Page 1

D

G

U

V

T

e

s

t

F3D3–Dual Lane

F3D3P–Dual Lane

F3D3S–Single Lane

F3D3SP–Single Lane

USER MANUAL

Original instructions

en

Single Lane/Dual Lane (with R404A or propane (R290) refrigerant)

FROZEN FRY DISPENSER F3D3S/F3D3/

F3D3SP/F3D3P

Page 2

Franke Foodservice Systems

29.0 7. 2 0 15

2004/108/EC (EMC Directive)

2006/42/EC (Machinery Directive)

EMC: EN 55014-1:2007, EN 55014-2:2007

MD: EN 60204-1:2006, EN ISO 12100:2010

2

07/2 0 15

Franke Foodservice Systems GmbH

Jurastrasse 3

797 13 Bad Säckingen

Germany

Phone: +49 7761 5533 0

www.franke.de

19004639

R404a R290 (Propan)

Single Lane Dual Lane Single Lane Dual Lane

718.390.599 718.387.897 718.390.030 718.387.300

718.390.792 7 18.390.740

718.390.03 1 718.390.586 718.390.032 7 18.390.587

718.390.793 7 18.390.741

718.390.062 718.390.839 7 18.392.147 718.390.796

This document reflects the technical status at the time of the revision.

We reserve the right to make technical changes.

Franke Foodservice Systems GmbH declares under

its sole responsibility that this/these appliance(s)

set forth in this declaration conform(s) to the regulations of these directives:

The conformity was tested using the harmonized EN

standards:

Declaration of Conformity

User manual Item no.:

Revision date:

Frozen fry dispenser F3D3S/F3D3/ F3D3SP/F3D3P

en

Item no.:

Page 3

3

07/2 0 15 Frozen fry dispenser F3D3S/F3D3/ F3D3SP/F3D3P

en

CONTENT

1 Safety ..................................................................................................................................4

1.1 Symbols from the user manual ...................................................................................4

1.2 Warning and prohibitory signs ................................................................................... 5

1.3 Proper use ................................................................................................................ 5

1.4 Safety instructions .................................................................................................... 6

2 Installation ..........................................................................................................................9

2.1 Technical data ........................................................................................................... 9

2.2 Removing the packaging box ..................................................................................... 11

2.3 Removing the pallet .................................................................................................. 12

2.4 Setting up the appliance ........................................................................................... 12

2.5 Changing the door hinge ........................................................................................... 13

2.6 Electrical connection ................................................................................................ 13

2.7 Final steps ................................................................................................................ 13

3 Appliance description ....................................................................................................... 15

3.1 Before starting up for the first time ........................................................................... 18

3.2 Daily procedure for starting up/switching on ............................................................ 19

3.3 Filling with fries ........................................................................................................ 21

3.4 Dispensing fries .......................................................................................................22

3.5 Daily procedure for decommissioning/switching off .................................................23

4 Cleaning ............................................................................................................................24

4.1 Defrosting ................................................................................................................24

4.2 Daily cleaning procedure ..........................................................................................25

5 Preventive maintenance ...................................................................................................26

5.1 Cleaning the filter .....................................................................................................26

5.2 Cleaning the condenser ribs .....................................................................................26

5.3 Customer service (electric components) .................................................................. 27

5.4 Customer service (cooling system)* .........................................................................28

6 Malfunctions/Troubleshooting ........................................................................................29

6.1 Error messages ........................................................................................................29

6.2 Malfunctions ............................................................................................................29

7 Decommissioning (storage/disposal) ..............................................................................32

7.1 S t orage ....................................................................................................................32

7.2 Disposal ...................................................................................................................32

* only F3D3SP/F3D3P

Page 4

4

07/2 0 15

!

!

i

Frozen fry dispenser F3D3S/F3D3/ F3D3SP/F3D3P

en

IMPORTANT!

Before initial use, the instructions on operating safety, use and maintenance must be read carefully and understood. Keep the user manual in the vicinity of the appliance for later reference.

SAFETY

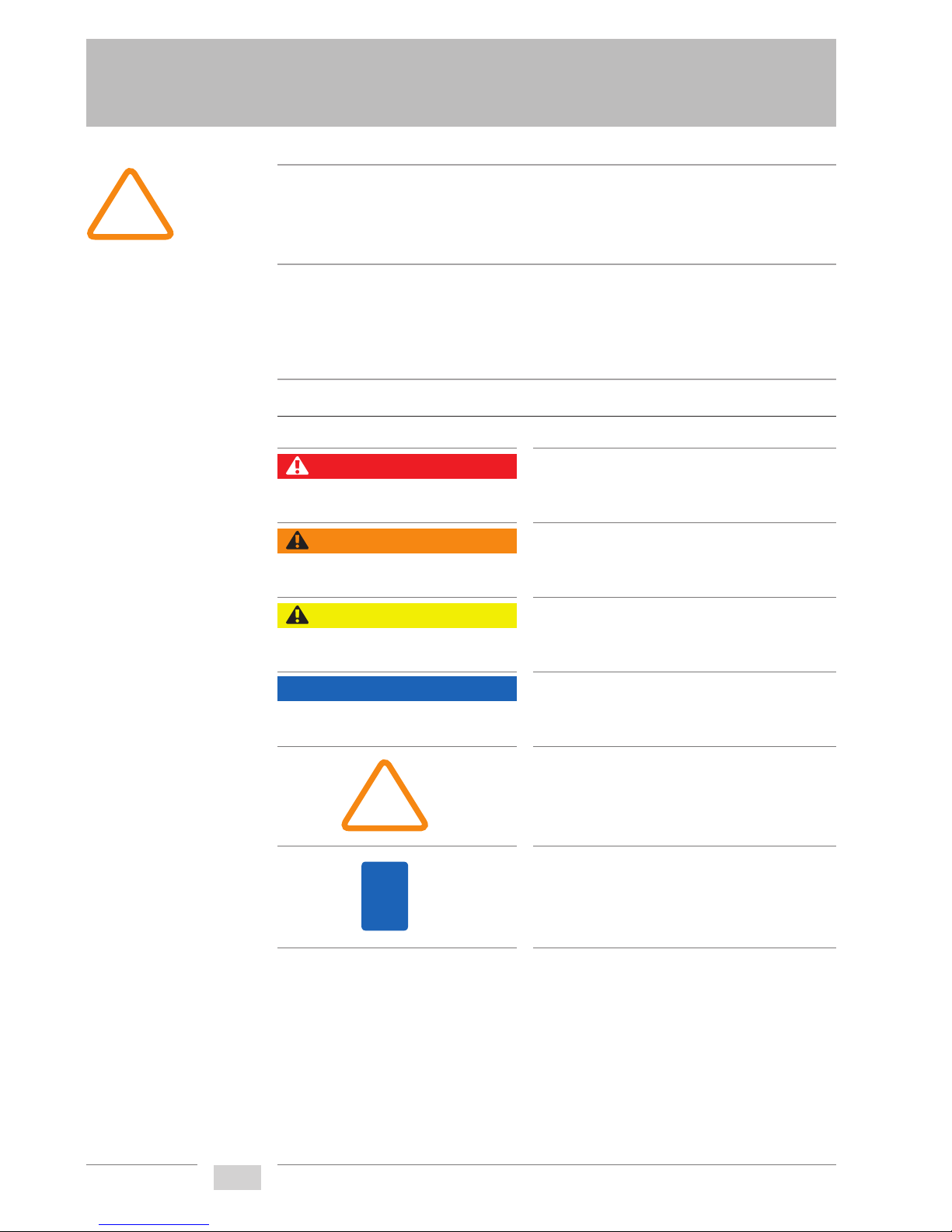

. SYMBOLS FROM THE USER MANUAL

Additional information, tips and recommendations

can be found here.

Important information can be found here.

NOTICE indicates a situation which, if not avoided,

may result in damage to the appliance.

CAUTION indicates a potentially hazardous situation

which, if not avoided, may result in minor or moderate injury.

WARNING indicates a potentially hazardous situation which, if not avoided, may result in injury.

DANGER indicates a potentially hazardous situation

which, if not avoided, may result in fatal or serious

injury.

DANGER

WARNING

CAUTION

NOTICE

Page 5

5

07/2 0 15

!

Frozen fry dispenser F3D3S/F3D3/ F3D3SP/F3D3P

en

IMPORTANT!

- The appliance must only be operated by trained personnel. Each operator of the appliance

must have read and understood the user manual.

- Children and people with restricted physical, sensory or cognitive abilities must never be left

alone with the appliance and must always be supervised.

- Adhere to the maintenance and cleaning intervals. Regular maintenance and cleaning preserves the operating safety and performance of the appliance.

- Give the user manual to the next owner if the appliance is sold or passed on to a new owner.

- The appliance is not suitable for storing frozen products (french fries) for extended periods; it

is only intended as an intermediate storage location between the freezer room and the deep

fr y er.

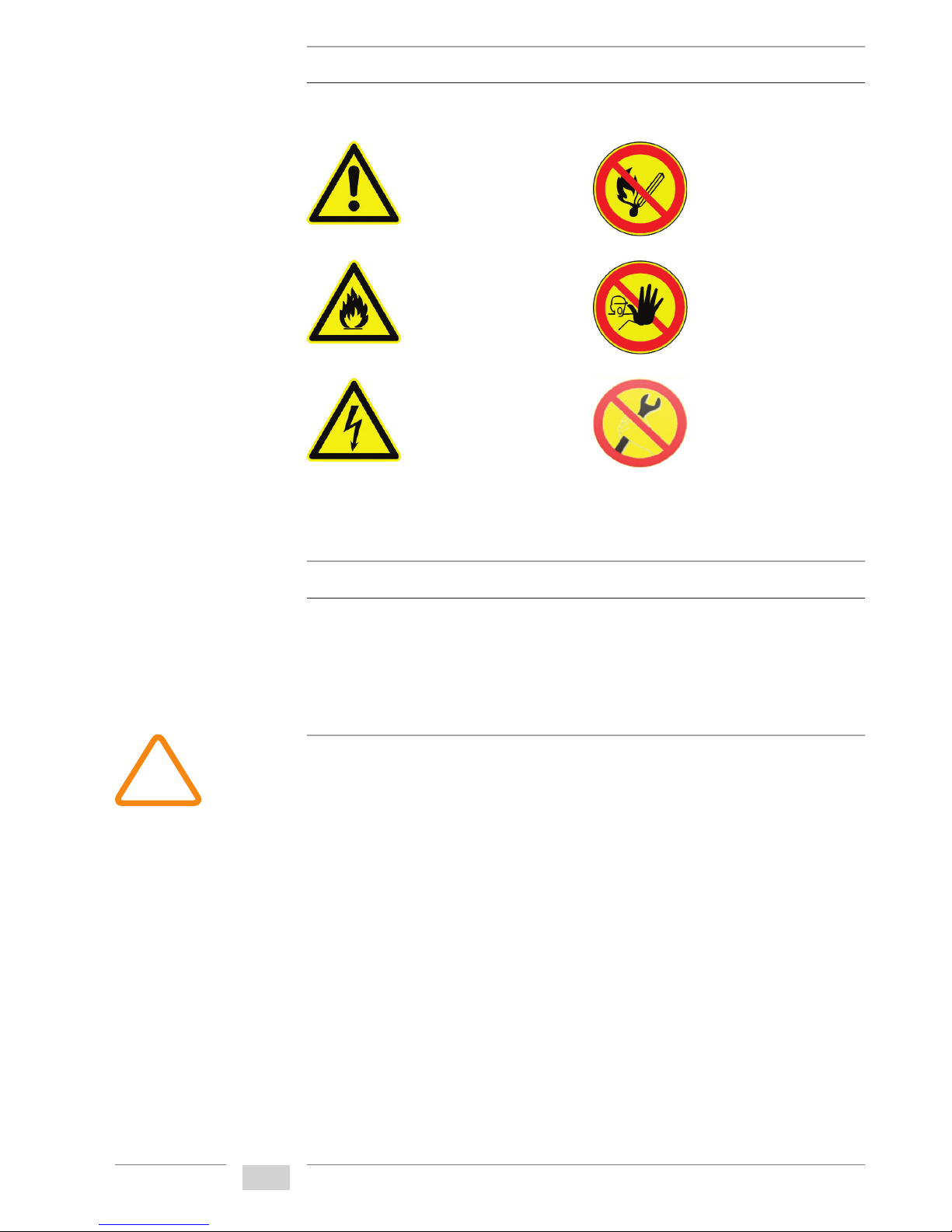

Warning of dangerous

electric voltage

Warning of flammable

materials

Maintenance and repair

work by unauthorized

persons is prohibited.

Access is prohibited to

unauthorized persons

Fire, open flames and

smoking is prohibited

General warning

. WARNING AND PROHIBITORY SIGNS

. PROPER USE

This is technical equipment that is only intended for use in the food service industry.

The appliance may only be used for its intended purpose, i.e. for the intermediate storage and

filling of frozen products (french fries). Any other use is considered inappropriate.

Page 6

6

07/2 0 15 Frozen fry dispenser F3D3S/F3D3/ F3D3SP/F3D3P

en

- It may only be used for its intended purpose.

- The appliance is not suitable to be set up and used outdoors. It is intended for use in kitchens

where it is protected against the weather, excessively high temperatures and humidity, and a

corrosive atmosphere.

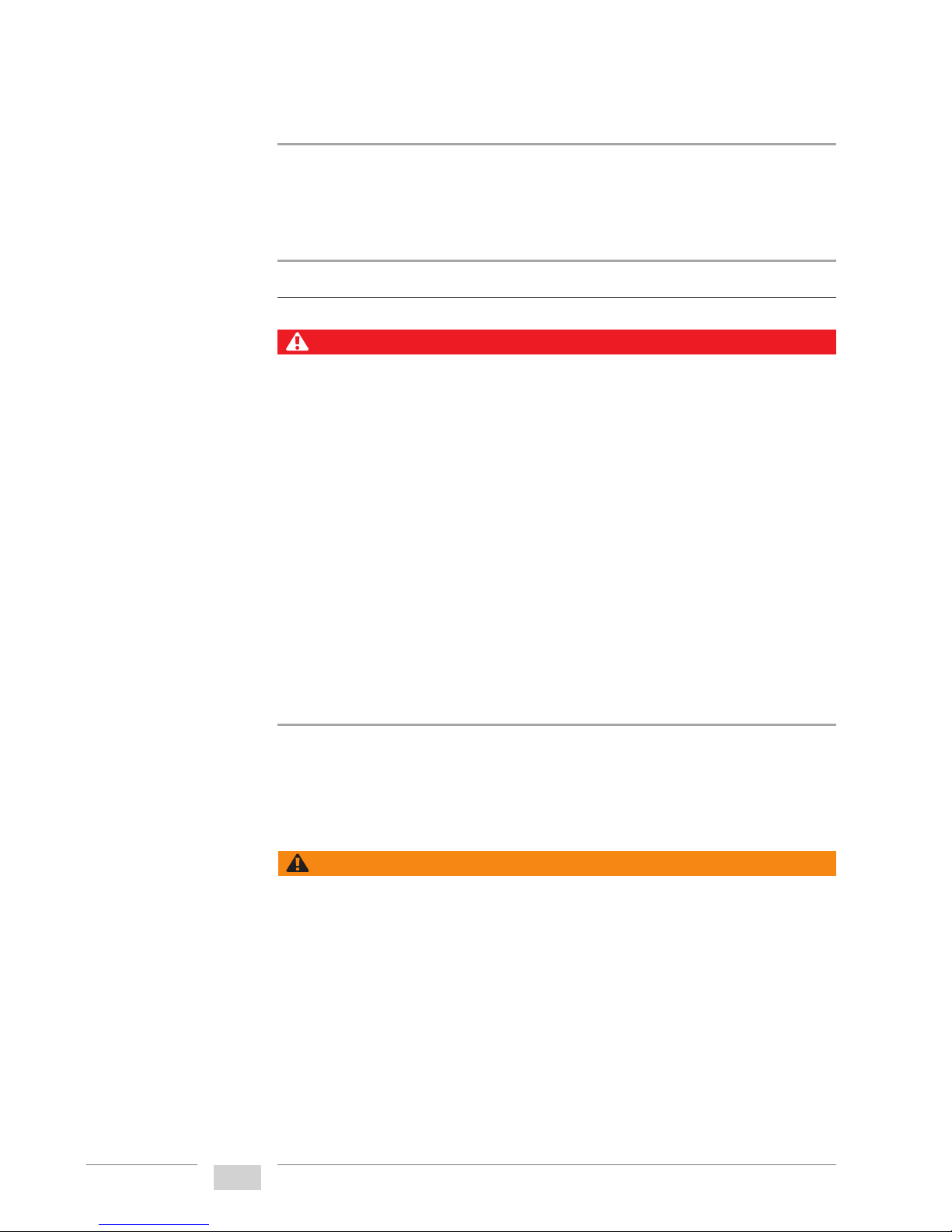

DANGER

Risk of fatal injury from electric shock!

- If the appliance is damaged or malfunctioning, disconnect it from the power supply before performing repair, maintenance or cleaning work.

- Adhere to the safety instructions on the appliance itself (see figure), such as on the power

supply filter housing.

- Do not connect the appliance to the power supply if the connection cable is damaged. Have

the damaged cable replaced with an equivalent cable by a qualified electrician. Do not put the

appliance back into service beforehand.

- Never repair the appliance yourself.

- Have the necessary repairs carried out by a qualified specialist with original spare parts.

Moisture on the electrical components can lead to a short circuit and to serious or even

fatal injury on contact.

- Never clean the appliance with a direct water jet, a sponge or a high-pressure water jet.

- Never connect the appliance to the power supply while the appliance is wet.

- Disconnect the appliance from the power supply immediately if the appliance becomes wet

during operation.

. SAFETY INSTRUCTIONS

WARNING

Danger of fire!

The cooling circuit is filled with R290 (propane)*. Propane is highly flammable. The cooling

coils are contained in the side walls. If the cooling coils are damaged, highly flammable

propane will escape.

An analysis or repair of the cooling system is only allowed under certain conditions!

- Never repair the cooling system yourself!

- If you experience problems, contact the technical customer service. The appliance may only

be repaired by a refrigeration technician under certain conditions!

- Read the chapter “Maintenance/repair”!

* only F3D3SP/F3D3P

Page 7

7

07/2 0 15 Frozen fry dispenser F3D3S/F3D3/ F3D3SP/F3D3P

en

CAUTION

Risk of injury when unpacking!

A tilt indicator is mounted on the shipping box. It must show the correct display (see Fig.

01).

- Only unpack the appliance if the tilt indicator shows the correct display.

- Do not unpack the appliance if the tilt indicator display is incorrect. Contact technical customer service.

The straps on the shipping box are under tension. The wood of the pallet can splinter.

- Keep an adequate distance when cutting the straps.

- Wear gloves and goggles when unpacking.

The appliance is very heavy, top heavy and can easily tip. Therefore, the pallet is designed

so the appliance can only be pushed forward off the pallet with the aid of 2 metal ramps.

- Do not unpack the appliance alone. The appliance should be unpacked by two or three people.

- Do not try to push the appliance off the pallet sideways or toward the rear.

CAUTION

Risk of injury!

The condenser ribs are sharp and can cause cutting injuries.

- Do not touch the condenser ribs while cleaning.

- Wear suitable gloves while cleaning.

The cooling lines can become very hot and cause burns.

- Do not touch the cooling lines while cleaning.

- Wear suitable gloves while cleaning.

CAUTION

Danger of molds, microbes and viruses!

If the appliance is inadequately cleaned, food residues will deposit on interior surfaces

(especially in the hoppers) and on the wire racks.

- Adhere to the cleaning intervals.

- Read the “Cleaning” chapter.

Page 8

8

07/2 0 15 Frozen fry dispenser F3D3S/F3D3/ F3D3SP/F3D3P

en

NOTICE

Appliance damage!

Rinsing with water that is too hot can deform the hopper(s).

- Clean the hopper(s) with lukewarm water only.

Components that are frozen together may damage the appliance.

- Never place wet components into the freezer.

- Carefully dry the components after cleaning.

Heavy objects may damage the basket wire racks and the drip pans.

- Only place frying baskets on the basket wire racks and drip pans when the baskets are empty.

NOTICE

Rust on stainless steel surfaces!

Abrasive cleaning agents and sharp objects cause iron residue that can rust.

- Do not use abrasive cleaning agents, steel wool, brushes, scrapers or other sharp objects for

cleaning.

- Use cleaning fleece made of artificial fibers to remove stubborn dirt.

Page 9

9

07/2 0 15

X

Y1

Y3

Y2

Y4

Z4

Z3

Z1

Z2

Y1

Y3

Y2

Y4

X

Z1

Z2 Z3 Z4

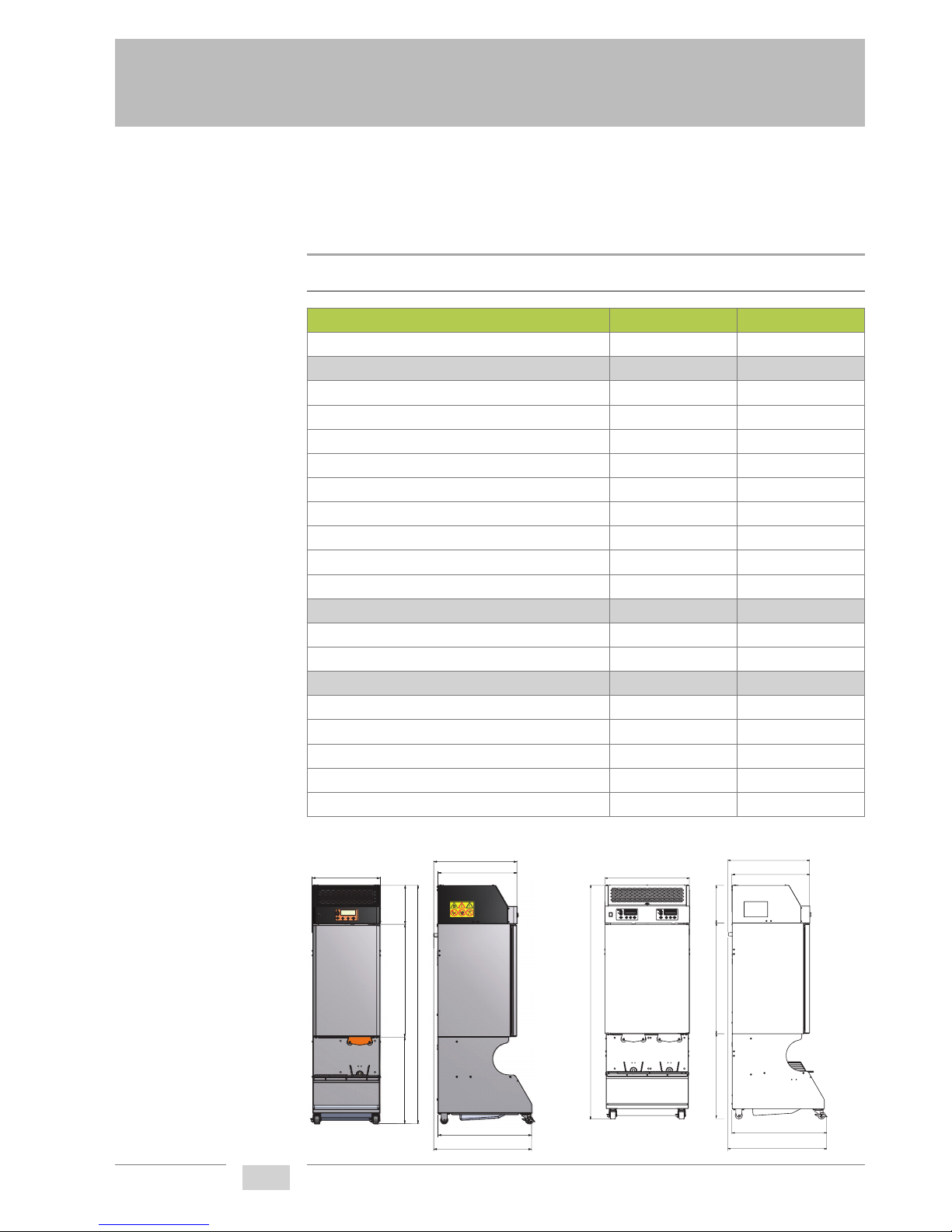

Single Lane Dual Lane

* F3D3SP/F3D3P

** F3D3S/F3D3

Frozen fry dispenser F3D3S/F3D3/ F3D3SP/F3D3P

en

Model Single Lane Dual Lane

Noise emission

< 70dB (A) < 70dB (A)

Dimensions (mm)

Width X 558.5 714.3

Depth Y1* 689. 3 689. 3

Depth Y2* 814.1 814.1

Depth Y3** 655.8 655.8

Depth Y4** 781.1 78 1.1

Height Z1 1983.0 1983.0

Height Z2 723.0 723.0

Height Z3 940.0 940.0

Height Z4 320.1 320.1

Weight (kg)

Net -.- -.-

Shipping weight -.- -.-

Electrical connection (F3D3P/F3D3SP)

Voltage 230 V 230 V

Phases 1 Ph/L/N/PE 1 Ph/L/N/PE

Power 0.6 kW 0.6 kW

Frequency 50 Hz 50 Hz

Amperes 3.7 A 3.7 A

The appliance must be installed by qualified specialists according to the manufacturer's instructions and building, food and electrical regulations.

Locally applicable accident prevention regulations must be followed. If accident prevention regulations are not observed, the manufacturer is released from any liability.

INSTALLATION

. TECHNICAL DATA

Page 10

10

07/2 0 15

1

718.390.599, 718.387.897,

718.390.030, 718.387.300,

718.390.792, 718.390.740

2

718.390.031, 7 18.390.586,

718.390.032, 718.390.587,

718.390.793, 7 18.390.741

3

718.390.062, 7 18.390.839,

718.392.147, 718.390.796

Frozen fry dispenser F3D3S/F3D3/ F3D3SP/F3D3P

en

* The dosing quantity calibration can be changed (instructions on calibrating the dosing quantity can be found in

the Service Manual).

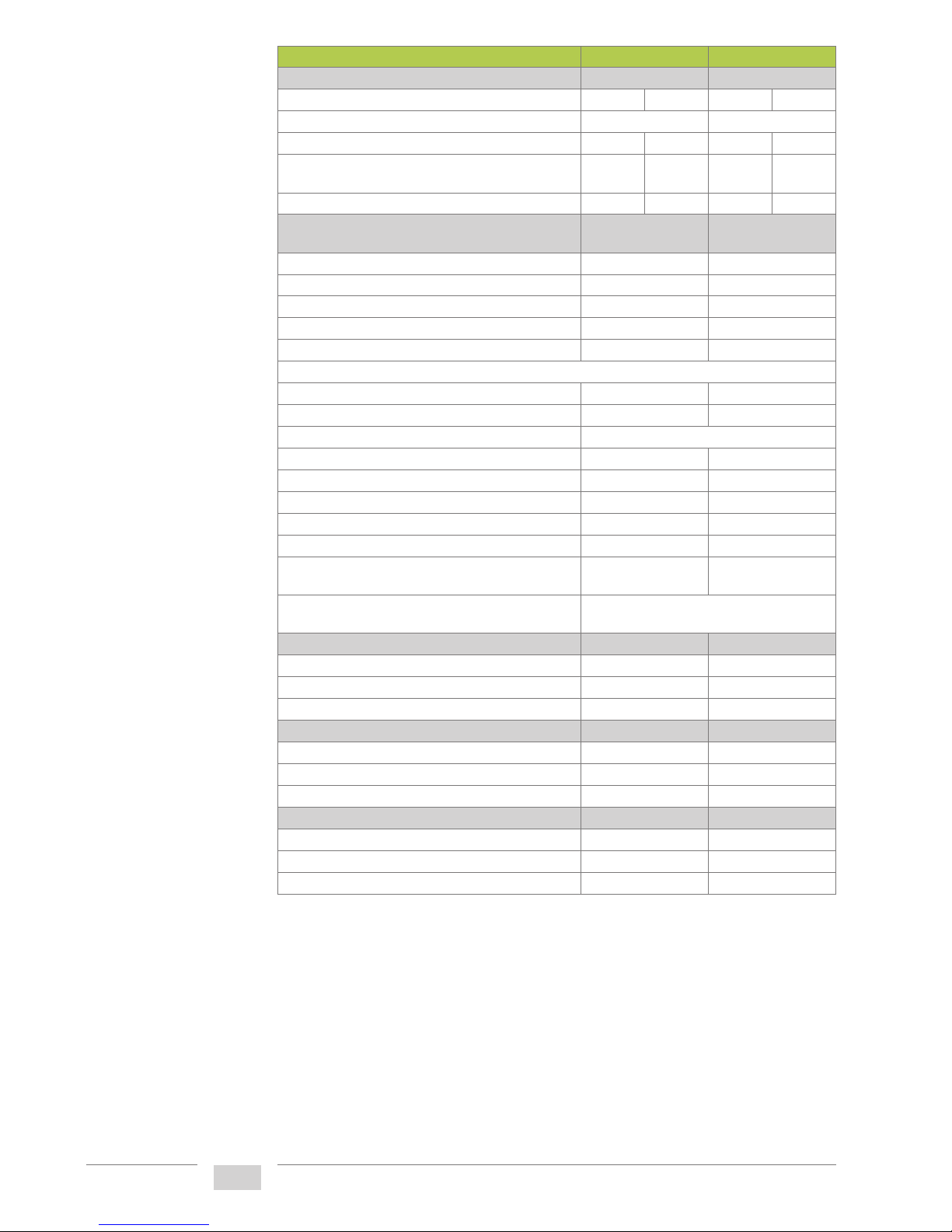

Model Single Lane Dual Lane

Electrical connection (F3D3/F3D3S)

Voltage 230 V 120 V 230 V 120 V

Phases 1 Ph/L/N/PE 1 Ph/L/N/PE

Power 1.3 kW 1.3 kW 1.3 kW 1.3 kW

Frequency

50 & 60

Hz

60 Hz

50 & 60

Hz

60 Hz

Amperes 5.5 A 11.0 A 5.5 A 11.0 A

Operating conditions and installation requirements

Max. ambient temperature 33 °C 33 °C

Max. humidity 60 % 60 %

Minimum rear clearance 30mm 30mm

Minimum top clearance 100 mm 100 mm

Minimum side clearance None None

Energy consumption (24 h) (F3D3P/F3D3SP)

4.05 kWh 5.1 kW h

Energy consumption (24 h) (F3D3/F3D3S)

6.2 kWh 7.5 kWh

Cooling system

Closed system, cold wall construction

Refrigerant (F3D3P/F3D3SP)

R290 R290

Refrigerant (F3D3/F3D3S)

R404A R404A

Climate class

N N

Operating temperature

–18 °C to –23 °C –18 °C to –23 °C

French fry capacity

Up to 18kg Up to 26kg

Dispensing rate

Up to 350 baskets

per hour

Up to 700 baskets

per hour

Dispensing accuracy

Plus/minus 10% of the calibration weight

for the large dosing quantity

Load size

1

[Small] 0.75 lb. (340 g) 0.75 lb. (340 g)

[Medium] 1.0 lb. (454 g) 1.0 lb. (454 g)

[Large] 1.5 lb. (680 g) 1.5 lb. (680 g)

Load size

2

[Small] 417 g 417 g

[Medium] 500 g 500 g

[Large] 625 g 625 g

Load size

3

[Small] 280 g 280 g

[Medium] 625 g 625 g

[Large] 833 g 833 g

Page 11

11

07/2 0 15 Frozen fry dispenser F3D3S/F3D3/ F3D3SP/F3D3P

en

Fig. 03: Removing

the accessories box.

Fig. 02: Lifting

off the packaging

box.

CAUTION

Risk of injury!

The straps on the shipping box are under tension. The wood of the pallet can splinter.

- Keep an adequate distance when cutting the straps.

- Wear gloves and goggles when unpacking.

- Cut the plastic straps with scissors.

- Lift off the packaging box (with 2 people, see Fig.

02).

- Cut the plastic straps of the accessories box with

scissors (see Fig. 03).

The accessories box contains removable components. Do not discard.

Procedure:

The tilt indicator must show the correct display (see Fig. 01).

Fig. 01: Tilt indicator:

Correct: The appliance can be

unpacked.

Incorrect: The appliance must not be

unpacked; contact

technical customer

service.

CAUTION

Risk of injury!

A tilt indicator is mounted on the shipping box. The tilt indicator must show the correct

display (see Fig. 01).

- Only unpack the appliance if the tilt indicator shows the correct display.

- Do not unpack the appliance if the tilt indicator display is incorrect. Contact technical customer service.

. REMOVING THE PACKAGING BOX

Page 12

12

07/2 0 15 Frozen fry dispenser F3D3S/F3D3/ F3D3SP/F3D3P

en

Fig. 04: Pushing the appliance off the pallet.

Configuration 2

Configuration 1

Frozen fry dispenser Deep fryers Bagging station

Bagging station Deep fryers Frozen fry dispenser

. REMOVING THE PALLET

- Get two people to grasp the appliance at both sides.

- Carefully push the appliance forward. Hold the pallet

in place. If necessary, carefully shift the appliance

back and forth (see Fig. 04).

Pushing the appliance forward causes 2 metal

ramps to be extended which can be used to

push the appliance off the pallet without requiring a fork lift.

- Push the appliance down along the metal ramps until

the front castors touch the ground.

- Carefully push the appliance off the metal ramps

until all 4 castors are on the floor.

CAUTION

Risk of injury!

The appliance is very heavy, top heavy and can easily tip. Therefore, the pallet is designed

so the appliance can only be pushed forward off the pallet with the aid of 2 metal ramps.

- Do not unpack the appliance alone. The appliance should be unpacked by two or three people.

- Do not try to push the appliance off the pallet sideways or toward the rear.

. SETTING UP THE APPLIANCE

The appliance must be set up horizontally. The ventilation openings in the housing must be kept

clear. Note the minimum clearances (see "Technical data").

The setup location must be suitable for cleaning the appliance and for rolling it forward for rear

access (for maintenance).

The appliance is set up next to the frying station. The following configurations are possible:

Page 13

13

07/2 0 15 Frozen fry dispenser F3D3S/F3D3/ F3D3SP/F3D3P

en

IMPORTANT!

The appliance must be integrated in a potential equalization system. The corresponding clamp

is marked with a label. This connection must comply with regulations and must be tested for

effectiveness.

. CHANGING THE DOOR HINGE

The freezer should open on the side from which the fries are easier to fill.

The appliance is delivered with a right-hinged door by default. Depending on the situation, the

hinges may need to be changed. Instructions on changing the hinges can be found in the Service

Manual.

. ELECTRICAL CONNECTION

Locally applicable electrical installation and safety regulations must be obser ved.

The connection to the electrical supply grid must conform to the relevant standards.

Before establishing the power connection, check that the voltage and frequency given on the

rating plate match the values of the electrical supply grid.

- Move the appliance into position and lock the brakes of the two front castors.

- F3D3P/F3D3SP: Insert the connector into a 230V (50Hz) power socket. The power cable

provided is 3m long.

- F3D3/F3D3S: Insert the connector into a 230V (50 & 60Hz) or 120 V (60 Hz) power socket.

The power cable provided is 3m long.

. FINAL STEPS

Pulling off the protective films

- Carefully pull the protective film off the stainless steel surfaces.

- Remove any glue residues with a suitable solvent.

Page 14

14

07/2 0 15

i

Frozen fry dispenser F3D3S/F3D3/ F3D3SP/F3D3P

en

Cleaning the stainless steel surfaces

NOTICE

Rust on stainless steel surfaces!

Abrasive cleaning agents and sharp objects cause iron residue that can rust.

- Do not use abrasive cleaning agents, steel wool, brushes, scrapers or other sharp objects for

cleaning.

- Use cleaning fleece made of artificial fibers to remove stubborn dirt.

- Clean the stainless steel surfaces with a moist cloth (lukewarm water and neutral soap).

- Wipe clean with clear water.

- Wipe dry thoroughly.

Removing limescale deposits and lime stains

If cleaning with a neutral soap is not sufficient, limescale deposits can be removed with a 25%

solution of vinegar. Give the vinegar solution time to act, rinse with clear water and wipe dry.

Page 15

15

07/2 0 15 Frozen fry dispenser F3D3S/F3D3/ F3D3SP/F3D3P

en

APPLIANCE DESCRIPTION

The F3D3 is used to easily portion frozen fries without a loss in quality. The semi-automatic

equipment ensures that filled frying baskets are made available according to need. The F3D3

Dual Lane is particularly flexible due to the two separately operable dispenser lanes.

R404A or the environmentally friendly R290 is used as the refrigerant. R290 has no damaging influence on the ozone layer (ODP), a negligible greenhouse effect (GWP) and is available

worldwide. Because of its efficient energy properties, R290 is highly suitable as a coolant for

this application. Special precautions must be taken into consideration due to the coolant's high

flammability.

The F3D3 is available in 4 different models:

- F3D3S Single Lane: with one dispenser lane, using R404A refrigerant

- F3D3SP Single Lane: with one dispenser lane, using propane refrigerant

- F3D3 Dual Lane: with two dispenser lanes, using R404A refrigerant

- F3D3P Dual Lane: with two dispenser lanes, using propane refrigerant

Accessories (optional), only for the dual lane models

- Side basket wire rack

- Collecting pan for the side basket wire rack

Scope of delivery (components)

Non-removable components (permanently installed in the freezer):

- Bucket with filler doors

Removable components (in appliance):

- Hopper (Single Lane: 1 unit, Dual Lane: 2 units)

- Deflector (Single Lane: 1 unit, Dual Lane: 2 units)

- Freezer bottom (1 unit)

- Wire rack (1 unit)

Removable components (in accessories box):

- Upper basket wire rack with basket guides (1 unit)

- Lower basket wire rack (1 unit)

- Lower drip pan (1 unit)

- Crumb tray (1 unit) (option)

Page 16

16

07/2 0 15

F3D3S und F3D3SP–Single Lane

Frozen fry dispenser F3D3S/F3D3/ F3D3SP/F3D3P

en

Warning and prohibitory signs

Storage area for

unused baskets

Castors without brake

Castors with brake

Lower drip pan (plastic)

Lower basket wire rack

Upper basket wire rack with basket guide

Freezer bottom

Handles for manually turning the drum

Deflector (rubber)

Hopper with

drum

Control panel of the

dispenser lane

Access plates to condenser

F3D3SP Type label

Compressor cabinet

Power switch

F3D3S type label behind

the air filter

Crumb Tray (option)

Page 17

17

07/2 0 15

F3D3 und F3D3P–Dual Lane

Frozen fry dispenser F3D3S/F3D3/ F3D3SP/F3D3P

en

Warning and prohibitory signs

Storage area for

unused baskets

Castors without brake

Castors with brake

Lower drip pan (plastic)

Lower basket wire rack

Upper basket wire rack with basket guides

Freezer bottom

Handles for manually

turning the drum

Deflector (rubber)

Hopper with

drum

Control panels of the

dispenser lanes

Access plates to condenser

F3D3P Type label

Compressor cabinet

Power switch

F3D3S type label behind

the air filter

Crumb Tray (option)

Wire rack

Page 18

18

07/2 0 15 Frozen fry dispenser F3D3S/F3D3/ F3D3SP/F3D3P

en

ACTION–1 button: Performs the actions that are displayed on the screen

– Inc (= increase)

ATTENTION symbol (with 3 LEDs at the corners):

Indicates the status of the dispenser lane:

- Lamps are off: The appliance is ready to operate.

- Lamps light up: Indicates a low filling level. The appliance continues to dispense fries.

- Lamps flash: Indicates an error. The screen displays an error message.

BASKET symbol (with 7 green

LEDs):

When the BASKET symbol

lights up, the dispenser lane is

ready to dispense the product

into the frying basket.

ACTION–3 button: Performs the actions that are displayed on the screen – OK (= confirm), Reset, 2 LEDs

flash!

ACTION–2 button: Performs the actions displayed on the screen – Dec

(= decrease).

LCD screen:

- Displays the current operating

temperature of the freezer.

- Displays error messages and possible causes.

- Displays the appliance setup and

diagnosis programs with possible

measures or decision options.

ON/OFF button: For switching on the

dispenser lane. Press for 4 seconds until

both LEDs light up.

Control panel for the dispenser lane

There is one control panel for each dispenser lane. The dispenser lanes can be operated separately. If necessary, one of the dispenser lanes can be switched off (F3D3P–Dual Lane).

. BEFORE STARTING UP FOR THE FIRST TIME

Before starting up for the first time, all components of the appliance must be cleaned.

Cleaning removable components

The removable components are located, firstly, in the appliance itself and, secondly, in the accessories box (see scope of delivery).

Page 19

19

07/2 0 15

i

Frozen fry dispenser F3D3S/F3D3/ F3D3SP/F3D3P

en

. DAILY PROCEDURE FOR STARTING UP/SWITCHING

ON

Assembling the appliance

NOTICE

Appliance damage!

Components that are frozen together may damage the appliance.

- Never place wet components into the freezer.

NOTICE

Appliance damage!

Rinsing with water that is too hot can deform the hopper(s).

- Clean the hopper(s) with lukewarm water only.

Components that are frozen together may damage the appliance.

- Never place wet components into the freezer.

- Carefully dry the components after cleaning.

- Wash and disinfect all components in the rinsing sink one after the other.

- Set all components upright to air dry.

- Place the hopper upside down so the water can drain out of it.

Cleaning the interior and non-removable components

- Wipe off and disinfect the refrigerator and the bucket (see Fig. 05) with a cloth.

- In particular, wipe off and disinfect the front and back of the filler doors and the entire bucket.

- Carefully wipe all parts dry with a sterile fabric.

Tip:

The filler doors of the bucket are spring-loaded and can be opened by pushing on them carefully.

All parts of the bucket are more easily accessible for cleaning with the filler doors fully open.

Fig. 05: Bucket with filler doors

Page 20

20

07/2 0 15

i

Frozen fry dispenser F3D3S/F3D3/ F3D3SP/F3D3P

en

Roll the appliance into position and block the brakes of

the front castors.

OptionOption

Mount the side basket wire

rack (if present)

Position the collecting pan

under the basket wire rack.

Place the upper basket wire

rack onto the cross supports.

Tip:

If the hub is not fully engaged,

the hopper will not be in the

right position and the freezer

will not be able to close.

In this case, turn the drum

slightly at the handle until the

hub fully engages.

Insert the hopper. Ensure that

the hub is fully engaged in the

drum. Turn the drum at the

handle if necessary until the

hub engages.

Slide the deflector into the

hopper with the short side

first.

Insert the lower basket wire

rack.

Insert the lower drip pan.

Insert the freezer bottom

with the right orientation. The

slanted surface must face

down and toward the rear.

Press it down.

Insert the wire rack (in the

freezer above the hopper(s)).

Only for dual lane models

Insert the crumb tray.

Page 21

21

07/2 0 15

!

Frozen fry dispenser F3D3S/F3D3/ F3D3SP/F3D3P

en

Close the freezer.Repeat steps 2 and 3 until

the hopper(s) is/are full (see

"Technical data", french fry

capacity).

Carefully pour the fries into

the hopper from above, being

careful that the fries do not

break. Hold the bag in such a

way that most fries fall parallel to the drum.

Fully tear open the bag hold-

ing the frozen fries. Be careful

not to break or crush the

fries.

. FILLING WITH FRIES

IMPORTANT!

The products should not be filled until the required operating temperature is reached.

Fig. 06: Display with temperature

(actual value).

Switching on/letting cool to the operating temperature

- Close the freezer.

- Switch the cooling system on at the power switch. The indicator lamp in the switch lights up.

The cooling process begins. The current temperature is shown on the display as the

freezer cools (see Fig. 06). After approx. 3 hours, the appliance will have reached the

required operating temperature (–18 to –23°C). Depending on the ambient conditions

(room temperature and humidity), cooling may take longer.

NOTICE

Ice on the freezer walls

prevents the appliance

from reaching its operating

temperature.

- Do not leave the freezer

door open longer than is

necessary for filling.

- Defrost the appliance daily

(see the "Cleaning" chapter).

Remove the wire rack.

Check the hopper. Remove

any product remnants.

Page 22

22

07/2 0 15

i

Frozen fry dispenser F3D3S/F3D3/ F3D3SP/F3D3P

en

Option

Remove the filled basket and

immediately place it into the

de ep fryer.

The screen displays [Filling].

The filling process is displayed

on the screen by a growing,

horizontal bar.

Place an empty deep fryer

basket under the dispenser

and push it back against the

dispensing pressure switch.

The basket is filled.

The appliance is ready to dispense fries when the BASKET

symbol lights up. [Ready]

appears on the screen.

Change the load size if necessary. The load size is set to

[small] by default.

Press the ON/OFF button for

4 seconds until the button

LEDs light up. The dispenser

lane is switched on.

. DISPENSING FRIES

NOTICE

Loss in quality!

The product thaws quickly in the filled frying basket. The filled baskets should not be

stored on the storage areas of the frozen fry dispensers or on the deep fryer for long

periods.

- Only fill a basket if the deep fryer is ready to use.

Setting the load size

The current load size is

displayed at the bottom left

of the screen (e.g. small =

standard)

Press the ACTION–3 button.

The display changes to the

next load size (e.g. medium).

Press until the desired load

size is displayed on the

screen.

Page 23

23

07/2 0 15

i

Frozen fry dispenser F3D3S/F3D3/ F3D3SP/F3D3P

en

1. Press the ON/OFF button for 4 seconds until the button LEDs go out. The dispenser lane is

switched off.

2. Press the power switch to disconnect the appliance from the power supply. The indicator

lamp in the switch goes out.

3. Take the hopper out of the appliance.

4. Fill the remaining fries from the hopper into a suitable storage container and store them in

the freezer room.

Setting down the empty frying baskets

NOTICE

Appliance damage!

Heavy objects may damage the basket wire racks and the drip pans.

- Only place frying baskets on the basket wire racks and drip pans when the baskets are empty.

Empty frying baskets can be set down on the intended area in the appliance until they are

refilled:

Location Single Lane Dual Lane

Lower basket wire rack 3 baskets 4 baskets

Upper basket wire rack (+

dispensing stations)

2 (+1) baskets 2 (+2) baskets

Side basket wire rack (if

present)

Tip:

In restaurants with continuous opening hours, the freezer should be switched off for 2-3 hours

daily.

It is recommended to keep the filling quantity of the hopper relatively low before closing the

restaurant for the day so that only a small quantity of fries needs to be kept in the freezer room

overnight.

For a more convenient timing of the cleaning process, the F3D3/F3D3P–Dual Lane offers the

option of switching off only one of the two dispenser lanes before closing for the day. The components can then be taken out of the appliance and cleaned.

. DAILY PROCEDURE FOR DECOMMISSIONING/

SWITCHING OFF

The appliance must be emptied, defrosted and cleaned every day after closing.

Page 24

24

07/2 0 15 Frozen fry dispenser F3D3S/F3D3/ F3D3SP/F3D3P

en

NOTICE

Damage!

The freezer should only be defrosted passively.

- Switch off the appliance at the power switch and leave the door open.

- Never scratch the ice layers off the freezer walls to accelerate the defrosting process.

3. Let the appliance defrost with the door open.

4. Remove the collecting pan of the side basket wire rack (if present).

DANGER

Risk of fatal injury from electric shock!

- Before cleaning: Disconnect the appliance from the power supply.

Moisture on the electrical components can lead to a short circuit and to serious or even

fatal injury on contact.

- Never clean the appliance with a direct water jet, a sponge or a high-pressure water jet.

CLEANING

. DEFROSTING

The appliance must be disconnected from the power supply. No products must be located inside

the appliance.

1. Take all removable components except for the bottom drip pan out of the appliance. The drip

pan will catch the dripping melt water.

2. Remove the deflector from the hopper(s).

Page 25

25

07/2 0 15

i

Frozen fry dispenser F3D3S/F3D3/ F3D3SP/F3D3P

en

- Remove the lower drip pan, wash it in the rinsing sink and set it upright to dry.

- Wipe off and disinfect the entire basket wire rack area with the cross supports, side walls and

the rear wall using a cloth.

- Thoroughly dry the interior and the basket wire rack area with a sterile cloth.

- Close the freezer door.

Tip:

The filler doors of the bucket are spring-loaded and can be opened by pushing on them carefully.

All parts of the bucket are more easily accessible for cleaning with the filler doors fully open.

Fig. 07: Bucket with filler doors

. DAILY CLEANING PROCEDURE

NOTICE

Appliance damage!

Rinsing with water that is too hot can deform the hopper(s).

- Clean the hopper(s) with lukewarm water only.

Components that are frozen together may damage the appliance.

- Never place wet components into the freezer.

- Carefully dry the components after cleaning.

- Wash and disinfect all components taken out of the appliance in the rinsing sink one after the

othe r.

- Set all components upright to air dry.

- Place the hopper upside down so the water can drain out of it.

After the appliance is fully defrosted:

- Wipe off and disinfect the refrigerator and the bucket (see Fig. 07) with a cloth.

- In particular, wipe off and disinfect the front and back of the filler doors and the entire bucket.

Page 26

26

07/2 0 15

!

Frozen fry dispenser F3D3S/F3D3/ F3D3SP/F3D3P

en

IMPORTANT!

Clean condensers have a major influence on the service life of the compressor.

- Remove the access plate to the condenser.

- Remove the filter from the appliance.

- Clean the filter in the rinsing sink using a household dishwashing detergent.

- Rinse with clear water.

- Let dr y.

- Insert the filter.

- Close the access plate.

DANGER

Risk of fatal injury from electric shock!

- Before performing maintenance: Disconnect the appliance from the power supply.

- Have the necessary repairs carried out by a qualified specialist with original spare parts.

PREVENTIVE MAINTENANCE

Dishwashing detergent

Required tools/material

1 x monthly

Cleaning interval

. CLEANING THE FILTER

. CLEANING THE CONDENSER RIBS

Page 27

27

07/2 0 15 Frozen fry dispenser F3D3S/F3D3/ F3D3SP/F3D3P

en

- Remove the access plate to the condenser.

- Remove the filter from the appliance.

- Free the condenser ribs of dust and dirt using a brush with soft bristles or a vacuum cleaner.

- Insert the filter.

- Close the access plate.

CAUTION

Risk of injury!

The condenser ribs are sharp. Contact may result in cutting injuries.

- Do not touch the condenser ribs.

- Wear gloves if necessary.

Brush with soft bristles

Alternative:

Vacuum cleaner

Required tools/material

1 x monthly

Cleaning interval

. CUSTOMER SERVICE (ELECTRIC COMPONENTS)

- In case of malfunction, contact technical customer service.

- Please provide the item number and type. This information is located on the rating plate.

Page 28

28

07/2 0 15 Frozen fry dispenser F3D3S/F3D3/ F3D3SP/F3D3P

en

- Work on cooling systems must never be carried out in rooms at the restaurant.

- The appliance may be repaired in a suitable workshop. It is important to ensure that there is

sufficient ventilation!

- The appliance may only be kept outside in the open air for the duration of the work on the

cooling system.

- The work may only be carried out by a qualified (certified) specialist company. The relevant

local standards and laws for this qualification are valid.

Certain requirements apply to work (analysis/repair/maintenance) on cooling systems that must

be strictly observed. If these requirements are not fulfilled then this will result in the expiry of

the guarantee cover and the manufacturer accepts no liability.

WARNING

Danger of fire!

The cooling circuit is filled with R290 (propane). Propane is highly flammable.

Work (analysis/repair/maintenance) on the cooling system is only allowed under certain

conditions!

- Never repair the cooling system yourself!

- If you experience problems, contact the technical customer service. The appliance may only

be repaired by a refrigeration technician under certain conditions!

. CUSTOMER SERVICE (COOLING SYSTEM)*

* only F3D3SP/F3D3P

Page 29

29

07/2 0 15 Frozen fry dispenser F3D3S/F3D3/ F3D3SP/F3D3P

en

Problem Cause Remedy

1

The power

switch is

switched on but

the freezer is not

running.

The connector is not plugged into

the socket.

Connect the power connector (switch on the power switch).

The power socket is faulty.

Plug the connector into another socket. Have the faulty power

socket repaired by an electrician.

The fuse tripped. Check if the fuse tripped. Reset it if necessary.

Error message Problem Remedies

Filling level in hopper is

low (enough for filling 3

to 4 baskets)

Fill the hopper with fries.

ATTENTION: If the machine continues dispensing until the hopper

is almost empty, the filling process is interrupted and error message

Err04 is displayed.

Bucket error Call technical customer service.

1. The hopper is empty

2. There is a clump

of fries (bridge) in the

hopper

1. Fill with fries.

or

2. Check the hopper for clumped fries and release/remove the bridge if

necessary.

3. Press [Reset] (ACTION–3 button).

The filler doors are

blocked

1. Check the filler doors for blockage.

2. Press [Reset] (ACTION–3 button).

Load cell problem Call technical customer service.

MALFUNCTIONS/TROUBLESHOOTING

. ERROR MESSAGES

The error messages are displayed on the control panel screen.

. MALFUNCTIONS

Page 30

30

07/2 0 15 Frozen fry dispenser F3D3S/F3D3/ F3D3SP/F3D3P

en

Problem Cause Remedy

2

The freezer is

running but

cannot reach the

required operating temperature

(-18 °C).

Ice formation on the inside walls,

especially on the temperature

sensor.

Take all products and components out of the appliance and defrost the appliance (see the "Cleaning" chapter). Recommendation: To avoid ice formation, do not keep the freezer door open

longer than necessary. Defrost daily.

The filter is soiled. Clean the filter (see the "Preventive maintenance" chapter).

The condenser ribs are soiled.

Clean the condenser ribs (see the "Preventive maintenance"

chapter).

None of the measures taken

correct the problem (defrosting,

cleaning of the filter and condenser

ribs).

Call technical customer service.

3

The dispenser

lanes cannot be

switched on.

No line power.

Switch on the power switch. (Start up the appliance, see the

"Daily startup" chapter).

Plug in the connector (start up the appliance, see the "Daily

procedure for starting up" chapter).

The ON/OFF button was not

pressed long enough.

Press the ON/OFF button for 4 seconds until the button LEDs

light up.

4

The freezer door

does not close

properly.

The hopper(s) is/are not properly

engaged in the drum hub.

Press the hopper into the appliance, turning the drum at the

handle if necessary.

5

The drum does

not turn.

The hopper is empty. The screen

displays the error message Err04

and the Action–3 [Reset] button

flashes.

Fill the hopper with fries. Press [Reset]. The filling process

begins.

In the hopper, fries are baked

together to form a "bridge". The

screen displays the error message

Err04 and the ACTION–3 [Reset]

button flashes.

Shake the hopper and redistribute the fries to break up the

bridge. Proceed carefully so as not to break the fries. Press

[Reset]. The filling process begins.

6

The lifting module does not go

up or down.

The lift motor is faulty. Call technical customer service.

7

The basket

symbol does not

light up.

The dispenser lane is switched off.

Press the ON/OFF button for 4 seconds until the button LEDs

light up.

The required loading size was not

reached.

See no. 12

8

The ACTION–3

button [Reset]

flashes.

The filling process is aborted prematurely.

Press [Reset]. The filling process begins.

In the hopper, fries are baked

together to form a "bridge". The

screen displays error message

Err04 and the ACTION–3 [Reset]

button flashes.

Shake the hopper and redistribute the fries to break up the

bridge. Proceed carefully so as not to break the fries.

Page 31

31

07/2 0 15 Frozen fry dispenser F3D3S/F3D3/ F3D3SP/F3D3P

en

Problem Cause Remedy

9

The appliance

does not dispense the product and error

message Err04

is displayed.

The hopper is empty.

Fill the hopper with fries. Press [Reset]. The filling process

begins.

In the hopper, the fries are baked

together to form a "bridge" (very

hard).

Shake the hopper and redistribute the fries to break up the

bridge. Proceed carefully so as not to break the fries. If necessary, remove very hard clumps. Press [Reset]. The filling

process begins.

10

The appliance does not

dispense the

product and

error message

Err02 or Err07 is

displayed.

The bucket is missing. Insert the bucket.

The filler door motor is faulty. Call technical customer service.

11

The [Low product warning]

error message

appears.

The filling level in the hopper is low

(only 3–4 fillings).

Fill the hopper with fries. Attention: If the machine continues

dispensing until the hopper is empty, the filling process is

aborted and error message Err04 is displayed.

The frozen fries created a hollow

space around the sensor in the

hopper.

Shake the hopper and redistribute the fries to close the hollow

space. Proceed carefully so as not to break the fries.

12

The hopper is

empty but error

message Err04

is not displayed.

The "Low product" sensor is soiled. Clean the "Low product" sensor.

The "Low product" sensor is faulty. Call technical customer service.

13

The loading

weights are

permanently

incorrect (either

too light or too

heavy).

The deflector is missing from the

hopper.

Slide in the deflector.

The deflector is damaged (e.g.

cracked on the side).

Replace the deflector. (The deflector is a wear part and should

be replaced in good time).

The freezer bottom is not correctly

positioned.

Take out the freezer bottom and insert it correctly.

14

The filler doors

do not open to

dispense fries.

The basket symbol does not light

up.

Wait for the BASKET symbol to light up. The fries are now

dispensed.

The basket wire rack is not positioned correctly.

Take out the basket wire rack and insert it correctly.

The Err04 and [Low product warn-

ing] error messages appear.

Fill the hopper with fries.

The ACTION–3 button [Reset]

flashes.

See error 8.

15

The filler doors

do not close after the fries are

dispensed.

Fries are jammed in the filler

doors.

Remove all fries from the filler doors.

The return spring of the filler door

is broken.

Close the filler doors manually. If the filler doors open again by

themselves, call technical customer service.

The filler door sensor is faulty.

If the filler doors cannot be closed manually, call technical

customer service.

16

The load size

cannot be

changed on the

operator panel.

The filling process is not yet finished.

The filling process is finished when the BASKET symbol LEDs

light up and [Ready] appears on the screen. The load size can

now be changed.

Page 32

32

07/2 0 15 Frozen fry dispenser F3D3S/F3D3/ F3D3SP/F3D3P

en

Disassembly of the appliance must be per formed by qualified specialists according to the manufacturer's instructions.

- Follow the local safety regulations.

- Dispose of the appliance in accordance with local regulations.

- It is essential that you observe the laws and regulations for the disposal of environmentally

harmful substances. Obtain detailed information about their disposal – such substances

include refrigerants or plastics.

- Before disassembly, all food remnants must be removed and the appliance must be thoroughly

cleaned.

DANGER

Risk of fatal injury from electric shock!

- Ensure that the appliance is disconnected from the power supply.

DECOMMISSIONING (STORAGE/DISPOSAL)

. STORAGE

Storage conditions

The storage area must be dry and well ventilated.

Procedure

- Disconnect the appliance from the power supply.

- Remove all food and beverages from the appliance.

- Clean the interior and the accessories.

- Using a cloth, apply a thin protective film of Vaseline oil onto the metal surfaces.

- Leave the doors and drawers slightly open to guarantee good air circulation.

. DISPOSAL

Page 33

33

07/2 0 15

!

Frozen fry dispenser F3D3S/F3D3/ F3D3SP/F3D3P

en

IMPORTANT!

Releasing refrigerant into the atmosphere is strictly forbidden!

Special regulations apply when disposing of refrigerant:

Special regulations apply when disposing of used

electrical appliances:

The customer assumes responsibility for proper disposal of the delivered product after the end

of its service life at the customer's own expense, in accordance with legal regulations. The

customer releases Franke from the obligations under Section 10, Paragraph 2, of the German

Electrical and Electronic Equipment Act (ElektroG) and claims by third parties in this connection.

The entitlement by Franke to be released by the customer is not subject to any statute of limitations and ends after utilization with proper disposal by the customer. If the product is passed

on to a third party, the customer must ensure that the disposal requirement is fulfilled upon the

end of service life. In the event that the customer requests disposal by Franke, Franke GmbH will

prepare a quotation for the customer for the return and disposal of the waste appliance at the

time of disposal. The customer will be charged for transport and disposal costs.

The refrigerant used is either R404A or R290. The necessary specifications on handling the

coolant are given in the manufacturer's data sheet. If you would like more information about this

product, please contact the manufacturer:

R

Linde AG

Werksgruppe Technische Gase

Seitnerstrasse 70

82049 Höllriegelskreuth

Germany

Tel. +49 (0) 89/7446–0

Ra

Arkema Direction de la Communication

Financière

4-8, cours Michelet – La Défense 10

92091 Paris La Défense Cedex

France

Tel. +33 (0) 1 49 00 74 63

Fax +33 (0) 1 49 00 50 24

Page 34

G:\FCE_Engineering\100_user_manuals\GM\Frozen_ fry_dispenser_F3D\FrozenFr yDispenserF3D_allversions.indd

Russia

... and over 30 Market Managers

throughout Europe

Poland

United Kingdom

Germany

Headquarter/Sales Office/Logistics

Sales Office/Logistics Sales Office/Logistics

Sales Office Production/Sales Office/Logistics

Franke Foodservice Systems GmbH

Jurastrasse 3

797 13 Bad Säckingen

Germany

Phone: +49 7761 5533 0

www.franke.de

Franke Foodservice Systems GmbH

Speicherstr. 4

44809 Bochum

Germany

Phone: +49 234 3380 0

www.franke.de

Franke Neva LLC

Volgogradsky prospect 43, Building 3

109316 Moscow

Russia

Phone: +7 495 225 5658

www.franke.ru

Franke Foodservice Systems

Poland Sp. z o. o.

ul. Polnocna 11

81-029 Gdynia

Poland

Phone: +48 58 660 9100

www.franke.pl

Franke Foodservice Systems GmbH

Unit 2A Broom Business Park

Bridge Way

Chesterfield

S419QG

UK

Phone: +44 1246 264280

www.franke.co.uk

LocationsLocations

en

Loading...

Loading...