Page 1

LIMITED LIFETIME WARRANTY

Franke Consumer Products, Inc., Kitchen Systems Division extends the following

warranty to the original purchaser of its faucets effective January 1, 2003.

All faucets installed in a private residence will carry a limited lifetime warranty on all

mechanical parts to be free of manufacturing defects in material and workmanship

under normal usage. All chrome finishes carry a limited lifetime warranty; all other

finishes are warranted for five (5) years form the original date of purchase.

INSTRUCTION MANUAL

This warranty applies only to the original owner, providing the product has been

installed in accordance with our installation instructions, used as recommended and in

a normal residential application. In the event of a warranty claim, the owner will be

required to provide proof of purchase - save sales receipt. This warranty covers all

components which make the product operational. Franke, at its option, may repair or

replace the product or components necessary to restore the product to good working

condition. Franke reserves the right to inspect the installation prior to the actual

replacement of the product or component part.

This warranty does not cover misuse or abuse, accidental damages, scuffs or scratches,

improper installation, abnormal usage, negligence or damage caused by improper

maintenance or cleaning. Normal wear of parts is excluded from the warranty. Damage

caused by impurities or acts beyond our control are not covered. Any product or part

which has been repaired or altered in any manner outside of Franke's factory, unless

previously authorized in writing by Franke, will void warranty. Any replacement

excludes transportation and any labor re-installation costs. This warranty does not

allow recovery of incidental or consequential damages such as loss of use, delay,

property damage or other consequential damage, and Franke accepts no liability for

such damages.

The Franke warranty is limited to the above conditions and to the warranty period

specified herein and is exclusive. Franke DISCLAIMS all other warranties, expressed

or implied, including IMPLIED WARRANTIES OF MERCHANTABILITY AND/OR

FITNESS FOR AS PARTICULAR PURPOSE. This warranty gives you specific legal

rights that may vary from state to state.

Further information

For any further information about our products, about the installation of them or about

the guarantee, please dial the number of the customer service:

FF6000 . FF7000

Phone number +1-215-822-6590 Franke Consumer Products Inc. - Kitchen Systems Division

Or: 1-800-626-5771 3050 Campus Drive, Suite Hatfield, PA 19440

Fax number + 1-215-822-5873

InstallationGuide(Print)-FF6000&FF7000_I

8/8

KITCHEN

SYSTEMS

Page 2

TECHNICAL DATA

ENGLISH

Standard water flow 1.5 gpm - 45 PSI

Maximum water flow 2.2 gpm - 60 PSI

Recommended pressure range 25-100 PSI - Over 100 PSI PRV required

Complies with Proposition 65, NSF 61, UPC and C-UPC requirements

FAUCET INSTALLATION

1. Remove all contents from the package and check for completeness. NOTE:

Product comes pre-assembled.

NOTE:

Call us immediately if you see inconsistencies.

(1-800-626-5771)

or visit

www.frankeksd.com

info.fks@franke.com

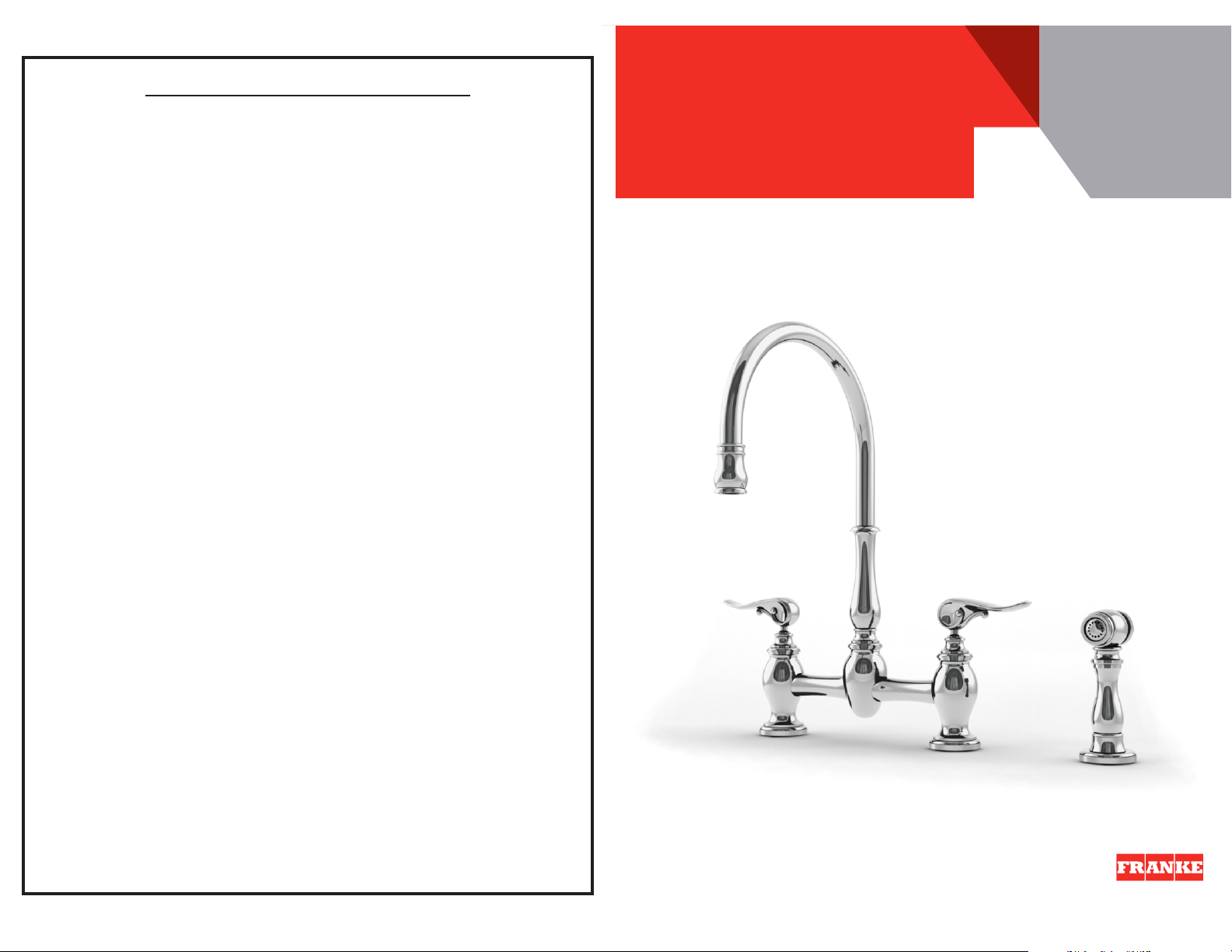

CONTENTS IN BOX

1 Faucet

2 Sidespray Assembly

3 Diverter Connection

4 Tee Valve & Diverter

5 Mounting Nut

1

4

5

2

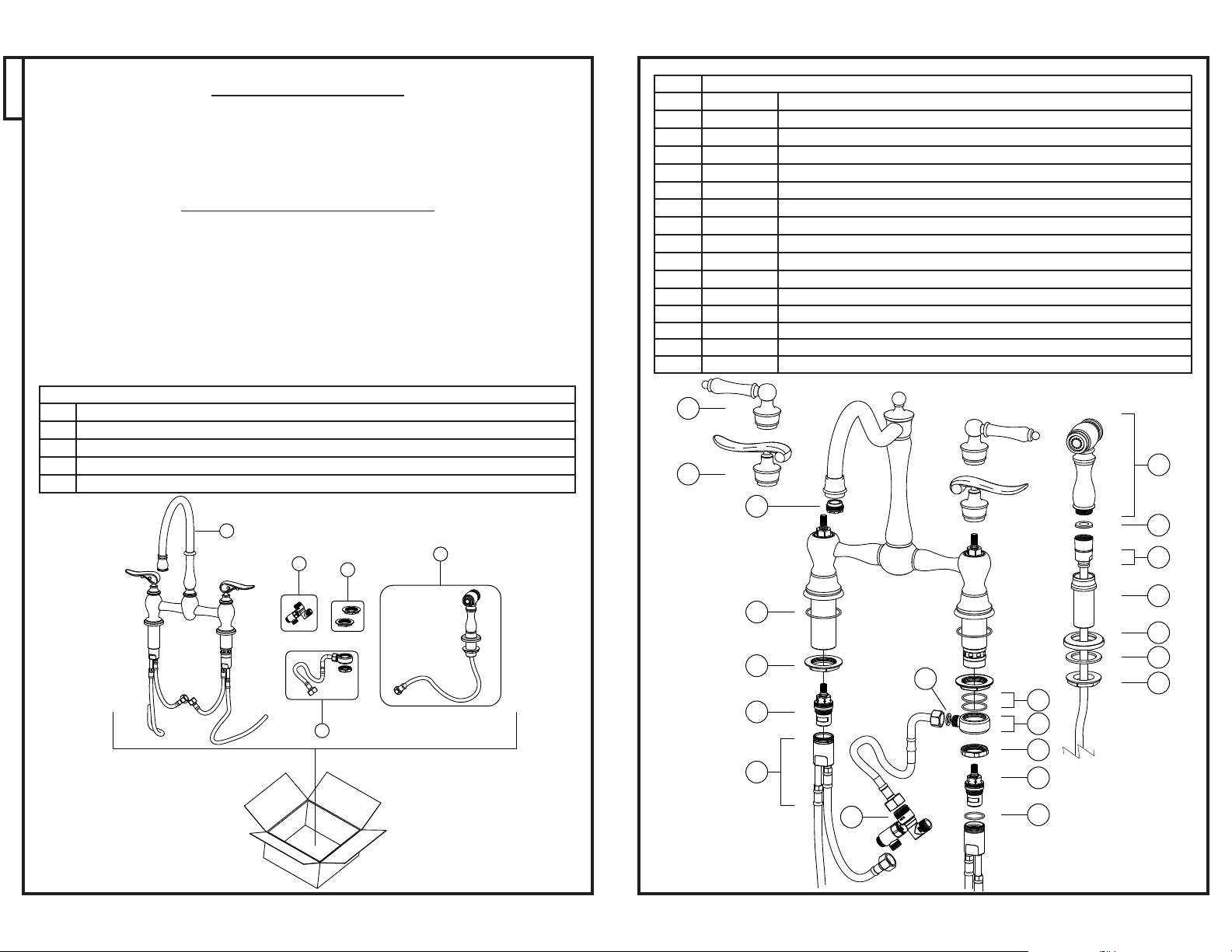

SPARE / REPLACEMENT PARTS LIST - FF7000

1 Cartridge Cold, Lead Free

10210

2 Cartridge Hot, Lead Free

10211

3 Banjo Diverting Locknut

10418

4 Aerator 2.2 GPM (For Aerator 1.5 GPM = 10560)

10698

Handle, Standard Lever Lalingua

Handle, Decorative Lalingua

Tee Body & Diverter

Sidespray Head & Grip

Diverting Hose & Banjo Fitting

Valve Body & Connection Hoses

Locknut for Faucet

Locknut for Sidespray92037

Hose for Sidespray10564

Sidespray Base Shank10406 *

Escutcheon Flange10407 *

Bridge Faucet Sealing Kit3-058

10

11

12

13

14

15

16

3-021 *

5

3-022 *

6

3-033

7

3-034 *

8

3-047

9

3-048

92038

*NOTE: Specify color finish when

5

ordering replacement parts

6

4

8

16

13

14

16

15

11

16

1

3

16

9

16

12

3

10

7

2/8

2

16

7/8

Page 3

SPARE / REPLACEMENT PARTS LIST - FF6000

1 Cartridge Cold, Lead Free

10210

2 Cartridge Hot, Lead Free

10211

3

10

11

12

13

14

15

16

10418

4

10698

3-019 *

5

3-020 *

6

3-033

7

3-034 *

8

3-047

9

3-048

92038

Banjo Diverting Locknut

Aerator 2.2 GPM (For Aerator 1.5 GPM = 10560)

Handle, Standard Lever Swan

Handle, Decorative Swan

Tee Body & Diverter

Sidespray Head & Grip

Diverting Hose & Banjo Fitting

Valve Body & Connection Hoses

Locknut for Faucet

Locknut for Sidespray92037

Hose for Sidespray10564

Sidespray Base Shank10406 *

Escutcheon Flange10407 *

Bridge Faucet Sealing Kit3-058

5

6

*NOTE: Specify color finish when

ordering replacement parts

8

2. Flush pipe work to ensure it is free from debris.

3. Cut mounting holes 1 3/8" diameter (8” center-to-center spread requirement for

faucet) in the desired position in sink.

4. Remove faucet and hardware from its protective packaging. Faucet comes

assembled.

5. Detach hose fittings from tee body, temporarily remove locknut from diverting side.

6. Slide banjo fitting down from its location.

7. Unscrew plastic mounting nuts from the faucet shanks.

8. Place the escutcheons (for FF6000) and large 'O'rings (for FF6000 and/or FF7000)

over the faucet shanks and place the faucet into the desired position.

ATTENTION: The rubber ‘O’ring should be sitting on top of the countertop and

between the faucet escutcheons. DO NOT use putty or other sealant at this location.

NOTES:

Solid surface installation: The sub-countertop mounting surface needs to be flat and

free of debris; otherwise the faucet will not sit properly.

Tile installation: Avoid installations near or on top of grout lines. The faucet will not sit

secure when sitting on such.

Escutcheon

‘O’ Ring

16

11

10

4

16

13

14

15

16

12

1

16

9

3

2

9. Assure that the handles and spout are properly aligned in correct positions; spout

should swivel face forward into sink and handles should point outward parallel with

bridge faucet. Handles should 1/4" turn towards front of sink (counter-clockwise

1/4" turn for hot side & clockwise 1/4" turn for cold side).

10. Slide plastic mounting nuts over supply lines. Install the plastic mounting nuts to

the threaded shanks from underneath the sink.

11. Tighten plastic mounting nuts with required plumbers wrench (1 7/16" size).

12. Slide banjo-divert fitting over the cold side supply lines followed with the thread

brass locknut into its location. Ensure fitting hose is positioned between both

shanks and fitting hose turns downwards inline with other supply lines.

13. Tighten threaded brass locknut with required plumbers wrench (1 7/16" size).

7

16

3/86/8

Page 4

14. Connect and tighten shorter supply hoses onto diverter-tee. Use open end wrench.

15. Next, install the sidespray assembly by installing rubber gasket & escutcheon

flange along with base shank into 1-3/8” mounting hole.

16. From underneath the sink, install plastic mounting nut onto base shank until fully

tightened.

17. Set sidespray into place. Insert spray hose into base.

STANDARD MAINTENANCE AND

TROUBLE SHOOTING

CLEANING OF THE SPRAY HEAD

Any deposits which may accumulate on the nozzle can be removed by simply running

a finger over the face of the sprayer and then running the water for a few seconds.

In extreme cases this step may have to be repeated.

Banjo Fitting

Sidespray Hose

18. Install and tighten end of hose onto diverter (M15 fitting).

19. Connect the inlet supply lines to the angle stop wall valves. Do not allow the

supply tubes to twist or bend sharply.

20. Open faucet handle - cold side first - by turning handle clockwise. Let the faucet

run on cold for 15 to 30 seconds.

21. Turn off cold side handle.

22. Open faucet handle - hot side second - by turning handle counter-clockwise. Let the

faucet run on hot for 15 to 30 seconds.

23. Open both faucet handles. Let the faucet run for 15 to 30 seconds.

24. Pull sidespray hose out of its base and point the open end towards the sink drain.

25. Let the sidespray run for 15 to 30 seconds. When sidespray is depressed, ensure

spout turns off and turns back on when spray is not in use.

26. Turn faucet off.

27. Check / test for leaks under the cabinet.

REPLACING THE CARTRIDGE

1. Shut off the water supply to the faucet.

2. Open the faucet briefly to relieve any pressure

inside the faucet.

3. Move the faucet handles to the “OFF” position.

5. Disconnect supply lines from angle wall valves

and from diverting tee.

6. Use an adjustable wrench to untighten bottom valve

body.

7. Remove cartridge from valve body seat.

8. Install the new cartridges into valve body.

13. Re-assemble faucet in reverse order.

14. Test for leakage.

REQUIRED TOOLS:

17mm Socket Wrench

3/4” Wrench

GENERAL MAINTENANCE

Clean aerator periodically.

Do not use harsh detergents, solvents, chemical agents, metallic sponges, etc. that could

harm the surface and damage the finish.

Clean only with a soft sponge and soapy water.

4/8

5/8

Loading...

Loading...