Friedrich MW09C1H, MW12C1H, MR09C1H, MR12C1H User Manual 2

Service and Parts Manual

2 0 11

SPLIT TYPE ROOM AIR CONDITIONER WALL MOUNTED TYPE

MODELS

INDOOR UNIT |

MW09C1H |

MW12C1H |

|

|

|

OUTDOOR UNIT |

MR09C1H |

MR12C1H |

|

|

|

Table of Contents

Model and product code .................................................................................................. |

3 |

|

Summary and features |

......................................................................................................... |

4 |

|

||

1.SafetyPrecautions |

............................................................................................................... |

5-7 |

|

||

2.Specifications ........................................................................................................................... |

8 |

|

2.1Unit Specifications........................................................................................................... |

|

8-11 |

2.2 Operation Date............................................................................................................... |

12 |

|

2.3Expanded capacity data tables for both cooling and heating ...................................... |

13 |

|

2.4Operation Characteristic Curve...................................................................................... |

14 |

|

2.5 Noise criteria curve tables for both models.................................................................... |

15 |

|

3.ConstructionViews.............................................................................................................. |

16 |

|

3.1IndoorUnit ....................................................................................................................... |

16 |

|

3.2OutdoorUnit .................................................................................................................... |

16 |

|

4.RefrigerantSystemDiagram |

....................................................................................... |

17 |

|

||

5.SchematicDiagram |

.............................................................................................................. |

18-21 |

|

||

5.1ElectricalDate |

|

18 |

|

|

|

5.2ElectricalWiring ........................................................................................................... |

|

18-19 |

5.3PrintedCircuitBoard ..................................................................................................... |

|

20-21 |

6.FunctionandControl ....................................................................................................... |

22-35 |

|

7. Installation Manual............................................................................................................ |

36-43 |

|

8.Troubleshooting ................................................................................................................... |

|

44-72 |

9.1Precautions before ....................................................Performing Inspection or Repair |

44 |

|

9.2Confirmation ................................................................................................................. |

44 |

|

9.3Judgement by Flashing LED of Indoor/Outdoor UnIT ........................................................... |

44-51 |

|

9.4 How to Check simply the main part .................................................................................... |

52-62 |

|

9. Removal Procedure |

....................................................................................................... |

73-78 |

|

||

10. Exploded Views and Parts List |

............................................................................. |

79-85 |

|

||

2

Model and product code

Model and product code

Voltage range |

Complete unit model |

Indoor unit model |

Outdoor unit model |

|

|

|

|

|

|

115V ~ 60HzM |

M09CIH |

MW09CIH |

MR09CIH |

|

|

|

|

|

|

115V ~ 60HzM |

M12CH |

MW12CIH |

MR12CIH |

|

|

|

|

|

|

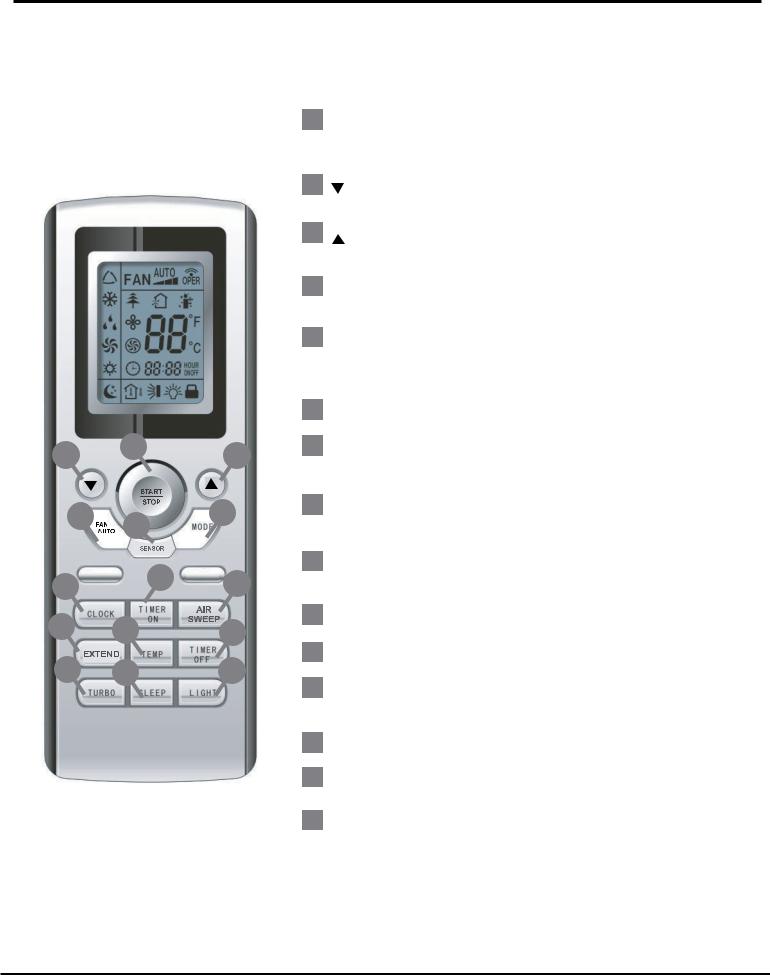

3

Summary and features

Summary and features

OutdoorUnit

MR09CIH

MR012CIH

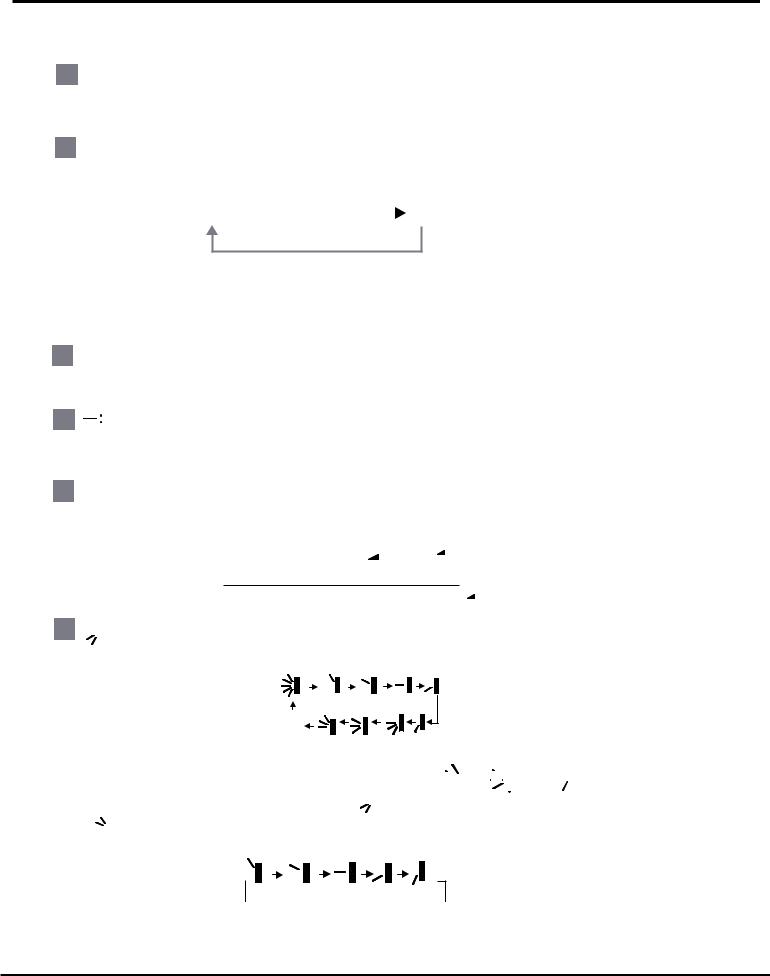

Remote control windo w

YB1FAF

4

IMPORTANT SAFETY INFORMATION

The information contained in this manual is intended for use by a qualified service technician who is familiar with the safety procedures required for installation and repair, and who is equipped with the proper tools and test instruments required to service this product.

Installation or repairs made by unqualifi ed persons can result in subjecting the unqualifi ed person making such repairs as well as the persons being served by the equipment to hazards resulting in injury or electrical shock which can be serious or even fatal.

Safety warnings have been placed throughout this manual to alert you to potential hazards that may be encountered. If you install or perform service on equipment, it is your responsibility to read and obey these warnings to guard against any bodily injury or property damage which may result to you or others.

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read, understand and obey all safety messages.

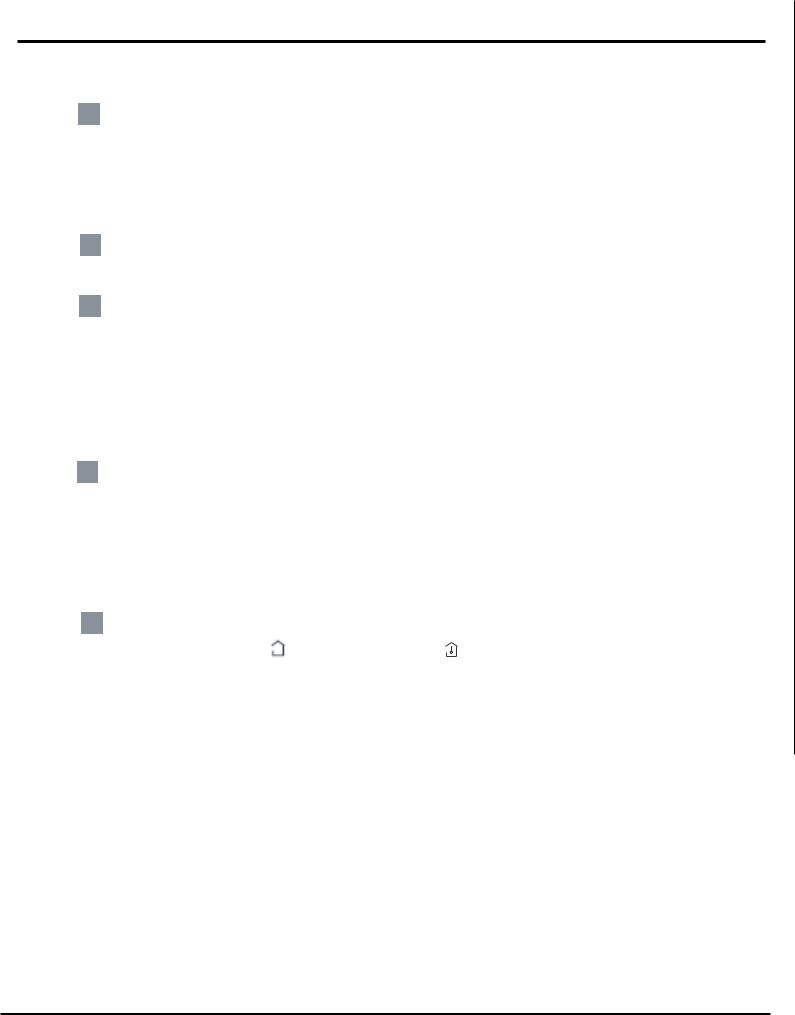

This is a safety Alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol with the word “WARNING” or “CAUTION”.

These words mean:

WARNING

WARNING

CAUTION

CAUTION

You can be killed or seriously injured if you do not follow instructions.

You can receive minor or moderate injury if you do not follow instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what will happen if the instructions are not followed.

|

A message to alert you of potential property damage will have the word “NOTICE”. |

|

NOTICE |

||

Potential property damage can occur if instructions are not followed. |

||

|

||

|

|

PERSONAL INJURY OR DEATH HAZARDS

ELECTRICAL HAZARDS:

•Unplug and/or disconnect all electrical power to the unit before performing inspections, maintenance, or service.

•Make sure to follow proper lockout/tag out procedures.

•Always work in the company of a qualifi ed assistant if possible.

•Capacitors, even when disconnected from the electrical power source, retain an electrical charge potential capable of causing electric shock or electrocution.

•Handle, discharge, and test capacitors according to safe, established, standards, and approved procedures.

•Extreme care, proper judgment, and safety procedures must be exercised if it becomes necessary to test or troubleshoot equipment with the power on to the unit.

5

•Do not spray or pour water on the return air grille, discharge air grille, evaporator coil, control panel, and sleeve on the room side of the air conditioning unit while cleaning.

•Electrical component malfunction caused by water could result in electric shock or other electrically unsafe conditions when the power is restored and the unit is turned on, even after the exterior is dry.

•Never operate the A/C unit with wet hands.

•Use air conditioner on a single dedicated circuit within the specifi ed amperage rating.

•Use on a properly grounded outlet only.

•Do not remove ground prong of plug.

•Do not cut or modify the power supply cord.

•Do not use extension cords with the unit.

•Follow all safety precautions and use proper and adequate protective safety aids such as: gloves, goggles, clothing, adequately insulated tools, and testing equipment etc.

•Failure to follow proper safety procedures and/or these warnings can result in serious injury or death.

REFRIGERATION SYSTEM REPAIR HAZARDS:

•Use approved standard refrigerant recovering procedures and equipment to relieve pressure before opening system for repair.

•Do not allow liquid refrigerant to contact skin. Direct contact with liquid refrigerant can result in minor to moderate injury.

•Be extremely careful when using an oxy-acetylene torch. Direct contact with the torch’s fl ame or hot surfaces can cause serious burns.

•Make sure to protect personal and surrounding property with fi re proof materials.

•Have a fi re extinguisher at hand while using a torch.

•Provide adequate ventilation to vent off toxic fumes, and work with a qualifi ed assistant whenever possible.

•Always use a pressure regulator when using dry nitrogen to test the sealed refrigeration system for leaks, fl ushing etc.

•Make sure to follow all safety precautions and to use proper protective safety aids such as: gloves, safety glasses, clothing etc.

•Failure to follow proper safety procedures and/or these warnings can result in serious injury or death.

MECHANICAL HAZARDS:

•Extreme care, proper judgment and all safety procedures must be followed when testing, troubleshooting, handling, or working around unit with moving and/or rotating parts.

•Be careful when, handling and working around exposed edges and corners of the sleeve, chassis, and other unit components especially the sharp fi ns of the indoor and outdoor coils.

•Use proper and adequate protective aids such as: gloves, clothing, safety glasses etc.

•Failure to follow proper safety procedures and/or these warnings can result in serious injury or death.

6

PROPERTY DAMAGE HAZARDS

FIRE DAMAGE HAZARDS:

•Read the Installation/Operation Manual for the air conditioning unit prior to operating.

•Use air conditioner on a single dedicated circuit within the specifi ed amperage rating.

•Connect to a properly grounded outlet only.

•Do not remove ground prong of plug.

•Do not cut or modify the power supply cord.

•Do not use extension cords with the unit.

•Be extremely careful when using acetylene torch and protect surrounding property.

•Failure to follow these instructions can result in fi re and minor to serious property damage.

WATER DAMAGE HAZARDS:

•Improper installation, maintenance or servicing of the air conditioner unit can result in water damage to personal items or property.

•Insure that the unit has a suffi cient pitch to the outside to allow water to drain from the unit.

•Do not drill holes in the bottom of the drain pan or the underside of the unit.

•Failure to follow these instructions can result in damage to the unit and/or minor to serious property damage.

7

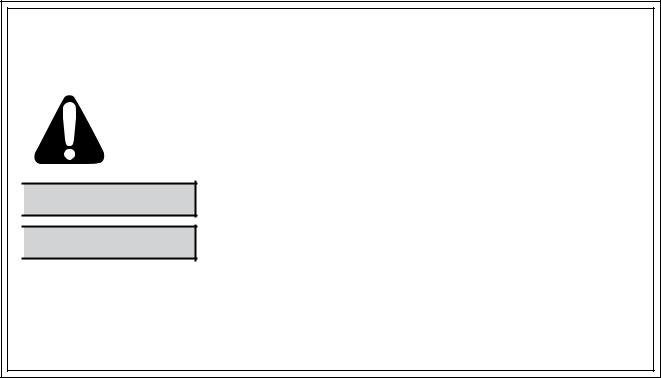

Specifi cations

Model |

|

|

|

|

|

|

Outdoor Unit MR09C1H |

|

|

|

|

|

|

|

MW09CIH |

||

Function |

|

|

|

|

COOLING |

|||

Rated Voltage |

|

|

|

|

115V~ |

|||

Frequency |

|

High |

Hz |

70 |

|

|||

(Inverter different Compressor |

Standard |

Hz |

41 |

|

||||

speed) |

|

|

|

Low |

Hz |

15 |

|

|

Total Capacity |

|

High |

W / Btu/h |

3100/10600 |

|

|||

(Inverter different Compressor |

Standard |

W / Btu/h |

2650/9000 |

|

||||

speed) |

|

|

|

Low |

W / Btu/h |

1300/4435 |

|

|

Power Input |

|

High |

W |

1050 |

|

|||

(Inverter different Compressor |

Standard |

W |

640 |

|

||||

speed) |

|

|

|

Low |

W |

180 |

|

|

Rated Input |

|

High |

W |

1050 |

|

|||

|

|

|

|

|

|

|||

Standard |

W |

640 |

|

|||||

|

|

|

|

|||||

Rated Current |

|

High |

A |

16.8 |

|

|||

|

|

|

|

|

|

|||

Standard |

A |

7.0 |

|

|||||

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Turbo |

|

330 |

|

|

|

|

|

|

SH |

|

CFM |

|

|

|

|

|

|

|

|

|||

Air Flow Volume |

|

H |

CFM |

294 |

|

|||

|

|

|

|

M |

CFM |

253 |

|

|

|

|

|

|

L |

CFM |

218 |

|

|

Dehumidifying Volume |

|

|

|

pints/hour |

1.69 |

|

||

STD |

|

|

|

|

|

W/W |

14.0 |

|

|

|

|

|

|

|

|

22 |

|

Indoor |

unit |

|

|

|

|

MW09CIH |

||

Fan Motor |

|

Turbo |

r/min |

1260 |

|

|||

|

SH |

|

||||||

|

|

Speed |

|

H |

r/min |

1050 |

|

|

|

|

|

M |

r/min |

920 |

|

||

|

|

|

|

|

||||

|

|

|

|

L |

r/min |

730 |

|

|

|

|

Output |

|

|

|

W |

20 |

|

|

|

Capacitor |

|

|

|

F |

4.0 |

|

|

|

RLA |

|

|

|

A |

0.38 |

|

Fan |

|

Type |

|

|

|

|

Cross flow fan |

|

|

|

Diameter-Length |

|

|

|

in. |

3.62 X 25.4 |

|

Evaporator |

|

|

|

|

Aluminum fin-copper tube |

|||

|

Pipe Diameter |

|

in. |

216 |

|

Row-Fin Gap |

|

in. |

0.019 - 0.055 |

|

width (L) |

|

in. |

25.4 X 1 X 10.5 |

|

|

|

|

|

Swing |

Model |

|

|

MP24AA |

Motor |

Output |

|

W |

2.4 |

Fuse (A) |

|

|

A |

PCB 3.15A |

Sound Pressure Level |

H |

dB (A) |

34 |

|

|

|

M |

dB (A) |

30 |

|

|

L |

dB (A) |

26 |

Sound Power Level |

H |

dB (A) |

44 |

|

|

|

M |

dB (A) |

40 |

|

|

L |

dB (A) |

36 |

|

|

|

in. |

33 1/433.X3X107/8.8X117 1/8 |

|

|

|

in. |

36X10X14 |

Net Weight /Gross Weight |

|

lbs |

16X2422.3X130.9 |

|

Remark:s

Remark:s

Rating conditions

Rating conditions are:

are:

Cooling:

Cooling: Indoor air temperature

Indoor air temperature 80¡F

80¡F D.B. / 67¡F W.B.

D.B. / 67¡F W.B.

Outdoor air temperature

Outdoor air temperature 95.0¡F D.B. / 75¡F W.B.

95.0¡F D.B. / 75¡F W.B.

Heating:

Heating: Indoor air temperature

Indoor air temperature 70¡F

70¡F D.B./ 60¡F W.B.

D.B./ 60¡F W.B.

Outdoor air temperature

Outdoor air temperature 47¡F D.B. / 43¡F W.B.

47¡F D.B. / 43¡F W.B.

8

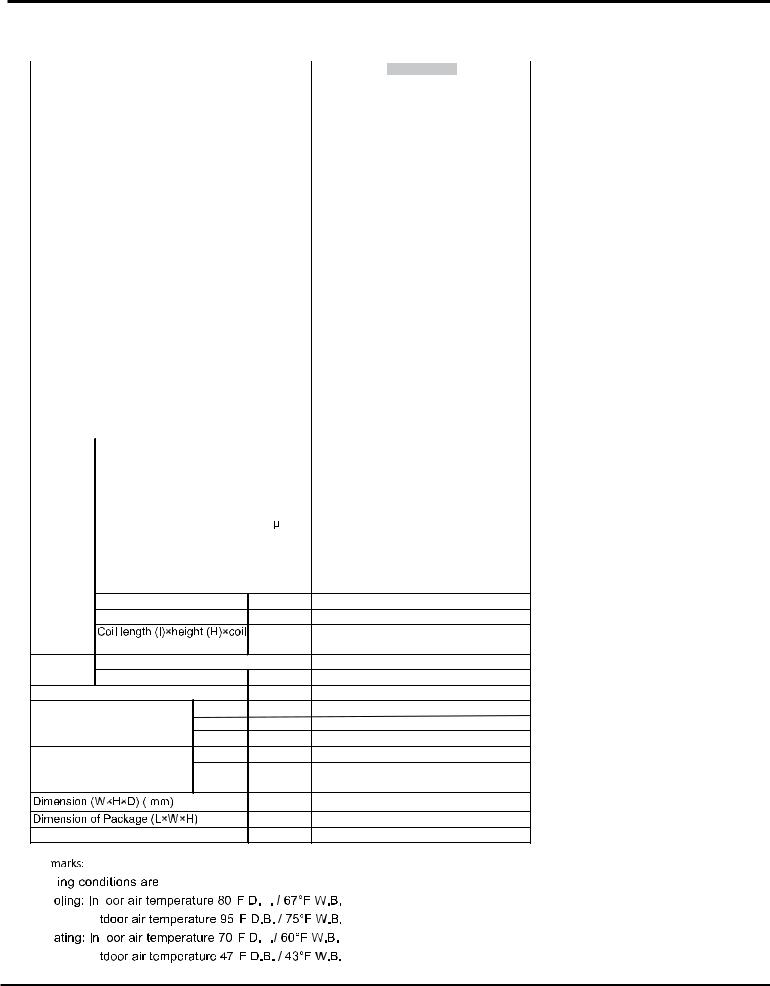

Specifications

12K of 115V Models

Model |

|

|

|

|

|

|

|

|

|

|

|

Outdoor |

Unit MR12CH |

- SYSTEM |

||

|

|

|

|

|

|

|

|

|

|

|

|

MW12CIH |

|

|||

Function |

|

|

|

|

|

COOLING |

||||||||||

Rated Voltage |

|

|

|

|

|

208115-230V~ |

||||||||||

Frequency |

|

High |

|

Hz |

70 |

|

||||||||||

(Inverter different Compressor |

Standard |

|

Hz |

41 |

|

|||||||||||

speed) |

|

|

|

|

|

|

|

|

Low |

|

Hz |

15 |

|

|||

Total Capacity |

|

High |

|

W / Btu/h |

4100/14000 |

|||||||||||

(Inverter different Compressor |

Standard |

|

W / Btu/h |

3520/12000 |

||||||||||||

speed) |

|

|

|

|

|

|

|

|

Low |

|

W / Btu/h |

1320/4500 |

|

|||

Power Input |

|

High |

|

W |

1050 |

|

||||||||||

(Inverter different Compressor |

Standard |

|

W |

640 |

|

|||||||||||

speed) |

|

|

|

|

|

|

|

|

Low |

|

W |

180 |

|

|||

Rated Input |

|

High |

|

W |

1050 |

|

||||||||||

|

Standard |

|

W |

640 |

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

Rated Current |

|

High |

|

A |

6.5 |

|

||||||||||

|

Standard |

|

A |

3.2 |

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

Turbo |

|

CFM |

300 |

|

|

|

|

|

|

|

|

|

|

|

|

|

SH |

|

|

|||

Air Flow Volume |

|

H |

|

CFM |

277 |

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

M |

|

CFM |

253 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

L |

|

CFM |

218 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

Dehumidifying Volume |

|

|

|

pints/hour |

2.54 |

|

||||||||||

EER / C.O.P |

|

|

|

W/W |

12. .00 |

|

||||||||||

SEER/HSPF |

|

|

|

|

22 |

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Indoor |

unit |

|

|

|

|

|

|

|

||||||||

Fan Motor |

|

|

|

|

TurboSH |

|

r/min |

1260 |

|

|||||||

|

|

|

|

|

|

|

Speed |

|

H |

|

r/min |

1050 |

|

|||

|

|

|

|

|

|

|

|

M |

|

r/min |

920 |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

L |

|

r/min |

730 |

|

|

|

|

|

|

|

|

|

Output |

|

|

|

W |

20 |

|

|||

|

|

|

|

|

|

|

Capacitor |

|

|

|

F |

1.0 |

|

|||

|

|

|

|

|

|

|

RLA |

|

|

|

A |

0.2 |

|

|||

Fan |

|

|

|

|

Type |

|

|

|

|

|

Cross flow fan |

|||||

|

|

|

|

|

|

|

Diameter-Length |

|

|

in. |

|

3.62X25.4 |

||||

Evaporator |

|

|

|

|

|

Aluminum fin-copper tube |

||||||||||

|

|

|

|

|

|

|

Pipe Diameter |

|

|

in. |

.276 |

|

||||

|

|

|

|

|

|

|

Row-Fin Gap |

|

|

in. |

.077-.055 |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

in. |

|

25.4X1X10.5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

width (L) |

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

Swing |

|

|

|

|

Model |

|

|

|

|

|

MP24AA |

|||||

Motor |

|

|

|

|

Output |

|

|

|

W |

2.4 |

|

|||||

Fuse (A) |

|

|

|

A |

|

PCB 3.15A |

||||||||||

Sound Pressure Level |

|

H |

|

dB (A) |

34 |

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

M |

|

dB (A) |

30 |

|

|

|

|

|

|

|

|

|

|

|

|

|

L |

|

dB (A) |

26 |

|

|

Sound Power Level |

|

H |

|

dB (A) |

44 |

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

M |

|

dB (A) |

40 |

|

|

|

|

|

|

|

|

|

|

|

|

|

L |

|

dB (A) |

36 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

in. |

33 1/433X.3X107/8.3X77.11/8 |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

in. |

|

36X10X14 |

|

Net Weight /Gross Weight |

|

|

lbs |

.2622.3/30.9 |

|

|||||||||||

Remarks |

|

|

|

|

|

|

|

|||||||||

Rating conditions |

|

|

|

|

|

|

|

|||||||||

|

|

|

|

Indoor |

temperature |

|

|

.B. |

||||||||

|

|

Cooling: |

|

|

|

|

|

|||||||||

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

Outdoor |

temperature |

|

|

.B. |

|||||

Heating: |

|

Indoor |

temperature |

|

|

.B. |

||||||||||

|

|

|

||||||||||||||

|

|

|

|

|

|

|

Outdoor |

temperature |

|

|

.B. |

|||||

9

Specifications

Outdoor Unit |

|

|

|

MR09C1H |

|

|

Manufacturer/trademark |

|

|

SANYO |

|

|

|

|

|

|

|

|

Model |

|

|

C-6RZ110H1A |

|

|

|

|

|

|

|

|

Type |

|

|

Twin rotory |

|

Compressor |

|

|

|

|

|

L.R.A. (A) |

A |

33 |

|

||

|

|

|

|

|

|

|

RLA(A) |

A |

4.59 |

|

|

|

|

|

|

|

|

|

Power Input(W) |

W |

800 |

|

|

|

|

|

|

|

|

|

Overload Protector |

|

|

Int11l-3979 |

|

|

|

|

|

|

|

Throttling Method |

|

Electronic Expansion Valve |

|||

|

|

throttling |

|||

|

|

|

|

||

|

|

|

|

|

|

Starting Method |

|

|

Transducer starting |

||

|

|

|

|

|

|

Working Temp Range |

F |

41 - 115 |

|

||

|

|

|

|

|

|

Heat |

Coil |

|

Aluminum fin-copper tube |

||

Exchanger |

|

|

|

|

|

Pipe Diameter |

mm |

.275 |

|

||

Coil |

|

||||

|

|

|

|

|

|

Rows-Fin Gap |

in. |

2 - .005 |

|

||

|

|

||||

|

|

|

|

|

|

Coil length (l) x height (H) x coil width (L) |

|

|

23.94 X 20 X 1.73 |

||

|

|

|

|

|

|

|

Speed |

rpm |

900/650 |

|

|

|

|

|

|

|

|

Fan Motor |

Output of Fan Motor |

W |

40 |

|

|

|

|

|

|

|

|

RLA |

A |

0.17 |

|

||

|

|

||||

|

|

|

|

|

|

|

Capacitor |

•F |

/ |

|

|

|

|

|

|

|

|

Air Flow Volume of Outdoor Unit |

CFM |

1118 |

|

||

|

|

|

|

|

|

Fan |

Type-Piece |

|

|

Axial fan - 1 |

|

|

|

|

|

|

|

Diameter |

in. |

15.7 |

|

||

|

|

||||

|

|

|

|

|

|

Defrosting Method |

|

/ |

|

||

|

|

|

|

|

|

Climate Type |

|

|

|

T1 |

|

|

|

|

|

|

|

Isolation |

|

|

|

I |

|

|

|

|

|

|

|

Moisture Protection |

|

|

IP24 |

||

|

|

|

|

|

|

Permissible Excessive Operating |

PSI |

552 |

|

||

Pressure for the Discharge Side |

|

||||

|

|

|

|

||

Permissible Excessive Operating |

PSI |

175 |

|

||

Pressure for the Suction Side |

|

||||

|

|

|

|

||

|

|

|

|

|

|

Sound Pressure Level |

dB (A) |

53 |

|

||

Sound Power Level |

dB (A) |

63 |

|

||

Dimension (W×H×D) |

in. |

|

|

||

|

33333/8.4XX2312.1/26 XX21.231/2 |

|

|||

|

|

|

|

|

|

Dimension of Package (L×W×H) |

in. |

|

34.6 X 14.2 X 22.3 |

||

|

|

|

|

|

|

Net Weight /Gross Weight |

lbs |

79.4/90.4 |

|

||

|

|

|

|

|

|

Refrigerant |

Name of refrigerant |

|

|

R410A |

|

|

|

|

|

|

|

Weight |

lbs |

2.65 |

|

||

|

|

||||

|

Factory Prescharge |

ft |

25 |

|

|

|

|

|

|

|

|

Connection |

Gas additional charge |

02/H |

.33 |

|

|

Pipe |

|

|

|

|

|

Liquid Pipe Diameter |

mm |

|

Φ6(1/4”) |

||

|

|

|

|

|

|

|

Gas Pipe Diameter |

mm |

|

Φ9(3/8”) |

|

|

|

|

|

|

|

Max. Interunit Height Difference |

ft |

33 |

|

||

|

|

|

|

|

|

Max. Interunit Piping Length |

ft |

66 |

|

||

|

|

|

|

|

|

The above data is subject to change without notice. Please refer to the nameplate of the unit.

10

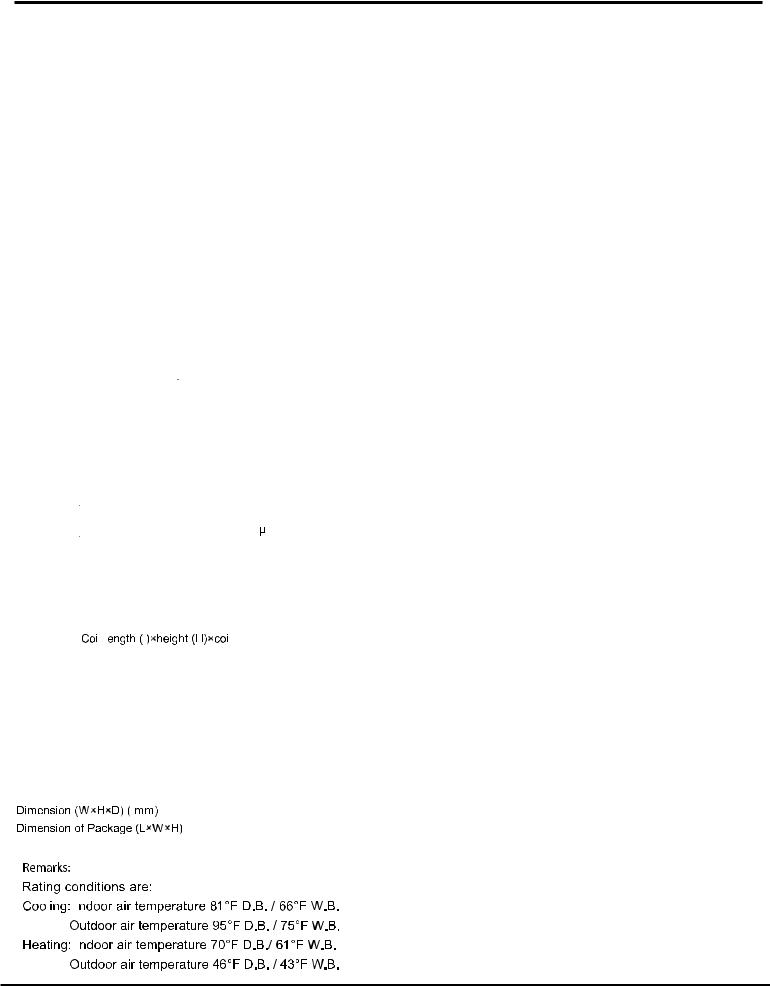

Specifications

Outdoor Unit |

|

|

|

MR12C1H |

|

|

Manufacturer/trademark |

|

|

SANYO |

|

|

|

|

|

|

|

|

Model |

|

|

C-6RZ110H1A |

|

|

|

|

|

|

|

|

Type |

|

|

Twin rotory |

|

Compressor |

|

|

|

|

|

L.R.A. (A) |

A |

33 |

|

||

|

|

|

|

|

|

|

RLA(A) |

A |

4.59 |

|

|

|

|

|

|

|

|

|

Power Input(W) |

W |

800 |

|

|

|

|

|

|

|

|

|

Overload Protector |

|

|

Int11l-3979 |

|

|

|

|

|

|

|

Throttling Method |

|

Electronic Expansion Valve |

|||

|

|

throttling |

|||

|

|

|

|

||

|

|

|

|

|

|

Starting Method |

|

|

Transducer starting |

||

|

|

|

|

|

|

Working Temp Range |

F |

41 - 115 |

|

||

|

|

|

|

|

|

Heat |

Coil |

|

|

Aluminum fin-copper tube |

|

Exchanger |

|

|

|

|

|

Pipe Diameter |

mm |

.275 |

|

||

Coil |

|

||||

|

|

|

|

|

|

Rows-Fin Gap |

in. |

2 - .005 |

|

||

|

|

||||

|

|

|

|

|

|

Coil length (l) x height (H) x coil width (L) |

mm |

|

747X508X44 |

||

|

|

|

|

|

|

|

Speed |

rpm |

900/680 |

|

|

|

|

|

|

|

|

Fan Motor |

Output of Fan Motor |

W |

40 |

|

|

|

|

|

|

|

|

RLA |

A |

0.17 |

|

||

|

|

||||

|

|

|

|

|

|

|

Capacitor |

•F |

/ |

|

|

|

|

|

|

|

|

Air Flow Volume of Outdoor Unit |

CFM |

1118 |

|

||

|

|

|

|

|

|

Fan |

Type-Piece |

|

|

Axial fan |

|

|

|

|

|

|

|

Diameter |

in. |

15.7 |

|

||

|

|

||||

|

|

|

|

|

|

Defrosting Method |

|

/ |

|

||

|

|

|

|

|

|

Climate Type |

|

|

|

T1 |

|

|

|

|

|

|

|

Isolation |

|

|

|

I |

|

|

|

|

|

|

|

Moisture Protection |

|

|

IP24 |

||

|

|

|

|

|

|

Permissible Excessive Operating |

PSI |

552 |

|

||

Pressure for the Discharge Side |

|

||||

|

|

|

|

||

Permissible Excessive Operating |

PSI |

175 |

|

||

Pressure for the Suction Side |

|

||||

|

|

|

|

||

|

|

|

|

|

|

Sound Pressure Level |

dB (A) |

55 |

|

||

Sound Power Level |

dB (A) |

65 |

|

||

Dimension (W×H×D) |

in. |

|

|||

|

33 3/833X.423X 121/2.6XX1221.1/23 |

|

|||

|

|

|

|

|

|

Dimension of Package (L×W×H) |

in. |

|

34.6 X 14.2 X 22.3 |

||

|

|

|

|

|

|

Net Weight /Gross Weight |

lbs |

79.4/90.4 |

|

||

|

|

|

|

|

|

Refrigerant |

Name of refrigerant |

|

|

R410A |

|

|

|

|

|

|

|

Weight |

lbs |

2.65 |

|

||

|

|

||||

|

Factory Prescharge |

ft |

25 |

|

|

|

|

|

|

|

|

Connection |

Gas additional charge |

H |

|

1/4 oz per ft |

|

Pipe |

|

|

|

|

|

Liquid Pipe Diameter |

mm |

|

Φ6(1/4”) |

||

|

|

|

|

|

|

|

Gas Pipe Diameter |

mm |

|

Φ9(3/8”) |

|

|

|

|

|

|

|

Max. Interunit Height Difference |

ft |

33 |

|

||

|

|

|

|

|

|

Max. Interunit Piping Length |

ft |

66 |

|

||

|

|

|

|

|

|

The above data is subject to change without notice. Please refer to the nameplate of the unit.

11

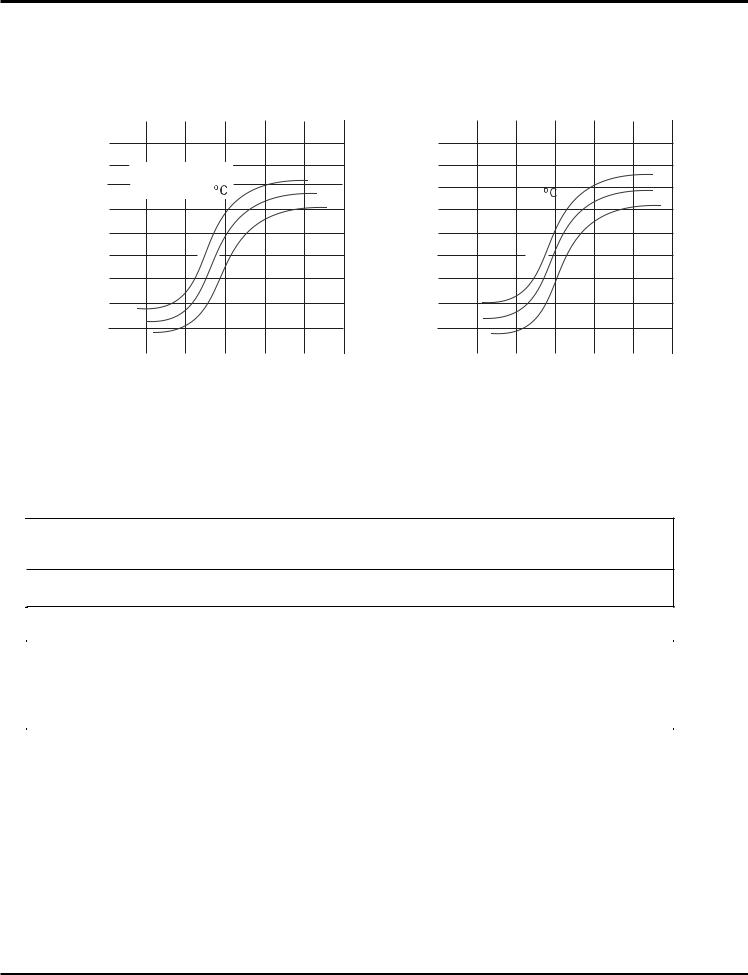

Specifications

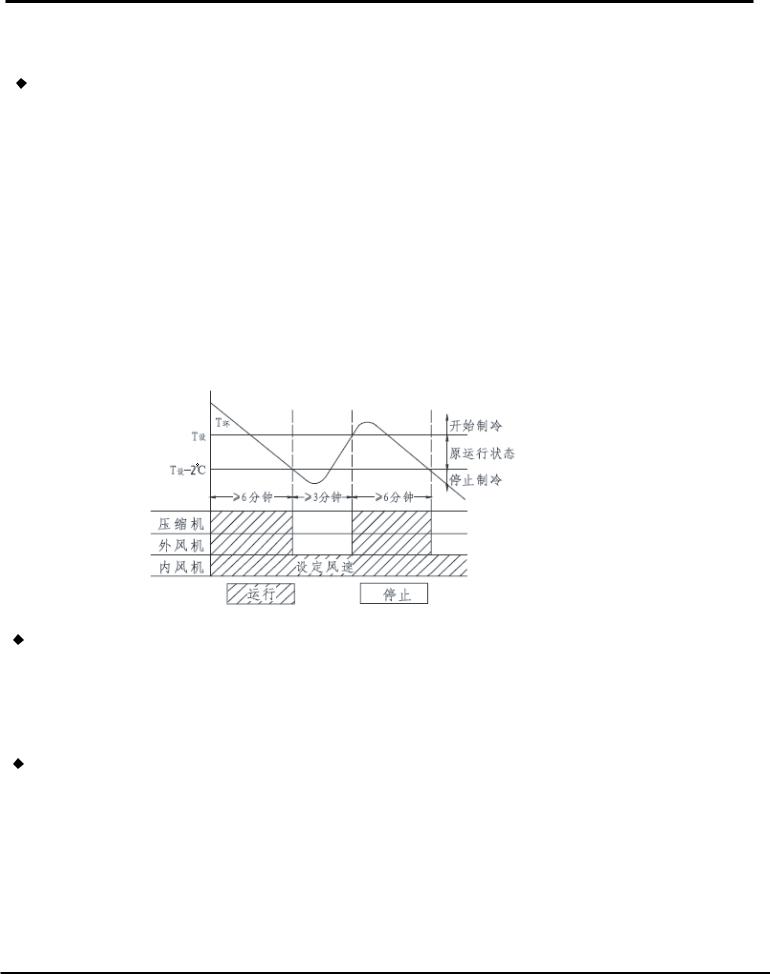

Appending date

Table showing operation frequency limits for cooling and heating

|

|

|

Outdoor Relative Humidity 40% |

|||||

|

140 |

|

|

|

|

|

|

|

(%) |

130 |

|

|

|

|

|

||

|

Indoor Wet Bulb |

|

59°F |

|

||||

Ratio |

120 |

|

Temperature( |

) |

|

68°F |

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

Change |

110 |

|

|

|

|

|

77°F |

|

|

|

|

|

|

|

|

||

100 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Capacity |

80 |

|

|

|

|

|

|

|

60 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

40 |

|

|

|

|

|

|

|

|

20 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

15 |

35 |

55 |

75 |

95 |

|

|

|

|

|

Compressor Frequency(Hz) |

|||||

|

|

|

Outdoor Relative Humidity 72% |

||||||||

|

140 |

|

|

|

|

|

|

|

|

|

|

(%) |

130 |

|

|

|

|

|

|

|

|

59°F |

|

|

Indoor Wet Bulb |

|

|

||||||||

|

|

|

|

||||||||

Ratio |

120 |

|

Temperature( |

) |

|

|

60.8°F |

||||

|

|

|

|

||||||||

Change |

110 |

|

|

|

|

|

|

|

|

62.6°F |

|

|

|

|

|

|

|

|

|

||||

100 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

Capacity |

80 |

|

|

|

|

|

|

|

|

|

|

60 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

40 |

|

|

|

|

|

|

|

|

|

|

|

20 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

15 |

35 |

|

55 |

75 |

95 |

|

|||

|

|

|

Compressor Frequency(Hz) |

||||||||

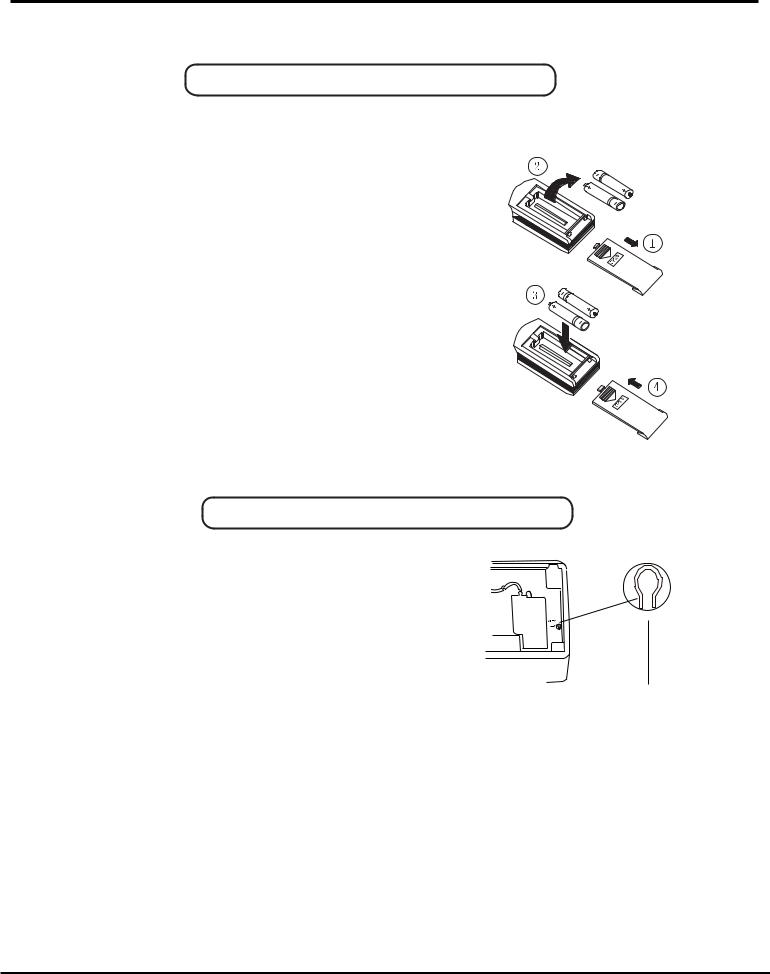

Performance date for both cooling and heating

COOLING:

|

Temperature Condition |

|

Standard |

Heat exchanger pipe |

|

Outdoor fan |

Compressor |

||||||||

|

(°F) |

|

|

|

|

|

Model |

pressure |

temp. |

|

Indoor fan |

mode |

revolution |

||

|

|

Indoor |

Outdoor |

name |

P (MPa) |

EVP (°F)C |

OD(°F) |

mode |

|

(rps) |

|||||

|

|

|

|

|

|

|

|

09K |

0.8 to 1.1 |

53 to 57 |

105 to 104 |

Turbo |

High |

Rated |

|

|

|

80.80/6706/.92 |

|

|

95/– |

12K |

0.8 to 1.0 |

50 to 54 |

109 to 113 |

Turbo |

High |

Rated |

|||

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

HEATING: |

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Temperature Condition |

|

Standard |

Heat exchanger pipe |

|

|

Compressor |

||||||||

|

(°F) |

|

|

|

|

|

|

|

temp. |

|

|

|

|||

|

|

|

|

|

|

Model |

pressure |

|

Indoor fan |

Outdoor fan |

revolution |

||||

|

|

Indoor |

Outdoor |

name |

P (MPa) |

EVP (°F) |

COD(°C) |

mode |

mode |

(rps) |

|||||

|

|

|

|

|

|

|

|

09K |

2.8 to 3.2 |

99 to 100 |

2 to 4 |

Turbo |

High |

Rated |

|

|

|

|

|

|

|

|

|

||||||||

|

66.67/6098/ |

.08 |

|

46.47/4399/ 2.99 |

|

||||||||||

|

|

|

|

|

|

|

|

|

|

||||||

12K |

2.8 to 3.2 |

108 to 111 |

0 to 3 |

Turbo |

High |

Rated |

|||||||||

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

||||||||

NOTES :

(1)Measure surface temperature of heat exchanger pipe around center of heat exchanger path U bent. (Thermistor themometer)

(2)Connecting piping condition : 7.6 m

12

Specifications

Expanded capacity data tables for both cooling and heating

Cooling

Capacity Ratio (%)

110 |

|

|

• Conditions |

|

Indoor: DB80°F/WB67°F.06˚F/WB66.92˚F |

100 |

Indoor air flow : TURBO |

Pipe length : 7.6m |

|

90 |

|

80 |

|

70

90 |

91 |

93 |

95 |

97 |

99 |

100 |

102 |

104 |

106 |

108 |

111 |

113 |

115 |

Outdoor temp. (˚F)

Capacity Variation Ratio According to Pipe Length

110

•Conditions

Indoor: DB80°F/WB67°F

105 |

Outdoor: DB95°F/WB75°F |

Indoor air flow: TURBO

100 |

|

|

|

|

|

95 |

|

|

|

|

|

90 |

Standard pipe length 7.6m |

|

|

|

|

85 |

|

|

|

|

|

|

|

Maximum pipe length 20m |

|

||

80 |

|

|

|

|

|

05 |

10 |

15 |

20 |

25 |

30 |

Total pipe length (m)

110 |

|

|

|

|

|

|

|

|

|

|

|

• Conditions |

|

|

|

105 |

|

|

|

Indoor: DB80°F/WB67°F |

|

|

|

|

|

|

|

Outdoor: DB95°F/WB75°F |

|

||

|

|

|

|

Indoor air flow: TURBO |

|

||

100 |

|

|

|

|

|

|

|

95 |

|

|

|

|

|

|

|

90 |

|

|

|

|

|

|

|

85 |

|

Maximum Elevation 7.6m |

|

|

|

||

|

|

|

|

|

|||

80 |

01 |

.5 |

3.04 |

.5 |

6.07 |

.5 |

9.0 |

Total Elevation (m)

13

Specifications

Operation Characteristic Curve

Cooling |

9 btu unit |

|

|

25.0 |

• Conditions |

|

|

|

|

|

|

|

|

|

22.5 |

Indoor: DB80°F/WB67°F |

|

|

|

|

|

|

||

|

Outdoor: DB95°F/WB75°F |

|

|

|

|

|

||||

|

|

|

|

|

|

|

||||

|

20.0 |

Indoor air flow : TURBO |

|

|

|

|

|

|||

|

Pipe lengt: 7.6m |

|

|

|

|

|

|

|||

(A) |

|

|

|

|

|

|

|

|||

17.5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Current |

15.0 |

|

|

|

|

|

|

|

|

|

12.5 |

|

|

|

|

|

|

|

|

|

|

10.0 |

|

|

|

|

|

|

|

|

|

|

|

7.5 |

|

|

|

|

|

115V |

|

|

|

|

5.0 |

|

|

|

|

|

|

|

|

|

|

2.5 |

|

|

|

|

|

|

|

|

|

|

0 |

|

|

|

|

|

|

|

|

|

|

01 |

02 |

03 |

04 |

05 |

06 |

07 |

09 |

80 |

0 |

Compressor speed (rps)

|

|

|

1 2 Ko12f11btu5 VUunitn i ts |

|

|

|

|

|||

Cooling |

|

|

|

|

|

|

|

|

|

|

|

25.0 |

• Conditions |

|

|

|

|

|

|

|

|

|

22.5 |

Indoor: DB80: °F/WB67°F |

|

|

|

|

|

|

||

|

Outdoor: DB95°F/WB75°F |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|||

|

20.0 |

Indoor air flow : TURBO |

|

|

|

|

|

|||

|

Pipe length: 7.6m |

|

|

|

|

|

|

|||

(A) |

|

|

|

|

|

|

|

|||

17.5 |

|

|

|

|

|

|

|

|

|

|

15.0 |

|

|

|

|

|

|

|

|

|

|

Current |

|

|

|

|

|

|

|

|

|

|

12.5 |

|

|

|

|

|

|

|

|

|

|

10.0 |

|

|

|

|

|

115V |

|

|

||

|

|

|

|

|

|

|

|

|||

|

7.5 |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

5.0 |

|

|

|

|

|

|

|

|

|

|

2.5 |

|

|

|

|

|

|

|

|

|

|

0 |

|

|

|

|

|

|

|

|

|

|

01 |

02 |

03 |

04 |

05 |

06 |

07 |

09 |

80 |

0 |

Compressor speed (rps)

14

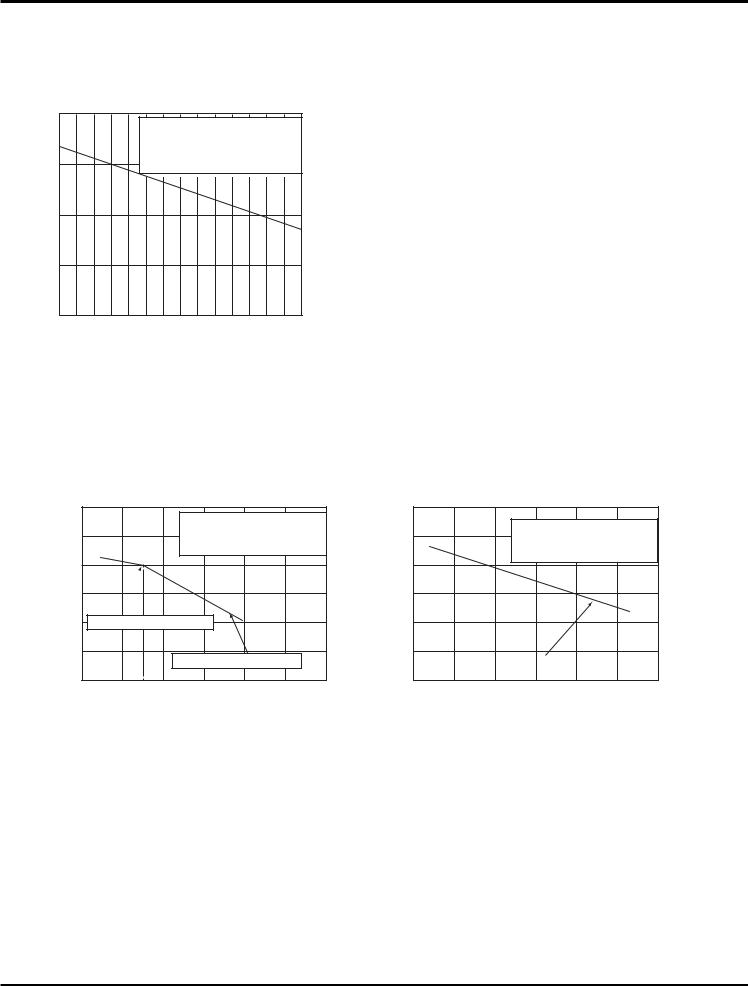

Specifications

2.5 Noise criteria curve tables for both models

Noise/dB(A)

40

35

30

25

|

|

|

|

0 9 KU n i ts |

|

|

|

|

|

|

|

|

|

|

|

|

09 btu units |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

70 |

|

|

|

|

|

|

|

Indoor side noise when blowing |

|

|

|

Outdoor side noise |

|

|

|

||||

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

60 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Noise/dB(A) |

50 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

40 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

30 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Low |

MiddleH |

igh |

Turbo |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

20 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Indoor fan motor rotating speed |

|

|

0 |

20 |

40 |

60 |

80 |

100 |

|||

Compressor frequency/Hz

Noise/dB(A)

40

35

30

25

20

|

|

|

|

1 2 KU n i ts |

|

|

|

|

|

|

|

|

|

|

|

|

|

12 btu unit |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

70 |

|

|

|

|

|

|

||

|

Indoor side noise when blowing |

|

|

|

|

Outdoor side noise |

|

|

|

||||

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

60 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Noise/dB(A) |

50 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

40 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

30 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Low |

MiddleH |

igh |

Turbo |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

20 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Indoor fan motor rotating speed |

|

|

0 |

20 |

40 |

60 |

80 |

100 |

||||

Compressor frequency/Hz

15

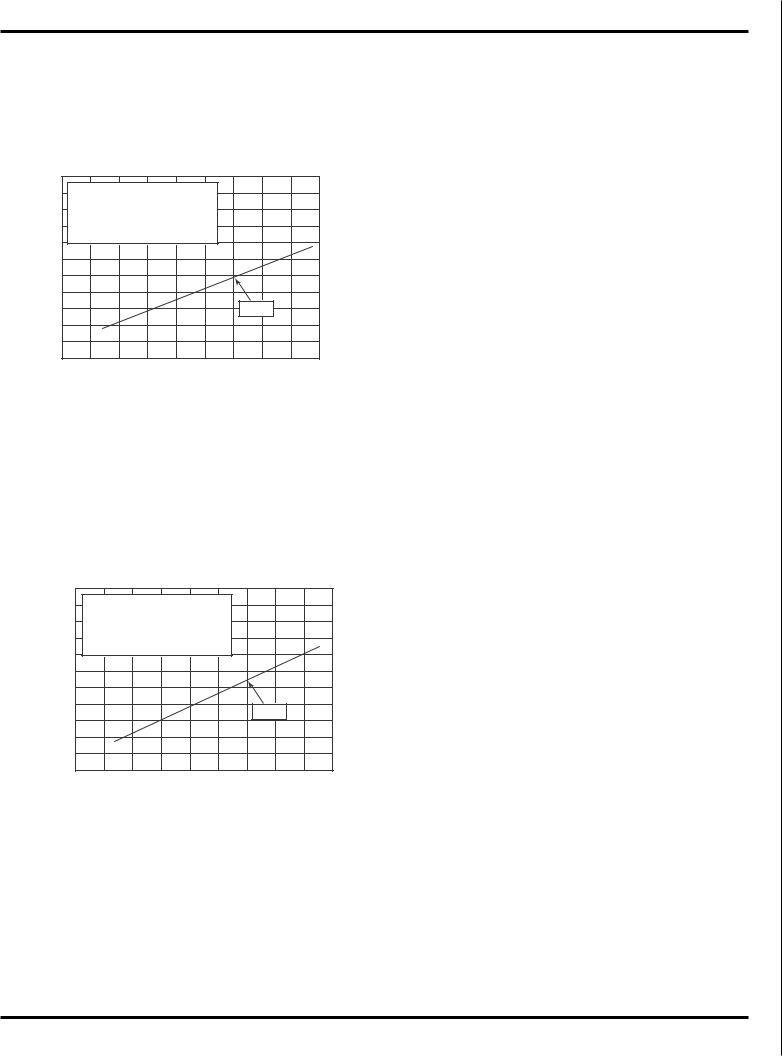

Constrction views

3.Construction Views

3.1Indoor Unit

W

H

D

5131/45 |

21542 |

6163/49 |

Unit:m m

3.2 Outdoor Unit

W2 |

D4 |

|

H2

W3

D2

W4

D3

System |

|

Indoor Unit (mm) |

|

|

|

|

Outdoor Unit (mm) |

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

Model |

|

|

Cabinet |

|

|

Cabinet |

|

|

|

|

Additional Dimensions |

|

|||||

Number |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

W |

|

H |

|

D |

W2 |

H2 |

D4 |

|

D2 |

|

W3 |

D3 |

W4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

09K |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

0 |

9K |

|

33 1/4 |

|

10 7/8 |

|

7 1/8 |

30 3/4 |

23 1/2 |

10 7/8 |

|

12 1/2 |

|

33 3/8 |

11 |

21 1/2 |

|

|

|

|

|

|

|

|||||||||||

|

12K |

|

|

|

|

||||||||||||

|

1 |

2K |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

16

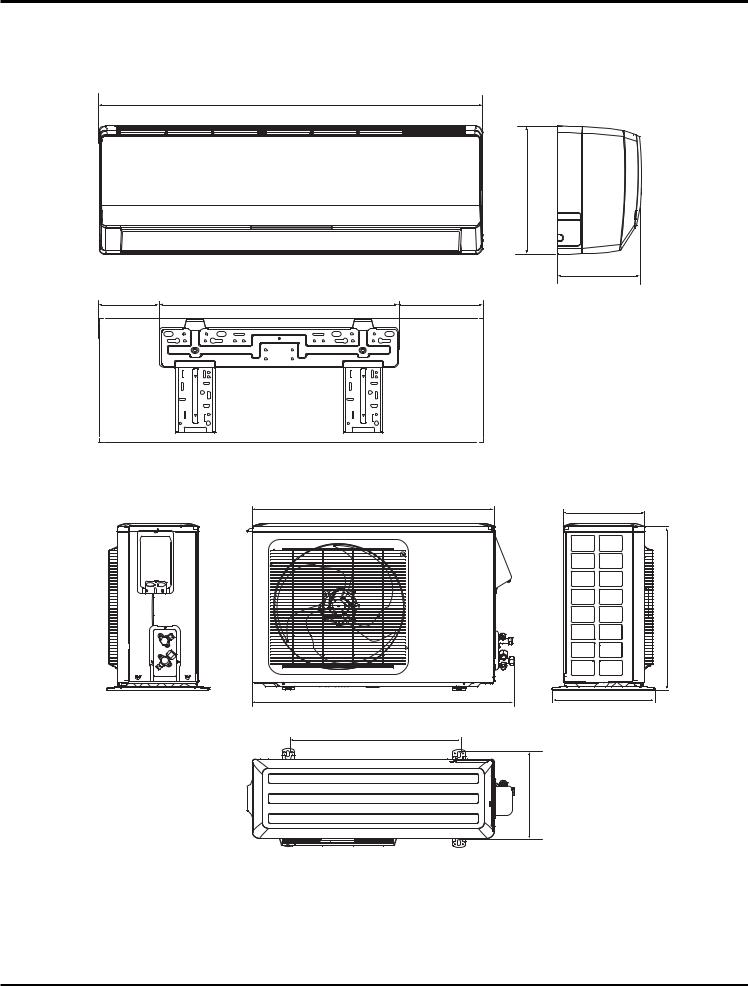

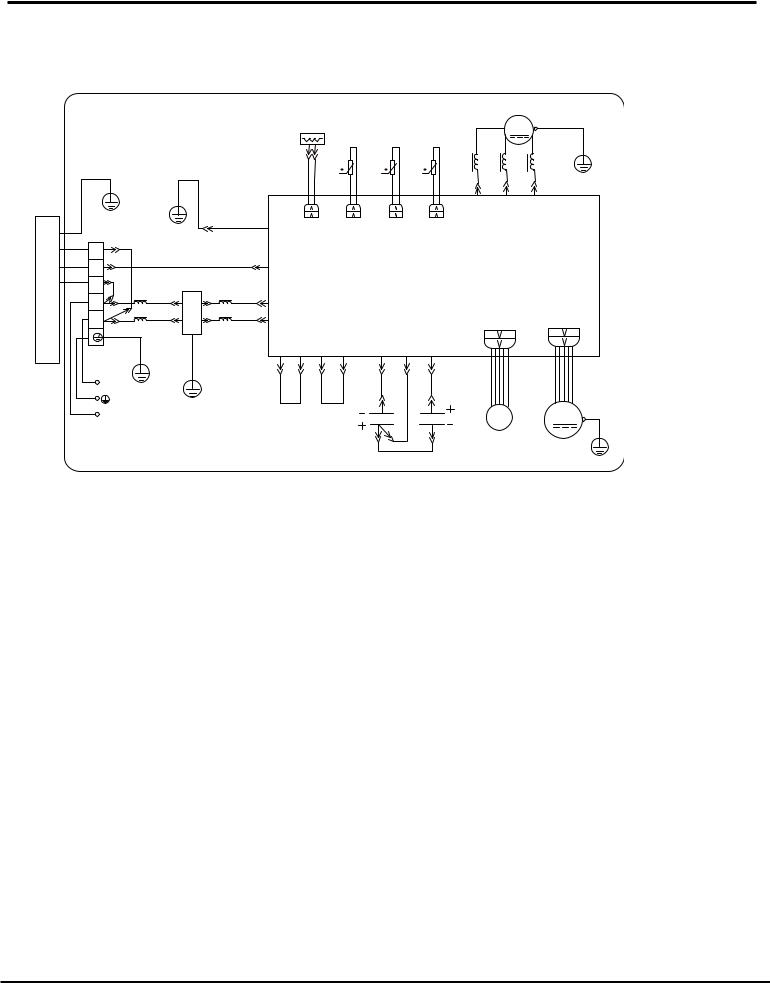

Refrigerant System Diagram

4. Refrigerant System Diagram

Cooling Models

INDOOR UNIT |

OUTDOOR UNIT |

GAS SIDE

3-WAY VALVE

HEAT EXCHANGE (EVAPORATOR)

Muffler |

|

Discharge |

|

Suction |

Accumlator |

COMPRESSOR |

|

HEAT EXCHANGE (CONDENSER)

LIQUID SIDE |

|

|

2-WAY VALVE |

Strainer |

Electric Expansion Strainer |

|

|

Valve |

COOLING

COOLING

17

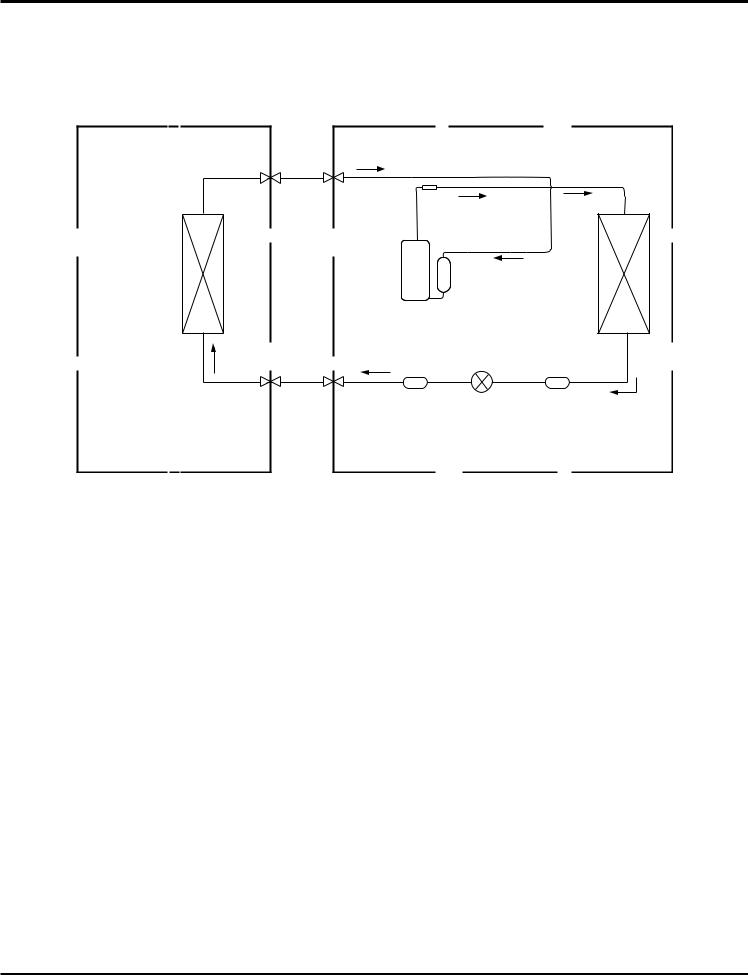

Schematic Diagram

5.Schematic Diagram

5.1Electrical Date

Indoor Unit

Indoor Unit

Symbol |

Color symbol |

Symbol |

Color symbol |

|

|

|

|

WH |

WHITE |

BN |

BROWN |

|

|

|

|

YE |

YELLOW |

BU |

BLUE |

|

|

|

|

RD |

RED |

BK |

BLACK |

|

|

|

|

YEGN |

YELLOW GREEN |

|

PROTECTIVE EARTH |

|

|

|

|

Outdoor Unit

Outdoor Unit

Symbol |

Parts name |

Symbol |

Color symbol |

|

|

|

|

L1 |

REACROR |

WH |

WHITE |

|

|

|

|

PCB1~PCB2 |

PRINTED CIRCUIT BOARD |

YE |

YELLOW |

|

|

|

|

S10/S11S40/S70/S80/S90 |

CONNECTOR |

RD |

RED |

|

|

|

|

SAT |

OVERLOAD |

BN |

SAT OVERLOAD BN BROWN |

|

|

|

|

COMP |

COMPRESSOR |

BU |

BLUE |

|

|

|

|

|

PROTECTIVE EARTH |

BK |

BLACK |

|

|

|

|

|

|

YEGN |

YELLOW GREEN |

|

|

|

|

5.2 Electrical wiring

These circuit diagrams are subject to change without notice, please refer to the one supplied with the unit.

Indoor Unit

Indoor Unit

ROOM |

TUBE |

DISPLAY |

TEM.SENSOR |

TEM.SENSOR |

AP1 |

|

|

|

|

|

CN1 CN2 |

00

RT1 |

RT2 |

|

13 |

|

|

|

|

|

|

|

|

|

XT1 |

|

|

|

|

N |

W4 BU |

|

|

|

DISP-1 |

DISP-2 |

L1 |

N(1) |

|

|

|

|

|

|||

ROOM |

TUBE |

COM-OUT |

W5 BK |

|

||

|

|

2 |

||||

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

W3 BN |

3 |

|

|

|

|

|

L1 |

|

|

|

|

|

|

|

|

CAP |

|

|

|

|

W2 YEGN |

|

|

AP2 |

|

AC-L |

L-OUT |

||

|

|

|

K4 |

|

W1 YEGN |

|

JUMP |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

EVAPORATOR |

ELECTRIC BOX |

|

|

|

|

|

G |

G |

PGF PG |

SWING-UD |

TR_OUT TR_IN |

|

|

|

|

|

|

|

|

|||

TC

M2

M1

II I

OUTDOOR UNIT

FAN MOTOR |

SWING MOTOR(U.D) |

TRANSFORMER |

18

Schematic Diagram

OUTDOOR UNIT

OUTDOOR UNIT

Cooling Models of 115V

|

|

|

|

|

|

|

|

|

|

|

|

COMP |

|

|

|

|

CT1,2 |

TUBE |

OUTROOM EXHUAST |

|

|

R COMP E |

|||

|

|

|

|

TEM.SENSOR TEM.SENSORTEM.SENSOR |

|

S |

C |

|||||

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RT3 |

RT4 |

RT5 |

|

L2 |

|

L2 |

L2 |

|

|

W3YEGN |

|

W10 RD |

0 |

0 |

0 |

|

|

|||

|

|

|

W5 BU |

W6 YE |

W7 BK |

|||||||

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

U |

V |

W |

I |

|

G |

|

OVERHEAT |

OUTTUBE |

OUTROOM EXHAUST |

|

|

|

|

||

XT2 |

G |

E |

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|||

NW15 BU

DN(1)

O |

2 |

|

|

|

|

W4 BK |

|

COMU |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

O |

3 |

W14 BN |

|

FILTER |

|

|

|

|

|

|

AP1 |

|

|

R |

L1 |

|

L4 |

|

|

|

|

|

|

|

|||

L |

W1 BN |

1 |

3 |

W17 RD |

AC-L1 |

|

|

|

|

|

|||

|

L1 |

|

L4 |

|

|

|

|

|

|||||

U |

N |

W2BU |

2 |

4 |

W16 WH |

AC-N1 |

|

|

|

|

CN1 |

||

N |

|

|

|

|

E |

|

|

|

|

|

|

|

|

I |

|

W13 YEGN |

|

|

|

|

|

AC-N3AC-N4AC-L3 AC-L2 |

AC-N5 |

AC-L2 AC-L4 |

|

||

T |

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

POWER |

|

|

W18 YEGN |

|

|

|

|

|

|

|

||

|

|

N |

G |

|

|

|

|

|

|

W20 BU W23 OG W21 BN |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

G |

|

|

W19 BU |

W24 RD |

C3 |

|

C4 |

|

|

|

L |

|

|

|

|

|

1 |

2 |

|

|||

|

|

|

|

|

|

|

|

EKV |

|||||

|

|

|

|

|

|

|

|

|

|

|

2 |

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

||

W22 WH

W8 YEGN

G

OFAN

M

FAN MOTOR

G

19

Schematic Diagram

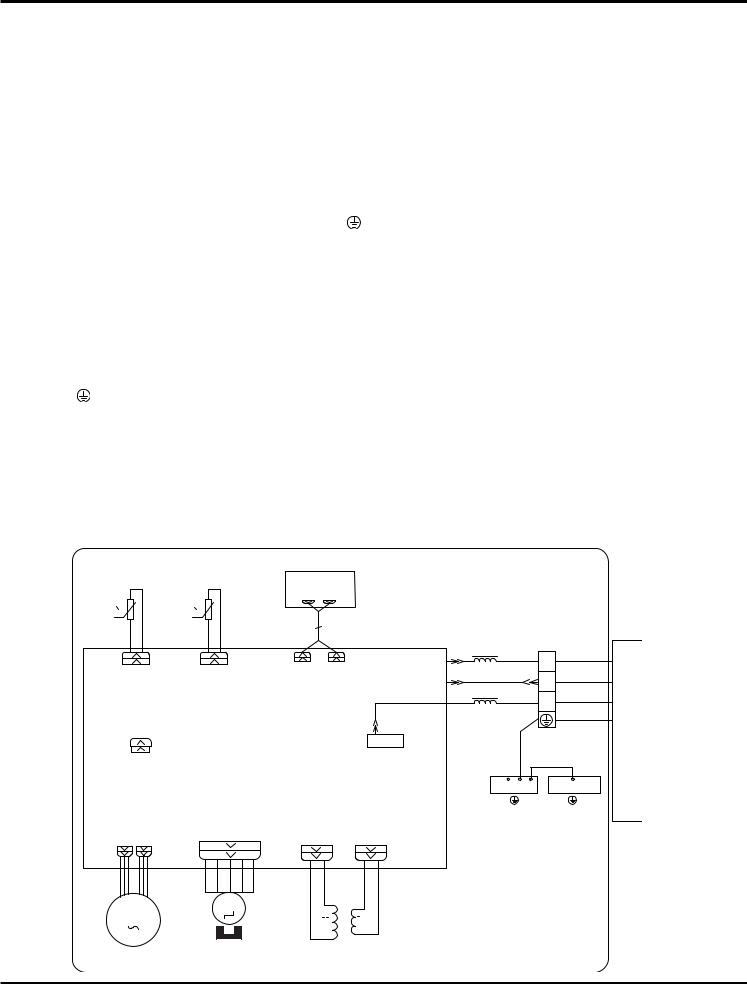

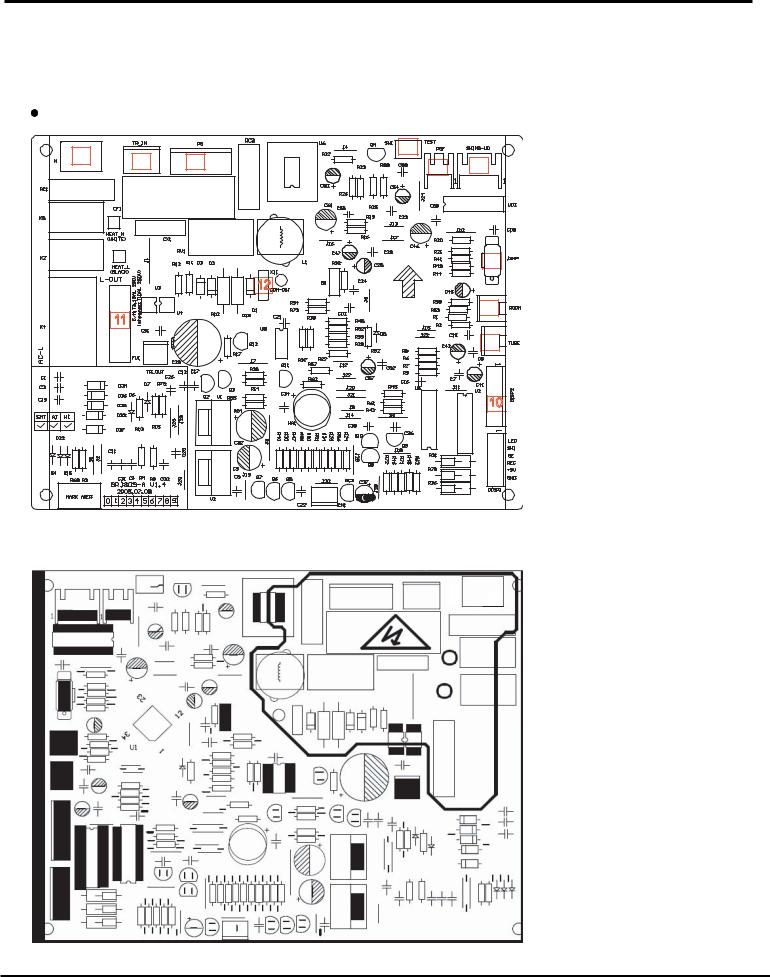

5.3 PRINTED CIRCUIT BOARD

TOP VIEW |

|

|

|

|

1 |

|

|

4 |

|

2 |

3 |

|

|

|

|

5 |

6 |

||

|

|

|

||

|

|

|

|

7 |

|

|

|

12 |

|

|

|

|

|

8 |

|

11 |

|

|

|

|

|

|

|

9 |

|

|

|

|

10 |

BOTTOM VIEW

BOTTOM VIEW

1 |

Interface of neutral wire |

|

|

2 |

Transformer input |

|

|

3 |

Interface of PG motor |

|

|

4 |

Auto button |

|

|

5 |

Feedback from PG motor |

|

|

6 |

Up&Down swing |

|

|

7 |

Jumper cap |

|

|

8 |

Indoor temperature sensor |

|

|

9 |

Pipe temperature sensor |

|

|

10 |

DISP-1, DISP-2 display interface |

|

|

11 |

Protective tube |

|

|

12 |

Communication interface |

|

|

20

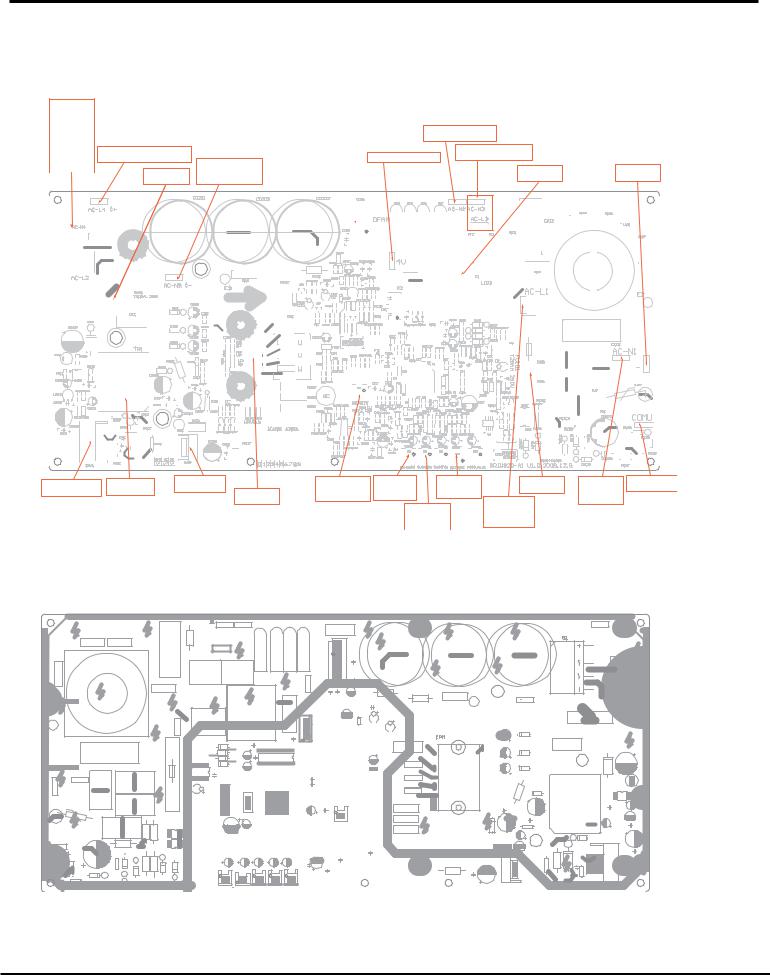

Schematic Diagram

TOP VIEW

TOP VIEW

Terminal of jump wire, live wire and

neutral wire, AC-N4 joint

AC-N3, |

|

External connect high- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||

AC-L2 joint |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||

|

capacity positive terminal |

External connect high- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

AC-L3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

capacity negative |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Protective |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

tube |

terminal |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|