Page 1

Constant Pressure Water System

SubDrive300

Installation Manual

Page 2

Contents

Description and Features ................................................................................4

Included Items ..................................................................................................5

How It Works .....................................................................................................6

Pump Sizing and Drive Confi guration ............................................................8

Underload Sensitivity for Shallow Wells ........................................................9

Before Getting Started ...................................................................................10

Controller Location Selection ................................................................. 11-12

Circuit Breaker and Wire Sizing ....................................................................13

Quick Reference Guide ............................................................................ 14-15

Pressure Tank .................................................................................................16

Installation Procedure ....................................................................................17

Wiring Connections .................................................................................. 18-20

Start-Up and Operation .................................................................................21

Specifi cations .................................................................................................22

Mounting Dimensions ....................................................................................23

Diagnostic Fault Codes ..................................................................................24

System Troubleshooting Guide .....................................................................25

Underload Smart Reset .................................................................................26

Over Temperature Foldback ..........................................................................26

Tables

1. SubDrive Models .......................................................................................3

2. Breaker Size and Maximum Cable Length ...........................................13

3. Minimum Pressure Tank Size .................................................................16

4. Pressure Tank Precharge .......................................................................16

2

Figures

1. Shipping and Mounting Screws .............................................................17

2. Motor Lead Connections .......................................................................18

3. Power and Pressure Sensor Connections ............................................19

4. Pressure Sensor ......................................................................................20

5. Underload “Smart Reset” Well Recovery Time ....................................26

Page 3

Table 1: SubDrive Models

Model Name Part Number Use with Motor Series

SubDrive300 5870206300 (NEMA 4) 234 317 xxxx (5.0 Hp)

3

Page 4

Description and Features

The Franklin Electric SubDrive300 is a dependable residential and light

commercial water system controller that uses advanced electronics to

enhance the performance of standard submersible pumps. When used with

the specifi ed Franklin Electric motor (see Table 1), the SubDrive eliminates

pressure cycling associated with conventional water well systems and

owners of private water well systems can enjoy “city-like” water pressure.

In addition, the reduced tank size (see Table 3) allows installation in small

spaces. Key features of the SubDrive include:

4

• Constant water pressure with a wide range of settings (25-80 psi)

• Smaller pressure tank can be used

• Fits the pump to the application – pump speed is controlled to

provide the optimum performance without overloading the motor

• Flexibility – you can use this unit with standard off-the-shelf pumps

• No in-rush (power-on transient) current

• Low motor start-up current (soft-starting)

• Active Power Factor Correction minimizes input RMS current

• Protection features

- Dry well conditions – using smart pump monitoring (see Page 26)

- Bound pump – with auto-reversing torque

- High voltage / lightning surge

- Low line voltage

- Open motor circuit

- Short circuit

Page 5

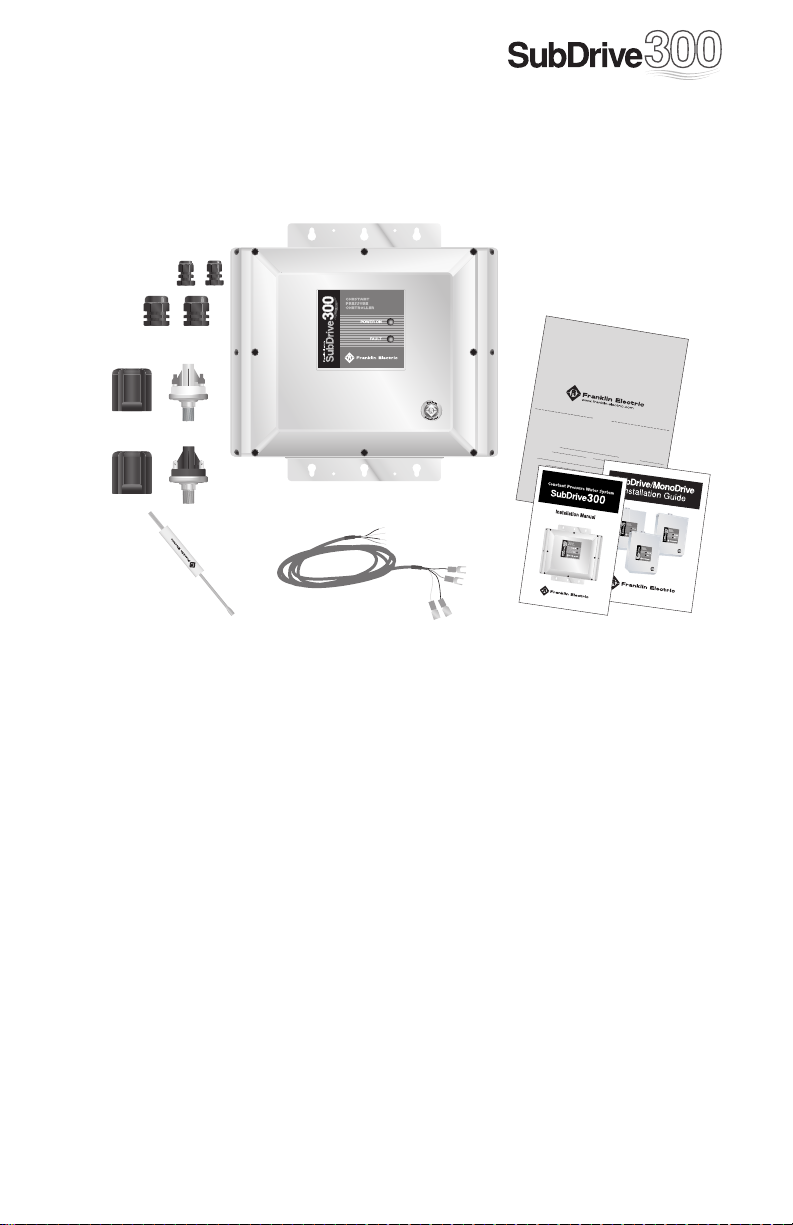

Included Items

A

B

C

D

I

Franklin

Ele

ctri

c is n

Sub

ow o

Driv

e 150 and M

f

fer

ing an int

Driv

e must

onoDr

rod

uct

ive.

ory

be

warran

registered with Franklin

The

sio

ex

n.

•

If a S

ubD

rive is

not

to excee

•

The

re

gist

ration card

•

As with

our standard

ship.

•

Thi

s Ext

ended W

SubDrive Extended W

T

erm

of wa

rranty: 3

must be

Y

ears

regist

from date o

ered

within

30

days

Product

Ins

tal

led (check one):

Instal

lation Name / Own

er

Instal

lation

Add

ress

Ins

tal

ler

Instal

ler

Add

ress

Dist

ribu

tor

Date

of I

nstallation

SubD

rive/Mon

oDrive Serial

Nu

mber

(exampl

This warranty

card

Street,

must be return

Bluffto

n,

warrant

ed t

IN 46

o

714

Franklin Electric,Att

y

.

by

mail,

or faxe

d to

260-

ty exte

ten

ded war

nsion

ran

on S

ty i

Ele

ubDriv

s f

ree,

ctri

c in order t

e 75,

bu

t the

Su

o activat

y f

tur

ten

ded wa

rive 75

arrant

t to excee

0

3

3

8

0

)

e Code

Pu

Coordinat

his f

orm must

or tha

t un

it

covers

e date.

ranklin Elect

ric

rranty covers

, SubDrive 150

y Reg

d 4 years from manufacture dat

?

SubDrive 15

Phone Nu

State Zip

Phone Nu

State Zip

Phone Nu

(example:

01A23

)

mp Mfg.

/ Mod

el

or –

Sub

Drive Products,

be

fill

ed

out

bDriv

e/M

e the war

ono

-

ran

ty exte

n

-

3 year

s from t

he

date of i

nstallatio

n,

no

later

tha

n 30 days

afte

r i

nstallati

def

ects i

on.

n material

an

d workman

-

an

d MonoD

rive con

tro

llers.

istrati

01000

on

e. Warra

nty

0

(

5

8

7

0

2

0

4

1

5

0

)

?

MonoDrive

( )

mber

mber

mber

( )

400

to val

E. Sprin

idate t

g

he e

xten

d

ed

registere

d, t

he

d

4 year

warrant

s from i

ts manufac

must

be

returned to F

warrant

y

, the ex

arr

ant

y covers only SubD

Cut or fold here

f in

stal

lation, no

of i

nstallatio

n date.

?

SubDrive 75

(

5

8

7

0

2

City

Cit

y

SubDrive Dat

e: 00

0451

)

n: In

side Sales

827-5

800

.All

fie

lds in t

E

F

A. Controller Unit

B. Strain Relief Fittings

C. Pressure Shut-off

Sensor and Boot

D. Pressure Sensor and Boot

G

E. Sensor Adjustment Tool

F. Sensor Cable

G. Installation Manual

H. Installation Guide

I. Warranty Card

H

5

Page 6

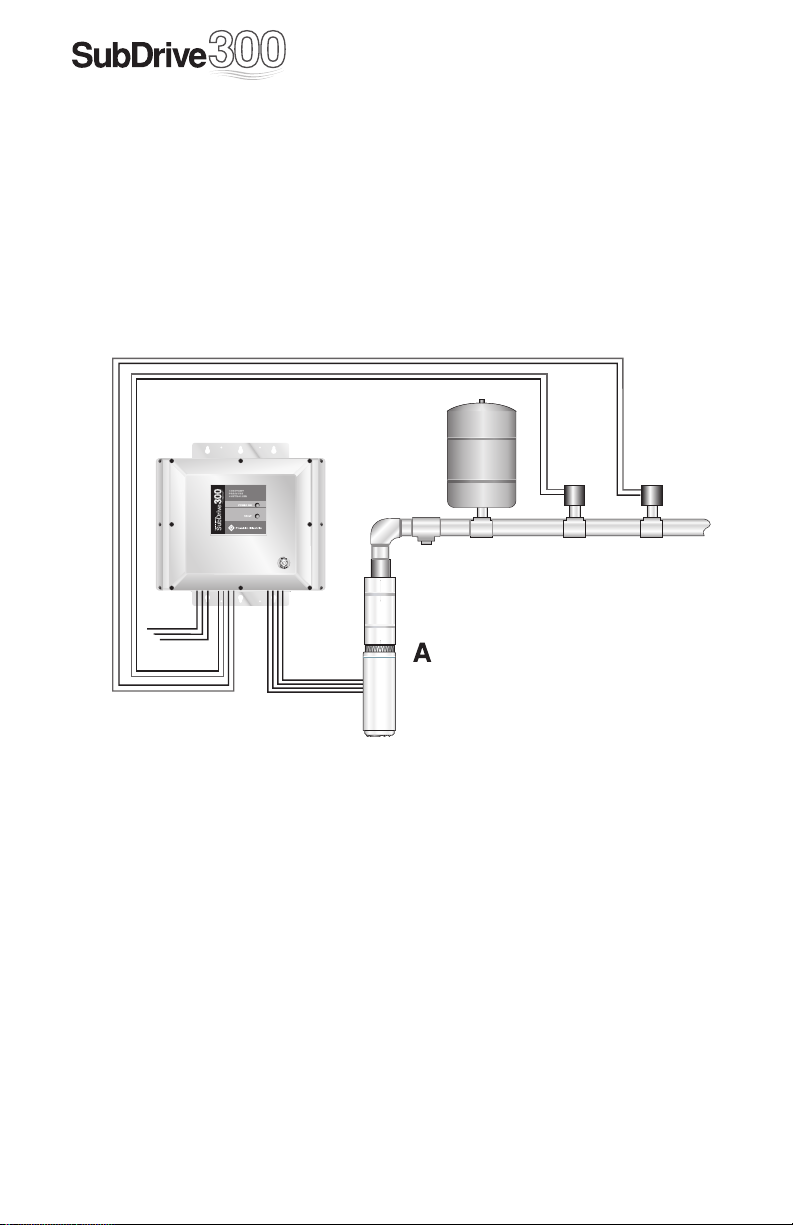

How It Works

The Franklin Electric SubDrive300 is designed to be part of a system that

consists of only four components:

A. Standard Pump and Franklin Electric Motor.

B. SubDrive Controller.

C. Small Pressure Tank (for tank size, see Table 3).

D. Franklin Electric Pressure Sensor (provided).

E. Franklin Electric Pressure Shut-Off Sensor (provided).

B

Pressure

C

Sensor

Leads

Pressure

Shut-o

Sensor

Leads

DE

Pressure

Relief Valve

PUMP

Power Supply

From Circuit Breaker

Constant Pressure

The Franklin Electric SubDrive300 provides consistent pressure regulation

using advanced electronics to drive a standard motor and pump according

to the pressure demands indicated by a highly accurate, heavy-duty,

long-life pressure sensor. By adjusting the motor/pump speed, the

SubDrive300 can deliver constant pressure dependably, even as water

demand changes. For example, a small demand on the system, such as

a bathroom faucet, results in the motor/pump running at a relatively low

speed. As greater demands are placed on the system, such as opening

additional faucets or using appliances, the speed increases accordingly to

maintain the desired system pressure.

MOTOR

6

Page 7

Motor Soft Start

Normally, when there is a demand for water, the SubDrive300 will

be operating to accurately maintain system pressure. Whenever the

SubDrive300 detects that water is being used, the controller always “ramps

up” the motor speed while gradually increasing voltage, resulting in a cooler

motor and lower start-up current compared to conventional water systems.

In those cases where the demand for water is small, the system may cycle

on and off at low speed. Due to the controller’s soft-start feature and

sensor’s robust design, this will not harm the motor or the pressure sensor.

System Diagnostics

In addition to regulating pump pressure and accurately controlling motor

operation, the SubDrive300 continuously monitors system performance and

can detect a variety of abnormal conditions. In many cases, the controller

will compensate as needed to maintain continuous system operation. But

if there is high risk of equipment damage, the controller will protect the

system and display the fault condition. If possible, the controller will try to

restart itself when the fault condition subsides.

Unique Features

SubDrive controllers provide the ultimate in system performance, utilizing

Franklin Electric’s three-phase motor series for maximum starting torque,

high effi ciency and smooth operation. SubDrives convert residential single-

phase 60Hz power into the variable-frequency three-phase needed by the

motor. In addition, SubDrives can spin a smaller pump slightly faster to

boost output to roughly double its 60Hz horsepower rating. This allows use

of smaller pumps for less system cost. If a smaller pump of the desired fl ow

rating is not available, the controller can be confi gured to use larger pumps

up to the horsepower rating of the motor.

7

Page 8

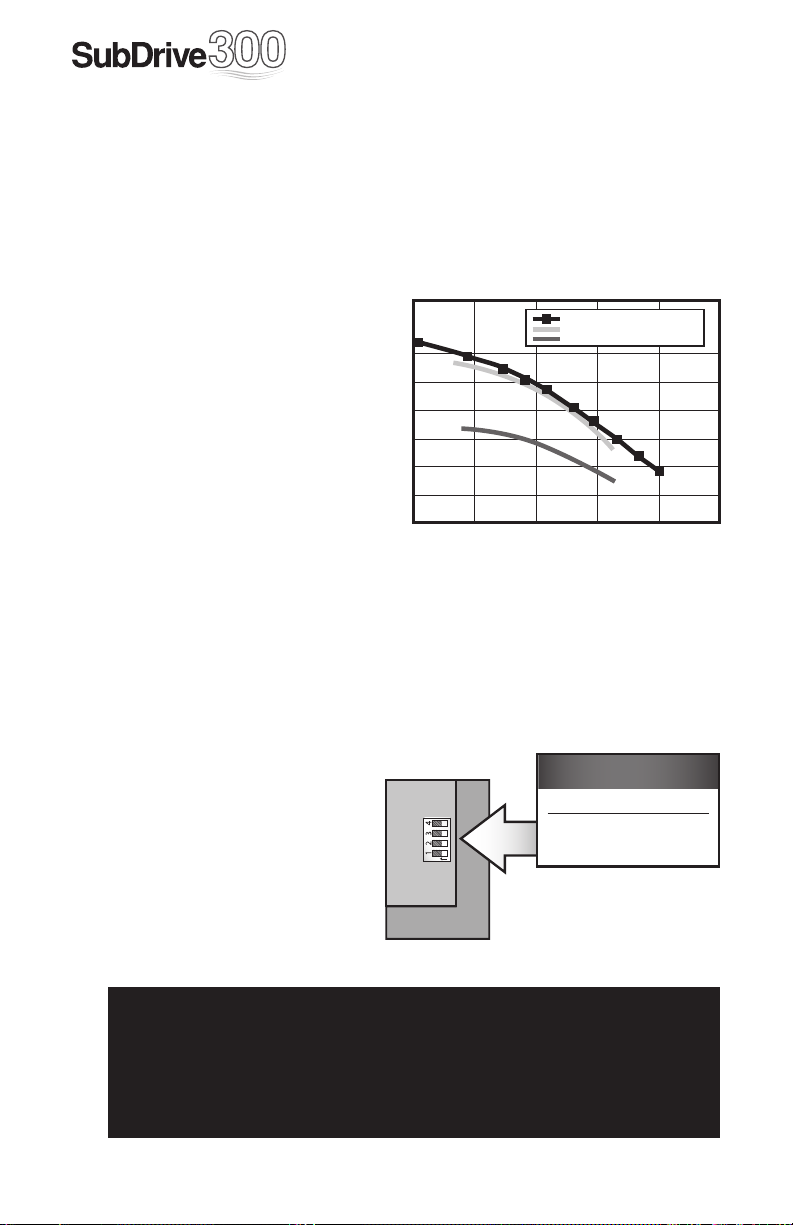

Pump Sizing

The SubDrive300 is confi gured at the factory for use with 3 Hp pumps that

are mounted to 5 Hp Franklin Electric three-phase motors. In general, the

SubDrive300 will enhance the performance of a 3 Hp pump to a similar

or better performance than a conventional 5 Hp pump of the same

fl owrating (pump series).

To select the proper 3 Hp

pump, fi rst choose a 5 Hp

curve that meets the

application’s head and fl ow

requirements. Use the 3 Hp

pump in the same pump

series (fl ow rating). The

SubDrive300 will adjust the

speed of this pump to

produce the performance

of the 5 Hp curve. An

example of this is

illustrated in the graph at right.

Typical SubDrive300 Performance

700

600

500

400

300

Total Head (ft)

200

100

51530456075

)Q(1.XJUI4VC%SJWF

$POWFOUJPOBM)Q(1.1VNQ

$POWFOUJPOBM)Q(1.1VNQ

Flow GPM

Drive Confi guration

The SubDrive300 can also be set up to run a 5 Hp pump if desired, but the

larger pump will still produce to the 5 Hp curve and may only be operated

with a 5 Hp motor. To operate a different pump size, a DIP switch must be

positioned to select the correct pump rating. Otherwise, the SubDrive300

may trigger erroneous faults.

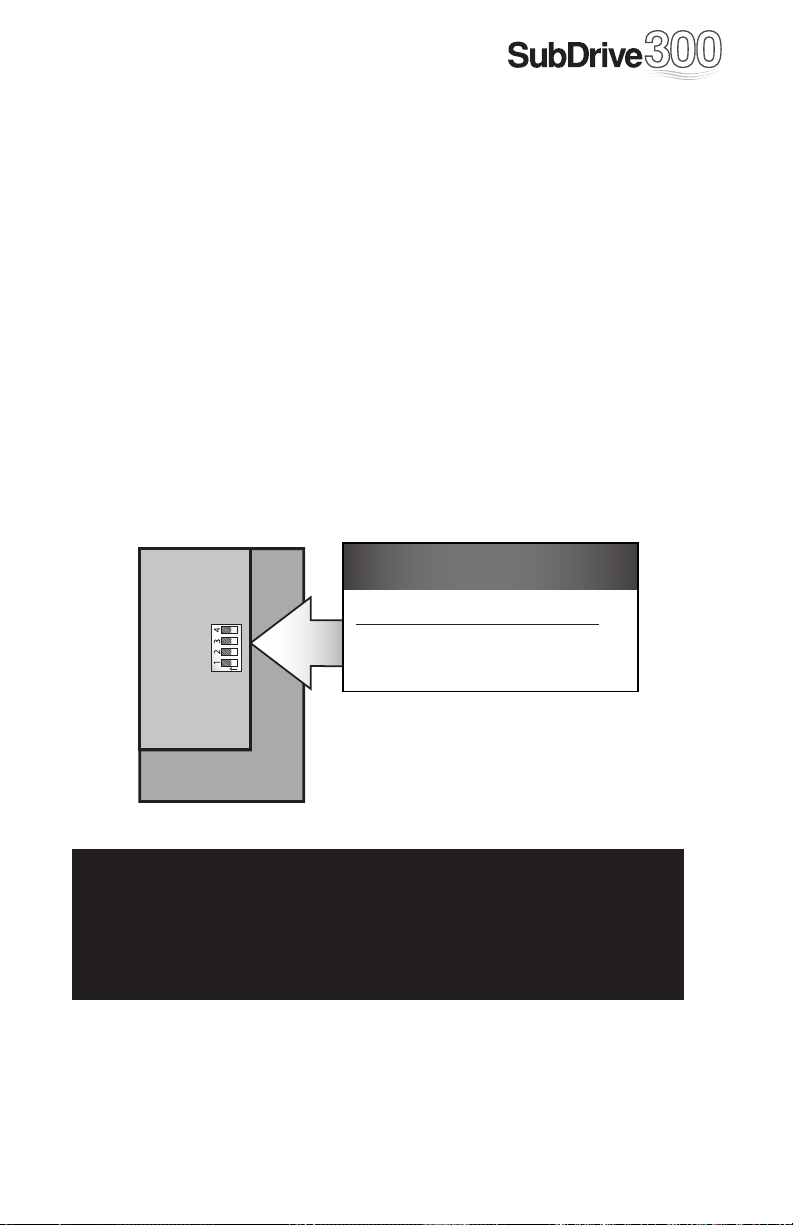

To confi gure the SubDrive300

for a 5 Hp pump, locate the DIP

switch marked “SW1” at the

lower right corner of the main

circuit board. Use a small

screwdriver (provided)

to change the DIP switch

setting according to the chart

as shown.

SW1

N

O

Configuration Switch

1 Pump Size

OFF 3.0 Hp

ON 5.0 Hp

8

!

▲ WARNING

Serious or fatal electrical shock may result from contact with internal

electrical components. DO NOT, under any circumstances, attempt

to modify DIP switch settings until power has been removed and 5

minutes have passed for internal voltages to discharge!

Page 9

Underload Sensitivity for

Shallow Wells

The SubDrive300 controller is confi gured at the factory to ensure detection

of Underload faults in a wide variety of pumping applications. In rare cases

(as with certain pumps in shallow wells) this trip level may result in nuisance

faults. If the pump is installed in a shallow well, activate the controller and

observe system behavior. Once the controller begins to regulate pressure,

check operation at several fl ow rates to make sure the default sensitivity

does not induce nuisance Underload trips.

If it becomes necessary to desensitize the Underload trip level, remove

power and allow the controller to discharge. Once the internal voltages have

dissipated, locate the DIP switch marked “SW1” at the lower right corner

of the main circuit board. Use a small screwdriver (provided) to change

Position 3 to the “ON” position to select the lower Underload sensitivity as

shown in the chart below.

Configuration Switch

POS Underload Sensitivity

SW1

N

O

!

▲ WARNING

Serious or fatal electrical shock may result from contact with internal

electrical components. DO NOT, under any circumstances, attempt

to modify DIP switch settings until power has been removed and 5

minutes have passed for internal voltages to discharge!

3 OFF Normal (default)

ON Low (shallow wells)

9

Page 10

Before Getting Started

!

▲ WARNING

Serious or fatal electrical shock may result from failure

to connect the ground terminal to the motor, SubDrive

controller, metal plumbing, or other metal near the motor

or cable, using wire no smaller than motor cable wires. To

minimize risk of electrical shock, disconnect power before

working on or around the SubDrive300 system.

CAPACITORS INSIDE THE SUBDRIVE300 CONTROLLER CAN STILL HOLD LETHAL VOLTAGE EVEN AFTER

POWER HAS BEEN DISCONNECTED.

ALLOW 5 MINUTES FOR DANGEROUS INTERNAL

VOLTAGE TO DISCHARGE BEFORE REMOVING

SUBDRIVE300 COVER.

Do not use motor in swimming areas.

!

▲ ATTENTION

This equipment should be installed by technically qualifi ed

personnel. Failure to install it in compliance with national

and local electrical codes and within Franklin Electric

recommendations may result in electrical shock or fi re

hazard, unsatisfactory performance, or equipment failure.

Installation information is available through pump

manufacturers and distributors, or directly from Franklin

Electric at our toll-free number 1-800-348-2420.

10

!

▲ CAUTION

Use SubDrive300 only with Franklin Electric 4-inch

submersible motors as specifi ed in this manual (see Table

1). Use of this unit with any other Franklin Electric motor or

with motors from other manufacturers may result in damage to both motor and electronics.

Page 11

Controller Location Selection

The SubDrive controller is intended for operation in ambient temperatures

up to 125°F (51°C) at 230 VAC input. The following recommendations will

help in selection of the proper location of the SubDrive unit:

1. A tank tee is recommended for mounting the tank, pressure sensor,

pressure gauge, and pressure relief valve at one junction. If a tank

tee is not used, the pressure sensor should be located within 6 feet

(1.8 meters) of the pressure tank to minimize pressure fl uctuations.

There should be no elbows between the tank and pressure sensor.

2. The unit should be mounted on a sturdy supporting structure such as a

wall or supporting post. Please take into account the weight of the unit,

which weighs approximately 34 pounds (15.5 kg).

3. The electronics inside the SubDrive are air-cooled. As a result, there

should be at least 6 inches of clearance above and below the unit to

allow room for air fl ow.

!

▲ CAUTION

There should be at least 6 inches of clearance above and below the

unit to allow room for air fl ow.

6"

min.

Pressure

Shut-off

Sensor

*

6"

min.

Clearance

For

Air Flow

PUMP

MOTOR

Pressure

Tank

Pressure

Relief Valve

Pressure

Sensor

6 Feet or Less

(Pressure Tank to PressureSensor)

* NOTE: there should be no elbows between the tank and pressure sensor.

11

Page 12

Power Supply

From Circuit Breaker

Pressure Sensor

Wiring

4. For indoor or outdoor installations.

5. The SubDrive300 should only be mounted with the wiring end

oriented downward. The controller should not be placed in direct

sunlight or other locations subject to direct rain or snow.

6. The mounting location should have access to 230 VAC electrical

supply and to the submersible motor wiring. To avoid possible

interference with other appliances, please refer to the enclosed

Installation Guide and observe all precautions regarding power

cable routing.

7. To assure maximum weather protection, the unit must be mounted

vertically with the cover properly aligned and secured with all eight

lid screws.

Wiring

To M oto r

Wiring

To M oto r

CORRECT INCORRECT

Pressure Sensor

Wiring

Power Supply

From Circuit Breaker

12

Page 13

Circuit Breaker and Wire Sizing

The minimum circuit breaker size and maximum allowable wire lengths for

connection of motor to the SubDrive300 are given in the following table:

Table 2: Minimum Breaker Size and Maximum Cable Length (in Feet)

Controller

Model

SubDrive300 234 317 xxxx 5 40 140 230 370 590 920 1430

A 10-foot section of cable is provided with the SubDrive300 to connect

the pressure sensors.

NOTE:

• Maximum allowable wire lengths are measured between the

• Aluminum wires should not be used with the SubDrive300.

• Wire sizing between the service entrance and the controller must

• SubDrive300 minimum breaker amps may be lower than AIM

Franklin Electric

Motor Model HP

controller and motor.

be suffi cient to provide the required maximum input amps to the

controller while conforming to local standards and codes.

Manual specifi cations for the motors listed due to the soft-starting

characteristic of the SubDrive300 controller.

Breaker

Amps

AWG Copper Wire Size

14 12 10 8 6 4

13

Page 14

Quick Reference Guid

e

u

a

e

o

a

u

From Power Source

L1 L2

(Input)

Power Supply

From Circuit Breaker*

P/N 587 020 6300

PRESSURE

INT

NO NO

FAN

SENSOR

SHUT-OFF

RELAY

COM

INV

PFC

FAN

FAN

Sensor Connection

PRESSURE

SENSOR

BlkRed GrnWh

SW1

O

SW2

PRESSURE

SHUT-OFF

Congur

1

N

OFF

ON

Outp

NOTICE

The Safety earth ground connections

are marked at their terminals using

the “ ” symbol

* Note: To avoid possible interference with other appliances,

please refer to the enclosed installation guide and observe all

precautions regarding power cable routing

14

P

Fr

El

M

Page 15

SubDrive300 (not to scale)

a

tion Switch

Pump Size

3.0 Hp

5.0 Hp

t to Motor

Red Yel Blk

(Brn) (Blu e) (Blk)

(Output)

mp

nklin

ctric

tor

Tank Precharge

Ination Valve

minimum tank size

Pressure Gauge

Pressure

Relief Valve

Discharge into

drain rated for

max pump output

at relief pressure

WARNING

Submersible pumps can

develop very high pressure in

some situations. Always

install a pressure relief valve

able to pass full pump ow at

100 PSI. Install the pressure

relief valve between the

pump and pressure tank.

Pressure Tank

See Table 3

(page 16) for

recommened

Pressure

Sensor

Pressure

Shut-o

Sensor

Drain Valve

Pressure Setting Guide

Pressure Switch

Set Point (PSI)

25

30

35

40

45

50 (Factory set)

55

60

65

70

75

80

Sensor Cable

Supplied

Pressure Tank

Pre-Charge (PSI)

To Residence

18

21

25

28

32

35

39

42

46

49

53

56

15

Page 16

Pressure Tank

The SubDrive needs only a small pressure tank to maintain constant

pressure (see table below for recommended tank size). For pumps rated 12

gpm or more, a slightly larger tank is recommended for optimum pressure

regulation. The SubDrive can also use an existing tank with a much larger

capacity

Table 3: Minimum Pressure Tank Size (Total Capacity)

The pressure tank pre-charge setting should be 70% of the system pressure

sensor setting as indicated in the following table.

Table 4: Pressure Tank Precharge (PSI)

.

Pump Flow Rating Controller Model Minimum Tank Size

Less than 12 gpm SubDrive300 8 gallon

12 gpm and higher SubDrive300 20 gallon

System Pressure

(at Pressure Sensor)

25 18

30 21

35 25

40 28

45 32

50 35 Factory Setting

55 39

60 42

65 46

70 49

75 53

80 56

NOTE: Check tank precharge regularly to maintain optimum

pressure regulation.

Pressure Tank

Setting (±2 psi)

16

Page 17

Installation Procedure

1. Disconnect electrical power at the main breaker.

2. Drain the system (if applicable).

3. Install the pressure sensor and pressure shut-off sensor at the

pressure tank tee downstream of the pressure tank (the pressure

tank should be between the pressure sensor and the pump). The

sensors have a ¼-18 National Pipe Thread (NPT) connection.

The pressure sensors should not be installed in an inverted

orientation (up-side down). Make sure the pressure sensor and tank

are not located more than 3 feet off the main piping.

4. Install the unit to the wall using four mounting screws (not included) as

shown in Figure 1 below. Remove the SubDrive lid by removing the eight

lid screws.

Mounting Screw Locations

Lid Screws (Included Quantity 8)

(User Supplied Quantity 4)

Figure 1: Mounting Screws

17

Page 18

Wiring Connections

!

▲ WARNING

Serious or fatal electrical shock may result from failure to connect

the motor, the SubDrive300, metal plumbing and all other metal near

the motor, or cable to the power supply ground terminal, using wire

no smaller than motor cable wires. To reduce risk of electrical shock,

disconnect power before working on or around the water system.

Do not use motor in swimming areas.

1. Verify that the power has been shut off at the main breaker.

2. Verify that the dedicated branch circuit for the SubDrive300 is

equipped with a properly-sized circuit breaker. Refer to Table 2

(Page 13) for minimum breaker size.

3. Use the appropriate strain relief or conduit connectors. Type B liquid

tight fi ttings are recommended for maximum weather protection.

4. Remove the SubDrive300 lid.

5. Feed the motor leads through the opening on the bottom right side

of the unit and connect them to the terminal block positions marked

GND (Green ground wire), Red, Yellow and Black (Figure 2).

18

SW1

N

O

SW2

PRESSURE

INT

NO NO

FAN

SENSOR

SHUT-OFF

RELAY

COM

INV

PFC

FAN

FAN

Figure 2: Motor Lead Connections

Output to Motor

Red Yel Blk

(Brn) (Blue) (B lk)

(Output)

Page 19

SW1

N

O

SW2

From Power Source

PRESSURE

L2L1

(Input)

INT

NO NO

FAN

SENSOR

SHUT-OFF

INV

PFC

FAN

FAN

RELAY

COM

Sensor Connection

PRESSURE

SENSOR

PRESSURE

SHUT-OFF

BlkRed GrnWh

Figure 3: Power and Pressure

Sensor Connections

6. Feed the 230 VAC power leads through the bottom left side of the

SubDrive300 controller and connect them to the terminals marked

L1, L2, and GND (Figure 3).

A 10-foot section of pressure sensor cable is provided with the

controller, but it is possible to use similar 22 AWG wire for distances

up to 100 feet from the pressure sensor. A 100-foot section of

pressure sensor cable is available as an accessory.

7. Feed the pressure sensor leads through the smaller opening located in the

bottom middle of the SubDrive300 unit and press on the quick

connect terminals.

8. Verify that the SubDrive300 unit is properly confi gured for the

horsepower rating of the motor and pump being used. Please refer to

the section on Pump Sizing for information on drive confi guration.

9. Replace the lid. Do not over-tighten the screws.

19

Page 20

Remove Rubber End Cap To Adjust Pressure

With 7/32" Allen Wrench

Pressure

Sensor

Boot

Non-Adjustable

Set at 100PSI

Quick Connect

lead connect

Figure 4A:

Pressure Sensor

Pressure Shut-off Sensor

Figure 4B:

10A. Connect the other end of the pressure sensor cable with the two

spade terminals to the pressure sensor. The connections are

interchangeable (Figure 4A).

10B. Connect the other end of the pressure sensor cable with the two

¼" quick connect terminals to the pressure shut-off sensor. The

connections are interchangeable (Figure 4B).

11. Set the pressure tank pre-charge at 70% of the desired water

pressure setting. To check the tank’s pre-charge, de-pressurize

the water system by opening a tap. Measure the tank pre-charge

with a pressure gauge at its infl ation valve and make the necessary

adjustments.

12. The pressure sensor communicates the system pressure to the

SubDrive300 controller. The sensor is preset at the factory to 50 psi,

but can be adjusted by the installer using the following procedure:

a. Remove the rubber end-cap (Figure 4A).

b. Using a 7/32” Allen wrench (provided), turn the adjusting screw

clockwise to increase pressure and counter-clockwise to

decrease pressure. The adjustment range is between 25 and 80

psi (¼ turn = approximately 3 psi).

c. Replace the rubber end cap.

d. Reset the pressure tank pre-charge to the appropriate pressure.

e. Cover the pressure sensor terminals with the rubber boot

provided (Figure 4A).

20

!

▲ CAUTION

When increasing the pressure, do not exceed the mechanical stop on

the pressure sensor or 80 psi. The pressure sensor may be damaged.

NOTE: Ensure that the system is properly grounded all the way to the service

entrance panel. Improper grounding may result in the loss of voltage surge

protection and interference fi ltering.

Page 21

Start-Up and Operation

Apply power to the controller. A steady green light indicates that the

SubDrive300 has power but the pump is not running. The green

light will fl ash continuously when the pump is running.

Leaky Systems

Leaky water systems might keep the controller running due to the accurate

pressure sensing capability of the pressure sensor. Continuous running

or starts and stops do not hurt the controller, pump or motor. However,

to reduce the on-time of the controller/pump/motor, a “Bump-Mode”

procedure is installed. During low fl ow (or leaky) conditions this feature

periodically increases the speed of the pump several PSI above the set

point and shuts off the pump. This adds some time to bleed off before the

system starts up again.

NOTE: Conventional private water systems intermittently fi ll a pressure

tank as commanded by a standard pressure switch (e.g. 30 - 50 psi). The

SubDrive300 maintains a constant pressure at the pressure sensor up to the

maximum capability of the motor and pump.

Although the pressure is constant at the pressure sensor, pressure drops

may be noticeable in other areas of the home when additional taps are

opened. This is due to restrictions in the plumbing and will be more

pronounced the farther the taps are from the pressure sensor. This would

be true of any system, and if observed, should not be interpreted as a

failure in the performance of the SubDrive300.

21

Page 22

Specifi cations

Voltage 190-260 VAC

Frequency 50/60 Hz

Input from

Power Source

(single-phase)

Current (max) 36 Amps (RMS)

Power Factor 1.0 (constant)

Power (idle) 65 Watts

Power (max) 7200 Watts

Voltage Adjusts with Frequency

Output to Motor

(three-phase)

Pressure Setting

Operating

Conditions

Controller Size

(approximate)

For Use With

(A)

(C)

Frequency Range

Current (max) 17.8 Amps (RMS, each phase)

Factory preset 50 psi

Adjustment range 25-80 psi

NEMA 4 (indoor/outdoor)

Temperature (at 230 VAC

input)

Relative Humidity

Outer dimensions 14 ¾” H × 15 ¾” W × 8 ¾” D

(B)

Weight 34 lbs (15.5kg)

Pump (60Hz)

Motor (3-phase) 234317- series (5.0 Hp)

30-80 Hz (3 Hp pump)

30-60 Hz (5 Hp pump)

Model 5870206300

-13 to 125°F

(-25 to 51°C)

0-100%, non-condensing or

condensing

3.0 Hp (default)

5.0 Hp

NOTES: (A) Operating temperature is specifi ed at full output power when installed as

described in Controller Location Selection on Page 11.

(B) Refer to Page 23 for detailed mounting dimensions.

(C) If a pump other than the default rating is used, refer to Page 8 for

drive confi guration.

22

Page 23

Mounting Dimensions

15.34”

8.75”

14.75”

12.00”

4.75”

23

Page 24

Diagnostic Fault Codes

Should an application or system problem occur, built-in diagnostics will

protect the system. The red “FAULT” light on the front of the SubDrive300

controller will fl ash a given number of times to indicate the nature of the

fault. In some cases, the system will shut itself off until corrective action has

been taken. Fault codes and the recommended corrective action for each

are listed in the following chart.

# of

Flashes Fault Possible Cause Corrective Action

Wait for well to recover and

automatic restart timer to time

out. If the problem does not

correct, check motor and pump.

See description of “Smart Reset”

on Page 26.

Check for loose connections.

Check line voltage. Report low

voltage to the power company.

Unit will start automatically when

the proper power is supplied.

Unit will attempt to free a locked

pump. If unsuccessful, check the

motor and pump.

1

2

3

Motor

Underload

Undervoltage

Locked

Pump

Air-locked pump.

Overpumped or dry well.

Worn pump. Damaged

shaft or coupling. Blocked

pump or screen.

Low line voltage.

Misconnected input leads.

Motor/pump misaligned.

Abrasive/Sand-bound pump.

Dragging pump or motor.

24

4

5

Open Circuit

Short Circuit

6

Over Current

7

** “Cycle input power” refers to turning the power off until both lights fade off,

then applying power again.

Overheated

Controller

Reserved for factory use

Loose connection.

Defective motor or cable.

When fault is indicated

immediately after power-up,

short circuit due to loose

connection, defective cable,

splice or motor.

When fault is indicated

while motor is running, over

current due to loose debris

trapped in pump.

High ambient temperature.

Direct sunlight. Obstruction

of air-fl ow.

Check motor wiring. Make certain

all connections are tight. Make

certain proper motor is installed.

Cycle input power** to reset.

Check motor wiring. Cycle input

power** to reset.

Check pump.

This fault automaticallyresets

when the temperature returns to a

safe level.

Page 25

System Troubleshooting Guide

Symptom Possible Cause Corrective Action

Verify motor connections.

See Figure 2 in the “Wiring

Connections” section.

Make sure there is at least 6” of room

around the controller for movement

of air. Avoid direct sunlight. Reduce

ambient temperature below 125°F

(51°C). Increase input voltage if

below 230 VAC.

Use pump with higher fl ow rating

(if head requirement is still satisfi ed).

Check tank for bladder damage.

Replace if necessary.

Reset the tank pre-charge pressure

(should be 70% of pressure sensor

setting).

Use larger tank

(refer to Table 3 on Page 16 for

minimum Pressure Tank size).

Re-seat the pitless adapter. Replace

seal as needed.

Check for leaky faucets, valves

and/or pipe fi ttings and repair.

Water fl ow rate

is not as high as

expected.

Excessive

pressure

fl uctuations.

Motor runs

continuously with

no fl ow demand.

Motor is running backwards.

Temperature in the controller

is too high. If the controller’s

heat exchanger becomes too

hot, the controller will reduce

the speed of the pump to

lower the power consumption.

Pump capacity cannot supply

the demand.

Waterlogged tank.

Pressure tank is too small for

fl ow rating of the pump.

Leak in the pitless adapter.

Leak in the household or

outdoor plumbing

25

Page 26

Underload Smart Reset

If a motor Underload fault condition occurs, the most likely cause is an

overpumped or dry well. To allow the well to recover, the SubDrive300

controller will wait 30 seconds to 5 minutes, determined by duration of

the previous run time, before restarting the motor. For example, the fi rst

time the fault occurs, the controller will wait 30 seconds before attempting

to restart the pump. If the system would then run for 1 minute and an

Underload fault recurs, the controller will wait 4 minutes before attempting

to restart the pump. This schedule allows for the minimum off-time possible

based on the recovery time of the well.

Figure 5: “Smart Reset” Well Recovery Time

6.0

5.0

4.0

3.0

2.0

Off Time (Min.)

1.0

26

0.0

123 45678

0

Run Time (Min.)

Over-Temperature Foldback

The SubDrive300 controller is designed for full power operation in ambient

temperatures up to 125°F (51°C) as long as the input voltage is kept at 230

VAC. Under extreme thermal conditions, the controller will reduce output

power in an attempt to avoid shutdown. Full pump output is restored when

the controller temperature cools to a safe level.

Page 27

TOLL-FREE HELP FROM A FRIEND

Franklin Electric

Submersible Service Hotline

800-348-2420

Page 28

400 E. Spring Street

Bluffton, IN 46714

Tel: 260-824-2900

Fax: 260-824-2909

www.franklin-electric.com

225286101 Rev. 1

M1491 11.05

Loading...

Loading...