Page 1

WALK-IN VAN

CHASSIS

STI-471-6

A24-01451-000

Operator’s Manual

Page 2

Introduction

This manual provides information needed to operate

and understand the chassis and its components.

More detailed information is contained in the Owner’s

Warranty Information for North America booklet, and

in the vehicle’s workshop and maintenance manuals.

Freightliner chassis are equipped with various chassis and cab components. Not all of the information

contained in this manual applies to every chassis. If

parts on your chassis differ from those shown, they

may have been installed by the body builder.

The safety or performance of your vehicle could be

adversely affected by the installation of nonstandard

components. Note the limitations and specifications

provided in the vehicle and chassis manuals, and

consult your selling dealer before making any alterations to the vehicle or chassis.

For your reference, keep this manual in the vehicle

at all times.

IMPORTANT: Descriptions and specifications in

this manual were in effect at the time of printing.

Freightliner Custom Chassis Corporation reserves the right to discontinue models and to

change specifications or design at any time

without notice and without incurring obligation.

Descriptions and specifications contained in this

publication provide no warranty, expressed or

implied, and are subject to revisions and editions without notice.

Environmental Concerns and

Recommendations

Whenever you see instructions in this manual to discard materials, you should first attempt to reclaim

and recycle them. To preserve our environment, follow appropriate environmental rules and regulations

when disposing of materials.

Event Data Recorder

This vehicle is equipped with one or more devices

that record specific vehicle data. The type and

amount of data recorded varies depending on how

the vehicle is equipped (such as the brand of engine,

if an air bag is installed, or if the vehicle features a

collision avoidance system, etc.).

This vehicle is equipped with an event data recorder

(EDR). The main purpose of an EDR is to record

data in certain crash or near-crash situations, such

as air bag deployment or hitting a road obstacle, that

will assist in understanding how a vehicle’s systems

performed. The EDR is designed to record data related to vehicle dynamics and safety systems for approximately 60 seconds. This data can help provide

a better understanding of the circumstances in which

crashes and injuries occur. Data recorded includes

the following items:

•

how various systems in the vehicle were operating

•

engine system information

•

how far (if at all) the driver was depressing the

accelerator

•

if the driver was depressing the brake pedal

•

how fast the vehicle was traveling

NOTE: Data is not recorded by the EDR under

normal driving conditions. Personal data such

as name, gender, age, and crash location are

not recorded. However, other parties such as

law enforcement could combine the EDR data

with the type of personally identifying data routinely acquired during a crash investigation.

To read data recorded by an EDR, special equipment

is required, and access to the vehicle or the EDR is

needed. In addition to the vehicle manufacturer, other

parties that have the special equipment, such as law

enforcement, can read the information if they have

access to the vehicle or the EDR.

Emissions and Fuel Efficiency

Compliance

This vehicle must be regularly inspected and maintained as indicated in the Walk-In Van Chassis Main-

tenance Manual, and in the Pre- and Post-Trip Inspections and Maintenance chapter in this manual, in

order to continue satisfactory performance and ensure coverage of the vehicle under the manufacturer’s warranty. Many maintenance procedures ensure

that the vehicle and engine continue to comply with

applicable emissions standards. Maintenance procedures, using components engineered to comply with

greenhouse gas emissions and fuel efficiency regulations, may be performed by an authorized Daimler

Foreword

STI-471-6 (11/15)

A24-01451-000

Printed in U.S.A.

Page 3

Trucks North America dealer, an independent outlet,

or the vehicle owner or operator.

The vehicle owner is responsible for determining the

suitability of replacement components to maintain

compliance with federal and local jurisdictional regulations. Components including, but not limited to, lowrolling resistance tires are specifically designed and

manufactured to exacting standards for regulatory

fuel efficiency and greenhouse gas emissions compliance. It is important that these components are always replaced with components that meet or exceed

the performance of the originally installed components.

Customer Assistance Center

Having trouble finding service? Call the Customer

Assistance Center at 1-800-385-4357 or 1-800-FTLHELP. Call night or day, weekdays or weekends, for

dealer referral, vehicle information, breakdown coordination, or Fleetpack assistance. Our people are

knowledgeable, professional, and committed to following through to help you keep your vehicle moving.

Please visit

www.Daimler-

TrucksNorthAmerica.com

.

Reporting Safety Defects

If you believe that your vehicle has a defect which

could cause a crash or could cause injury or

death, you should immediately inform the National

Highway Traffic Safety Administration (NHTSA) in

addition to notifying Freightliner Custom Chassis

Corporation.

If the NHTSA receives similar complaints, it may

open an investigation, and if it finds that a safety

defect exists in a group of vehicles, it may order a

recall and remedy campaign. However, NHTSA

cannot become involved in individual problems

between you, your dealer, or Freightliner Custom

Chassis Corporation.

To contact NHTSA, you may call the Vehicle

Safety Hotline toll-free at 1-888-327-4236 (TTY:

1-800-424-9153); go to

www.safercar.gov;or

write to: Administrator, NHTSA, 1200 New Jersey

Avenue, SE, Washington, DC 20590. You can also

obtain other information about motor vehicle safety

from

www.safercar.gov.

Canadian customers who wish to report a safetyrelated defect to Transport Canada, Defect Investigations and Recalls, may telephone the toll-free

hotline 1-800-333-0510, or contact Transport

Canada by mail at: Transport Canada, ASFAD,

Place de Ville Tower C, 330 Sparks Street, Ottawa, Ontario, Canada K1A 0N5.

For additional road safety information, please visit

the Road Safety website at:

www.tc.gc.ca/

roadsafety

.

© 1997–2016 Daimler Trucks North America LLC. All rights reserved. Daimler Trucks North America LLC is a Daimler

company.

No part of this publication, in whole or part, may be translated, reproduced, stored in a retrieval system, or transmitted

in any form by any means, electronic, mechanical, photocopying, recording, or otherwise, without the prior written permission of Daimler Trucks North America LLC. For additional information, please contact Daimler Trucks North

America LLC, Service Systems and Documentation, P.O. Box 3849, Portland OR 97208-3849 U.S.A. or refer to

www.Daimler-TrucksNorthAmerica.comand www.FreightlinerTrucks.com.

Foreword

Page 4

Contents

Chapter Page

Introduction, Environmental Concerns and Recommendations,

Event Data Recorder, Emissions and Fuel Efficiency Compliance,

Customer Assistance Center, Reporting Safety Defects .................... Foreword

1 Vehicle Identification ...................................................... 1.1

2 Instruments ............................................................. 2.1

3 Controls ................................................................ 3.1

4 Engines ................................................................ 4.1

5 Transmissions ........................................................... 5.1

6 Steering System ......................................................... 6.1

7 Hydraulic and Air Brake Systems ........................................... 7.1

8 Compressed Natural Gas Fuel System ....................................... 8.1

9 Hybrid Electric Vehicle .................................................... 9.1

10 Pre- and Post-Trip Checklists ............................................. 10.1

11 Pre- and Post-Trip Inspections and Maintenance .............................. 11.1

12 Cleaning and Care ...................................................... 12.1

13 In an Emergency ....................................................... 13.1

14 Towing ................................................................ 14.1

15 GM Gasoline Engine .................................................... 15.1

16 Hydraulic Hybrid ........................................................ 16.1

17 Propane Fuel System .................................................... 17.1

18 Specifications .......................................................... 18.1

Index .................................................................. I.1

Page 5

1

Vehicle Identification

Component Information Label ....................................................... 1.1

Vehicle Identification Number (VIN) .................................................. 1.1

Emissions Labels ................................................................. 1.1

Page 6

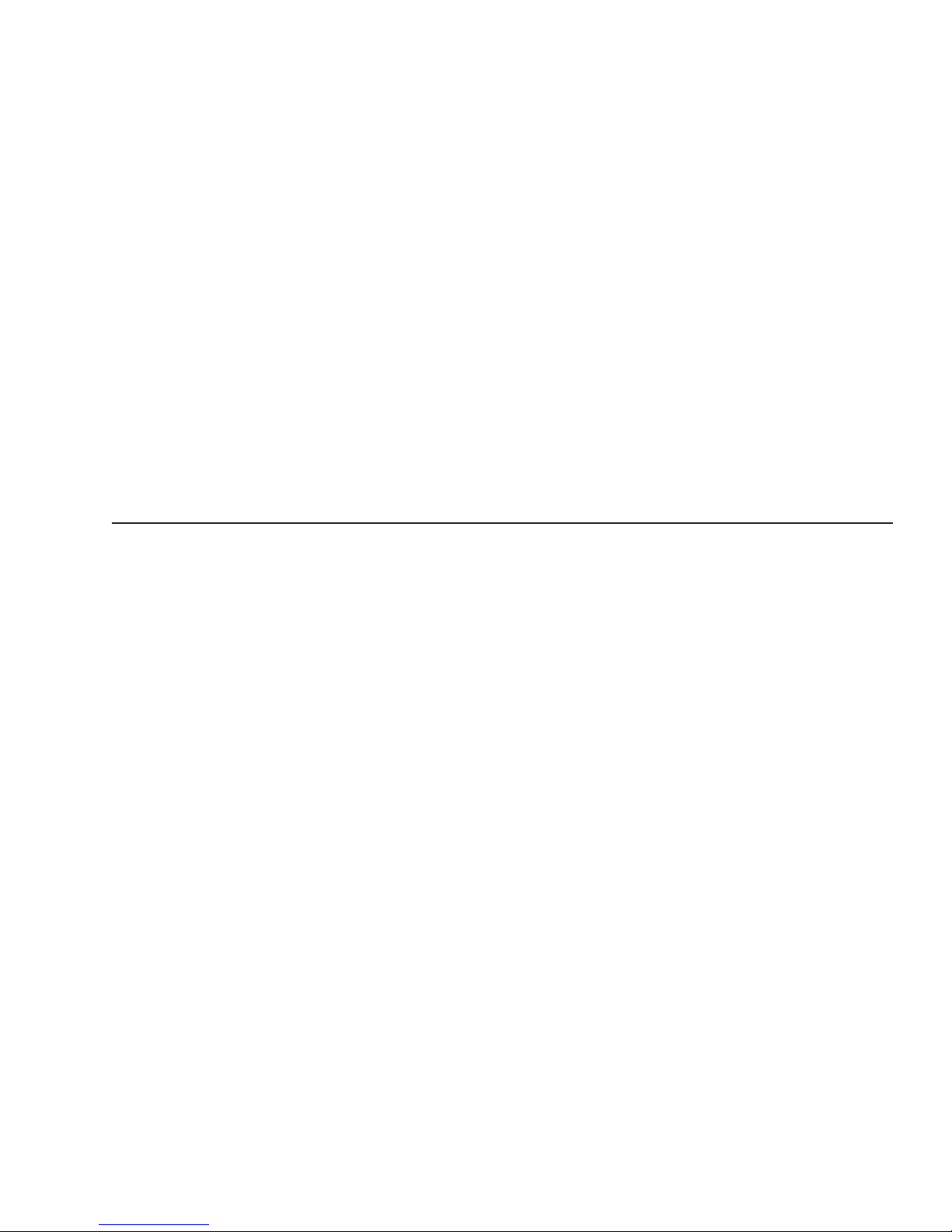

Component Information Label

NOTE: Labels shown in this chapter are examples only. Actual specifications may vary from

vehicle to vehicle.

The component information label lists the manufacturer, month and year of manufacture, vehicle identification number (VIN), gross vehicle weight rating

(GVWR), front and rear gross axle weight ratings

(GAWR), and tire and wheel information. It also indicates if the vehicle has been certified as compliant

with Federal Motor Vehicle Safety Standard

(FMVSS). See

Fig. 1.1.

The tire and rim portion of the component information

label certifies suitable tire and rim combinations that

can be installed on the vehicle for the given gross

axle weight rating. Tires and rims installed on the

vehicle at the time of manufacture may have a higher

load capacity than that certified by the tire and rim

label. If the tires and rims currently on the vehicle

have a lower load capacity than that shown on the

tire and rim label, then the tires and rims determine

the load limitations on each of the axles.

Incomplete vehicles intended for service in the U.S.

have an incomplete vehicle certification label attached by the final-stage manufacturer. This label will

be attached to the incomplete vehicle document included with the vehicle, and certifies that the vehicle

conforms to all applicable FMVSS regulations in effect on the date of completion.

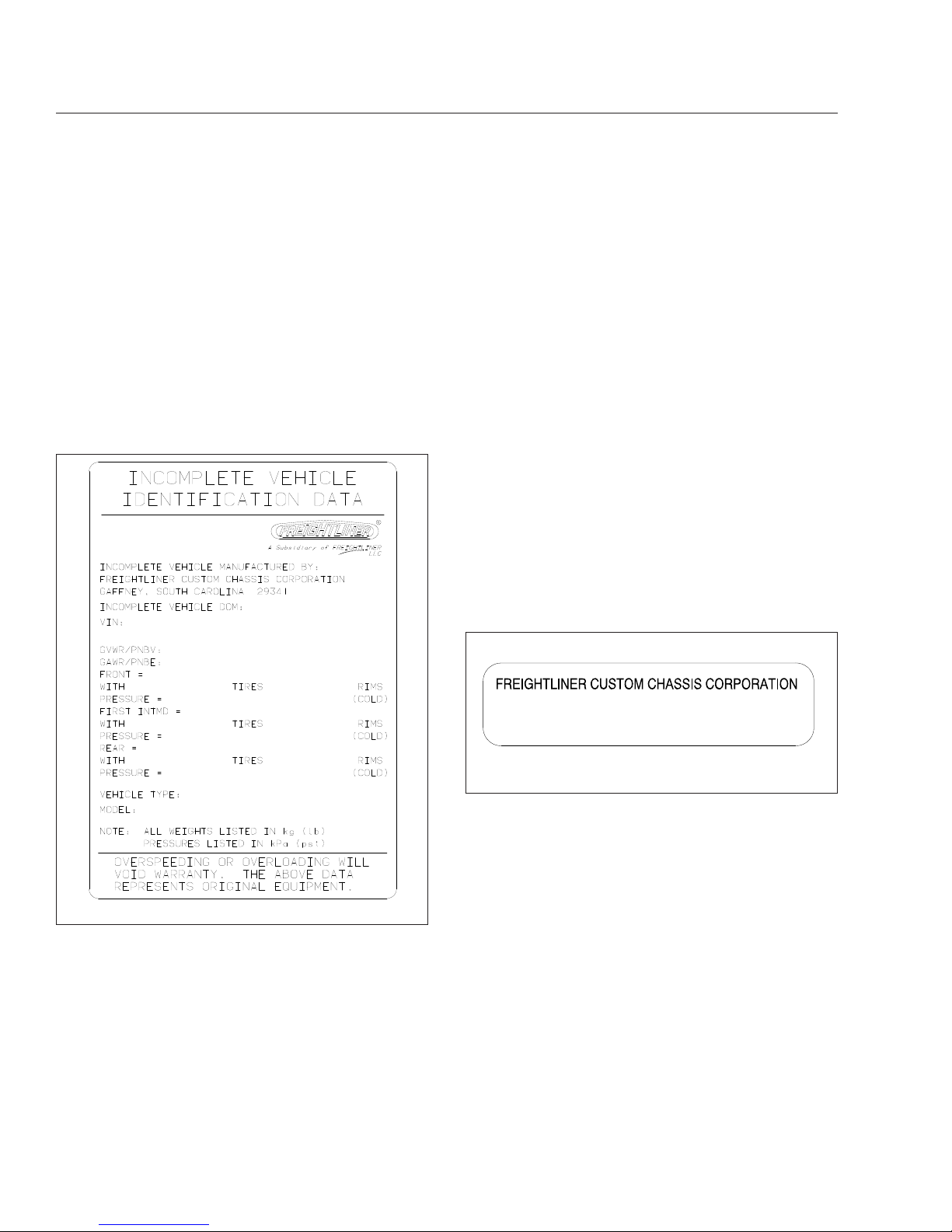

Vehicle Identification Number

(VIN)

The chassis vehicle identification number is permanently attached to the chassis in the engine compartment (depending on vehicle options, usually on the

metal panel where the steering driveline enters the

engine compartment). See

Fig. 1.2. The last six dig-

its are the chassis serial number. The chassis number is stamped on the left frame rail, over the front

axle. A VIN label is also mounted by the body

builder. Mounting locations vary, to include the glove

box. See

Fig. 1.3.

NOTE: Always include the chassis serial number (last six digits of the VIN) when communicating with Daimler Trucks North America.

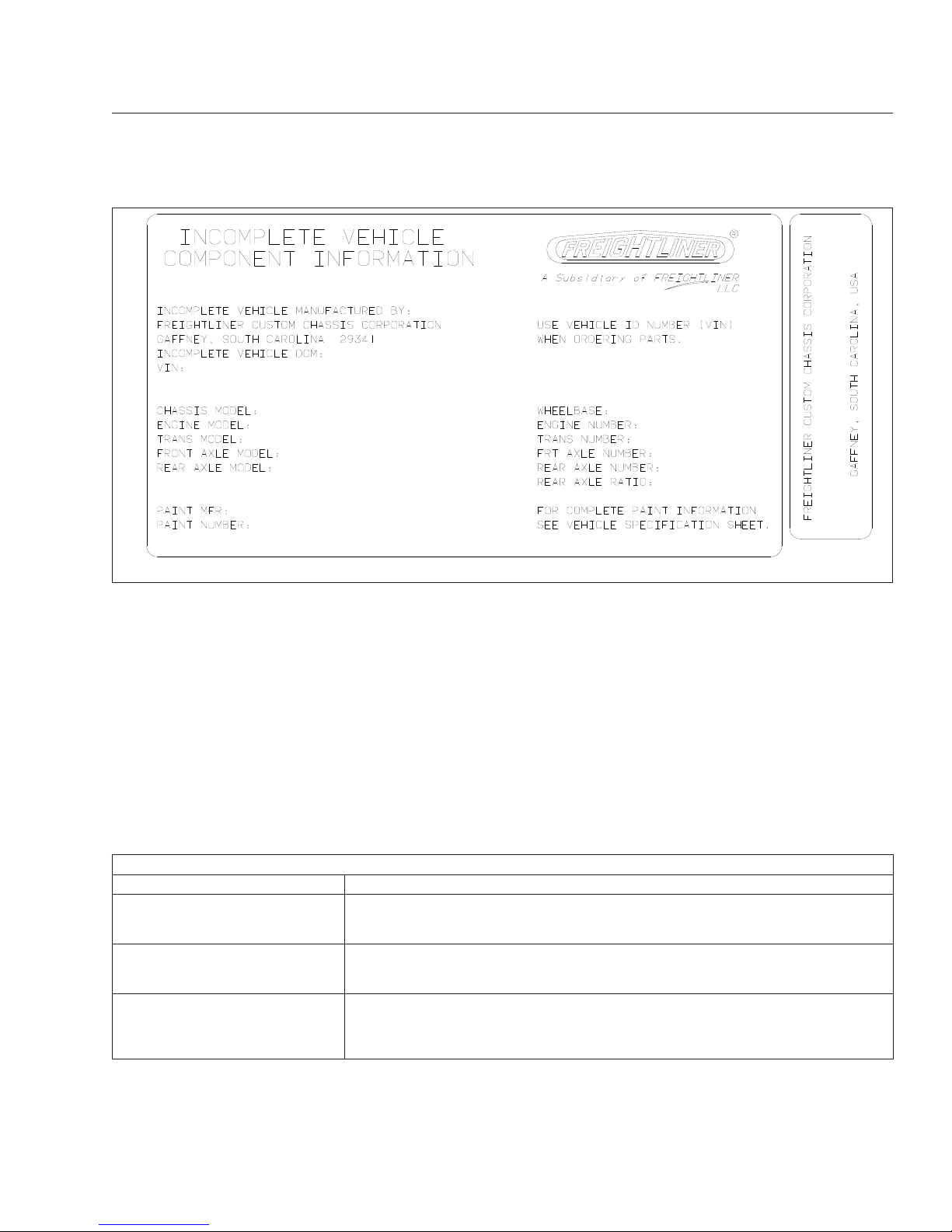

Emissions Labels

Aftertreatment System Indicators

Label

Engines and vehicles manufactured after December

31, 2006 and domiciled in the U.S. or Canada are

required to meet all EPA regulations effective as of

the vehicle build date, and are equipped with an

emission aftertreatment system (ATS). Vehicles domiciled outside of the U.S. and Canada may not

09/11/2002 f080123

Fig. 1.1, Component Information Label

GAFFNEY, SOUTH CAROLINA, USA

4UZA4FVC0TC748531

f080061a

04/18/2005

Fig. 1.2, Vehicle Identification Number (VIN) Label

Vehicle Identification

1.1

Page 7

have aftertreatment equipment, depending upon local

statutory emissions guidelines. See Table 1.1.

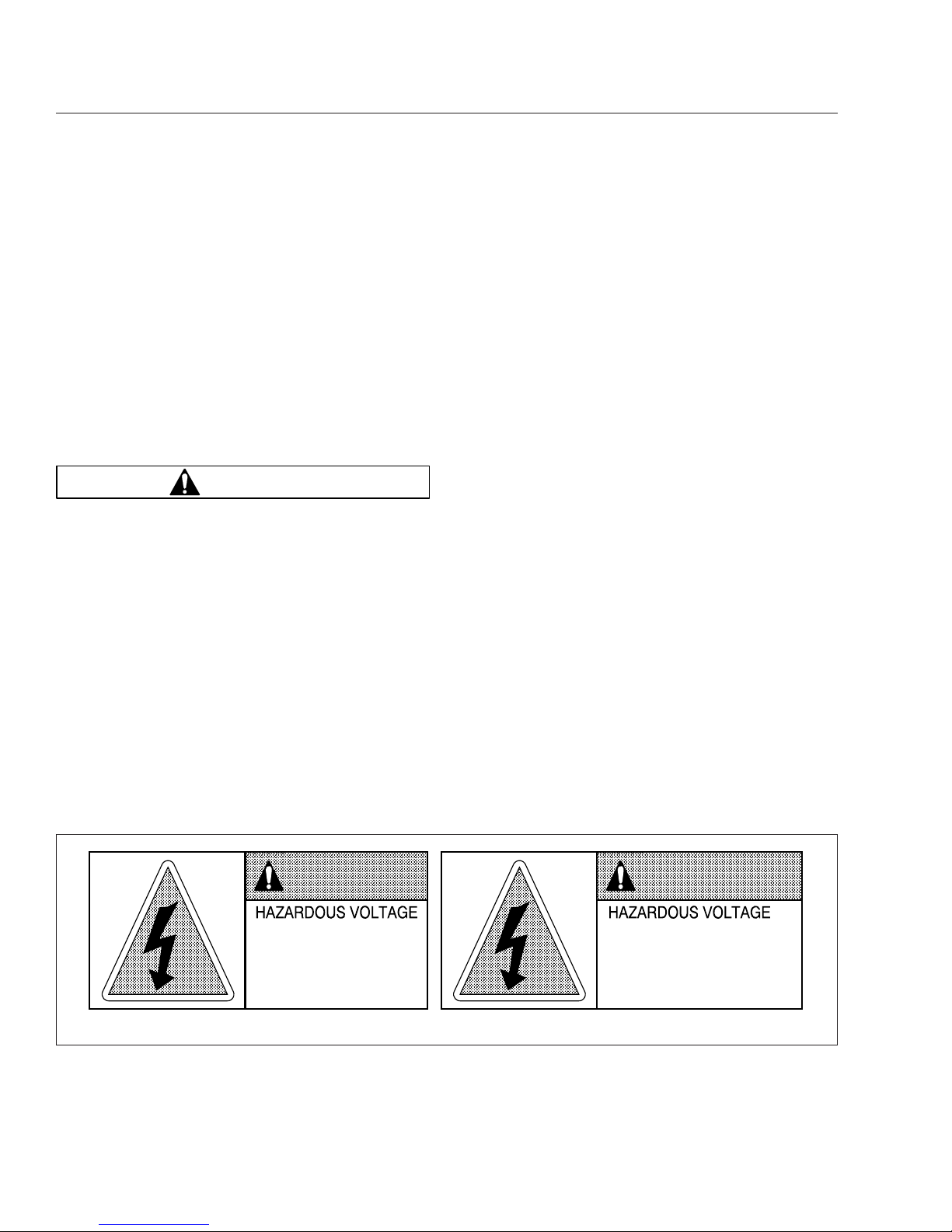

A reference label included with the driver’s documentation package contains important warning indicators

in the instrument cluster that pertain to the ATS. See

Fig. 1.4.

It is a violation of U.S. federal law to alter exhaust

plumbing, ATS, or other components in any way that

would bring the engine/vehicle out of compliance with

certification requirements [Ref: 42 U.S.C. S7522(a)

(3)]. It is the owner’s responsibility to maintain the

vehicle so that it conforms to EPA regulations.

Vehicle Emission Control Information

Label

Model year 2013 and later vehicles meet additional

requirements as specified by federal greenhouse gas

and fuel efficiency regulations (GHG14). Model year

2017 and later vehicles meet similar requirements as

specified by GHG17 requirements. These vehicles

are equipped with components that increase fuel efficiency and reduce GHG emissions. Components

may include, but are not limited to, low-rolling resistance tires.

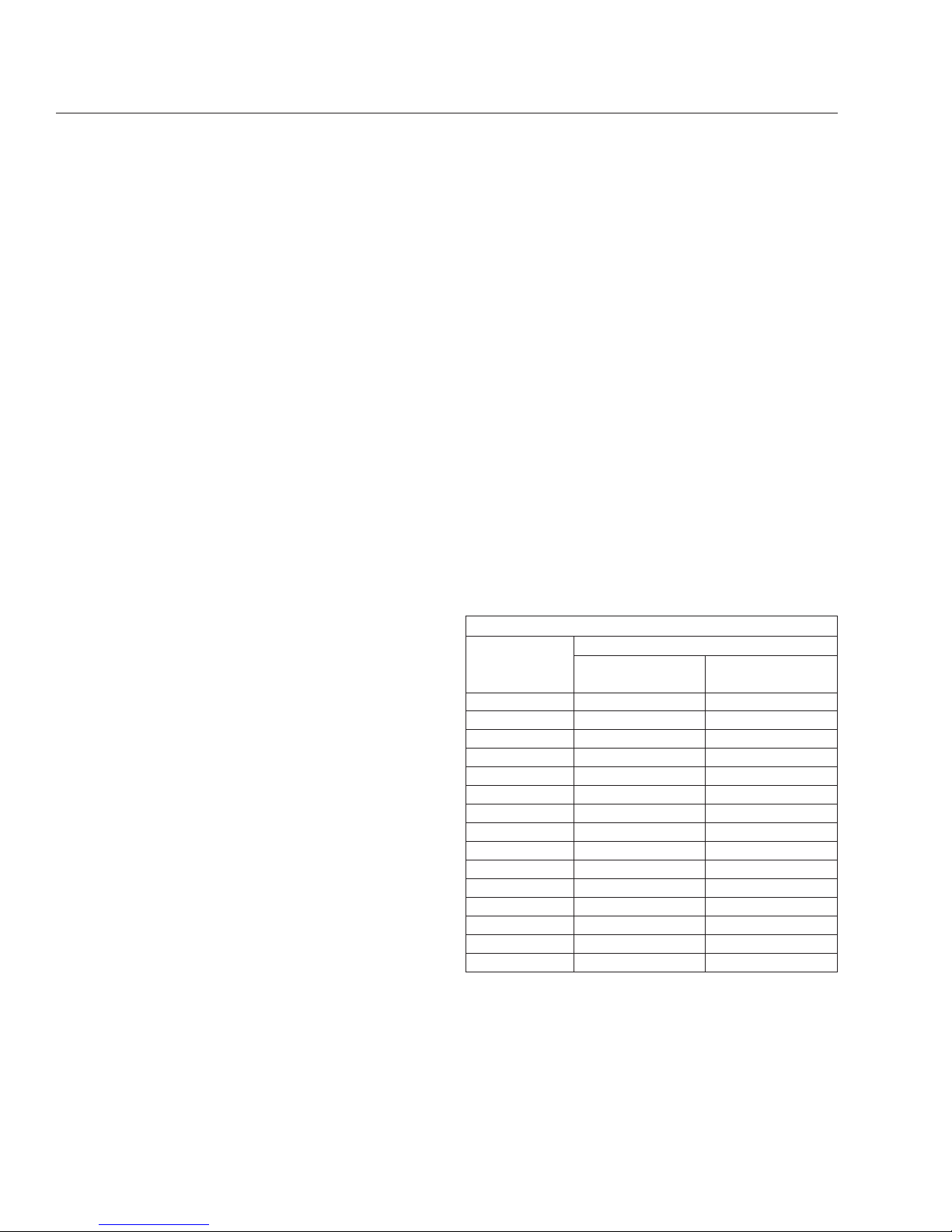

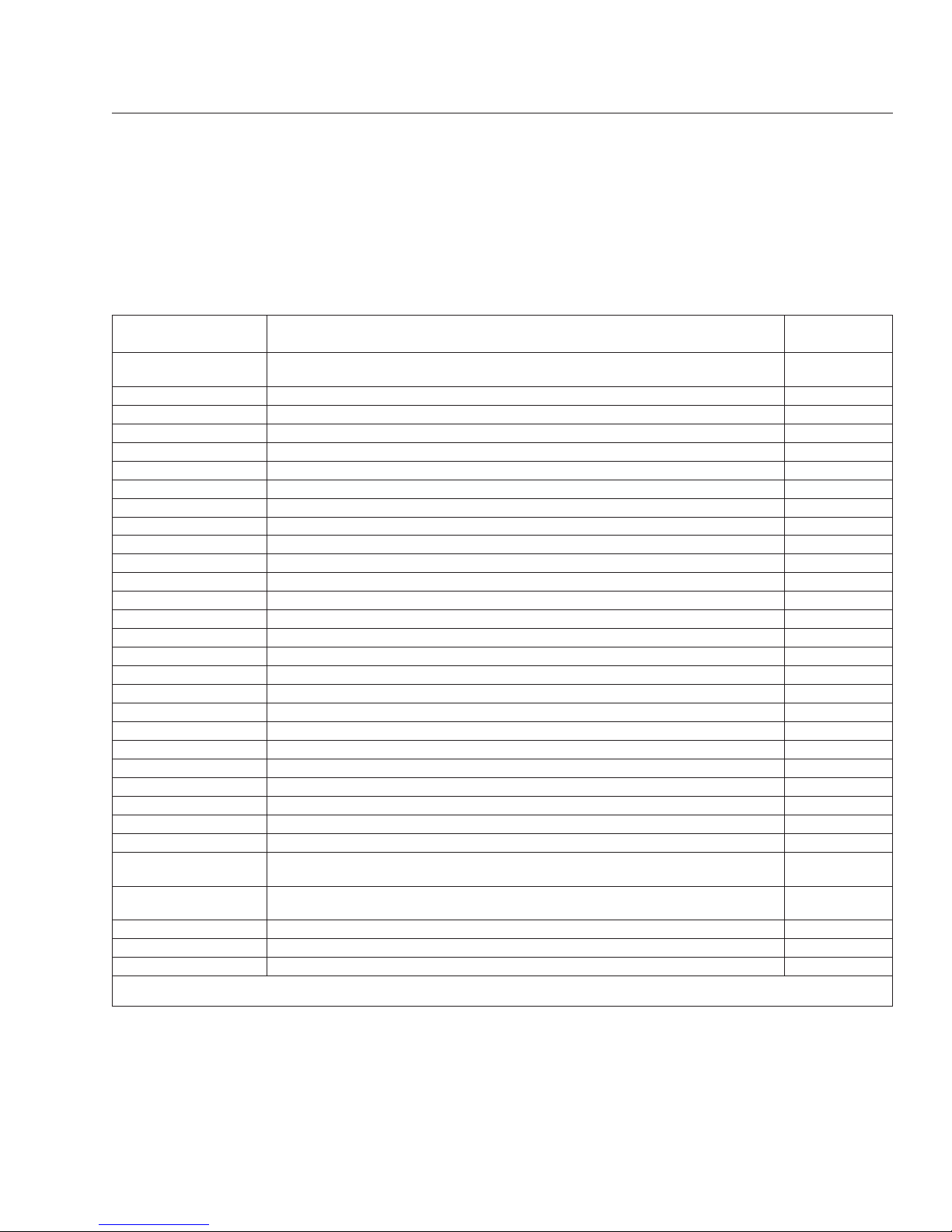

Applicable Emissions System Based on Build Date and EPA Regulations

Build Date Regulation: Emissions Components

January 1, 2007–December 31,

2009

EPA07 (reduce nitrogen oxides (NOx) emissions to 1.1 g/bhp-hr, and reduce

particulate matter emissions to 0.01 g/bhp-hr): Aftertreatment device (ATD) containing

a diesel particulate filter that traps soot and ash.

*

January 1, 2010–December 31,

2012

EPA10 (reduce NOx emissions to 0.2 g/bhp-hr): EPA07-type ATD, with additional

selective catalyst reduction (SCR) technology that utilizes diesel exhaust fluid (DEF)

to convert NOx to nitrogen and water vapor.

From March 5, 2012–December

31, 2015

GHG14: Aerodynamic and fuel efficiency components including, but not limited to,

tires, cab/sleeper side extenders, chassis fairings, bumper, hood, vehicle speed

limiters, and idle reduction timers specifically designed to meet regulatory fuel

efficiency and greenhouse gas emissions standards.

12/04/2001

f080122

Fig. 1.3, Vehicle Identification Number Label, Typical

Vehicle Identification

1.2

Page 8

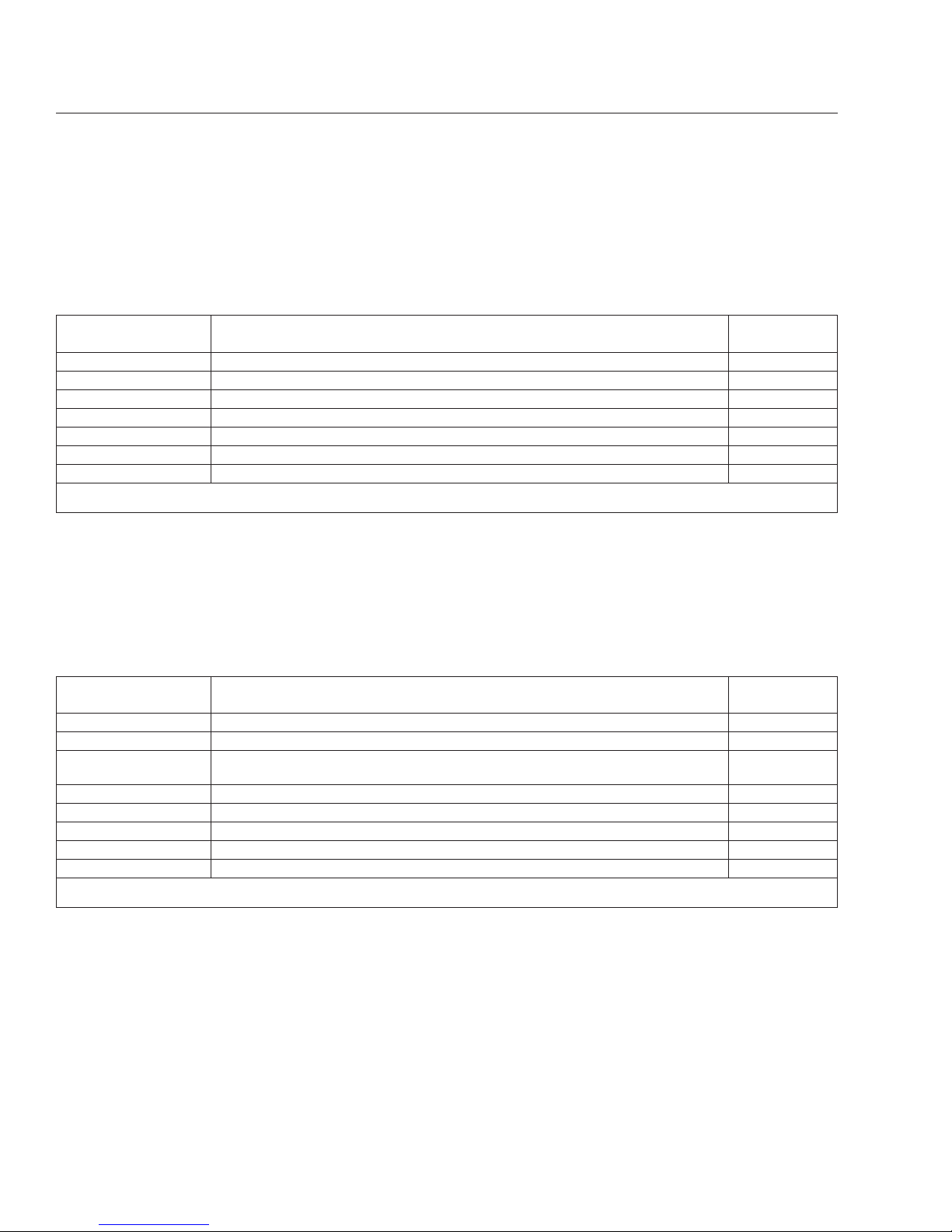

Applicable Emissions System Based on Build Date and EPA Regulations

Build Date Regulation: Emissions Components

From January 1, 2016

GHG17: GHG14 components plus OBD16 instrumentation and sensor upgrades, and

component technology that meets NHTSA and EPA 2017 fuel efficiency and

greenhouse gas emission standards (GHG17) requirements.

*

Cummins, Detroit, and Mercedes-Benz ATD’s are also equipped with a diesel oxidation catalyst to break down pollutants.

Table 1.1, Applicable Emissions System Based on Build Date and EPA Regulations

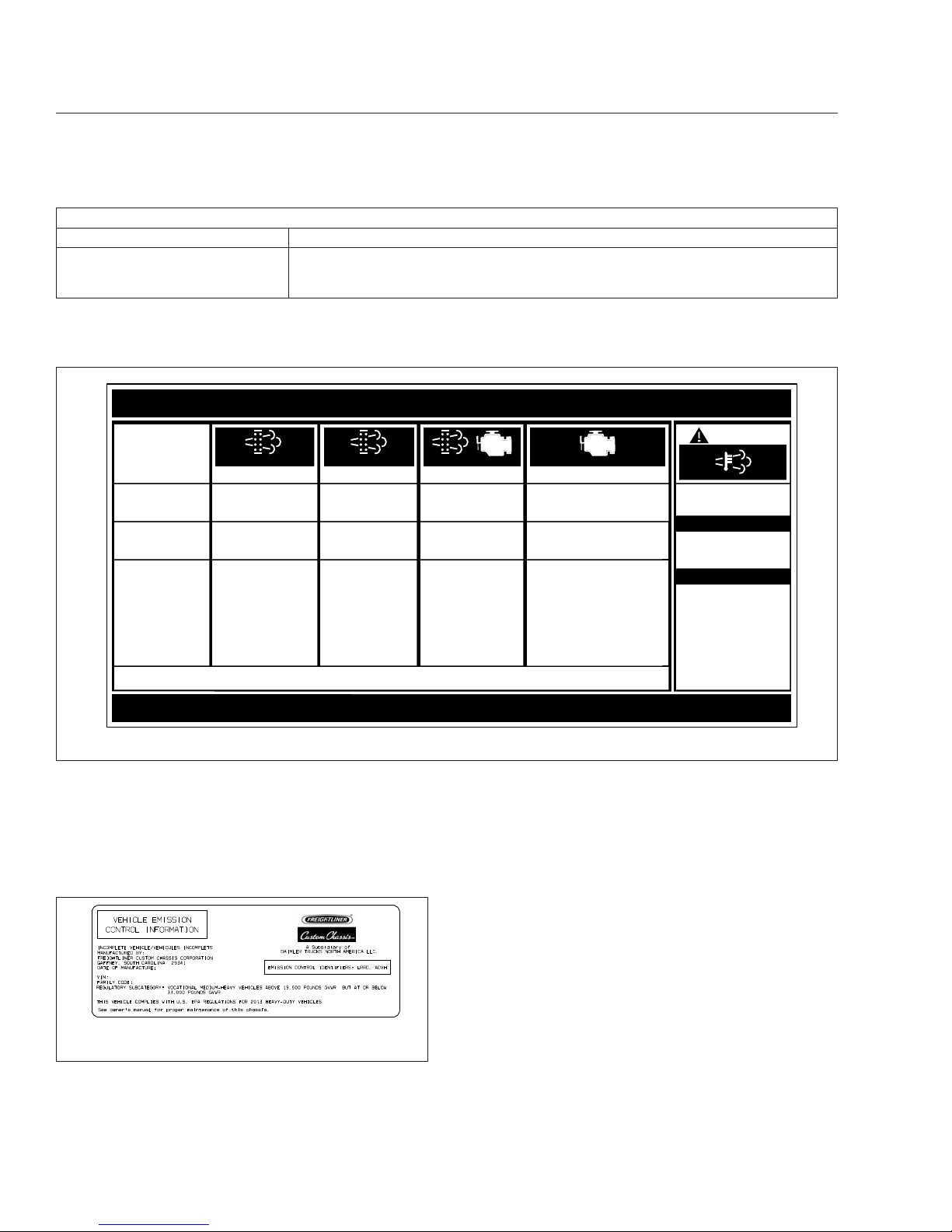

A Vehicle Emission Control Information Label indicates compliance with GHG14 regulations. See

Fig. 1.5. It is the owner’s responsibility to maintain

the vehicle so that it conforms to EPA and NHTSA

regulations.

Certified Clean Idle Label

The California Air Resources Board (CARB) requires

model year 2008 and newer heavy-duty diesel engines to be equipped with a non-programmable engine shutdown system that automatically shuts down

the engine after five minutes of idling in order to limit

emissions of particulate matter and NOx.

Certified vehicles are equipped with a label placed

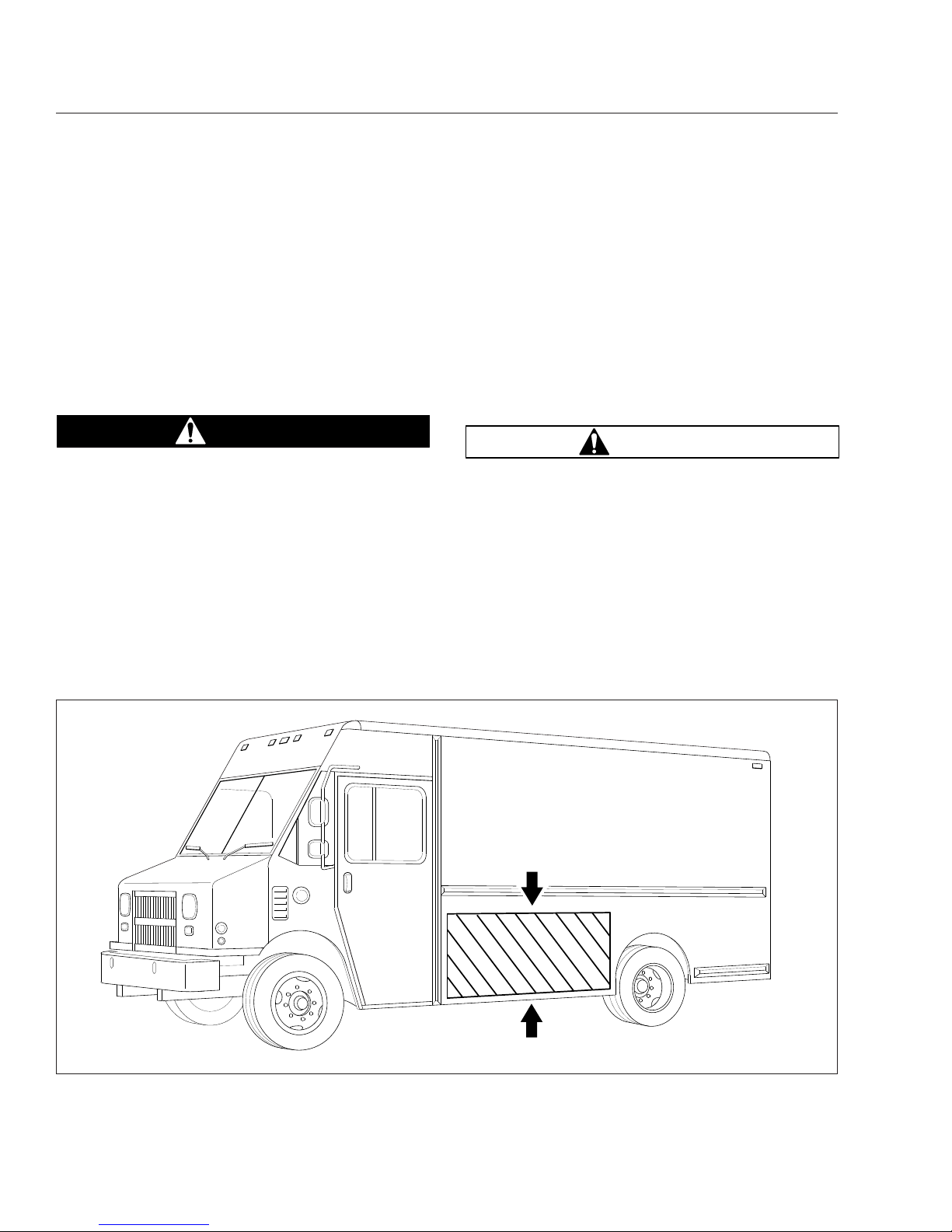

near the bottom edge of the driver-side door. See

Fig. 1.6.

f080156

EXHAUST AFTERTREATMENT SYSTEM INFORMATION

Switch.

Level 1 Level 3Level 2 Level 4

Filter Regeneration

Recommended.

Filter is reaching

Bring vehicle to

highway speeds to

Filter

Regeneration

Filter is now

reaching maximum

capacity

.

To avoid engine

derate, bring vehicle

Parked Regeneration

Required − Engine

Derate

Filter has reached

maximum capacity

.

Vehicle must be

parked, and a Parked

Service Regeneration Required.

Engine Derate To Idle Only.

Filter has exceeded maximum

capacity.

Vehicle must be parked, and a

Service Regeneration must be

(Solid)

(Flashing) (Flashing)

CHECK

INDICATOR

LAMP(S)

Indicator Lamp

Message(s)

Diesel Particulate

Filter Condition

Required Action

capacity

.

STOP

allow for an

Automatic

Regeneration or

perform a Parked

to highway speeds

to allow for an

Automatic

Regeneration, or

perform a Parked

Regeneration as

soon as possible.

Regeneration must

be performed.

Engine will begin

derate.

performed. Check engine

operator’s manual for details.

Engine will shut down.

For a driver performed Parked Regeneration, vehicle must be equipped with a dash mounted Regeneration Switch.

02/20/2009

W

ARNING

HEST (High Exhaust

System Temperature)

Exhaust components

and exhaust gas are at

high temperature. When

stationary, keep away

from people and

flammable materials or

vapors.

A regeneration is in

progress.

Flashing

Solid

Regeneration.

Necessary

Fig. 1.4, ATS Indicators

03/02/2012 f080183

Fig. 1.5, Vehicle Emission Control Information Label

Vehicle Identification

1.3

Page 9

CERTIFIED

CLEAN IDLE

02/20/2012 f080179

Fig. 1.6, CARB Clean Idle Label

Vehicle Identification

1.4

Page 10

2

Instruments

Ametek Instrument Panel ........................................................... 2.1

Warning and Indicator Lights ........................................................ 2.9

Speedometer and Tachometer ...................................................... 2.16

Standard Instruments ............................................................. 2.17

Optional Instruments ............................................................. 2.19

Page 11

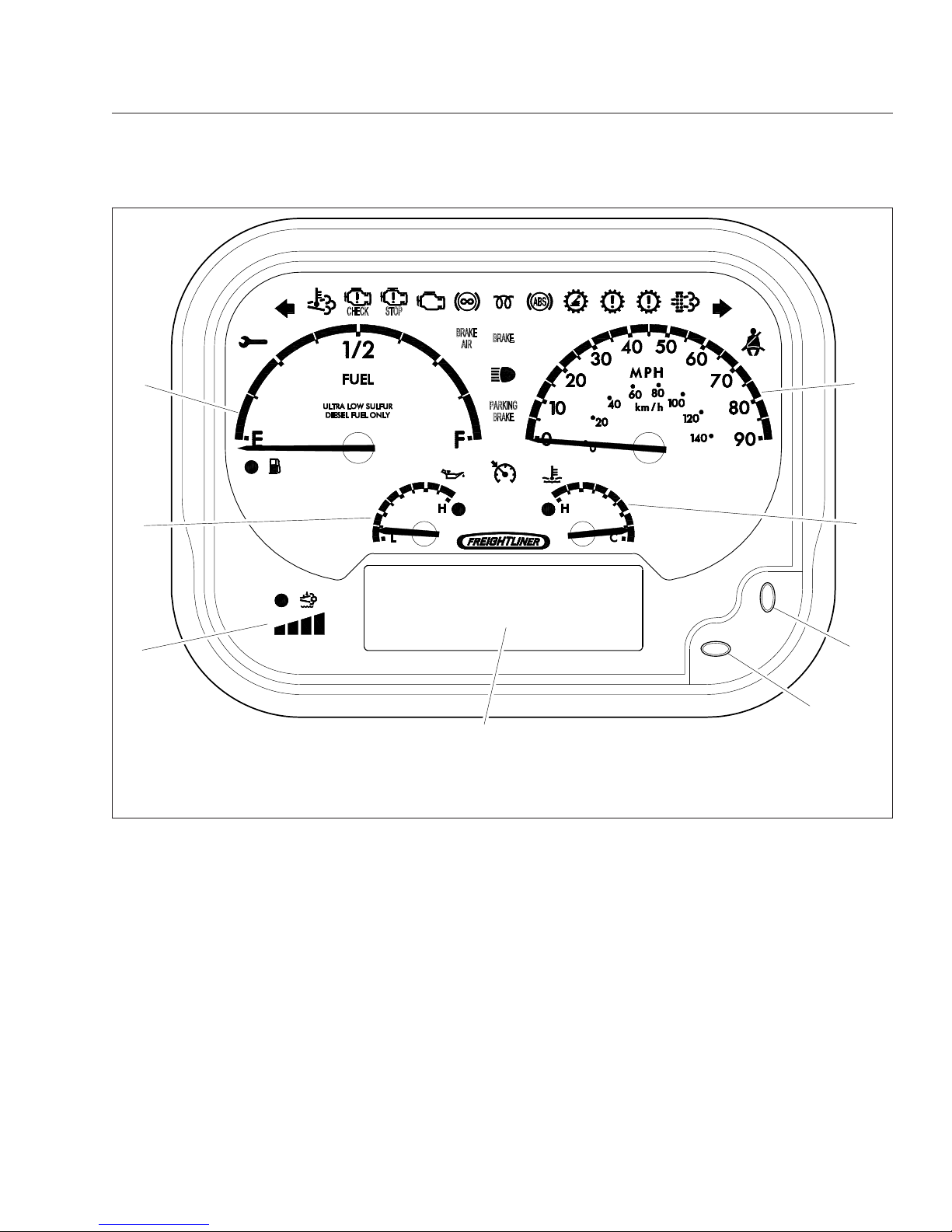

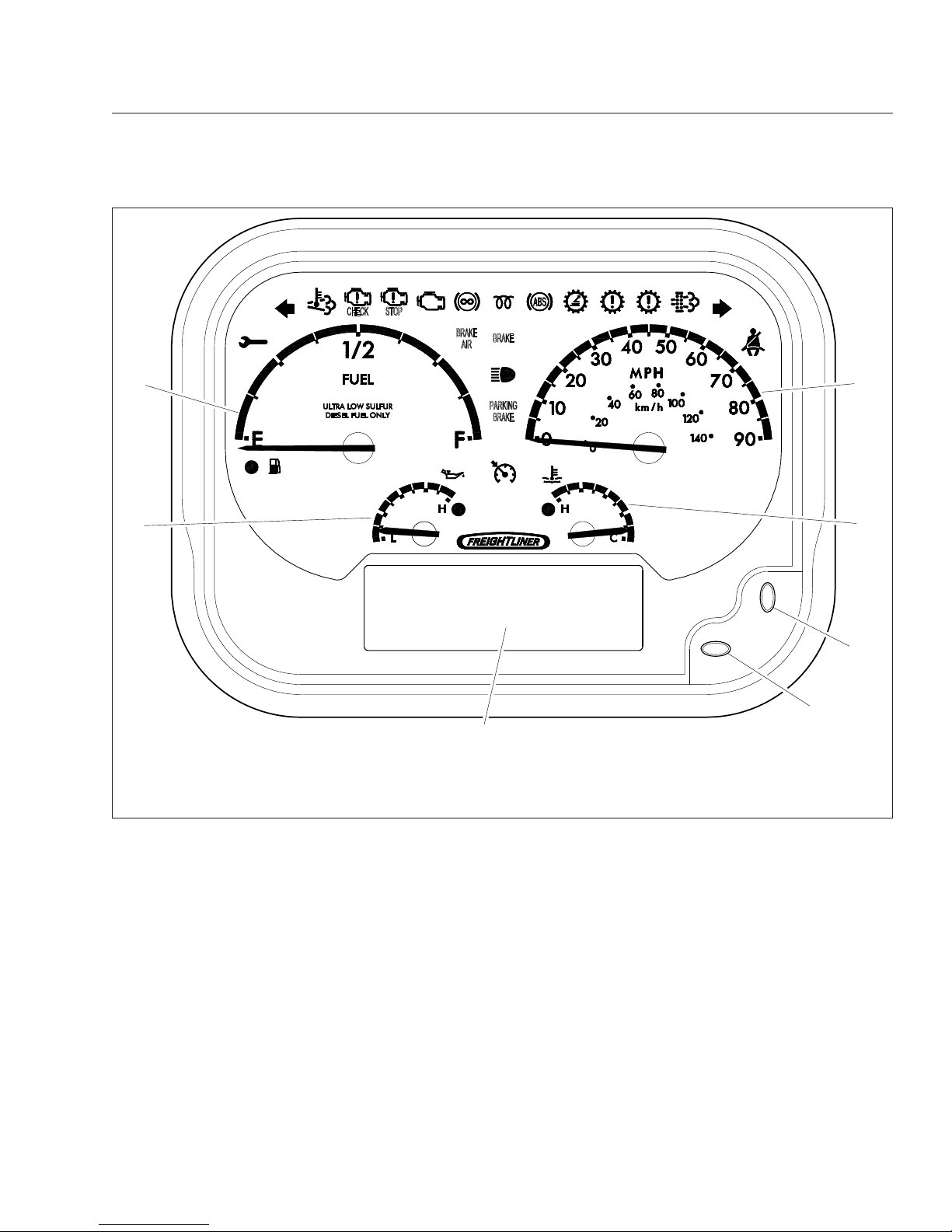

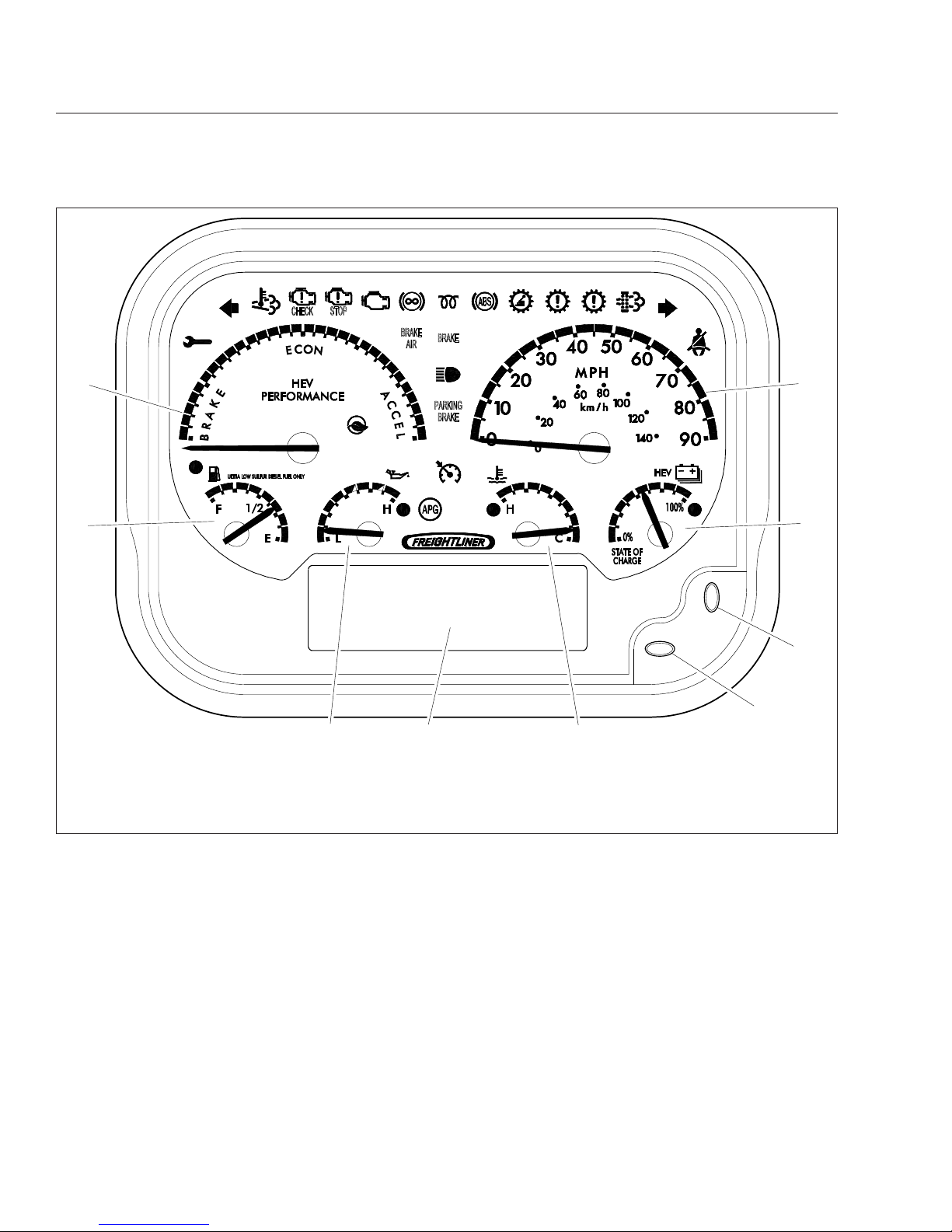

Ametek Instrument Panel

The following information describes a typical instrument panel manufactured by Ametek.

Figure 2.1 and

Fig. 2.2 show instrument panels for vehicles that are

compliant with EPA10 and newer regulations, for

both diesel and hybrid-electric vehicles (HEV).

Fig-

ure 2.3 and Fig. 2.4 show instrument panels for ve-

hicles that are EPA07-compliant for both diesel and

HEV vehicles.

NOTE: These instrument panels are shown with

a standard U.S. speedometer, which shows

miles per hour (mph) more prominently than kilometers per hour (km/h).

Message Display Center

The message display is a graphical, backlit, liquid

crystal display (LCD) that relays information to the

vehicle operator. The messages displayed include:

•

Odometer

•

Trip Odometer 1/Trip Odometer 2

•

Chassis Battery Voltage

•

Instantaneous Fuel Rate

•

Average Fuel Rate

•

Gear Attained Status

•

Transmission Temperature

•

Hour Meter

•

Boost Pressure

•

Engine Oil Pressure

•

Coolant Temperature

•

Fuel Level

•

Percent Engine Load

•

Engine RPM

During normal operation, the LCD displays the odometer value and chassis battery voltage on the top

line, and driver selected parameters, such as the trip

odometer and fuel rate, on the second and third

lines.

Priority Messages

Priority messages (including warning messages) are

displayed in the LCD due to various inputs or data

messages. Unless noted otherwise, the priority message will take over the whole screen, allowing multiple messages to be displayed in five second intervals.

Self-Test

When the ignition is turned on, a required self-test

automatically begins. Gauge needles will reset to

zero during the self-test, and then immediately move

to the position dictated by the data received. During

this time, the warning lights, alarm (buzzer), and

driver display screen will also perform a self-test.

NOTE: The driver can activate or deactivate the

start-up self-test by accessing the setup menu.

Menu System

The menu system is shown on the driver display

screen once the self-test is finished. The menu system responds to input from the driver and remains

active as long as the ignition is on. In order for the

driver to operate the menu system, the ignition must

be ON, and the park brake must be set (ON). The

main features of the menu system are described

below.

•

Setup—this is used to set various parameters,

which are saved when the ignition is turned off.

Setup has select display units, startup screen,

LCD contrast, and reset parameters.

•

Maintenance—shows various maintenance intervals such as engine oil, air filter, etc.

•

Diagnostics—this is used for setting and reading inputs and outputs and checking the

gauges. It also shows the hardware and software version of the instrument panel, and has

menus to retrieve active error codes from the

engine, transmission, and ABS controllers.

NOTE: No lines can be highlighted in the menu

system screen. To get to the sections that can

be highlighted, press the right arrow toggle button and hold it for two seconds. The display

screen will change and the options shown can

then be highlighted. Once a selection has been

chosen and changes are made, press the right

arrow toggle button to go back to the main message display screen.

Instruments

2.1

Page 12

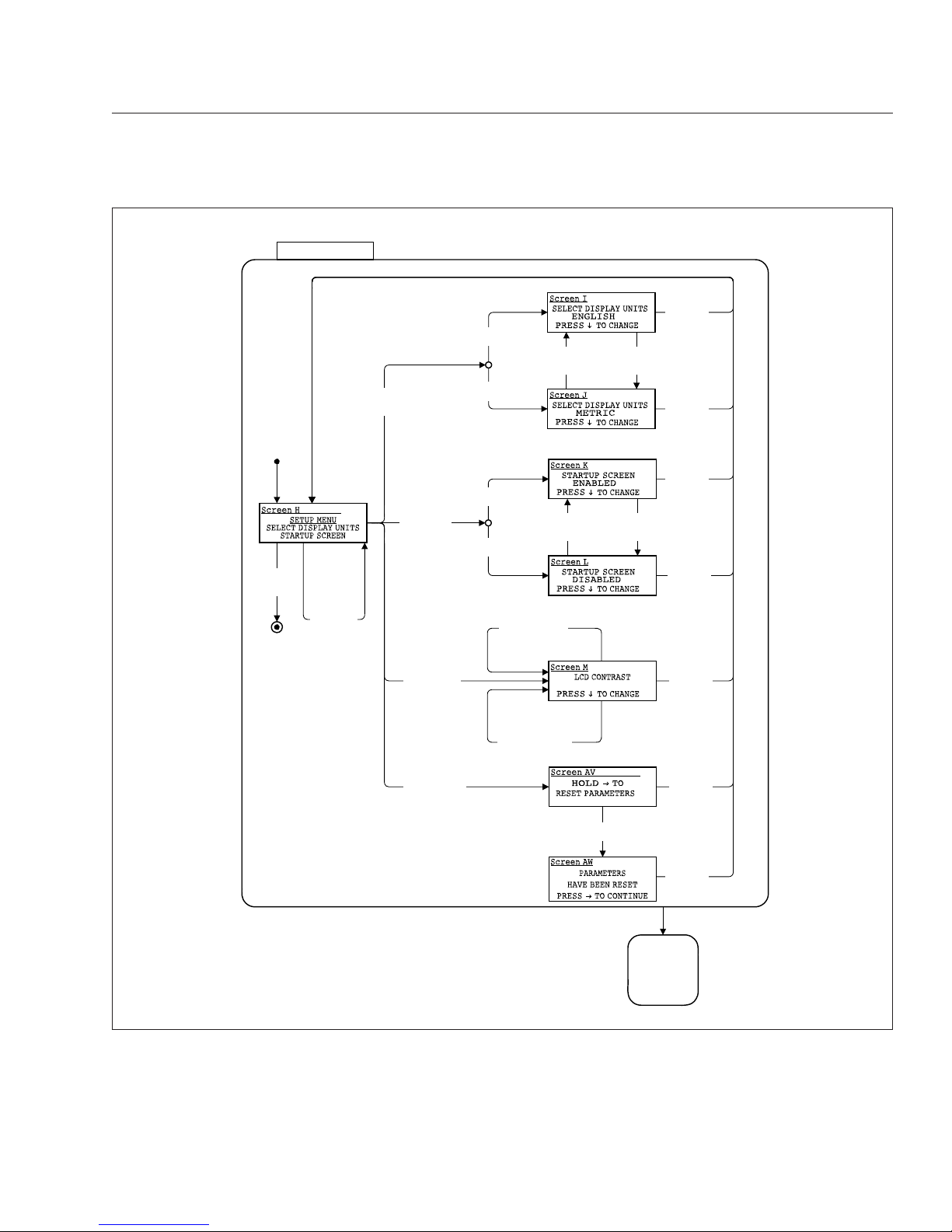

Setup Menu

Select Display Units

The set units screen allows the driver to choose between English or metric units of measurement for the

displayed values. To navigate to the set units screen,

see

Fig. 2.5, screens H, I, and J.

Startup Screen

The startup screen selection allows the driver to turn

the startup screen on or off.

LCD Contrast

Select contrast from the menu to set the LCD contrast. Use the down toggle button to set the contrast

to the desired level. To navigate to the contrast

screen, see

Fig. 2.5, screen M.

Reset Parameters

The reset parameters screen is included with vehicles that have the Allison transmission prognostics

feature.

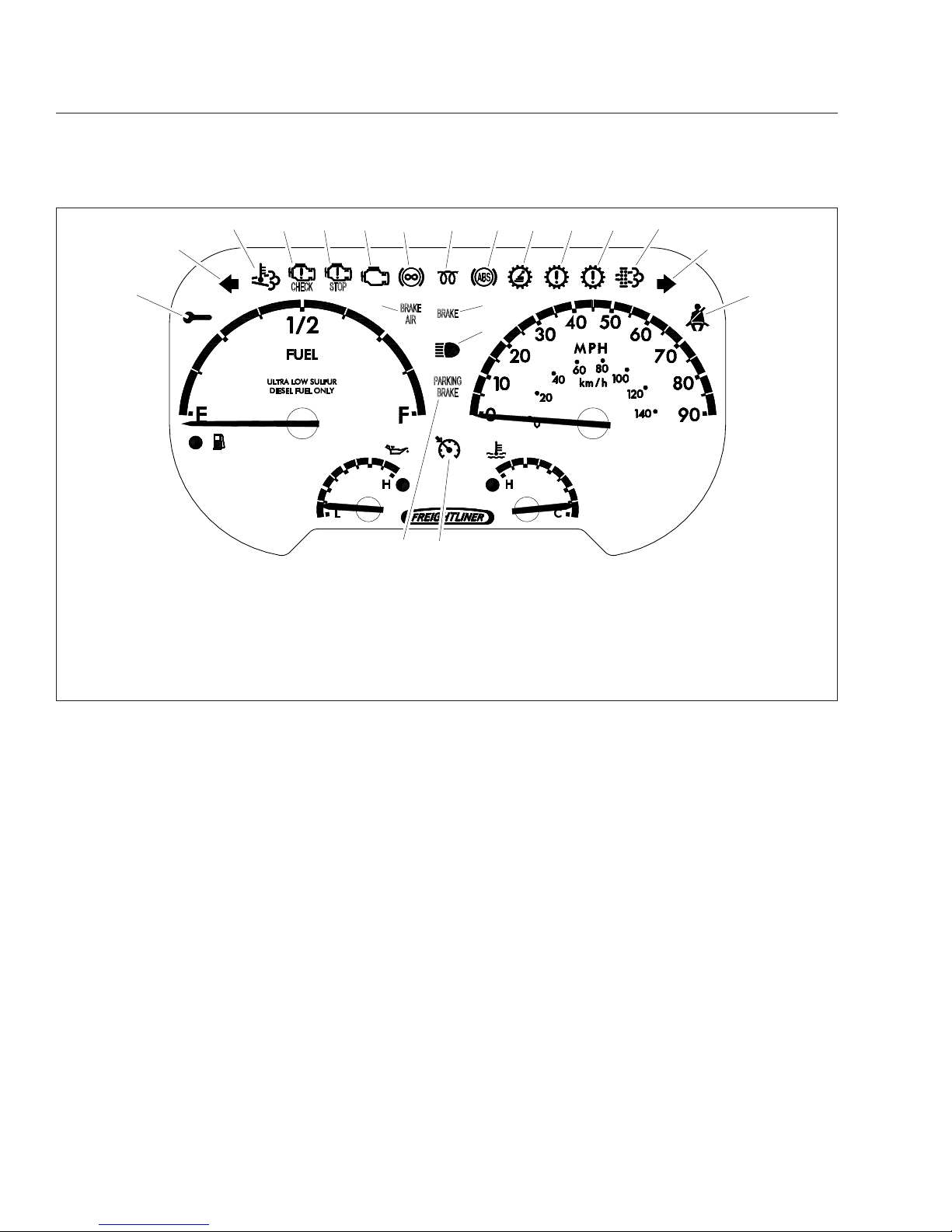

10/13/2009 f611051

1

2

3

6

8

7

4

5

1. Fuel Gauge

2. Speedometer

3. Coolant Temperature Gauge

4. Toggle Button, Right

5. Toggle Button, Down

6. Message Display Center

7. Diesel Exhaust Fluid (DEF) Gauge

8. Engine Oil Pressure Gauge

Fig. 2.1, Typical Ametek Instrument Panel (diesel), EPA10 and Newer Engines

Instruments

2.2

Page 13

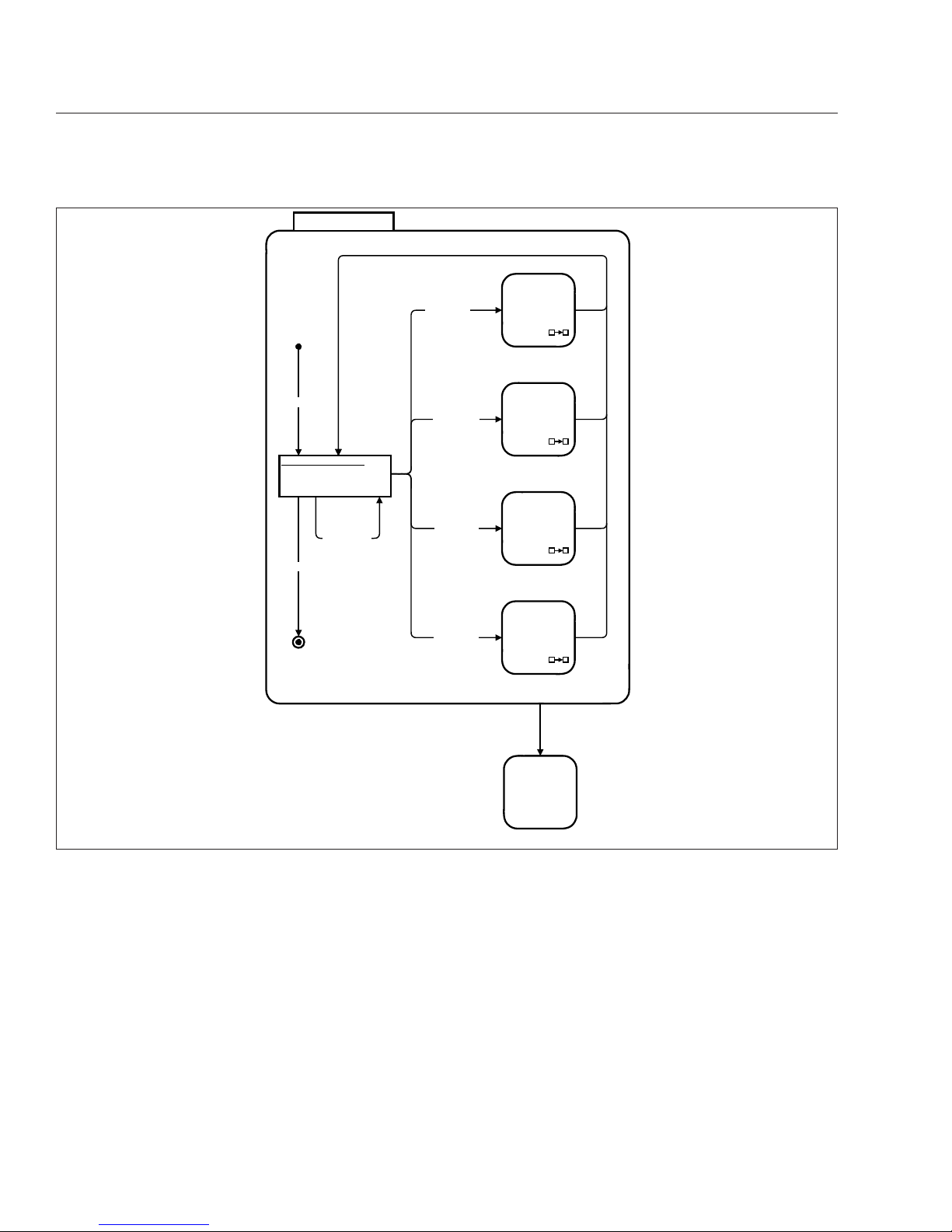

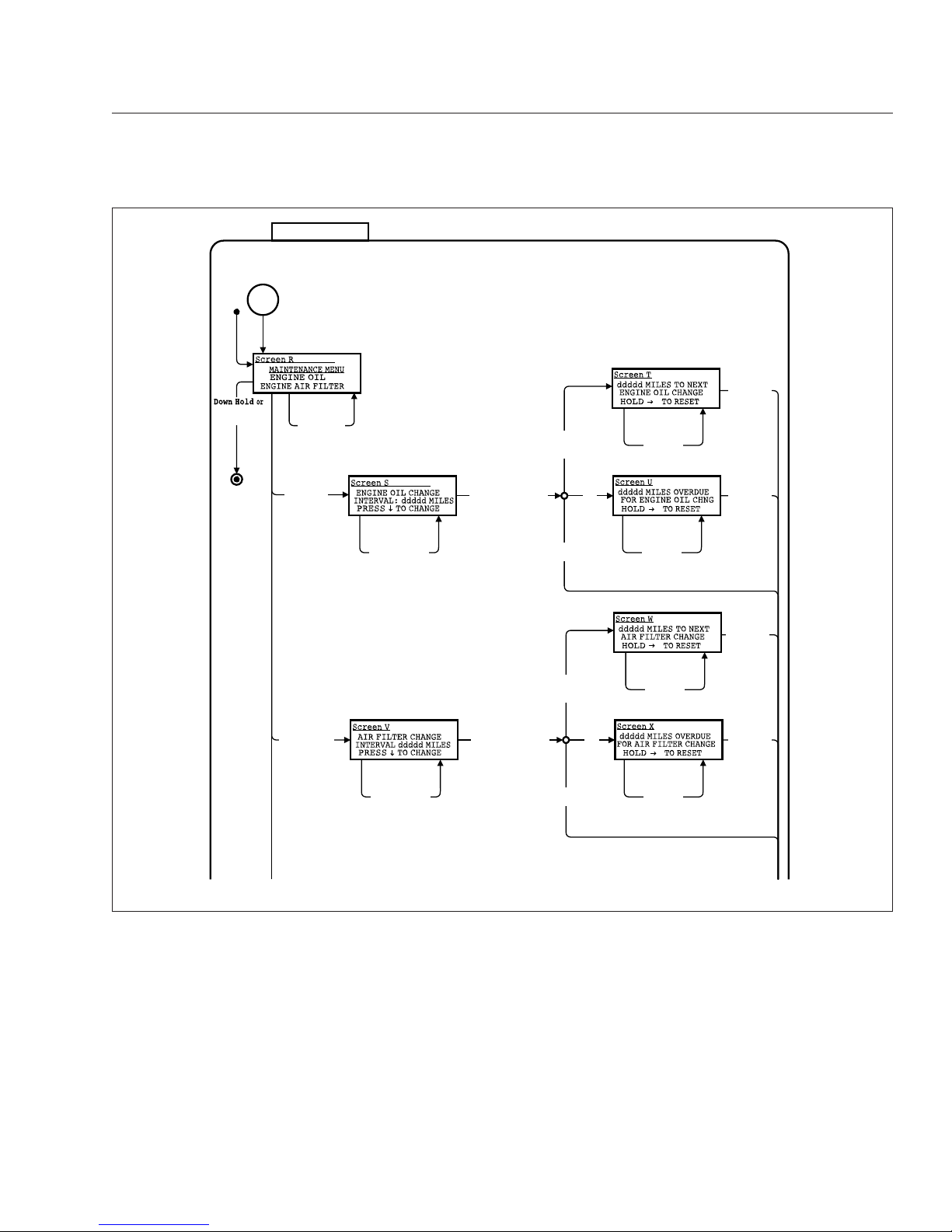

Maintenance Menu

The maintenance menu has the following three sub

menus:

•

maintenance intervals

•

transmission oil life remaining

•

transmission oil filter life monitor

Maintenance Intervals

The maintenance intervals menu allows the driver to

set the change intervals for engine oil and engine air

filter. If the intervals are set to zero, the maintenance

warnings must be disabled.

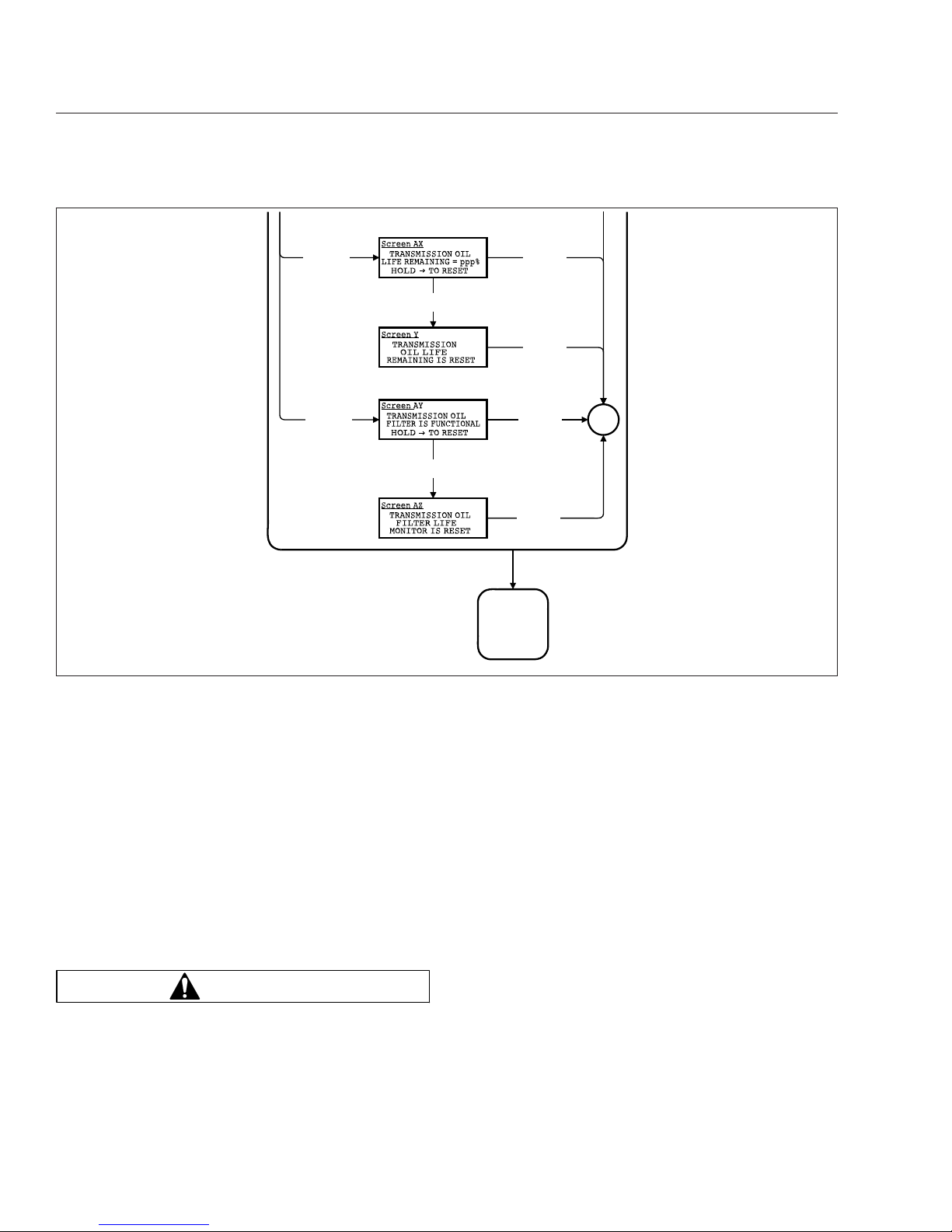

Transmission Oil Life Remaining

If transmission prognostics are enabled, this menu

indicates how much useful oil life remains.

Transmission Oil Filter Life Monitor

If transmission prognostics are enabled, the transmission oil filter life monitor tells the driver if the

transmission oil filter is clogged and in need of repair.

A message will appear on the display screen as

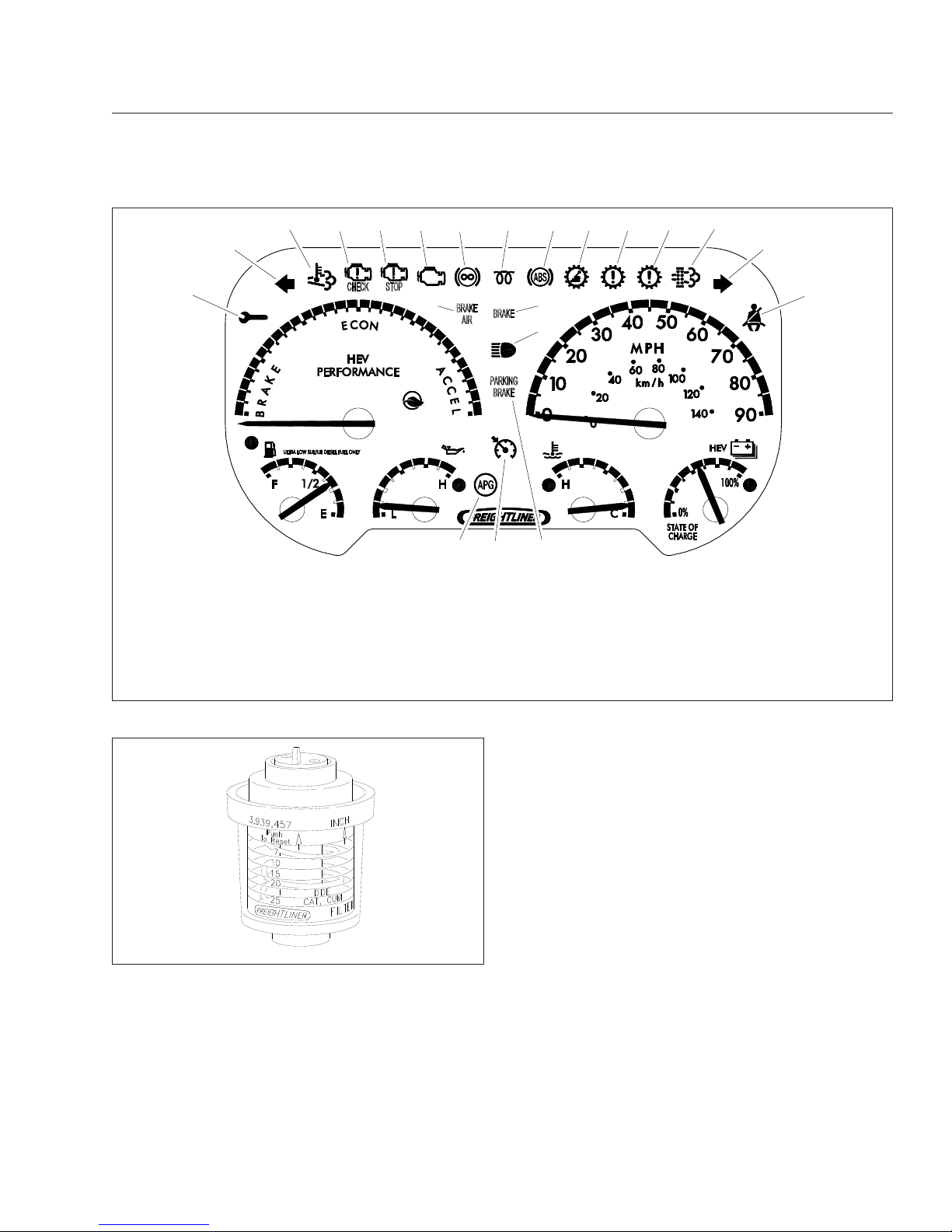

10/13/2009 f611053

1

2

9

3

7

10

86

4

5

1. HEV Performance Gauge

2. Speedometer

3. HEV Battery Gauge

4. Toggle Button, Right

5. Toggle Button, Down

6. Coolant Temperature Gauge

7. Message Display Center

8. Engine Oil Pressure Gauge

9. Diesel Exhaust Fluid (DEF) Gauge

10. Fuel Gauge

Fig. 2.2, Typical Ametek Instrument Panel (HEV), EPA10 and Newer Engines

Instruments

2.3

Page 14

TRANS OIL FILTER FUNCTIONAL or TRANS OIL

FILTER CLOGGED.

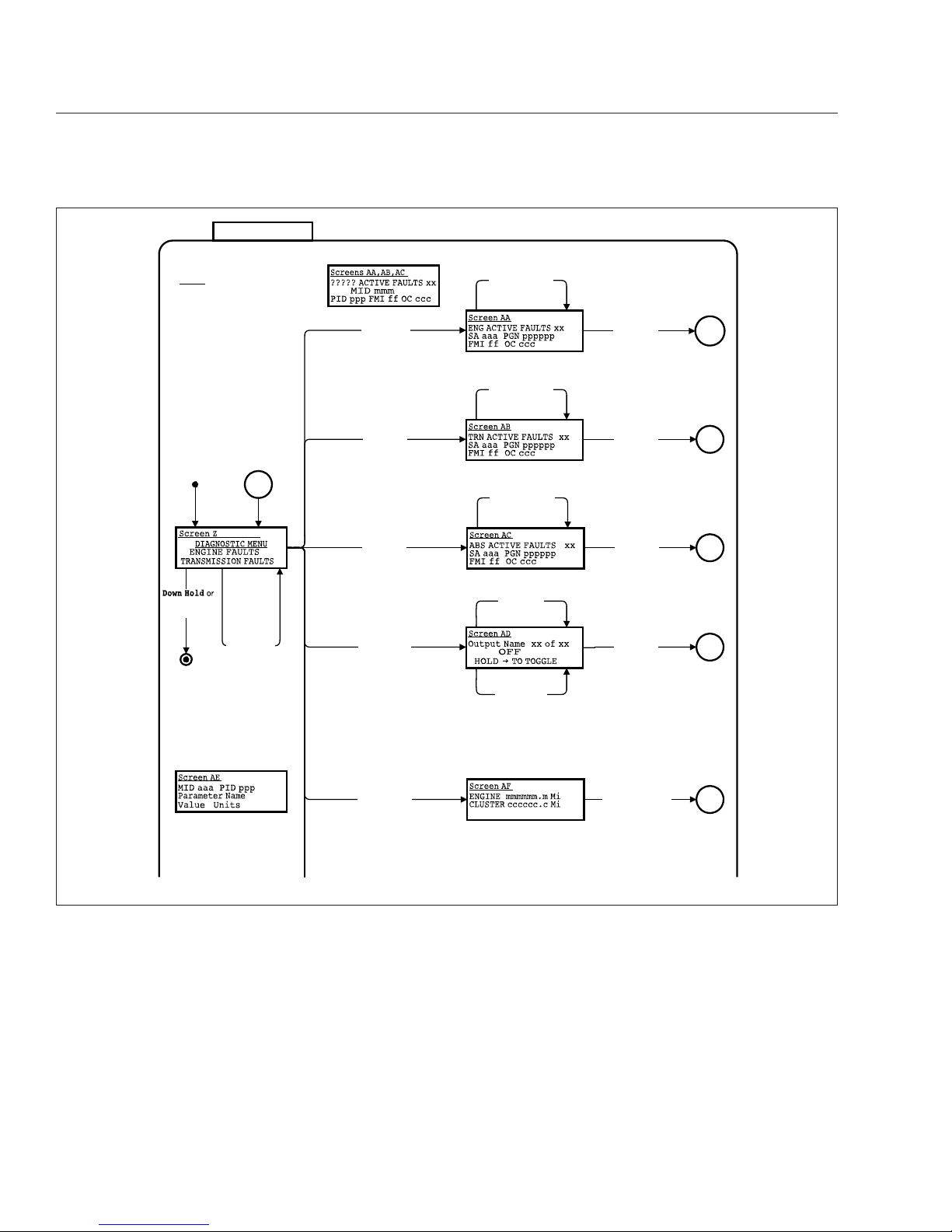

Diagnostic Menu

The diagnostic menu contains the following items:

•

engine faults

•

transmission faults

•

ABS faults

•

check outputs

•

odometer diagnostics

•

check gauges

•

check indicators (warning lamps)

•

check LCD

•

check binary inputs

•

check analog inputs

•

check datalink

•

hardware/software version

All of the items in the diagnostic menu can be accessed by using the toggle buttons and selecting the

auxiliary screens. Then navigate to the diagnostic

09/23/2009 f611049

1

2

3

6

7

4

5

1. Fuel Gauge

2. Speedometer

3. Coolant Temperature Gauge

4. Toggle Button, Right

5. Toggle Button, Down

6. Message Display Center

7. Engine Oil Pressure Gauge

Fig. 2.3, Typical Ametek Instrument Panel (diesel), EPA07-Compliant

Instruments

2.4

Page 15

sub-menu. Some of the more frequently used diagnostic menus are described further below.

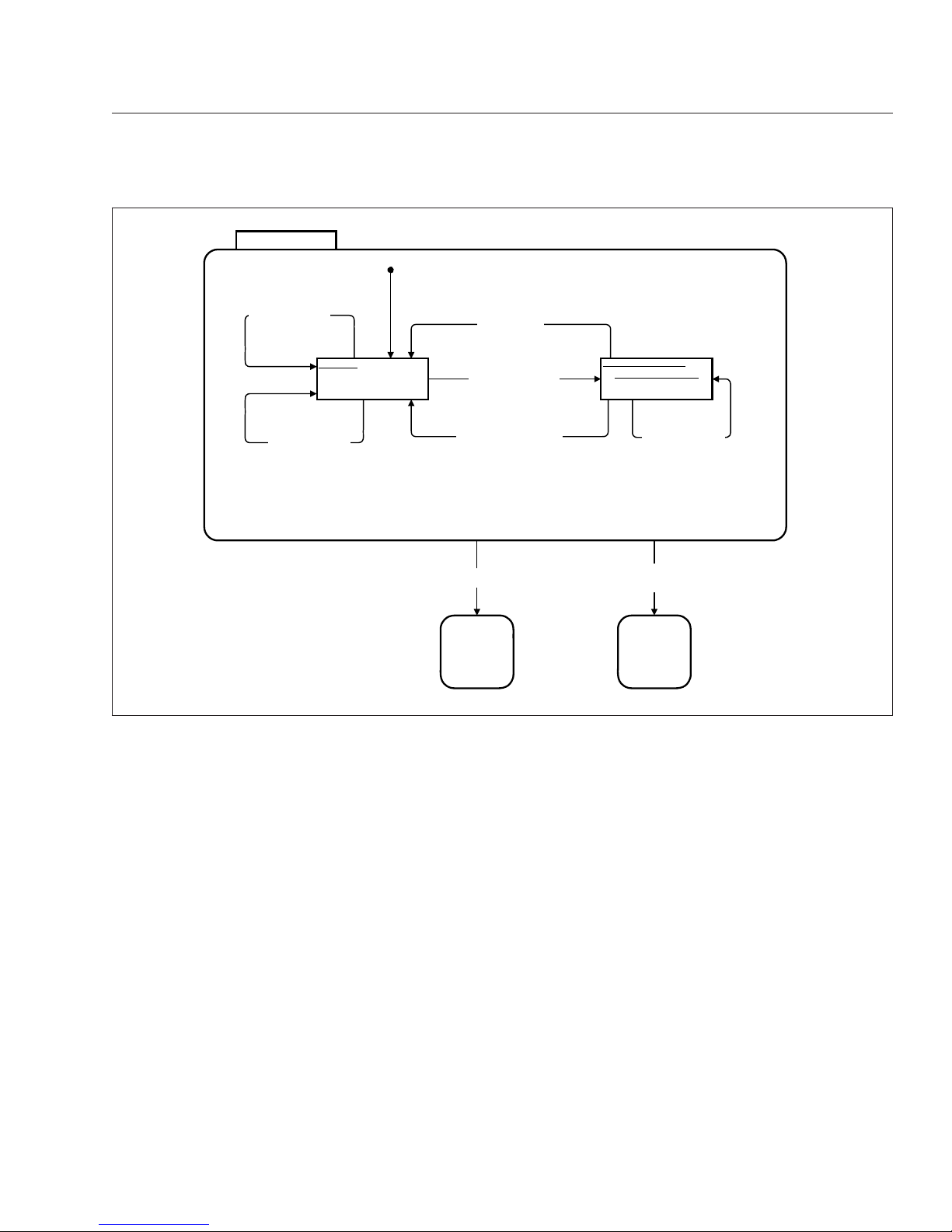

Engine Faults

This screen displays engine fault codes that are received from the engine electronic control unit (ECU).

To navigate to the engine fault screen, see

Fig. 2.6,

screen AA.

Transmission Faults

This screen displays transmission fault codes that

are received from the transmission ECU. To navigate

to the transmission fault screen, see

Fig. 2.6, screen

AB.

ABS Diagnostics

This screen displays Antilock Brake System (ABS)

fault codes that are received from the ABS ECU. To

navigate to the ABS diagnostic screen, see

Fig. 2.6,

screen AC.

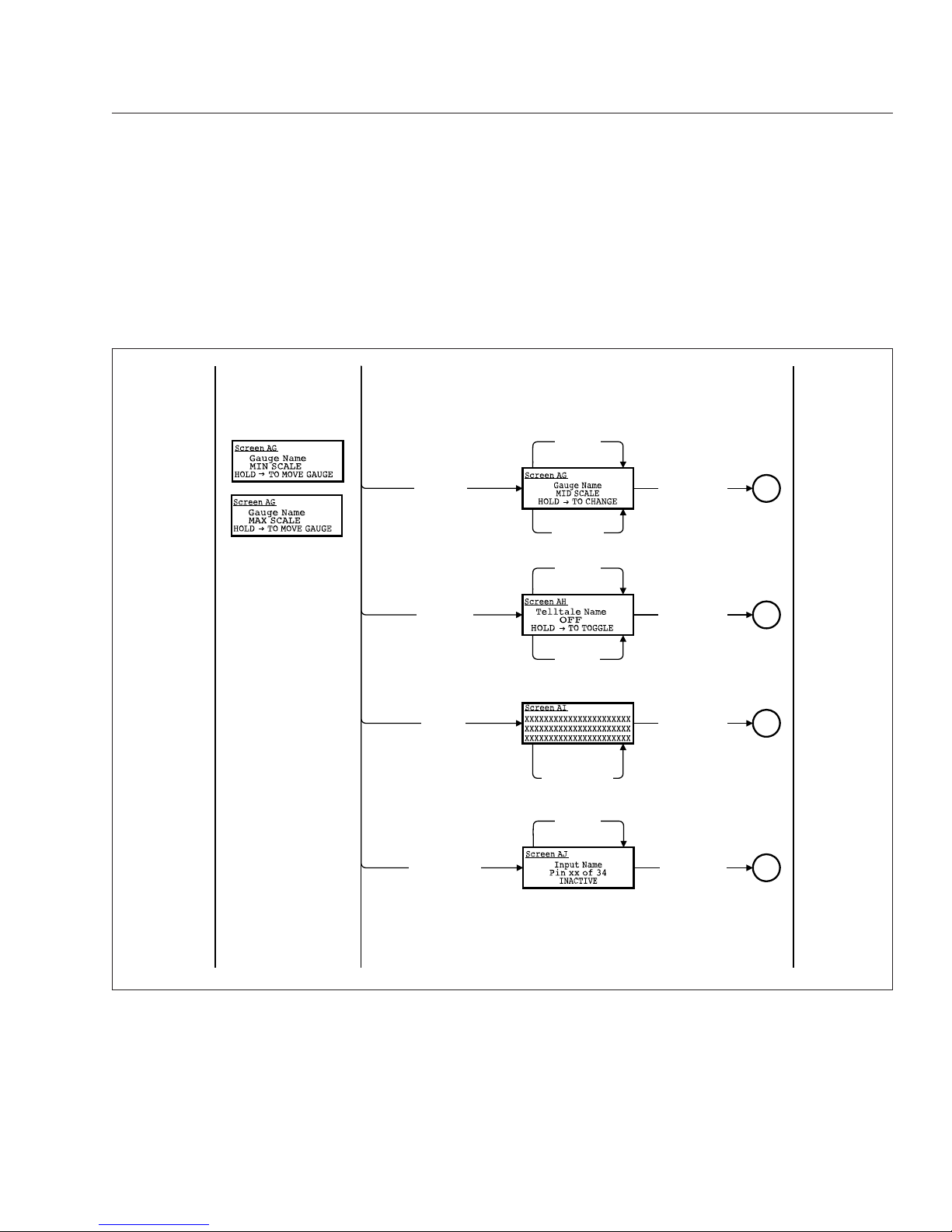

Check Gauges

The check gauges screen allows the driver to set

each gauge as a percentage of scale (either 0, 50, or

09/23/2009 f611050

1

2

3

7

9

86

4

5

1. HEV Performance Gauge

2. Speedometer

3. HEV Battery Gauge

4. Toggle Button, Right

5. Toggle Button, Down

6. Coolant Temperature Gauge

7. Message Display Center

8. Engine Oil Pressure Gauge

9. Fuel Gauge

Fig. 2.4, Typical Ametek Instrument Panel (HEV), EPA07-Compliant

Instruments

2.5

Page 16

100%), as shown in the LCD. To navigate to the

check gauges screen, see

Fig. 2.7, AG screens.

SETUP

Down Hold

Or (Right & Exit

highlighted)

Down Press

Current Units

=

Metric

Down Press

Current Units

=

English

Current Units

=

English

Current Units

=

Metric

Down Press

Startup Screen

=

Disabled

Down Press

Startup Screen

=

Enabled

Startup Screen

=

Enabled

Startup Screen

=

Disabled

Down Press

Not At Min Contrast /

Decrease Contrast

Down Press

At Min Contrast /

Set Contrast to Max

Right Press

Startup Screen

highlighted

Right Press

Select Display

Units highlighted

Right Press

Display Contrast

highlighted

Right Press

Or

Down Hold

Right Press

Or

Down Hold

Right Press

Or

Down Hold

Right Press

Or

Down Hold

Right Press

Or

Down Hold

Down Press

Highlight next

line of list.

At middle,

wrap to top

Right Hold

Reset Parameters

Right Press

Reset Parameters

highlighted

Right Press

Or

Down Hold

Right Press

Or

Down Hold

AUXILIARY

SCREENS

09/23/2009 f040792

Fig. 2.5, Setup Menu Screens

Instruments

2.6

Page 17

Warning Lamp

The warning lamp screen allows the driver to test

each warning lamp (not the vehicle load) on and then

off, displaying the lamp name and status in the LCD.

To navigate to the warning lamp screen, see

Fig. 2.7, screen AH.

Check LCD

Selecting the check LCD screen displays the Freightliner Custom Chassis Corporation (FCCC) logo in

normal and reverse video three times and then returns to the menu. To navigate to the check LCD

screen, see

Fig. 2.7, screen AI.

Diagnostics

Note 5:

Screen Z scrolls to display the

following items:

ENGINE FAULTS

TRANSMIS

SION FAULTS

ABS FAULTS

CHECK OUTPUTS

CHECK DATA INPUTS

ODOMETER DIAGNOSTICS

CHECK GAUGES

CHECK WARNING LAMPS

CHECK LCD

CHECK BINARY INPUTS

CHECK ANALOG INPUTS

CHECK DATA LINK

VERSION INFORMATION

EXIT

The text DIAGNOSTIC MENU

remains fixed on the first line.

Down Press

Display Next Fault

Down Press

Display Next Fault

Down Press

Display Next Fault

Right Press

Or

Down Hold

Down Press

Change to

Next Output

Right Press

Or

Down Hold

Right Hold

Toggle Output

State Between

Off and On

Menu

Right Press

Engine Faults

Highlighted

Right Press

Trans Faults

Highlighted

Right Press

ABS Faults

Highlighted

Right Press

Check Outputs

Highlighted

Menu

(Right & Exit

highlighted)

Menu

Right Press

Or

Down Hold

Menu

Right Press

Or

Down Hold

Menu

Screens AA,AB,AC Format For J1587

Screen AE For J1587

Down Press

Highlight next

line of list.

At bottom,

wrap to top

Right || Hold Down

Right Press

Odometer Diag

Highlighted

Menu

09/23/2009 f040795

Fig. 2.6, Diagnostic Menu Screens, Screen 1

Instruments

2.7

Page 18

Check Binary Inputs

The check binary inputs screen displays the pin number and status of each binary input. The toggle buttons allow the driver to select each binary input. This

information is continuously updated to assist in

troubleshooting. To navigate to the check binary inputs screen, see

Fig. 2.7, screen AJ.

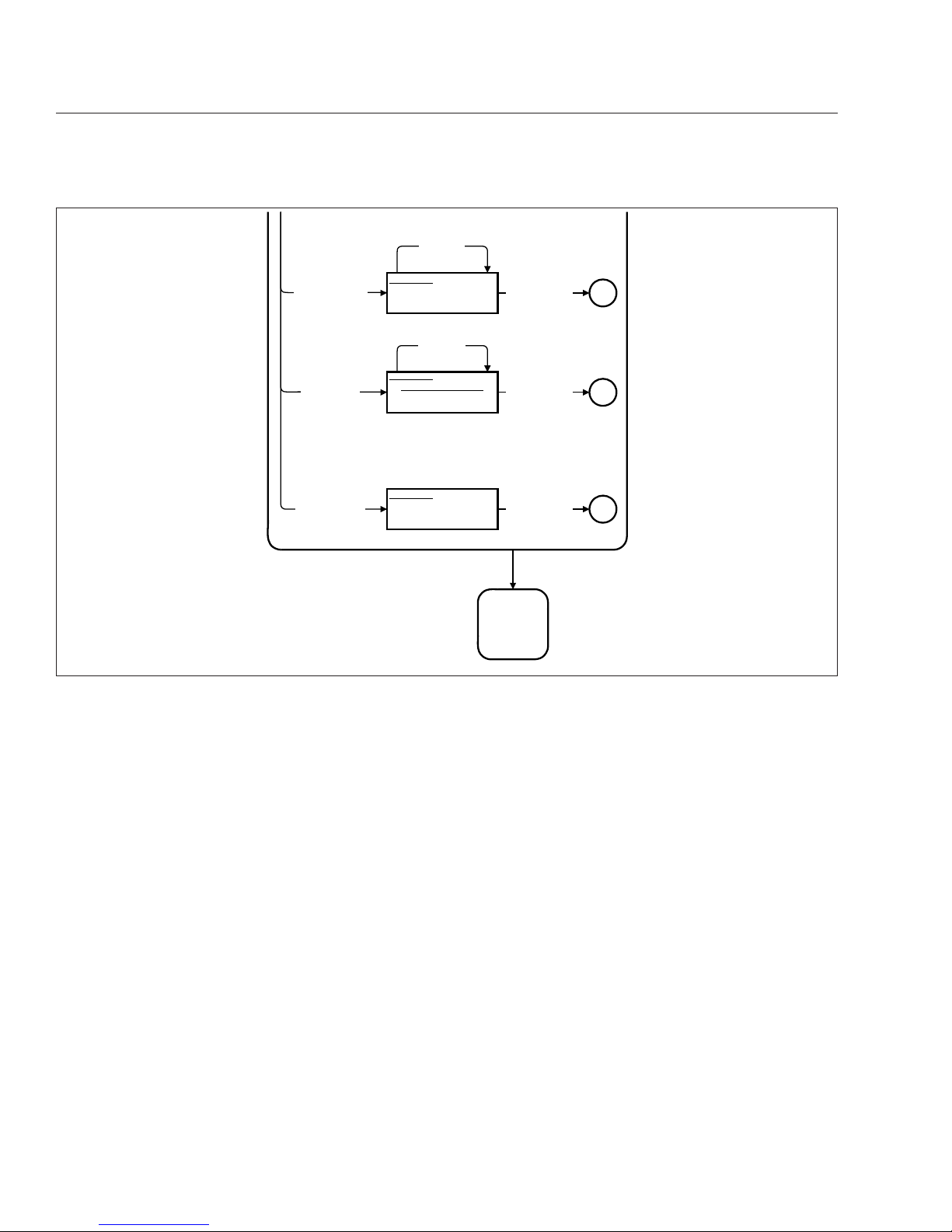

Check Analog Inputs

The check analog inputs screen displays the pin

number and actual value of each analog input defined in the system. The toggle buttons allow the

driver to select each analog input. This information is

continuously updated to assist in troubleshooting. To

navigate to the check analog input screen, see

Fig. 2.8, screen AK.

Check Datalink

The check datalink screen allows the driver to view

all devices that communicate on the J1939, J1587,

and GMLAN datalinks. To navigate to the check datalink screen, see

Fig. 2.8, screen AL.

Down Press

Change to

Next Gauge

Right Hold

Step Gauge to

Next Position

Right || Hold Down

Down Press

Change to

Next Telltale

Right Hold

Toggle State

Between

Off and On

Right || Hold Down

Every 1.5 Seconds /

Invert Video of

Displayed Image

Right ||

9 Seconds Elapsed

|| Hold Down

Down Press

Change to

Next Input

Right || Hold Down

Right Press

Check Gauges

Highlighted

Right Press

Warning Lamps

Highlighted

Right Press

Check LCD

Highlighted

Right Press

Check Binary Inputs

Highlighted

Menu

Menu

Menu

Menu

Other Text for Screen AG

09/23/2009 f040796

Fig. 2.7, Diagnostic Menu Screens, Screen 2

Instruments

2.8

Page 19

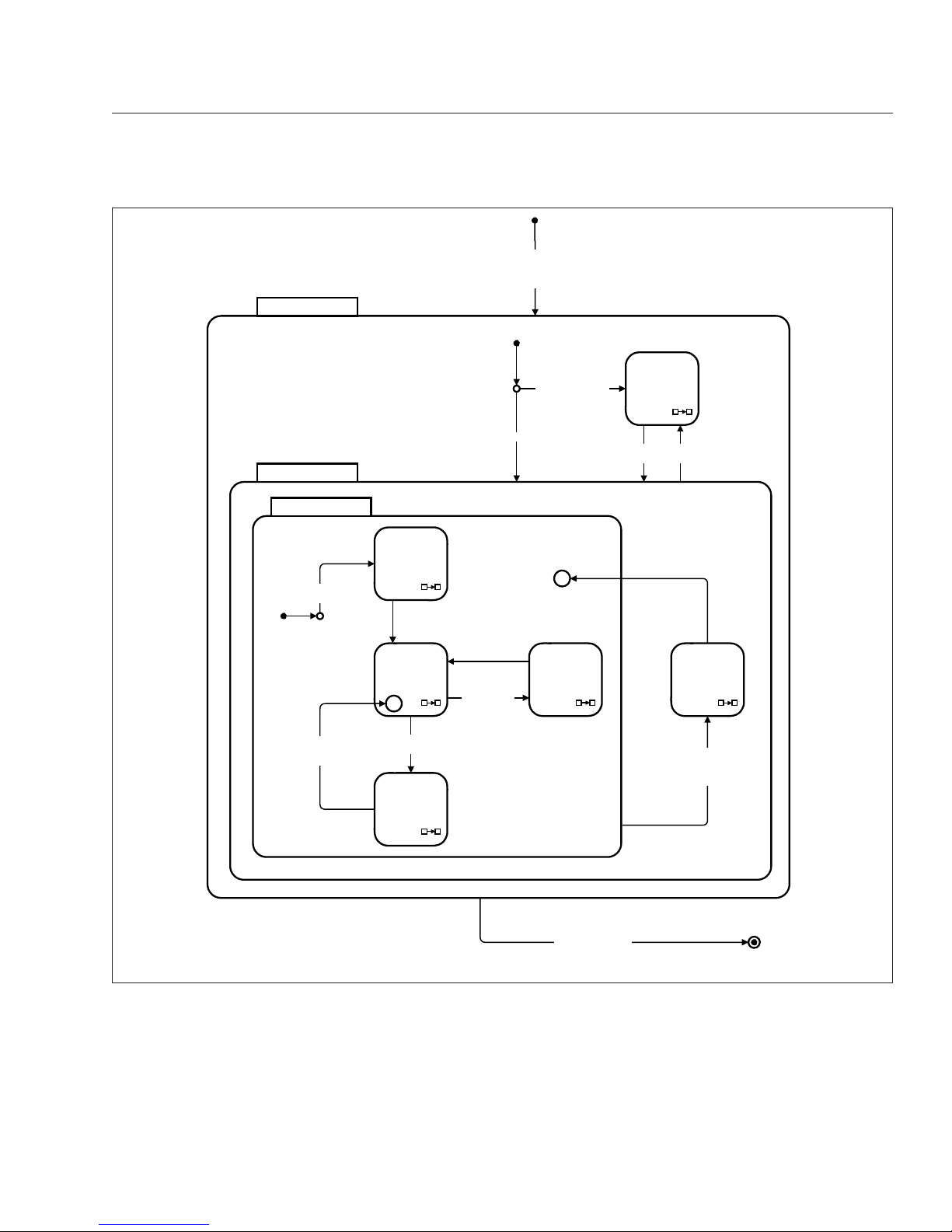

Menu Navigation

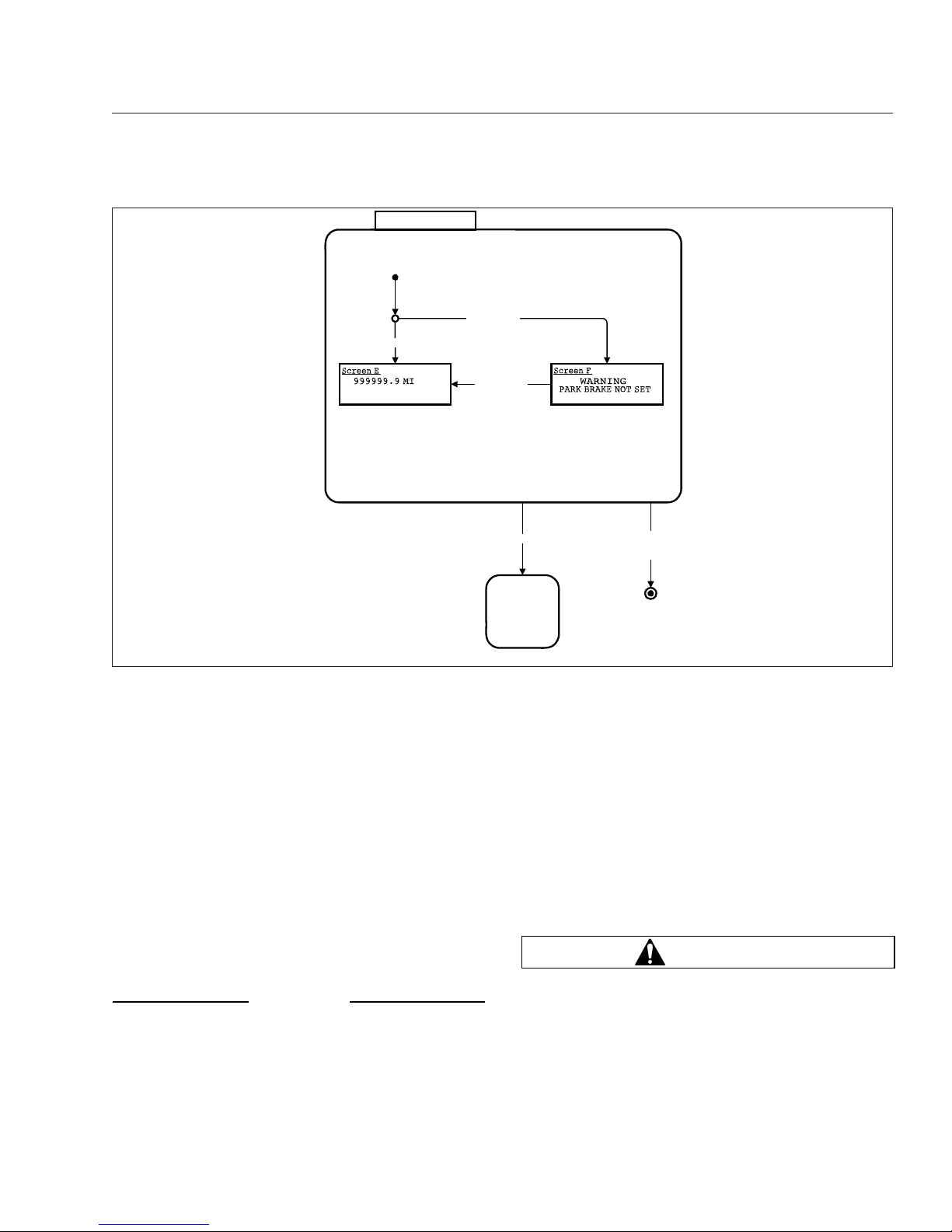

The menu navigation road maps are provided to illustrate the screens that are available in the menu

system. The paths to specific screens are shown,

along with instructions for using the toggle buttons to

move from one screen to another. Refer to the road

maps to change items shown in lines one, two, and

three of the display screen, view the setup screens,

diagnostics, etc. See

Fig. 2.5, Fig. 2.6, Fig. 2.7,

Fig. 2.8, Fig. 2.9, Fig. 2.10, Fig. 2.11, Fig. 2.12,

Fig. 2.13, Fig. 2.14, Fig. 2.15, Fig. 2.16, and

Fig. 2.17.

IMPORTANT: Follow the steps below to change

the three items (also known as favorites) shown

in the message display center. The message

display center is referred to as screen C in

Fig. 2.11.

1.

With the vehicle in park, turn the ignition to ON,

and allow the self test to complete.

2.

Press the down toggle button to select an item to

change. The selected item will now be highlighted.

3.

Press the right toggle button once to enter the

favorites display menu, shown in

Fig. 2.11,as

screen D.

4.

Use the down toggle button to scroll through the

available items.

5.

Highlight the new item, then press the right

toggle button. The selected item will now appear

in the message display center.

Warning and Indicator Lights

General Information

The warning and indicator lights are located in the

instrument panel and contain all of the standard and

optional warning and indicator lights. See Fig. 2.18

and Fig. 2.19 for diesel and HEV compliant warning

and indicator lights respectively.

02/06/2012 f040797

AUXILIARY

SCREENS

SOFTWARE VER: x.yy

CONFIG: ccccccc

HARDWARE VER: z

Right || Hold Down

Right Press

Version Information

Highlighted

Menu

Screen AM

Input Name

Pin pp of 26

xx.x Units

Down Press

Change to

Next Input

Right || Hold Down

ECUs on Data Bus

J1939 SA xx

J1939 SA yy

Down Press

Scroll Screen

Down 1 Line

Right || Hold Down

Right Press

Check Analog Inputs

Highlighted

Right Press

Check Data Link

Highlighted

Menu

Menu

Screen AK

Screen AL

Fig. 2.8, Diagnostic Menu Screens, Screen 3

Instruments

2.9

Page 20

Maintenance Warning Light

When the amber maintenance warning light illuminates, the message display center will alert the driver

as follows:

•

Oil Change Required—alerts the driver that the

engine has reached the recommended oil

change interval.

H*

SELF TEST

DISPLAY

MESSAGES

WARNING

MESSAGES

Active Warning

Messages

No Warnings Active or

All Warnings

Acknowledged

Right Hold

Park Brake On

IGNITION ON

IGNITION

OFF

Ignition

Off

Ignition On or

Headlamps On or

Marker Lamps On or

Park Brake Off

Ignition

On

Ignition Off &

Headlamps Off &

Marker Lamps Off &

Park Brake On

Self Test

Enabled

AUXILIARY

SCREENS

ACTIVE

Ignition Off &

( Headlamps On or

Marker Lamps On or

Park Brake Off )

Ignition On

USB Drive Present &

Park Brake On &

Vehicle Speed = 0 &

Not in Self Test

H*

NORMAL MODE

DOWNLOAD

MODE

09/23/2009 f040788

Fig. 2.9, Ignition On, Normal Mode

Instruments

2.10

Page 21

•

Air Filter Reminder—the air filter requires

checking or replacement.

•

Transmission Prognostics Warning—if the

transmission has prognostics enabled.

Left-Turn Signal Arrow

The green left-turn signal arrow flashes on and off

whenever the outside left-turn signal lights are flashing. Both turn signal arrows flash when the hazard

warning flasher is on.

High Exhaust System Temperature

(HEST) Lamp

Indicates potentially hazardous exhaust temperatures

at the outlet of the tail pipe if speed is below 5 mph

(8 km/h). It does not signify the need for service; it

only alerts the vehicle operator of high exhaust temperatures. See the engine operation manual for details.

The amber HEST lamp will illuminate as follows:

•

Slow (10-second) flash, indicates a regeneration is in progress, and the driver is not controlling the engine idle speed.

•

Solid illumination indicates a regeneration is in

progress, with high exhaust temperatures at

the outlet of the tailpipe, if the speed is below

5 mph (8km/h). It does not signify the need for

service; it only alerts the vehicle operator of

high exhaust temperatures. See the engine

operator’s manual for details.

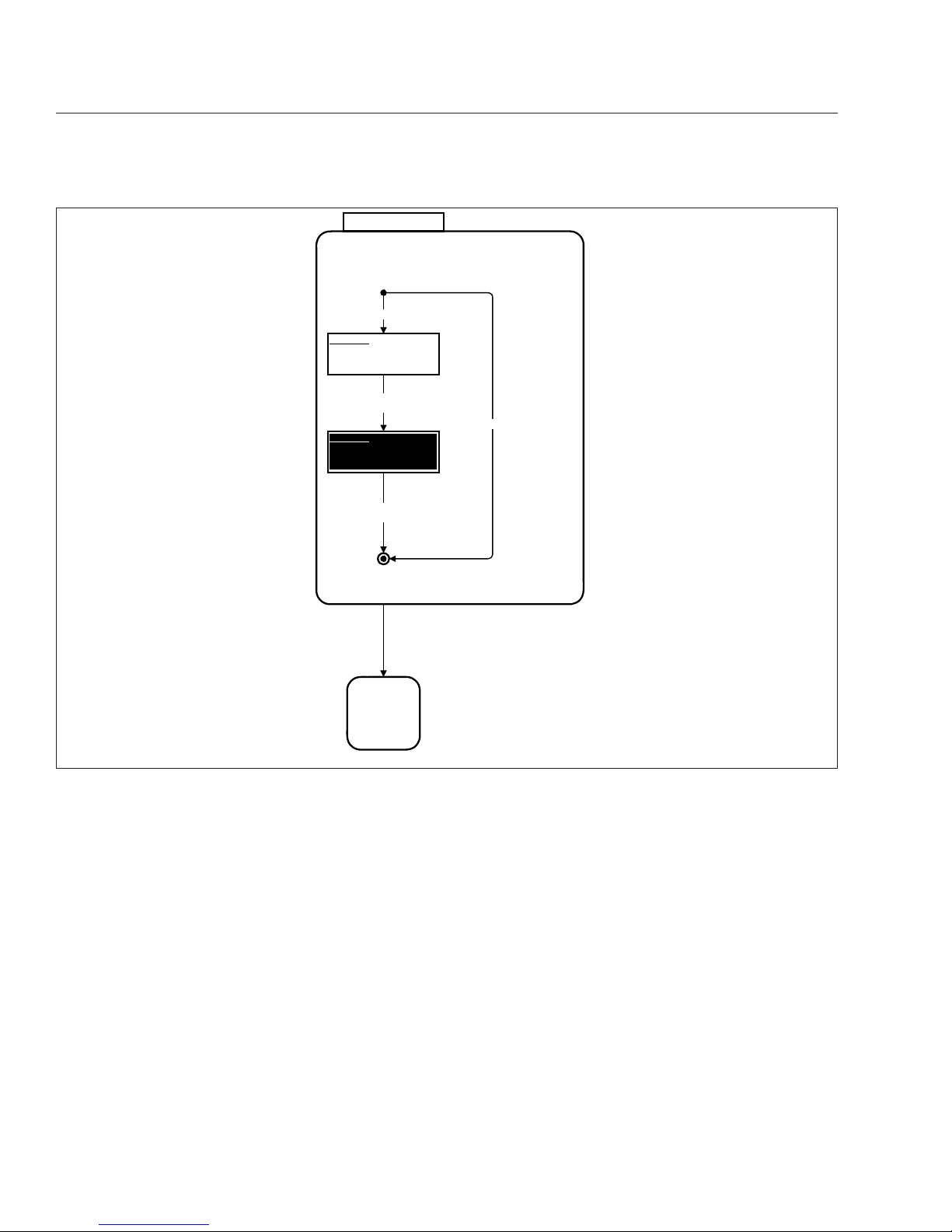

SELF TEST

DISPLAY

MESSAGES

XXXXXXXXXXXXXXXXXXXXXX

XXXXXXXXXXXXXXXXXXXXXX

XXXXXXXXXXXXXXXXXXXXXX

XXXXXXXXXXXXXXXXXXXXXX

XXXXXXXXXXXXXXXXXXXXXX

XXXXXXXXXXXXXXXXXXXXXX

Screen Displayed

for 1.5 Seconds

Screen Displayed

for 1.5 Seconds

Startup Screen Enabled

The Self Test screens display the FCCC

logo in normal video (Screen A) and in

reverse video (Screen B)

Startup Screen Disabled

Screen A

Screen B

02/06/2012 f040789

Fig. 2.10, Self Test

Instruments

2.11

Page 22

Check Engine Indicator

The amber check engine (CHECK) indicator light illuminates when the engine control unit senses a malfunction in the electronic engine control system.

Stop Engine Warning

The red stop engine (STOP) warning light illuminates

if a malfunction that could cause engine damage occurs. In most cases, the CHECK engine warning will

illuminate before the stop engine warning. When the

stop engine warning light illuminates, immediately

park the vehicle in a safe location and shut down the

engine. Continued operation with the stop engine

warning illuminated will lead to automatic engine

shutdown and possible engine damage.

Malfunction Indicator Lamp

The amber Malfunction Indicator Lamp (MIL) indicates an engine emissions-related fault. See the engine operators manual for details.

Engine Brake Light

A green engine brake light illuminates when the engine brake is applied.

Wait to Start Warning Light

The amber wait to start indicator light illuminates with

the ignition switch in the ON position prior to engine

start-up. Do not crank the engine until the wait to

start indicator light goes out.

DISPLAY MESSAGES

Selected Line 1 Data

Selected Line 2 Data

Selected Line 3 Data

Favorites Display Menu

Average Fuel Economy

Gear Attained Status

Right Press

Highlight First Item in List

Down Press

Move to, and Highlight,

Next Item in List

Right Press

Put Data For Highlighted Item

In Display Line

CurrentLine

Down Hold

Make No Changes

Down Press

Highlight

CurrentLine

HighlightTimer

= 5 sec.

WARNING

MESSAGES

AUXILIARY

SCREENS

New Warning

Message Active

Right Hold

Park Brake On

HighlightTimer

= 0

Right Hold

Reset Highlighted Item

(if resettable)

Screen C

Screen D

11/23/2011 f040790

Fig. 2.11, Display Messages

Instruments

2.12

Page 23

ABS Indicator

The amber ABS indicator light illuminates when there

is a malfunction in the vehicle antilock brake system

(ABS).

Shift Inhibit Indicator

On vehicles equipped with Allison 2100/2200/2500

series transmissions, the amber shift inhibit indicator

light illuminates whenever all conditions for safe

transmission shifting have not been met.

Check Transmission Indicator

The amber check transmission indicator illuminates

when the temperature of the transmission fluid goes

above the preset level set by the transmission manufacturer.

For more information, see the transmission manufacturer’s manual provided with the vehicle.

AUXILIARY SCREENS

SETUP

MAINTENANCE

DIAGNOSTICS

Down Press

Highlight next

line of list.

At middle,

wrap to top

MAINTENANCE

DIAGNOSTICS

Right Press

Setup

highlighted

Right Press

Diagnostics

highlighted

Right Press

Maintenance

highlighted

SETUP

SETUP.

DISPLAY

MESSAGES

Down Hold

TRIP DATA

Right Press

Trip Data

highlighted

Screen G

02/06/2012 f040791

Fig. 2.12, Auxiliary Screens

Instruments

2.13

Page 24

Stop Transmission (hybrid only)

The red warning light illuminates when the transmission control unit senses a malfunction.

Diesel Particulate Filter (DPF) Lamp

A solid amber illuminated DPF lamp indicates a regeneration is required. Change to a more challenging

duty cycle, such as highway driving, to raise exhaust

temperatures for at least 20 minutes, or perform a

stationary regeneration. See the engine operation

manual for details.

A blinking DPF lamp indicates that a stationary regeneration is required immediately. An engine derate

and shutdown will occur. See the instructions in the

MAINTENANCE

(Right & Exit

highlighted)

Right Press

Engine Oil

Highlighted

Right Press

Engine Air Filter

Highlighted

Down Press

Highlight next

line of list.

At middle,

wrap to top

Maint

Menu

Down Press

Display Next

Value of

Air

Change Distance

Air Change Baseline

+

Air

Change Distance

>=

Odometer

Air Change

Distance

= 0

else

Right Press

Air Change Distance

=

Current Displayed

Value

Right Hold

Air Change

Baseline

=

Odometer

Right Hold

Air Change

Baseline

=

Odometer

Right Press

Or

Down Hold

Right Press

Or

Down Hold

Down Press

Display Next

Value of

Oil

Change Distance

Oil Change Baseline

+

Oil Change Distance

>=

Odometer

else

Right Press

Oil Change Distance

=

Current Displayed

Value

Right Hold

Oil Change

Baseline

=

Odometer

Right Hold

Oil Change

Baseline

=

Odometer

Right Press

Or

Down Hold

Right Press

Or

Down Hold

Oil Change

Distance

= 0

09/23/2009 f040793

Fig. 2.13, Maintenance Menu Screens, Screen 1

Instruments

2.14

Page 25

engine manufacturer’s operator’s manual to perform

a stationary regeneration.

Right-Turn Signal Arrow

The green right-turn signal arrow flashes on and off

whenever the outside right-turn signal lights are

flashing. Both turn signal arrows flash when the hazard warning flasher is on.

Fasten Seat Belt Warning

The red fasten seat belt warning light (seat belt icon)

illuminates for 30 seconds after the ignition switch is

turned on.

WARNING

If the vehicle is equipped with an air suspension

system, do not move the vehicle with the air suspension deflated. Doing so could result in a loss

of vehicle control, possibly causing personal injury and property damage.

Air Brake Indicator

The red air brake indicator activates if the pneumatic

brake system air is low, or if the air suspension is

low.

Hydraulic Brake System Warning

The red brake system warning illuminates if there is

a hydraulic brake system failure, or if the vehicle is

powered and the engine is not running.

Headlight High-Beam Indicator

The blue high-beam indicator light illuminates when

the headlights are switched to the high-beam position.

Parking Brake On Indicator

The red parking brake indicator will flash for two minutes if the parking brake is not set when the ignition

is turned off. It will also flash if the park brake is set

02/06/2012 f040794

AUXILIARY

SCREENS

Right Hold

Send SPN 1584 = 39

Right Press

Transmission

Oil Life

Highlighted

Right Press

Transmission

Oil Filter

Highlighted

Right Press

Or

Down Hold

Right Press

Or

Down Hold

Right Press

Or

Down Hold

Maint

Menu

Right Hold

Send SPN 1584 = 37

Right Press

Or

Down Hold

Fig. 2.14, Maintenance Menu Screens, Screen 2

Instruments

2.15

Page 26

and the vehicle is moving at a speed of 2 mph (3

km/h) or more. The emergency buzzer will sound

until the parking brake is released and the driver display screen will show a PARK BRAKE SET message.

Cruise Control Indicator

A green indicator illuminates when the cruise control

is activated.

Auxiliary Power Generator (hybrid

only)

A green indicator illuminates when the auxiliary

power generator is activated.

Speedometer and Tachometer

Standard speedometers are shown in Fig. 2.1,

Fig. 2.2, Fig. 2.3, and Fig. 2.4, item 2 respectively.

Optional speedometer faces are available. The

NAFTA version (not shown) of the speedometer face

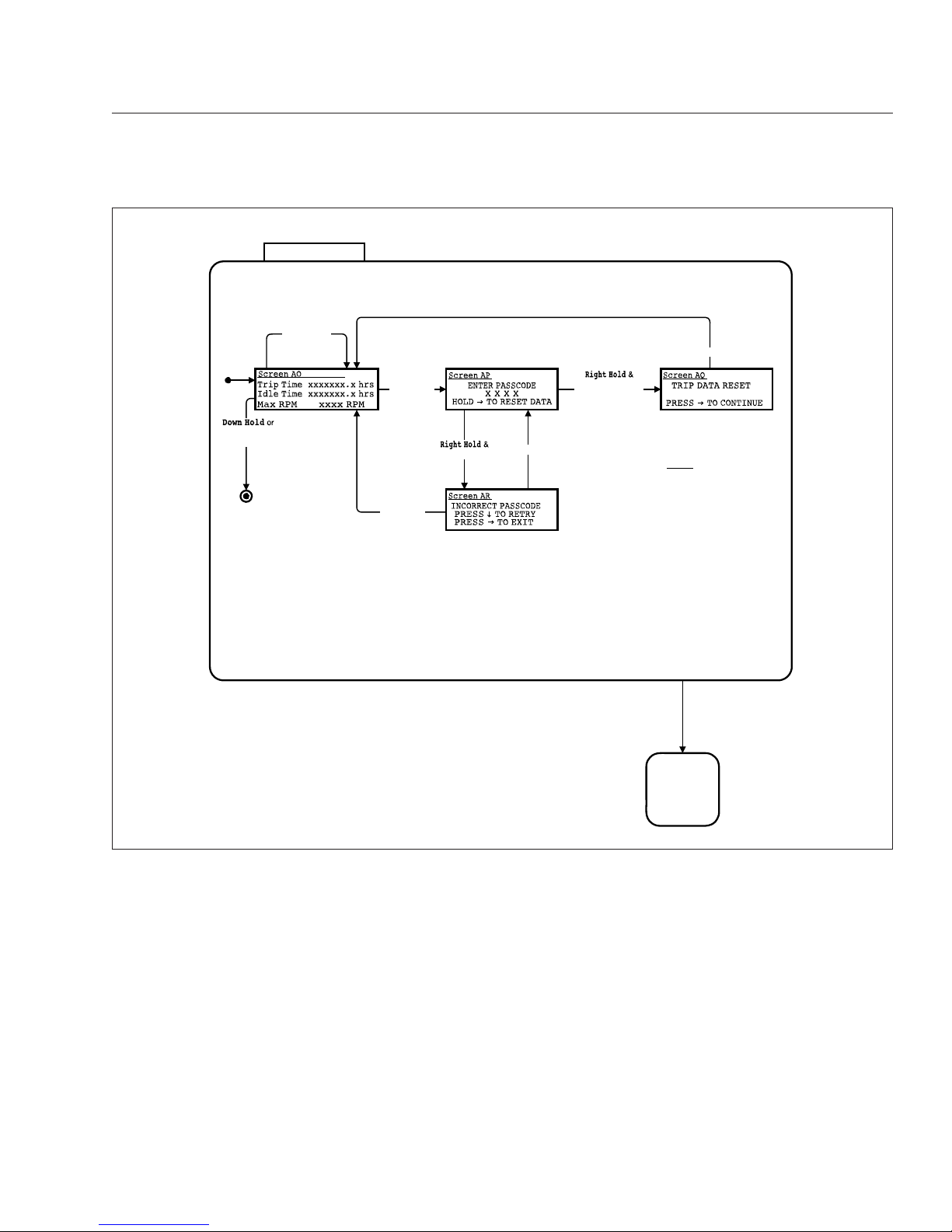

Trip Data

AUXILIARY

SCREENS

Note 6:

Screen AO scrolls to display

the following items:

Trip Time

Idle Time

Max RPM

Avg RPM

Max Speed

Avg Speed

Avg Fuel Economy

Reset All

Exit

Right Press

Reset All

Highlighted

Correct Passcode /

Reset Trip

Data

Right Press

Down Press

Highlight next

line of list.

At bottom,

wrap to top

(Right & Exit

highlighted)

Wrong Passcode /

Down Press

Right Press

09/23/2009 f040798

Fig. 2.15, Trip Data

Instruments

2.16

Page 27

reverses this arrangement, with km/h in larger numbers.

A tachometer is available as an option. See "Optional

Instruments."

Standard Instruments

Fuel Level Gauge

The fuel level gauge indicates the amount of fuel in

the fuel tank.

Low Fuel Warning Light

The low fuel warning light illuminates when the fuel

level in the fuel tank drops to a predetermined level.

When the low fuel warning light illuminates, refill the

fuel tank as soon as possible.

Engine Oil Pressure Gauge

NOTICE

A sudden decrease or absence of oil pressure

may indicate mechanical failure. Bring the vehicle

to a safe stop and investigate the cause to prevent further damage. Do not operate the engine

until the cause has been determined and corrected.

The engine oil pressure gauge is mission-critical. If

the engine oil pressure falls below preset levels, the

check engine light will illuminate. If the condition

does not improve, the CHECK engine light will also

illuminate and the buzzer will sound. At this point, the

engine will derate or shut down, depending on the

type of engine protection system installed.

02/06/2012 f040799

WARNING MESSAGES

DISPLAY

MESSAGES

H*

WARNING

Warning Message

No Warning

Messages in List /

Msg Displayed for 5 Sec. /

Display Next Entry in

Warning Message List

Any Button Press

/

Display 1st Message

in Warning

Message List

Screen AN

Fig. 2.16, Warning Messages

Instruments

2.17

Page 28

Low Oil Pressure Warning

The low oil pressure (oil can symbol) warning light

illuminates and a buzzer sounds when the oil pressure falls below the minimum oil pressure recommended by the engine manufacturer.

High Coolant Temperature Warning

A red high coolant temperature (thermometer symbol) warning light illuminates when the engine is running and the engine coolant temperature exceeds the

maximum coolant temperature recommended by the

engine manufacturer.

Coolant Temperature Gauge

NOTICE

A sudden increase in coolant temperature may

indicate engine or cooling system failure. Bring

the vehicle to a safe stop and investigate the

cause to prevent further damage. Do not operate

the engine until the cause has been determined

and corrected.

The coolant temperature gauge is mission-critical. If

the coolant temperature rises above preset levels,

the check engine light will illuminate. If the condition

does not improve, the CHECK engine light will also

illuminate and the buzzer will sound. At this point, the

engine will derate or shut down, depending on the

type of engine protection system installed.

Primary and Secondary Air Pressure

Gauges

WARNING

If air pressure falls below minimum pressure, the

braking ability of the vehicle will be limited. Slow

the vehicle down and bring it to a gradual stop.

Do not attempt to move the vehicle until air pressure has risen above the minimum level. Moving

a vehicle without adequate braking power could

IGNITION OFF

Park Brake On

Park Brake On

Park Brake Off

IGNITION

ON

Headlamps Off &

Marker Lamps Off &

Park Brake On

Ignition On

02/06/2012 f040800

Fig. 2.17, Ignition Off (shown when ignition is keyed OFF)

Instruments

2.18

Page 29

cause an accident resulting in property damage,

personal injury, or death.

Air pressure gauges register the pressure in the primary and secondary air systems. Normal pressure

with the engine running is 100 to 120 psi (689 to 827

kPa) in both systems.

Air pressure gauges are required on all vehicles with

air brakes. A low-air-pressure warning light and

buzzer, connected to both the primary and secondary

systems, activate when air pressure in either system

drops below a minimum pressure of 65 to 75 psi

(448 to 517 kPa).

When the engine is started, the warning light and

buzzer remain on until air pressure in both systems

exceeds minimum pressure.

Optional Instruments

Air Intake Restriction Gauge

An intake-air restriction indicator, mounted in the engine compartment, measures the vacuum on the engine side of the air cleaner at the air cleaner outlet.

See

Fig. 2.20.

Air intake restriction vacuum is measured in inches

of water (inH

2

O). For vehicles equipped with a

graduated indicator or a restriction gauge on the

dash, check the gauge with the engine off. If restriction reaches 25 inH

2

O, replace the air cleaner element. Reset the indicator by pressing the button on

the bottom.

NOTE: Rain or snow can wet the filter and

cause a higher than normal reading temporarily.

09/21/2009 f611052

1

2

345678910111213

14

15

1920

17

18

16

1. Maintenance Warning Light

2. Left-Turn Signal Arrow

3. High Exhaust System

Temperature (HEST) Lamp

4. Check Engine Indicator

5. Stop Engine Warning

6. Malfunction Indicator Lamp

7. Engine Brake Light

8. Wait to Start Warning Light

9. ABS Indicator

10. Shift Inhibit Indicator

11. Check Transmission Indicator

12. Stop Transmission (hybrid only)

13. Diesel Particulate Filter (DPF)

Lamp

14. Right-Turn Signal Arrow

15. Fasten Seat Belt Warning

16. Air Brake Indicator (low air

warning)

17. Hydraulic Brake System Warning

18. Headlight High-Beam Indicator

19. Cruise Control Indicator

20. Parking Brake On Indicator

Fig. 2.18, Warning Lights, Diesel

Instruments

2.19

Page 30

Single Air Pressure Gauge for

Hydraulic Brakes with Air Provision

This option is only available with hydraulic brakes

with air provision.

Transmission Fluid Temperature

Gauge

With an Allison automatic transmission, the transmission fluid temperature gauge reading should not exceed 250°F (121°C) during normal operation. If this

occurs, a warning light will activate to alert the driver.

Tachometer

A tachometer indicates engine speed in revolutions

per minute (rpm) and serves as a guide for shifting

the transmission and for keeping the engine in the

appropriate rpm range. For low idle and rated rpm,

see the engine identification plate.

09/21/2009 f611054

1

2

345678910111213

14

15

2021

17

18

16

19

1. Maintenance Warning Light

2. Left-Turn Signal Arrow

3. High Exhaust System

Temperature (HEST) Lamp

4. Check Engine Indicator

5. Stop Engine Warning

6. Malfunction Indicator Lamp

7. Engine Brake Light

8. Wait to Start Warning Light

9. ABS Indicator

10. Shift Inhibit Indicator

11. Check Transmission Indicator

12. Stop Transmission Indicator

13. Diesel Particulate Filter (DPF)

Lamp

14. Right-Turn Signal Arrow

15. Fasten Seat Belt Warning

16. Air Brake Indicator (low air

warning)

17. Hydraulic Brake System Warning

18. Headlight High-Beam Indicator

19. Parking Brake On Indicator

20. Cruise Control Indicator

21. Auxiliary Power Generator

Fig. 2.19, Warning Lights, Hybrid Electric Vehicle

01/18/95

f600148a

Fig. 2.20, Air Intake Restriction Gauge

Instruments

2.20

Page 31

3

Controls

Ignition Switch and Key ............................................................ 3.1

Electrical System General Information ................................................ 3.1

Lighting Controls .................................................................. 3.1

Turn Signal Switch ................................................................ 3.3

Horn Controls .................................................................... 3.3

Powertrain Controls ............................................................... 3.3

Braking and Steering Controls ....................................................... 3.5

Dash-Mounted Controls ............................................................ 3.6

Page 32

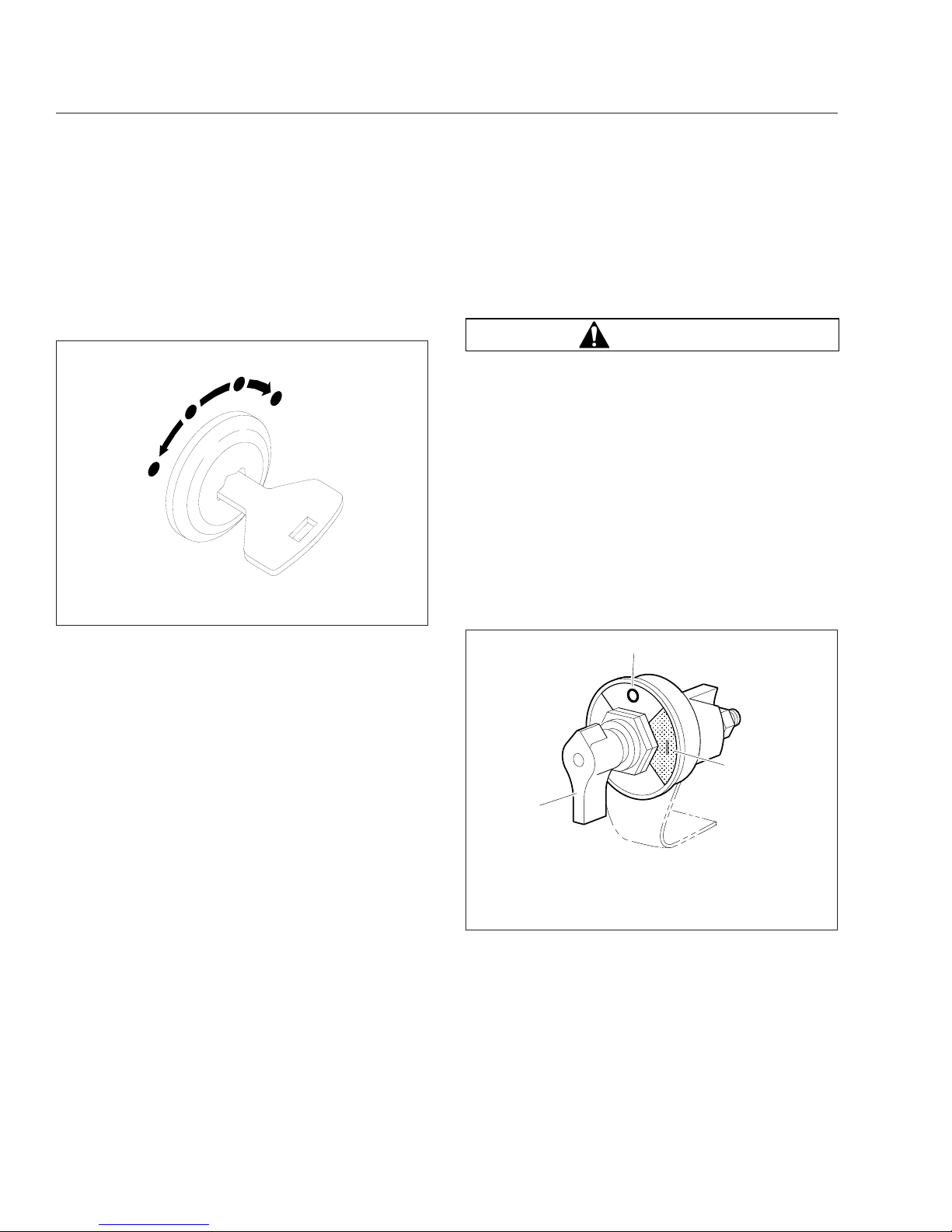

Ignition Switch and Key

On most vehicles, the ignition switch can be turned

to four positions: ACCESSORY, OFF, ON, and

START. See

Fig. 3.1. An optional three-position key-

less ignition switch does not have the ACCESSORY

position.

The key can be inserted and removed only from the

OFF position. The headlights (low beams), brake

lights, fog lights, dome lights, clearance lights, turn

signals, hazard warning lights, and the parking lights

operate with the ignition switch in the OFF position,

regardless of whether the key is inserted.

Turn the key fully clockwise to the START position,

only when starting the engine. When the engine

starts, release the key. When released, the key will

rotate counterclockwise to the ON position.

In the ON position (key turned 45 degrees clockwise), all electrical systems are operable. The warning lights and the buzzer for low engine oil pressure

operate until the engine is started and minimum engine oil pressure is achieved.

Electrical System General

Information

The Walk-In Van chassis uses multiple electrical signals that are carried along a simplified set of wires,

reducing the size of wiring bundles. There are significantly fewer wires overall, meaning less chance of

damage, shorts, and other problems. The information

in this chapter is to help familiarize the driver with the

basic electrical system. Servicing the electrical system should be done only by qualified technicians.

Special skills and equipment are required. Take the

vehicle to an authorized Freightliner service facility

for repairs.

WARNING

Do not attempt to modify, add, splice, or remove

electrical wiring on this vehicle. Doing so could

damage the electrical system and result in a fire

that could cause serious personal injury or property damage.

Battery Disconnect Switch (optional)

Some Walk-In Van chassis may be equipped with a

battery disconnect switch that can be used to prevent

unwanted drain from the vehicle battery when the

vehicle is not in use or is in storage. It can also rapidly disconnect from power supplies in the event of

an emergency. Mounting locations may vary. See

Fig. 3.2.

Lighting Controls

The lighting controls mentioned under this heading

generally operate through switches located on the

dash.

07/10/96

1

2

3

4

f601179

1. Accessory (optional)

2. Off

3. On

4. Start

Fig. 3.1, Ignition Switch Positions

f545041

2

3

1

05/16/2007

1. Power-Off Position

2. Battery Disconnected (red area)

3. Power-On Position (green area)

Fig. 3.2, Battery Disconnect Switch (optional)

Controls

3.1

Page 33

Headlight and Panel Light Controls

The control knob for the headlights, side marker

lights, taillights, parking lights, license plate lights,

and panel lights is located on the instrument panel.

See

Fig. 3.3 and Fig. 3.4. Control knob positions are

as follows:

•

All lights are off if the knob is pushed all the

way in.

•

If pulled out to the first stop, all lights are on

except the headlights.

•

If pulled all the way out, all lights including the

headlights are on.

•

Turn the knob to the right to brighten the panel

lights or turn it to the left to dim them.

•

Turn the knob all the way to the left (past the

click stop) to operate the courtesy lights.

Headlight High-Beam/Dimmer Switch

The headlight high beams are activated by pulling

the turn signal lever toward the driver. When the

headlights are on high beam, the high-beam indicator

light comes on in the instrument panel.

Hazard Warning Light Tab

The hazard warning light tab is located on the steering column under the turn signal lever. See Fig. 3.5.

Pull the tab out to turn on the hazard warning lights.

When the hazard warning light tab is pulled out, all of

the turn signal lights and both of the indicator lights

on the control panel will flash. To cancel the warning

lights, press the tab in.

An additional hazard warning light control knob may

be installed on the dash near the headlight controls.

To activate the hazard warning lights, pull this knob

out.

A

B

C

D

E

08/01/96

f601188

A. Off

B. All Lights Except Headlights

C. All Lights including Headlights

D. Panel Light Brightness

E. Courtesy Lights

Fig. 3.3, Headlight Control Knob

f601269

02/24/97

1

2

3

4

1. Windshield Wiper/Washer Control Knob

2. Headlight Control Knob

3. Cargo Light Switch

4. Cab Fan Switch

Fig. 3.4, Left-Hand Dash Panel

11/27/2007 f462122

Fig. 3.5, Hazard Warning Light Tab

Controls

3.2

Page 34

Turn Signal Switch

The turn signal switch lever is mounted on the steering column. See

Fig. 3.6. Pushing the lever down

turns on the left-turn signal lights; pulling the lever up

turns on the right-turn signal lights. When one of the

signal lights is on, a green indicator light flashes at

the left or right side of the warning and indicator light

panel. When the turn is completed, the signal will

cancel and the lever will return to the neutral position.

NOTE: The hazard warning light indicator on the

turn signal lever is to instruct the driver to pull

the hazard warning light tab that is located

under the turn signal lever.

Horn Controls

To sound the electric horn, push the horn icon on the

steering wheel. See

Fig. 3.7.

Powertrain Controls

Allison Automatic Transmissions

Allison automatic transmissions have either 6 or 7

shift positions on the selector lever. See

Fig. 3.8.

The selector lever is lighted for night driving. Electronically controlled transmissions have a pushbutton selector. See

Chapter 5 for complete trans-

mission operating instructions.

f545174

1

2

03/16/2015

1. Headlight High-Beam/Dimmer Switch

2. Hazard Warning Light Indicator

Fig. 3.6, Turn Signal Lever

f462078a

06/28/2007

1

1. Horn Pad/Icon

Fig. 3.7, Horn Control

1

P

R

N

3

D

4

09/12/2006

f261381

Fig. 3.8, T-Handle Shift Control (typical)

Controls

3.3

Page 35

Cruise Control (optional)

WARNING

Do not use the cruise control system when driving conditions do not permit maintaining a constant speed, such as heavy traffic or on roads

that are winding, icy, snow covered, slippery, or

roads with a loose driving surface. Failure to follow this precaution could cause a collision or

loss of vehicle control, possibly resulting in personal injury or property damage.

NOTE: The maximum cruise control speed allowed is 75 mph (121 km/h). However, some

vehicles may have a maximum cruise control

speed that is lower than 75 mph (121 km/h), if

the vehicle was ordered that way.

The cruise control is activated by two dash switches.

See Fig. 3.9.

•

The On/Off Switch—this two-position rocker

switch bears the legend SPD CNTL on the

lower half of the switch. When the cruise control is on, an amber light illuminates in the top

part of the switch.

•

The Set/Resume Switch—this three-position

paddle switch bears the legend RES/ACC

above the paddle and SET/CST below the

paddle.

1.

To cruise at a particular speed, do these steps:

1.1

Press the upper half of the On/Off (rocker)

switch on the instrument panel.

1.2

Hold the accelerator pedal down until the

speedometer reaches the desired speed.

1.3

Momentarily lower the paddle of the Set/

Resume switch to SET/CST.

2.

To disengage the cruise control, do these steps:

2.1

Press down the brake pedal (on automatic

or manual transmission) or

Press down the clutch pedal (on manual

transmission only)

2.2

Press the lower half of the On/Off (rocker)

switch on the instrument panel.

3.

To resume a preselected cruise speed, do these

steps:

3.1

If the On/Off (rocker) switch on the instrument panel is off, turn it on.

3.2

Momentarily raise the paddle of the Set/

Resume switch to RES/ACC. Cruise will

return to the last speed selected.

NOTE: If the ignition is shut off, the speed

memory will be lost.

4.

To adjust cruise speed up, raise the paddle of

the Set/Resume switch to RES/ACC and hold it

there until the vehicle accelerates to the new

speed, as desired.

5.

To adjust the cruise speed down, lower the

paddle of the Set/Resume switch to SET/CST

and hold it there until the vehicle decelerates to

the new speed, as desired.

NOTE: For more information about cruise control operation, see the engine manufacturer’s

service manual.

09/13/2001

1

2

f610510

To turn the cruise control on, press the upper half of the

On/Off (rocker) switch. To turn cruise control off, press

the lower half of the On/Off (rocker) switch.

1. Cruise Control On/Off (rocker) Switch

2. Cruise Control Set/Resume (paddle) Switch

Fig. 3.9, Cruise Control Switches, Dash-Mounted

Controls

3.4

Page 36

Manual Dump Valve (optional)

On vehicles equipped with a manual dump valve,

there are two ways to deflate the rear suspension.

With the key in the OFF position, toggle the dump

valve into the "lower" position. If the key is in the ON

position, the parking brake must be set (ON) before

the dump valve is toggled into the "lower" position.

NOTE: If the key is turned to the ON position

and the parking brake is not engaged, the override will cause reinflation of the air ride system.

Backup Alarm (optional)

An optional backup alarm, sounds when Reverse ®)

gear is engaged. Check the operation of the backup

alarm daily, if so equipped.

Braking and Steering Controls

Parking Brake Control

Hand-Operated Parking Brake

On all vehicles, a parking brake control lever is located to the left of the steering column. To apply the

parking brake, depress the brake pedal, then pull up

on the parking brake lever. To release the parking

brake, depress the brake pedal and push the parking

brake lever all the way down.

IMPORTANT: Take care to hold on to the parking brake lever while releasing it. Do NOT allow

the lever to slam down while releasing it.

NOTICE

Overtightening of the knob can lead to cable

breakage and/or damage to the knob and lever.

If the parking brake does not hold the vehicle securely, depress the brake pedal and release the

parking brake. Turn the knob on the end of the lever

clockwise to increase the parking brake application.

If the parking brake still doesn’t hold the vehicle securely (after adjustment), check the brake lining

thickness. For instructions, see Group 42 of the

Walk-In Van Chassis Maintenance Manual.

Hydraulic Parking Brake (optional)

To apply the hydraulic parking brake, pull the yellow

knob labeled PARKING BRAKE on the dash panel.

In order to release the hydraulic parking brake, the

engine must be running (hydraulic pressure is

needed to release the brake) and the gear selector

must be in the Neutral (N) position. To release the

parking brake, push the knob in.

CAUTION

On vehicles with hydraulic parking brakes, loss

of all hydraulic pressure will cause the parking

brake to automatically engage.

NOTE: If the gear selector is not in the Neutral

(N) position and the parking brake is on, a

buzzer will sound to let the driver know to place

the gear selector in the Neutral (N) position.

If the ignition key is in the OFF position and the

parking brake is not applied, a buzzer will sound

to let you know that you should apply the parking brake.

With the engine shut down, the hydraulic pump

will actuate with your foot on the brake pedal;

this could cause the battery to run down. If the

engine is inoperable, see the "Emergency Release of Parking Brake" procedure that follows.

Emergency Release of Parking Brake

(automatic transmission)

If your engine will not start and you want to release

the parking brake, do the following. Block the wheels

and turn the ignition switch to the ON position.

NOTICE

Do not crank the engine for more than 30 seconds at a time during any of the following procedures. Wait two minutes after each try to allow

the starter to cool. Failure to do so could cause

starter damage.

Use the ignition switch to turn the engine over several times with the gear shift selector in the Neutral

(N) position and the parking brake knob in the released (pushed) position.

NOTE: The emergency release will not work in

all cases. The system requires hydraulic fluid to

provide pressure for the procedure to work.

Since the system is pressurized when the brake

is released, the parking brake will come back on

Controls

3.5

Page 37

in 10 minutes, or longer depending on internal

pressure.

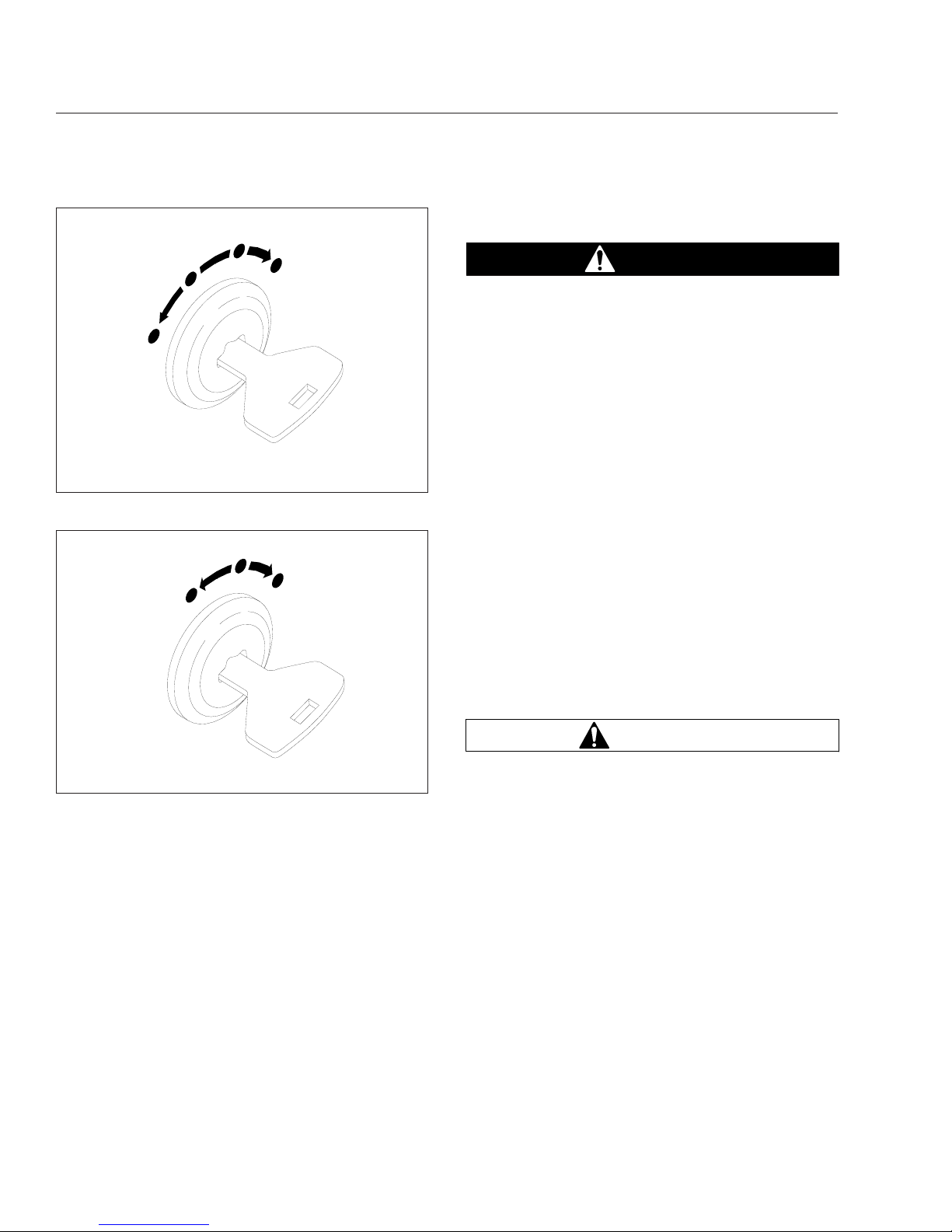

Tilt/Telescope Steering Column

Lever Adjustment (optional)

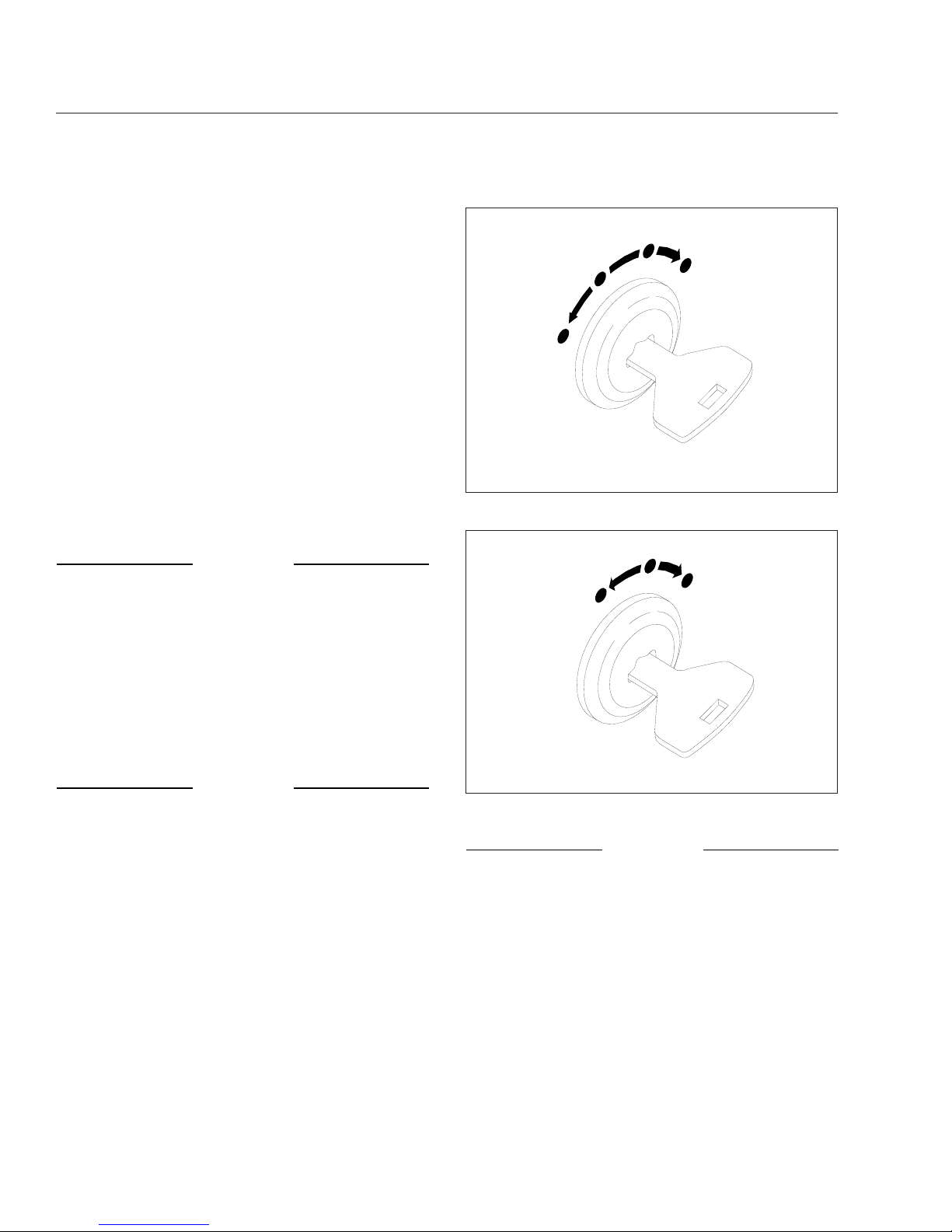

To change the position of the steering wheel, pull the

lever upward and move the steering wheel to the desired position. See Fig. 3.10. Release the lever to

lock the position. The steering wheel can be tilted up

to provide easier exit and reentry.

If the chassis is equipped with a telescoping steering

column, push the lever down and extend or retract

the steering wheel as desired.

Foot Pedal Adjustment (optional)

If the tilt/telescope steering column is equipped with

a foot pedal adjustment, depress the foot pedal to

move the steering column to the desired position.

Release the foot pedal to lock the position. See

Fig. 3.11.

Dash-Mounted Controls

Aftertreatment System (ATS) Regen

Switch

A regen switch is located on or under the dash with

which the driver can control two states. See

Fig. 3.12. These include:

•

Request regeneration

•

Default (automatic regeneration)

10/12/2007

f462115

1

1. Tilt/Telescope Lever

Fig. 3.10, Tilt/Telescope Steering Column with Lever

Adjustment

f462016

1

05/11/2005

1. Tilt/Telescope Foot Pedal

Fig. 3.11, Tilt/Telescope Steering Column with Foot

Pedal Adjustment

f610848

03/09/2012

RGEN

Fig. 3.12, ATS Regen Switch

Controls

3.6

Page 38

See the engine operation manual for details on

operation of the regen switch.

Low Idle Adjustment Switch

NOTE: The low idle adjustment switch is not

available on hydraulic hybrid units.

On some vehicles equipped with Cummins ISB engines, the engine low idle speed can be adjusted in

25 rpm increments with a low idle adjustment switch.

On these vehicles, the engine control unit is programmed to allow low idle speeds between 700 and

875 rpm.

Windshield Wiper Switch

The windshield wipers are controlled by a dashmounted knob. See

Fig. 3.4. For a single wipe cycle,

turn the knob counterclockwise. Hold it in this position until the wipers start, then release the knob. For

steady wiping at low speed, turn the knob clockwise

one position. For high-speed wiping, turn the knob

clockwise to the high-speed position.

NOTE: Heavy snow or ice can overload the

wiper motor. A circuit breaker will stop the motor

until it cools. Make sure that the windshield is

cleared of snow or ice to prevent a circuit overload.

Windshield Washer Switch

Push in and hold the windshield wiper control knob

until the desired amount of washer fluid is sprayed

on the windshield. See

Fig. 3.4. The wipers will oper-

ate on low speed until they are turned off.

Controls

3.7

Page 39

4

Engines

Engine Starting ................................................................... 4.1

Engine Operation ................................................................. 4.2

High Idle Options ................................................................. 4.3

Exhaust Aftertreatment System (ATS) ................................................. 4.3

Engine Shutdown ................................................................. 4.9

Page 40

Engine Starting

General Information

This engine chapter is to serve as a guide for best

practices only. Each make and model engine may

have operating characteristics that are unique to that

particular engine, and will be documented in the engine manufacturer’s literature. Always refer to specific

instructions and recommendations from the engine

manufacturer.

NOTE: Before starting the engine, read Chap-

ter 2

and Chapter 3 of this manual for detailed

information on how to read the instruments and

operate the controls.

Normal Starting

WARNING

Do not use any starting aid, such as ether, in engines with an air intake heater. This could cause

an explosion and serious personal injury or

death.

NOTE: Cummins engines are run on a dynamometer before being shipped from the factory.

They do not require a break-in period.

IMPORTANT: Special break-in oils are not recommended for new or rebuilt Cummins engines.

NOTICE

If a vehicle does not start on the first attempt,

make sure that the engine has completely

stopped rotating before reapplying the starter

switch. Failure to do so can cause the pinion to

release and re-engage, which could cause ring

gear and starter pinion damage.

Moving a vehicle with the starter and/or using the

starter to bump the engine for maintenance procedures is strictly prohibited. Use of these methods to bump the engine over or move the vehicle

can cause the pinion to release and re-engage,

which could cause ring gear and starter pinion

damage.

IMPORTANT: Ring gear and starter pinion damage caused by improper starting procedures is

not warrantable.

NOTICE

Do not crank the engine for more than 30 seconds at a time. Wait two minutes after each try to

allow the starter to cool. Failure to do so could

cause starter damage.

NOTICE

If the engine is equipped with a turbocharger,

protect the turbocharger during start-up by not

depressing the accelerator pedal until normal engine idle oil pressure registers on the gauge.

1.

Before engine start-up, complete the pre- and

post-trip inspections and maintenance procedures in Chapter 10.

2.

Set the parking brake.

3.

Place the transmission in neutral.

4.

Turn the key to the ON position and allow the

gauge sweep to complete. The audible alert will

sound for approximately four seconds.

During cold conditions, the WAIT TO START

lamp may illuminate. Wait until the lamp goes out

before turning the key to START.

5.

After the gauge sweep has completed, turn the

key to the START position.

NOTICE

Do not rev the engine if the oil pressure gauge

indicates no oil pressure. Shut down the engine

if oil pressure does not build within approximately ten seconds. Check to determine the

cause of the problem. Operating the engine with

no oil pressure will damage the engine.

6.

Apply load gradually during the warm-up period.

NOTICE

If the oil pressure gauge indicates no oil pressure, shut down the engine within approximately

ten seconds to avoid engine damage.

7.

Check the oil pressure gauge for any drop in lubricating oil pressure or mechanical malfunction

in the lubricating oil system. Minimum oil pressure at idle is 7 psi (50 kPa).

Engines

4.1

Page 41

Cold-Weather Starting

See the engine manufacturer’s operation manual for

starting aids that are approved for specific engines.

If the unit is equipped with a block heater, start the

block heater two to four hours before travel.

Engine Operation

Normal Operation

WARNING

Do not operate the engine in an area where flammable vapors such as gasoline or diesel fumes

are present. Shut off the engine when in an area

where flammable liquids or gases are being

handled. Failure to observe these precautions