Installation Manual

TYPE : Multi zone

ENGLISH

FRANÇAIS

ESPAÑOL

960-911-05

2 Multi zone

MULTI ZONE INSTALLATION

INSTRUCTIONS

Installation Manual 3

ENGLISH

Multi zone Air Conditioner Installation Manual

TABLE OF CONTENTS

Installation Parts Provided ................................................4

Product Introduction .............................................................5

Indoor Unit ............................................................................5

Outdoor Unit..........................................................................5

Safety Precautions ................................................................6

Installation of Indoor, Outdoor Unit.....................................9

Select the best location ........................................................9

Seaside Applications and Installation..................................11

Piping length and elevation.................................................12

Installation............................................................................13

Connecting the piping .........................................................13

How to mount......................................................................16

Wiring Connection...............................................................17

Conduit connection .............................................................17

Ceiling dimension and hanging bolt location ......................18

How to mount......................................................................19

Wiring Connection...............................................................19

Conduit connection .............................................................19

Remote controller installation..............................................21

Wired remote controller installation.....................................23

Installer Setting - Test Run Mode........................................24

Installer Setting - Thermistor...............................................25

Installer Setting - Group Setting..........................................26

Installer Setting - Celsius / Fahrenheit Switching ...............27

Installer Setting - E.S.P. ......................................................28

Ceiling dimension and hanging bolt location ......................29

Conduit connection .............................................................30

How to Fix ...........................................................................30

Wiring Connection...............................................................30

Installation of Wired Remote Controller(Optional) ..............31

Installation of Decorative Panel ..........................................33

Drain Piping ........................................................................35

Flaring Work and Connection of Piping............................38

Flaring work ........................................................................38

Connection of piping - Outdoor...........................................39

Connecting the Cable between Indoor Unit and Outdoor

Unit........................................................................................40

Connect the cable to the Indoor unit...................................40

Connect the cable to the Outdoor unit................................41

Connection method of the connecting cable(Example) ......42

Checking the Drainage, Insulating the Pipe and Special

Piping Applications .............................................................43

Checking the drainage ........................................................43

Insulating the Pipe and Special Piping Applications...........43

Extended line length setting...............................................44

Air Purging and Evacuation ...............................................45

Leak Checking ....................................................................45

Evacuation ..........................................................................46

Charging ...............................................................................47

❏ Level gauge

❏ Screw driver

❏ Electric drill

❏ Hole core drill [ø50mm(2 inch)]

❏ Flaring tool set

❏ Specified torque wrenches

1.8kg.m, 4.2kg.m, 5.5kg.m, 6.6kg.m

(different depending on model No.)

❏ Adjustable wrench

❏ A glass of water

❏ Screw driver

❏ Hexagonal wrench(4mm)

❏ Refrigerant Gas Leak Detector

❏ Vacuum pump

❏ Gauge manifold

❏ Owner's manual

❏ Thermometer

❏ Remote Control Holder

Installation Requirements

Required Tools

4 Multi zone

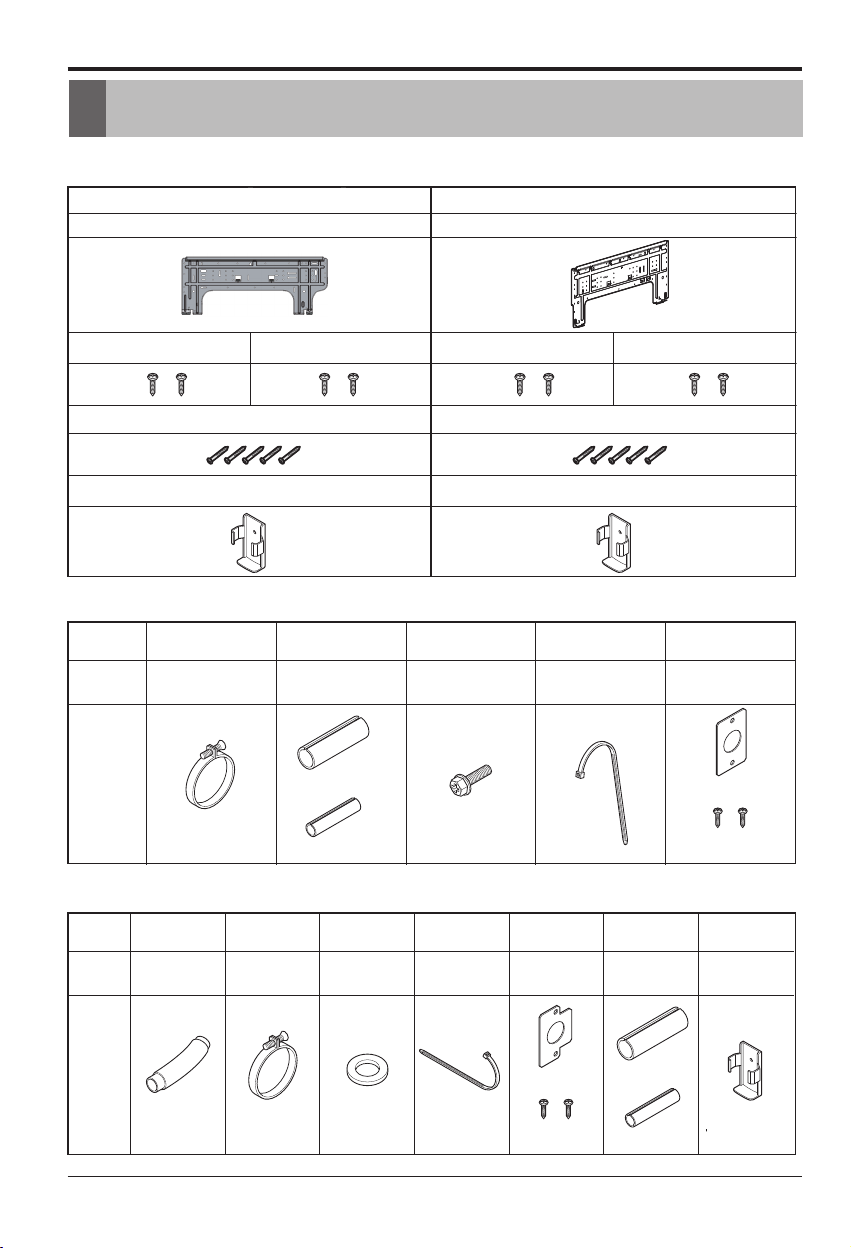

Installation Parts Provided

Installation Parts Provided

[Wall-mounted Type]

Type 1 Type 2

Installation plate Installation plate

Type "B" screw Type "C" screw Type "B" screw Type "C" screw

Type “A” screw Type “A” screw

Remote control holderRemote control holder

[Ceiling Concealed Duct Type]

Name

Quantity

Clamp metal

1 EA

Insulation for

fitting

1 set

Screws for

duct flanges

1 set

Clamp

8 EA

Conduit

Bracket

1 EA

Shape

[Ceiling Cassette Type]

Name

Quantity

Shape

Drain hose

1 EA

Clamp metal

1 EA

for gas pipe

for liquid pipe

Washer for

hanging backet

8 EA

Clamp

8 EA 1 EA

Conduit

Bracket

Conduit Bracket

Screw(M4) 2EA

Conduit Bracket

Screw(M4) 2EA

Insulation for Remote

fitting

1 SET 1 EA

for gas pipe

for liquid pipe

control holder

Installation Manual 5

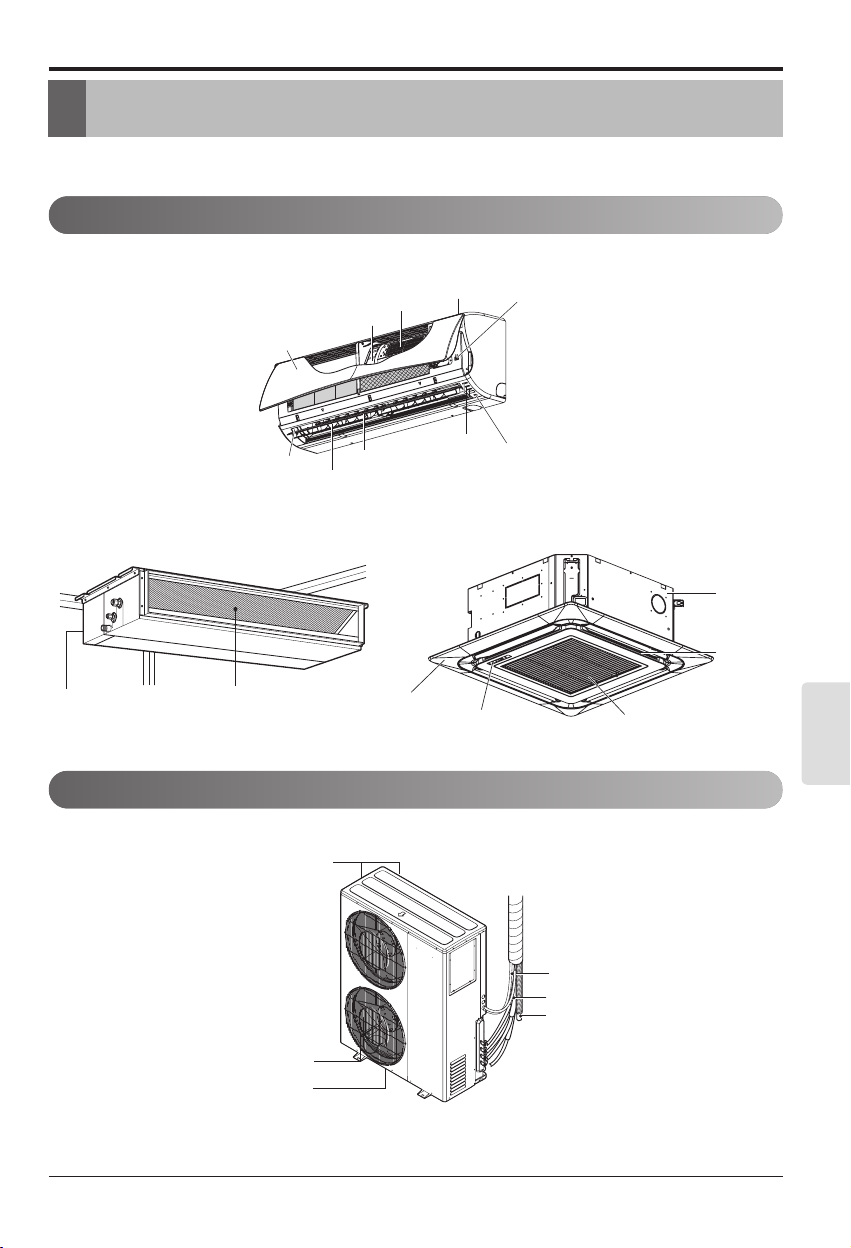

Product Introduction

ENGLISH

Here is a brief introduction of the indoor and outdoor units. Please see the information specific to

your indoor unit type.

more than

70 cm

more than

more than

30 cm

(1

1.8 inch)

more than

30 cm

(11.8 inch)

Air Intake

(side, rear)

Connection pipe

Drain hose

Connecting wire

Control cover

more than 30 cm

(11.8 inch)

Cabinet

Air Discharge

Air Inlet

Signal receiver

Front Panel

Air outlet vents

Air Inlet

[Ceiling Concealed Duct Type]

[Wall-mounted Type]

[Ceiling Cassette Type]

Operation lamp

Signal Receiver

ON/OFF button

Air inlet

Plasma filter

Air filter

Front grille

Vertical louver

Air outlet

Horizontal vaneHorizontal vaneHorizontal vane

more than

30 cm

(1

1.8 inch)

Air outlet vents

Base plate

Connection pipe

Drain hose

Connecting wire

Air intake vents

Horizontal vane

Outdoor Unit

❈ The figure can be changed according to model.

Indoor Unit

Product Introduction

6 Multi zone

Safety Precautions

To prevent the injury of the user or other people and property damage, the following instructions

must be followed.

■ Be sure to read before installing the air conditioner.

■ Be sure to observe the cautions specified here as they include important items related to safety.

■ Incorrect operation due to ignoring instruction will cause harm or damage. The seriousness is

classified by the following indications.

■ The meanings of the symbols used in this manual are as shown below.

WARNING

CAUTION

This symbol indicates the possibility of death or serious injury.

This symbol indicates the possibility of injury or damage to properties only.

Be sure not to do.

Be sure to follow the instruction.

Safety Precautions

WARNING

■ Installation

Always perform grounding.

• Otherwise, it may cause electrical shock.

Ensure that the power cord

used is not frayed or damaged

in anyway.

• Otherwise, it may cause a fire or

electrical shock.

Please contact a licensed service

center or installer to install this

equipment.

•

Otherwise, it may cause a fire, electrical shock, explosion or injury.

Securely attach the electrical

part cover to the indoor unit

and the service panel to the

outdoor unit.

•

If the electrical part cover of the indoor

unit and the service panel of the outdoor unit are not attached securely, it

could result in a fire or electric shock

due to dust, water, etc.

Ensure a dedicated circuit

breaker is installed as well as

an independent electrical dis-

connect.

• No installation may cause a fire

and electrical shock.

Do not keep or use flammable

gases or combustibles near the

air conditioner.

• Otherwise, it may cause a fire or

the failure of product.

Use a vacuum pump or Inert (nitrogen) gas when doing leakage test or air purge. Do not use oxy-

gen, compressed air or other gases which may be flammable or harmful. Doing so causes risk for

fire, explosion, injury or death.

• There is the risk of death, injury, fire or explosion.

Ensure that the outdoor system is free of dam-

age prior to installation.

• It may cause injury or an accident.

Do not service this equipment unless you are a

licensed contractor.

• It will cause a fire or electrical shock.

Installation Manual 7

Safety Precautions

ENGLISH

Ensure that system is properly secured once in-

stallation is complete.

• Otherwise, it may result in personal injury.

Use caution when unpacking and installing.

• Sharp edges may cause injury.

Do not use the power cord

near the heating tools.

• Otherwise, it may cause a fire

and electrical shock.

Do not open the suction inlet

of the indoor/outdoor unit

during operation.

• Otherwise, it may electrical

shock and failure.

If equipment is submerged.

Please shut off power and

call a service center.

• Otherwise, it may cause the

failure of machine or electrical

shock.

Hold the plug by the head

when taking it out.

• It may cause electric shock

and damage.

Never touch the metal parts

of the unit when removing the

filter.

• They are sharp and may

cause injury.

Do not use the equipment as

a step or a shelf.

• It may cause an injury through

dropping of the unit or falling

down.

Do not place a heavy object

on the power cord.

• Otherwise, it may cause a fire

or electrical shock.

When the product is sub-

merged into water, always

contact the service center.

• Otherwise, it may cause a fire

or electrical shock.

Take care so that children

may not step on the outdoor

unit.

• Otherwise, children may be

seriously injured due to falling

down.

Ensure system is installed on

a dedicated circuit.

• It will cause an electric shock

or a fire due to heat generation.

Do not use the damaged

power cord.

• Otherwise, it may cause a fire

or electrical shock.

Do not alter the power cord

without seeking assistance

from a licensed professional.

• Otherwise, it may cause a fire

or electrical shock.

Ensure power cord is se-

curely in place and care is

taken to prevent cord from

being pulled loose.

• Otherwise, it may cause a fire

or electrical shock.

Unplug the unit if strange

sounds, smell, or smoke

comes from it.

• Otherwise, it may cause electrical shock or a fire.

Keep unit clear of any heat

source.

• Otherwise, it may cause a fire.

■ Operation

8 Multi zone

Safety Precautions

CAUTION

■ Installation

Ensure drain is securely fastened.

• Otherwise, it may cause water leakage.

Install in area where consideration of sur-

roundings have been made, noise and heat

may not affect those nearby.

• Otherwise, it may cause dispute with the neighbors.

Always check for leaks at all connections, if

leak is found perform proper repairs.

• Otherwise, it may cause the failure of product.

Ensure equipment is level during installation.

• Otherwise, it may cause vibration or water leakage.

Avoid excessive cooling and perform ventila-

tion sometimes.

• Otherwise, it may do harm to your health.

Use a soft cloth to clean. Do not use wax,

thinner, or a strong detergent.

• The appearance of the air conditioner may deteriorate, change color, or develop surface

flaws.

Do not use an appliance for special purposes

such as preserving animals vegetables, preci-

sion machine, or art articles.

• Otherwise, it may damage your properties.

Do not block or restrict the airflow inlet or

outlet.

• Otherwise, it may cause the failure of appliance

or an accident.

■ Operation

Installation Manual 9

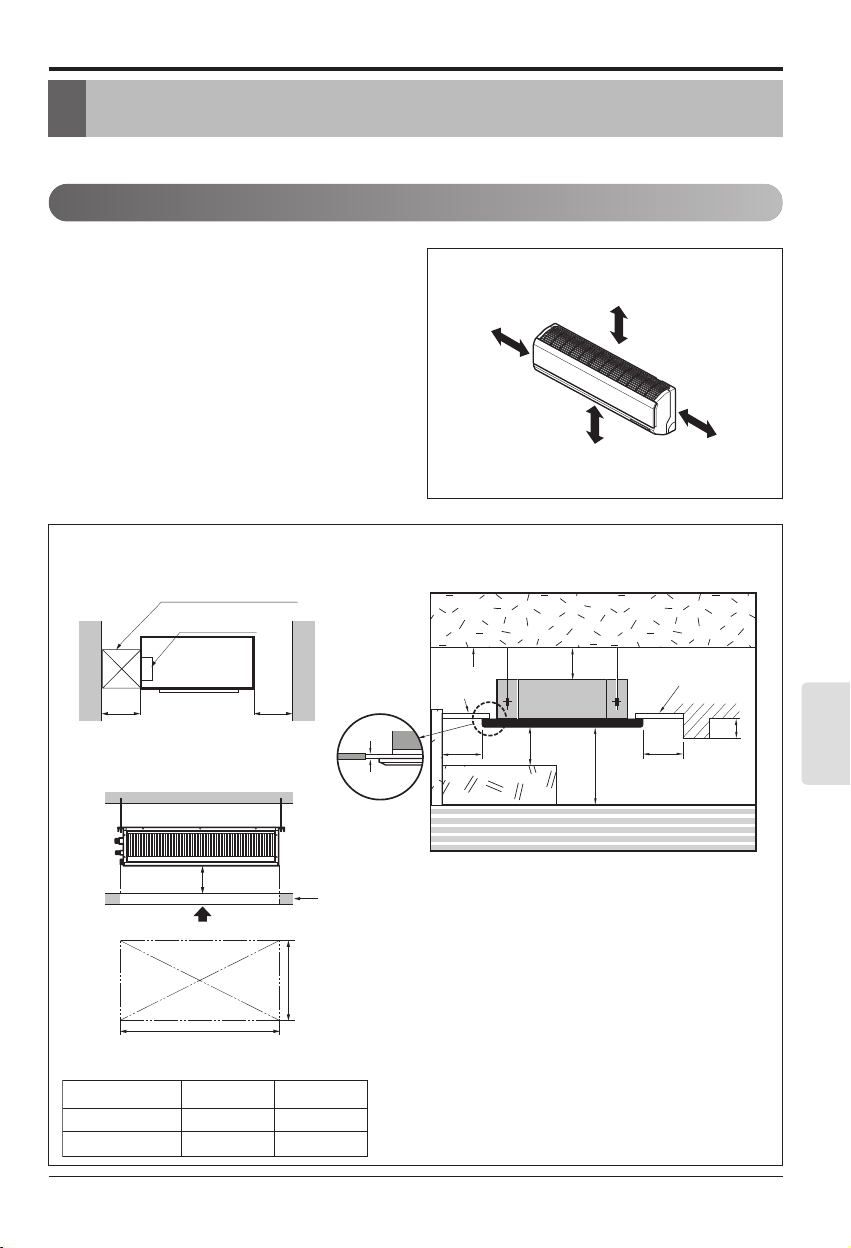

Installation of Indoor, Outdoor Unit

ENGLISH

Read completely, then follow step by step.

Indoor unit

1. Do not have any heat or steam near the unit.

2. Select a place where there are no obstacles

in front of the unit.

3. Make sure that condensation drainage can

be conveniently routed away.

4. Do not install near a doorway.

5. Ensure the unit is unobstructed, allow proper

space on all sides according to the arrows

and distance measurements in the figures.

6. Use a Metal Detector or Metal Scanner to

locate studs to prevent unnecessary damage

to the wall.

Select the best location

Top view

Front view

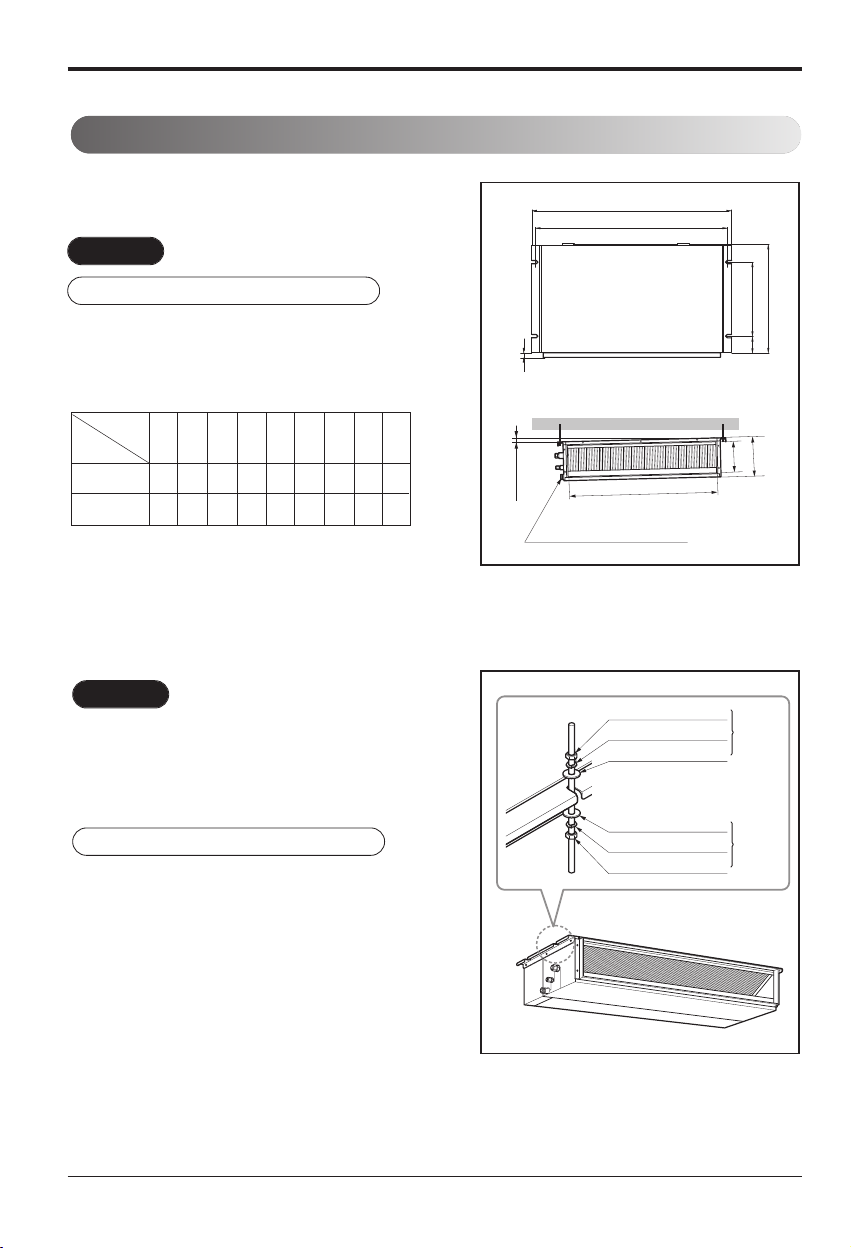

H=20(25/32) or more

Service Space

Ceiling

A

B

Capacity(Btu/h class)

AB

9/12k 600(23-5/8) 900(35-7/16)

18k 600(23-5/8) 1100(43-5/16)

Unit:mm(inch)

[Ceiling Concealed Duct Type] [Ceiling Cassette Type]

* Suitable dimention “H” is necessary to get a slope to

drain as show in the figure.

600

(23-5/8)

600

(23-5/8)

Inspection hole

[600(23-5/8) x 600(23-5/8)]

Control box

Ceiling

Ceiling Board

Ceiling Board

Floor

Unit:mm(inch)

At least 1800(70-

7

/

8

)

3600(141-

23

/

32

) or less

1000(39-

3

/

8

)

or more

500(19-11/16)

or more

10(13/32)

or more

500(19-11/16)

or more

300(11-

13

/

16

) or less

30(1-3/16)

±3(1/8)

More than 200(7-7/8)

Recommended height

2000(78-3/4)

More than

100(3-15/16)

More than

100(3-15/16)

Unit:mm(inch)

[Wall-mounted Type]

❈

Note : remove obstructions to prevent blockage of airflow path

Installation of Indoor, Outdoor Unit

10 Multi zone

Installation of Indoor, Outdoor Unit

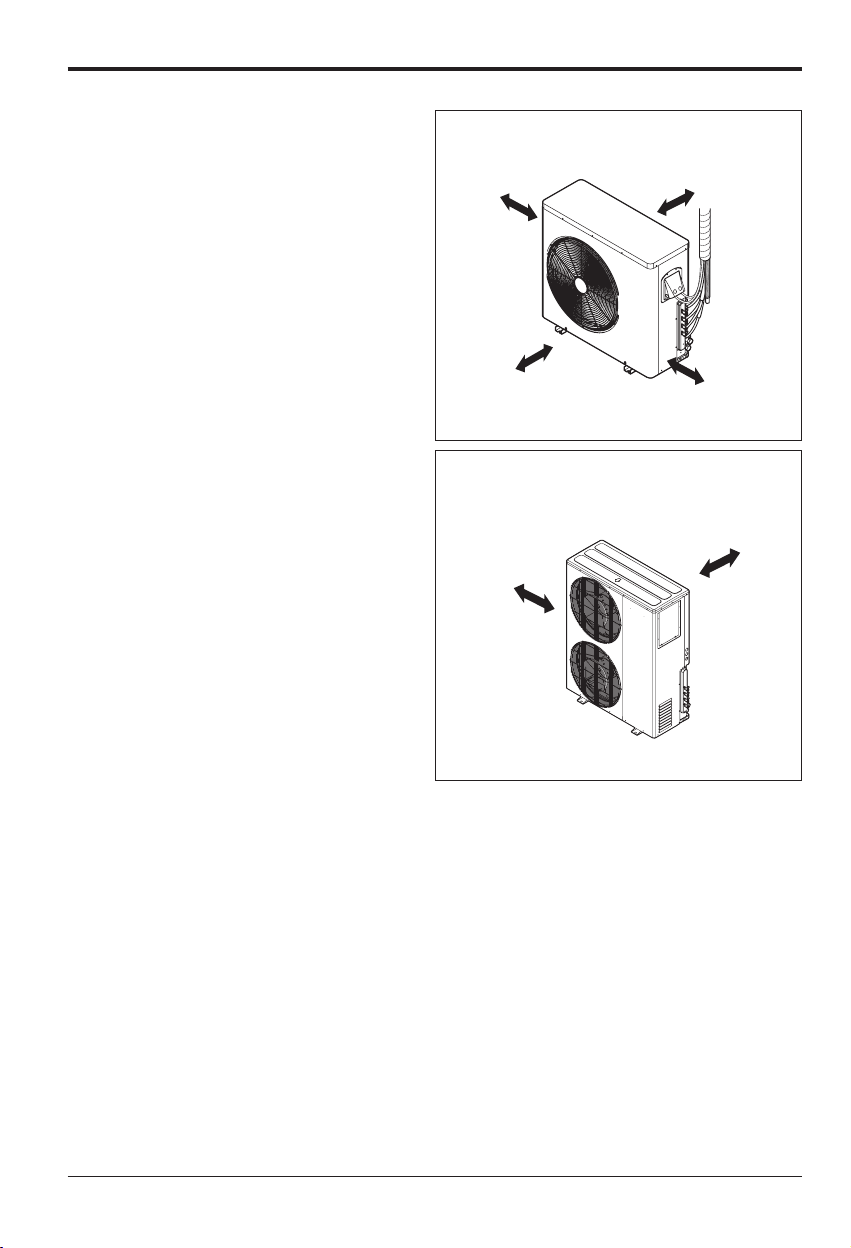

Outdoor unit

1. If an awning is built over the unit to prevent

direct sunlight or rain exposure, make sure

that heat radiation from the condenser is not

restricted.

2. Ensure the unit is unobstructed, allow proper

space on all sides according to the arrows

and distance measurements in the figures.

3. Do not place animals and plants in the path

of the warm air.

4. Take the air conditioner weight into account

and select a place where noise and vibration

are minimum.

5.

Select a place so that the warm air and sound

from the air conditioner does not disturb

neighbors.

Rooftop Installations:

If the outdoor unit is installed on a roof

structure, be sure to level the unit. Ensure the

roof structure and anchoring method are

adequate for the unit location. Consult local

codes regarding rooftop mounting.

more than 700

(27 9/16)

more than 300

(11 13/16)

more than 300

(11 13/16)

more than 600

(23 21/32)

more than 300

(11 13/16)

more than 300

(11 13/16)

Unit:mm(inch)

Unit:mm(inch)

Installation Manual 11

Installation of Indoor, Outdoor Unit

ENGLISH

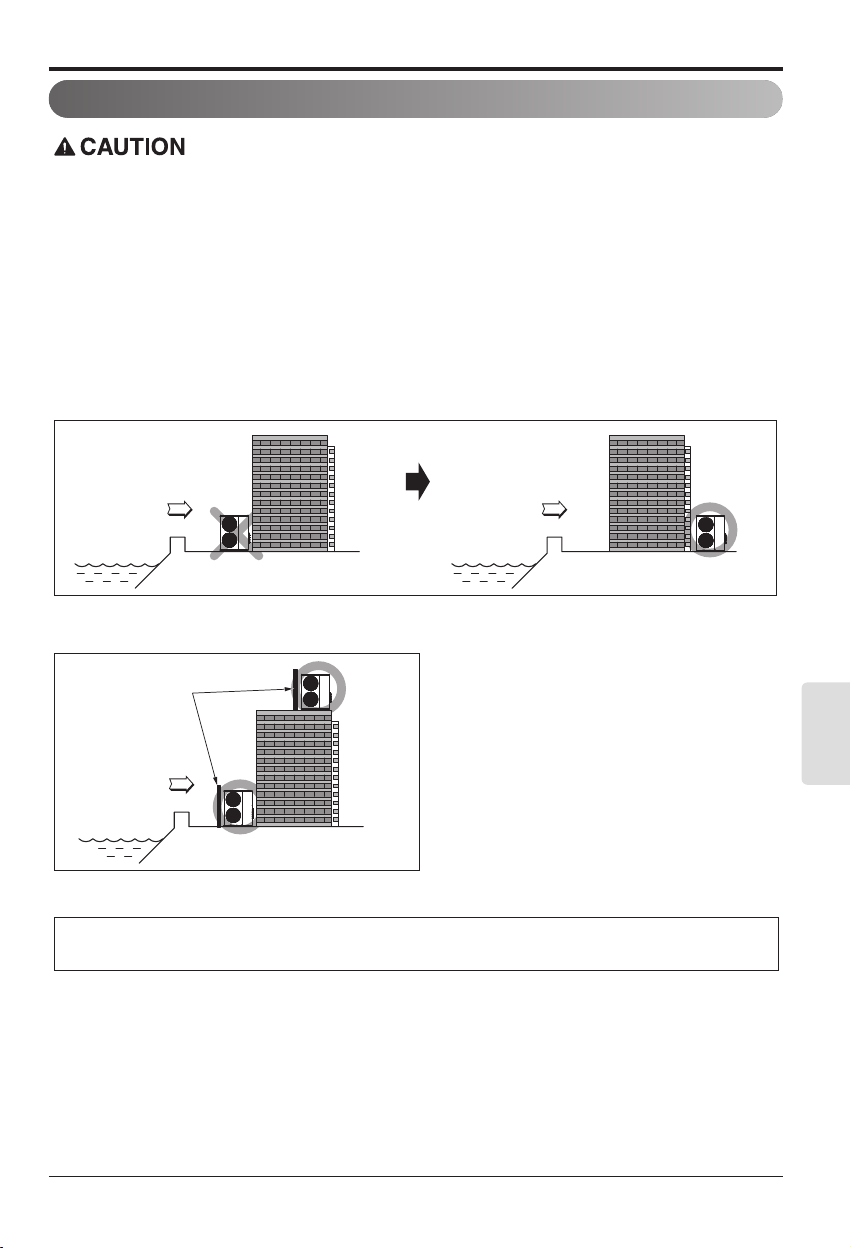

Seaside Applications and Installation

1.

Air conditioners should not be installed in areas where corrosive gases, such as acid or alkaline gas, are

produced.

2. Do not install the product where it could be exposed to sea wind (salty wind) directly. It can result

corrosion on the product. Corrosion, particularly on the condenser and evaporator fins, could

cause product malfunction or inefficient performance.

3. If outdoor unit is installed close to the seaside, it should avoid direct exposure to the sea wind.

1) If the outdoor unit is to be installed close to the seaside, direct exposure to the sea wind should be avoided.

Install the outdoor unit on the opposite side of the sea wind direction.

2)

In case, to install the outdoor unit on the seaside, set up a windbreaker/barrier, to lessen the unit's exposure to sea air

3) Select a well-drained place.

• It should be strong enough (like concrete) to obstruct

the wind from the sea.

• The height and width should be more than 150% of

the outdoor unit.

• A minimum of 70cm (27 1/16 inches)

of space between outdoor unit and the windbreak

for easy air flow.

Sea wind Sea wind

Sea wind

Windbreaker/Barrier

Periodic ( more than once/year ) cleaning of the dust or salt particles stuck on the heat exchanger

using water is recommended.

1. Selecting the location(Outdoor Unit)

12 Multi zone

Installation of Indoor, Outdoor Unit

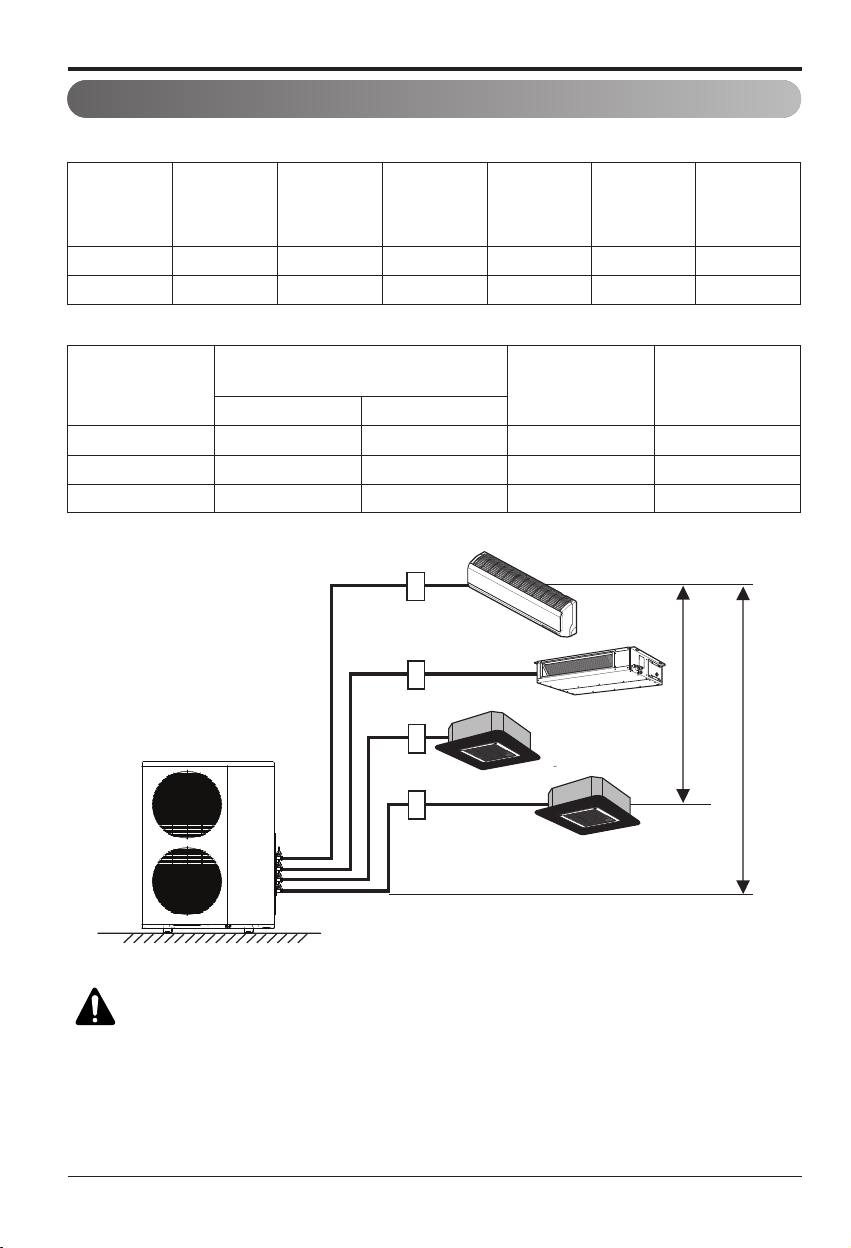

Multi Piping Type

Piping length and elevation

CAUTION: Capacity is based on standard length and maximum allowance

length is on the basis of reliability.

9k 9.52(3/8) 6.35(1/4) 7.5(25) 20(0.22)

12k 9.52(3/8) 6.35(1/4) 7.5(25) 20(0.22)

18k 12.7(1/2) 6.35(1/4) 7.5(25) 20(0.22)

Gas Liquid

Standard

Pipe Length

Unit : m(ft)

Additional

Refrigerant

Unit : g/m(oz/ft)

Indoor unit

Capacity

(Btu/h class)

Pipe Diameter

Unit : mm(inch)

Unit : m(ft)

24k 75(246) 25(82) 3(10) 15(49) 7.5(25) 18k

36k 75(246) 25(82) 3(10) 15(49) 7.5(25) 18k

Outdoor Unit

Capacity

(Btu/h class)

Max total length

of all pipes

(A+B)/(A+B+C)/

(A+B+C+D)

Max length of

each pipe

(A/B/C/D)

Min length of

each pipe

(A/B/C/D)

Max Elevation

between each

indoor unit and

outdoor unit (h1)

Max elevation

between indoor

units (h2)

Max.Combination

of Indoor unit

(Btu/h class)

A

B

h2

C

D

h1

Installation Manual 13

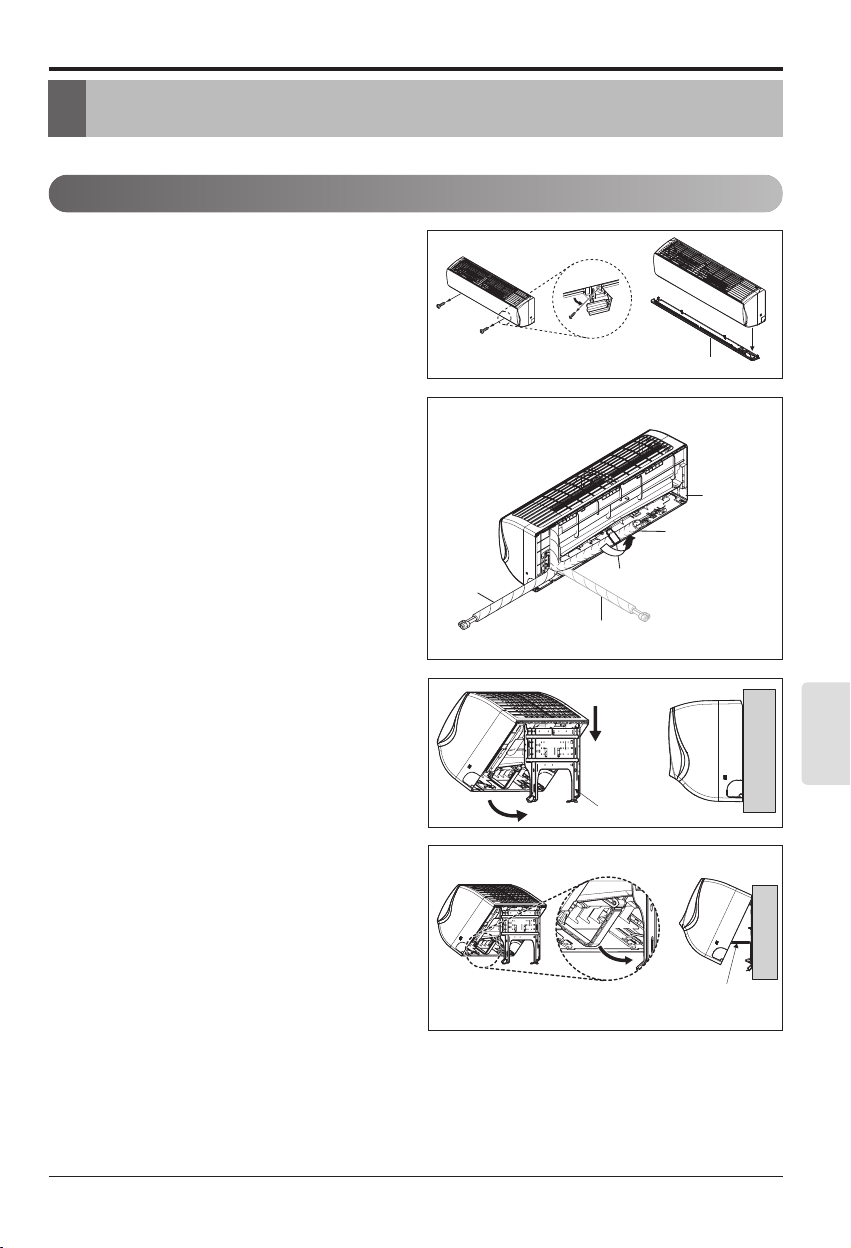

Installation

ENGLISH

Connecting the piping

[Wall-mounted Type]

1. Pull the screw cap at the bottom of the indoor unit

2. Remove the chassis cover from the unit by

loosening screws

3. Pull back the tubing holder.

4. Remove pipe port cover and positioning

the tubing

5. Indoor unit installation

1) Hook the indoor unit onto the upper portion of

the installation plate.( engage the three

hooks at the top of the indoor unit with the

upper edge of the installation plate) Ensure

that the hooks are properly seated on the installation plate by moving it left and right

2) Unlock the tubing holder from the chassis

and mount between the chassis and installation plate in order to separate the bottom side

of the indoor unit from the wall

Installation

Chassis cover

Indoor unit back side view

Right

Pipe Port

Left

Tubing holder

Backwards

Installation plate

Tubing Holder

14 Multi zone

Installation

Connecting the piping to the indoor unit

and drain hose to drain pipe.

1. Align the center of the pipes and

sufficiently tighten the flare nut by hand.

2. Tighten the flare nut with a wrench.

3. Next, extend the indoor unit's drain hose.

Then attach the drain pipe.

mm inch kgf.m (lbf·ft)

Ø6.35 1/4 1.8~2.5 (13~18)

Ø9.52 3/8 3.4~4.2 (24~30)

Ø12.7 1/2 5.5~6.6 (40~48)

Outside diameter Torque

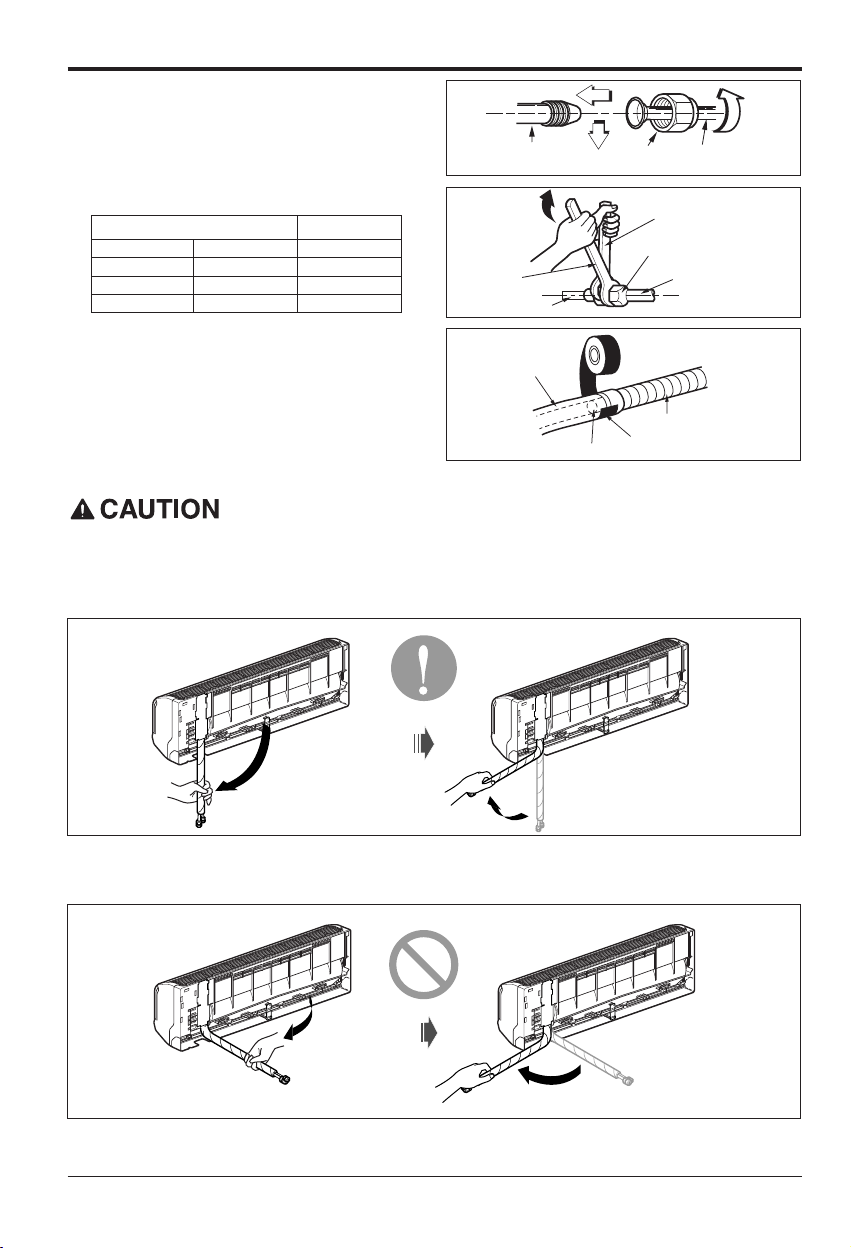

Installation Information. For left piping. Follow the instruction below.

Good case

• Press on the upper side of clamp and unfold the tubing to slowly downward.

Bad case

• Bending the pipe from right to left may cause damage to the tubing.

Indoor unit tubing Flare nut Pipes

Open-end wrench (fixed)

Flare nut

Wrench

Indoor unit tubing

Drain pipe

Adhesive

Connection pipe

Indoor unit drain hose

Vinyl tape(narrow)

Installation Manual 15

Installation

ENGLISH

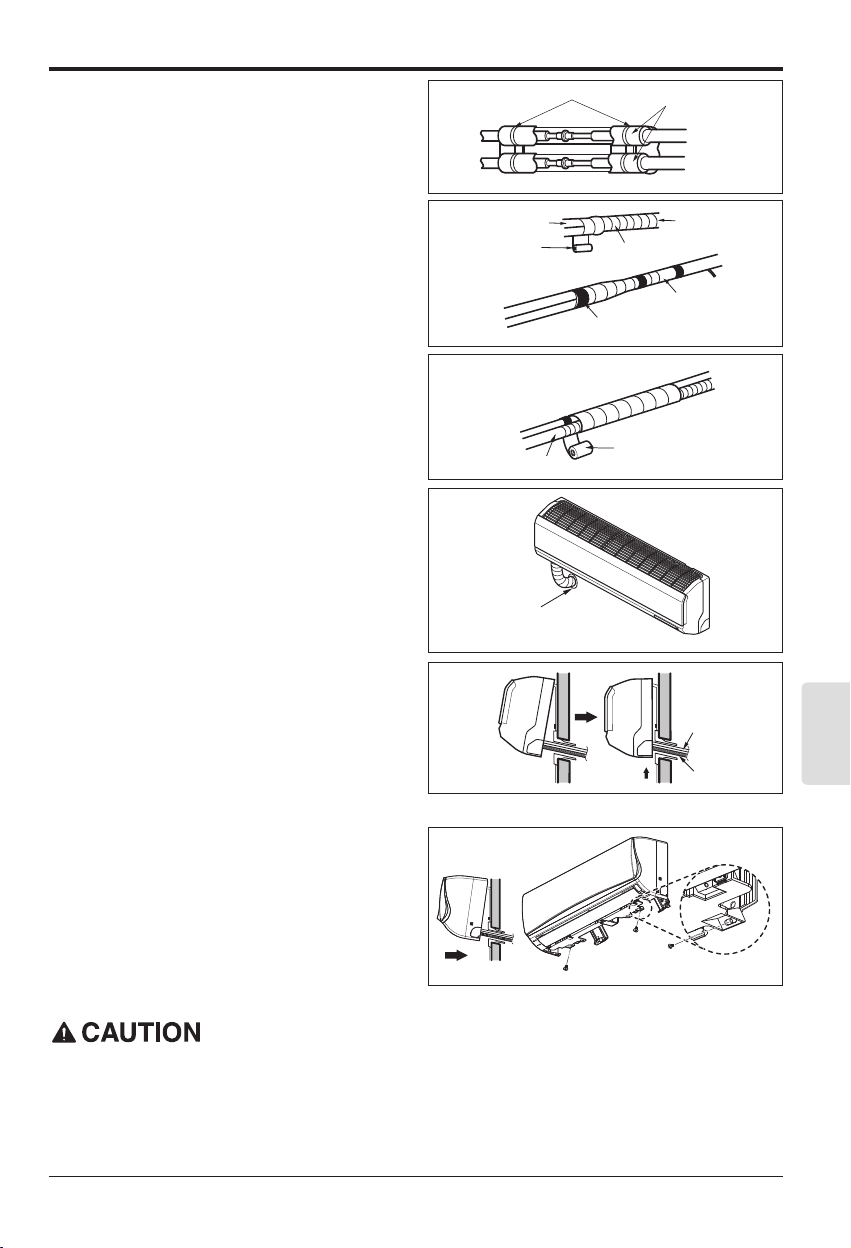

Wrap the insulation material around the

connecting portion.

1. Overlap the connection pipe insulation and the

indoor unit pipe heat insulation material. Bind

them together with vinyl tape so that there is no

gap.

2. Wrap the area which accommodates the rear

piping housing section with vinyl tape.

3. Bundle the piping and drain hose together by

wrapping them with vinyl tape over the range

within which they fit into the rear piping housing

section.

Reroute the pipings and the drain hose across

the back of the chassis.

Finishing the indoor unit installation

1.

Mount the tubing holder in the original positon.

2.

Ensure that the hooks are properly seated on the

installation plate by moving it left and right.

3. Press the lower left and right sides of the unit

against the installation plate until the hooks engage into their slots (clicking sound).

4.

Finish the assembly by screwing the unit to the

installation plate by using two pieces of type "C"

screws. And assemble a chassis cover.

If the split type Indoor unit is installed in a wall having hole or opening near by or back side of the

unit, then the air from other side of the wall can come inside the condition space through that hole

/ opening. That air can cause unwanted dew / water droplet formation when it comes in contact

with body of the indoor unit. So all hole or opening on the wall must be blocked very well to avoid

water dropping from the body of the unit.

Connection pipe

Vinyl tape (wide)

Drain hose

Piping for

passage through

piping hole

Plastic bands

Insulation material

Wrap with vinyl tape

Vinyl tape(narrow)

Vinyl tape(wide)

Indoor unit pipe

Pipe

Connecting

Drain hose

Type 'C' screw

16 Multi zone

Installation

The wall you select should be strong and solid enough to prevent vibration

1. Mount the installation plate on the wall with

type "A" screws. If mounting the unit on a concrete wall, use anchor bolts.

• Mount the installation plate horizontally by aligning the centerline using a level.

2. Measure the wall and mark the centerline. It is also important to use caution concerning the

location of the installation plate-routing of the wiring to power outlets is through the walls

typically. Drilling the hole through the wall for piping connections must be done safely.

How to mount

Ø70

(2 3/4)

133(5 1/4)

95(5 3/4)

217(8 17/32)

175(6 7/8)

442(17 13/32) 442(17 13/32)

Ø70

(2 3/4)

Installation Plate

Enganche

del chasis

Type "A" Screws

Right rear piping

Left rear piping

Installation Plate

Place a level on raised tab

Unit Outline

Ø70

(2 3/4)

Ø70

(2 3/4)

69(2 23/32)

56(2 7/32)

207(8 5/32)

105(4 1/8)

460(18 1/8) 570(22 7/16)

Installation Plate

Enganche

del chasis

Type "A" Screws

Left rear piping

Installation Plate

Place a level on raised tab

Unit Outline

Right

rear

piping

Measuring Tape

Hanger

Measuring Tape

Indoor Type

Capacity (kBtu/h)

Type

Wall-mounted Type

9/12

Type 1

18

Type 2

<Type 1>

<Type 2>

Installation Manual 17

Installation

ENGLISH

1. Connect the wires to the terminals on the

control board individually according to the

outdoor unit connection.

• Ensure that the color of the wires of outdoor

unit and the terminal No. are the same as

those of indoor unit respectively.

2. Attach the Grille onto the cabinet.

• Grasp the lower left and right side of the

Grille and engage four tabs on the top inside

edge of the chassis.

• Press the Grille toward the chassis until it

goes back into place.

Conduit connection

1. Set the connecting cable into the terminal

block of indoor unit, and tighten set screw to

lock the conduit bracket to the indoor unit.

2. Join the conduit and the conduit bracket

together.

Connecting cable

Lock nut

Conduit

Conduit

bracket

CAUTION :

Must use

the elbow type (L-Type)

conduit.

Wiring Connection

Terminal Block in Indoor

1(L1) 2(L2) 3 4

Connected to Outdoor Unit

Connecting cable

View

Terminal block

Connecting cable

Cable retainer

18 Multi zone

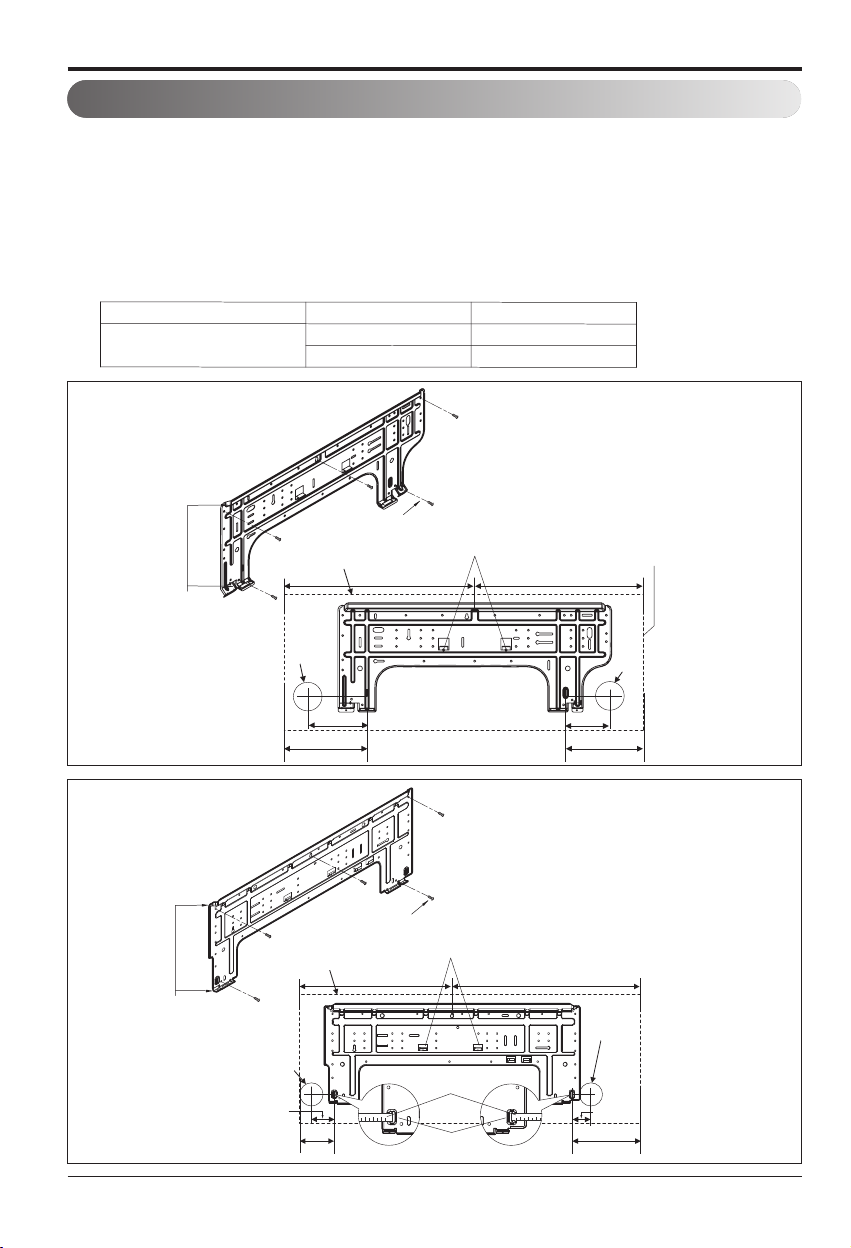

Installation

[Ceiling Concealed Duct Type]

Ceiling dimension and hanging bolt location

Installation of Unit

Install the unit above the ceiling correctly.

• Apply a joint-canvas between the unit and duct

to absorb unnecessary vibration.

• Apply a filter Accessory at air return hole.

• Install the unit leaning to a drainage hole side as

a figure for easy water drainage.

• A place where the unit will be leveled and that

can support the weight of the unit.

• A place where the unit can withstand its

vibration.

• A place where service can be easily performed.

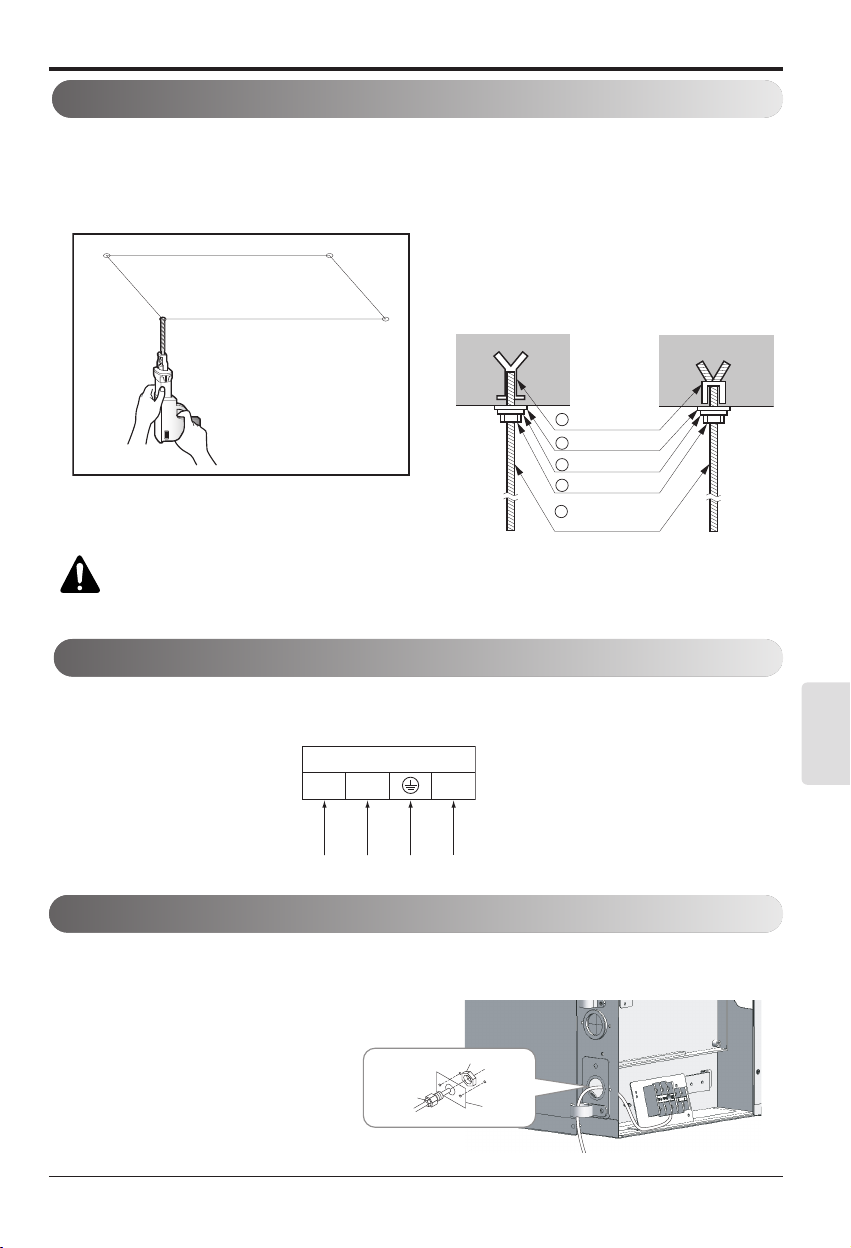

CASE 1

POSITION OF SUSPENSION BOLT

CASE 2

POSITION OF CONSOLE BOLT

B

A

Unit:mm(inch)

Dimension

Capacity

Btu/h class

ABCDEFGHI

850 900 383 570 93.5 190 20.6 795 163

12k

(33 15/32) (35 15/32) (15 3/32) (22 7/16) (3 11/16) (7 1/2) (13/16) (31 5/16) (6 13/32)

1130 1180 383 570 93.5 190 20.6 1065 163

18k

(44 1/2) (46 1/2) (15 3/32) (22 7/16) (3 11/16) (7 1/2) (13/16) (41 15/16) (6 13/32)

G

1/100

H

Drainage hole

M10 Nut

M10 SP. washer

M10 washer

M10 washer

M10 SP. washer

M10 Nut

X 4

X 4

X 4

X 4

X 4

X 4

CE

I

(Local

supply)

(Local

supply)

D

F

Installation Manual 19

Installation

ENGLISH

• Select and mark the position for fixing

bolts.

• Drill the hole for set anchor on the face of

ceiling.

• Insert the set anchor and washer onto the

suspension bolts for locking the

suspension bolts on the ceiling.

• Mount the suspension bolts to the set

anchor firmly.

• Secure the installation plates onto the

suspension bolts (adjust level roughly)

using nuts, washers and spring washers.

CAUTION : Tighten the nut and bolt to prevent unit falling.

Connect the wires to the terminals on the control board individually according to the outdoor unit connection.

• Ensure that the color of the wires of outdoor unit and the terminal No. are the same as those of indoor unit respectively.

Conduit connection

1. Remove the bushing rubber product attached on the indoor unit.

2. Set the connecting cable into the terminal block of indoor unit, and tighten set screw to lock the

conduit bracket to the indoor unit.

3. Join the conduit and the conduit bracket together.

Lock nut

Conduit

mounting

plate

Conduit

Wiring Connection

How to mount

Old building New building

1 Set anchor

2 Plate washer

3 Spring washer

4 Nut

5 Suspension

bolts

Terminal Block of Indoor Unit

1(L1) 2(L2) 3

Connected to outdooor unit

20 Multi zone

Installation

Front of view

1. Install declination of the indoor unit is very important for the drain of the duct type air conditioner.

2. Minimum thickness of the insulation for the connecting pipe shall be 19mm(1/32 inch).

• The unit must be horizontal or declined to the drain hose connected when

finished installation.

INSULATION, OTHERS

Insulate the joint and tubes completely.

All thermal insulation must comply with local requirement.

INDOOR UNIT

■ After all workings are finished, check the working and operation.

• Air distribution ............... Is the air circulation good?

• Drain ............................. Is the drainage smoothly and no sweating?

• Gas leakage ................. Is the piping connection correctly?

• Wiring ........................... Is the wiring connection correctly?

• Lock-bolt ....................... Is the lock-bolt of compressor loosened?

• Insulation....................... Is the unit fully insulated?

• Ground .......................... Is the unit safely grounded?

THERMAL INSULATION

TEST AND CHECK

CAUTION

Ceiling

Drainage hole

Drain Pump use

Refrigerant pipe and thermal

insulator(Local supply)

Hose clip for thermal insulator

Thermal insulator for refrigerant pipe

(Local supply)

(Local supply)

Union for gas pipe

Union for liquid pipe

Insulation

Thermal insulator for refrigerant pipe

(Local supply)

Hose clip for thermal insulator(Local supply)

Make sure that there is no clearance here.

Rubber

No clearance

Thermal insulator for

piping(Local supply)

Overlap with thermal

insulator for piping.

Felt

Cabinet

Installation Manual 21

Installation

ENGLISH

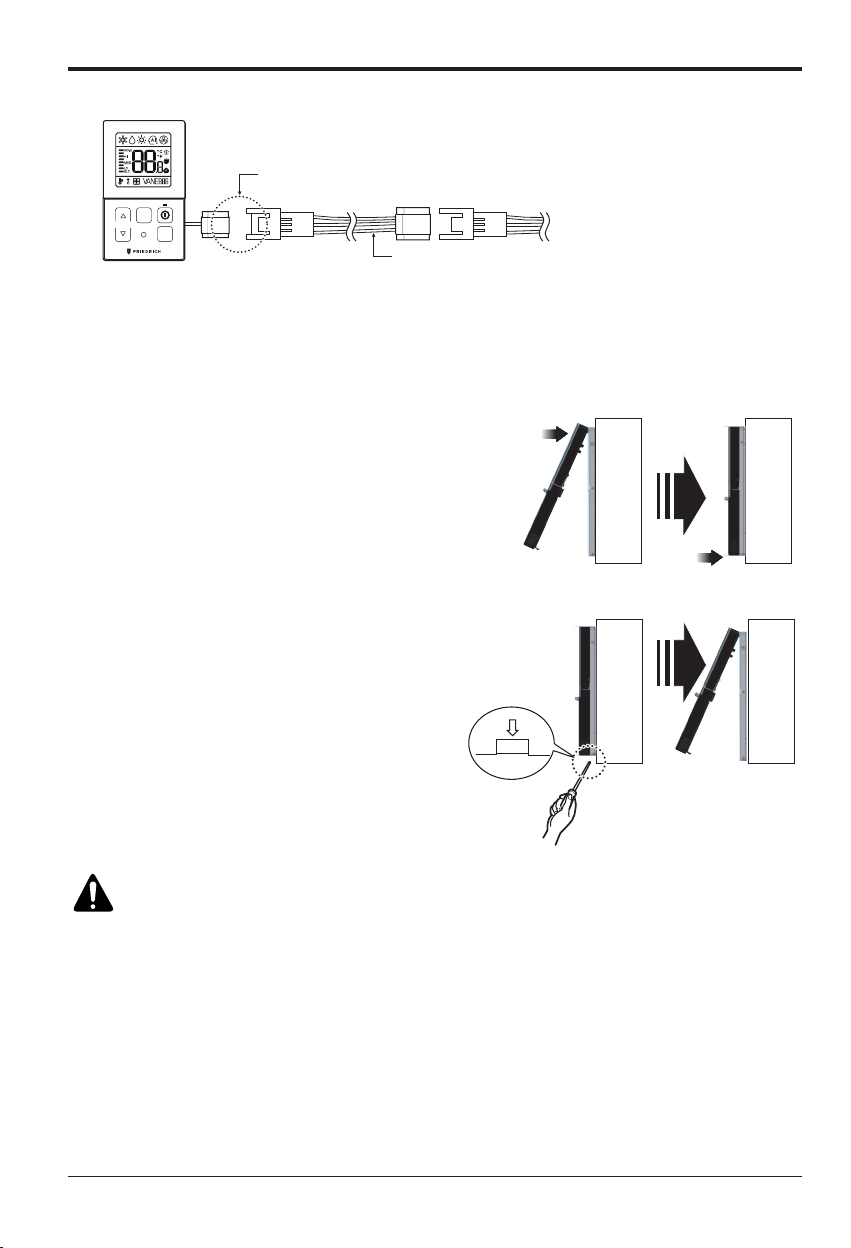

Remote controller installation

Please fix tightly using provided screw after placing remote controller setup board

on the place where you like to setup.

- Please set it up not to bend because poor setup could take place if setup board bends.

Please set up remote controller board fit to the reclamation box if there is a reclamation box.

Can set up Wired remote controller cable into three directions.

- Setup direction: the surface of wall reclamation, upper, right

- If setting up remote controller cable into upper and right side, please set up after removing remote

controller cable guide groove.

* Remove guide groove with long nose.

① Reclamation to the surface of the wall

② Upper part guide groove

③ Right part guide groove

<Wire guide grooves>

22 Multi zone

Installation

Please fix remote controller upper part into

the setup board attached to the surface of

the wall, as the picture below, and then,

connect with setup board by pressing

lower part.

- Please connect not to make a gap at the remote

controller and setup board’s upper and lower, right

and left part.

When separating remote controller from

setup board, as the picture below, after

inserting into the lower separating hole

using screw driver and then, spinning

clockwise, remote controller is separated.

- There are two separating holes. Please

individually separate one at a time.

- Please be careful not to damage the inside

components when separating.

Please connect indoor unit and remote controller using connection cable.

Please use extension cable if the distance between wired remote controller and

indoor unit is more than 10m.

Wall

Side

Wall

Side

Wall

Side

Wall

Side

<Connecting order>

<Separating order>

Please check if connector is normally connected.

Connecting cable

Indoor

Unit side

TEMP

FAN

SPEED

OPER

MODE

CAUTION :

When installing the wired remote controller, do not bury it in the wall.

(It can cause damage in the temperature sensor.)

Do not install the cable to be 50m or above.

(It can cause communication error.)

• When installing the extension cable, check the connecting direction of the connector of the

remote controller side and the product side for correct installation.

• If you install the extension cable in the opposite direction, the connector will not be connected.

• Specification of extension cable: 2547 1007 22# 2 core 3 shield 5 or above.

• Apply totally enclosed noncombustible conduit in case of local building code Requiring plenum

cable usage.

Installation Manual 23

Installation

ENGLISH

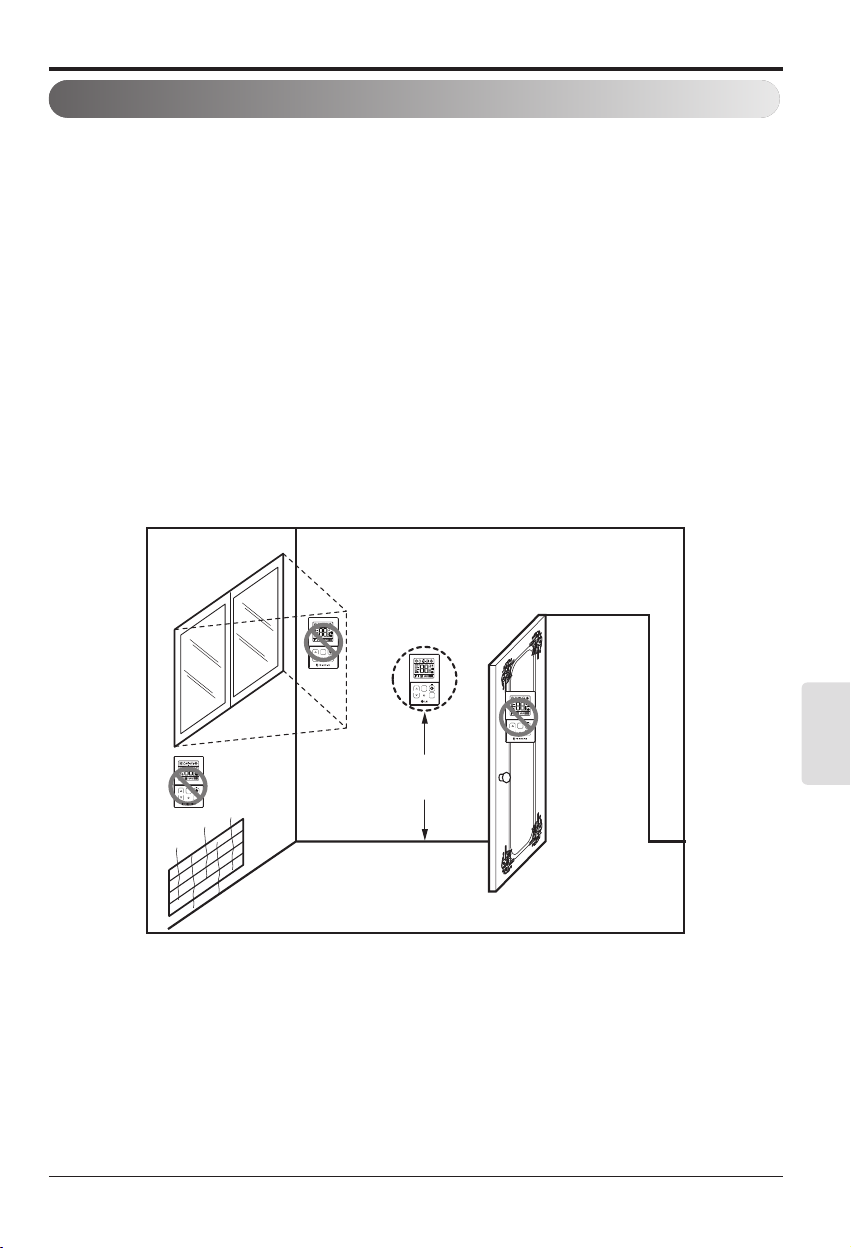

Wired remote controller installation

Since the room temperature sensor is in the remote controller, the remote controller box should be

installed in a place away from direct sunlight, high humidity and direct supply of cold air to maintain

proper space temperature. Install the remote controller about 5ft(1.5m) above the floor in an area

with good air circulation at an average temperature.

Do not install the remote controller where it can be affected by:

- Drafts, or dead spots behind doors and in corners.

- Hot or cold air from ducts.

- Radiant heat from sun or appliances.

- Concealed pipes and chimneys.

- Uncontrolled areas such as an outside wall behind the remote controller.

- This remote controller is equipped with LCD. display. For proper display of the remote controller

LCD's, the remote controller should be installed properly as shown in Fig.1.

(The standard height is 4~5 ft (1.2~1.5 m) from floor level.)

[Fig.1]

TEMP

no

TEMP

no

FAN

SPEED

OPER

MODE

yes

FAN

SPEED

TEMP

OPER

MODE

FAN

SPEED

TEMP

OPER

MODE

5feet

FAN

SPEED

OPER

MODE

(1.5meters)

24 Multi zone

Installation

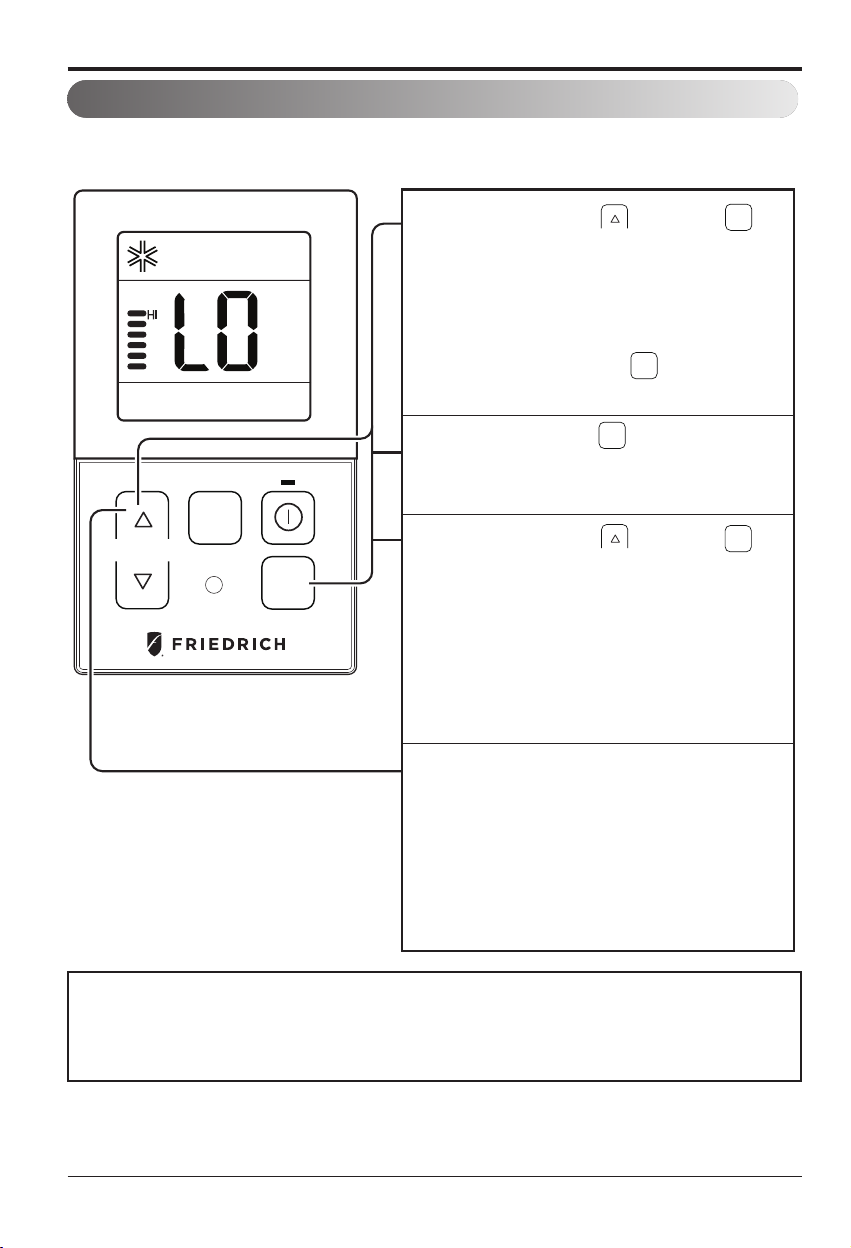

After installing the product, you must run a Test Run mode.

For details related to this operation, refer to the product manual.

• What is the test run mode??

- This means the operation of the product under the cooling, strong wind, and Comp on state

without performing room temperature control in order to confirm the installed state during the

product installation.

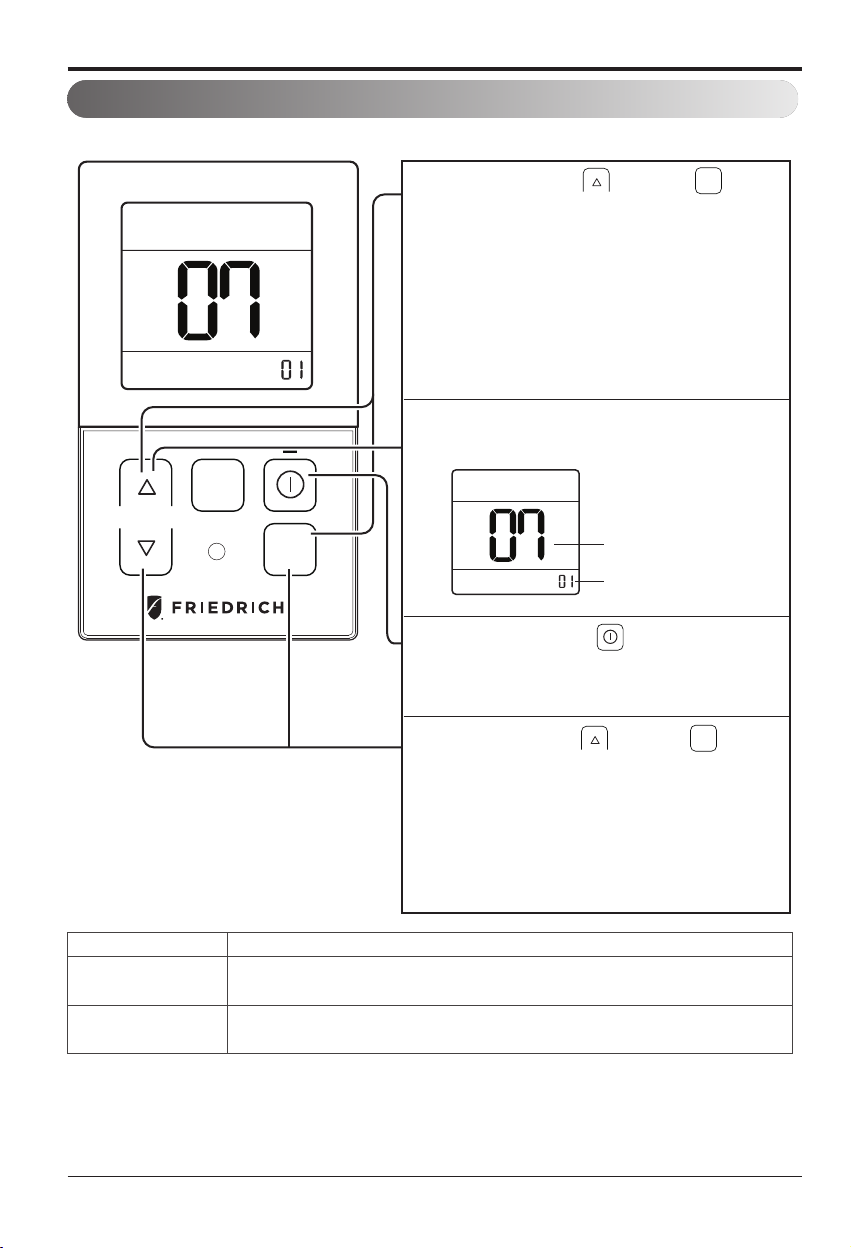

Installer Setting - Test Run Mode

TEMP

FAN

SPEED

OPER

MODE

When pressing the button and

1

button simultaneously for more than 3

seconds, the system will be entered into

the installer setting mode.

- After entering into the installer setting

mode, select the test run mode code

value by pressing the button.

* Test run mode code value : 01

When pressing the button, the test

2

operation mode will be performed, and it is

displayed as shown in the left figure.

When pressing the button and

3

button simultaneously for more than 3

seconds after the setting has been

completed, the setting mode will be

released.

- If there isn’t any button input for more

than 25 seconds, the installer setting

mode will also be released.

When approx. 18 minutes are elapsed after

4

starting of the test oper-mode, the system

will be stopped automatically and converted

to the standby state.

- If any button is inputted during the test run

mode, the test run mode will be forced to

be relreased.

OPER

MODE

OPER

MODE

OPER

MODE

OPER

MODE

Installation Manual 25

Installation

ENGLISH

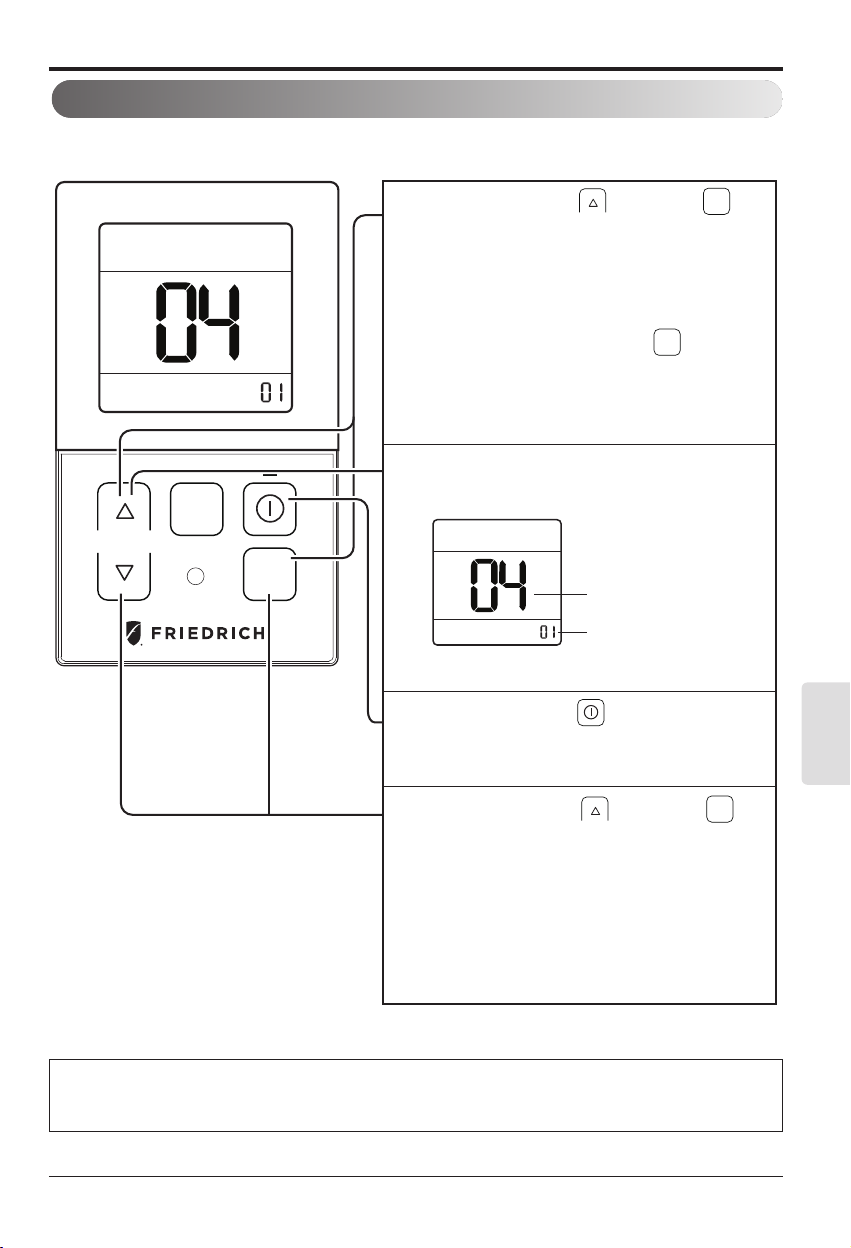

Installer Setting - Thermistor

This is the function to select the temperature sensor to judge the room temperature.

• As the characteristic of the ‘2TH’ function can be different in accordance with the products,

refer to the product instruction manual for its detail.

TEMP

FAN

SPEED

OPER

MODE

When pressing the button and

1

button simultaneously for more than 3

seconds, the system will be entered into the

installer setting mode.

- After entering into the installer setting

mode, select the thermistor sensor setting

code value by pressing the

button.

* Thermistor sensor selection code value :

04

Select the desired setting value with the

2

temperature up(▲), down(▼) button.

Code value

Val ue

When pressing the button, currently

3

established thermistor sensor location will

be set up.

OPER

MODE

OPER

MODE

*Setting value

01: Remote

controller

02: Indoor unit

03: 2TH

OPER

When pressing the button and

4

button simultaneously for more than 3

seconds after the setting has been

completed, the setting mode will be

released.

- If there isn’t any button input for more than

25 seconds, the installer setting mode will

also be released.

MODE

26 Multi zone

Installation

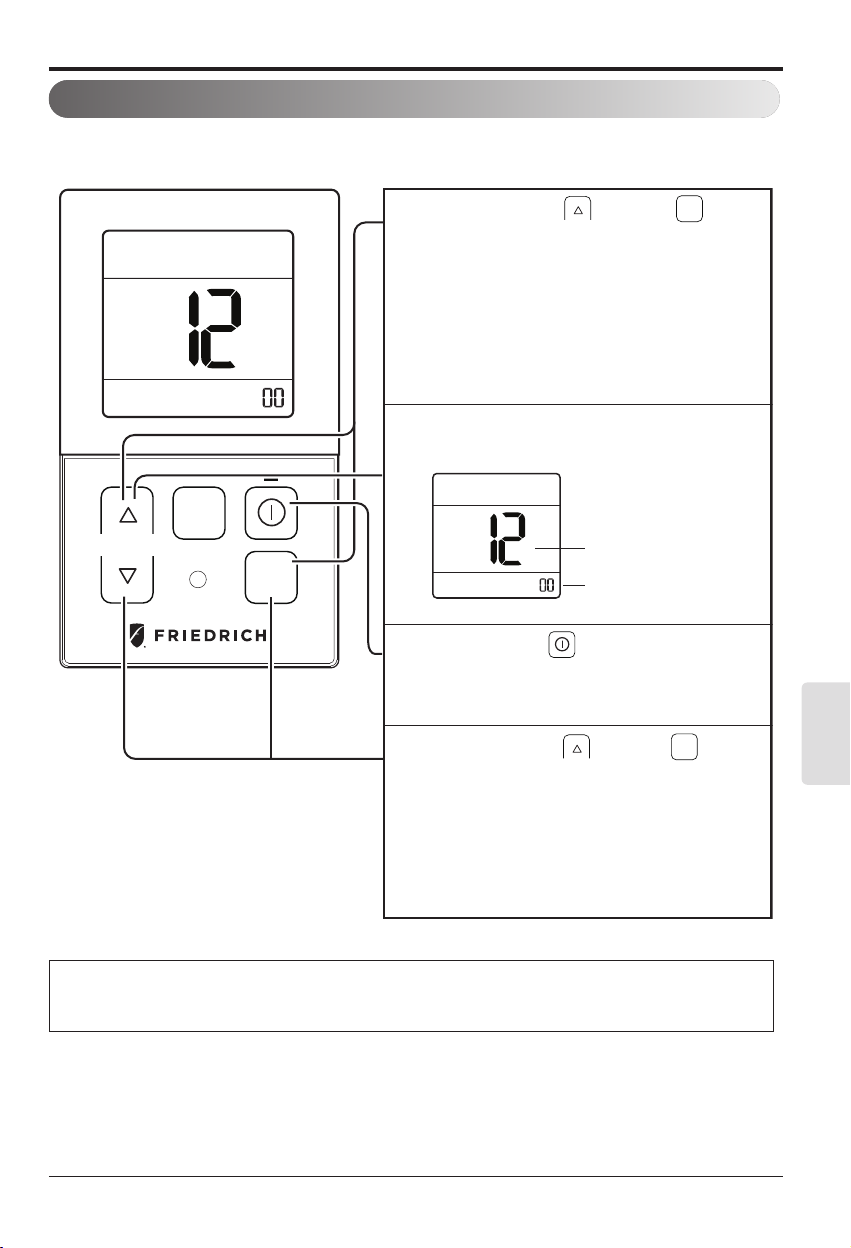

TEMP

FAN

SPEED

OPER

MODE

When pressing the button and button

simultaneously for more than 3 seconds, the

system will be entered into the installer setting

mode.

- After entering into the installer setting mode,

select the ceiling height setting code value by

pressing the oper-mode button.

* Remote controller master/slave setting code

value : 07

1

Select the desired setting value with the

temperature up(▲), down(▼) button.

2

When pressing the button, currently

established static pressure value will be set

up.

3

When pressing the button and button

simultaneously for more than 3 seconds after the

setting has been completed, the setting mode will

be released.

- If there isn’t any button input for more than 25

seconds, the installer setting mode will also be

released.

4

OPER

MODE

Code value

*Setting value

00:Slave

01:Master

OPER

MODE

Val ue

* Refer to the 'group control' part for details

- When controlling in groups, basic operation settings, airflow strength weak/medium/strong,

lock setting of the remote controller, time settings, and other functions may be restricted.

Remote controller Function

Master

Indoor unit operates based on master remote controller at group control.

(Master is set when delivering from the warehouse.)

Slave

Setup all remote controllers except one master remote controller to slave at

group control

It is a function for settings in group control, or 2-remote controller control.

Installer Setting - Group Setting

Installation Manual 27

Installation

ENGLISH

Installer Setting - Celsius / Fahrenheit Switching

• Whenever press temp up(▲), down(▼) button in Fahrenheit mode, the temperature will

increase/drop 2 degrees.

This function is used for switching the display between Celsius and Fahrenheit.

(Optimized only for U.S.A)

TEMP

FAN

SPEED

OPER

MODE

When pressing the button and button

1

simultaneously for more than 3 seconds, the

system will be entered into the installer setting

mode.

- After entering into the installer setting mode,

select the ceiling height setting code value by

pressing the oper-mode button.

* Celsius/Fahrenheit setting code value : 07

Select the desired setting value with the

2

temperature up(▲), down(▼) button.

Code value

Val ue

When pressing button, currently

3

established celsius/Fahrenheit setting value

will be set up.

When pressing the button and button

4

simultaneously for more than 3 seconds after the

setting has been completed, the setting mode will

be released.

- If there isn’t any button input for more than 25

seconds, the installer setting mode will also be

released.

OPER

MODE

*Setting value

00:Celsius

01:Fahrenheit

OPER

MODE

28 Multi zone

Installation

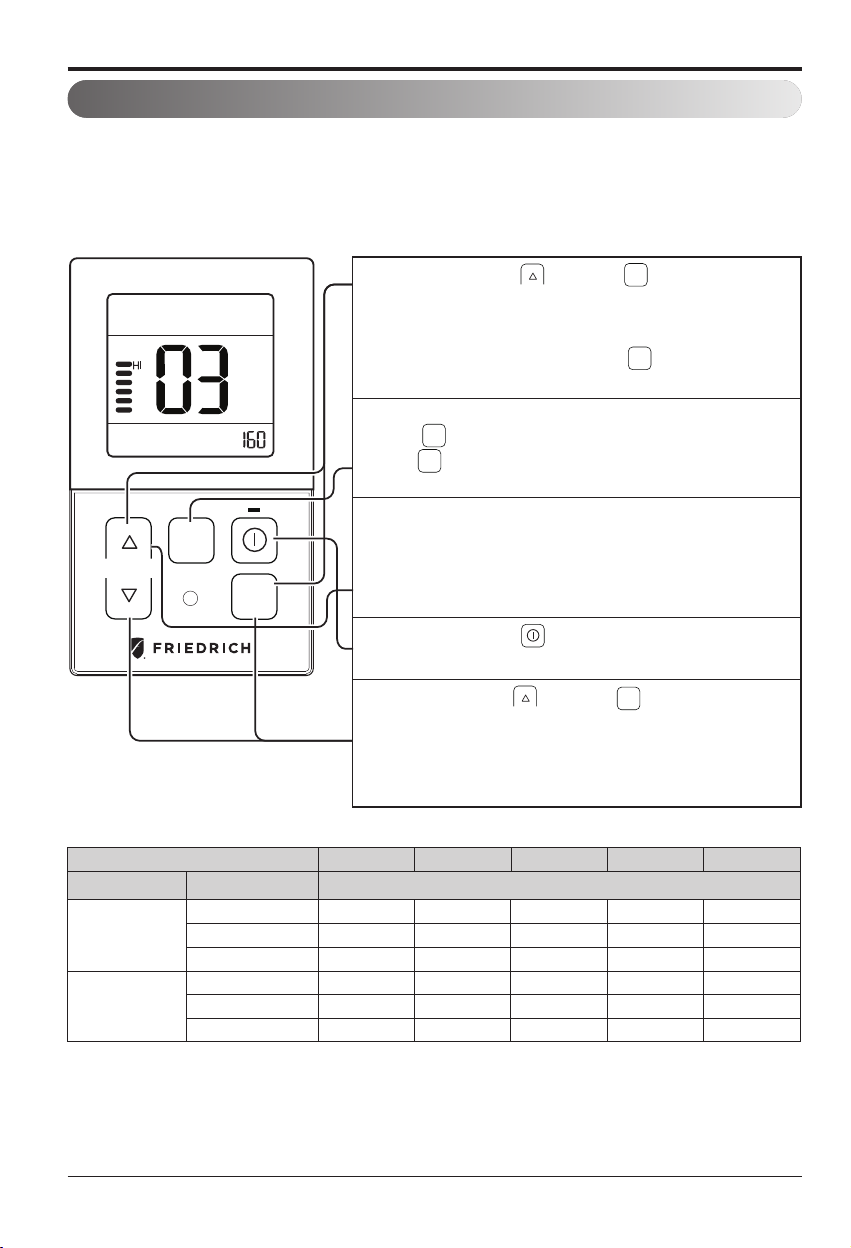

Installer Setting - E.S.P.

This is the function that decides the strength of the wind for each wind level and because this

function is to make the installation easier.

• If you set ESP incorrectly, the air conditioner may malfunction.

• This setting must be carried out by a certificated-technician.

TEMP

FAN

SPEED

OPER

MODE

OPER

MODE

OPER

MODE

OPER

MODE

When pressing the button and button

1

simultaneously for more than 3 seconds, the system will be

entered into the installer setting mode.

- After entering into the installer setting mode, select the

E.S.P code value by pressing the button.

* E.S.P code value : 03

Select the desired air flow rate with

2

3

4

5

FAN

SPEED

the button. Whenever pressing

FAN

the button, [SLo

SPEED

Select the desired air flow rate value with the temperature

up(▲), down(▼) button.

* E.S.P value range : 0~255

-

E.S.P value will be indicated at the upper right section of the

display window.

When pressing the button, currently established E.S.P

value will be set up.

When pressing the button and button simultaneously

for more than 3 seconds after the setting has been completed,

the setting mode will be released.

- If there isn’t any button input for more than 25 seconds, the

installer setting mode will also be released.

→Lo→

Med→Hi→Po] will be indicated.

Static pressure(mmAq)

Model name

MD12Y3JM

MD18Y3JM

01234

Step(H/M/L)

9.5 CMM(335cfm) 82 90 99 109 118

8.5 CMM(300cfm) 75 84 94 104 114

7.5 CMM(265cfm) 69 77 88 99 110

15 CMM(530cfm) 90 97 105 114 122

13.5 CMM(477cfm) 82 90 99 109 119

11.5 CMM(406cfm) 75 84 93 103 114

Setting value

Installation Manual 29

Installation

ENGLISH

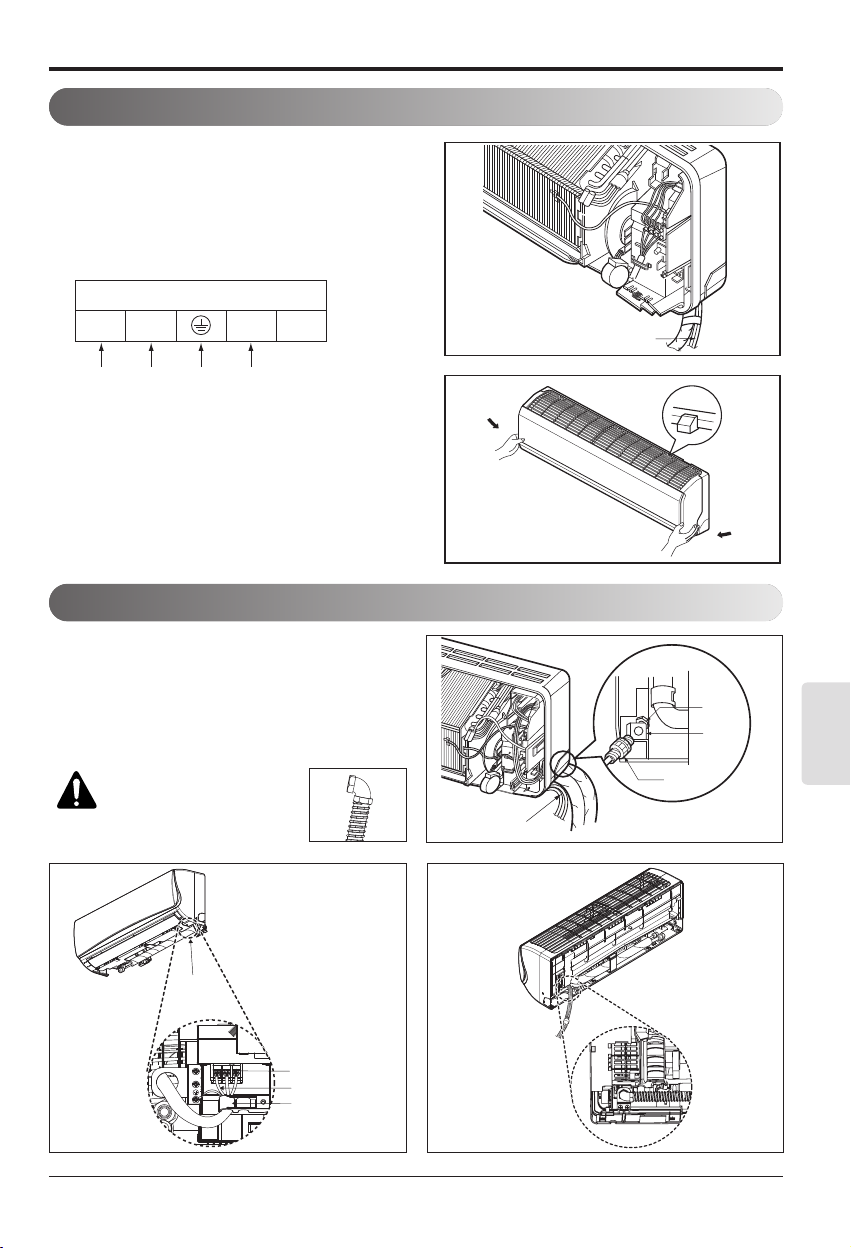

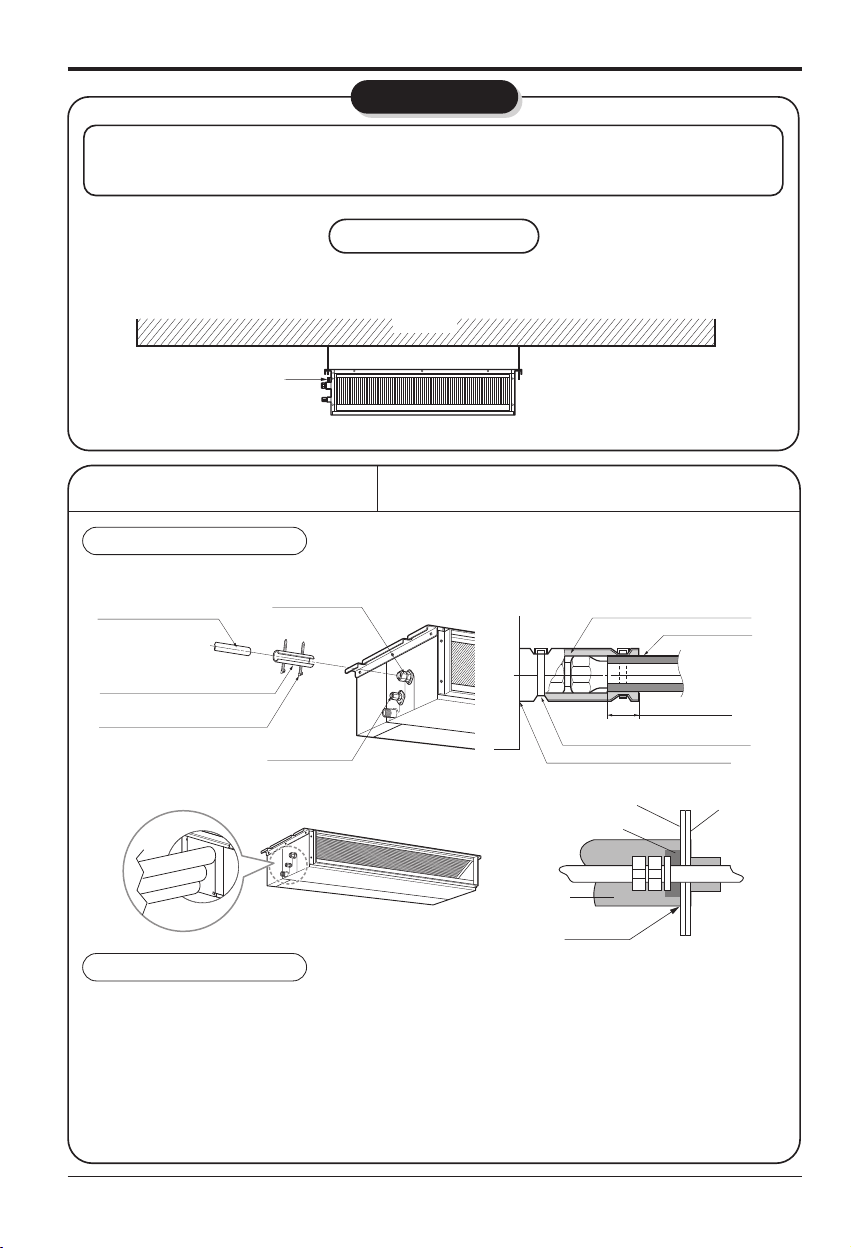

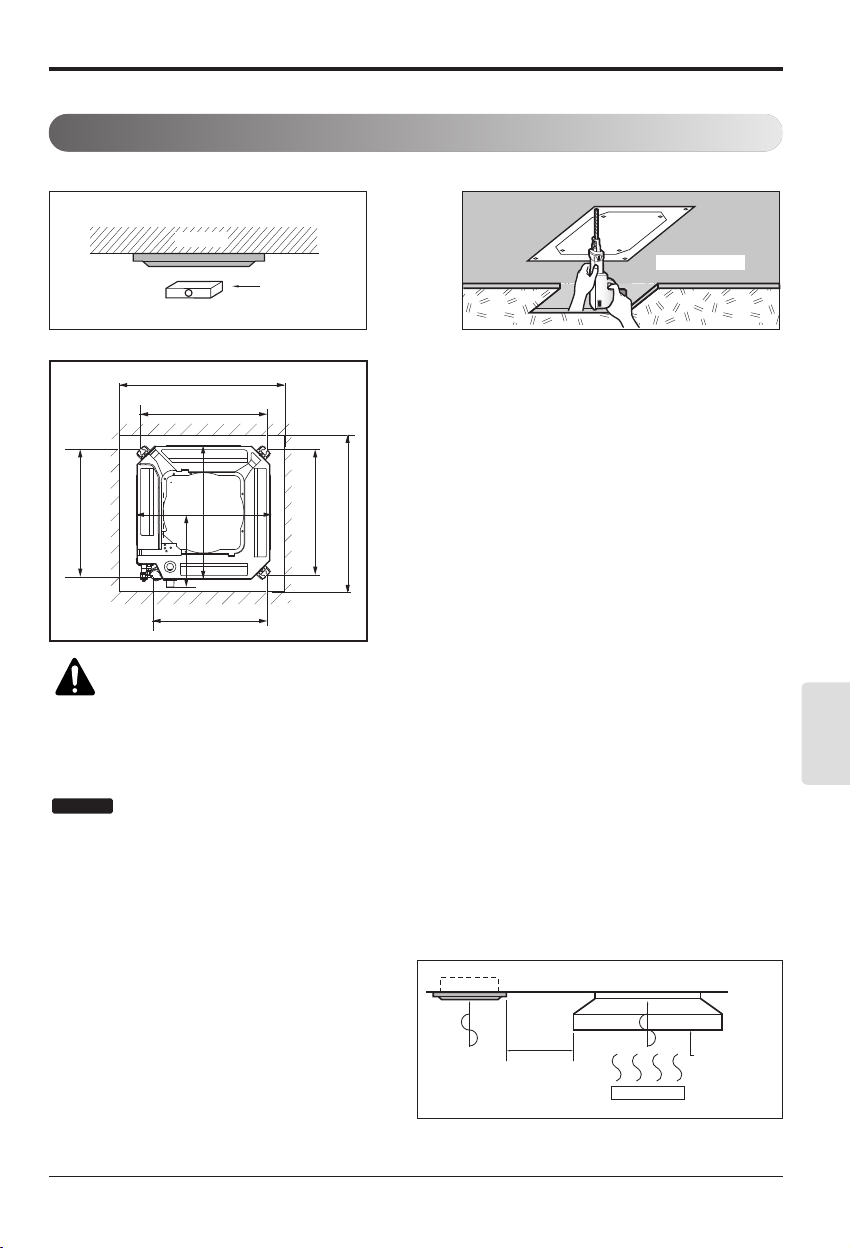

[Ceiling Cassette Type]

Ceiling dimension and hanging bolt location

• The dimensions of the paper model for installation are the same as those of the ceiling opening dimensions.

• Avoid the following installation location.

1. Such places as restaurants and kitchen where considerable amount of oil steam and flour is generated.

These may cause heat exchange efficiency reduction, or water drops, drain pump mal-function.

In these cases, take the following actions;

• Make sure that ventilation fan is enough to cover all noxious gases from this place.

• Ensure enough distance from the cooking room to install the air conditioner in such a place where it may not suck oily

steam.

2. Avoid installng air conditioner in such places where

cooking oil or iron powder is generated.

3. Avoid places where inflammable gas is generated.

4. Avoid place where noxious gas is

generated.

5. Avoid places near high frequency

generators.

CAUTION :

• This air-conditioner uses a drain pump.

• Install the unit horizontally using a level gauge.

• During the installation, care should be taken not to damage electric wires.

• Select and mark the position for fixing bolts and piping

hole.

• Decide the position for fixing bolts slightly tilted to the

drain direction after considering the direction of drain

hose.

• Drill the hole for anchor bolt on the wall.

Ceiling

Ceiling board

Level gauge

585~660(23 1/16~26) (Ceiling Opening)

517(20 3/8)

570(22 15/32)

Unit Size

570(22 15/32)

Unit Size

523(20 19/32)

319(12 9/16)

461(18 5/32)

517(20 3/8)

585~660(23 1/16~26) (Ceiling Opening)

Unit: mm(inch)

NOTICE

Air conditioner

Take enough

distance

Cooking table

Use the ventilation fan

for smoke-collecting

hood with sufficient

capacity.

30 Multi zone

Installation

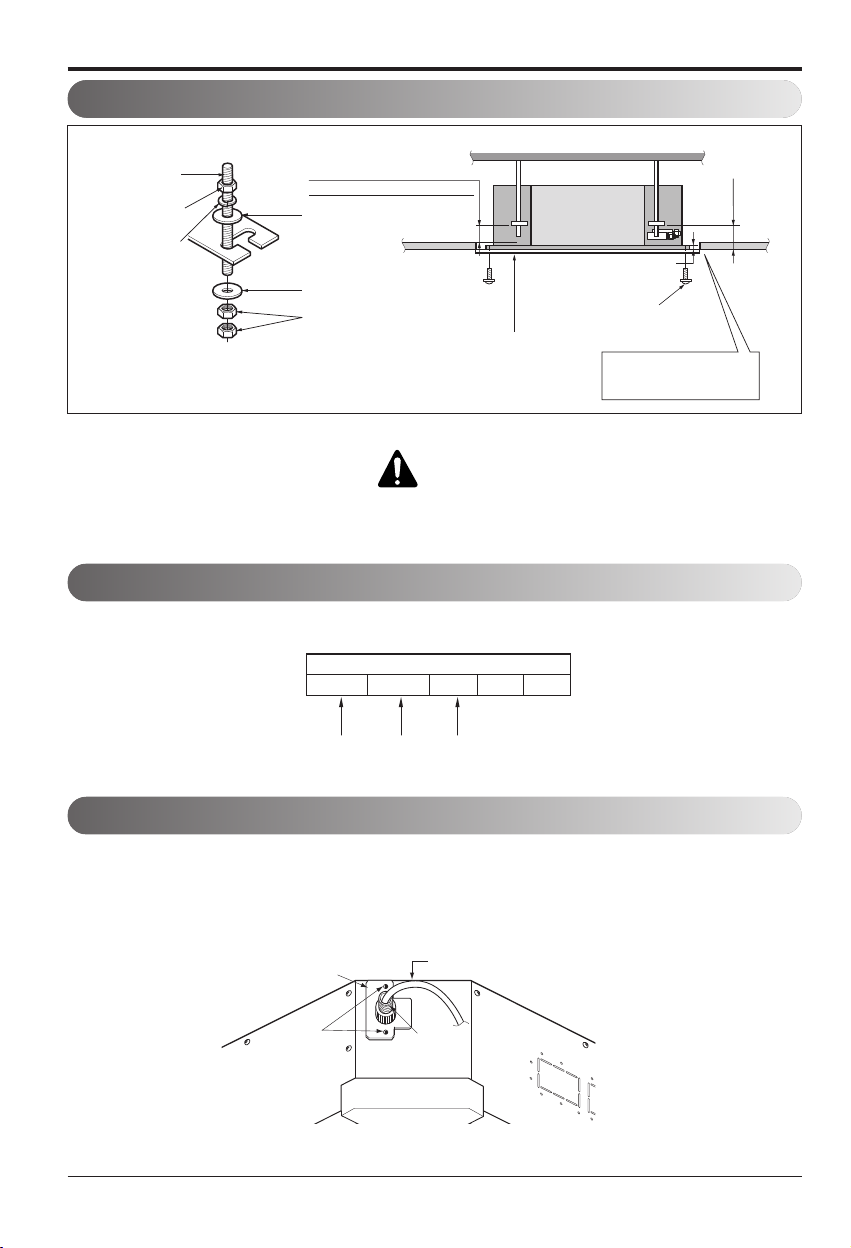

• The following parts are local purchasing.

① Hanging Bolt - W 3/8 or M10

② Nut - W 3/8 or M10

③ Spring Washer - M10

④ Plate Washer - M10

CAUTION : Tighten the nut and bolt to

prevent unit from falling off.

Wiring Connection

How to Fix

Connecting Cable

Conduit

Screw

Conduit bracket

Conduit connection

• Remove the busing rubber product attached on the indoor unit.

• Join the conduit and the conduit bracket together using nut.

• Set the connecting cable into the terminal block of indoor unit, and tighten set screw to lock the

conduit bracket to the indoor unit.

• Open the control box cover and connect the remote control cord and indoor power wires.

Hanging bolt

(W3/8 or M10)

Nut

(W3/8 or M10)

Spring washer

(M10)

Keep the length of the bolt

from the bracket to 40mm(1-9/16 inch)

Flat washer for M10

(accessory)

Flat washer for M10

(accessory)

Nut

(W3/8 or M10)

Ceiling board

Ceiling

Air Conditioner body

Keep the length of 31~34mm(1.22~1.34inch)

between the air conditioner bottom surfac

e and the ceiling surface

Set screw of

Paper model

for installation

paper model (4 pieces)

Open the ceiling board

along the outer edge of the

paper model

150mm

(5-7/8 inch)

Ceiling board

TQ/TR series

Terminal Block of Indoor Unit

1(L1) 2(L2) 3 4 5

Connected to outdoor unit

Installation Manual 31

Installation

ENGLISH

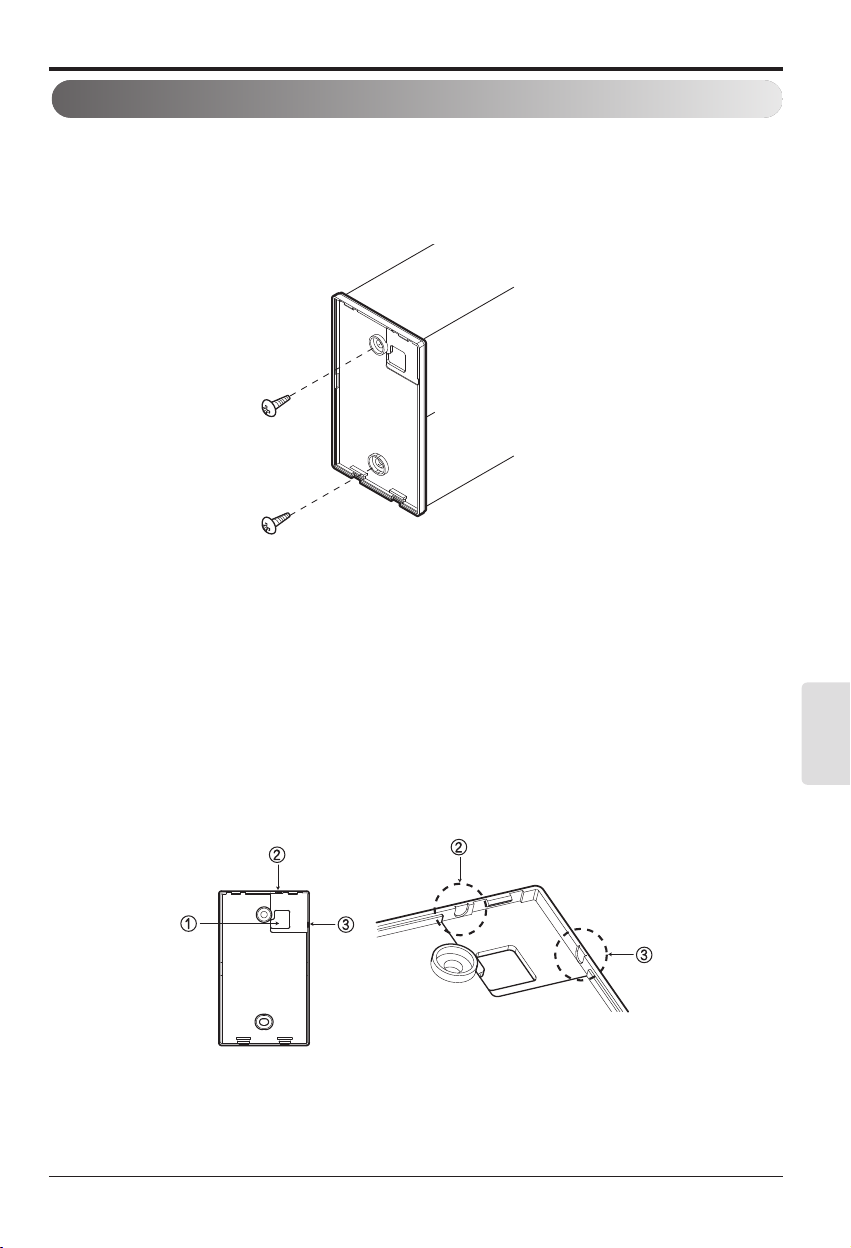

Installation of Wired Remote Controller(Optional)

1

2

3

2

3

<Wire guide grooves>

1. Please fix tightly using provided screw after placing remote controller setup board

on the place where you like to setup.

- Please set it up not to bend because poor setup could take place if setup board bends.

Please set up remote controller board fit to the reclamation box if there is a reclamation box.

- Install the product so as not to make a gap with the wall side and to prevent shaking after the installation.

2. Can set up Wired remote controller cable into three directions.

- Setup direction: the surface of wall reclamation, upper, right

- If setting up remote controller cable into upper and right side, please set up after removing remote controller cable guide groove.

❈

Remove guide groove with long nose.

①

Reclamation to the surface of the wall

②

Upper part guide groove

③

Right part guide groove

32 Multi zone

Installation

Wall

Side

Wall

Side

Wall

Side

Wall

Side

<Connecting order>

<Separating order>

3. Please fix remote controller upper part into

the setup board attached to the surface of the

wall, as the picture below, and then, connect

with setup board by pressing lower part.

- Please connect not to make a gap at the remote controller

and setup board’s upper and lower, right and left part.

- Before assembly with the installation board, arrange the

Cable not to interfere with circuit parts.

When separating remote controller from setup

board, as the picture below, after inserting into

the lower separating hole using screw driver

and then, spinning clockwise, remote controller is separated.

- There are two separating holes. Please individually separate one at a time.

- Please be careful not to damage the inside

components when separating.

4. Please connect indoor unit and remote controller using connection cable.

Please check if connector is normally connected.

Connecting cable

Indoor

Unit side

When installing the wired remote controller, do not bury it in the wall.

(It can cause damage in the temperature sensor.)

Do not install the cable to be 50m(164ft) or above.

(It can cause communication error.)

• When installing the extension cable, check the connecting direction of the connector of the remote controller side and the product side for correct installation.

• If you install the extension cable in the opposite direction, the connector will not be connected.

• Specification of extension cable: 2547 1007 22# 2 core 3 shield 5 or above.

CAUTION

12V Red

Signal Yellow

GND Black

Installation Manual 33

Installation

ENGLISH

Installation of Decorative Panel

The decorative panel has its installation direction.

Before installing the decorative panel, always remove the paper template.

1. Remove the packing and take out air inlet

grille from front panel.

2. Remove the Corner covers of the panel.

3. Fit the panel on the unit by inserting

hooks as shown in picture.

4. Insert two screws on diagonal corners of

panel. Do not tighten the bolts

completely. (The fixing screws are

included in the indoor unit box.)

Check the alignment of panel with the

ceiling. Height can be adjusted using

hanging bolts as shown in picture. Insert

the other two screws and tighten all

screws completely.

Front grille

Coner cover

Hook clip

Hook

34 Multi zone

Installation

5. Fit the corner covers.

6. Open two screws of control panel cover.

7. Connect one display connector and two

vane control connectors of front panel to

indoor unit PCB.

The position marking on PCB is as:

Display connector : CN-DISPLAY

Vane control connector: CN-VANE 1,2

8. Close the cover for control box.

9. Install the air inlet grille and Filter on the

panel.

Screw

CN-VANE 1,2

CN-DISPLAY

Installation Manual 35

Installation

ENGLISH

CAUTION:

Cool air leakage causes sweating/condensation.

Ensure panel is sealed properly.

Air conditioner

unit

Ceiling

board

Decorative panel

Decorative

panel

Fit the insulator (this part) and

be careful for cool air leakage

Good example

Air

Cool air leakage

(no good)

Bad example

Ceiling

board

Air conditioner unit

HEAT INSULATION

1. Use the heat insulation material for the refrigerant piping which has an excellent heat-

resistance [over 120°C(248°F)].

2. Precautions in high humidity

circumstance:

This air conditioner has been tested

according to the "KS Standard

Conditions with Mist" and confirmed

that there is not any default. However, if

it is operated for a long time in high

humid atmosphere [dew point

temperature: more than 23°C(73.4°F)],

water drops are liable to fall. In this

case, add heat insulation material

according to the following procedure:

• Heat insulation material to be prepared... Adiabatic glass wool with thickness 10(0.4) to 20

mm(0.8 inch).

• Stick glass wool on all air conditioners that are located in ceiling atmosphere.

Drain Piping

Wall-mounted Type

1. The drain hose should point downward for

optimum drainage.

2. Incorrect Installation Examples:

Downward slope

Do not raise

Accumulated

drain water

Tip of drain hose

dipped in water

Air

Kinking

Water

leakage

Water

leakage

Ditch

Less than 50mm

(1 31/32 inch) gap

Water

leakage

Indoor unit

Fastening band

(accessory)

Refrigerant piping

Thermal insulator

(accessory)

36 Multi zone

Installation

CAUTION : The supplied

flexible drain hose should not

be curved, neither screwed.

The curved or screwed hose

may cause a leakage of water.

[Ceiling Concealed Duct/Ceiling Cassette Type]

• Drain piping must have down-slope (1/50 to 1/100): be

sure not to provide up-and-down slope to prevent

reversal flow.

• During drain piping connection, be careful not to exert

extra force on the drain port on the indoor unit.

• The outside diameter of the drain connection on the

indoor unit is 32mm(1 1/4 inch).

•

Be sure to install heat insulation on the drain piping.

Piping material: Polyvinyl chloride pipe inner

diometes Ø 25mm(1 inch) and pipe fittings

• Connect the main drain pipe to the exterior and

leave it provisionally until the test comes to an

end.

• Feed water to the flexible drain hose and check

the piping for leakage.

• Be sure to check the drain pump for normal

operating and noise when electrical wiring is

complete.

• When the test is complete, connect the flexible

drain hose to the drain port on the indoor unit.

The air conditioner uses a drain pump to drain water.

Use the following procedure to test the drain pump operation:

Heat insulation material: Polyethylene foam

with thickness more than 8mm(5/16 inch).

Drain test

Maintenance

drain port

Upward

routing

not allowed

Pipe clamp

Indoor unit

1/50~1/100

MAX : 700 mm(27 9/16 inch)

Feed water

Drain Pump

Drain pan

Flexible drain hose

(accessory)

Main

drain pipe

Glue the joint

Drain

port

Drain hose connection

Use the clip (accessory)

1/50~1/100

Flexible drain hoseFlexible drain hoseFlexible drain hose

❈ The figure can be changed according to model.

Installation Manual 37

Installation

ENGLISH

Attention

1. Possible drain-head height is up to

700mm(27 9/16 inch). So, it must be

installed below 700mm(27 9/16 inch).

2. Keep the drain hose downward up to

1/50~1/100 inclination.

Ex) length : 100 inch ⇨ height: 1~2 inch.

Prevent any upward flow or reverse flow in

any part.

3. 5mm(3/16 inch) or thicker formed thermal

insulator is provided for the drain pipe.

4. Upward routing is not allowed.

5. Be sure to check the drain pump for normal

operation and abnormal noise when

electrical wiring is complete.

1/50~1/100

MAX 700mm

(27 9/16 inch)

Elbow

Drain pump

Unit

Drain pipe

(Local supply)

Thermal insulator

(Local supply)

Wall

Drain hose

38 Multi zone

Flaring Work and Connection of Piping

Flaring work

Main cause of gas leakage is defect in flaring

work. Carry out correct flaring work in the

following procedure.

1) Cut the pipes and the cable.

■ Use the accessory piping kit or the pipes

purchased locally.

■ Measure the distance between the

indoor and the outdoor unit.

■ Cut the pipes a little longer than

measured distance.

■ Cut the cable 1.5m(4.9ft) longer than the

pipe length.

2) Burrs removal

■ Completely remove all burrs from the cut

cross section of pipe/tube.

■ Put the end of the copper tube/pipe to

downward direction as you remove burrs

in order to avoid to let burrs drop in the

tubing.

3) Putting nut on

■ Remove flare nuts attached to indoor

and outdoor units, than put them on

pipe/tube having completed burr

removal.

(Not possible to put them on after flaring

work)

4) Flaring work

■ Carry out flaring work using flaring tool

as shown below.

Firmly hold copper tube in a bar(or die) as

indicated dimension in the table above.

5) Check

■ Compare the flared work with figure.

■ If flare is noted to be defective, cut off

the flared section and do flaring work

again.

mm inch mm inch

Ø6.35 1/4 1.1~1.3 0.04~0.05

Ø9.52 3/8 1.5~1.7 0.06~0.07

Ø12.7 1/2 1.6~1.8 0.06~0.07

Outside diameter A

Flaring Work and Connection of Piping

Copper

tube

Point down

Bar

Copper pipe

Smooth all round

Even length

all round

Slanted Uneven Rough

90

Pipe

Reamer

Flare nut

Copper tube

Bar

"A"

Clamp handle

Inside is shining without scratches.

Inclined

Red arrow mark

= Improper flaring =

Surface

damaged

Cracked Uneven

Handle

Yoke

Cone

thickness

Installation Manual 39

Flaring Work and Connection of Piping

ENGLISH

Align the center of the piping and sufficiently

tighten the flare nut by hand.

Connecting pipe order

1) A~D-UNIT gas side pipe

2) A~D-UNIT liquid side pipe

Finally, tighten the flare nut with torque wrench

until the wrench clicks.

• When tightening the flare nut with torque

wrench ensure the direction for tightening

follows the arrow on the wrench.

Main gas

side valve

Main liquid

side valve

Gas side piping

Liquid

side piping

A-UNIT

B-UNIT

C-UNIT

D-UNIT

Outdoor unit(36 kBtu/h class)

Connection of piping - Outdoor

Outside diameter Torque

mm inch kgf.m(lbf.ft)

Ø6.35 1/4

1.8~2.5 (13~18)

Ø9.52 3/8

3.4~4.2 (24~30)

Ø12.7 1/2

5.5~6.6 (40~48)

(Only Indoor Units

18 kBtu/h class )

40 Multi zone

Connecting the Cable between Indoor Unit and Outdoor Unit

Connect the cable to the indoor unit by connecting the wires to the terminals on the control

board individually according to the outdoor unit connection. (Ensure that the color of the wires

of the outdoor unit and the terminal No. are the same as those of the indoor unit.)

The ground wire should be longer than the common wires.

The circuit diagram is not subject to change without notice.

When installing, refer to the electrical diagram behind the front panel of Indoor Unit.

The wiring for the outdoor unit can be found on the inside of the Outdoor Unit control cover.

Connect the cable to the Indoor unit.

RECOMMENDATION:

• The circuit diagram is subject to change without notice.

• Be sure to connect wires according to the wiring diagram.

• Connect the wires firmly, so that they can not be pulled out easily.

• Connect the wires according to color codes by referring to the wiring diagram.

RECOMMENDATION:

Provide a

circuit breaker between power

source and the outdoor unit as

shown below.

RECOMMENDATION:

The power cord connected to the outdoor unit should

comply with the following specifications: NRTL Recognized(for example, UL or

ETL recognized and CSA certified).

Line voltage

(208/230V)

GN/YL

20mm

(25/32 inch)

GN/YL

20mm

(25/32 inch)

RECOMMENDATION: When using separate wires as the power cord, please secure

separate wires in the control box panel using tie wraps to hold all wires in place.

■ Power supply cable

■ Connecting cable

The minimum recommended wire size for the 18kBtu/h unit

is AWG 14-3, the minimum wire size for the 24/36kBtu/h

unit is AWG 12-3.

As always, final wire selection is governed by local codes

and should be installed by a licensed professional

contractor.

The power connecting cable between the outdoor and

indoor units must comply with the following specifications:

NRTL Recognized (for example, UL or ETL recognized and

CSA certified).

AWG 18-4 is the minimum recommended wire size,

however, the selected conductors must comply with local

codes and be suitable for installation in wet locations.

Connecting the Cable between Indoor Unit and Outdoor Unit

Outdoor Unit

Capacity

(Btu/h class)

24/36k 1ø,208/230V 25A

Power source

Fuse or breaker

Capacity

Main power source

Air

Conditioner

Circuit Breaker

Use a circuit breaker

or time delay fuse.

Installation Manual 41

Connecting the Cable between Indoor Unit and Outdoor Unit

ENGLISH

Connect the cable to the Outdoor unit.

1. Remove the control cover by removing screws.

Connect the wires to the terminals on the

control board following the diagrams below.

2. Secure the cable onto the control board with the

holder (clamp).

3. Re-attach the cover control to the original

position using the screws.

:

1. Use connection cable NRTL(UL, ETL, CAS…) listed and stranded copper(4) THHN conductors,

sunlight (UV) resistant ROHS compliant PVC jacket 600V direct burial listed, approved for wet

conditions. Temperature rated for –20℃(-4℉) to 90℃(194℉). And this cable should be enclosed

in conduit.

WARNING:

• Be sure to comply with local and national codes while running the wire from the indoor unit to

the outdoor unit(size of wire and wiring method, etc).

• Every wire must be connected firmly.

• No wire should be allowed to touch refrigerant tubing, the compressor or any moving parts.

• The communication wirings of air conditioner should be separate and isolated from external

device’s electric wiring such as computers, elevator, radio & Television broadcasting facilities,

as well as medical imaging offices.

Outdoor unit

Terminal

block

Conduit Ports

Power supply

cable

Connecting cable

(to the indoor unit)

Screw

Cover control

24/36 kBtu/h class

Indoor Unit Terminal Block Indoor Unit Terminal Block

A Unit B Unit

1(L1) 2(L2) 3 1(L1) 2(L2) 3

L1 L2

POWER SUPPLY A UNIT

NOTICE

1(L1) 2(L2) 3(B) 3(A) 1(L1) 2(L2) 3(C) 3(D)

B UNIT

Indoor Unit Terminal Block

C Unit

1(L1) 2(L2) 3

C UNIT

D UNIT

36k Only

Indoor Unit Terminal Block

D Unit

1(L1) 2(L2) 3

IF 3 POLE DISCONNECT IS

REQUIRED INSTALL AT

EACH INDOOR UNIT.

42 Multi zone

Connecting the Cable between Indoor Unit and Outdoor Unit

(1) Remove the side panel and knockouts of conduit

panel. (for low voltage line)

(2) Pull out connection cable through conduit.

(3) After conduit to the panel, fix nut to the opposite

side of panel.

(4) Pass the connection cabel through the hole.

(5) Properly connect the cable on the terminal block.

(6) Fix the connection cable with cord clamp

provided on the unit not to have strain at the

terminal when the connection cable is pulled

outside up to a 35 pound weight

WARNING: Loose wiring may cause

the terminal to overheat or result in

unit malfunction. A fire hazard may

also exist. Therefore, be sure all

wiring is tightly connected.

When connecting each power wire to the

corresponding terminal, follow instructions "How

to connect wiring to the terminals" and fasten the

wire tightly with the fixing screw of the terminal

plate.

How to connect wiring to the terminals

◼ For strand wiring

(1) Cut the wire end with a wire cutter or wire-

cutting pliers, then strip the insulation to

expose the strand wiring about 10 mm(3/8").

(2) Using a screwdriver, remove the terminal

screw(s) on the terminal plate.

(3) Using a round terminal fastener or pliers,

securely clamp each stripped wire end with a

round terminal.

(4) Position the round terminal wire, and replace

and tighten the terminal screw using a

screwdriver.

Connection method of the connecting cable(Example)

Power supply cable

Connecting Cable

Strip 10 mm(3/8")

Round

terminal

Connecting cable

Loosening the

terminal block

screw

Fastening the

wire tightly

Strand wire

Terminal

block

Side panel

Cord clamp

Conduit hole

Power supply cable

(1Ø, 208/230V)

Connecting cable

(1Ø, 208/230V)

Taping

(for sealing)

Lock nut

(field supply)

Conduit

(field supply)

Conduit panel

Indoor Unit A

Indoor Unit B

Indoor Unit C

Indoor Unit D

Installation Manual 43

Checking the Drainage, Insulating the Pipe and Special Piping Applications

ENGLISH

Insulating the Pipe and Special Piping Applications

Insulate the piping by wrapping the

connecting portion of the indoor unit

with insulation material and secure it

with two kinds of vinyl tape.

• If you want to connect an additional drain

hose, the end of the drain outlet should be

routed above the ground. Secure the drain

hose appropriately.

In cases where the outdoor unit is

installed below the indoor unit

perform the following:

1. Tape the piping, drain hose and connecting

cable from down to up.

2. Secure the taped piping along the exterior

wall using saddle or equivalent.

In cases where the Outdoor unit is

installed above the Indoor unit

perform the following.

1. Tape the piping and connecting cable from

down to up.

2. Secure the taped piping along the exterior

wall. Form a trap to prevent water entering

the room.

3. Secure the piping onto the wall using a

saddle or equivalent.

Plastic

band

Taping

Drain hose

Pipings

Seal a small

opening around

the pipings with

gum type sealant.

Seal a small opening

around the pipings

with gum type sealant.

Trap

Trap

1. Remove the Air Filter.

2. Check the drainage.

• Spray one or two glasses of water upon the

evaporator.

• Ensure that water flows drain hose of indoor

unit without any leakage.

❈ The figure can be changed according to model.

Checking the drainage

Checking the Drainage, Insulating the Pipe and Special Piping Applications

44 Multi zone

Long Pipe Setting

Extended line length setting

1

SW01N

234

1. Open the top cover of outdoor unit.

2. Select one of the two selectable modes as follows.

3. Set the Zone as shown in Fig.

4. Close the top cover and check whether the product works normally.

WARNING: Do not open the top cover or Set the pipe length when

operating the product.

Installation Manual 45

Air Purging and Evacuation

ENGLISH

Air and moisture remaining in the refrigerant system have undesirable effects as indicated below.

1. Pressure in the system rises.

2. Operating current rises.

3. Cooling(or heating) efficiency drops.

4. Moisture in the refrigerant circuit may freeze and block capillary tubing.

5. Water may lead to corrosion of parts in the refrigeration system.

Therefore, the indoor/outdoor unit and connecting tube must be checked for leaks, and vacuumed

to remove incondensible gas and moisture in the system.

Preparation

• Check that each tube(both liquid and gas side

tubes) between the indoor and outdoor units have

been properly connected and all wiring for the test

run has been completed. Remove the service

valve caps from both the gas and the liquid sides

on the outdoor unit. Check that both the liquid and

the gas side service valves on the outdoor unit

are kept closed at this stage.

Leakage test

• Connect the manifold valve(with pressure gauges)

and dry nitrogen gas cylinder to this service port

with charge hoses.

CAUTION: Be sure to use a

manifold valve for leak testing.

The high side manifold valve must

always be kept closed.

• Pressurize the system to no more than 550

P.S.I.G. with dry nitrogen gas and close the

cylinder valve when the gauge reading

reached 550 P.S.I.G. Next, test for leaks with

liquid soap.

CAUTION:

To avoid nitrogen

entering the refrigerant system in a

liquid state, the top of the cylinder must be

higher than its bottom when you

pressurize the system. Usually, the cylinder

is used in a vertical standing position.

:

Leakage testing shoud be done

for each indoor unit connection set,

separately.

1. Do a leakage test of all joints of the

tubing(both indoor and outdoor) and both gas

and liquid side service valves with soap

bubbles.

Bubbles indicate a leak. Be sure to wipe off

the soap with a clean cloth.

2. After the system is found to be free of leaks,

relieve the nitrogen pressure by loosening

the charge hose connector at the nitrogen

cylinder. When the system pressure is

reduced to normal, disconnect the hose from

the cylinder.

Leak Checking

❈ The figure can be changed according to model.

Air Purging and Evacuation

NOTICE

Outdoor unit

Manifold valve

Pressure

gauge

Indoor unit

Lo Hi

Charge hose

Nitrogen gas

cylinder(in vertical

standing position)

46 Multi zone

Air Purging and Evacuation

1. Connect the charge hose end described in

the preceding steps to the vacuum pump to

evacuate the tubing and indoor unit.

Confirm the "Lo" knob of the manifold valve is

open. Then, run the vacuum pump.

The operation time for evacuation varies with

tubing length and capacity of the pump.

[Each Room] The vacuum pump must be

operated less than 0.8torr of the gage

pressure.

2. When the desired vacuum is reached, close

the "Lo" knob of the manifold valve and stop

the vacuum pump.

Finishing the job

1. With a service valve wrench, turn the valve

stem of liquid side valve counter-clockwise to

fully open the valve.

2. Turn the valve stem of gas side valve

counter-clockwise to fully open the valve.

3. Loosen the charge hose connected to the

gas side service port slightly to release the

pressure, then remove the hose.

4. Replace the flare nut and its bonnet on the

gas side service port and fasten the flare nut

securely with an adjustable wrench. This

process is very important to prevent leakage

from the system.

5. Replace the valve caps at both gas and liquid

side service valves and fasten them tight.

This completes air purging with a vacuum

pump.

The air conditioner is now ready for test

running.

: Repeat evacuation procedure for each

indoor unit.

NOTICE

Indoor unit

Outdoor unit

Lo Hi

Manifold valve

Vacuum pump

Pressure

gauge

Open

Close

Evacuation

❈ The figure can be changed according to model.

Installation Manual 47

Charging

ENGLISH

Important:

If you are ever uncertain of the unit charge, reclaim, evacuate and weigh in the correct charge

using the charge amount specified on the Unit`s specification label.

Additional charge(oz ) = (Total Installation Piping Length-Standard Total Piping Length) x 0.22

Charging

■ If installed total piping length is more than standard total length, additional refrigerant charging is

necessary.

Below standard total piping length, additional refrigerant charging is not required.

24k 75(246) 25(82) 3(9.8) 20(0.22) 22.5(74)

36k 75(246) 25(82) 3(9.8) 20(0.22) 30(98.4)

Outdoor Unit

Capacity (Btu/h

class)

Max total length of all

pipes (A+B)/(A+B+C)/

(A+B+C+D)

Max length of each

pipe (A/B/C/D)

Min length of each

pipe (A/B/C/D)

Additional Refrigerant

Unit : g/m (oz/ft)

Standard Total Piping

Length (No Add`l

refrigerant)

Unit:m(ft)

❈ If the total additional charge value after calculation comes out to be negative, then do not

consider additional charge.

Each branch pipe

a=82ft

b=16ft

c=49ft

Additional Charge

= {(82+16+49)-98.4} x 0.22 = 10.69 oz

a

b

c

9k

9k

9k

EX) MR36TQY3JM

48 Multi zone

Manuel d'installation

TYPE : Multi zone

FRANÇAIS

IMPORTANT!

Veuillez lire ces instructions au complet avant d’installer ce produit.

ATTENTION:

Mesures de sécurité

REMARQUE POUR L’INSTALLEUR :

Lors du câblage :

Lors du transport :

Lors de l’installation...

Lors de la connexion de la tuyauterie de réfrigération

Lors de la réparation

Ce système de climatisation réunit strictement les standards de sécurité et de fonctionnement. En tant qu’installeur ou technicien spécialisé, une partie

importante de votre travail consiste à installer et à réaliser le service technique de ce système d’une manière telle qu’il fonctionne de façon sûre et

efficiente.

Un défaut d’installation, du service technique ou dans l’entretien, et une réparation ou une modification

inappropriées peuvent annuler la garantie.

Le poids de l’unité de condensation exige des précautions et des procédures de manipulation appropriées au

moment de déposer ou déplacer l’unité afin d’éviter des blessures personnelles. Veillez à éviter également le

contact avec les bords pointus ou aiguisés.

Un choc électrique peut provoquer des blessures personnelles graves, voire la mort.

Seulement un électricien qualifié et expérimenté doit réaliser le câblage du système.

• Utilisez toujours des protections de sécurité pour les yeux et des gants de travail lors de l’installation de l’appareil.

• Assurez-vous toujours que l’alimentation soit coupée. Vérifiez-le à l’aide des dispositifs et des instruments appropriés.

• Gardez les mains loin du ventilateur lorsque l’appareil est branché.

• Le R410A provoque des gelures.

• Le R410A est toxique lorsqu’il est brûlé.

• Ne mettez pas l’unité sous tension jusqu’à ce que tout le câblage et le drainage soient complétés ou rebranchés et vérifiés.

• Des voltages électriques très dangereux sont utilisés dans ce système. Lisez avec soin le diagramme de câblage et ces instructions lors du

câblage. Des connexions inappropriées et une mise à la terre incorrecte peuvent provoquer des blessures, voire la mort.

• Mettez l’unité à la terre suivant les codes électriques locaux.

• Serrez bien les câbles. Un câble mal serré peut provoquer la surchauffe des points de connexion et constitue un risque d’incendie.

• Gardez tous les drainages les plus courts possible.

• Utilisez la méthode d’évasement pour raccorder les tuyaux.

• Vérifiez soigneusement s’il y a des pertes avant de commencer le drainage d’essai.

• Coupez l’alimentation principale (dans le tableau d’alimentation principale) avant d’ouvrir l’unité pour vérifier ou réparer les pièces et les

câbles électriques.

• Eloignez vos doigts et vos vêtements de toutes les pièces mobiles.

• Nettoyez le secteur après avoir fini. Assurez-vous qu’il n’y ait pas de tournure de fer ni de morceaux de câbles à l’intérieur de l’unité réparée.

Levez et transportez avec soin les unités intérieure et extérieure.

Cherchez de l’aide pour le faire et fléchissez vos genoux pour le déposer afin d’éviter l’effort de votre dos. Les bords aiguisés ou les rebords

tranchants d’aluminium du climatiseur peuvent vous couper les doigts.

...dans un mur : assurez-vous que le mur soit assez fort pour supporter le poids de l’unité.

Il peut être nécessaire de construire un cadre en bois ou en métal afin d’assurer un support supplémentaire.