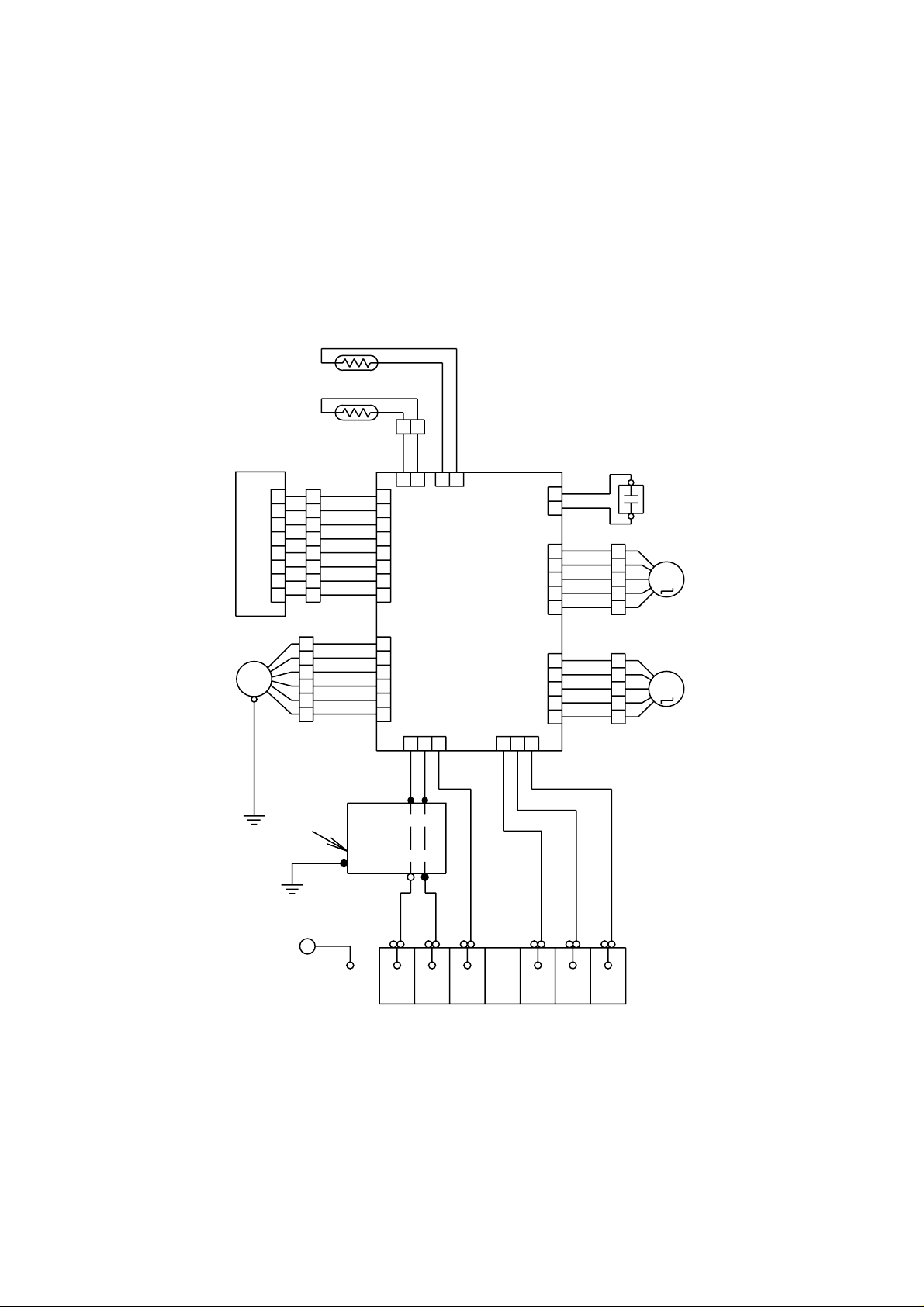

Page 6

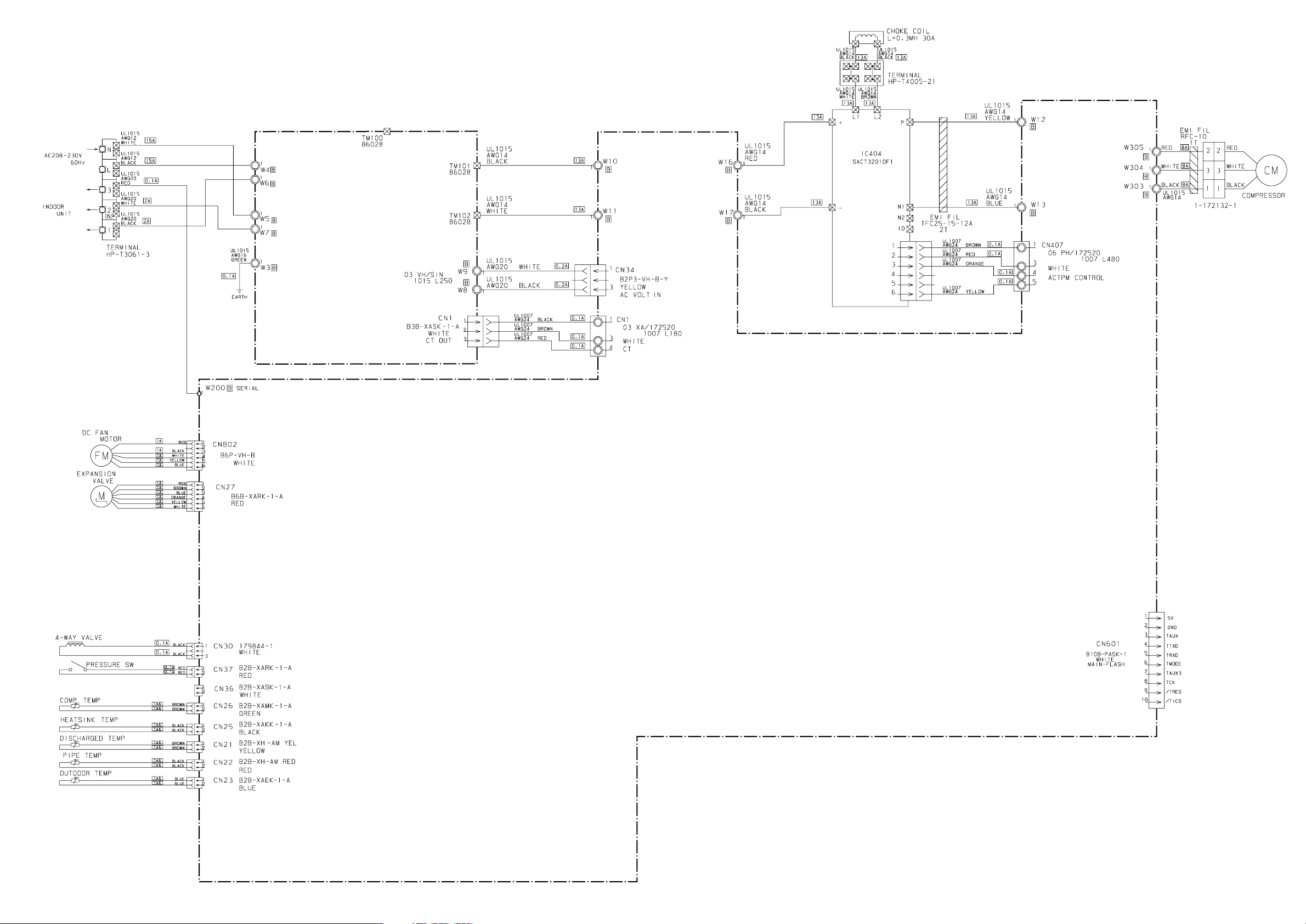

CIRCUIT DIAGRAM

INDOOR UNIT

ROOM TEMPERATURE THERMISTOR

PIPE TEMPERATURE THERMISTOR

1

CN7 CN8

1

2

3

4

5

6

7

8

1

2

3

4

5

6

FAN MOTOR

INDICATOR PCB ASSY

FM

1

2

3

4

5

CN201

6

7

8

1

2

3

4

5

6

7

8

BLACK

4

WHITE

6

RED

3

PINK

5

PURPLE

2

BLUE

1

BROWN

RED

ORANGE

YELLOW

WHITE

BLUE

PURPLE

GRAY

1

2

BLACK

BLACK

GRAY

GRAY

2

2

1

CN13CN5

CONTROLLER PCB ASSY

CN1 CN17

123

123

1

2

1

2

3

CN10 CN4

4

5

1

2

3

CN11

4

5

WHITE

WHITE

BROWN

RED

ORANGE

YELLOW

WHITE

BROWN

RED

ORANGE

YELLOW

WHITE

1

2

3

4

5

1

2

3

4

5

FAN MOTOR

CAPACITOR

STEP MOTOR

M

(UP/DOWN)

STEP MOTOR

M

( LEFT / RIGHT )

GREEN / YELLOW

Use T3.15A-250V

Fuse on F101

GREEN

POWER SUPPLY PCB

G

RED

WHITE

BLACK

L

N

WHITE

WHITE

BLACK

31

2

1

RED

BLACK

TERMINAL

3

2

52005.05.25

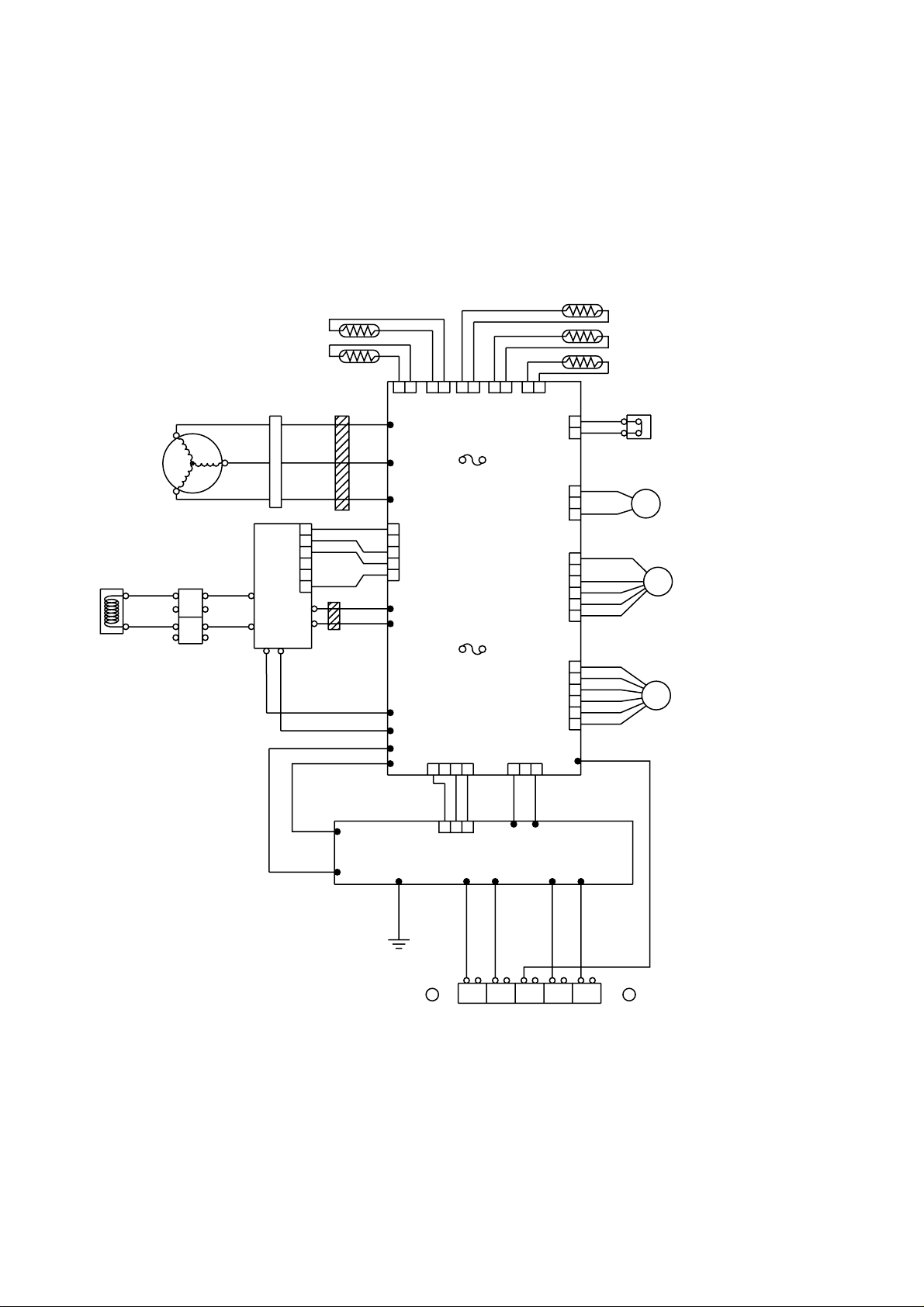

Page 7

OUTDOOR UNIT

COMPRESSOR

BLACK

BLACK

CHOKE COIL

PIPE TEMPERATURE

THERMISTOR

DISCHARG TEMPERATURE

THERMISTOR

CONNECTOR

U

W

RED RED

WHITE

V

BLACK

ACTIVE

FILTER

MODULE

TERMINAL

WHITE

BROWN

L1

L2

+

-

EMI FILTER

WHITE

BLACK

BROWN

1

RED

2

ORANGE

3

4

5

YELLOW

6

P

N

EMI FILTER

1T

YELLOW

2T

BLACK

BLACK

BROWN

12 12 12 12 12

CN21

CN22

U

W305

V

W304

F4 T 5A-250V

W

W303

1

CONTROLLER PCB ASSY

2

CN407

3

4

5

W12

BLUE

W13

F2 T 3.15A-250V

RED

W16

W17

W10

CN1

W11

1

CN23

FUSE

FUSE

432

CN26

BLUE

BROWN

CN25

CN34

1

BLACK

CN37

CN30

CN802

CN27

W200

32

OUTDOOR TEMPERATURE

THERMISTOR

COMPRESSOR TEMPERATURE

THERMISTOR

HEAT SINK TEMPERATURE

THERMISTOR

RED

1

RED

2

BLACK

1

2

BLACK

3

RED

1

2

BLACK

3

WHITE

4

YELLOW

5

BLUE

6

RED

1

BROWN

2

BLUE

3

ORANGE

4

YELLOW

5

WHITE

6

HIGH PRESSURE SWITCH

4WV

SOLENOID COIL

FM FANMOTOR

EXPANSION VALVE COIL

EV

WHITE

BLACK

BLACK

BROWN

RED

32

TM102

1

CN1

POWER SUPPLY PCB ASSY

TM101

W3

GREEN

EARTH EARTH

W6 W7

BLACK

13LN

GG

WHITE

2 (N)

WHITE

W9 W8

BLACK

W4

BLACK

W5

WHITE

RED

62005.05.25

Page 8

INDOOR PCB CIRCUIT DIAGRAM

CONTROLLER PCB ASSY

K01AL-050SHSE-C1

72006.05.25

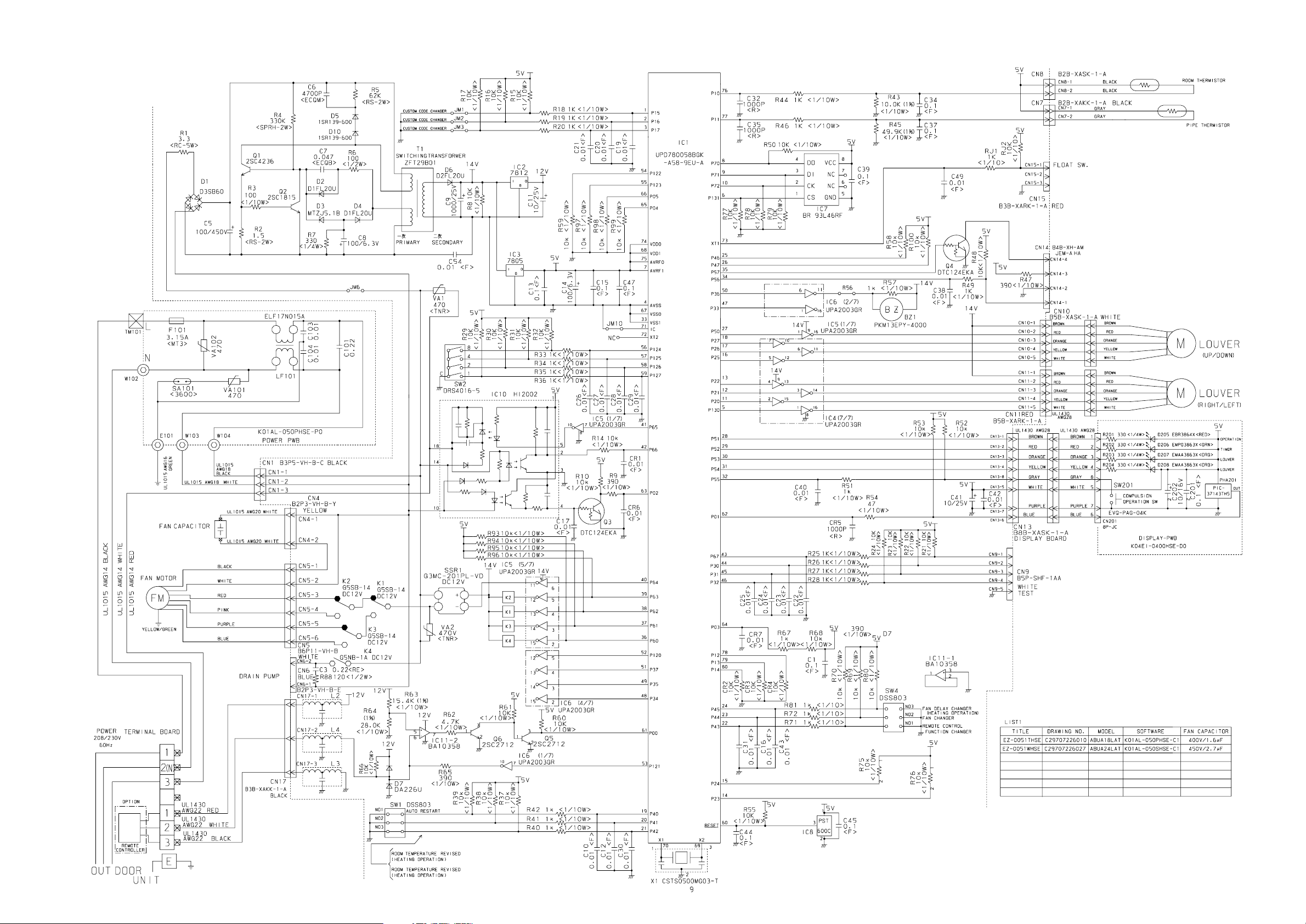

Page 9

OUTDOOR PCB CIRCUIT DIAGRAM

POWER SUPPLY PCB ASSY

K04BA-0500HUE-P0

INVERTER ASSEMBLY

EZ-005FHUE

CONTROLLER PCB ASSY

K04AW-0502HUE-C1

82006.05.25

Page 10

OUTDOOR UNIT

CONTROLLER PCB ASSEMBLY

K04AW-0502HUE-C1

600/450V x 4

92006.05.25

Page 11

OUTDOOR UNIT

POWER SUPPLY PCB ASSEMBLY

K04BA-0500HUE-P0

TM100

POWER SOURCE

230V

60Hz

TO INDOOR UNIT

EARTH

AC VOLT OUT

BLACK

WHITE

W4

W5

W6

BLACK

W7

WHITE

W3

GREEN

W8

BLACK

W9

WHITE

RCH4730-021PF07

L1

B

VA101

470V

<TNR>

VA102

470V

<TNR>

B

C101

3.3

<LE>

SA100

RA-302M

B

B

B

B

B

C104

0.033

<YE>

C105

0.033

<YE>

C106

3.3

<LE>

L2

N200500K1D7C

C107

3.3

<LE>

CT1

CT-1B

D60

5V

DAN217U

220/16V

R60 1.0K

<1/10W>

(1%)

C60

<PJ>

L4

RCH4730-021PF07

+

VR1

B2K

R61 3.74K

<1/10W>

(1%)

C111

3.3

<LE>

R68 22K

<1/10W>

C64

0.1

<F>

C112

0.015

<YE>

C113

0.015

<YE>

C65

0.1

<F>

5V

TM101

TM102

CN1

B3B-XASK-1-A

WHITE

1

2

3

CT OUT

2006.05.29 10

Page 12

ERROR CONTENTS

(Indoor unit)

OERATION

TIMER

SWING

SWING

MANUALAUTO

OPERATION lamp (Red)

TIMER lamp (Green)

SWING lamp (Orange)

SWING lamp (Orange)

Operation can be checked by lighting and flashing of the display section OPERATION, , and

TIMER lamps.

Perform judgment in accordance with the following.

TEST RUNNING

When the air conditioner is run by pressing the remote control unit test run button, the OPERATION and

TIMER lamps flash slowly at the same time.

ERROR

The OPERATION, TIMER, and SWING lamps operate as follows (Table) according to the error contents.

Error contents

Indoor unit circuit board error

Indoor unit room temperature sensor wire opened

Indoor unit room temperature sensor wire short circuited

Indoor unit piping sensor wire opened

Indoor unit piping sensor short circuited

Indoor unit fan error 6 times

Outdoor unit circuit board error

Miswiring between outdoor unit and indoor unit

Outdoor unit discharge temperature sensor error

Outdoor unit piping sensor error

OPERATION TIMER SWING

(RED) (GREEN) (ORANGE)

2 times

2 times

3 times

3 times

5 times

5 times

Error display

5 times

3 times

Outdoor unit outdoor temperature sensor error 4 times

Fast flashing

:

Slow flashing

:

Off

:

112006.05.24

Page 13

ERROR CONTENTS

(outdoor unit)

1. Make a TEST RUN in accordance with the installation instruction sheet for the indoor unit.

2. OUTDOOR UNIT LEDS

When a malfunction occurs in the outdoor unit, the LED on

the circuit board lights to indicate the error. Refer to the following table for the description of each error according to the

LED.

LED

1 flash

2 flash

3 flash

4 flash

7 flash

8 flash

9 flash

12 flash

13 flash

14 flash

15 flash

16 flash

lighting

Communication error

(Indoor unit - Outdoor unit)

Discharg pipe temperature sensor

Outdoor heat exchanger temperature sensor

Outdoor temperature sensor

Compressor temperature sensor

Heat sink temperature sensor

Pressure switch abnormal

IPM error

Compressor rotor position cannot detect

Compressor cannot operate

Outdoor fan abnormal (upper fan)

Outdoor fan abnormal (lower fan)

No error

Error contents

2. When the product is operating:

1

Press the PUMP DOWN switch on the outdoor unit.

The LED on the outdoor unit circuit board lights, and

operation stops. At this point, recovery has not been

completed, so do not close the two- and three-way

valves.

The pump down operation (cooling operation) be-

2

gins after three minutes. Close the three-way valve

(liquid) after operation starts.

After2-3minutes, operation stops. Close the three-

3

way valve (gas) within one minute after operations

stops.

The LED will go out three minutes after it stops. Dis-

4

connect the power supply after confirming that the

LED has gone out.

*When the pump down operation is repeated, temporarily disconnect

the power supply after opening the closed valves (both liquid and gas).

Reconnect the power supply after2-3minutes and perform the pump

down operation.

*When the start of the operation after pump down operation has been

completed, temporarily disconnect the power supply after opening the

closed valves (both liquid and gas).

Reconnect the power supply after 2-3 minutes and be sure to perform

a test operation for cooling.

3-way valve

(Liquid)

SPECIAL INSTALLATION

SETTING

PUMP DOWN (Refrigerant collecting operation)

Perform the following procedures to collect the refrigerant

when moving the indoor unit or the outdoor unit.

1. When the product is stopped:

1

Press the PUMP DOWN switch on the outdoor unit.

(The LED on the outdoor unit circuit board lights.)

The pump down operation (cooling operation) be-

2

gins right away. After oparation starts, close the

three-way valve (liquid).

3

After2-3minutes, operation stops. Close the threeway valve (gas) within one minute after operations

stops.

4

The LED will go out three minutes after it stops.Disconnect the power supply after confirming that the

LED has gone out.

3-way valve

(Gas)

PUMP DOWN SW (SW2)

DANGER

This part (Choke coil) generates high voltages.

Never touch this part.

122006.02.14

Page 14

DISASSEMBLY ASSEMBLY

INDOOR UNIT

653-2

509

173

365-1

870-1

365-2

580

365-2

870-1

240

653-2

743

174

365-1

508

132006.05.25

Page 15

INDOOR UNIT

470

764

439

160

577

418

127

196-1

124

235

68

138

184-1

124

187

108

578

68

142006.05.25

Page 16

INDOOR UNIT

983

983

152006.05.25

Page 17

INDOOR UNIT

416

385

417

771

488

8-1

472

443

473

162006.05.25

Page 18

INDOOR UNIT

146

735

652-1

800

OPTIONAL PARTS

172006.05.29

Page 19

INDOOR UNIT

982

182006.06.13

Page 20

INDOOR UNIT

503

408

520

554

555

876-2

684

558

500

521

505

876-1

505

505

361-2

407

361-2

361-3

361-2

502

361-3

69

69

506

505

361

361-2

320

361-3

69

69

321

192006.05.29

Page 21

OUTDOOR UNIT

1

6

3

4

2

5

202006.05.29

Page 22

OUTDOOR UNIT

10

9

15

13

14

11

17

18

8

2006.06.13 21

Page 23

OUTDOOR UNIT

26

23

19

22

31

24

25

27

28

12

29

12

30

20

222006.05.29

Page 24

OUTDOOR UNIT

35

38

37

36

33 34

232006.05.29

Page 25

PARTS LIST

a

INDOOR UNIT

Ref. Part No. Ord. Ref. Part No. Ord.

No MS24Y3F Q'ty No MS24Y3F Q'ty

8-1 Air Filter 67220192 500 Protect Cover 67220242

34 Capacitor (Fan Motor) 67220218 502 SupportStay 67220243

56 Sirocco Fan Assy 67220193 503 LouverShaft 67220244

67 Rubber (Vibration-proof) 67220219 505 LouverStopper 67220004

68 Cap, Plastic 67220220 506 Louver Rod 67220007

69 Louver 67220008 508 Cosmetic Panel-R 67220245

108 Base Assy 67220013 509 Cosmetic Panel-L 67220246

109 Casing, Plastic 67220002 514 Control Box Cover 67220247

124 Kit (Dew Proof Plate) 67220221 520 Flap Base 67230058

126 Motor Fixing Table Assy 67220222 521 LouverLink Cover 67220006

127 Drain Hose Assy 67220015 554 Flap Link-Upper (Step Motor-V) 67220248

138 Kit (Separate Wall-A) 67220215 555 Flap Link-Lower (Step Motor-V) 67220249

146 EvaporatorAssy KB07 67220216 558 Motor Rod-A (Step Motor-V) 67220250

160 Drain Pan Assy (Kit) 67220217 577 Catch TL-119 67220014

164 Fan Motor Assy-IN 67220224 578 Base Bracket (Reinforcement Met

173 HangerBracket-L 67220228 580 Top Cover 67220001

174 HangerBracket-R 67220225 581 Protector, Metal (Fan Motor) 67220252

184-1 Thermistor Spring-A 67206400 625 Cord Bushing KR-51 67230030

187 Clamp No. 1219 67220226 628 Locking Spacer-B 67207461

195 Clamp SKB-100 67220227 652-1 Thermistor Holder Pipe 67206704

196-1 Clamp SKB-3M 67207409 653-2 Bolt 67220253

223 Control Box 67220229 684 Motor Base 67220254

234 Thermistor Assy-Room 67203510 731 Holder (Guide Rail) 67200566

235 Thermistor Assy-Pipe 67203511 735 Distributor Assy 67220255

236 Controller PCB Assy 67203712 743 Remote Control Unit Holder 67203202

(K01AL-050SHSE-C1)

240 Remote Control Unit 37220230 764 Drain Cap 67220256

320 Flap (Upper)-G 67230061 771 Panel 67220257

321 Flap (Lower) 67230062 800 Bypass Pipe Assy 67220258

338 Motor Fixture 67200588

361 Bushing 67210058

361-2 Bushing-B, Plastic 67230060

361-3 Bushing-C, Plastic 67230059

365-1 Special Screw 67220231

365-2 Special Screw 67220232

381 Locking Spacer, KGLS-4S 67207460

385 Indicator PCB Assy 67230056

407 Motor Rod 67220233

408 LouverLink 67220005

416 Insulation (Panel)-A 67220234

417 Insulation (Panel)-B 67220235

418 Insulation (Flap Base) 67220236

439 Drain Pan Wire 67220237

443 Arm Bracket 67220238

470 Separate Wall-B (Kit) 67220239

472 Grille Support 67220240

473 Filter Bracket 67220241

488 Grill-G 67220000

(K01AL-050SHSE-C1)

755 Casing Cover 67220003

DescriptionDescription

67220251

2006.06.13 24

Page 26

OUTDOOR UNIT

Ref. Part No. Ord.

No MR24UY3F Q'ty

1 Top Panel Sub Assy 67201640

2 Front Panel 67201601

3 Fan Guard 67201602

4 Grip Side 67201603

5 Service Panel Sub Assy 67201688

6 Right Panel 67201605

8 Propeller Fan Assy 67201607

9 Motor, Induction 67201608

10 Condenser-A Assy 67201609

11 CoilChoke 67201633

12 Strainer Assy 67201611

13 Separate Wall Assy 67201647

14 Cap Foot 67201650

15 Base Assy 67201648

17 3-Way Valve Assy (3/8) 67201614

18 3-Way Valve Assy (5/8) 67201615

19 Check Joint Assy 67201616

20 CompressorAssy 67201689

22 4-Way Valve 67201619

23 Solenoid 67201681

24 Pressure Switch 67201621

25 Inlet Pipe Cond A Assy 67201622

26 Inlet Pipe Cond B Assy 67201690

27 Outlet Pipe Cond A Assy 67201691

28 Expansion Valve Assy 67201692

29 Coil (Expansion Valve) 67201422

30 Distributor 67201693

31 Discharge Pipe A Assy 67201694

33 Terminal2P 67220181

34 Terminal5P 67201632

35 ACTPM 67201627

36 Holder Thermo 67201628

Description

37 Inverter PCB Assy 67201695

38 Power PCB Assy 67201696

---- Fuse 3.15A-250V 67201697

---- Thermistor (Outdoor Temp.) 67201686

---- Heat Exchanger Thermistor 67201698

---- Thermistor (Discharge) 67201635

---- Compressor Thermistor 67201637

---- Thermistor 67201430

---- Heatsink Thermistor 67201685

---- Transformer 67201699

---- Varistor 67201700

---- Arrester 67201701

---- Relay 67201702

---- Relay 67201703

---- Switch Push 67201704

---- Switch Slide 67201705

---- Drain Pipe Assy 67201706

---- Drain Cap 67201707

2006.05.25 25

Page 27

STANDARD ACCESSORIES

The following installation parts are furnished. Use them as required.

INDOOR UNIT ACCESSORIES

Name and Shape Part No.Application

Cosmetic Panel-L

Cosmetic Panel-R

Tapping screw ( 4 x 10)

Installation template

Hanger bracket (left)

Hanger bracket- (right)

Anchor bolt (M12)

Special nut

Q'ty

1

1

2

For positioning the indoor unit.

For under ceiling type.

1

For suspending the indoor unit from

1

ceiling.

1

4

4

9358536018

9358535011

0700009037

9359107002

9358596005

9358595008

313806339400

Spring washer

Wall bracket

Tapping screw ( 4 x 20)

Coupler heat insulator (large)

Coupler heat insulator (small)

Nylon fastener

Drain hose

Insulation (drain hose)

4

For suspending the indoor unit on

2

the wall.

For fixing the wall bracket.

6

For indoor side pipe joint.

(Large pipe)

1

For indoor side pipe joint.

(Small pipe)

1

For fixing the drain hose.

1

1

Adhesive type 70 x 230

1

0700007125

9358597002

0700076107

9350716012

313209328104

312300787605

9359242000

9359225003

VT wire

For fixing the drain hose

L 280 mm

1

262006.05.29

313806350303

Page 28

REMOTE CONTROL UNIT

Name and Shape Part No.Application

Remote control unit

Battery (penlight)

Remote control unit holder

Tapping screw

( 3 x 12)

Q'ty

Use for air conditioner operation

1

(AR-JW5)

2

For remote control unit

Use are remote control unit holder

1

For remote control unit holder

2

installation

Wired remote controller unit is also available

: UTB-UUB (Parts No. 9075887004)

9371190051

0600185534

9305642014

0700019098

OUTDOOR UNIT ACCESSORIES

Name and Shape

Drain pipe

Drain cap

Q'ty

1

For outdoor unit drain piping work

(May not be supplied, depending

on the model)

5

Application

Part No.

9303029015

313166024302

272006.05.29

Page 29

0605G3090

Loading...

Loading...