Page 1

Instructions for use and installation

GB

Cooker Hood

Istruzioni per l’uso e l’installazione

IT

Cappa

Mode d’emploi et installation

FR

Hotte de Cuisine

Bedienungsanleitung und Einrichtung

DE

Dunstabzugshaube

Kullanım ve montaj talimatları

TR

Davlumbaz

FCBU 1204 C

Page 2

INDEX

RECOMMENDATIONS AND SUGGESTIONS ..................................................................................................................... 3

CHARACTERISTICS ............................................................................................................................................................. 4

CHARACTERISTICS ............................................................................................................................................................. 5

INSTALLATION...................................................................................................................................................................... 6

USE ........................................................................................................................................................................................ 9

MAINTENANCE................................................................................................................................................................... 11

EN

INDICE

CONSIGLI E SUGGERIMENTI............................................................................................................................................ 13

CARATTERISTICHE............................................................................................................................................................ 14

CARATTERISTICHE............................................................................................................................................................ 15

INSTALLAZIONE ................................................................................................................................................................. 16

USO...................................................................................................................................................................................... 19

MANUTENZIONE ................................................................................................................................................................ 21

SOMMAIRE

CONSEILS ET SUGGESTIONS.......................................................................................................................................... 23

CARACTERISTIQUES......................................................................................................................................................... 24

CARACTERISTIQUES......................................................................................................................................................... 25

INSTALLATION.................................................................................................................................................................... 26

UTILISATION .......................................................................................................................................................................29

ENTRETIEN......................................................................................................................................................................... 31

INHALTSVERZEICHNIS

EMPFEHLUNGEN UND HINWEISE ................................................................................................................................... 33

CHARAKTERISTIKEN......................................................................................................................................................... 34

CHARAKTERISTIKEN......................................................................................................................................................... 35

MONTAGE ...........................................................................................................................................................................36

BEDIENUNG........................................................................................................................................................................ 39

WARTUNG........................................................................................................................................................................... 41

IÇERIKLER

TAVSIYELER VE ÖNERILER.............................................................................................................................................. 43

ÖZELLIKLER........................................................................................................................................................................ 44

ÖZELLIKLER........................................................................................................................................................................ 45

MONTAJ............................................................................................................................................................................... 46

KULLANIM ........................................................................................................................................................................... 49

BAKIM .................................................................................................................................................................................. 51

IT

FR

DE

TR

2

2

Page 3

RECOMMENDATIONS AND SUGGESTIONS

650 mm min.

2°

The Instructions for Use apply to several versions of this appliance. Accordingly, you may find

descriptions of individual features that do not apply to you r specific appliance.

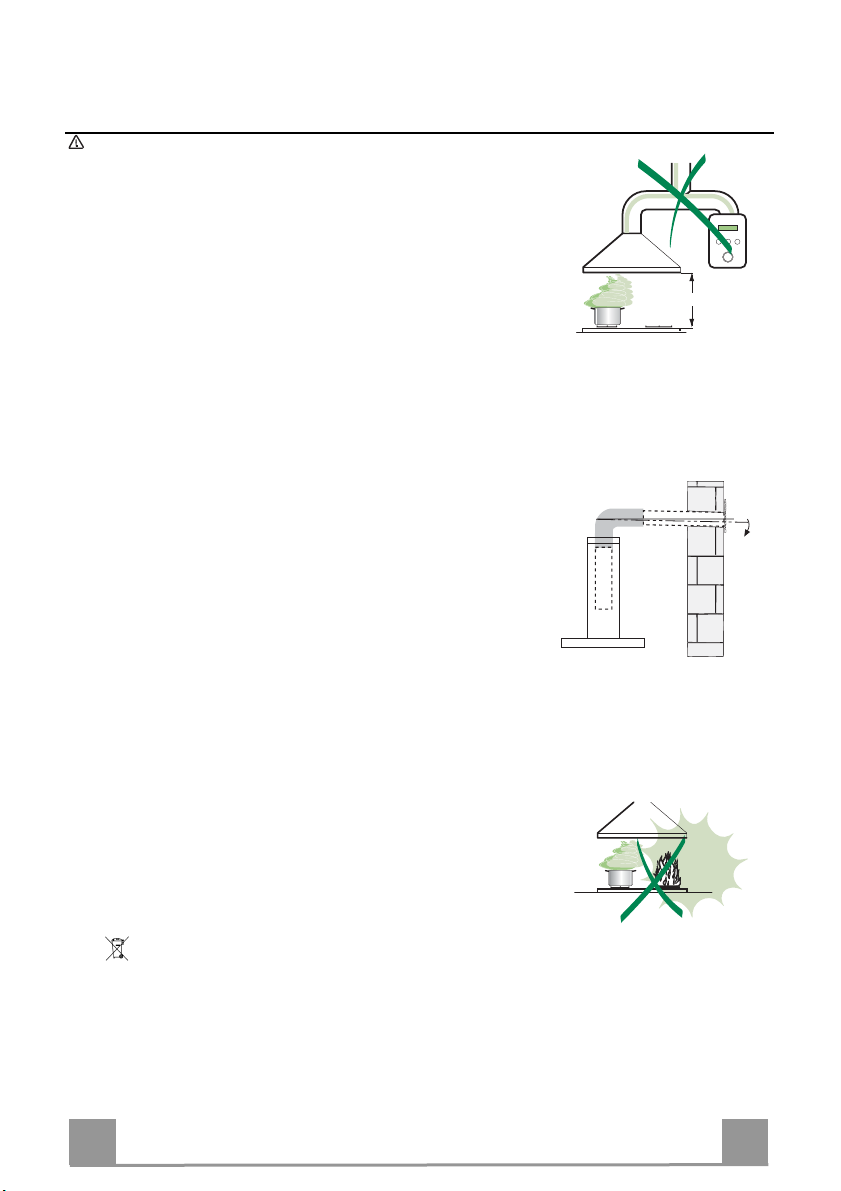

INSTALLATION

• The manufacturer will not be held liable for any damages resulting from incorrect or improper

installation.

• The minimum safety distance between the cooker top and the extractor hood is 650 mm (some

models can be installed at a lower height, please refer to the paragraphs on working dimensions

and installation).

• Check that the mains voltage corresponds to that indicated on the rating plate fixed to the inside of

the hood.

• For Class I appliances, check that the domestic po wer supply guarantees adequate earthing.

Connect the extractor to the exhaust flue through a pipe of minimum diameter 120 mm. The route

of the flue must be as short as possible.

• Do not connect the extractor hood to exhaust ducts carrying combustion fumes (boilers, fireplaces,

etc.).

• If the extractor is used in conjunction with non-electrical appliances (e.g. gas burning appliances), a

sufficient degree of aeration must be guaranteed in the room in order to prevent the backflow of

exhaust gas. The kitchen must have an opening communicating directly with the open air in order

to guarantee the entry of clean air. When the cooker hood is used in conjunction with appliances

supplied with energy other than electric, the negative pressure in the room must not exceed 0,04

mbar to prevent fumes being drawn back into the room b y the cooker hood.

• In the event of damage to the power cable, it must be replaced by the manufacturer or by the

technical service department, in order to prevent an y risks.

• If the instructions for installation for the gas hob specify a greater distance specified above, this has

to be taken into account. Regulations concerning the discharge of air have to be fulfilled.

USE

• The extractor hood has been designed ex clusively for domestic use to eliminate kitchen smells.

• Never use the hood for purposes other than for wh ich it has been designed.

• Never leave high naked flames under the hood wh en it is in operation.

• Adjust the flame intensity to direct it onto the bottom of the pan only, making sure that it does not

engulf the sides.

• Deep fat fryers must be continuously monitor ed during use: overheated oil can burst into flames.

• Do not flambè under the range hood; risk of fire

• This appliance is not intended for use by persons (including children) with reduced physical, sensory or mental capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction concerning use of the appli ance by a person responsible for their safety.

• Children should be supervised to ensure that they d o not play with the appliance.

• “ CAUTION: Accessible parts may become hot when use d with cooking appliances.”.

MAINTENANCE

• Switch off or unplug the appliance from the mains supply before carrying out any maintenance

work.

• Clean and/or replace the Filters after the specified ti me period (Fire hazard).

• Clean the hood using a damp cloth and a neutral liq uid detergent.

The symbol on the product or on its packaging indicates that thi s product may not be treated as household waste. Instead it shall be handed over to the

applicable collection point for the recy cling of electrical and electronic equipment . By ensuring this product is disposed of corre ctly, you will help prevent potential neg ative

consequences for the environment and h uman health, which could otherwise be cau sed by inappropriate waste handling of this product. For more detailed information

about recycling of this product, p lease contact your local city o ffice, your household waste disp osal service or the shop where you purchased the product

.

EN

3

3

Page 4

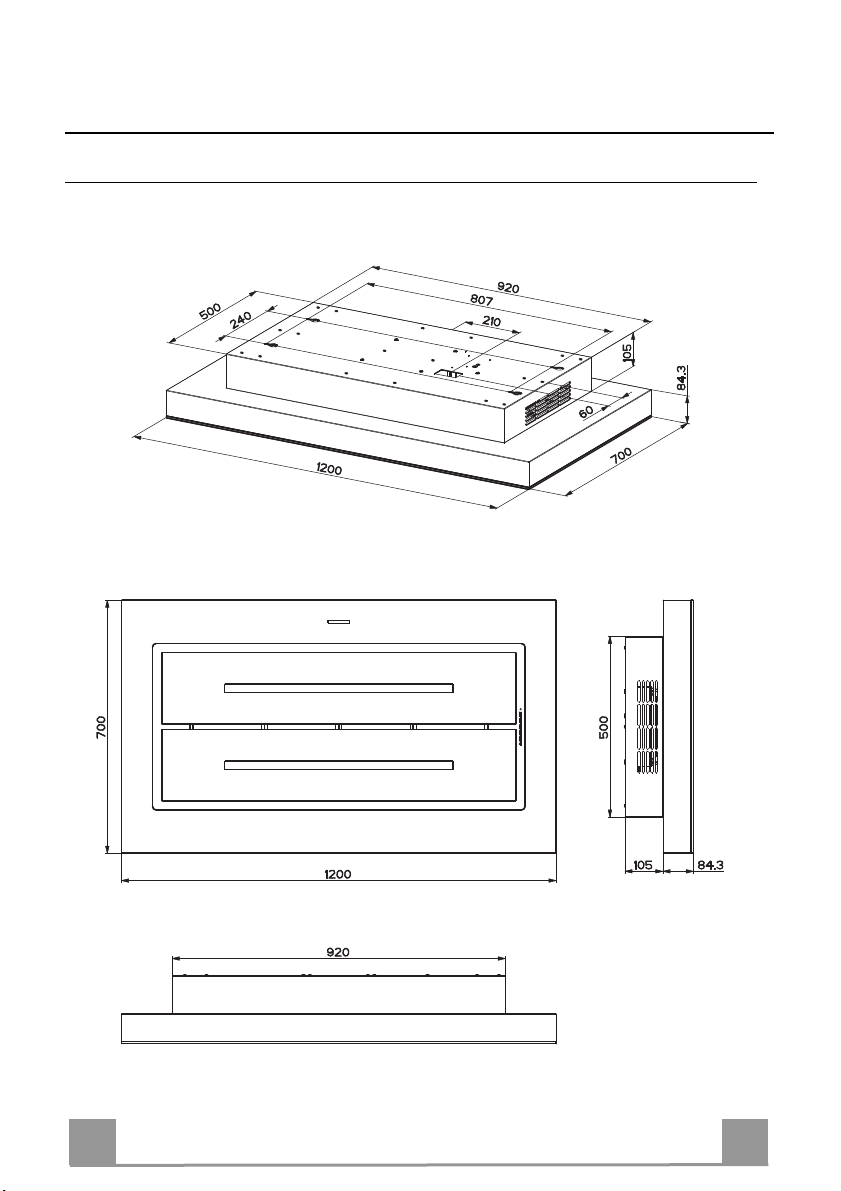

CHARACTERISTICS

Dimensions

EN

4

4

Page 5

Components

Ref. Q.ty Product Components

1 1 Hood Body, complete with: Controls, Light, Blower,

Filters.

2 Charcoal Filters.

Ref. Q.ty Installation Components

11 4 Wall Plugs ø 10

12g 4 Screws M6 x 80

12h 4 Screws 5,2 x 70

22 4 6.4 mm int. dia washers

23 4 M6 nuts

Q.ty Documentation

1 Instruction Manual

Fixing the Hood

• In all cases where the ceiling is not strong enough at the suspension point, the installer must

provide strengthening using suitable plates and backing pieces anchored to the structurally

sound parts.

2

EN

5

5

Page 6

INSTALLATION

Drilling the Ceiling/shelf and fixing the frame

DRILLING THE CEILING/SHELF

• Use a plumb line to mark the centre of the hob on the ceiling/support shelf.

• Using the measurements of the Dimensional Drawing, mark the holes for the installation.

• Drill the holes at the points marked:

• For concrete ceilings, drill for plugs appropriate to the screw size.

• For hollow brick ceilings with wall thickness of 20 mm: drill ø 10 mm(immediately insert

the Dowels 11 supplied).

• For wooden beam ceilings, drill according to the wood screws used.

• For wooden shelf, drill ø 7 mm.

• For the power supply cable feed, drill ø 10 mm.

• For the air outlet (Ducted Version), drill according to the diameter of the external air exhaust duct connection.

• Insert two screws of the following type, crossing them and leaving 4-5 mm from the ceiling:

• For concrete ceilings, use the appropriate plugs for the screw size (not provided).

• for Cavity ceiling with inner space, with wall thickness of approx. 20 mm, Screws 12h,

supplied.

• For wooden beam ceilings, use 4 wood screws (not provided).

• For wooden shelf, use 4 screws 12g with washers 22 and nuts 23, provided.

EN

6

6

Page 7

a

c d

e

b

6x

EN

4x

7

7

Page 8

ELECTRICAL CONNECTION

• Connect the hood to the mains through a two-pole switch having a contact gap of at least 3

mm..

•

Before carry

must be disconnected by removing the plug

from the power socket or turning off the

main switch.

• From the inside of the hood canopy connect

up the power supply cable.

• Open the terminal box by unfastening the

screws on cover (A), connect the power

supply to the wiring in the box and then

close the cover again.

Fix the Charcoal Filter on the Metal grease

•

filters like as indicated in picture.

ing out any operation the Hood

EN

8

8

Page 9

USE

LS1T1 T2 T3 T4

Control panel

Button Led Function

L - Turns the lights ON/OFF at maximum strength.

Press and hold for approx. 2 seconds to turn the lighting system on and off at reduced intensity.

T1 Fixed Turns the motor on/off at speed one.

T2 Fixed Turns the Motor on at speed two.

T3 Fixed Turns the Motor on at speed three.

T4 Fixed

S1 Fixed Signals the Metal Grease Filter saturation alarm, indicating that it is necessary to wash the filters. The

Flashing When this is activated, it signals the Activated Charcoal Filter saturation alarm, indicating that the filter

Delay function:

Press and hold the button for approx. 3 seconds to Activate/Deactivate the Delay function

(automatic switching off of the Motor, the Fans and the Lighting with a 30' delay).

Cannot be enabled when Intensive or 24h are on.

Press and hold the button for approximately 5 seconds, with all the loads turned off (Motor and Lights),

to turn the Activated Charcoal Filter alarm on. The relevant LED flashes twice to confirm.

To turn the alarm off, press the button again and hold for at least 5 seconds. The relevant LED flashes

once.

Press and hold the button for approximately 3 seconds, with all the loads turned off (Motor and Lights),

to perform a reset. The LED S1 flashes three times.

T

urns the Motor on

This speed is timed to run for 6 minutes. At the end of this time, the system returns automatically to the

speed that was set before. If it is activated with the motor turned off, it will switch to OFF at the end of

the time.

Press and hold for 5 seconds to enable the remote control, indicated by the LED flashing twice.

Press and hold for 5 seconds to disable the remote control, indicated by the LED flashing just once.

alarm is triggered after the Hood has been in operation for 100 working hours. (Reset see the parag.

Maintenance)

must be changed; the Metal Grease Filters must also be washed. The Activated Charcoal Filter saturation alarm comes into operation after the Hood has been working for 200 hours. (Activation and Reset

see the parag. Maintenance)

at INTENSIVE Speed.

EN

9

9

Page 10

REMOTE CONTROL

The appliance can be controlled using a remote control powered

by a 1.5 V carbon-zinc alkaline batteries of the standard LR03AAA type (not included).

• Do not place the remote control near to heat sources.

• Used batteries must be disposed of in the proper manner.

Remote control panel

Motor Motor On / Off.

Decreases the working speed each time it is pressed.

Increases the working speed each time it is pressed.

Intensive Activates the Intensive function

Delay Activates / Deactivates the Delay function

Light Lights On / Off

Press for 2 seconds to

modify the intensity of the Light.

EN

1

10

Page 11

MAINTENANCE

Metal grease filters

These can be washed in the dishwasher, and need to be cleaned

whenever the S1 Led comes on or at least once every 2 months

use, or more frequently if use is particularly intensive.

CLEANING THE FILTERS

Resetting the alarm signal

• Turn the Lights and the Suction Motor off.

• Press T3 and hold for at least 3 seconds, until LED flashes

three times in confirmation.

Cleaning the Filters

• Open the doors.

• Remove the Filter, pushing it towards the back of the unit and

at the same time pulling downward.

• Wash the filter without bending it, and leave it to dry thoroughly before replacing (if the surface of the filter changes

colour over time, this will have absolutely no effect on its efficiency).

• Replace, taking care to ensure that the handle faces forwards.

• Close the doors again.

EN

1

11

Page 12

Activated Charcoal Filter (Recirculation Version)

Can be washed in the dishwasher. It must be washed when Led S1 flashes or at least once

every 4 months, or more frequently if use is particularly intense. Guaranteed to operate after

washing for up to a maximum of 5 times before requiring replacement. The Alarm signal, if it

has been activated, only appears when the Suction motor is turned on.

Activating the alarm signal

• In Recirculation Version Hoods, the Filter Saturation Alarm must be activated on installation or at a later date.

• Turn the Lights and the Suction Motor off.

• Press button T2 and hold it for 5 seconds until the LED flashes twice in confirmation:

CHANGING

Resetting the alarm signal

• Turn the Lights and the Suction Motor off.

• Press T3 and hold for at least 3 seconds, until

LED flashes three times in confirmation.

Changing the Filter

• Open the doors.

• Remove the Metal Grease Filter.

• Remove the metal filter stops from the grease

filter and clean the saturated activated charcoal

odour filter.

• Replace the clean activated charcoal odour filter,

hooking it back up to the grease filter using the

metal filter stops.

• Replace the Metal grease filters.

• Close the doors.

Lighting unit

Warning: This appliance is fitted with a white LED lamp classed

as 1M according to EN 60825-1: 1994 + A1:2002 + A2:2001

standards; maximum optical power emitted @439nm: 7µW. Do

not look directly at the light through optical devices (binoculars,

magnifying glasses…).

• For replacement contact technical support. ("To purchase contact technical support")

EN

1

12

Page 13

Franke S.p.a.

Via Pignolini,2

37019 Peschiera del Garda (VR)

www.franke.it

991.0339.703_ver4

Loading...

Loading...