Page 1

You’re about to begin a very happy and delicious

relationship. Let’s get started.

This is no ordinary upright cooker.

Welcome to your new

Franke upright cooker

FFD090X5S - 90CM DUAL FUEL UPRIGHT COOKER

Page 2

2

AN IMPORTANT NOTE

Please read this document and the safety information carefully before you first use

your upright cooker.

SUPPORT

Speak to our customer service representatives.

Australia: 03 9700 9100 | info@prks.com.au

New Zealand: 09 964 0400 | info@prks.co.nz

WARRANTY

Your Franke product is protected by a 2-year warranty. Should you ever need to make a

warranty enquiry, simply contact our service department.

Australia: 03 9700 9100 | service@prks.com.au

New Zealand: 09 964 0400 | service@prks.co.nz

GET SOCIAL

Keep up to date on all things Franke by following us on Facebook and Instagram.

@FrankeAUS

#makeitwonderful

“Let’s let everyone else be ordinary,

while we make it wonderful”

Page 3

Contents 3

Chapter 1: Ready, set up, go

5 Warnings

7 What’s in the box?

7 Final preparation

7 Installation instructions

20 Setting the time

20 Environmental information

20 Disposal

Chapter 2: Life with your Franke Upright cooker

22 Functions

23 Operating your upright cooker

23 Using the touch clocok

Chapter 3: Getting the most out of your Franke Upright cooker

25 Cleaning and care

25 Interior lighting

25 Tips for using burners correctly

Chapter 4: Problem, meet solution

27 Trouble shooting

Chapter 5: Last, but not least

29 Warnings, hazards, risks and legal

Looking for something?

32 Glossary

CONTENTS

Page 4

Chapter 1 Ready, set up, go

4

READY, SET UP, GO

CHAPTER 1

Your Franke upright cooker is designed to be set up

quickly and easily - so you can start creating delicious

masterpieces even sooner.

Page 5

5

WARNINGS

1. This appliance is not intended for use by persons (including children) with reduced physical,

sensory or mental capabilities, or lack of experience or knowledge, unless they have been given

supervision or instruction concerning the use of the appliance by a person responsible for their

safety. Children should be supervised to ensure that they do not play with the appliance.

2. DO NOT USE OR STORE FLAMMABLE MATERIALS IN THE APPLIANCE STORAGE DRAWER OR

NEAR THIS APPLIANCE. DO NOT SPRAY AEROSOLS IN THE VACINITY OF THIS APPLIANCE WHILE

IT IS IN OPERATION.

3. DO NOT MODIFY THIS APPLIANCE. This appliance is not suitable for use with aftermarket lids

or covers.

4. WHERE THIS APPLIANCE IS INSTALLED IN MARINE CRAFT OR IN CARAVANS, IT SHALL NOT BE

USED AS A SPACE HEATER.

5. After removing the packaging, make sure to check if there is any damage to the appliance. If there

is any damage, never attempt to use the appliance and immediately contact your a uthorised

Service Centre. As packaging materials can be dangerous to children, they need to be collected

immediately and put out of reach.

6. In certain circumstances electrical appliances may be a safety hazard. The unit MUST be

connected to the electrical supply before operation to enable the electronic ignition to work. The

electrical connection must be accessible after installation. The appliance must be electrically

isolated before any maintenance can be performed.

7. Do not place heavy objects on this appliance (cooktop or door), use for storage or as a cutting

surface, as sharp edges can damage the surface. This appliance is designed for cooking only. If

any damage such as chips or cracks are seen in the glass, turn off all control knobs and do not

use until the appliance has been inspected by an authorised service person or replaced.

8. This appliance is designed for domestic household use only and for the cooking of domestic food

products. Use as a commercial appliance will void the warranty. It should not to be used outdoors

and must be fully installed. Do not use the appliance until fully installed. If this appliance is

installed on a base, measures must be taken to prevent the appliance from slipping from the base.

9. Damage can occur to bench tops if pots and pans are able to overlap the bench top. This can

result in heat being transferred to the bench top. Ensure that correct sized pots & pans are used.

Refer to guide in instructions.

10. Do not allow pot handles or utensils to be placed near gas burners in operation, as they can cause

the handles to become hot to touch. Always turn handles away when small children are nearby. It

is recommended that children are kept away from the cooktop at all times.

11. Danger of fire: Do not store items on the cooking surfaces.

12. CAUTION: The cooking process has to be supervised. A short term cooking process has to be

supervised continuously.

13. WARNING: Unattended cooking on a hob with fat or oil can be dangerous and may result in a fire.

14. Do not leave the cooktop while cooking with solid or liquid oils. There may be flaming up in

conditions of extreme heating. Never pour water onto the flames occurring from oil. Immediately

turn the cooktop off and cover the pan with a lid or fire blanket in order to smother the flame.

15. If the electrical supply cord is damaged, either when being installed or after installation, it must be

replaced by the manufacturer, its service agent or similarly qualified persons in order to prevent

a hazard.

16. The appliance is not intended to be operated by means of an external timer or separate remote

control system.

17. Electrical connection must be made as per local wiring rules and regulations.. Do not disconnect

the appliance with wet hands or bare feet, and do not disconnect the power cord with extreme

force. If the electrical supply is restricted, means of all-pole disconnection must be accessible and

incorporated in the fixed wiring in accordance with the wiring rules.

Chapter 1 Ready, set up, go

Page 6

6Chapter 1 Ready, set up, go

18. Ensure that the kitchen is well ventilated or mechanical ventilation is in use while cooking on

the appliance.

19. The cooktop and oven will become hot during and directly after use. Do not touch any components

during this time, as they may be hot and can cause burns. To avoid burns young children should be

kept away. Care should be taken to avoid touching heating elements inside the oven.

20. Cleaning may only be commenced on the appliance once it has cooled down and is turned off.

Failure to clean properly can damage the unit. Do not use a steam jet or any other high pressure

cleaning equipment to clean the appliance.

21. Do not use harsh abrasive cleaners or sharp metal scrapers to clean the glass surface as they can

scratch the surface, which may result in the glass shattering. Clean the glass using a warm damp

cloth (e.g. dishcloth).

22. When the appliance is not being used, the knobs must be kept in the ‘OFF’ position.

23. The appliance must be installed and put into operation by an authorised person under the

conditions provided by the manufacturer in this manual. The manufacturer cannot be held

responsible for any damage that might occur due to faulty installation. Do not modify

this appliance.

24. Use the anti-tilt kit to prevent the appliance from accidentally falling over.

25. The appliance must not be installed behind a decorative door in order to avoid overheating.

Page 7

Chapter 1 Ready, set up, go

7

WHAT’S IN THE BOX?

1 x Franke oven

1 x Wire shelf

1 x Slider bracket

1 x Universal pan

1 x Telescopic runner

1 x Wiring/gas connectors

3 x Gas trivets

5 x Burners

FINAL PREPARATION

Before using the oven, remove any protective wrap from the stainless steel. All stainless steel body

parts should be wiped with hot, soapy water and with a liquid stainless steel cleanser.

If buildup occurs, do not use steel wool, abrasive cloths, cleaners, or powders! If it is necessary to

scrape stainless steel to remove encrusted materials, soak with hot, wet cloths to loosen the material,

then use a wood or nylon scraper. Do not use a metal knife, spatula, or any other metal tool to scrape

stainless steel! Scratches are almost impossible to remove.

Before using the oven for food preparation, wash the cavity thoroughly with a warm soap and water

solution to remove film residues and any dust or debris from installation, then rinse and wiped dry.

INSTALLATION INSTRUCTIONS

Check the appliance for damage after unpacking it, and don’t connect the appliance if it has been

damaged in transport.

This appliance shall be installed only by authorised persons and in accordance with the manufacturer’s

installation instructions, local gas fitting regulations, municipal building codes, electrical wiring

regulations, AS/NZS 5601 - Gas Installations and any other statutory regulations.

Only a licensed professional may connect the appliance – damage caused by incorrect installation is

not covered under the warranty.

Ensure that the panels of the cabinetry around the oven are heat resistant, and the glues and materials

can withstand temperatures of at least 120 degrees Celsius.

Ensure there is adequate air flow around the rear of the oven and there is a gap between the oven and

kitchen unit.

Page 8

Chapter 1 Ready, set up, go

8

LOCAL AUTHORITY REQUIREMENTS

Before installation, unpack all parts from carton, remove all internal packaging and check for da

mage. Check Gas Type and specifications plate placed on the rear of the unit, alternatively there is a

second label supplied. All gas fitting work, service and repairs can only be performed by an authorised

person in accordance with AS/NZS 5601 and local gas regulations. Failure to comply with this

condition will void the warranty. Always unplug the appliance before carrying out any maintenance

operations or repairs. The walls of the units must not be higher than worktop and must be capable of

resisting temperatures of 65⁰ K ( 65°C Above Amb.Temp. ) or higher. Do not install the appliance near

flammable materials (eg. curtains). The final act of any installation or gas type conversion must be the

full testing of this appliance, which includes leak testing, ignition of each burner and the functionality

of the burners separately and together. Keep all the dangerous packing parts (polystyrene foam, bags,

cardboard, staples, etc.) away from children.

Any walls of the adjacent furniture pieces and the wall behind the cooker must be made of

heat-resistant material that can withstand a minimum temperature of 65° K ( 65°C Above Amb.Temp.)

REQUIREMENTS

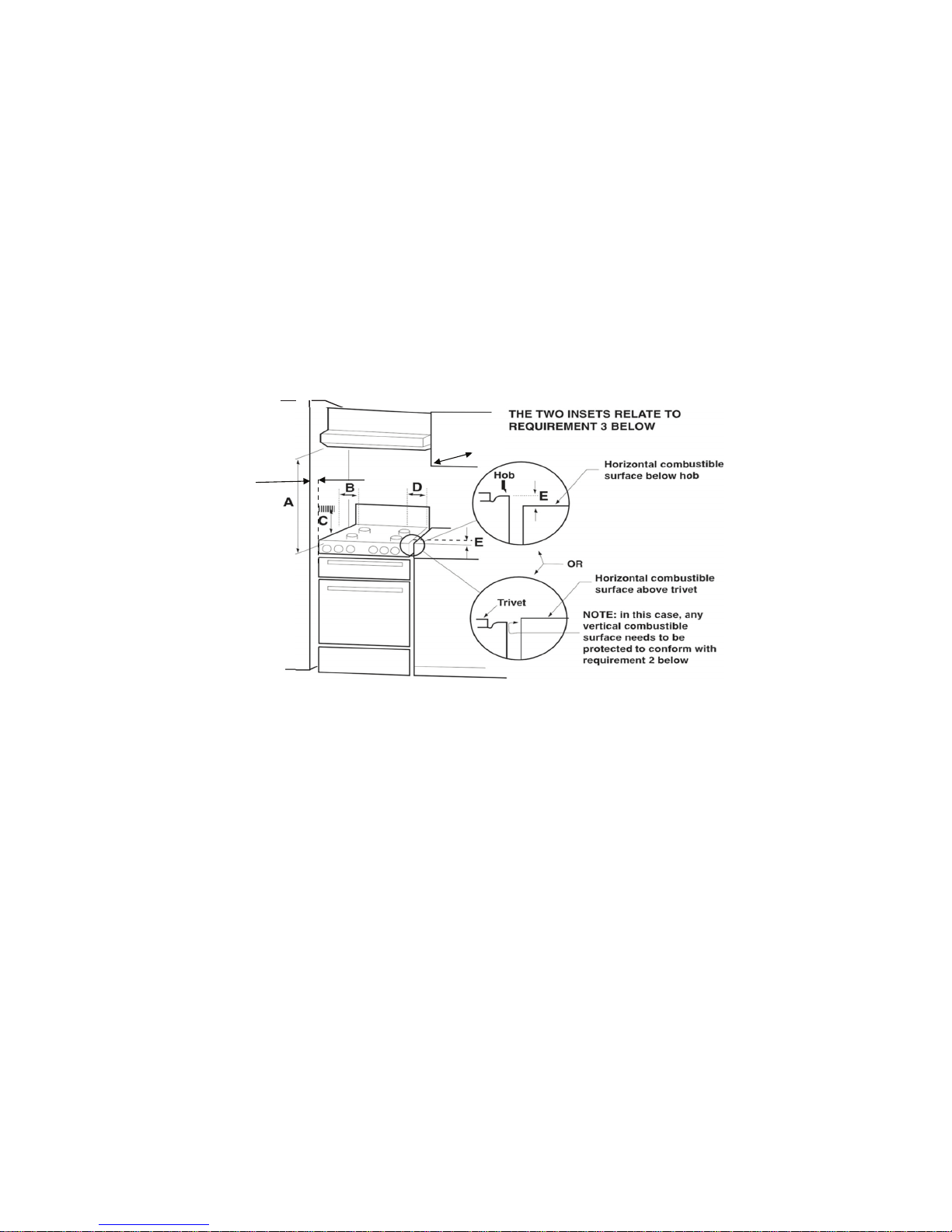

1. Overhead clearances – (Measurement A)

Range hoods and exhaust fans shall be installed in accordance with the manufacturer’s instructions.

However, in no case shall the clearance between the highest part of the hob of the cooking appliance

and a range hood or an overhead exaust fan be less than 700 mm. Any other downward facing

combustible surface less than 700 mm above the highest part of the hob shall be protected for the full

width and depth of the cooking surface area in accordance with clause 5.12.1.2. However, in no case

shall the clearance to any surface be less than 450mm. The maximum depth of wall cabinet above the

cooking shall be 400 mm.

2. Side clearances – (Measurements B & C)

Where B, measured from the periphery of the nearest burner to any vertical combustible surface, is

less than 200 mm, the surface shall be protected in accordance with Clause 5.12.1.2 to a height C of

not less than 200 mm above the level of the backguard for the full width of the cooking surface area.

Where the cooking appliance is fitted with a “splash back”, protection of the rear wall is not required.

The appliance can be installed between two walls. A single sidewall that exceeds the height of the

work surface is possible. This must be at a minimum distance of 70 mm from the edge of the cooker.

3. Additional requirements for Freestanding and Elevated Cooking Appliances (Measurements D & E)

Where D, the distance from the periphery of the nearest burner to a horizontal combustible surface is

less than 200 mm, then E shall be 10 mm or more, or the horizontal surface shall be above the trivet.

See inserts above.

Fig. 01

400mm max.

Clearance above and around domestic cookers

Page 9

Chapter 1 Ready, set up, go

9

IMPORTANT INFORMATION FOR INSTALLAING AND SERVICING THE APPLIANCE

The cooker can be installed separately, as a freestanding unit, or between kitchen units or between

a kitchen unit and the wall. This appliance is not connected to devices which exhaust combustion

products. Special attention must be focused on the prescriptions described below regarding room

aeration and ventilation. The dimensions of the appliance are listed below:

APPLIANCE SERVICING

IMPORTANT!

ALL SERVICING AND MAINTENANCE ARE TO BE COMPLETED BY THE MANUFACTURER’S

AUTHORISED PERSONNEL ONLY.

Before carrying any servicing operation disconnect the appliance from gas and electric supply and

extra appliance from final installation place in order to have access to the appliance for proper

servicing intervention.

GAS CONVERSION

WARNING!

Before carrying out this operation, disconnect the appliance from gas and electricity. Gas

conversion shall be conducted by a factory-trained professional. Call the customer service

hotline to identify a factory-trained professional near your home. The gas conversion

procedure for this range includes differents steps:

1. Pressure regulator

2. Surface burners

3. Main oven burner

4. Visual checks prior to closure of oven bottom panel

5. Adjustment of minimum setting

The conversion is not completed if all 5 steps have not been concluded properly.

Before performing the gas conversion, locate the package containing the replacement nozzle shipped

with every range.

IMPORTANT: Each nozzle has a number indicating its flow diameter printed on the body.

Consult the table on page 20 for matching nozzles to burners. Save the nozzles removed from the

range for future use.

STEP 1: PRESSURE REGULATOR.

For NG or ULPG installation ref. to fig. 7 and chapter ‘Appliance gas connection’ at pag 7

LENGTH DEPTH HEIGHT with worktop stamped HEIGHT with worktop welded

897mm 600mm adjustable 870-940mm adjustable 890-960mm

Fig.2 Fig.3

Cooker with worktop stamped Cooker with worktop welded

Page 10

Chapter 1 Ready, set up, go

10

STEP 2: SURFACE BURNERS

For surface burners conversion ref to table 1 chapter ‘Adaption to various types of gas’ at page 8 and

chapter ‘Conversion to different types of gas’ at page 12

STEP 3: MAIN OVEN BURNER

For main oven burner conversion ref to table 1 chapter ‘Adaption to various types of gas’ at page 8 and

chapter ‘Conversion to different types of gas’ at page 12

STEP 4: VISUAL CHECKS

The following visual check must be performed to ensure that the conversion has been carried out

properly and without damage to other components of the range. Verify that the flame of the oven

burner be completely blue and with regular aspect as shown below.

CONNECTION OF THERMOCOUPLE TO THERMOSTAT

The thermocouple for oven burner is connected to the magnet. Tight gently the connection. The tip of

the spark plug or thermocouple must fully overlap at least the first gas emission hole of the burner.

After performing all these visual checks, reinstall the bottom panel of the oven compartment and

proceed to setting the minimum for each burner.

STEP 5: MINIMUM FLAME ADJUSTMENT

WARNING!

These adjustments should be made only for use of the appliance with Natural gas. For use with ULPG,

the choke screw must be fully turned in a clockwise direction.

Surface burners

Light one burner at a time and set the knob to the MINIMUM position (small flame). Remove the knob.

The range is equipped with a safety valve. Using a small-size slotted screwdriver, locate the choke

valve on the valve body and turn the choke screw to the right or left until the burner flame is adjusted

to desired minimum. Make sure that the flame does not go out when switching quickly from the

MAXIMUM to the MINIMUM position.

Oven burner

Set the oven temperature control knob to the MAXIMUM setting. Close the oven door and operate the

oven for at least 10 minutes. Set the knob to the MINIMUM setting. Remove the knob. With a slotted

screwdriver turn the choking screw (bypass screw at the left side of the thermostat bar) and, while

observing the flame at the same time through the bottom oven porthole, evaluate the consistency of

the flame so it remains on when switching quickly from MINIMUM to MAXIMUM setting.

Room Ventilation

To ensure that the appliance operates correctly, the room

where it is installed must be continuously ventilated.

The room volume should not be less than 25m3 and the

quantity of air should be based on the regular combustion

of gas and on the ventilation of the room. Natural air will

flow through permanent openings in the walls of the room

to be ventilated. These openings will be connected with

the outside environment and should have a minimum

cross-section defined by current national standards

regarding room ventilation (Fig. 04).

These openings should be built so that they cannot be

clogged. Indirect ventilation is also permitted by taking air

from the rooms adjacent to the one to be ventilated.

Fig. 04

Page 11

Chapter 1 Ready, set up, go

11

Location and Aeration

Gas cooking appliances must always evacuate the combustion products by means of hoods connected

to chimneys, flues or directly outside (Fig. 05). If a hood cannot be installed It is possible to use a fan

installed on a window or directly facing outdoors, to be operated together with the appliance ( Fig. 06),

provided that there is strict compliance with the ventilation regulations.

APPLIANCE GAS CONNECTION

IMPORTANT: This appliance must be installed by an authorised person.

WARNING: DO NOT MODIFY THIS APPLIANCE

If the appliance cannot be adjusted to perform correctly, contact the service department.

This appliance utilises a threaded 1/2” gas male fitting. To connect the appliance to the gas

network with a flexible hose, a supplemental hose nipple fitting is needed which is supplied with

the appliance. (Fig. 07)

Gas Regulator

The gas connection is via 1/2” tapered thread. Connect the cooker to the gas supply and test for

leaks. NEVER use a naked flame to check for gas leaks.

Natural Gas: Gas regulator supplied with the appliance must be installed.

ULPG: Test point adaptor to be fitted and checked at time of installation.

Fig. 05

Fig. 06

Fig. 07

Gas inlet (mm) - Nat gas

From RH rear side: 70mm

Up from floor cooker with worktop stamped: 655-725mm

Up from floor cooker with worktop welded: 675-745mm

Gas inlet (mm) - ULPG

From RH rear side: 70mm

Up from floor cooker with worktop stamped: 570-640mm

Up from floor cooker with worktop welded: 590-660mm

Gas inlet positions with different leg heights - mm

Page 12

Chapter 1 Ready, set up, go

12

Using a flexible connection

This appliance is approved for connection with a flexible hose, which complies with the AS/NZS

1869 (Australian Approved), 10mm ID, class B or D, between 1-1.2m long. Connection shall be in

compliance with AS/NZS 5601 for a high level connection. The hose should not be subjected to

abrasion, kinking or permanent deformation and should be able to be inspected along its entire length.

Unions compatible with the hose fittings must be used and connections tested for gas leaks. The fixed

consumer piping outlet should be at approximately the same height as the cooker connection point,

pointing downwards and approximately 150mm to the side of the cooker. The hose should be clear of

the floor when the cooker is in the installed position.

When installing the hose restraint device, the appliance anchor point is the rear panel.

Using a Copper Pipe connection

The cooker must be connected to the gas supply with upstream connection of an isolation valve in

accordance with the respectively valid regulations. We recommend that the isolation valve be fitted

prior to the cooker to enable isolation of the cooker from the gas supply. The valve must be easily

accessible at all times. To find out the gas type factory settings, see label on the rear of the appliance.

Test the operation of the cooker before leaving

Note: These burners have no aeration adjustment.

Check correct operation of the ignitions system and operation of the regulator and operation of the

burners individually and in combination. Burner flames should be clear blue, with no yellow tipping.

If the burners show any abnormality check that the burners are correctly located. If satisfactory

performance cannot be obtained, contact service.

Important

Before leaving instruct the owner in the use of the

cooker it should be expressly noted that we cannot

accept any liability for direct or indirect damage

caused by wrong connection or improper installation.

When being repaired, the appliance must always be

disconnected from the mains supply; if required,

notify our customer service.

Burners Gas type Pressure (kPa) Injector (mm) Mj/hr By-pass size (mm)

Small Natural 1.00 0.90 4.00 0.30 regulated

Small ULPG 2.75 0.54 4.00 0.30

Medium Natural 1.00 1.18 7.00 0.36 regulated

Medium ULPG 2.75 0.70 7.00 0.36

Large Natural 1.00 1.55 11.50 0.52 regulated

Large ULPG 2.75 0.92 11.50 0.52

Wok Natural 1.00 1.80 14.50 0.65 regulated

Wok ULPG 2.75 1.02 14.50 0.65

Wok 2way Natural 1.00

Ex. 1.80

int. 0.50

17.50

Ex. 0.65 reg.

int. 0.34 reg.

Wok 2way ULPG 2.75

Ex. 1.02

int. 0.50

17.50

Ex. 0.65 reg.

int. 0.34 reg.

Oven Natural 1.00 1.95 16.50 0.62 regulated

Oven ULPG 2.75 1.10 16.50 0.62

TABLE N°1

Adaption to various types of gas

Burners Dimensions (mm)

Auxiliary ø50

Semi-rapid ø70

Rapid ø95

Wok ø125

Wok 2 ways ø135

TABLE N°2: GAS BURNER DIMENSION

Page 13

Chapter 1 Ready, set up, go

13

SUPPORT LEGS AND BACKGUARD INSTALLATION

The cookers are supplied with four transit supports (one for each corner). Four support legs are

supplied separately and are fitted on location to the four corners of the lower support frame. Each

support leg is pushed over the relevant transit support until flush with the support frame. Each leg

is adjusted by screwing the lowe r section in or out as required for fitting to a 900mm bench height.

For lower bench tops adjust the height of the legs to 180mm so the hob is located 10mm above the

horizontal combustible surface, ref. AS/NZS 5601.

Fig. 08

Legs should be installed with the appliance close to

its final destination, as the legs are not designed for

excessive force and will snap off if too much side force

is exerted on them (dragging along or angled too much).

When fitting, try to keep the appliance as close to a

horizontal position as possible. Use of a pallet jack is

recommended. If the legs are not used and the cooker is

mounted onto a plinth, four transit supports allow

for clearance.

With the legs fitted, the backguard supplied with the

appliance can be fitted.

Follow the instructions shown in Fig. 09.

ATTENTION: TAKE CARE DO NOT OBSTRUCT THE

OUTLET OPENINGS ON THE BACKGUARD; THEY MUST

BE UNOBSTRUCTED FOR PROPER OPERATION

Fig 09

Page 14

Chapter 1 Ready, set up, go

14

Left Side o f oven,

chain not attached

ANTI-TILT DEVICE AND STRAIN RELIEF FLEXIBLE HOSE DEVICE

ANTI-TILTING CHAIN/HOSE RESTRAINING CHAIN

A chain must be fitted by the installer within 50mm of the hose connection point to prevent strain on

the hose when the cooker is pulled forward. The chain should restrict the appliance movement to no

more than 80% of the hose length. After the chain is installed, check that there is no strain on the hose

or gas connections when the cooker is pulled as far forward as the chain allows.

The cooker is also supplied with two chains which are connected to the rear left and right of the

appliance. The chains should be connected to the wall directly behind the chains as low as possible

to prevent the appliance from tilting forward. If the appliance is installed between two cupboards,

drill a hole on each side of the cupboards, pass the chains through the holes and anchor the chains

within each cupboard. Ensure the chain connections are strong enough to support the weight of the

appliance and taught to prevent it from tilting forward.

WARNING! In order to prevent accidental tipping of the appliance, for example a child climbing onto

the open oven door, the stabilising means must be installed. Ensure the chains are correctly anchored

to prevent the appliance from tilting forward and to prevent strain on the hose when the cooker is

pulled forward.

MAKE SURE THE ANTI-TILTING CHAINS ARE TAUGHT WHEN ANCHORED AND ANTI TILT

RESTRAINT IS INSTALLED TO PREVENT THE APPLIANCE TILTING

Please refer to the next two pages for examples of incorrect and correct chain installation.

Accidental tipping

Chains are provided as a preventative

measure against accidental tipping. These

chains must be fitted as part of the installers

compliance. Failure for your installer to

fit chains in accordance with the relevant

installation code will make the installation

of your upright cooker noncompliant and

class an

illegal installation.

Incorrect installation

The photographs on this page are of one

single kind of incorrect installation (although

there are many) which does not have the

chains sufficiently secured, figure 1. Shows

an example of how far forward an oven

can tip when not secured properly. Note:

Correct installation is part of the installer

compliance.

Hole in c abinet t oo

large, a llowing the

upright oven to tilt

forward.

Unfortunately the example on this page is the way

many installers are installing uprights. This may

believe that they are using the correct method by

putting the chain through a hole into the adjacent

cabinet and screwing the chain to the back wall but

it will not work if not properly.

Putting the chain into the adjacent cabinet is the

preferred method, provided there is no slackness in

the chain.

Some installations only have a single chain affixed.

Both chains must be fixed as part of the installers

compliance. Failure to fix both chains will make the

installation non compliant

Loose Chain

Page 15

Chapter 1 Ready, set up, go

15

Left Side

Right Side

In order to prevent the oven from tipping

forward as shown on the previous page,

we need to make sure both chains

provided with the oven are used.

On the left side of the oven a 16mm

drill bit was used to drill through the

cabinetry into the adjacent cabinet,

as you can see the hole has not been

drilled hard up against the wall because

there is a 16 mm board at the rear of

the cabinet. The heigt of the hole from

the floor is level with where the chain

attaches to the oven.

The right side has been drilled much the

same, a new hole has been drilled below

the gas and power supply hole

Once the holes have been drilled the chains can be fed trough and the

upright can be fitted into position.

The chains then need to be pulled as tight as possible from inside

the cabinet using a self drilling wood screw. It is better to have the

screw fixed closer to the hole for better support. The left and right

side examples shown have two extra screws attached to the chain

which makes the installation neater by keeping the chain off the shelf

away from the gas and electricity supply, they will also provide added

support.

At this point the oven will be secured in location and will not move

forward at all, it is recommended that all upright oven chains be fitted in

this way.

Installation forms part of the installer compliance and that in line with

AGA regulations chains are designed to be installed to prevent cooker

from tilting. They are not designed to replace parental supervision when

the cooker is in use.

Page 16

Chapter 1 Ready, set up, go

16

WARNING: In order to prevent accidental tipping of the appliance, for example a child climbing onto

the open oven door, the stabilising means must be installed. Ensure the chains are correctly anchored

to prevent the appliance from tilting forward and to prevent strain on the hose when the cooker is

pulled forward.

MAKE SURE THE ANTI-TILTING CHAINS ARE TAUGHT WHEN ANCHORED TO PREVENT THE

APPLIANCE TILTING.

CONVERSION TO DIFFERENT TYPES OF GAS

Before performing any maintenance operation, disconnect the appliance from the gas supply and

electricity network.

REPLACING THE NOZZLES TO OPERATE WITH ANOTHER TYPE OF GAS

When converting to ULPG remove the NG gas regulator (if fitted) and fit ULPG test point adaptor.

If converting to Natural Gas, fit gas regulator

Follow the instructions below to change the burner nozzles on the work surface:

1) Pull out the plug from the electric outlet to avoid any type of electric contact.

2) Remove the grids from the work surface (Fig. 11).

3) Remove the burners (Fig. 11).

4) Unscrew the nozzles using a 7 mm spanner, and replace them (Fig.12) with those needed for the

new type of gas according to what is indicated in the Energy Consumption Table.

Fig 010

Fig. 11 (representation only)

Fig.12

Page 17

Chapter 1 Ready, set up, go

17

5) Burner “MINIMUM” adjustment:

Work surface burner adjustment: follow the instructions below to adjust the work surface

burner minimum:

• Light the burner and set the knob to the MINIMUM position (small flame).

• Remove the knob of the valve that is press fit on the rod of that valve.

• For all burners except for the wok burner, insert a small slotted screwdriver into the hole on the

valve rod (Fig. 13) and turn the choke screw to the right or left until the burner flame is adjusted

to minimum.

• The wok burner has 2 adjustment screws on either side of the body of the valve (Fig. 14). Screw A

is for the outer ring and screw B is for the inner ring. Turn the choke screw to the right or left until

the burner flame is adjusted to minimum.

• Ensure sure that the flame does not go out when s witching quickly from the MAXIMUM to the

MINIMUM position.

Fig. 13 Fig.14 Fig.15

Page 18

Chapter 1 Ready, set up, go

18

APPLIANCE ELECTRICAL CONNECTION

The electric connection must comply with the current legal standards and regulations. Before making

the connection, check that:

• The system electrical rating and the current outlet are adequate for the maximum power output of

the appliance (see the label applied to the bottom of the casing).

• The outlet or the system is equipped with an efficient ground connection in accordance with

the current legal standards and regulations. The manufacturer will not be responsible for the

noncompliance with these instructions.

• The power cord is supplied with a 15A plug, suitable for the load indicated on the label and a

standard 15A GPO.

• The power cord must be positioned so that a temperature of 75°C will not be reached

at any point.

• Do not use reductions, adapters or splitters since they might cause false contacts and lead to

dangerous overheating.

When the connection is made directly to the electric network:

• Use a device that ensures disconnection from the mains in which the contacts are opened to

a distance that permits complete disconnection according to the conditions for over-voltage

category III.

• The disconnection must be incorporated in the fixed wiring in accordance with the wiring rules.

• The ground wire must not be interrupted by the circuit-breaker.

• As an alternative, the electric connection can also be protected by a high-sensitivity residual

current circuit- breaker but this may be subject to nuisance tripping due to residual humidity in

heating elements.

• It is highly recommended to attach the special green-yellow ground wire to an efficient

ground system.

WARNING: If the power cord is replaced, the ground wire (yellow-green) connected to the

terminal, should be longer than the other wires by about 2 cm.

WARNING: if the supply cord is damaged, it must be replaced by the manufacturer or its

service agent or similarly qualified person in order to avoid a hazard.

Fig. 16

Letter L (phase) =brown w i r e ;

Letter N (neutral) = blue w i r e ;

Ground symbol = green - yello w

wi r e ;

Work surface operation Oven operation

Cross section

230V ~

Only gas burner

Multifunction electric oven 3 x 1.5mm

2

Gas oven/Electric grill 3 x 1mm

2

TABLE N°3: TYPES OF POWER CORDS

The appliance conforms to the regulation AS4551 regarding gas appliance for domestic use and

AS/NZS60335.26 regarding safety and CSPR 14 regarding electromagnetic compatibility.

Page 19

Chapter 1 Ready, set up, go

19

INSTALLATION CHECKLIST

1. Is the range mounted on its legs?

2. Is the backguard securely connected?

3. Has the anti-tip device been properly installed?

4. Does the clearance from the side cabinets comply with the manufacturers directions?

5. Is the electricity properly grounded?

6. Is the gas service line connected following the directions of the manufacturer?

7. Have all the proper valves, stoppers and gasket been installed between the range and the service

line?

8. Has the gas connection been checked for leaks?

9. Has the range been set for the type of gas available in the household?

10. Is the ignition of all oven burners functioning properly?

11. Does the flame appear sharp blue, with no yellow tipping, sooting or flame lifting?

12. Has the minimum setting for all burners been adjusted?

13. Is the oven ignition working properly?

14. Does the oven light work properly?

Before Leaving - Check all connections for gas leaks with soap and water. DO NOT use a naked flame

for detecting leaks. Ignite all burners both individually and concurrently to ensure correct operation

of gas valves, burners and ignition. Turn gas taps to low flame position and observe stability of the

flame for each burner individually and concurrently. When satisfied with the hotplate, please instruct

the user on the correct method of operation. In case the appliance fails to operate correctly after all

checks have been carried out, refer to the authorised service provider in your area.

Page 20

Chapter 1 Ready, set up, go

20

SETTING THE TIME

After connecting the unit to power, the symbols 0:00 will be shown on the display.

1. Press the ‘mem.’ button until the hour figure flashes.

2. Press the ‘plus and minus’ buttons to adjust the hour figure.

3. Press the ‘mem.’ button so the minute figures flash.

4. Press the ‘plus and minus’ to adjust the minute figure.

5. Press the ‘mem.’ button to confirm the new time settings.

ENVIRONMENTAL INFORMATION

This Franke appliance is particularly energy efficient, however to make the most out of it, and to save

even more energy make sure you adhere to the following steps:

1. Open the appliance door as infrequently as possible during operation.

2. It is best to bake several items on after the other, as the cooking compartment is still warm.

3. Only preheat the appliance if necessary for the recipe

4. For longer cooking times, you can switch the appliance off 10 minutes prior to the end cooking

time, and use the residual heat.

DISPOSAL

Dispose of all packaging in an environmentally friendly manner. Franke practises environmentally

conscious behaviour, and this appliance is labelled in accordance with the used electrical and

electronic appliances waste guidelines.

If you have any questions on disposals, please call the Franke customer service

team on 03 9700 9100.

Select Oven

Function

Select Oven

Temp.

Gas Cooktop

Control

Memory

PlusMinus

Page 21

21Chapter 2 Life with your Franke upright cooker

life with your franke

upright cooker

CHAPTER 2

We designed this upright cooker with one thing in mind.

How do we create a wonderfully simple user experience

for you, our customer?

Page 22

22Chapter 2 Life with your Franke upright cooker

UPRIGHT COOKER FUNCTIONS

Convection

A heating element plus fan force. This results in an even distribution of heat.

Default temperature 180°C.

Quick Start/Defrost

This function runs the rear fans and all elements. The heat generated is too

hot to cook in, but is perfect for preheating the oven (run at the required

temperature until the thermostat light turns off and on a couple of time, then

adjusts to the required function setting. To use as a defrost function, leave the

thermostat on 0. This allows air to flow over frozen food speeding up

defrost times.

Bottom Heat

A concealed element in the bottom of the oven provides a concentrated heat to

the base of food (ideal for pizzas). Default temperature 60°C.

Conventional Cooking

A top and bottom heating element work together to provide conventional

cooking. Default temperature 220°C.

Double Grilling with Fan

The inside radiant heating element, and top element are working with the fan.

Default temperature 210°C.

Radiant Grilling

The inner grill element maintains the temperature.

Default temperature 210°C.

Double Grilling

The inside heating element and top element working together.

Default temperature 210°C

Convention with Fan

Combination of both the heating elements and the fan. This is also the most

energy efficient setting. Lightly browned on the outside, moist on the inside

(ideal for roasting).

Page 23

23Chapter 2 Life with your Franke upright cooker

OPERATING YOUR UPRIGHT COOKER

To select a cooking function and choose your desired temperature:

1. Rotate the ‘left knob’ to choose the cooking function.

The symbol chosen will be shown.

2. Rotate the ‘right knob’ to adjust the temperature to your desired pre-set.

3. The oven will automatically begin cooking function.

4. The orange LED indicator shows if the oven has reached your desired temperature.

5. Rotate both control knobs to the off position to switch the oven off.

USING THE TOUCH CLOCK

Mains frequency detection

At power on mains frequency is determined. When the timer is connected to 60Hz, the Celsius symbol

is flashing during start-up.

Power On

At power on, the relay contact is opened. The display and AUTO symbol flashes and time of day starts

from 0:00. Power on state with flashing daytime remains until time of day is set.

Setting Time of Day

Press PLUS and MINUS button simultaneously. At Power On, also MODE button is possible.

Time of day can be set with PLUS or MINUS, while the colon between hours and minutes is flashing.

Quick setting mode starts when PLUS or MINUS is held for more than 1 second. If daytime setting

mode is selected while an automatic program is active, the automatic program Fig.27 is cancelled.

The Buzzer

The buzzer interval alarm signal sounds if minute minder has reached the end time. The signal can be

switched off by pressing any key or by passing the signal duration limit.

Changing the Buzzer frequency

First press Plus and Minus simultaneously (menu far editing the time) and then Mode for selecting the

menu far changing the buzzer frequency. While the text is visible the buzzer signal frequency can be

changed by touching Minus repetitively.

Note: If the touch pad is inactive, a visual alarm will only be reset when a valid key combination is

pressed far more than 2 seconds.

Clearing Programs and Manual function

The duration of the minute minder can be cleared by

a) “Clear Function”: First select minute minder program, then press PLUS and MINUS

button simultaneously. after this clear the display returns from adjustment mode to time

of day immediately.

b) Back counting of duration to zero. The timer remains in adjustment mode.

Minute Minder

While minute minder mode is selected, the Bell symbol flashes and the display reads the remaining

time in hours and minutes, only if the last minute is counting down the remaining seconds are

displayed. An active minute minder program is indicated by the statically illuminated Bell symbol. If

alarm time has finished, an acoustic interval signal sounds and the Bell symbol flashes. The minute

minder program runs independently of other programs.

Key Lock

After power on reset or when no key is pressed for 7 seconds, the key look function is activated.

Pressing a valid key or key combination for 2 seconds or more will deactivate the key lock.

Page 24

24

getting the most out of

your franke upright cooker

CHAPTER 3

Getting the most out of your Franke upright cooker.

Your Franke upright cooker turns work into play, and

inspires creativity every single day.

Chapter 3 Getting the most out of your Franke upright cooker

Page 25

25Chapter 3 Getting the most out of your Franke upright cooker

CLEANING AND CARE

We want your Franke Appliance to be looking this good for a long time to come. To ensure that the

various surfaces are not damaged through cleaning, please observe the following:

Glass: Glass cleaner and with a microfiber cloth.

Plastic: Hot soapy water with a soft cloth.

Control panel: Clean with a dish cloth and then dry with a soft cloth.

Interior enamelled surfaces: A mix of hot soapy water, vinegar and lemon juice. Wash with a dish

cloth, and then allow the cooking compartment to dry.

Accessories: Hot soapy water and if there are stubborn food deposits, use a stainless steel

scouring pad.

Rails: Hot soapy water and a dish cloth.

Stainless steel handle: Hot soapy water and a mild stainless steel cleaning product with a soft cloth.

INTERIOR LIGHTING

If the interior lighting bulb or cover is defective for any reason or the light no longer operates, please

call our service team for support.

TIPS FOR USING BURNERS CORRECTLY:

Use suitably sized pots for each burner (see tab. 4 and Fig. 20).

• When the liquid is boiling turn the knob to the MINIMUM position (small flame Fig. 18).

• Use pots with a cover when available.

• Large utensils exceeding the recommended maximum size can cause excessive heat to reflect

back onto the appliance, potentially damaging the appliance and causing a temperature hazard.

Fig. 20

BURNER PAN DIAMETER recommended (cm)

Auxiliary 12-14

Semi-rapid 14-26

Rapid 18-26

Wok 22-26

Wok 2 ways 22-50

Page 26

26Chapter 4 Problem, meet solution

problem, meet solution

CHAPTER 4

We don’t expect your experience with your new Franke

upright cooker to be anything but wonderful, but here’s

some trouble shooting remedies just in case.

Page 27

27Chapter 4 Problem, meet solution

TROUBLE SHOOTING

You shouldn’t have any issues with your Franke Appliance, however there are some problems which

can easily be fixed by trouble shooting the table below. If you can’t find your problem, or the remedy

has not fixed the issue, then give our friendly customer service team a call on 03 9700 9100.

Problem Solution

Oven or hob not working

Check the electricity is turned on. Check your fuses. If

the fuse continues to blow, call PR Kitchen & Washroom

Systems Pty Ltd service. Check the circuit breaker. Ensure

correct knob is positioned correctly. Dry or clean ignition

electrodes. Make sure flame ports and ignition areas are

clean and dry. Check gas main supply is on. Ensure

cap/crown correctly fitted. Replace or tighten light globes.

Heating up problems

Oven not pre-heated: Pre-heat oven for 10 minutes. Check

oven door is closed properly. Remove foil or trays from

bottom of oven. Change oven temperature. Pre-heat oven

before putting the food in to be cooked.

Unit smoking/odours

Turn the oven on high to remove protective oils. Persistent

gas smell: do not operate the cooker call PR Kitchen &

Washroom Systems Pty Ltd service.

Condensation

Note: some condensation

is normal and is to be

expected during cooking.

Reduce the amount of water used for cooking.

Leave the door open after cooking if food remains in

cooker for warming.

Oven shelves are tight

Remove oven shelf and re-insert.

Cooling fan runs after ovens

turns off

This is normal and not a fault.

Abnormal Operation

Any of the following are considered to be abnormal operation and may require servicing: Yellow tipping

of the hob burner flame. Sooting up of cooking utensils. Burners not igniting properly. Burners failing

to remain alight. Burners extinguished by cupboard doors. Gas valves, which are difficult to turn. In

case the appliance fails to operate correctly, contact the authorised service provider in your area”.

Page 28

28Chapter 5 Last but not least

last but not least

CHAPTER 5

This section contains the warnings, precautions and

legal notices to make sure everything runs smoothly.

Page 29

29Chapter 5 Last but not least

UPRIGHT COOKER DOOR PRECAUTIONS

Never apply pressure on the upright cooker door when it is closed or open. Never use the upright

cooker door as a seator bench or apply any pressure to it while it is open. Do not place cookware or

accessories on the

upright cooker door.

Glass that has become scratched poses a risk of cracking and ultimately shattering which is a serious

risk to injury. Ensure that glass scraper or any sharp objects are kept away from the upright cooker at

all times.

The hinges on the upright cooker door pose a threat for you hands to be trapped. Keep hands clear of

the opening with operating the upright cooker door.

ELECTRIC SHOCK HAZARD

Never carry out an repairs yourself, always get an authorized technician to do any repairs or

maintenance on your upright cooker. If any electrical components become damaged or there is

exposed wiring, there is a risk of electrical shock.

Ensure whenever the upright cooker is in operation and you come into contact with it, that appropriate

footwear is worn.

APPLIANCE USE AND MAINTENANCE

ATTENTION: Important Warnings.

ATTENTION: ATTENTION: TAKE CARE DO NOT OBSTRUCT THE

OUTLET OPENINGS ON THE BACKGUARD; THEY MUST BE

UNOBSTRUCTED FOR PROPER OPERATION

• For cookers resting on base

ATTENTION: if the cooker rest on a base, take the

measures necessary to prevent the cooker from sliding

along the support base.

• For cookers with electric ovens

ATTENTION: The unit becomes hot during use. Do not touch the heating elements inside the oven.

ATTENTION: The accessible parts can become hot during use. Keep children away from the

appliance.

• For glass doors

ATTENTION: Do not use harsh abrasive cleaning products or metal spatulas with sharp edges to

clean the oven door’s glass since this could scratch the surface and the glass could break.

• For gas cooktops

ATTENTION: Clean burner tops and trivets at least once a week, or after any spillage. Gas inlet

pipes should be checked periodically for leakages (see section on leak testing), at intervals not

exceeding 12 months. Lubrication of valves should only be performed by an authorised person,

and is required if the gas control knobs become stiff and difficult to turn.

Do not use steam cleaner to clean the appliance.

WARNING: DO NOT MODIFY THIS APPLIANCE

Please maintain your appliance regularly.

Page 30

30

REPLACING PARTS

Before performing any maintenance operations, disconnect the appliance from the g a s supply and

electricity network. To replace parts such as knobs and burners, just remove them from the seats

without dis assembling any part of the cooker. To replace parts such as nozzle supports, valves and

electric components follow the procedure described in the burner adjustment paragraph. To replace

the valve or the gas thermostat, it is also necessary to disassemble the two rear gas train brackets,

loosening the 4 screws (2 per bracket) that attach it to the rest of the cooker and, unscrew the nuts

that attach the front burner valves to the control support, after removing all the knobs. To replace the

gas or electric thermostat, also disassemble the rear cooker guard, loosening the relative screws, to

be able to pull down and reposition the thermostat bulb. To replace the oven bulb, just unscrew the

protection cap that projects out inside the oven (Fig.17).

WARNING: Ensure that the appliance is switched off before replacing the lamp to avoid the

possibility of electric shock.

WARNING: The power cord supplied with the appliance is connected to the appliance with an X type

connection (in compliance with standards AS/NZS 60335-1, AS/NZS 60335-2-6 and subsequent

amendments) for which it can be installed without the use of special tools, with the same type of cord

as the one installed.

If the power cord becomes worn or damaged, replace it based on the information reported in table 2.

To replace the power cable, lift the terminal board’s cover and replace the cable.

Chapter 5 Last but not least

Fig.17

Page 31

31Chapter 5 Last but not least

HAZARDS

The following is a comprehensive list of all hazards and risks this product possesses.

Risk of fire:

• Any combustible items left in or near the upright cooker during operation

• Be aware of baking paper coming into contact of the heating element.

Risk of burns:

• The appliance becomes very hot. Never touch any surfaces or compartments which has been

exposed to the heating elements.

• Accessories also become very hot. Use appropriate gloves and upright cookerware.

• Alcoholic vapours may catch fire. Never use a high quantity of alcohol in a cooking recipe.

Risk of scalding:

• Any liquid in the cooking compartment may become hot and potentially dangerous if not

handled carefully.

Risk of magnetism:

• Magnets are used during the creation and operation of the control panel.

Keep away all pace makers.

Risk of electric shock:

• The insulation and coating of upright cooker accessories may cause electric shock if they come

into contact with electrical components.

Risk of death or serious injury to human health:

• The cables and wiring harnesses at the rear of the upright cooker must not be tampered with or

come into contact with the hot appliance.

• If the appliance is not operating correctly, do not continue to operate it.

Discuss your problem with our customer service team.

Page 32

32

GLOSSARY

Abrasive - a course and harsh substance capable of polishing or cleaning a surface by rubbing or

grinding.

Buzzer - a device that makes a loud noise and is used to signal something.

Cabinetry - a collection of cupboards with drawers or shelves.

Circuit breaker - and automatic device for stopping the flow of current in an electrical circuit for

safety reasons.

Control display - an electrical component which depicts various function on a screen, usually LED.

Convection - a fan with a heating element which provides heat. This improves the

heat transfer.

Conventional - the heat source is stationary, usually radiating from the bottom or top.

Enamelled - a coat of paint which is extremely heat resistant. It is applied by fusion to the metal.

Food residue - a small amount of food which remains after cooking.

Heating element - converts electricity into heat through resistive current.

Insulation - protecting or shielding an object from excessive heat or moisture.

Licensed professional - a person who has had the proper training and prerequisite to complete a

certain job.

Manufacturer - the person or organisation which is the original producer of a product.

Metal scraper - a single edged tool used to scrape a surface clean.

Packaging - the materials used to wrap or protect goods.

Radiant grilling - dry heat applied from above or below from a heating element.

Rotary knob - a wheel which control certain function and can spin left or right.

Scalding - very hot burning and blistering

Timer - used to indicate how long a process has left remaining.

Trouble shooting - finding the causes of common problems.

User experience - the overall experience of a person using a product, in terms of how easy or

pleasing it is to use.

Warranty - a written guarantee promising to repair or replace a product under certain circumstances

within a certain time.

Glossary

Page 33

33

PR Kitchen & Washroom Systems

83 Bangholme Road

Dandenong South

VIC 3175

Australia

Phone +61 3 9700 9100

Fax +61 3 9700 9191

info@prks.com.au

www.franke.com.au

PR Kitchen & Washroom Systems NZ Ltd

P.O Box 53171, Auckland Airport

Auckland 2150

New Zealand

Phone 09 964 0400

Fax 09 964 0401

info@prks.co.nz

www.franke.co.nz

Loading...

Loading...