Page 1

ALTA X

Features

Worlds Toughest Drone Flight Time

Introducing the world's toughest drone: ALTA X.

Page 2

ALTA X folds to 30% of its full size to fit in

ALTA X is designed to be a platform that

In order to keep ALTA X in the field as

Speed

Packability

External Power

Easy Integration

Never worry about keeping up with the

the same case as ALTA 8 while still being

Five user accessible power expansions

can be customized for any aerial need;

much as possible all ALTA X parts can be

Easy Deployment

Flight Modes

Expandability

External Computer

We’re confident in ALTA X because we

action again, ALTA X has a top speed of

able to carry 175% ALTA 8’s payload. This

allow ALTA X to power any accessories or

from cinema, to forestry, and bridge

bought as spares and replaced onsite. Of

push it to the limit, and then well past -

over 60mph (95km/h), just make sure that

case is TSA approved and has been tested

payloads you need to do the job.

inspection, ALTA X is a versatile tool ready

course we will still offer factory checkups

over and over again so that we know our

the action can keep up with ALTA X!

to ensure ALTA X arrives to location ready

for any challenge.

and repair services should they be needed!

customers will have plenty of margin in the

to go!

Like all Freefly products, ALTA X is backed

User repairable

unpredictable real world.

High quality sensors and GPS modules

by a team of experts ready to answer any

Customer Service

Payload

allow ALTA X to maintain its position and

questions and make sure you get the job

ActiveBlade

height even in the most unfavorable

done.

ALTA X can carry up to a 35lb payload

weather conditions providing assurances

while maintaining a 2:1 thrust to weight

during autonomous waypoint missions and

ratio.

piloted flights.

Four ActiveBlades reduce the motor

vibrations to 1/5th the normal level. This

No assembly required! Using a clever rotating

Designed with the future in mind, ALTA X is

Some drone applications require real time

planar linkage ALTA X folds and unfolds with

modular and easily expandable to adapt to

onboard computing; ALTA X has the necessary

An effort to make ALTA X as light as possible

ease! This revolutionary feature allows ALTA X

ever changing technology. This expandability

mounts, power, and I/O so it can be upgraded

allows ALTA X to fly MōVI Carbon (20lb

to go from case to flight within minutes,

ensures that ALTA X will continue to be statewith an external computer.

payload) for 25 minutes, or a max payload for 8

reducing setup time and minimizing the risk of

of-the-art even after years of service.

minutes. Smaller payload flight times can

misassembly on the job.

exceed 40 minutes

innovative solution to reduce vibrations

increases the lifetime of ALTA X and helps

keep any payload stable.

Page 3

We’re confident in ALTA X because we

An effort to make ALTA X as light as possible

push it to the limit, and then well past over and over again so that we know our

customers will have plenty of margin in the

unpredictable real world.

Introducing ALTA X

allows ALTA X to fly MōVI Carbon (20lb

payload) for 25 minutes, or a max payload for 8

minutes. Smaller payload flight times can

exceed 40 minutes

ALTA X is a professional multi-rotor aircraft designed for demanding cinematic,

professional, and industrial applications. Completely redesigned from the ground up, ALTA X

is the next generation of the ALTA family. Built for the user, ALTA X emphasizes

expandability and customization to make sure it can stand up to all challenges thrown its

way, while still being the reliable workhorse drone that ALTA pilots know and love.

This Aircraft Flight Manual describes the complete operation of airframe and flight control

systems, and the normal maintenance of those items. Do not operate ALTA X without

reading and understanding this manual.

This manual is not a substitute for adequate flight training. Training requirements can vary

Page 4

when operating in different countries or under different flight conditions. Always consult

local regulations before flying ALTA X. In areas where there are no flight training

requirements, it is the sole determination of the pilot-in-command as to whether he or she

has the appropriate level of training or experience for a given flight. Always set and adhere

to personal minimums and fly within your own capabilities.

Throughout the manual warnings, cautions and notes are used to highlight various

important procedures. These are defined as follows:

{% hint style="danger" %} Warnings are used to highlight procedures which, if not strictly

observed, may result in personal injury. {% endhint %}

{% hint style="warning" %} Cautions are used to highlight procedures which, if not strictly

observed, may cause damage to equipment. {% endhint %}

{% hint style="info" %} Notes are used to highlight specific operating conditions, usability

tips and tricks or steps of a procedure. {% endhint %}

Legal

Disclaimer and Warning

Please read this disclaimer and warning carefully and review the ALTA X Aircraft Flight

Manual (AFM) prior to flight. If you have any questions, please contact

support@freeflysystems.com prior to using the ALTA X. You can review the most current

version of this manual on the ALTA X Support Page. By using ALTA X, you acknowledge that

you have read, understand and agree to this disclaimer. You agree that you are solely

responsible for your conduct while using ALTA X, and for any direct or indirect consequences

that may result from its use. You agree to only use ALTA X for proper purposes that are in

accordance with local and airspace rules and regulations.

ALTA X is not a toy and should be operated with extreme care, as improper operation

can cause damage to property, serious personal injury or death.

As with any multi-rotor aircraft, ALTA X is a complex and technical machine. Novice

Page 5

pilots should invest sufficient time on a flight simulator and seek training from an

experienced pilot prior to operation. The ALTA X Aircraft Flight Manual and a flight

simulator are no substitute for training with an experienced pilot, particularly when it

comes to learning how to safely operate ALTA X. Novice pilots should never fly without

the supervision of an experienced pilot.

Always check ALTA X and its components prior to operation.

Always maintain a safe distance from ALTA X when in use.

Never attempt to touch ALTA X when the propellers are moving.

Never fly ALTA X over or around people, power lines or other aircraft.

Never fly with any propellers that have visible imperfections or damage.

Always keep children and animals a safe distance away from ALTA X when in use and

when changing configurations.

Only use propellers supplied by Freefly Systems that are designed for use on ALTA X.

Always remove the propellers or power ALTA X using a low power source when making

a change to the configuration of ALTA X to prevent propeller strikes in the event of

unintentional motor starts.

Always remove the configuration jumper when making changes to the configuration of

ALTA X.

Always test ALTA X with the propellers removed to make sure that the motors are

spinning in the correct direction and that the motor assignment is correct with respect

to the Autopilot flight controller. If you have either of these wrong, the ALTA X will be

uncontrollable and dangerous.

It is your responsibility to perform a full system check of ALTA X prior to every flight.

It is your responsibility to learn how to safely operate ALTA X and to adhere to all

applicable rules and regulations.

Fly at your own risk.

ALTA X is a tuned system with custom components selected for each application.

Modification, removal, or substitution of ALTA X components will void the warranty

and can lead to unsafe operating conditions.

Limitations of Liability

IN NO EVENT SHALL FREEFLY BE LIABLE TO BUYER FOR ANY INDIRECT,

Page 6

CONSEQUENTIAL, PUNITIVE, INCIDENTAL, OR SPECIAL DAMAGES, OR ANY DAMAGES

WHATSOEVER RESULTING FROM THE USE OF ALTA OR FROM LOSS OF USE, DATA OR

PROFITS (HOWEVER CAUSED AND UNDER ANY THEORY OF LIABILITY), EVEN IF

FREEFLY HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. IN NO EVENT

SHALL FREEFLY’S LIABILITY FOR A PRODUCT (WHETHER ASSERTED AS A TORT CLAIM,

A CONTRACT CLAIM OR OTHERWISE) EXCEED THE AMOUNTS PAID TO FREEFLY FOR

SUCH PRODUCT. NOTWITHSTANDING ANYTHING HEREIN, IN NO EVENT SHALL

FREEFLY’S LIABILITY FOR ALL CLAIMS ARISING OUT OF OR RELATING TO THIS

AGREEMENT EXCEED THE AMOUNTS PAID BY BUYER TO FREEFLY FOR PRODUCT IN

THE LAST TWELVE (12) MONTHS. IN NO EVENT WILL FREEFLY BE LIABLE FOR COSTS OF

PROCUREMENT OR SUBSTITUTE GOODS BY BUYER. THE LIMITATIONS SET FORTH

HEREIN SHALL APPLY TO ALL LIABILITIES THAT MAY ARISE OUT OF THIRD-PARTY

CLAIMS AGAINST BUYER. THESE LIMITATIONS SHALL APPLY NOTWITHSTANDING ANY

FAILURE OF ESSENTIAL PURPOSE OF ANY LIMITED REMEDY. Freefly shall not be liable for

damages or injuries incurred directly or indirectly from the use of ALTA X including, but not

limited to, the following situations:

Failure of the operator to follow proper instructions and safety warnings found at

www.freeflysystems.com.

Failure of the operator to understand and operate the aircraft within the operating

limitations described in this manual.

Failure of the operator to follow onboard safety warnings while using ALTA X.

Failure of the operator to follow and comply with local rules and regulations.

Failure of the operator to follow and comply with the local communications law.

Failure of the operator to inspect ALTA X and its components prior to operation.

Failure of the operator to properly maintain and/or service ALTA X through an

authorized Freefly Service Center with genuine ALTA X parts.

Use of third-party products on ALTA X.

Use of ALTA X in a physically or mentally impaired capacity.

Use of ALTA X without sufficient training.

Use of ALTA X in unsafe conditions, including but not limited to, bad or severe weather,

such as rain, wind, snow, lightning, dust storms, etc., or in areas of magnetic or radio

interference, such as power stations, broadcasting and cell phone towers, government

Page 7

prohibited airspace, etc.

Improper operation, misjudgment or risky behavior while using ALTA X.

Infringement of third party data, audio, or video rights recorded when using ALTA X

Appendix

Specifications

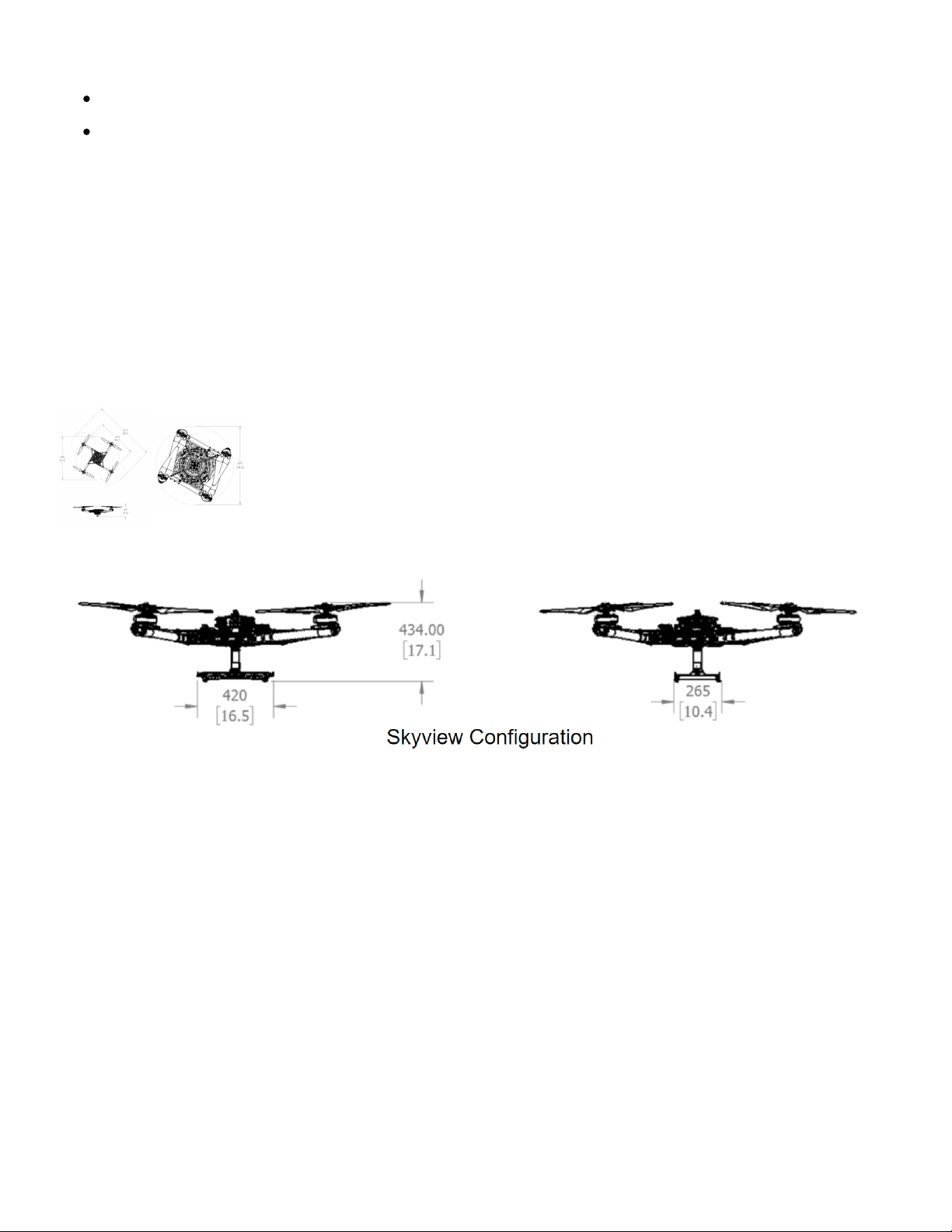

Dimensions

Dimension Length [mm]

Unfolded Diameter (not including props)

1415

Unfolded Diameter (Including Props)

2273

Folded Diameter

877

Height

387

Page 8

Dimension Length [mm]

Height (Skyview) 434

Powerplant

Number of Motors 4

Motor Max Continuous Power Output 100 A

Motor Max Instantaneous Peak Power Output 130 A (>3s)

Equivalent Kv 115 rpm/V

Propellers

Material Carbon Fiber Reinforced Nylon

Propeller Orientation (2x) CW and (2x) CCW Props

Propeller Type Folding - 840 x 230 mm (33 x 9in)

Battery

Cells 12S

Nominal Battery Voltage 44.4V

Charged Battery Voltage 50.4V

Battery Connectors XT-90

320 Amps per battery

Required Minimum Battery Discharge

Rating (Per Pack)

(assumes two batteries) 20C for a 16Ahr pack.

Weight

Maximum Gross for Takeoff 34.9kg

Maximum Payload 15.9kg

Typical Standard Empty Weight 10.4 kg

Page 9

Flight Controller

Autopilot Name Custom Auterion PX4 flight control stack

Flight Modes Manual, Altitude, Position, Mission, Loiter, Orbit, Return

Supported Inputs MAVlink SDK

Futaba, Spektrum, PX4 compatible SBUS and PPM

Supported Radios

receivers

Supported Radio Controller

Voltage feed provided for Futaba RX telemetry

Telemetry Systems

Minimum Radio Controller

5 (roll, pitch, yaw, throttle, mode)

Channels Required

Supported GNSS GPS/Glonass/Beidou/Galileo

Lighting and Indication

Orientation Lights Boom tip mounted LEDs

Orientation Light Color

Options

FPV Ability

User controlled in software - red, orange, yellow, green, cyan,

blue, purple, white, and off.

Yes, see the FPV integration section for instructions on how

to mount the FPV.

Isolation Systems

Vibration Isolation System Built-in (see chart below for weight suggestions)

Payload [lb] Payload [Kg] Isolator Durometer Cartridge Qty

0 - 3 * 0 - 1.4 30A 3

4 - 10 * 1.8 - 4.5 30A 6

11 - 19 ** 5.0 - 8.6 30A 9

20 - 23 ** 9.1 - 10.4 30A/40A 9

24 - 29 ** 10.9 - 13.2 40A 9

30 - 32 ** 13.6 - 14.5 40A/50A 9

Page 10

Payload [lb] Payload [Kg] Isolator Durometer Cartridge Qty

33 - 35 ** 15.0 - 15.9 50A 9

>35 *** >15.9 60A 9

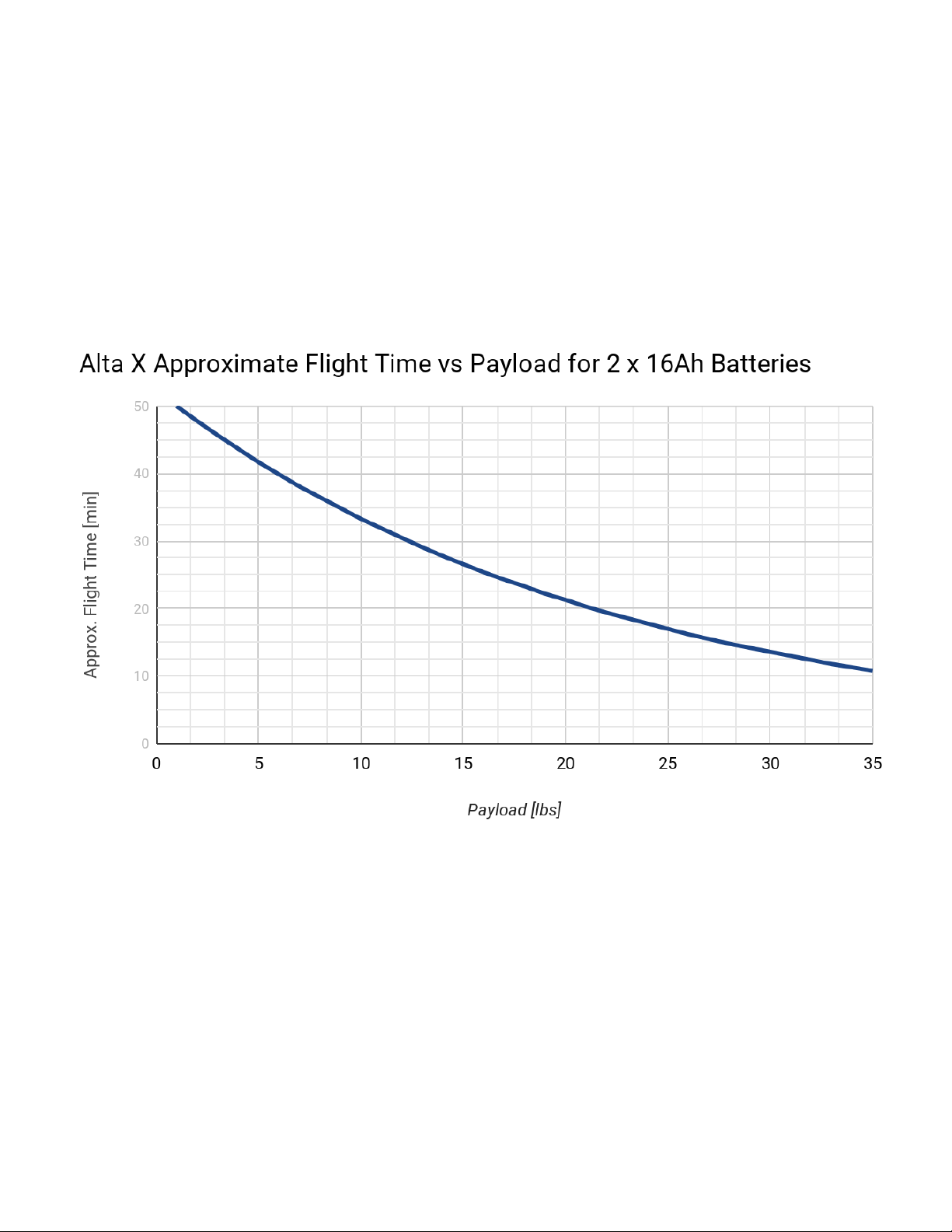

Performance Charts

Flight Time v. Payload

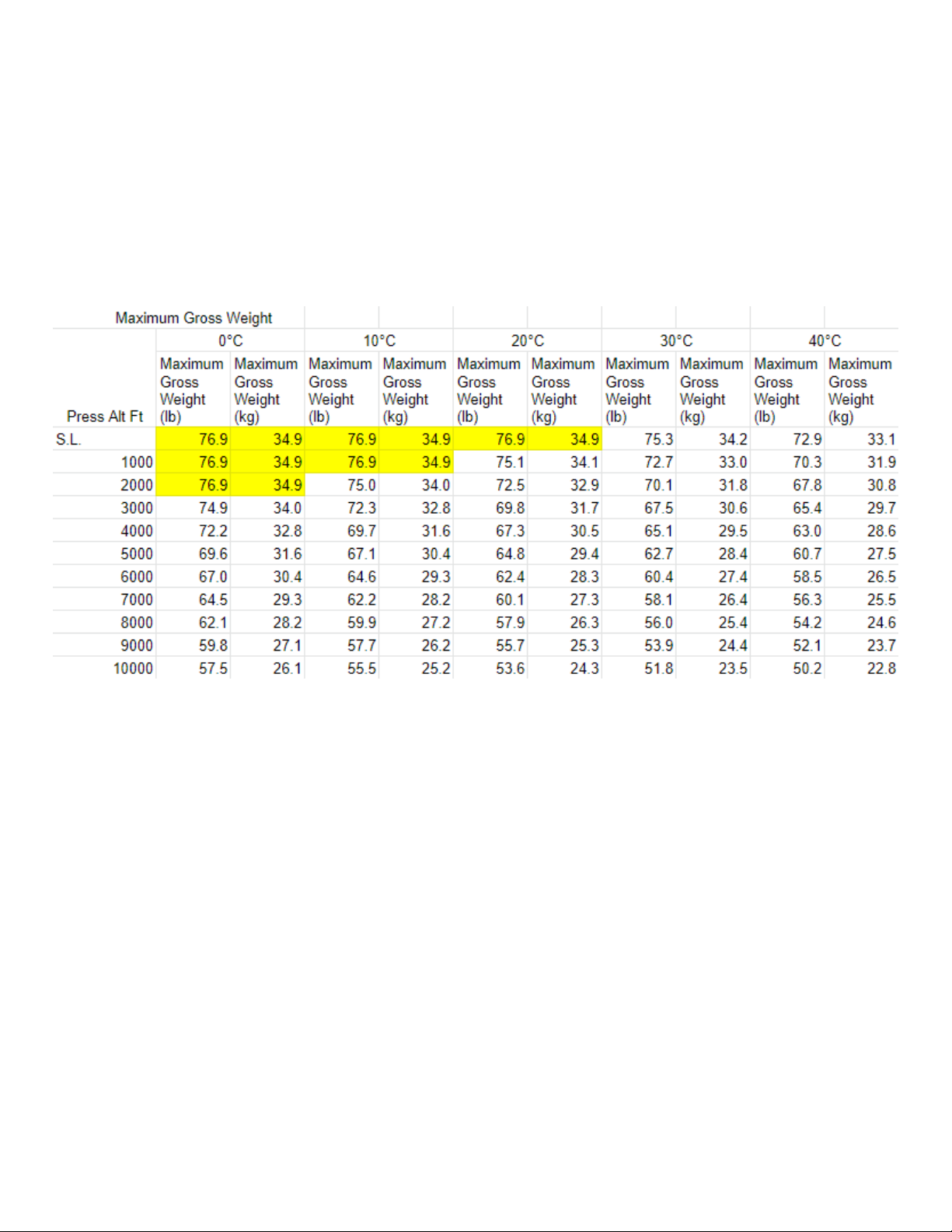

Maximum Gross Weight

To determine maximum gross weight, determine flight location pressure altitude and

temperature, and refer to the weight in the chart below. Gross Weight includes payload,

battery and structure weight.

Page 11

The maximum gross weight might exceed the weight allowed by regulatory agencies. When

determining gross weight, please consider any such local restrictions on aircraft weight when

planning aircraft weight.

{% hint style="info" %} The maximum gross weight at a defined density altitude was

established by calculating weight so that sufficient thrust margin for maneuvering is

maintained. {% endhint %}

{% hint style="info" %} Cells highlighted in yellow indicate where the weight is limited by the

maximum design weight {% endhint %}

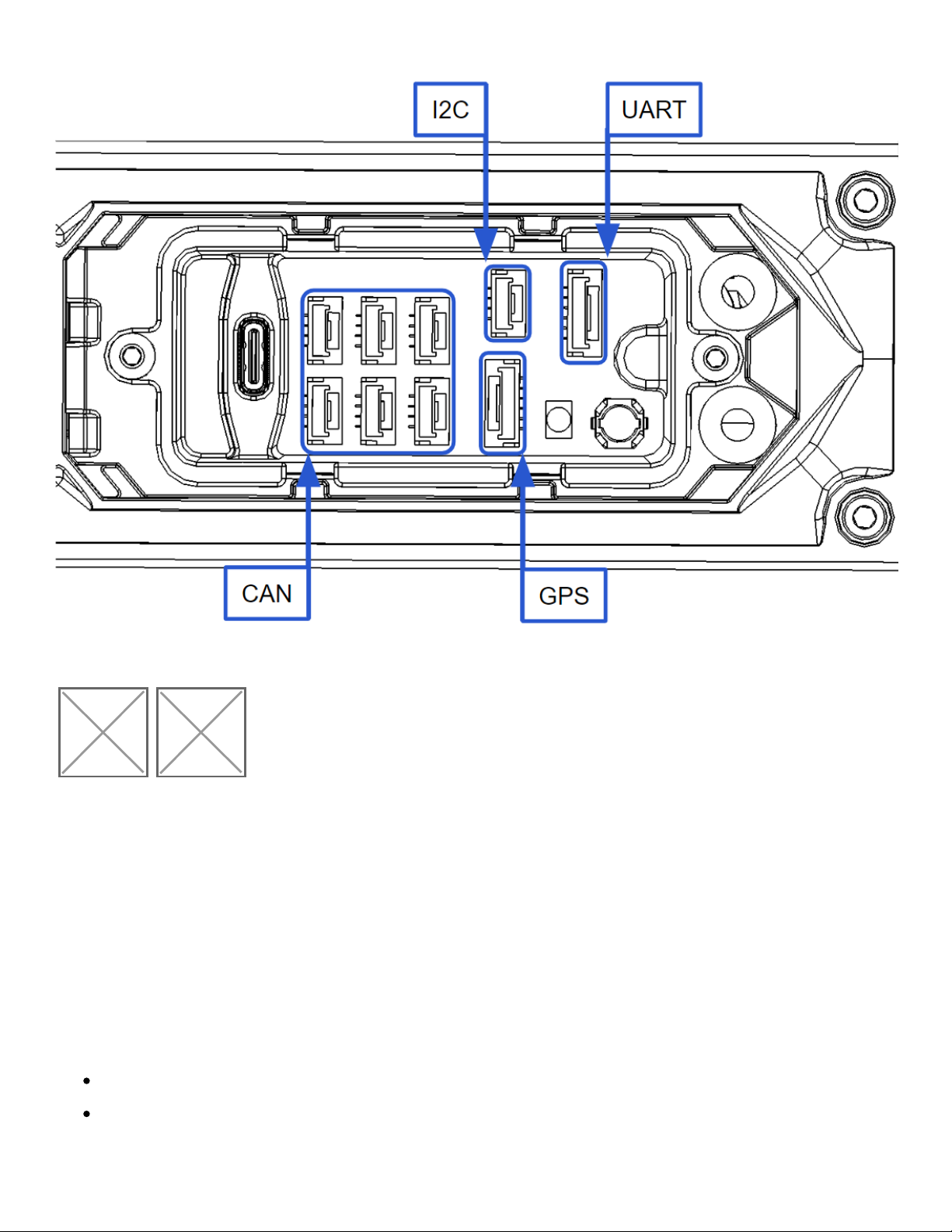

Expansion Ports

External Com Expansion

The external communications expansion port is located between booms 1 and 2 on the ALTA.

Page 12

GH-6 Pin GH-4 Pin

Image not found or type unknownImage not found or type unknown

5V External Power

The external expansion connector port 5V power is provided by a dedicated 5V 3A current

limited power supply separate of the redundant 5V power supplies for the flight controller.

Each output on the external expansion connectors is protected by a 1.1A hold 2.2A trip PTC

(Part number 0ZCG0110FF2C). The sum of the power supplying the following components

must be less than 3A:

Motor boom LEDs (approx 1A during flight with 2x red and 2x green LEDs)

Long range radio if not powered via other means (FRX Pro is powered by 12V)

Page 13

All internal CANbus peripherals on CAN expansion connectors

All external UART, I2C, and CANbus connectors

UART Port - GH-6 Pin

MAVLink serial communications at 57600b 8-N-1

Pin Signal Voltage (V)

1 VCC +5V

2 TX (Out) +3V

3 RX (In) +3V

4 CTS (In) +3V

5 RTS (Out) +3V

6 GND GND

GPS2 Port - GH-6 Pin

Nuttx console output at 57600b 8-N-1.

Pin Signal Voltage (V)

1 VCC +5V

2 TX (Out) +3V

3 RX (In) +3V

4 I2C1 SCL +3V

5 I2C1 SDA +3V

6 GND GND

CAN Ports - GH-4 Pin

Peripheral CANbus for future expansion.

Pin Signal Voltage (V)

1 VCC +5V

Page 14

Pin Signal Voltage (V)

2 CAN_H +5V

3 CAN_L +5V

4 GND GND

{% hint style="warning" %} WARNING: Internal Long Range RF CAN is 12V VCC, do not use!

{% endhint %}

I2C Ports - GH-4 Pin

I2C bus for future expansion

Pin Signal Voltage (V)

1 VCC +5V

2 I2C1 SCL +3V

3 I2C1 SDA +3V

4 GND GND

Power Expansion

The power expansion port is located between booms 1 and 2 on the ALTA; it contains three

externally-facing and two internally-facing direct battery connected power expansion

connectors with female socket pin XT-30 type connectors. Each external output is protected

by a 10A automotive mini blade type fuse. The replacement fuse part number is

0297010.WXNV.

The system and fuses are sized to supply 10A or less continuously on each external port

simultaneously; the internal connectors share the same fuse with the external connector J1.

Please note that the output voltage will vary with system battery voltage as the battery

discharges.

{% hint style="warning" %} Use of any other size fuse could cause the aircraft to crash if

shorted. {% endhint %}

Page 15

Maintenance

Interval Inspections

Every 15 Flights

ALTA X is designed to be as low-maintenance as possible. It is recommended to check ALTA

X’s fasteners regularly. This check should occur roughly after every 15 flights. To check ALTA

X’s fasteners, apply a tightening torque to each fastener on the chassis using the supplied

hex drivers. The fasteners should not slip.

Inspect Fastener Tightness

Check the tightness of the following fasteners:

Motor mount bolts

Boom clamping bolts

Prop hub bolts

Prop bolts

Top and bottom chassis bolts

Closeout panel bolts

FPV camera mounting plate bolts

Boom stay attachment bolts

GPS/Compass mounting bolts

{% hint style="info" %} If a fastener does slip, tighten it using the methods described in the

Fastener Installation section. Do not apply additional thread locking compound unless the

fastener has repeatedly come loose. {% endhint %}

Every 15 Flight Hours

Inspect Fastener Tightness

Page 16

Check the tightness of the fasteners as described above.

Inspection Wear Components

Inspect the following items. Replace if worn.

Propeller blades - Chips, cracks, or deep scratches

ActiveBlade bumpers

Broken or crushed

Inspect Boom Ring Latch Tightness

Check boom latching tightness by closing the latch. There should be a firm closing force and

click. Adjust the tension by using a 2.0mm hex wrench on the set screw located in the rear of

the latch link.

Replacement of Parts

Spare or replacement parts are available for sale separately at freeflysystems.com. Please

refer to the store for a current listing of all available spare parts.

{% hint style="warning" %} Use Of Threadlocker

Bolts and screws used in the daily use of this aircraft do not require threadlocking

compound. This includes the screws holding on the battery trays, vibration isolation system

and the Skyview landing gear parts.

However, for the structural fasteners described in parts of this section blue Loctite 243

compound or equivalent is required. Apply sparingly to the threads before insertion. {%

endhint %}

{% hint style="warning" %} Fastener Installation

The Freefly hex drivers included with ALTA X are designed to limit the torque that can be

applied to each bolt or screw and help prevent stripping the fastener head.

Thread all fasteners into their respective holes until snug (when the fastener head bottoms

Page 17

out and lightly clamps the two mating parts together).

To prevent excessive tightening and damaging the fastener or parts, twist the driver from

the smaller diameter knurled section of the tool between your thumb and index finger for

small fasteners (under size M3) or with your thumb and two forefingers for larger fasteners

(size M3 and larger). {% endhint %}

{% hint style="danger" %} Before performing any part replacement, ensure that ATLA X has

been unplugged from any power source. Leaving ALTA X powered while performing any work

on it can result in a potentially dangerous situation. {% endhint %}

Replacing ActiveBlade Bumpers

Push down on one side of the ActiveBlade assembly to open the gap and

1.

provide better access. Pull the bumper out from that side.

2. Repeat this for the second bumper.

To replace, insert the tail of the new bumper into the hole and pull into

3.

place, until the shoulder is fully seated. A circular motion may help with

seating.

To replace the second bumper, push down on the ActiveBlade assembly

4.

and again pull the tail of the bumper to seat.

Rock the the ActiveBlade assembly back and forth to make sure the

5.

bumpers are aligned.

****

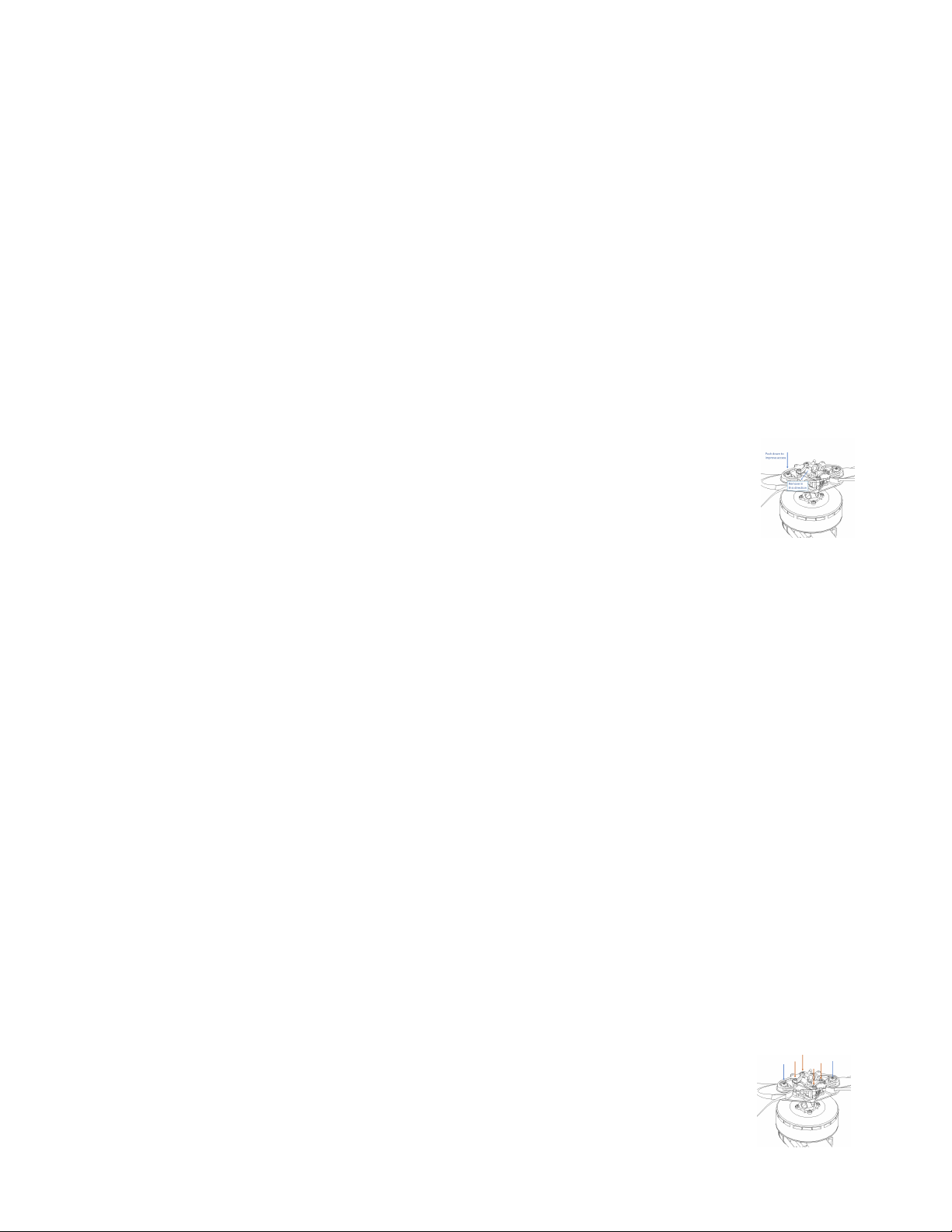

Replacing Propeller Sets

First, remove the ActiveBlade bumpers as detailed in the previous

1.

section.

2. Remove (2x) M5x30 bolts and (4x) M3x10 bolts and remove the top plate.

Page 18

3. Replace props and nylon washers if required.

Refit top plate and attach with (2x) M5x30 bolts and (4x) M3x10 bolts.

4.

Loctite 243 or equivalent must be used to secure these fasteners.

5. Reinsert the ActiveBlade bumpers as detailed in the previous section.

{% hint style="warning" %} Props are supplied as a weight matched and balanced pair. Only

fit props in the factory supplied pair. {% endhint %}

****

Replacing ActiveBlades

Remove (x4) M3x10 bolts by accessing through the top of the assembly

1.

as shown.

Fit new assembly and secure with (x4) M3x10 bolts. Loctite 243 or

2.

equivalent must be used to secure these fasteners.

Opening Chassis

Set aircraft on a stable level work surface.During disassembly, take care to note the

1.

location of fasteners and orientation of parts, as this will greatly help with reassembly.

Remove the following fasteners:

1.

(x4) M4x16 Combo - which secure the boom stays to the boom

2.

(x4) M3x10 FHCS - which secure the closeout panels

3.

2.

(x4) M3x10 Combo - which secure the closeout panels

4.

(x2) M3x10 Combo - which secure the battery connector mount

5.

(x2) M3x10 Combo - which secure the center ring

6.

(x4) M4x14 Combo - which secure the center ring

7.

Remaining M4 bolts that secure the top chassis to each hinge

The top chassis can now be removed from the machine, and the inner cover lifted off

3.

to access the enclosure area.

Page 19

To reassemble, refit the enclosure making sure it is well seated and there are no

4.

trapped wires.

Attach the power connector with (x2) M3x10 bolts before reseating the top chassis,

5.

making sure the orientation is correct.

Reassemble the remaining chassis fasteners. Take care to align the fasteners correctly.

6.

It is recommended to get all fasteners started before torquing. Loctite 243 or

equivalent should be used in all these locations.

`

Replacing Booms

{% hint style="info" %} If replacing more than one boom, replace one at a time to reduce the

chances of mixing up connections. {% endhint %}

1. Remove the top chassis as detailed in the previous section.

Page 20

Trace the wires from the boom to be replaced. There will be three cables from each

2.

boom, a power cable, an LED cable and a motor control cable. Carefully unplug each,

taking care to note the locations for when the replacement boom is fitted.

3. Remove any strain relieving zip ties. Take care to note the correct wire routing.

Loosen the three M4 bolts that clamp the boom, and carefully slide the boom out of

4.

the hinge.

Remove the corrugated tube from the old boom, noting its location on the harness. If

5.

being reused, remove the ActiveBlade assembly from the old boom.

6. Prepare the new boom assembly by attaching the corrugated tube.

Feed the wiring harness through the hinge, slide the boom into place and temporarily

7.

secure by lightly tightening the hinge bolts.

Connect new boom’s three cables, route the wires and secure with strain relief zip ties

8.

where needed. Make sure the corrugated tube is positioned correctly and strain

relieved to the chassis securely.

9. Replace the enclosure cover and reinstall the top chassis per the previous section.

The booms on ALTA X are clocked to improve yaw authority. Replacement booms are

supplied with alignment cards to allow accurate clocking of the motors. Their use is

10.

covered in this video. Before aligning the motors, completely remove the M4 boom

clamp fasteners, and apply Loctitie 243 or equivalent. Once aligned, torque fasteners.

11. Reattach the ActiveBlade assembly as described in previous section.

Updating Firmware

Autopilot and system component firmware is updated via the USB expansion port on ALTA

X located in the chassis closeout between booms 1 and 2. To update firmware download the

latest FW files from the ALTA X Firmware page and follow the instructions below.

Download the latest ALTA X FW from the ALTA X Firmware page on the

1.

support website.

Plug in a USB cable to your computer. Leave the other end unplugged from

2.

ALTA X for now.

Page 21

Remove the chassis closeout between Booms 1 and 2 to reveal the

3.

expansion board.

Hold down the USB MSC Button on the expansion board while plugging in

4.

the USB C to the expansion board on ALTA Pro. Your ALTA will show up in

your file browser as a USB disk named FF-ALTA.

5. You should see a folder named FF-ALTA.

Replace the ‘freefly’ folder in the root of the drive with the new one

6.

downloaded from the Freeflysystems.com website.

Unplug ALTA X from the USB and then apply USB power (or battery power

7.

with the props removed) while holding down the Boot button on the

expansion board.

ALTA X should display blue solid or flashing lights on its motors to show it

8.

is updating its FW. Once complete the system will boot normally and

display red and green directional lights on the motors.

{% hint style="info" %} For troubleshooting, you can view details of the bootloading process

by connecting to the GPS2 UART on the expansion connector with a USB to UART adapter

and a cable using the dronecode/PX4 UART standard pinout. The UART settings are 57600

baud, 8-N-1. {% endhint %}

{% hint style="warning" %} Test radio channels, arming, and disarming behavior after

firmware updates to ensure radio mapping has been preserved. Incorrect radio mapping can

lead to loss of control. {% endhint %}

{% hint style="danger" %} Do not use a battery to power ALTA X during FW updates! Using

USB power prevents unwanted motor spin-ups. {% endhint %}

Integrations

RX Transmitter

ALTA X allows for the installation of a radio control system. S.Bus, S.Bus2, DSM2, and DSMX

receiver types are supported. Some ALTA X emergency control modes (Return-to-Land and

Page 22

Autoland) may vary depending on the type of radio. Refer to the Flight Controller Modes

section of this manual for additional details.

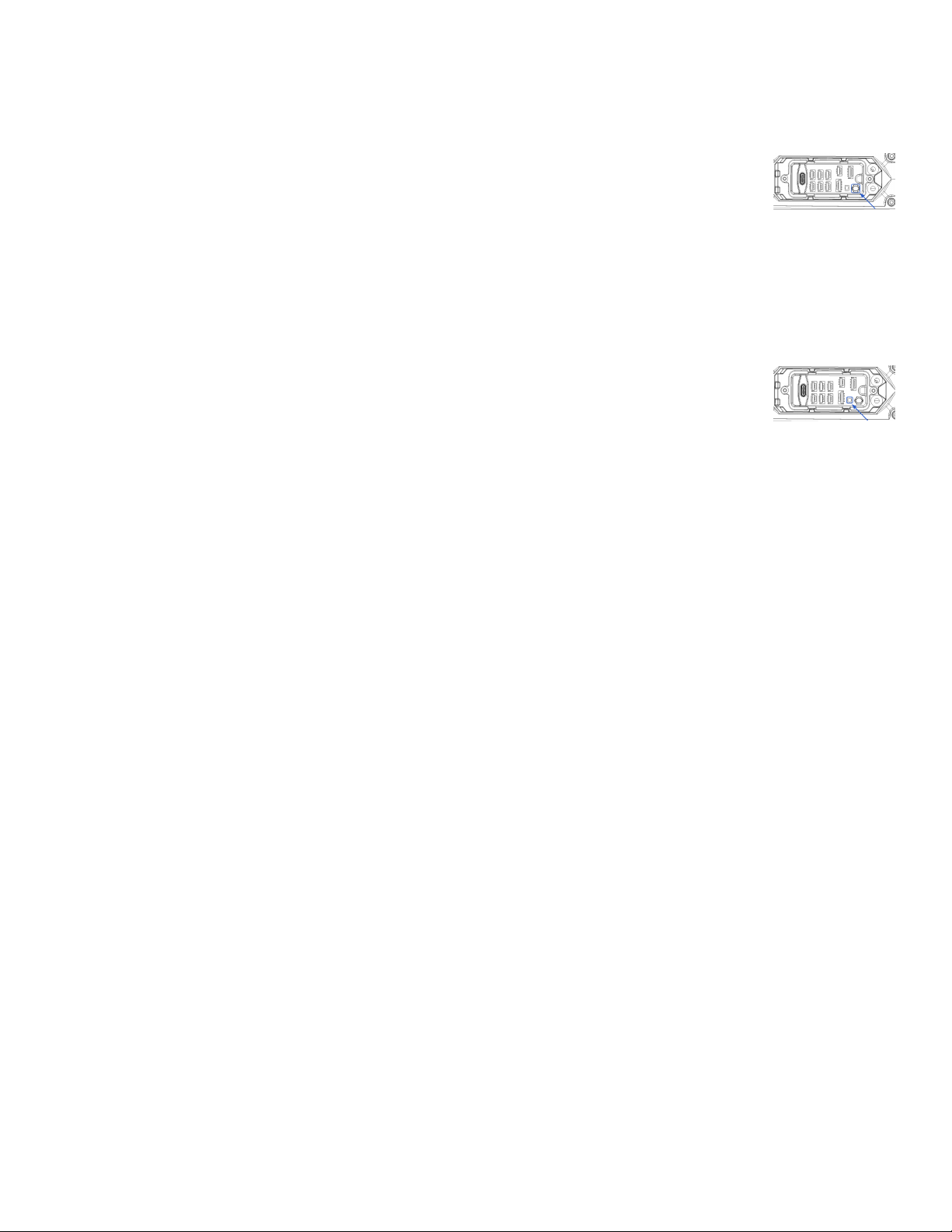

Installation of Futaba Radio

1. Locate the bay used for receiver installation (between booms 2 & 3 )

2. Remove quick release door with radio wires:

3. Plug signal wire into receiver.

If using telemetry, plug the telemetry wire located in the bay between

4.

booms 2 & 3 into the opposite side of the receiver.

5. Feed receiver antenna through bottom of chassis via the plastic ferrule.

Secure receiver using the provided double-sided tape to inside of

receiver housing.

6.

Replace the quick release door.

7. Route antenna wires into the two antenna tubes below ALTA X chassis.

8. Repeat installation process for dual receivers (if applicable).

Installation of Spectrum Radio

1. Locate the bay used for receiver installation (between booms 2 & 3 )

2. Remove quick release door with radio wires:

Page 23

3. Feed signal cable through panel grommet.

4. Plug in receiver/satellite into signal cable.

5. Attach receiver/satellite to exterior using double-sided tape.

Radio Controller Calibration and Mapping

ALTA X can be used with a variety of radio controllers. Different radio controllers can map

functions to different channels, so properly mapping controller channels to ALTA X functions

is an important step before flying. Radio calibration and channel mapping are performed

using the ALTA QGroundControl program or app.

If you are uncertain about your radio channel mapping, obtain assistance from an

experienced pilot or from Freefly Customer Support.

Calibrating Radios Using ALTA QGroundControl App

Calibrating any compatible radio is done using the ALTA QGroundControl app. This only

needs to be done when using a new radio with the ALTA X; ALTA X that were bought with a

radio have already gone through the Calibration and Mapping procedures.

1.

Power the ALTA X by plugging in a USB-C cable to the expansion port.

2.

The expansion port is located under the closeout between booms 1 and 2 .

3.

Once connected, the ALTA X electronics will be powered and you may turn on the radio.

4.

Open the ALTA QGroundControl program, navigate to the Radio tab in the Vehicle

Setup menu, and then initiate the radio calibration.

5.

Set the transmitter mode radio button that matches your radio configuration (this

ensures that QGroundControl displays the correct stick positions for you to follow

during calibration).

6.

Move the sticks to the positions indicated in the text (and on the radio image). Press

Next when the sticks are in position. Repeat for all positions.

7.

When prompted, move all other switches and dials through their full range (you will be

able to observe them moving on the Channel Monitor).

8.

Press Next to save the settings

Page 24

{% hint style="warning" %} Make sure to reset all trims and subtrims to zero before

continuing with calibrating and mapping your radio. {% endhint %}

Mapping Channels Using ALTA QGroundControl App

Radio channel mapping is accomplished with the ALTA Qgroundcontrol App. Prior to

mapping channels, ensure your radio controller and receivers are properly installed and

calibrated. Refer to the Radio Installation section of this manual and your radio controller’s

documentation.

1.

Power the ALTA X by plugging in a USB-C cable to the expansion port.

1.

The expansion port is located under the closeout between booms 1 and 2

2.

Once connected, the ALTA X electronics will be powered and you may turn on the

transmitter.

3.

Open the ALTA QGroundControl program, navigate to the Flight Mode tab in the

Vehicle Setup menu for access to the channel mapping.

4.

Channel mapping can be customized by the user on this menu to fit their preferences.

Below is a quick description of the items mapped to the transmitter and suggested

channels for each mapped item.

{% hint style="warning" %} Customers are advised to use tablets, laptops, or desktops to

perform the Radio Calibration and Channel Mapping; some mobile devices may crop these

menus. {% endhint %}

Function Descriptions

The following functions can be mapped to radio controller channels. These are found in the

Radio section of the Configurations menu in ALTA QGroundControl. Each function is also

represented by a chart that responds to control input allowing for quick verification of

mapping settings.

Controller

Use this to select the appropriate receiver. The following guide is compiled for convenience.

For complete specifications and which mode will work with your receiver, refer to your radio

Page 25

controller or receiver manuals.

DSM2/DSMX are typically used by Spektrum controllers

SBUS is typically used by Futaba controllers

Pitch/Roll/Yaw/Throttle

The Pitch, Roll, Yaw and Throttle controls are the basic flight controls and are mapped to the

two radio controller sticks.

Mode

The required Mode Switch selects between the three different flight modes: Manual,

Altitude, and Position. A three-position switch is recommended to select the three different

modes. However, a two-position switch may be used, but will only allow for selecting

between Manual Mode and (depending on radio controller mixes) either Altitude Mode or

Positon Mode . Other modes are available, but should be only used by experienced operators.

Return to Home Switch

The optional Return to Home Switch selects between the different Return-to-Land (RTH)

functions. At minimum a two-position switch is required for the Home Switch functions to

select between RTL Off, and initiate RTL functions.

Typical Channel Mappings

The following radio channel mapping configurations are recommendations only and can be

set in ALTA QGroundControl. Depending on exact radio models, these may help as an initial

configuration. However, it is up to the pilot setting up ALTA X for flight to determine if these

settings are appropriate.

Futaba 14SG/8FG

Function Channel Number Direction

Pitch 2 Normal

Roll 1 Normal

Yaw 4 Normal

Page 26

Function Channel Number Direction

Throttle 3 Reverse

Mode Switch 5 Normal

Home Switch 6 Normal

Spektrum DX18

Function Channel Number Direction

Pitch 3 Reverse

Roll 2 Reverse

Yaw 4 Reverse

Throttle 1 Normal

Mode Switch 6 Reverse

Home Switch 7 Normal

Page 27

FPV Camera and Transmitter

FPV System installation

Connect the FPV camera cable to the FPV extension located inside the

1.

chassis at the base of boom.

Screw the FPV mount to the top of the chassis with the (x4) M3x14

2.

screws and washers.

Screw the FPV camera bracket to the FPV mount with (x2) M2.5x5

3.

screws and washers.

Page 28

Screw the FPV camera to the bracket using the included (x4) M2x4

4.

screws and washers.

5. Plug the FPV cable into the back of the camera.

VTX System Installation

Connect the VTX cable to the VTX extension located inside the chassis at

1.

the base of boom #3

Screw the VTX and its mount to the interior of the closeout panel adjacent

2.

to the base of boom #3 using 2x M3x10 screws. Then plug in the VTX cable.

This can be done without removing the closeout panel.

Route the SMA mount and cable through the access port at the base of

3.

boom #3. Ensure you do not unplug the u.FL connector during this step.

Screw the SMA mount to the accessory mounting pattern using 2x M3x5

4.

screws

5. Attach the included TBS Triumph Antenna to the SMA jack and tighten.

Phoenix LIDAR

Freefly has tested the Phoenix LiDAR systems to ensure easy integration and compatibility.

To use ALTA X with the the miniRANGER system simply install the system using the Toad in

the Hole quick release, and then follow the normal LiDAR workflow as described by Phoenix

Aerial.

External Computer

To mount an external computer, first open the chassis. Directions for

1.

opening the chassis can be found in the maintenance section.

Page 29

Once the chassis is open use the 32x32 mm hole pattern in the lower

2.

chassis plate to mount the computer. The hole pattern is sized for M3

bolts.

After mounting the external computer and routing its power and I/O

3.

cables, close the chassis.

Skyview

Remove the (x4) M4x14 combo head bolts that secure the isolator

1.

assembly to the bottom of the aircraft.

Unbolt and remove the center battery support. Using a 10mm wrench,

2.

remove the 4 posts from the bottom of the chassis.

Secure the Skyview landing gear spacer to the chassis using (x4) M4x14

3.

combo head bolts. Attach the Skyview landing gear onto the spacer using

the TITH quick release.

Unbolt (x4) M4x10 socket heads and remove the spacer from the isolation

4.

assembly.

5. Attach the TITH plug using (x4) M4x8 socket head cap screws.

Attach the vibration isolation assembly to the stiffener ribs on top of the

6.

chassis using (x4) M4x14 Combo head screws.

7. ALTA X is now ready to fly in Skyview mode!

MoVI Carbon

To use MōVI Carbon with ALTA X we recommend using the 40 duro isolators that ship with

ALTA X. Install landing gear on MōVI Carbon and attach to ALTA X using the Toad in the

Page 30

Hole Quick Release. We recommend using qty 2 12s 16Ah flight packs with MōVI Carbon as

this will allow 20+ minute flight times. Default Movi Carbon tuning should work well with

ALTA X and FRX Pro can be added to MoVI Carbon to increase control range and robustness.

Isolator Cartridges

Isolator cartridges are available in different durometers, which gives the user the ability to

fine tune vibration damping performance for different payload weights or ambient

temperatures. Durometer options include 30A, 40A, 50A, 60A. The durometer of a cartridge

is shown in recessed lettering on each of the O-rings. Use the chart below as a general guide

choosing the correct isolator cartridges for your payload.

Payload [lb] Payload [Kg] Isolator Durometer Cartridge Qty

0 - 3 * 0 - 1.4 30A 3

4 - 10 * 1.8 - 4.5 30A 6

11 - 19 ** 5.0 - 8.6 30A 9

20 - 23 ** 9.1 - 10.4 30A/40A 9

24 - 29 ** 10.9 - 13.2 40A 9

30 - 32 ** 13.6 - 14.5 40A/50A 9

33 - 35 ** 15.0 - 15.9 50A 9

>35 *** >15.9 60A 9

{% hint style="info" %} * Depends on Payload Sensitivity - run as many isolators as possible.

** Mix and Match different durometers to attain desired vibration isolation qualities. When

shooting video it is desirable to run the softest isolators possible without bottoming out the

isolators.

*** 60A isolators should be used when the most rigid connection between payload and

aircraft is desirable. {% endhint %}

To install, place the cartridges between the two isolator plates. Ensure

1.

they are engaged in the track features and are parallel with the plates.

Page 31

Push inwards fully until they click, indicating the cartridges are locked in

2.

place. Pull outwards on the cartridge to ensure it is locked.

To remove, pinch the cartridge latch to unlock it from isolation plates

3.

and slide it outwards to disengage.

{% hint style="info" %} Flight testing may be required to determine the optimal isolator for

a given setup. {% endhint %}

5V/12V DC-DC Converters

Description & Specifications

The Freefly DC-DC converters draw power from the 50V battery bus and provide up to

120W of 5V or 12V DC. The converters utilize off the shelf converters mounted on a custom

heatsink with and a custom capacitor board to provide better transient response.

Spec 12V 5V

Operating input voltage range 18-75VDC 18-75VDC

Output voltage 12VDC 5VDC

Max output current (Note 1) 10A 24A

Max output power (Note 1) 120W 120W

Recommended max output power 100W 100W

Operating Temperature -40C to 85C -40C to 85C

Input power connector XT30 (Male Pins) XT30 (Male Pins)

Output power connector XT60 (Female Sockets) XT60 (Female Sockets)

Note 1: Above ambient temperatures of 50C, some current/power derating will be necessary.

Installation

The converter mounts onto any unused closeout. Installation steps:

Page 32

1. Remove two screws holding closeout door, remove closeout door

2. Install DC-DC converter using supplied button-head screws

3. Route & connect XT30 connector to inside of the power expansion board

4. Route XT60 connector to desired location

{% hint style="info" %} The internal XT30s of the power expansion board share the same

10A fuse as J1. {% endhint %}

Operation Notes

The power converter will power on automatically as soon as the battery is connected on the

aircraft.

The power converter will power on automatically as soon as the battery is connected on

the aircraft.

The converters have overcurrent & short circuit protection, and will restart

automatically upon clearing of overcurrent/short circuit condition.

{% hint style="warning" %} Caution! The DC-DC converter heatsink may get very hot when

drawing power. {% endhint %}

Procedures

Unpacking and Setup

1. Aircraft REMOVE from case

2. Prop straps REMOVE

3. Booms UNFOLD

4. Ring latches LOCK

5. Receivers and wiring CHECK

Page 33

SELECT and INSTALL as

6. Isolator cartridges

necessary

7. Payload mounting location CONFIGURE as necessary

To set up ALTA X for flight, remove it from the case, and remove the prop straps.

Unfold the booms by placing one hand on a boom and one hand on the airframe and then

unfolding the boom. The boom linkage system will unfold all booms at once. Once unfolded,

be sure to latch each side of the locking ring. These latches are redundant and ensure that

the booms stay in the open flight position during flight.

Check that the receivers and the electrical connectors that attach to the receivers are secure.

For information on installing isolator cartridges and setting up payload mounting locations,

refer to the Isolator Cartridges and Configuring GroundView or SkyView sections of this

manual.

Before Starting

1. Payload SECURED

2. Isolator Cartridges VERIFY SECURE

3. Propellers CHECK CONDITION, VERIFY TIGHT

4. Propeller Hubs

5. Motors CHECK CONDITION

6. Radio Controller ON, VERIFY TX BATTERY

7. Radio Controller Model SELECT

8. Aircraft Placement AWAY from people and obstacles

9. Battery Pack Voltage VERIFY ABOVE 48V

VERIFY SECURE

10. Battery Packs SECURE

11. Battery Leads CHECK CONDITION and CONNECT

12. Aircraft KEEP STATIONARY

Page 34

13. Flight Controller Allow to INITIALIZE

14. Blade Dampers VERIFY 8 PRESENT AND IN GOOD CONDITION

15. Orientation Lights VERIFY SOLID COLORED, DIM

16. Receiver VERIFY BOUND

17. ALTA X QGroundControl

19. Compass Calibration CALIBRATE if required

20 Radio Control Range Check AS REQUIRED

Check that the payload is secure by checking that the Toad In The Hole quick release lever is

fully clamped and closed and that the payload does not slip. Check that all isolator

cartridges are locked in place, especially if they have been recently replaced.

The blades should be checked for damage, including nicks and scrapes. If a propeller blade

has been nicked enough that it catches a fingernail, it should be replaced. Blade bolts should

be tight and blades should show little slop. There should be no slop between the propeller

hub and the motor.

CONNECT

VERIFY NO WARNINGS

ActiveBlade dampers should be present and in good condition

Motors should spin freely, and there should be no grinding or scraping sound from the motor.

The inside of the motor should be free of debris.

Always turn on the radio controller before powering ALTA X. Follow the battery installation

guidance in the Battery Installation section of this manual for battery installation

instructions.

While the Autopilot initializes, keep ALTA X as stable as possible.

If ALTA X moves during initialization, it may not boot properly and will fail to start or not

maintain heading.

Page 35

At the end of this process the LEDs will go from white to the user selected colors (stock

colors are green facing forward and red facing toward the rear of the aircraft) indicating

ALTA X is ready for arming.

Verify that there are no flight warnings by connecting to ALTA X via ALTA X

QGroundControl and checking for warnings or errors. For more information, see the ALTA

QGroundControl section of this manual.

Before Takeoff

1. Prop Area CLEAR

2. Mode Switch MANUAL

3. Home Switch UP/OFF

4. Radio Controller VERIFY CORRECT MODEL

5. Telemetry (if equipped) CHECK OPERATION

6. GPS Signal LOCKED (GREEN LIGHT)

7. ALTA X CHECK ORIENTATION and ARM

8. Orientation Lights VERIFY USER-DEFINED COLOR

9. Motors START, and VERIFY OPERATION

10. Flight Controls VERIFY CORRECT

11. Throttle AT MINIMUM

Prior to start, check the surrounding area to ensure people and objects are clear of ALTA X

and its props. Also ensure that there are no people or objects between the ALTA X’s takeoff

location and its intended flight path.

Ensure that ALTA X QGroundControl shows all sensors are calibrated and ready for flight.

{% hint style="danger" %} ALTA X’s props spin at a high RPM and the ends of the blades

move at high speeds. ALTA X’s props can cause severe injury or death or cause damage to

objects while rotating. Always ensure the area surrounding the props and ALTA X is clear of

people or objects prior to starting the motors. {% endhint %}

{% hint style="danger" %} Do not approach ALTA X while it is armed or motors are spinning.

Page 36

5. Orientation Lights VERIFY LIGHTS DIM

6. ALTA X QGroundControl CHECK for warnings

{% endhint %}

7. Batteries

To start the motors, hold full low throttle and full right yaw. Ensure that all the motors are

spinning. Raise RPMs slightly and move the pitch, roll, and yaw controls slightly. ALTA X

should pitch, roll, and yaw as commanded due to isolator cartridge flex. Ensure that the

ALTA X behaves as expected. If it does not, shut down ALTA X and ensure the propellers are

installed in the correct orientation and radio settings are correct.

{% hint style="danger" %} Do not make large yaw commands while on the ground with the

Skyview landing gear installed. Large yaw commands can cause instability. {% endhint %}

After checking flight control directions, advance the throttle directly from idle to hover

throttle. Prior to takeoff, do not advance throttle stick above idle until prepared for flight as

this can spool up motors undesirably. While throttling up for takeoff, do not loiter in ground

effect. Once in flight, use the Mode Switch to select between Manual, Altitude, or Position

Mode only after first confirming proper flight performance in Manual Mode.

{% hint style="danger" %} Only take off in Manual Mode or let the ALTA X take off

autonomously when doing a waypoints mission. Attempting to take off in Altitude or

Position Modes may cause ALTA X to tip over. {% endhint %}

{% hint style="danger" %} Altitude Mode and Position Mode are assistive only and are not a

replacement for pilot skill and ability. Pilots should be proficient in Manual Mode flight in

order to react to emergency situations as required. {% endhint %}

After Every Flight

1. Mode Switch MANUAL

2. Home Switch OFF

3. ALTA X LAND

4. Motors DISARM and STOP

Page 37

DISCONNECT AND REMOVE | | 8. | Radio Controller Power | TURN OFF | | 9. | Aircraft

Condition | INSPECT | | 10. | Motor and Prop Condition | INSPECT | | 11. | Battery Condition |

INSPECT |

Upon landing, disarm the motors by holding minimum throttle and full left yaw. This is

typically done on the left radio control stick by moving it to the bottom left corner with

mode 2 controllers. Disarming can only be done while in Manual Mode. Once the motors are

stopped and disarmed, the Orientations Lights will dim indicating it is safe to approach

ALTA X.

{% hint style="info" %} Only approach ALTA X after confirming that it is disarmed by

verifying the Orientation Lights have dimmed. {% endhint %}

The downwash from the propellers can disturb debris. This debris can be ingested by the

propellers or motors and cause damage. After the flight, ensure there is no damage to the

propeller blades and that the motors still spin freely and quietly. Take extra care when

operating in areas with large amounts of debris, such as sand, dirt, or gravel.

After flight is also a good time to check the condition of battery packs. Always refer to the

battery manufacturer’s recommendations for inspection and replacement intervals or

requirements.

After Last Flight

1. Propellers FOLD and PLACE inline with boom

2. Boom Latches UNLOCK

3. Booms FOLD

4. Prop Straps INSTALL

5. Payload REMOVE

6. ALTA X INSERT into case

Keeping ALTA X on the payload or landing gear easily facilitates the folding process as ALTA

X may be turned on the Toad In The Hole adapter while folding the propellers and booms.

Release each boom latch and then fold the booms inwards. Fold the propeller blades such

Page 38

that the booms with grey ActiveBlade bumpers are pointed towards each other. Install prop

straps to help keep props secure while placing ALTA X in the case.

Ensure the ALTA is placed in the case properly by matching the grey ActiveBlase bumpers to

the colored marks in the pelican case.

Pay special attention to the external GPS, 900/868MHz Telemetry radio and optional

accessories if installed (FPV camera and Tx) when putting the ALTA X back into its case

Emergency Procedures

Emergency Guidance

The emergency procedures listed in this section are the recommended practices for handling

the aircraft in the event of an aircraft emergency. This guidance should be considered and

applied as necessary.

The risk of an emergency can be reduced substantially through proper aircraft maintenance,

by performing thorough inspections before and after all flights, and with careful pre-flight

planning.

Emergency situations are dynamic events, and not all conditions or procedures can be

anticipated or applied during the event. These procedures are not a substitute for a

thorough understanding of aircraft systems and sound pilot judgment.

In general, if an emergency occurs, three basic actions can be applied to most situations:

1.

Maintain aircraft control—Small emergencies can quickly escalate if the pilot is

distracted attempting to troubleshoot the problem. Always maintain visual contact

with the aircraft during an emergency to reduce the likelihood of losing orientation.

2.

Analyze the situation—Once the aircraft is stabilized, begin to assess the cause of the

emergency if practical.

3.

Take appropriate action—In many cases, the appropriate action will be to land the

aircraft as soon as possible. Always consider the safety of yourself and others before

attempting to save the aircraft in an emergency.

Page 39

Alarm Indication

1. Mode Switch MANUAL

2. ALTA X LAND as soon as possible

3. ALTA X QGroundControl CHECK IN APP WARNINGS

Alarms are displayed if the flight controller determines there is a condition present that can

adversely affect the safety of the flight. Alarms are indicated by the Boom LEDs quickly

flashing.

Land as soon as possible when the Boom LEDs indicate a warning, and investigate the

problem while ALTA X is safely on the ground. It is best practice to set the mode switch to

Manual when an Alarm is observed to maintain full control authority of ALTA X.

Pilot Loss of Orientation

1. Control Inputs NEUTRALIZE

2. Mode Switch POSITION

3. Yaw NOSE AWAY

4. Roll VERIFY DIRECTION

Alarms are displayed if the flight controller determines there is a condition present that can

adversely affect the safety of the flight. Alarms are indicated by the Boom LEDs flashing.

Land as soon as possible when the Boom LEDs indicate a warning, and investigate the

problem while ALTA X is safely on the ground. It is best practice to set the mode switch to

Manual when an Alarm is observed to maintain full control authority of ALTA X.

{% hint style="warning" %} Position Mode may not function as expected if Position Lock has

not been achieved. It is best practice to wait for Position Lock prior to takeoff, even if

Position Mode is not planned to be used during the flight. {% endhint %}

Unexpected Flight Controller Behavior

Page 40

1. Control Inputs NEUTRALIZE

2. Mode Switch POSITION

3. ALTA X LAND as soon as possible

If ALTA X behaves unexpectedly, neutralize controls by centering the throttle/yaw and

pitch/roll sticks and observe ALTA X. If it is still flying in an uncommanded manner in either

Altitude or Position Mode, switch to Manual Mode. In most cases, unexpected behavior is due

to erroneous sensor readings, degraded GPS signal reception, or compass issues.

If the unexpected behavior occurred while in Manual mode, land as soon as possible and

check ALTA X QGroundControl for any warnings.

Battery Exhaustion

If battery cell voltage is below Alarm Voltage (all flight modes)

1. Boom LEDs SLOW FLASH

2. ALTA X LAND as soon as possible

If battery cell voltage is below Land Voltage while flying in Manual Mode

1. Boom LEDs SLOW FLASH

2. ALTA X LAND as soon as possible

If battery cell voltage is below Land Voltage while flying in Altitude or Position Mode

1. Boom LEDs SLOW FLASH

2. ALTA X WARNING popup in ALTA QGroundControl

3. Pitch and Roll MANEUVER away from people or objects

If the battery cell voltage drops below the Alarm Voltage, the boom LEDs will flash.

Terminate the flight and land as soon as possible.

Page 41

If the battery cell voltage drops below the Land Voltage, the boom LEDs will flash. The pilot

will remain in full control of the ALTA X in all three flight modes and full throttle authority is

available to the pilot in a battery exhaustion event

{% hint style="danger" %} ALTA X will only Autoland if the battery exhaustion failsafe is set

to RTL. {% endhint %}

Radio Loss of Signal (LOS)

1. Controller Battery CHECK

2. Controller Antenna REPOSITION

3. Mode Switch

POSITION | | 4. | Home Switch | Return-to-Land |

Loss of Signal (LOS) can occur if the radio controller stops transmitting a signal, or if ALTA

X is too far away to receive it. In the event ALTA X detects a LOS, it will automatically

execute a Return-to-Land or Autoland as configured in ALTA X QGroundControl if using an

S.Bus/S.Bus2 or DSM2/DSMX radio type. While ALTA X includes these emergency control

modes, it is always recommended to attempt to regain signal link with ALTA X to keep the

pilot in control of the aircraft.

Move the antenna orientation for best signal strength. Ensure the radio antenna matches

the direction of the receiver antennas. Move the radio away from objects to get a clear lineof-sight to ALTA X.

Set the Mode switch to Position and the Home switch to Return-to-Land so ALTA X will

continue to approach the home point if the signal is momentarily regained, resulting in

higher likelihood of regaining full signal reception.

If efforts to regain control signal are unsuccessful, ALTA X will begin either the Return-toLand and Autoland sequence as configured in ALTA X QGroundControl. Refer to the Flight

Controller Modes section of this manual for additional information regarding functionality

available with specific radio types.

Page 42

Loss of FPV Signal

1. Control Inputs AS REQUIRED

2. Visual Contact MAINTAIN

3. ALTA X POSITION for optimal signal reception

If visual contact or FPV signal is not maintained:

1. Mode Switch

POSITION | | 2. | Home Switch | RETURN TO HOME | | 3. | Throttle | AS REQUIRED |

An FPV Loss of Signal (LOS) can occur if the aircraft flies out of range or if it flies behind an

object that interrupts the signal. Maintaining visual contact is the preferred method to reestablish control of the aircraft, either with the pilot seeing the aircraft, or by the use of a

visual observer.

Yawing the aircraft can help signal reception if the body of the aircraft is blocking the line of

sight between the transmitter and receiver antennas.

If FPV signal or visual contact cannot be maintained, setting the Mode switch to Position

Mode and enabling Return-to-Land can be used to bring the aircraft back to signal reception

range.

{% hint style="danger" %} It is the responsibility of the pilot to see and avoid other aircraft,

people, or obstacles. Always maintain direct line of sight with ALTA X during flight, use visual

observers as operations require, and follow local regulations regarding see-and-avoid

requirements. {% endhint %}

Aircraft Setup

Arming and Disarming

Definitions

Page 43

Armed Aircraft will spin propellers, ready to fly

Disarmed Safe mode, no spinning propellers

Arming

To arm ALTA, put the throttle stick in the bottom right corner for 1.5 seconds. Upon arming,

the propellers will start spinning and the boom LED indicator lights will turn bright green/red.

If the ALTA does not arm, please check QGroundControl for errors or warnings.

{% hint style="warning" %} When armed, propellers will spin! Please follow all precautions

and stay a safe distance away from ALTA X. Before arming, make sure to stay clear of the

propellers. {% endhint %}

Disarming

To disarm ALTA, put the throttle stick on the bottom left corner for 1.5 seconds. Upon

disarming, the propellers will stop spinning and the boom LED indicators lights will dim. The

aircraft will only disarm in flight in manual mode. Once landed, it can be disarmed in altitude

and position modes.

{% hint style="danger" %} Holding the throttle/yaw stick low and left in manual mode while

flying can disarm the aircraft! {% endhint %}

Auto Disarm Modes

Under some conditions, ALTA will automatically disarm

Conditions ALTA X Behavior

If ALTA has not taken off after 2 minutes idling armed on the ground, it

Ground timeout

will automatically disarm. This timeout can be changed in parameter

before taking off

COM_DISARM_PRFLT (units are in seconds, a value of “0” disables this

timeout entirely).

Page 44

Conditions ALTA X Behavior

If ALTA has been previously flown but not power cycled, after 5 seconds

Ground timeout

after flight

Autoland

idling armed on the ground, it will automatically disarm. This timeout can

be changed in parameter COM_DISARM_LAND (units are in seconds, a

value of “0” disables this timeout entirely).

If ALTA detects landing in Autoland mode, it will disarm after 5 seconds

following the logic above. See section “Landing Modes” for more

information on the Landing Detector feature.

Flight Modes

ALTA X has three primary flight control modes which are selected using the Mode Switch:

Manual Mode, Altitude Mode, and Position Mode. ALTA X also has two emergency control

modes, Return-to-Land and Autoland, which are available only during certain situations. For

additional information, refer to the sub-section associated with each emergency control

mode.

{% hint style="danger" %} Altitude Mode and Position Mode are assistive only and are not a

replacement for pilot skill and ability. Pilots should be proficient in Manual Mode flight in

order to react to emergency situations as required. {% endhint %}

{% hint style="warning" %} Always center the control input sticks on the radio controller

when switching between control modes to prevent unexpected movement of the ALTA X. {%

endhint %}

Manual Mode

In Manual Mode, ALTA X will only stabilize its attitude. At neutral control input (middle pitch

and roll stick position), ALTA X will attempt to remain level. Throttle control is direct. In this

mode, it will blow with the wind, and will require constant throttle adjustment to hold

altitude.

Altitude Mode

Altitude Mode changes the throttle stick behavior to command climb and descent rates. The

Page 45

higher the throttle stick position, the faster ALTA X will climb. Conversely, the lower the

throttle stick position, the faster ALTA X will descend.

When the throttle stick is centered, ALTA X will enter Altitude Hold. In Altitude Hold, ALTA X

will maintain a target altitude and try to correct for vertical drift. If a disturbance moves

ALTA X away from this target altitude, ALTA X will climb or descend to return to the target

altitude.

{% hint style="danger" %} Altitude Mode is assistive only and is not a replacement for pilot

skill and ability. Pilots should be proficient in Manual Mode flight in order to react to

emergency situations as required. {% endhint %}

Position Mode

Position Mode changes the pitch/roll stick behavior to command ground speeds. Pitch and

roll stick deflection will command fore/aft and left/right ground speeds respectively.

Controlling altitude in Position Mode is the same as in Altitude Mode.

With pitch and roll controls centered, ALTA X will enter Position Hold. In Position Hold, ALTA

X will maintain its position over a given point on the ground and correct for disturbances.

Position Mode requires a strong GPS signal and communication with a minimum of 6

satellites. If a weak signal is present, ALTA X will not enter Position Mode

{% hint style="danger" %} Position Mode is assistive only and is not a replacement for pilot

skill and ability. Pilots should be proficient in Manual Mode flight in order to react to

emergency situations as required. {% endhint %}

{% hint style="danger" %} Flight using Position Mode in areas of degraded GPS signal, such

as near buildings or under dense tree cover, is not recommended. The automatic reversion to

Manual Mode can cause unexpected, abrupt changes in flight behavior. {% endhint %}

Waypoints Mode

Waypoints mode allows ALTA X to execute a predefined autonomous waypoint missions

that have been uploaded to the flight controller via ALTA QGroundControl (QGC). For more

information on all of the different options and abilities built into the Waypoint functionality

Page 46

you can read more in the PX4 Literature.

{% hint style="warning" %} ALTA X must have a GPS lock before takeoff to set a valid home

position in order to start a waypoints mission. Waypoint mode will be unavailable if the

aircraft took off before GPS lock was achieved. Operator must land and rearm with GPS

lock to enable. {% endhint %}

Return-to-Launch

Return-to-Launch Mode will command ALTA X to fly back to the defined Home Point. When

ALTA X first acquires a GPS position, it sets this as the Home Point of the flight. See the

Radio Channel Mapping section in this manual for more information on setting up the

Return-to-Launch Switch.

RTL can be initiated automatically with a LOS event if it is selected as the Signal Loss Action

in ALTA QGroundControl. RTL can also be initiated manually while flying in any Mode and

setting the Home Switch to RTL.

When initiated manually using the Home Switch, ALTA X will climb to the configured return

altitude, fly back to the Home Point, and descend to 10m. ALTA X will hover above the home

point and wait for a set amount of time and then land. The pilot can cancel the RTL

procedure by returning the Home Switch to off.

During an LOS event, RTL followed by Autoland will be initiated automatically. ALTA X will

first check its current altitude against configured RTL altitude. ALTA X will climb to Safe

Height. Next, ALTA X will fly back to the home position at the default waypoint speed set in

the ALTA X QGroundControl. Finally, upon reaching the home position, ALTA X will loiter for

45s and then begin to Autoland.

The Autoland function will land in place. The vertical speed at which the ALTA will descend

during an Autoland varies as the ALTA approaches the ground. Higher above the elevation of

the home point, ALTA X descends at a faster rate and gradually slows to the user-defined

Autoland Descent Rate before landing. By default, the aircraft will descend at 0.7m/s until

touchdown is detected.

{% hint style="danger" %} Autoland is intended to be a failsafe in case of loss of RC control

Page 47

only. If control is available, the operator should land in manual mode. High wind, sloped

ground, and narrow landing gear on the current payload can make the aircraft prone to tip

over when autolanding. Reducing the autoland velocity may result in missed land detection

for some weight combinations, which can have unpredictable results, so it is advised not to

change this value. {% endhint %}

{% hint style="warning" %} The RTL switch on the radio will override all other modes, and

prevent any mode switches. To return to a normal flight mode, make sure to toggle the RTL

switch to OFF. {% endhint %}

{% hint style="warning" %} Ensure that the RTL switch is OFF before takeoff. {% endhint %}

Landing Modes

It is suggested that the operator lands in Manual mode, as it offers the most control for a

precise touchdown. However it is possible to land in Altitude and Position modes as well. The

aircraft behaves a little differently in each mode:

Manual Mode

In manual mode, the operator will maneuver the aircraft over the landing spot, and descend

slowly using direct throttle control. As the aircraft nears the ground and enters ground

effect, the pilot will often need to reduce throttle a little bit to keep the aircraft descending.

Once touchdown is achieved, the operator should reduce throttle to zero promptly so that it

settles on the ground instead of possibly bouncing or dragging the gear. Disarm as normal.

Altitude Mode

Landing in altitude mode is different than manual because the throttle stick now controls

descent velocity rather than throttle directly. The aircraft will automatically adjust throttle

through ground effect to maintain the same descent velocity. The operator will still need to

manually control pitch and roll to maintain position over the desired landing site. Once the

aircraft is on the ground, bring throttle stick to minimum, and then switch to manual mode

and disarm. The aircraft will automatically disarm after 5 seconds if left running.

Page 48

Position Mode

Landing in position mode uses the same altitude control as in Altitude mode, but additionally

will control the position. This can be useful as it will fight the wind and drift automatically,

but the aircraft may maintain a pitch and roll to do so, requiring care to avoid a prop strike

on the ground or a tipover when using narrow landing gear. As the aircraft nears the ground,

the maximum angle will be reduced to prevent large scale reactions to stick moments, but

the operator should keep pitch and roll motions to a minimum when near the ground. Once

the aircraft is on the ground, bring throttle stick to minimum, and then switch to manual

mode and disarm. The aircraft will automatically disarm after 5 seconds if left running

Autoland Mode

It is possible to command the aircraft to autoland, as described above. It is not

recommended in cases other than failsafe, or after careful testing. Autoland is not as precise

as a human pilot, and certain payload combinations can result in tipovers or bouncing. Tall,

narrow landing gear is particularly susceptible to tipover on autoland in high winds.

{% hint style="danger" %} If the aircraft tips over with the props running, ALWAYS power

cycle the aircraft before attempting takeoff again. If the motors or props hit the ground,

they may not start on next arm and cause it to tip again. {% endhint %}

Important Parameters

Parameter Function

Controls the throttle setpoint required for hovering. This depends

on the weight of the aircraft, and is about 29% for no payload.

Default is 40% for a 15lb payload. Setting this parameter

MPC_THR_HOVER

correctly will eliminate drops or climbs when switching between

manual and either altitude or position mode with the throttle

stick at 50%.

BOOM(1-4)_COLOR Controls the color of each boom LED.

Page 49

Parameter Function

All parameters starting with 'OSD_' configure how the OSD looks

OSD_(*****)

and acts.

Sets what cell voltage the aircraft will flash the Boom lights and

OSD_BAT_ALARM

the OSD battery symbol to indicate low battery to the user.

Defines how far the aircraft is allowed to tilt while being

controlled in manual mode. This can be reduced for a little less

aggressive feeling for a pilot. Recommended to leave at 45

MPC_MAN_TILT_MAX

MPC_VEL_MANUAL

MPC_XY_CRUISE

degrees for maximum performance. Reducing to 35 degrees will

give a more gentle and slow flight handling. This parameter only

affects manual mode. In position and automodes, the aircraft

angle is set to 45 for performance.

Defines how fast the maximum speed the aircraft will fly in

position mode. This can be reduced for more fine control at lower

speeds.

Defines the default waypoint speed, as well as the RTL speed.

This can be increased up to 20m/s, however it is suggested to set

waypoint velocity separately for missions. If setting this high and

commanding slow waypoint velocities may result in the aircraft

slowing down too far in advance of a waypoint.

Controls stick expo in different modes, can be used to adjust the

feel of the aircraft while flying. More expo will require more stick

*_EXPO

MPC_Z_VEL_MAX_(

UP/DN)

input to get the same angle or speed when near zero stick, and

will increase rapidly to maximum once the stick is at higher

deflections.

Controls maximum climb and descent velocities in altitude,

position and waypoint modes.

Mission Planning

Creation/Modification/Execution

Page 50

Missions can be created, loaded, saved, and modified from the Plan View. An overview of

Plan View can be found in public QGC documentation. Click on (+) sign at the toolbar left of

the screen to enter waypoint addition mode. In this mode, users can add waypoints by

tapping or left clicking on the 2D map. A new plan can be created by clicking File -> New ->

Yes when in Plan View.

To modify a waypoint, first click on it. The selected waypoint will turn green. Click and hold

on clicking for a second time to drag the waypoint around the map. Latitude and longitude

values will change automatically.

When the initial waypoint is added, a Planned Home indicator is automatically added. Initial

waypoint will automatically be named as “Takeoff”. Planned Home is where the aircraft will

land if a return to home signal is sent, unless there are rally points. Takeoff location is the

first waypoint the vehicle will move towards as soon as mission mode is entered.

Users can observe mission specific values such as total mission time or total mission distance

from the panel at the top of the screen. Once users are finished modifying a mission the

mission needs to be uploaded to the vehicle. If a vehicle connection is established with the

QGroundControl, a button named “Upload Mission” will be highlighted as soon as user

makes a modification to the mission itself. Click on “Upload Mission” to load the mission file.

Afterwards, go to “Flight View”. Uploaded mission can be executed from the Flight View by

sliding the mission start slider or taking the vehicle into mission mode.

Detailed Mission Items

Page 51

Waypoint specific

Variables

Waypoint specific values -such as speed, altitude or commands- can be

modified by selecting a waypoint and using the detailed waypoint list at

the right hand side of the screen.

Planned Home (a.k.a Mission Start) item in the detailed waypoint list

Planned Home

Mission Ending

Home Position

can be used as a settings item. The altitude and flight speed values will

be passed to all other waypoints along the list.

Mission ending characteristics can be customized by toggling “return to

home” option.

The home position can be changed and centered to the middle of the

map from the settings item.

Advanced Users

Detailed waypoint list can be used to give commands at each waypoint. Command menu

can be accessed by clicking on the three horizontal lines (top right of waypoint details panel).

These commands will add an extra waypoint. The point of this waypoint is to indicate that

Page 52

there will be a command executed, it’s not really a physical waypoint. These commands

include the following options: return to home, go to another waypoint, land and takeoff.

Since the addition of the “command waypoint” might cause confusion, users are advised to

get hands-on experience with simpler missions.

The Flight Speed variable inside the detailed waypoint list assigns a speed value that will be

executed after vehicle passes the waypoint. For example, if default Flight Speed is set to 5

m/s and it is re-set to 20 m/s at third waypoint, vehicle will start to increase its speed from

5 m/s to 20 ms/ as soon as it passes waypoint three. So the target flight speed between

waypoint 3 and waypoint 4 will be 20 m/s. Unless flight speed is reset back to 5 m/s at

waypoint 4, 20 m/s value will be passed to rest of the waypoints.

Tuning

ALTA X is pretuned by Freefly, and can be flown without changes. However, each user may

have a different preference or use case for their aircraft. This section gives some guidance

for how to tune some of the behaviors of the aircraft to suit individual needs. It is NOT

recommended to tune low-level control parameters, as they could cause instability or control

issues which could result in a crash.

Issue Tuning Resolution

My aircraft is too

Reduce MPC_MAN_TILT_MAX to 30-35 degrees. Do not reduce

aggressive in manual

it further as it may not be able to handle wind.

mode

Decrease MPC_VEL_MANUAL - this value defines the maximum

My aircraft is too fast in

position mode

speed at full stick in position mode. If a more precise, slow

velocity is required, reducing this will cap the speed and give

more stick sensitivity at lower speed

Increase MC_XY_MAN_EXPO to decrease sensitivity for small

stick motions.

Page 53

Issue Tuning Resolution

My aircraft climbs or

descends too

quickly/slowly in altitude

and position mode

My aircraft accelerates

too slowly or quickly in

position mode

{% hint style="info" %} Loading the defaults or known-good presets will allow you to quickly

return functional ALTA X if there is ever uncertainty about changes to the tuning properties.

{% endhint %}

Adjust MPC_Z_VEL_MAX_DN and MPC_Z_VEL_MAX_UP. They

control the maximum speed

Adjust parameter MPC_ACC_HOR to increase or decrease the

acceleration used to reach the desired velocity. Value is m/s^2

Adjust parameters MPC_ACC_UP/DOWN_MAX to control how

fast the aircraft accelerates vertically.

Sensor Calibration

ALTA X features redundant, highly sensitive 3-axis magnetometers, gyroscopes, and

accelerometers that measure specific force, angular rate, and earth’s magnetic field to infer

heading and maintain stability. Occasionally, the sensors will require re-calibration.

{% hint style="info" %} ALTA X’s compass may require calibration if locations have changed.

For best results, it is recommended to perform manual compass calibrations away from

ferrous objects, buildings and vehicles. In addition, concrete can contain steel rebar which

may influence compass calibrations. {% endhint %}

{% hint style="info" %} Perform calibration without a payload attached and all motor

booms extended and latched. Folded booms will cause an inaccurate calibration.

It is recommended to use two people to perform the compass calibration as it requires

handling and rotating ALTA X. {% endhint %}

{% hint style="info" %} Alta X has 4 magnetometers, one in the GPS mast, and 3 internally