Page 1

F3D3 Dual and Single Lane Versions Frozen French

Fry Dispenser

Service Manual

Page 2

F3D3 Series Service Manual Table of Contents/Section 1.1

Section No. Content/Service Operation Issued/Updated

1.1 Table of Contents 11-13-12

1.1.1 Model Identification Guide 5-30-12

1.2.1 Franke Warranty Coverage 5-30-12

1.2.2 Franke Service Contact Information 5-30-12

1.3 F3D3 Series Trouble Shooting Guide 6-6-12

1.4 Display Error Message Guide 5-21-12

1.5 F3D3 Series Parts List & Component Diagrams

1.6 F3D3 Series Electric Schematics 5-24-12

1.7 Control P anel Quick-Guide 5-21-12

Setup, Diagnostic & Programming Instructions

1.8 Customer Level Access Instructions 5-30-12

1.9 Load Cell Calibration Instructions 5-30-12

1.10 Factory Level 1 Setup Access Instructions 5-30-12

1.11 Factory Level 3 Operating Parameter Access & Version Guide 11-13-12

1.11.1 Factory Level 3 Parameter Programming for BL 2.00 11-13-12

1.11.2 Factory Level 3 Parameter Prog r am ming for H47C1 11-13-12

1.11.3 Factory Level 3 Parameter Programming for H46P9 11-13-12

1.11.4 Factory Level 3 Display Menu for H46N ONLY 11-13-12

Part Replacement (See Section 4 for Refrigeration Repairs)

2.1 General Service Instructions, Warnings & Tools 5-24-12

2.2 Freezer Door Gasket Replacement 5-21-12

2.3 Automation Assemble [Complete] Replacement 5-22-12

2.4 Door Lift Slide Replacement 5-22-12

2.5 Drum Rotor Motor Replacement 5-22-12

2.6 Drum Rotor/Motor Block & Drive Shaft Replacement

2.7 Door Lift Motor Replacement 5-22-12

2.8 Door [Open] Motor Repl ace me nt 5-22-12

2.9 Product Door & Fi l l B uck et Ass e mbl y Replacement 5-22-12

2.10 Load Cell Replacement 5-30-12

2.11 Door-Closing Spring Replacement 5-22-12

2.12 Low Product Sensor Replacement 5-22-12

2.13 Basket Fill Plunger Switch Replacement 11-13-12

2.14 Door-Open Sensor R epl ace me nt 5-22-12

2.15 Touch Pad Controls Assembly Replacement 5-29-12

2.16 Main Power ON/OFF Switch Replacement 5-22-12

2.17 Temperature Controller Sensor Cable Replacement 5-22-12

2.18 24-Volt Power Supply Replacement 5-22-12

2.19 Compressor Relay Replacement (DIN Mounted) 5-22-12

2.20 Main PC Control Boar d Replacement 5-30-12

Questions? Call Franke Technical Support Group For Your Area. Page 1 Copyright 2012 Franke, Inc. All rights reserved.

Page 3

F3D3 Series Service Manual Table of Contents/Section 1.1

Section No. Content/Service Operation Issued/Updated

Part Replacement...Continued

2.21 Main Control Board Chip Replacement 5-29-12

2.22 Door Frame & Freezer Bottom Heater Replacement 5-23-12

2.23 Power Cord Replacement 5-23-12

2.24 Hopper Rotor Replacement 5-23-12

Part or Component Adjustments

3.1 Low Product Sensor Sensitivity Adjustment 5-23-12

3.2 Reverse Door Hinges/Door Swing 5-23-12

3.3 Adjusting Automation Assembly Alignment 5-23-12

3.4 Drum Rotor Motor Adjustment [When making noises] 5-23-12

3.5 Fry Hopper Hanger Alignment 5-23-12

3.6 Activate Backup Temp. Display – Two Lane Models ONLY 5-23-12

Refrigeration System Repair & Replacement

4.0 Propane Refrigeration System SERVICE RESTRICTION 5-23-12

4.1 Basic [Operator] Refrigerator Maintenance 5-23-12

4.2 Replace Condenser F an Mot or 5-24-12

4.3 Replace Start Relay & Replace Start Capacitor 5-24-12

4.4 Check System Pressure & Electronic Leak Detection 5-24-12

4.4.1 Checking for Leaks with Nitrogen Pressure 11-13-12

4.4.2 Cold Wall Evaporator Leak Detection 11-13-12

4.5 Repair Sy stem [R e fri g er ant] Leak 5-24-12

4.6 Replace Thermostatic Expansion Valve & Filter 5-24-12

4.7 Condenser Unit Replacement 5-24-12

Service Bulletins

none

Rev. 2 11-13-12

Questions? Call Franke Technical Support Group For Your Area. Page 2 Copyright 2012 Franke, Inc. All rights reserved.

Page 4

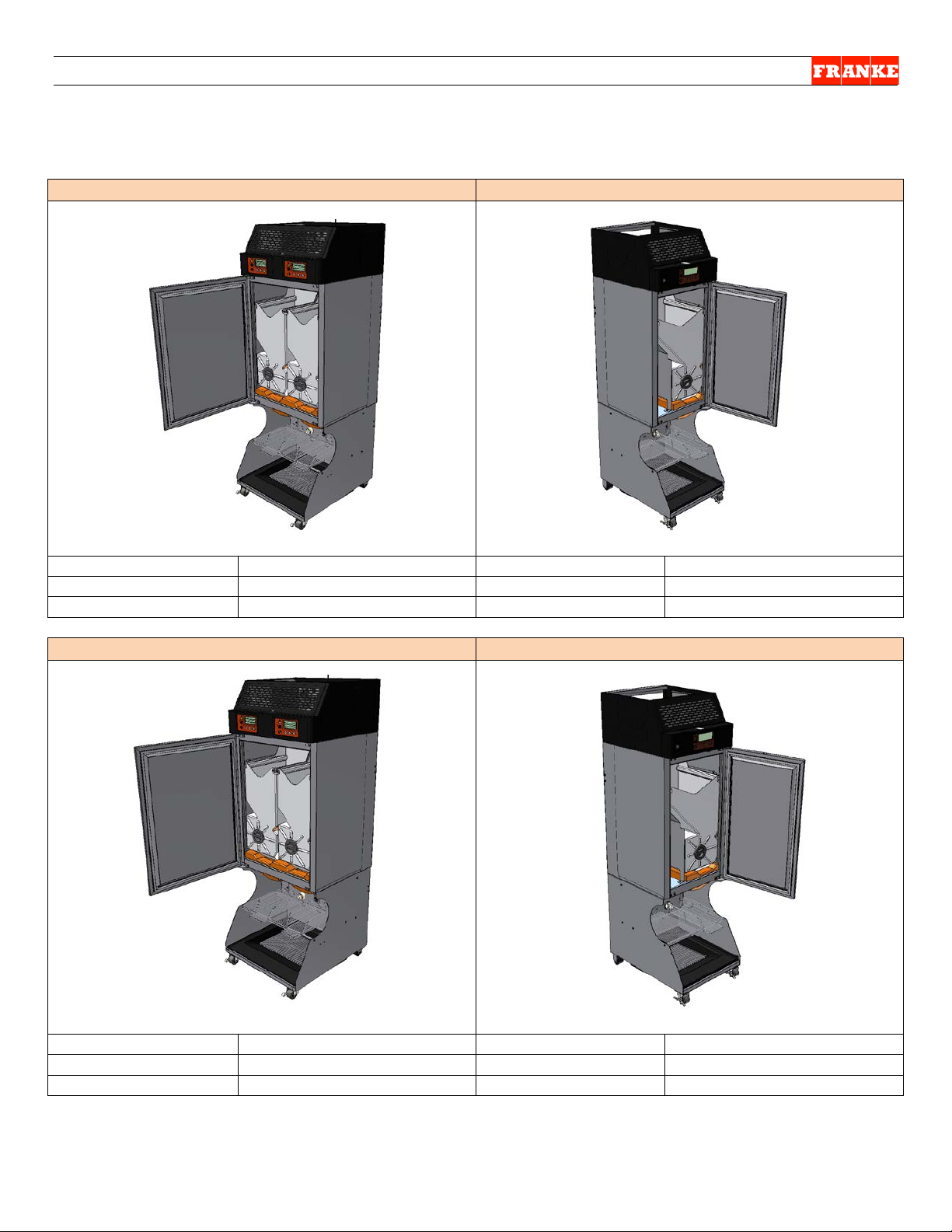

F3D3 Series Service Manual Model Identification 1.1.1

Model F3D3

Model F3D3S

Lanes & Controls:

Two Lanes

Lanes & Controls:

Single Lane

Unit Width:

711 mm (28”)

Unit Width:

559 mm (22”)

Refrigerant Type

R-404A

Refrigerant Type

R-404A

Model F3D3P

Model F3D3SP

Lanes & Controls:

Two Lanes

Lanes & Controls:

Single Lane

Unit Width:

711 mm (28”)

Unit Width:

559 mm (22”)

Refrigerant Type

R-290 PROPANE

Refrigerant Type

R-290 PROPANE

Model Identification Guide

(Shown Hinged-Left)

(Shown Hinged-Right)

(Shown Hinged-Left)

(Shown Hinged-Right)

Questions? Call Franke Technical Support Group For Your Area. Copyright 2012 Franke, Inc. All rights reserved.

Page 5

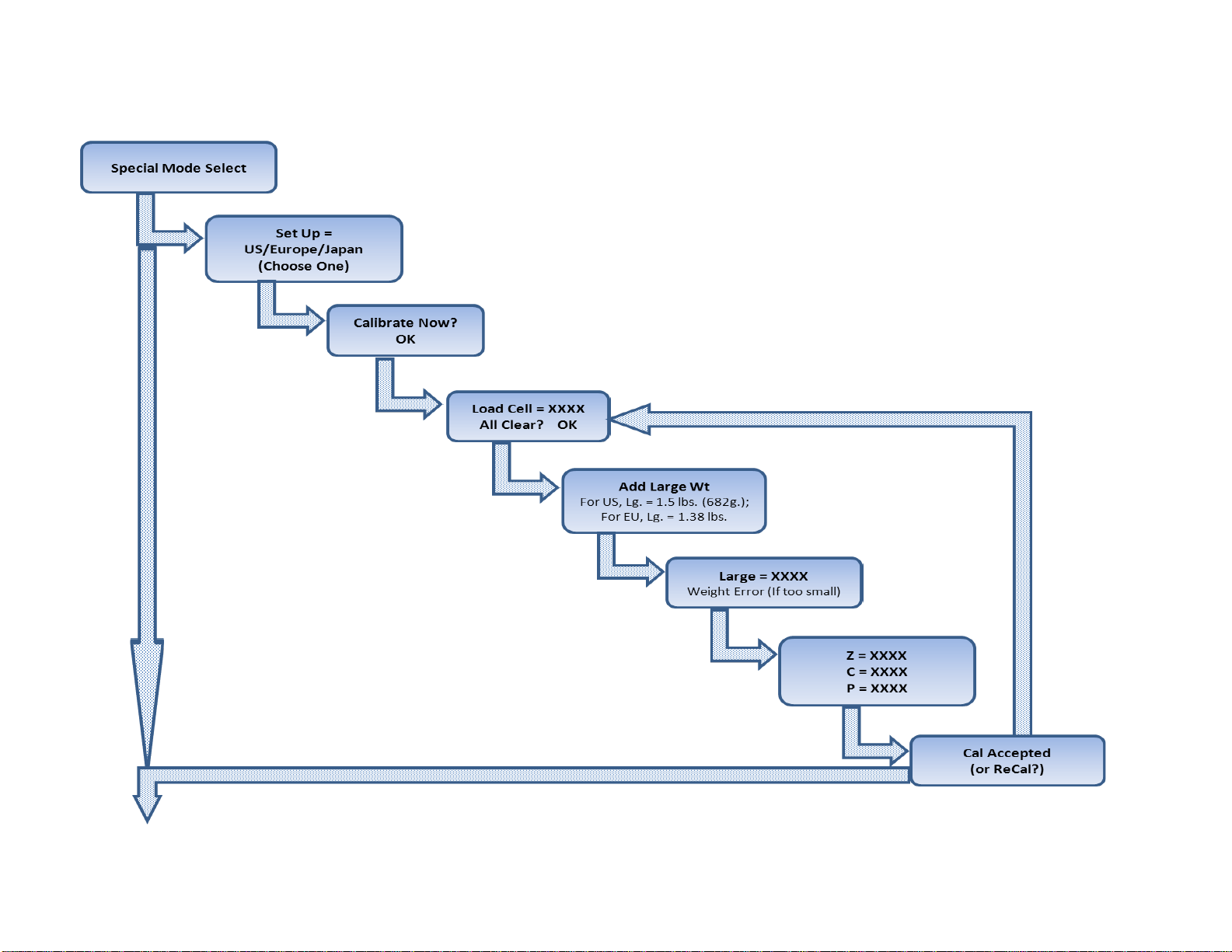

F3D3 Series Service Manual Factory Level 1 Setup Access / 1.10

To Access Factory Level 1 Setup Parameters:

Step

Action Required

Resulting Display

1

From Standby condition use 3rd touchpad to

enter: 3 3 3 3. [The Entry Code]

Special Mode Select

Cust Fact Exit

2

Press touchpad 2 = Fact(ory)

Factory Access Level

Lev1 Lev3 Exit

Press touchpad 1 = Lev1

Low Level Reset ?

Yes No Exit

4

Press touchpad 1 = Yes

Setup = US

Inc Dec Exit

Press touchpad 1 = Inc [to scroll through]:

to go back up list.]

Setup = Europe or

Inc Dec OK

When you press touchpad 3 = OK, screen

* Setting Country *

* Specific Params * then:

Setup Complete

Config = US [setup chosen] then:

Calibrate Menu

OK Exit

7A or

Press touchpad 3 = Exit

Shut [appears then screen

goes blank]

Press touchpad 1 = OK [to initiate calibration]

Calibrate Menu

OK Exit

8

Press touchpad 1 = OK

NOTE: See SM Section LCC

NOTE: All programming is done using the

1

2

3

Setup Access & Resetting

F3D3 Series Fries Dispensers have easy

access to Factory-Level (1) setup and

resetting, using the lane operator interface

touch panel & display. To access:

1) Leave unit plugged in.

2) Turn Main Power Switch ON.

3) Lane power must be OFF. Display will

show current freezer temperature.

three choice buttons labeled: 1, 2 and 3 above.

3

5

6

7B

Press touchpad 2 = Dec [to go back up list]:

NOTE: If you press 1 = Inc on Setup =

APMEA, nothing changes. [Press 2 = Dec -

goes to:

Restores all NUM [numbers]

[or actual setup]

Setup = Japan or

Setup = Latin AM

[America] or

Setup = Canada or

Setup = APMEA

Begin ?

Loadcell = 00XX [Tar Value]

All Clear ?

Questions? Call Franke Technical Support Group For Your Area. Copyright 2012Franke, Inc. All rights reserved.

for Load Cell Calibration Ins tr uctions.

Rev. 1 6/2012

Page 6

F3D3 Series Service Manual Factory Level 3 Parameter Access / 1.11

For To Access Factory Level 3 Parameters:

Step

Action Required

Resulting Display

1

From Standby condition use 3rd touchpad to enter: 3

3 3 3. [The Entry Code]

Special Mode Select

Cust Fact Exit

2

Press touchpad 2 = Fact(ory)

Factory Access Level

Press touchpad 2 = Lev3

Password ??

Inc OK Exit

Press touchpad 2 = OK [Icon will move right to next

Password ??

Inc OK Exit

Press touchpad 2 = OK [Icon will move right to next

Password ??

Inc OK Exit

Press touchpad 2 = OK [Icon will move right to last

Password ??

Inc OK Exit

Press touchpad 1 = Inc once, to raise to 1, then:

Password ??

Inc OK Exit

Press touchpad 2 = OK

Language [first Parameter]

++ -- ->

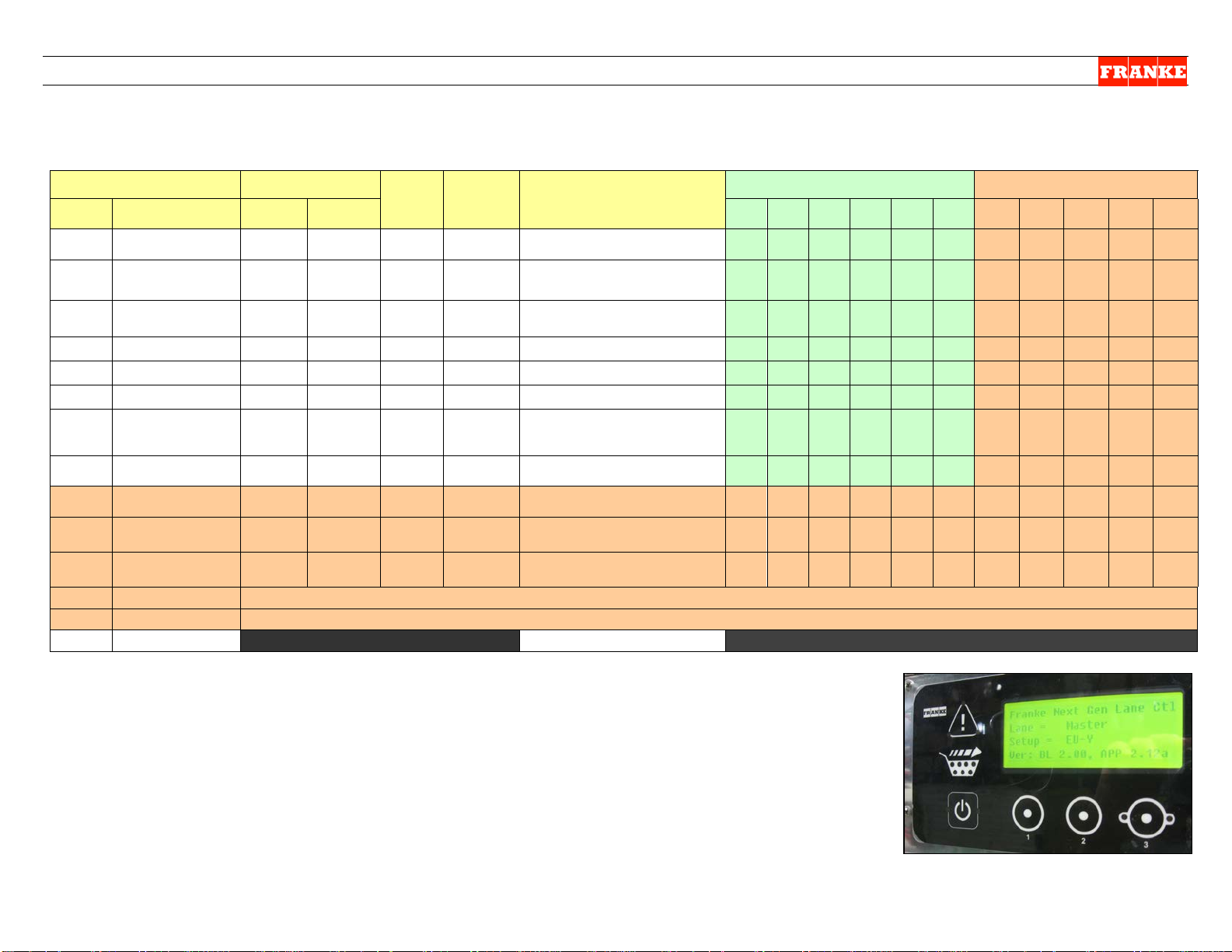

Software Version BL 2.00; APP 2.12a

On Lane Display

Parameter Table 1.11.1

Software Version: H47C1

On Chip Label*

Parameter Table 1.11.2

Software Version: H46P9

On Chip Label*

Parameter Table 1.11.3

NOTE: All programming is done using the three

1

3

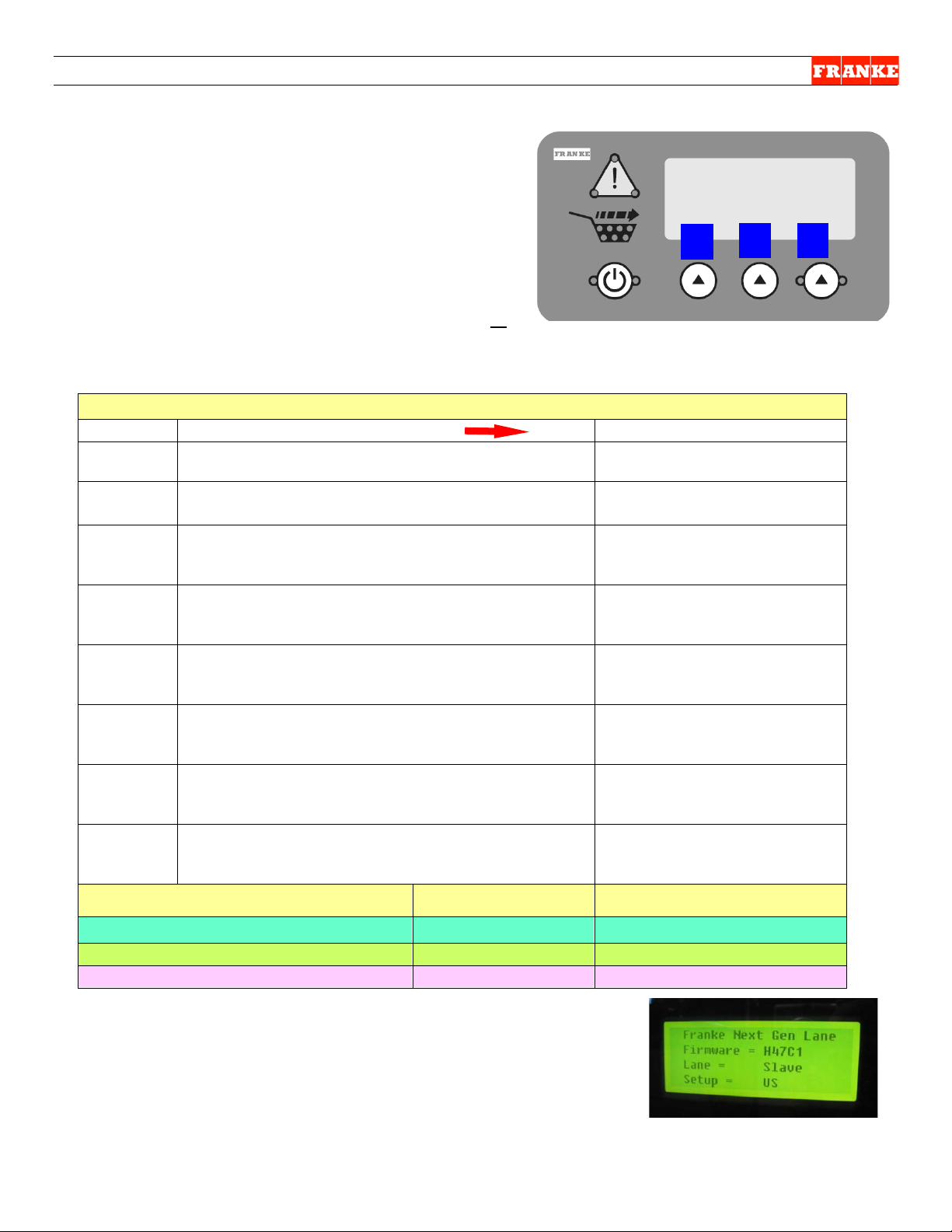

Parameter Access & Software Version

F3D3 Series Fries Dispensers provide easy access to

Factory Level operating and service diagnostic

parameters using the front operator interface touch

panel & display. To access:

1) Leave unit plugged in.

2) Turn Main Power Switch ON*.

3) Lane power must be OFF. Display will be blank or

show current freezer temperature, depending on

the model and lane.

choice buttons labeled: 1, 2 and 3 above.

Lev1 Lev3 Exit

2

3

4A

4B

4C

digit]

digit]

digit], then :

4D

5

For F3D3 Software Versi on To ID Version: Use Table:

∗ NOTE: The chip version is also displayed briefly during the

startup sequence ( a fter Calibration Valu es) , when the Main

POWER-ON switch is first turned ON. It appears as: Firmware =

H47C1, etc. on the second line.

Rev. 1 11/2012

Enter Password 0 _ _ _

Enter Password 0 0 _ _

Enter Password 0 0 0 _

Enter Password 0 0 0 0

Enter Password 0 0 0 1

P01 = English

Questions? Call Franke Technical Support Group For Your Area. Copyright 2012 Franke, Inc. All rights reserved.

Page 7

F3D3 Series Service Manual - Factory Lev3 Parameter Access / 1.11.1

To Access Factory Level 3 Parameters:

Step

Action Required

Resulting Display

1

From Standby condition use 3rd touchpad to

enter: 3 3 3 3. [The Entry Code]

Special Mode Select

Cust Fact Exit

2

Press touchpad 2 = Fact(ory)

Factory Access Level

Lev1 Lev3 Exit

Press touchpad 2 = Lev3

Password ??

Inc OK Exit

Press touchpad 2 = OK [Icon will move right to

Password ??

Inc OK Exit

Press touchpad 2 = OK [Icon will move right to

Password ??

Inc OK Exit

Press touchpad 2 = OK [Icon will move right to

Password ??

Inc OK Exit

Press touchpad 1 = Inc once, to raise to 1,

Password ??

Inc OK Exit

Press touchpad 2 = OK

Language [first Parameter]

++ -- ->

See Parameter Spreadsheet for P-numbers, functions & default settings.

NOTE Software Codes and exceptions that apply.

Notes:

Command Key: ++ to scroll up; -- to scroll down; -> to move flashing

underscore __ under next value; == to accept or OK value or setting

P02

Example:

Press 1 = ++ to increase temp. value [-0004]

Press 3 = == to accept (new) setting

Set Point [Refrig er at or t em p.]

++ -- ==

NOTE: All programming is done using the

1

2

3

Parameter Access & Programming

F3D3 Series Fries Dispensers provide easy

access to Factory Level operating and

service diagnostic parameters using the

front operator interface touch panel &

display. To access:

1) Leave unit plugged in.

2) Turn Main Power Switch ON.

3) Lane power must be OFF. Display will

be blank or show current freezer

temperature, depending on the lane.

three choice buttons labeled: 1, 2 and 3 above.

3

4A

4B

4C

4D

5

next digit]

next digit]

last digit], then:

then:

Enter Password 0 _ _ _

Enter Password 0 0 _ _

Enter Password 0 0 0 _

Enter Password 0 0 0 0

Enter Password 0 0 0 1

P01 = English

Set Point

Questions? Call Franke Technical Support Group For Your Area. Copyright 2012 Franke, Inc. All rights reserved.

Press 2 = -- to decrease temp. value [- 0006 ]

P02 = -0005 F

Rev. 1 6/2012

Page 8

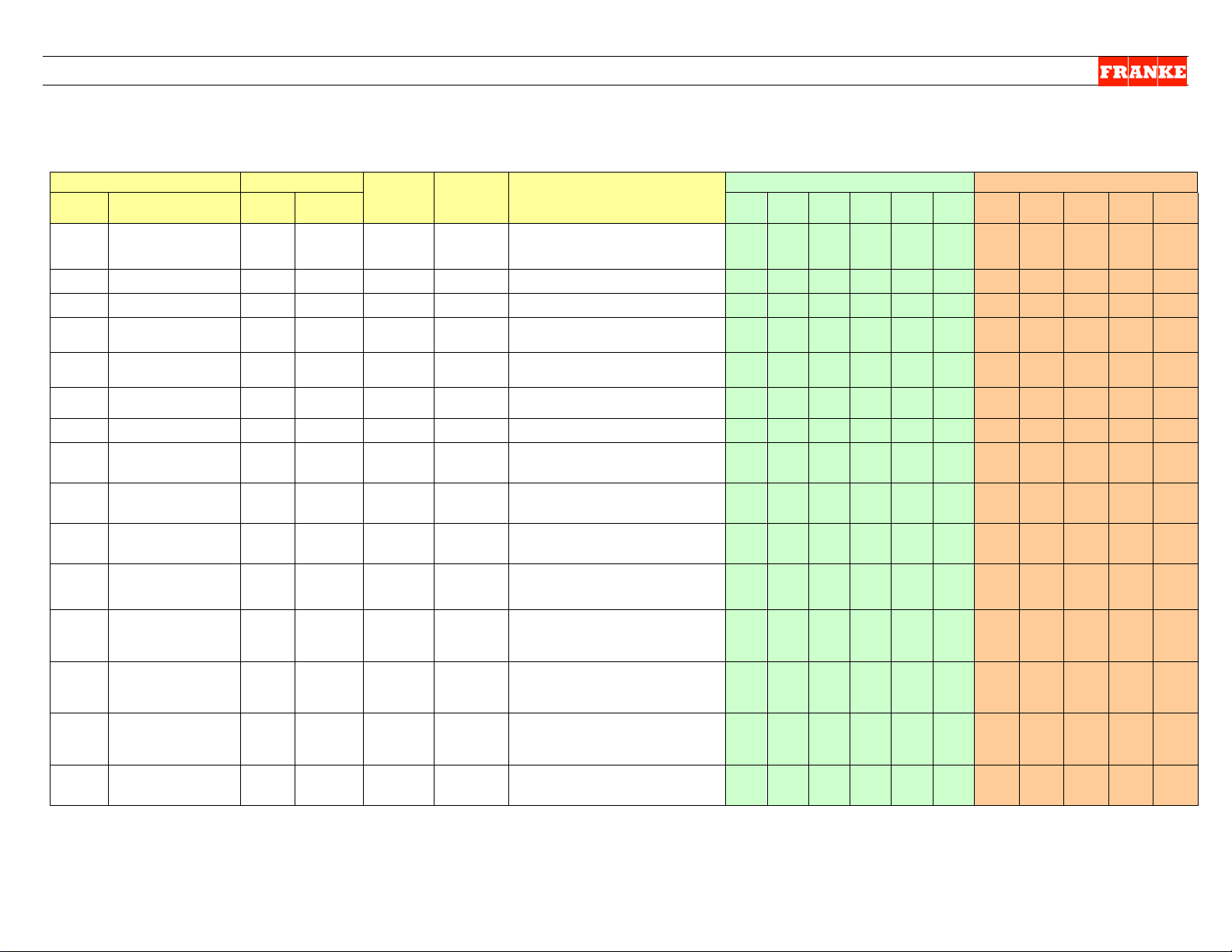

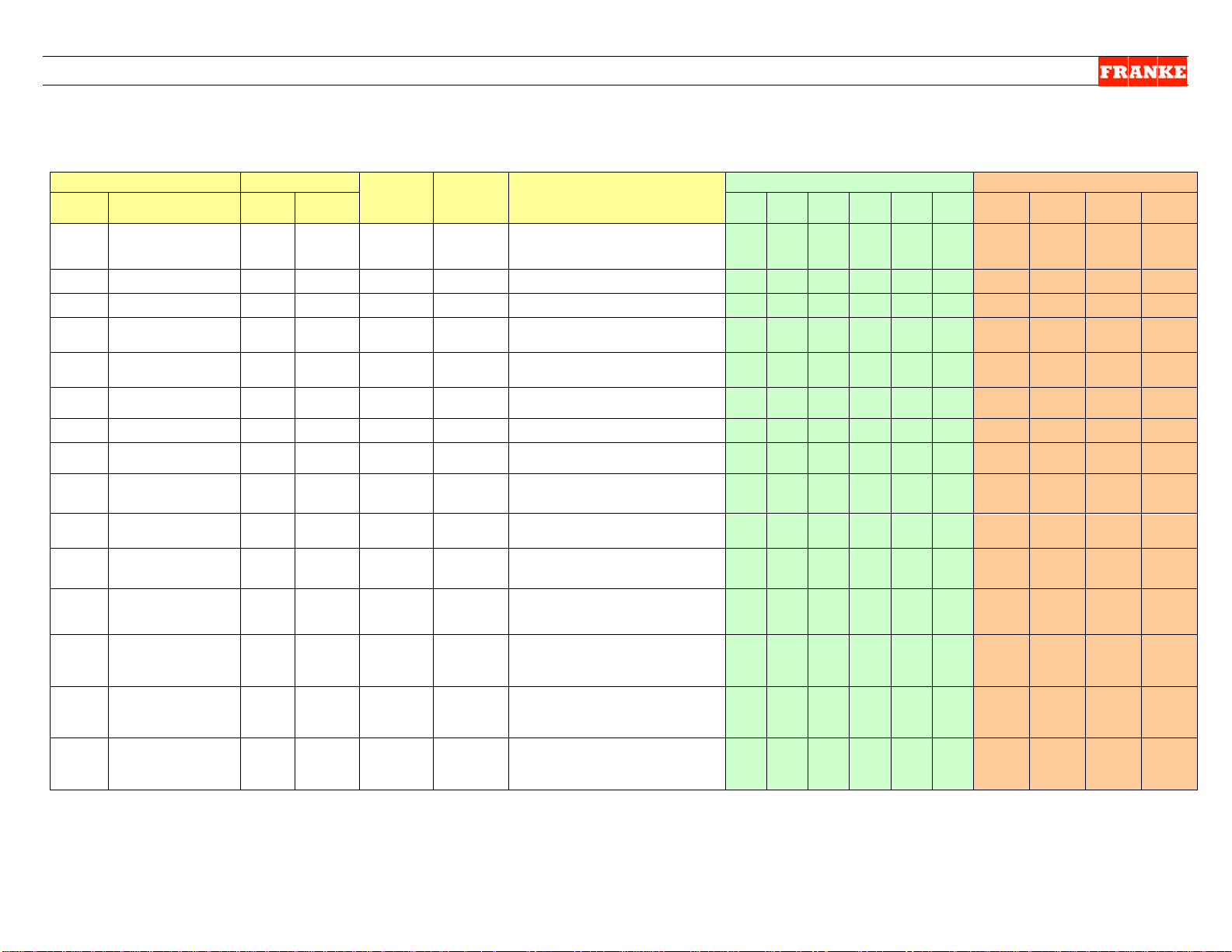

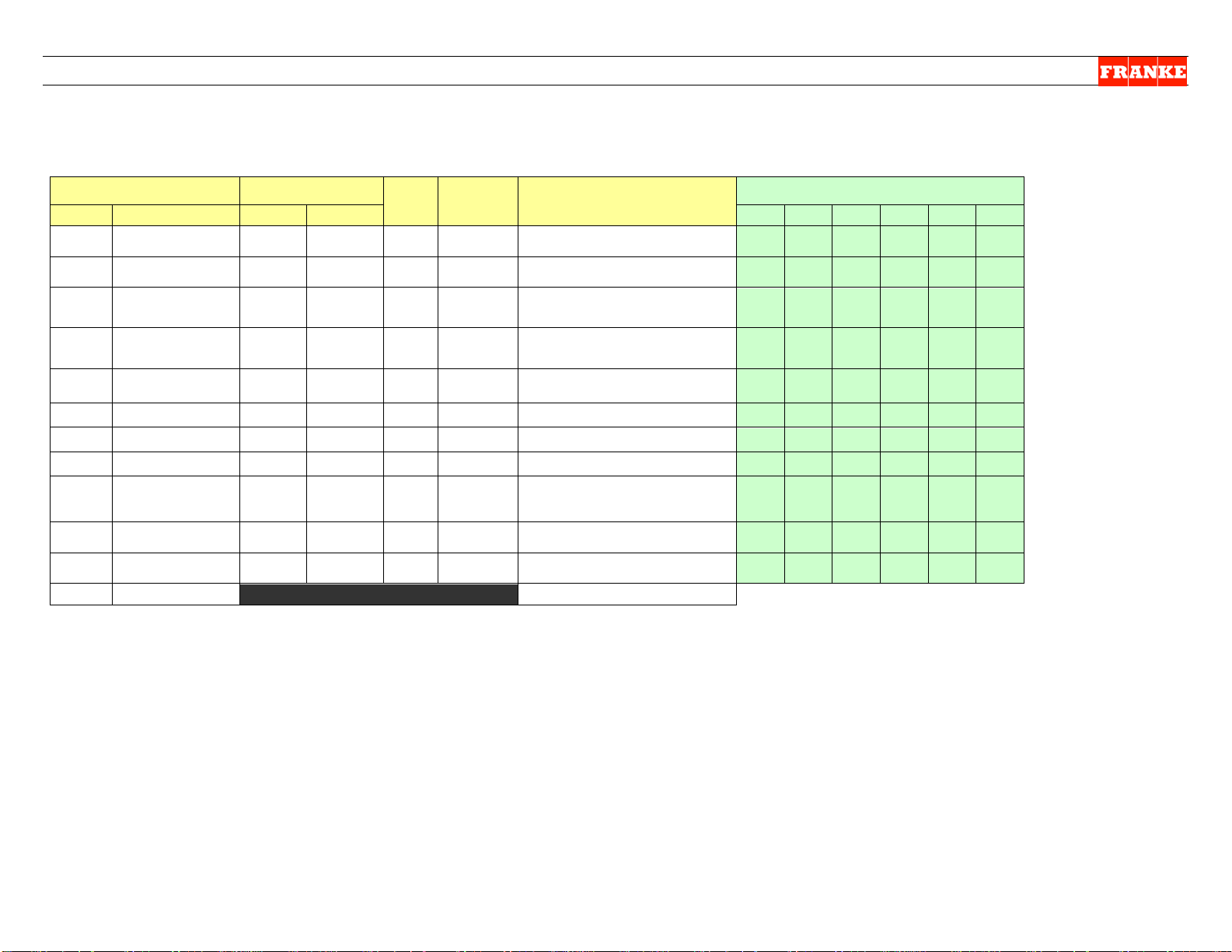

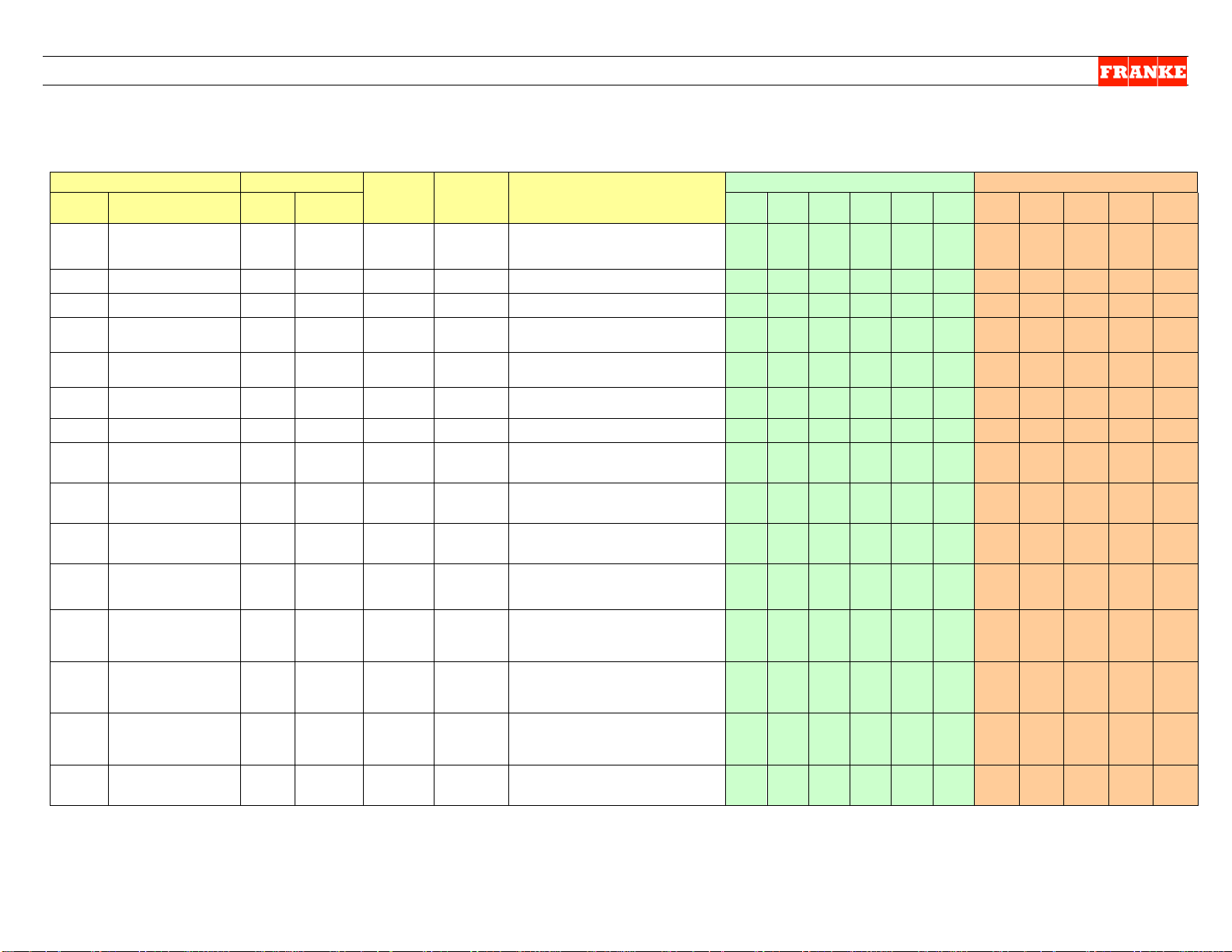

F3D3 Series Service Manual Factory Level 3 Parameter Access / 1.11.1

Parameter

Range

Unit3)

Default

Notes

Country Exceptions

No.

Name

Low

High

US

EU

JP

LA

CN

AP

EU-B

US-

GM

CAN-

GM

Other

-GM

EU-Y

P01

Language

1 5

1

1=English, 2=Deutsch,

5=French/English (Canada)

1 1 1 1 5 1 1 1 5 1 1

P02

Set Point

-50

20

Deg F

-5

Temperature set point

P03

Offset

P04

Point

-100

50

Deg F

40

alarm (LON Models only)

P05

High Alarm (Start

Up) Delay

1

300

minutes

100

signal, until message appears

P06

High Alarm Dwell

1

300

minutes

60

Temperature must remain (dwell)

for this time

P07

Hysteresis

0.5 5 Deg F

1.0

Used in temperature control

P09

Time

1

200

seconds

120

must be off before restarting.

P10

Down Shift LM

1

20=off

minutes

4

large to medium. 20 = Off

4 7 4 4 4 4 Off

Off

Off

Off

10

P11

Down Shift M1S

1

(20= off)

minutes

20 (off)

from medium to small. 20 = Off

Off 3 Off

Off

Off

Off

Off

Off

Off

Off

5

Off 7 Off

Off

Off

Off

Off

Off

Off

Off

10

P13

Thres(hold)

10

1500 750

counts/amp of motor current.

P14

Thres(hold)

10

1500 750

counts/amp of motor current.

Lift (Motor)

P16

Basket In Time

10

1500

mS

150

to trigger a dispense cycle

150

350

150

150

150

150

150

150

150

150

150

Factory Level 3 - Parameter Guide – Page 1

[For Latest Models with BL 2.00; APP 2.12a Chip Software1)]

Factory

3=Espanola, 4=Francais,

-30 30 Deg F 8 Temperature offset from sensor

High Alarm Set

Temperature that triggers a high

GM Exceptions

P12

P15

Compressor Off

Down Shift M2S

Drum (Motor)

Torq(ue)

Door (Motor)

Torq(ue)

Torq(ue)

Thres(hold)

(M)

(M)

(S)

19

19

1

10 1500 750

19

(20= off)

(M)

(M )

(M)

minutes 20 (off)

Time to wait after high alarm

Minimum time the compressor

Time for a size downshift from

Time for an initial size downshift

Time for subsequent size

downshift from medium to small.

20 = Off

Motor stops if threshold

exceeded. Approx 250

Motor stops if threshold

exceeded. Approx 250

Motor stops if threshold

exceeded. Approx 250

counts/motor current.

Time the basket must remain in

NOTES: 1) No Main Board Chip Label. Software Vers(ion): BL 2.00; APP 2.12a appears on Lane Display.

Questions? Call Franke Technical Support Group For Your Area. Copyright 2012 Franke, Inc. All rights reserved.

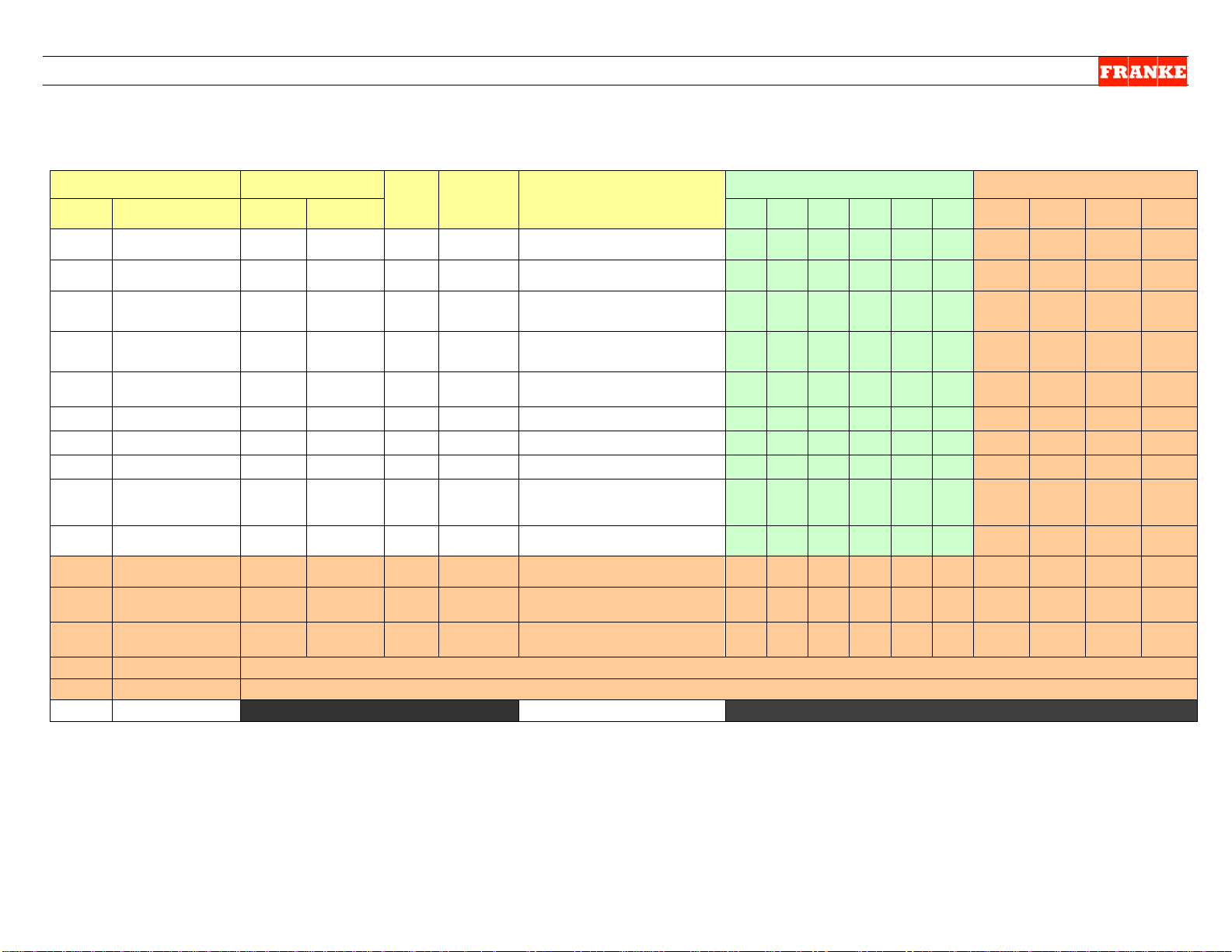

Page 9

F3D3 Series Service Manual Factory Level 3 Parameter Access / 1.11.1

Range

Unit3)

Default

Notes

Country Exceptions2)

No.

Name

Low

High

US

EU

JP

LA

CN

AP

EU-B

GM

GM

-GM

EU-Y

P17

Basket Out Time

10

1500

mS

50

out before enabling dispense

P18

Enable

Off

On On

being displayed.

P19

Enable

Off

On Off

slower) dispense for Japan.

Off

Off

On

Off

Off

Off

Off

Off

Off

Off

Off

P21

Large Fill Pct

P22

Medium Fill Pct

50

100

%

89

Reserved - Do not adjust.

P26

Toggle Rate

1 4

3

2 = Slow, 3 = Med, 4 = Fast)

P27

Display Units

C F

F

Temperature Display Units

Celsius or Fahrenheit

F C C C C C C F C

C

C

P28

Backdoor Type

English

Numeric

English

Displays numeric codes with

English or numeric codes only

Medium (Load)

75

P30

Factor

25

100 % 50

of large load

50

50

50

50

50

50

67

50

50

50

34

P31

Part Number

15 characters maximum. 1st must be 0-9 or F. 2nd must be 0-9, S, ‘.’ or ‘-‘. All others: 0-9, ‘-‘ or ‘.’

P32

Serial Number

P99

Factory Level 3 - Parameter Guide – Page 2

[For Latest Models with BL 2.00; APP 2.12a Chip Software1)]

Factory

Time the basket must remain

GM Exceptions

US-

CAN-

Other

P23

P29

Low Product

Hi Accuracy

Small Fill Pct

Dual Language

Factor

Small (Load)

Exit

50 100 % 90 Reserved - Do not adjust.

50 100 % 88 Reserved - Do not adjust.

25 100 % 67

15 characters maximum. All characters: 0-9 or ‘-‘

Prevents Low Product Warning

Enables high accuracy (but

If Dual Language is enabled,

this sets toggle rate: (1 = Off,

Weight of medium load as

percent of large load

Weight of small load as percent

Exits Level 3, if Entered

67 67 67 67 67 67 80 67 67 67

NOTES: 1) No Main Board Chip Label. Software Vers(ion): BL 2.00; APP 2.12a appears on Lane

Display. [How is this called up?]

2) Country Exceptions Abbreviations: US = North America; EU = Europe; JP = Japan; LA = Latin

America (South & Central); CN = Canada; AP = Asia, Pacific, Middle East & Australia

3) Unit Abbreviation: mS = Milliseconds

Questions? Call Franke Technical Support Group For Your Area. Copyright 2012 Franke, Inc. All rights reserved.

Page 10

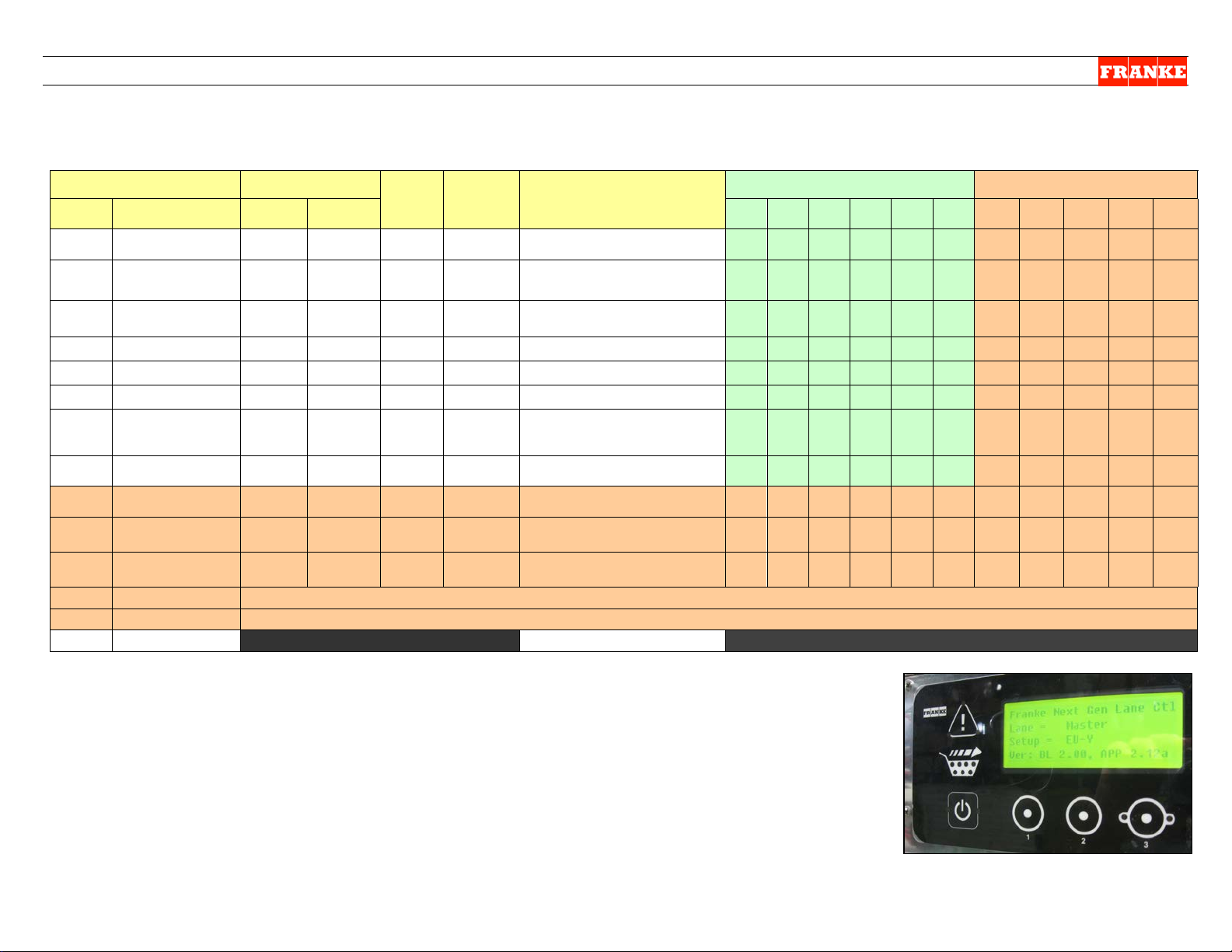

F3D3 Series Service Manual - Factory Lev3 Parameter Access / 1.11.2

To Access Factory Level 3 Parameters:

Step

Action Required

Resulting Display

1

From Standby condition use 3rd touchpad to

enter: 3 3 3 3. [The Entry Code]

Special Mode Select

Cust Fact Exit

2

Press touchpad 2 = Fact(ory)

Factory Access Level

Lev1 Lev3 Exit

Press touchpad 2 = Lev3

Password ??

Inc OK Exit

Press touchpad 2 = OK [Icon will move right to

Password ??

Inc OK Exit

Press touchpad 2 = OK [Icon will move right to

Password ??

Inc OK Exit

Press touchpad 2 = OK [Icon will move right to

Password ??

Inc OK Exit

Press touchpad 1 = Inc once, to raise to 1,

Password ??

Inc OK Exit

Press touchpad 2 = OK

Language [first Parameter]

++ -- ->

See Parameter Spreadsheet for P-numbers, functions & default settings.

NOTE Software Codes and exceptions that apply.

Notes:

Command Key: ++ to scroll up; -- to scroll down; -> to move flashing

underscore __ under next value; == to accept or OK value or setting

P02

Example:

Press 1 = ++ to increase temp. value [-0004]

Press 3 = == to accept (new) setting

Set Point [Refrig er at or t em p.]

++ -- ==

NOTE: All programming is done using the

1

2

3

Parameter Access & Programming

F3D3 Series Fries Dispensers provide easy

access to Factory Level operating and

service diagnostic parameters using the

front operator interface touch panel &

display. To access:

1) Leave unit plugged in.

2) Turn Main Power Switch ON.

3) Lane power must be OFF. Display will

be blank or show current freezer

temperature, depending on the lane.

three choice buttons labeled: 1, 2 and 3 above.

3

4A

4B

4C

4D

5

next digit]

next digit]

last digit], then:

then:

Enter Password 0 _ _ _

Enter Password 0 0 _ _

Enter Password 0 0 0 _

Enter Password 0 0 0 0

Enter Password 0 0 0 1

P01 = English

Set Point

Questions? Call Franke Technical Support Group For Your Area. Copyright 2012 Franke, Inc. All rights reserved.

Press 2 = -- to decrease temp. value [- 0006 ]

P02 = -0005 F

Rev. 1 11/2012

Page 11

F3D3 Series Service Manual Factory Level 3 Parameter Access / 1.11.2

Parameter

Range

Unit3)

Default

Notes

Country Exceptions

No.

Name

Low

High

US

EU

JP

LA

CN

AP

EU-B

US-GM

CAN-

GM

Other-

GM

P01

Language

1 5

1

1=English, 2=Deutsch,

5=French/English (Canada)

1 1 1 1 5 1 1 1 5

1

P02

Set Point

-50

20

Deg F

-5

Temperature set point

P03

Offset

P04

Point

-100

50

Deg F

40

alarm (LON Models only)

P05

High Alarm (Sta r t

Up) Delay

1

300

minutes

100

signal, until message appears

P06

High Alarm Dwell

1

300

minutes

60

Temperature must remain (dwell)

for this time

P07

Hysteresis

0.5 5 Deg F

1.0

Used in temperature control

P08

Ticks / Sec

1

100 60

keeping.

P09

Time

1

200

seconds

120

must be off before restarting.

P10

Down Shift LM

1

20=off

minutes

4

large to medium. 20 = Off

4 7 4 4 4 4 20

20

20

20

P11

Down Shift M1S

1

(20= off)

minutes

20 (off)

from medium to small. 20 = Off

20 3 20

20

20

20

20

20

20

20

P12

Down Shift M2S

1

(20= off)

minutes

20 (off)

20 = Off

20 7 20

20

20

20

20

20

20

20

P13

Thres(hold)

10

1500 750

counts/amp of motor current.

P14

Thres(hold)

10

1500 750

counts/amp of motor current.

P15

Lift (Motor)

Thres(hold)

10

1500 750

counts/motor current.

Factory Level 3 - Parameter Guide – Page 1

[For Models with firmware version F3D3 Main H47C1 ONLY

Factory

3=Espanola, 4=Francais,

-30 30 Deg F 8 Temperature offset from sensor

High Alarm Set

Temperature that triggers a high

1)

]

GM Exceptions

Compressor Off

Drum (Motor)

Torq(ue)

Door (Motor)

Torq(ue)

Torq(ue)

19

19

19

(M)

(M)

(S)

(M)

(M )

(M)

Time to wait after high alarm

Used to correct onboard time

Minimum time the compressor

Time for a size downshift from

Time for an initial size downshift

Time for subsequent size

downshift from medium to small.

Motor stops if threshold

exceeded. Approx 250

Motor stops if threshold

exceeded. Approx 250

Motor stops if threshold

exceeded. Approx 250

NOTES: 1) Software version is printed on label on Main Control Board Chip.

Questions? Call Franke Technical Support Group For Your Area. Copyright 2012 Franke, Inc. All rights reserved.

Page 12

F3D3 Series Service Manual Factory Level 3 Parameter Access / 1.11.2

Range

Unit3)

Default

Notes

Country Exceptions2)

No.

Name

Low

High

US

EU

JP

LA

CN

AP

EU-B

US-GM

GM

GM

P16

Basket In Time

10

1500

mS

150

to trigger a dispense cycle

150

350

150

150

150

150

150

150

150

150

P17

Basket Out Time

P18

Enable

Enable

Off

On Off

slower) dispense for Japan.

Off

Off

On

Off

Off

Off

Off

Off

Off

Off

P20

Enable

Off

On Off

calibration. (Off or On)

P21

Large Fill Pct

P22

Medium Fill Pct

50

100

%

89

Reserved - Do not adjust.

Small Fill Pct

50

100 % 88

Reserved - Do not adjust.

P26

Toggle Rate

1 4

3

2 = Slow, 3 = Med, 4 = Fast)

P27

Display Units

C F

F

Temperature Display Units

Celsius or Fahrenheit

F C C C C C C F C

C

P28

Backdoor Type

English

Numeric

English

Displays numeric codes with

English or numeric codes only

P29

Medium (Load)

Factor

67

67

67

67

67

67

80

67

67

67

P30

Factor

25

100 % 50

of large load

50

50

50

50

50

50

67

50

50

50

P31

Part Number

15 characters maximum. 1st must be 0-9 or F. 2nd must be 0-9, S, ‘.’ or ‘-‘. All others: 0-9, ‘-‘ or ‘.’

P32

Serial Number

15 characters maximum. All character s : 0-9 or ‘-‘

Exits Level 3, if Entered

P19

P23

Low Product

Hi Accuracy

Large Load

Dual Language

Factory Level 3 - Parameter Guide – Page 2

[For Models with firmware version F3D3 Main H47C1 ONLY

Factory

Time the basket must remain in

10 1500 mS 50

Off On On

50 100 % 90 Reserved - Do not adjust.

Time the basket must remain

out before enabling dispense

Prevents Low Product Warning

being displayed.

Enables high accuracy (but

Enables use of 1Kg load for

If Dual Language is enabled,

this sets toggle rate: (1 = Off,

1)

]

GM Exceptions

CAN-

Other-

Weight of medium load as

percent of large load

Weight of small load as percent

P99

Small (Load)

Exit

25 100 % 67

NOTES: 1) Software version is printed on label on Main Control Board Chip.

2) Country Exceptions Abbreviations: US = North America; EU = Europe; JP = Japan; LA = Latin

America (South & Central); CN = Canada; AP = Asia, Pacific, Middle East & Australia

3) Unit Abbreviation: mS = Milliseconds

Questions? Call Franke Technical Support Group For Your Area. Copyright 2012 Franke, Inc. All rights reserved.

Page 13

F3D3 Series Service Manual - Factory Lev3 Parameter Access / 1.11.3

To Access Factory Level 3 Parameters:

Step

Action Required

Resulting Display

1

From Standby condition use 3rd touchpad to

enter: 3 3 3 3. [The Entry Code]

Special Mode Select

Cust Fact Exit

2

Press touchpad 2 = Fact(ory)

Factory Access Level

Lev1 Lev3 Exit

Press touchpad 2 = Lev3

Password ??

Inc OK Exit

Press touchpad 2 = OK [Icon will move right to

Password ??

Inc OK Exit

Press touchpad 2 = OK [Icon will move right to

Password ??

Inc OK Exit

Press touchpad 2 = OK [Icon will move right to

Password ??

Inc OK Exit

Press touchpad 1 = Inc once, to raise to 1,

Password ??

Inc OK Exit

Press touchpad 2 = OK

Language [first Parameter]

++ -- ->

See Parameter Spreadsheet for P-numbers, functions & default settings.

NOTE Software Codes and exceptions that apply.

Notes:

Command Key: ++ to scroll up; -- to scroll down; -> to move flashing

underscore __ under next value; == to accept or OK value or setting

P02

Example:

Press 1 = ++ to increase temp. value [-0004]

Press 3 = == to accept (new) setting

Set Point [Refrig er at or t em p.]

++ -- ==

NOTE: All programming is done using the

1

2

3

Parameter Access & Programming

F3D3 Series Fries Dispensers provide easy

access to Factory Level operating and

service diagnostic parameters using the

front operator interface touch panel &

display. To access:

1) Leave unit plugged in.

2) Turn Main Power Switch ON.

3) Lane power must be OFF. Display will

be blank or show current freezer

temperature, depending on the lane.

three choice buttons labeled: 1, 2 and 3 above.

3

4A

4B

4C

4D

5

next digit]

next digit]

last digit], then:

then:

Enter Password 0 _ _ _

Enter Password 0 0 _ _

Enter Password 0 0 0 _

Enter Password 0 0 0 0

Enter Password 0 0 0 1

P01 = English

Set Point

Questions? Call Franke Technical Support Group For Your Area. Copyright 2012 Franke, Inc. All rights reserved.

Press 2 = -- to decrease temp. value [- 0006 ]

P02 = -0005 F

Rev. 1 11/2012

Page 14

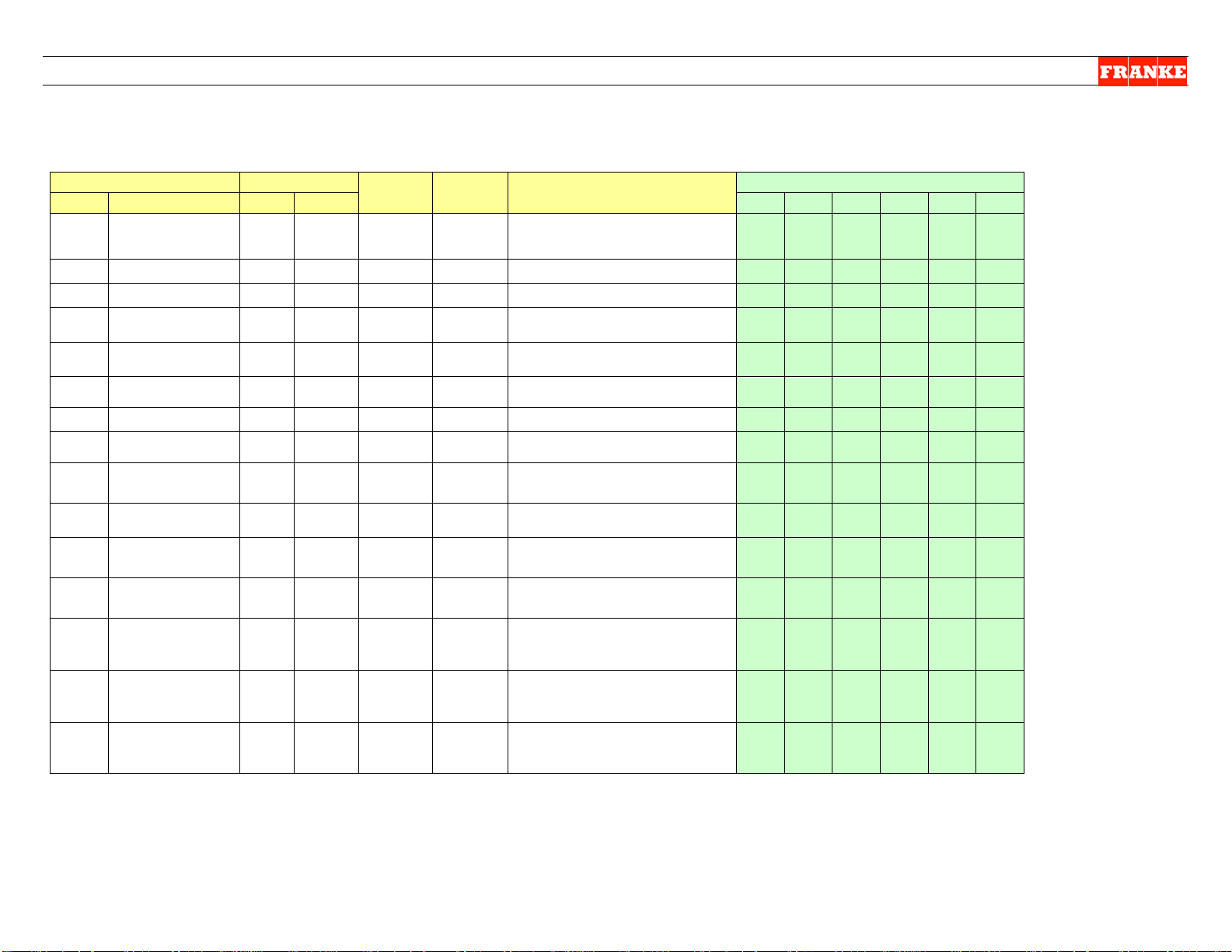

F3D3 Series Service Manual Factory Level 3 Parameter Access / 1.11.3

Parameter

Range

Unit3)

Default

Notes

Country Exceptions

No.

Name

Low

High

US

EU

JP

LA

CN

AP

P01

Language

1 5

1

1=English, 2=Deutsch,

5=French/English (Canada)

1 1 1 1 5

1

P02

Set Point

-50

20

Deg F

-5

Temperature set point

P03

Offset

-30

30

Deg F

0

Temperature offset from sensor

P04

High Alarm Set

Point

-100

50

Deg F

40

alarm (LON Models only)

P05

High Alarm (Sta r t

Up) Delay

1

300

minutes

100

signal, until message appears

P06

High Alarm Dwell

1

300

minutes

60

for this time

P07

Hysteresis

0.5 5 Deg F

1.0

Used in temperature control

P08

Ticks / Sec

1

100 60

Used to correct onboard time

keeping.

P09

Time

1

200

seconds

120

must be off before restarting.

P10

Down Shift LM

1

20=off

minutes

4

large to medium. 20 = Off

4 7 4 4 4

4

P11

Down Shift M1S

1

(20= off)

minutes

20 (off)

from medium to small. 20 = Off

20 3 20

20

20

20

P12

Down Shift M2S

1

(20= off)

minutes

20 (off)

from medium to small. 20 = Off

20 7 20

20

20

20

P13

Drum (Motor)

Thres(hold)

10

1500 750

current.

P14

Thres(hold)

10

1500 750

current.

P15

Thres(hold)

10

1500 750

Approx 250 counts/motor current.

NOTES: 1) Software version is printed on label on Main Control Board Chip.

Factory Level 3 - Parameter Guide – Page 1

[For Models with firmware version F3D3 Main H46P9 ONLY

Factory

3=Espanola, 4=Francais,

Temperature that triggers a high

1)

]

Compressor Off

Torq(ue)

Door (Motor)

Torq(ue)

Lift (Motor)

Torq(ue)

19

19

19

(M)

(M)

(S)

(M)

(M )

(M)

Time to wait after high alarm

Temperature must remain (dwell)

Minimum time the compressor

Time for a size downshift from

Time for an initial size downshift

Time for subsequent size downshift

Motor stops if threshold exceeded.

Approx 250 counts/amp of motor

Motor stops if threshold exceeded.

Approx 250 counts/amp of motor

Motor stops if threshold exceeded.

2) Country Exceptions Abbreviations: US = North America; EU = Europe; JP = Japan; LA = Latin

America (South & Central); CN = Canada; AP = Asia, Pacific, Middle East & Australia

Questions? Call Franke Technical Support Group For Your Area. Copyright 2012 Franke, Inc. All rights reserved.

Page 15

F3D3 Series Service Manual Factory Level 3 Parameter Access / 1.11.3

Parameter

Range

Unit3)

Default

Notes

Country Exceptions2)

No.

Name

Low

High

US

EU

JP

LA

CN

AP

P16

Basket In Time

10

1500

mS

150

to trigger a dispense cycle

150

350

150

150

150

150

P17

Basket Out Time

10

1500

mS

50

Time the basket must remain out

before enabling dispense

P18

Enable

Off

On On

being displayed.

P19

Enable

Off

On Off

slower) dispense for Japan.

Off

Off

On

Off

Off

Off

P20

Enable

Off

On Off

calibration. (Off or On)

P21

Large Fill Pct

50

100 % 90

Reserved - Do not adjust.

P22

Medium Fill Pct

50

100

%

89

Reserved - Do not adjust.

P23

Small Fill Pct

50

100 % 88

Reserved - Do not adjust.

P26

Toggle Rate

1 4

3

If Dual Language is enabled, this

Slow, 3 = Med, 4 = Fast)

P27

Display Units

C F

F

Celsius or Fahrenheit

F C C C C

C

P28

Backdoor Type

English

Numeric

English

English or numeric codes only

P99

Exit

Exits Level 3, if Entered

Low Product

Hi Accuracy

Large Load

Dual Language

Factory Level 3 - Parameter Guide – Page 2

[For Models with firmware version F3D3 Main H46P9 ONLY

Factory

Time the basket must remain in

Prevents Low Product Warning

Enables high accuracy (but

Enables use of 1Kg load for

sets toggle rate: (1 = Off, 2 =

Temperature Display Units

Displays numeric codes with

1)

]

NOTES: 1) Software version is printed on label on Main Control Board Chip.

2) Country Exceptions Abbreviations: US = North America; EU = Europe; JP = Japan; LA = Latin

America (South & Central); CN = Canada; AP = Asia, Pacific, Middle East & Australia

3) Unit Abbreviation: mS = Milliseconds

Questions? Call Franke Technical Support Group For Your Area. Copyright 2012 Franke, Inc. All rights reserved.

Page 16

F3D3 Series Service Manual - Display Menu for H46N Firmware/ 1.11.4

To Access Factory Level 3 Parameters:

Step

Action Required

Resulting Display

1

From Standby condition use 3rd touchpad to

enter: 3 3 3 3. [The Entry Code]

Special Mode Select

Cust Fact Exit

2

Press touchpad 2 = Fact(ory)

Factory Access Level

Lev1 Lev3 Exit

Press touchpad 2 = Lev3

Password ??

Inc OK Exit

Press touchpad 2 = OK [Icon will move right to

Password ??

Inc OK Exit

Press touchpad 2 = OK [Icon will move right to

Password ??

Inc OK Exit

Press touchpad 2 = OK [Icon will move right to

Password ??

Inc OK Exit

Press touchpad 1 = Inc once, to raise to 1,

Password ??

Inc OK Exit

5

Press touchpad 2 = OK

Special Mode Select

(Go to Page 2)

NOTE: All programming is done using the

1

2

3

Parameter Access & Programming

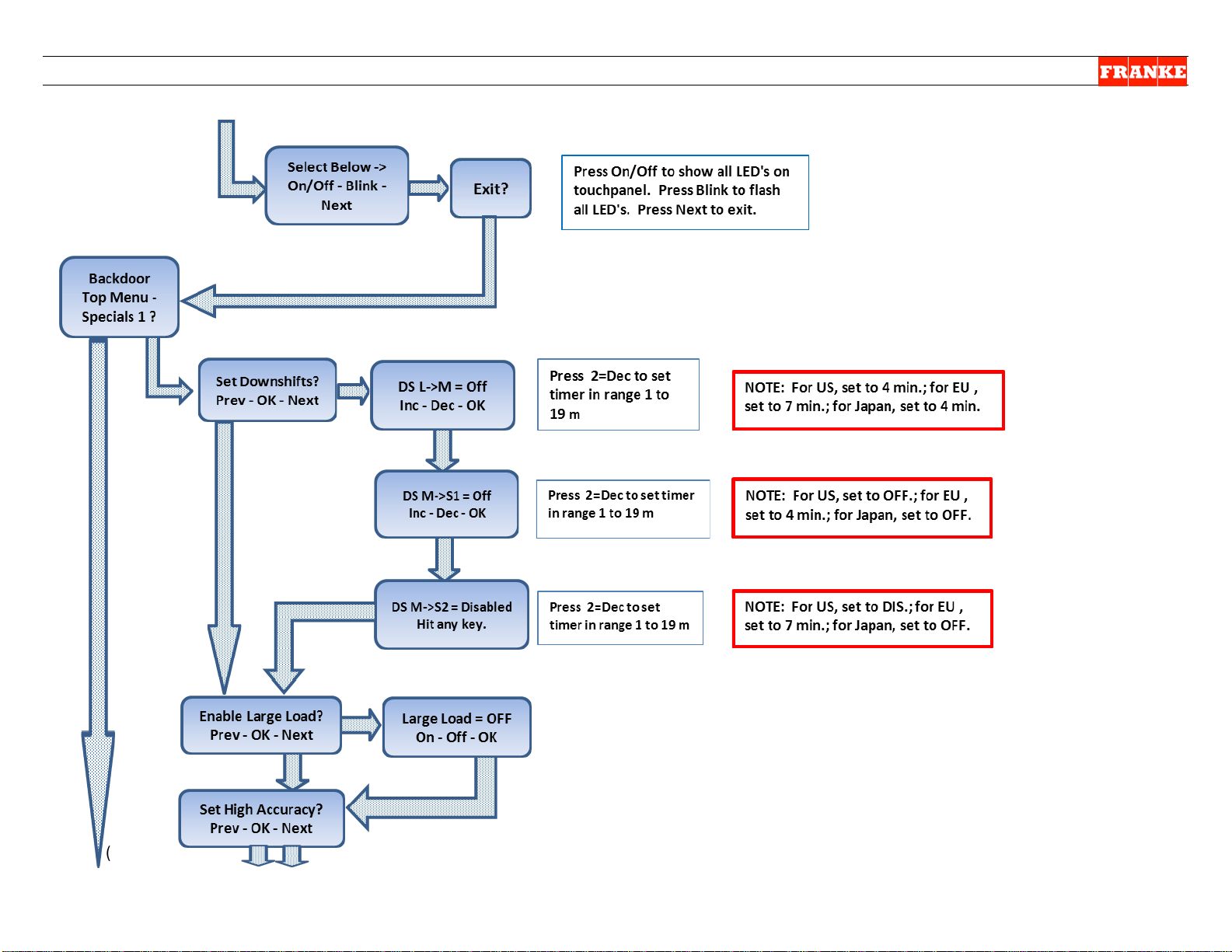

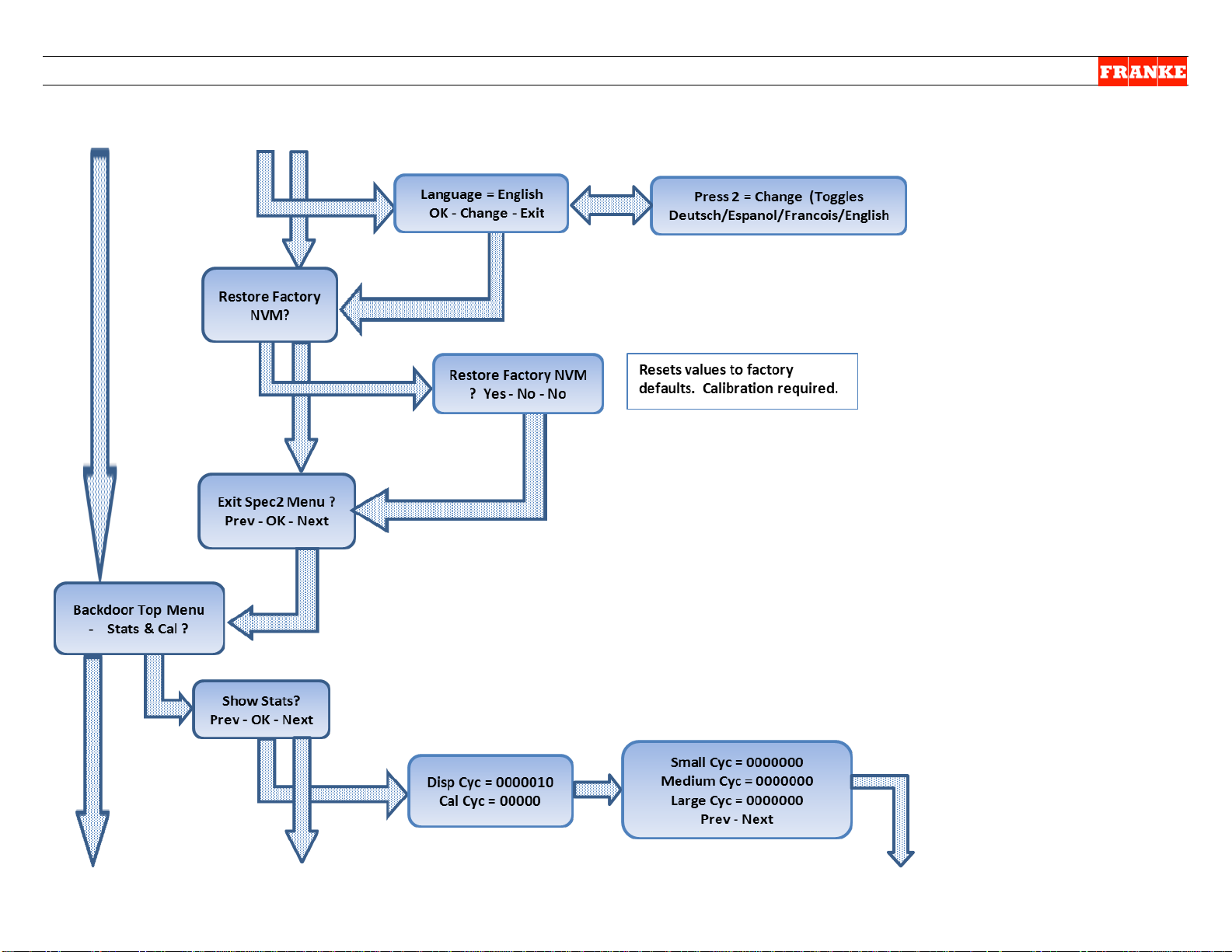

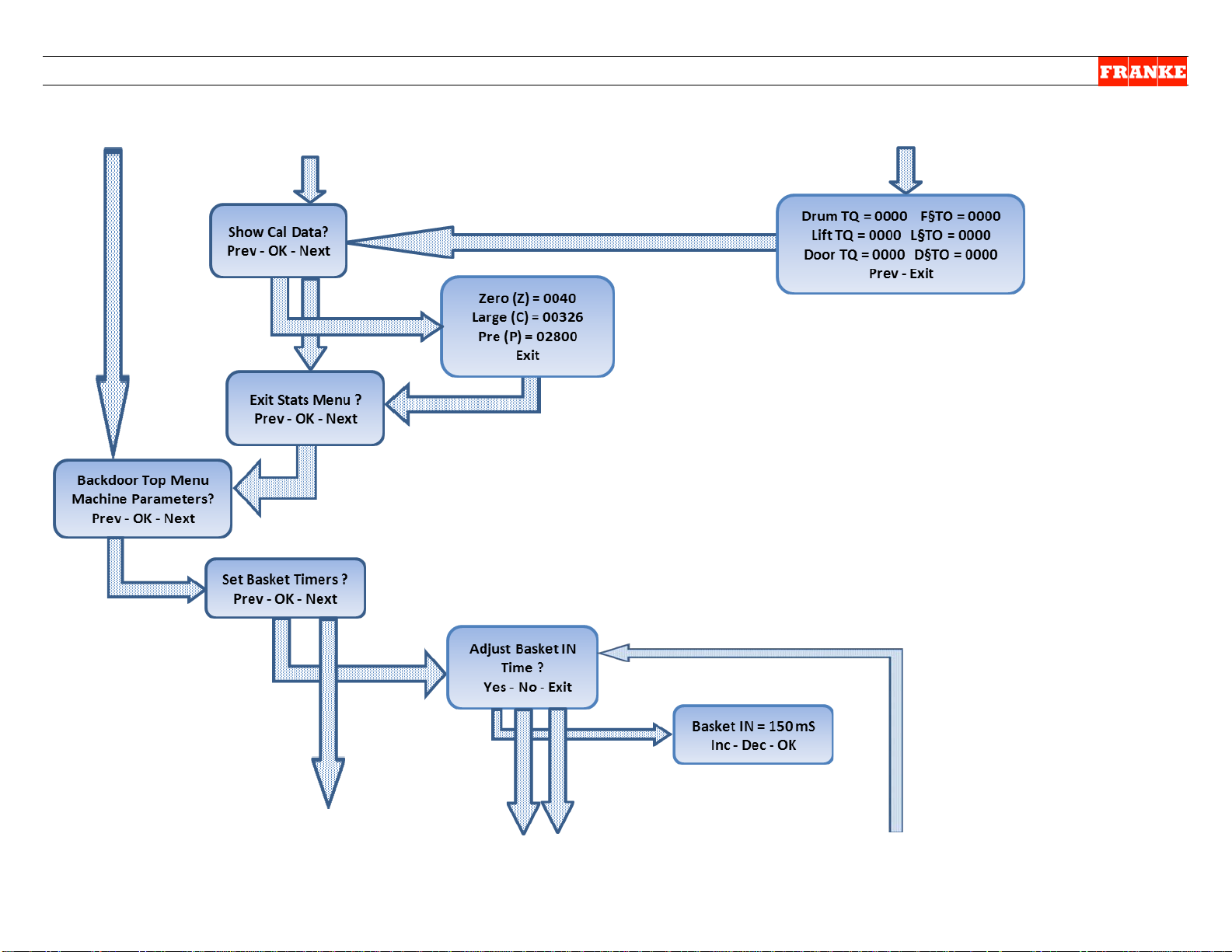

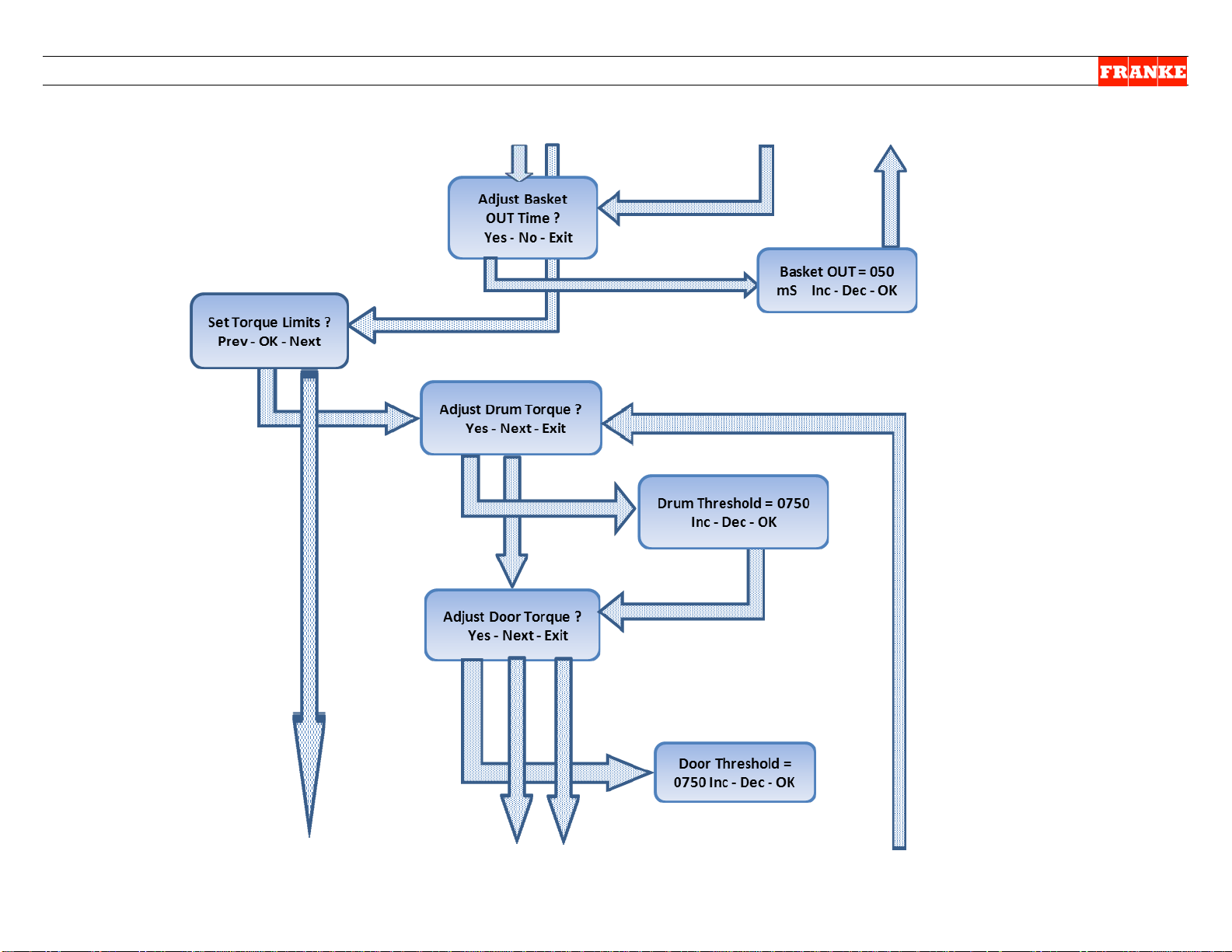

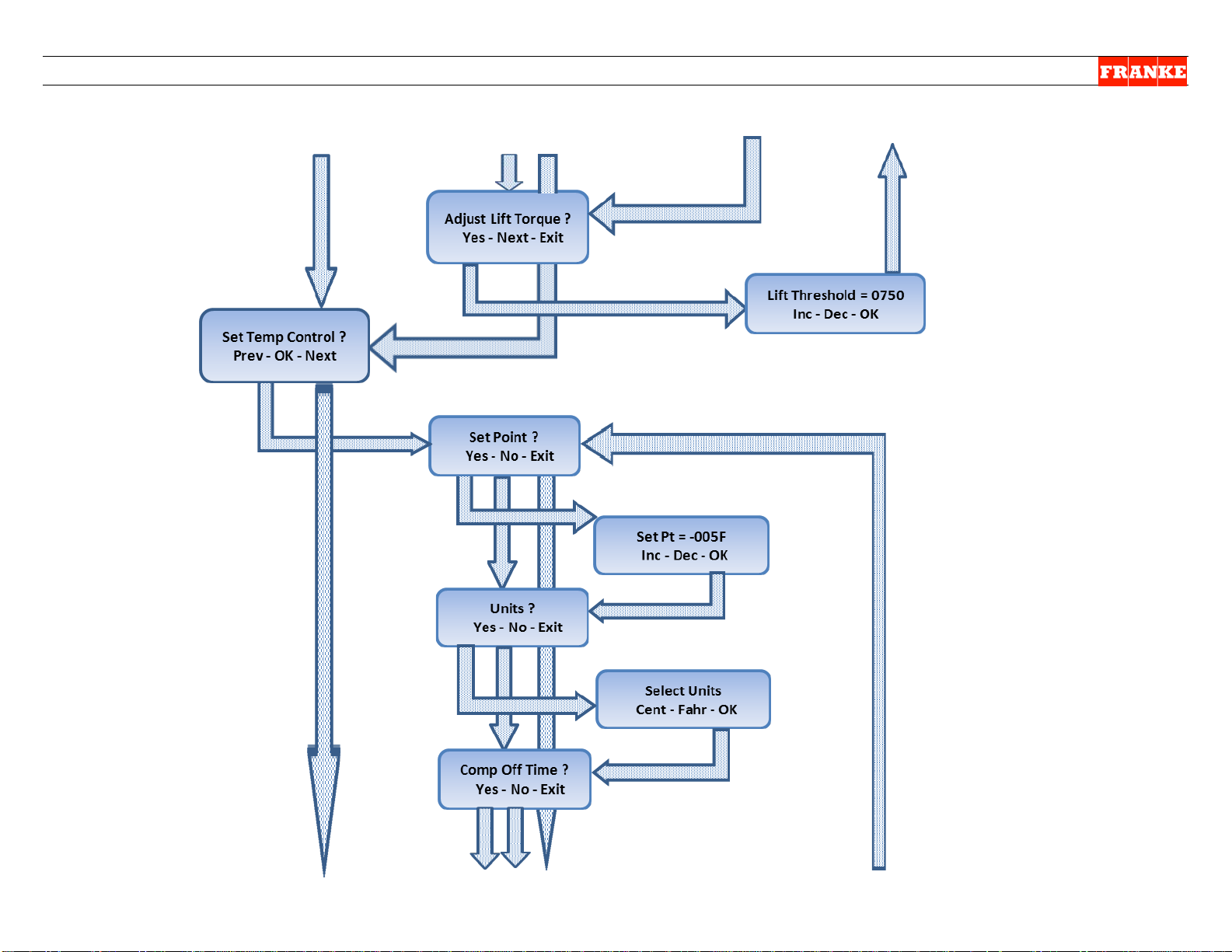

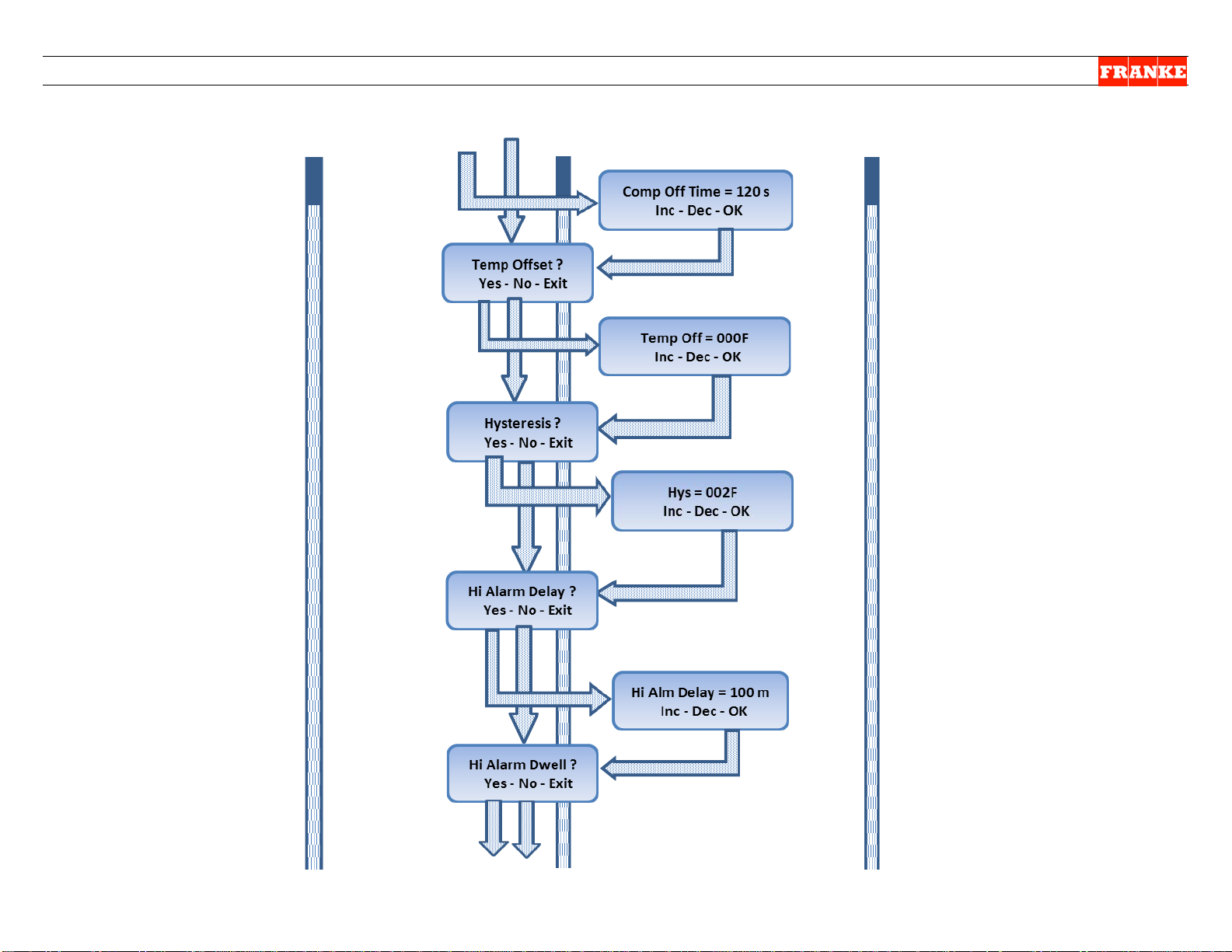

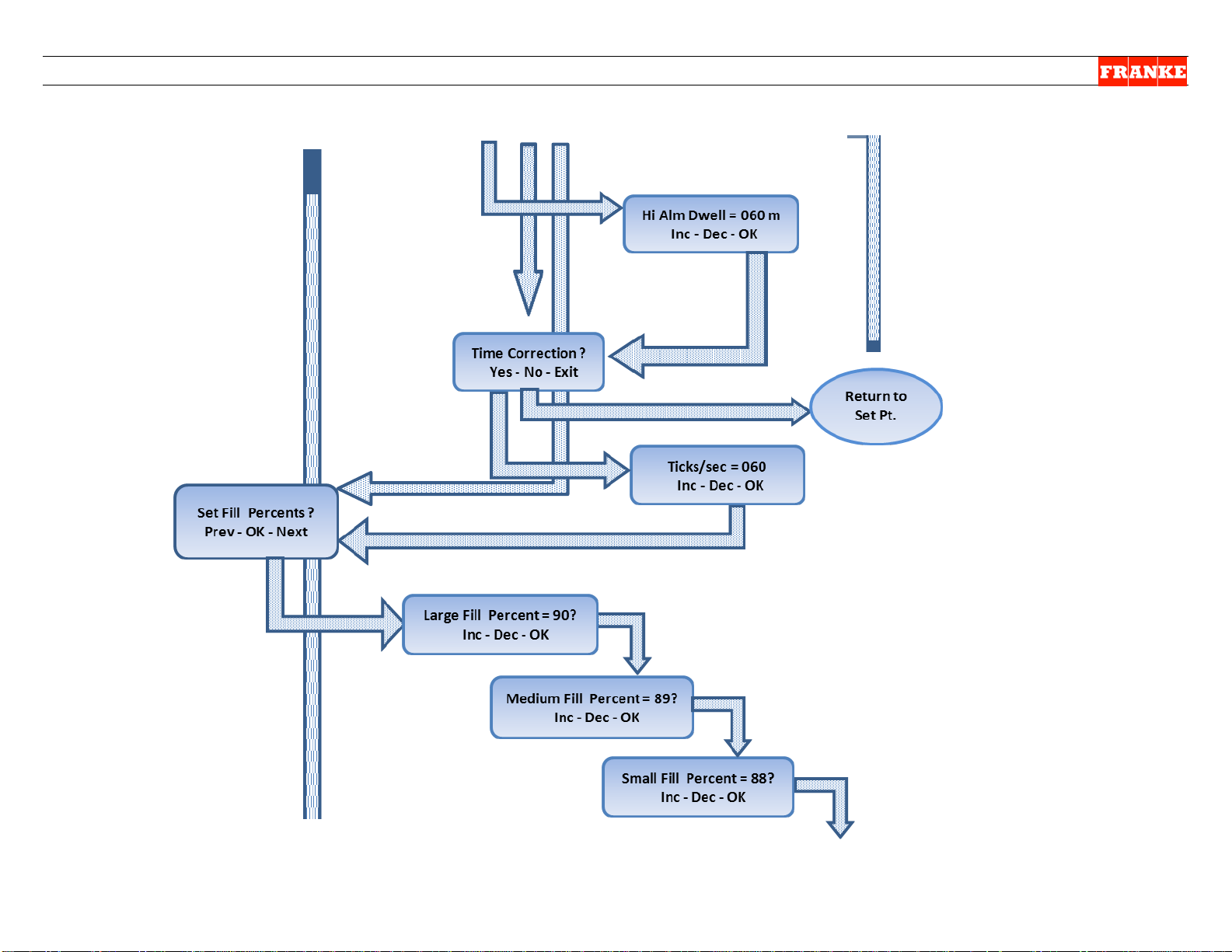

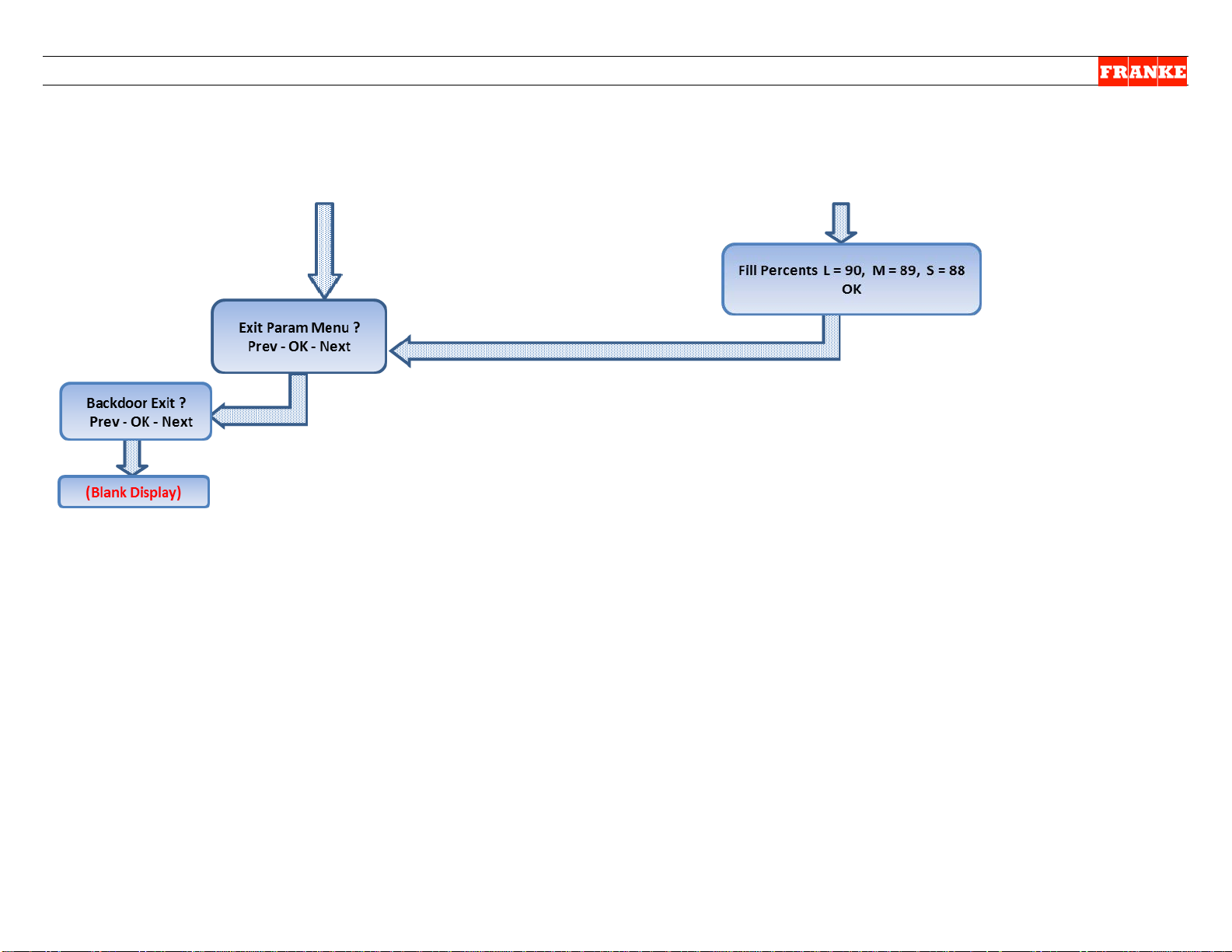

The original F3D3 Models (with H46N

Firmware) were programmed with Factory

Level operating and service diagnostic

parameters that required sequential boredown through multiple l evels, to check or

make any changes. Using the front

operator interface touch panel & display

to access:

1) Leave unit plugged in.

2) Turn Main Power Switch ON.

3) Lane power must be OFF. Display will

be blank or show current freezer

temperature, depending on the lane.

three choice buttons labeled: 1, 2 and 3 above.

3

4A

4B

4C

4D

next digit]

next digit]

last digit], then:

then:

Enter Password 0 _ _ _

Enter Password 0 0 _ _

Enter Password 0 0 0 _

Enter Password 0 0 0 0

Enter Password 0 0 0 1

Follow Flow Chart Diagr am on pa ges 2-12 to access Parameters.

Rev. 1 11/2012

Questions? Call Franke Technical Support Group For Your Area. Copyright 2012 Franke, Inc. All rights reserved.

Page 17

(Go to P age 3)

Page 2

For Models with Firmware F3D3 Main Version: H46N ONLY

Questions? Call Franke Technical Support Group For Your Area. Copyright 2012 Franke, Inc. All rights reserved.

Page 18

F3D3 Series Service Manual Display Menu for H46N Firmware/ 1.11.4

(From Page 2)

(Go to Pag e 4)

Page 3

For Models with Firmware F3D3 Main Version: H46N ONLY

Questions? Call Franke Technical Support Group For Your Area. Copyright 2012 Franke, Inc. All rights reserved.

Page 19

F3D3 Series Service Manual Display Menu for H46N Firmware/ 1.11.4

(From Page 3)

(Go to Page 5)

Page 4

For Models with Firmware F3D3 Main Version: H46N ONLY

Questions? Call Franke Technical Support Group For Your Area. Copyright 2012 Franke, Inc. All rights reserved.

Page 20

F3D3 Series Service Manual Display Menu for H46N Firmware/ 1.11.4

(From page 4)

(Go to P age 6)

Page 5

For Models with Firmware F3D3 Main Version: H46N ONLY

Questions? Call Franke Technical Support Group For Your Area. Copyright 2012 Franke, Inc. All rights reserved.

Page 21

F3D3 Series Service Manual Display Menu for H46N Firmware/ 1.11.4

(Go to P age 7)

Page 6

For Models with Firmware F3D3 Main Version: H46N ONLY

(From page 5)

Questions? Call Franke Technical Support Group For Your Area. Copyright 2012 Franke, Inc. All rights reserved.

Page 22

F3D3 Series Service Manual Display Menu for H46N Firmware/ 1.11.4

(From page 6)

(Go to P age 8)

Page 7

For Models with Firmware F3D3 Main Version: H46N ONLY

Questions? Call Franke Technical Support Group For Your Area. Copyright 2012 Franke, Inc. All rights reserved.

Page 23

F3D3 Series Service Manual Display Menu for H46N Firmware/ 1.11.4

(Go to P age 9)

Page 8

For Models with Firmware F3D3 Main Version: H46N ONLY

(From Page 7)

Questions? Call Franke Technical Support Group For Your Area. Copyright 2012 Franke, Inc. All rights reserved.

Page 24

F3D3 Series Service Manual Display Menu for H46N Firmware/ 1.11.4

(Go to p age 10)

Page 9

For Models with Firmware F3D3 Main Version: H46N ONLY

(From Page 8)

Questions? Call Franke Technical Support Group For Your Area. Copyright 2012 Franke, Inc. All rights reserved.

Page 25

F3D3 Series Service Manual Display Menu for H46N Firmware/ 1.11.4

(Go to P age 11)

Page 10

For Models with Firmware F3D3 Main Version: H46N ONLY

(From Page 9)

Questions? Call Franke Technical Support Group For Your Area. Copyright 2012 Franke, Inc. All rights reserved.

Page 26

F3D3 Series Service Manual Display Menu for H46N Firmware/ 1.11.4

Page 11

For Models with Firmware F3D3 Main Version: H46N ONLY

(From Page 10)

(Go to Page 12)

Questions? Call Franke Technical Support Group For Your Area. Copyright 2012 Franke, Inc. All rights reserved.

Page 27

F3D3 Series Service Manual Display Menu for H46N Firmware/ 1.11.4

Page 12

For Models with Firmware F3D3 Main Version: H46N ONLY

(From page 11)

Questions? Call Franke Technical Support Group For Your Area. Copyright 2012 Franke, Inc. All rights reserved.

Page 28

F3D3 Series Service Manual - Factory Lev3 Parameter Access / 1.11A

To Access Factory Level 3 Parameters:

Step

Action Required

Resulting Display

1

From Standby condition use 3rd touchpad to

enter: 3 3 3 3. [The Entry Code]

Special Mode Select

Cust Fact Exit

2

Press touchpad 2 = Fact(ory)

Factory Access Level

Lev1 Lev3 Exit

Press touchpad 2 = Lev3

Password ??

Inc OK Exit

Press touchpad 2 = OK [Icon will move right to

Password ??

Inc OK Exit

Press touchpad 2 = OK [Icon will move right to

Password ??

Inc OK Exit

Press touchpad 2 = OK [Icon will move right to

Password ??

Inc OK Exit

Press touchpad 1 = Inc once, to raise to 1,

Password ??

Inc OK Exit

Press touchpad 2 = OK

Language [first Parameter]

++ -- ->

See Parameter Spreadsheet for P-numbers, functions & default settings.

NOTE Software Codes and exceptions that apply.

Notes:

Command Key: ++ to scroll up; -- to scroll down; -> to move flashing

underscore __ under next value; == to accept or OK value or setting

P02

Example:

Press 1 = ++ to increase temp. value [-0004]

Press 3 = == to accept (new) setting

Set Point [Refrig er at or t em p.]

++ -- ==

NOTE: All programming is done using the

1

2

3

Parameter Access & Programming

F3D3 Series Fries Dispensers provide easy

access to Factory Level operating and

service diagnostic parameters using the

front operator interface touch panel &

display. To access:

1) Leave unit plugged in.

2) Turn Main Power Switch ON.

3) Lane power must be OFF. Display will

be blank or show current freezer

temperature, depending on the lane.

three choice buttons labeled: 1, 2 and 3 above.

3

4A

4B

4C

4D

5

next digit]

next digit]

last digit], then:

then:

Enter Password 0 _ _ _

Enter Password 0 0 _ _

Enter Password 0 0 0 _

Enter Password 0 0 0 0

Enter Password 0 0 0 1

P01 = English

Set Point

Questions? Call Franke Technical Support Group For Your Area. Copyright 2012 Franke, Inc. All rights reserved.

Press 2 = -- to decrease temp. value [- 0006 ]

P02 = -0005 F

Rev. 1 6/2012

Page 29

F3D3 Series Service Manual Factory Level 3 Parameter Access / 1.11A

Parameter

Range

Unit3)

Default

Notes

Country Exceptions

No.

Name

Low

High

US

EU

JP

LA

CN

AP

EU-B

US-

GM

CAN-

GM

Other

-GM

EU-Y

P01

Language

1 5

1

1=English, 2=Deutsch,

5=French/English (Canada)

1 1 1 1 5 1 1 1 5 1 1

P02

Set Point

-50

20

Deg F

-5

Temperature set point

P03

Offset

P04

Point

-100

50

Deg F

40

alarm (LON Models only)

P05

High Alarm (Start

Up) Delay

1

300

minutes

100

signal, until message appears

P06

High Alarm Dwell

1

300

minutes

60

Temperature must remain (dwell)

for this time

P07

Hysteresis

0.5 5 Deg F

1.0

Used in temperature control

P09

Time

1

200

seconds

120

must be off before restarting.

P10

Down Shift LM

1

20=off

minutes

4

large to medium. 20 = Off

4 7 4 4 4 4 Off

Off

Off

Off

10

P11

Down Shift M1S

1

(20= off)

minutes

20 (off)

from medium to small. 20 = Off

Off 3 Off

Off

Off

Off

Off

Off

Off

Off

5

Off 7 Off

Off

Off

Off

Off

Off

Off

Off

10

P13

Thres(hold)

10

1500 750

counts/amp of motor current.

P14

Thres(hold)

10

1500 750

counts/amp of motor current.

Lift (Motor)

P16

Basket In Time

10

1500

mS

150

to trigger a dispense cycle

150

350

150

150

150

150

150

150

150

150

150

Factory Level 3 - Parameter Guide – Page 1

[For Latest Models with BL 2.00; APP 2.12a Chip Software1)]

Factory

3=Espanola, 4=Francais,

-30 30 Deg F 8 Temperature offset from sensor

High Alarm Set

Temperature that triggers a high

GM Exceptions

P12

P15

Compressor Off

Down Shift M2S

Drum (Motor)

Torq(ue)

Door (Motor)

Torq(ue)

Torq(ue)

Thres(hold)

(M)

(M)

(S)

19

19

1

10 1500 750

19

(20= off)

(M)

(M )

(M)

minutes 20 (off)

Time to wait after high alarm

Minimum time the compressor

Time for a size downshift from

Time for an initial size downshift

Time for subsequent size

downshift from medium to small.

20 = Off

Motor stops if threshold

exceeded. Approx 250

Motor stops if threshold

exceeded. Approx 250

Motor stops if threshold

exceeded. Approx 250

counts/motor current.

Time the basket must remain in

NOTES: 1) No Main Board Chip Label. Software Vers(ion): BL 2.00; APP 2.12a appears on Lane Display.

Questions? Call Franke Technical Support Group For Your Area. Copyright 2012 Franke, Inc. All rights reserved.

Page 30

F3D3 Series Service Manual Factory Level 3 Parameter Access / 1.11A

Range

Unit3)

Default

Notes

Country Exceptions2)

No.

Name

Low

High

US

EU

JP

LA

CN

AP

EU-B

GM

GM

-GM

EU-Y

P17

Basket Out Time

10

1500

mS

50

out before enabling dispense

P18

Enable

Off

On On

being displayed.

P19

Enable

Off

On Off

slower) dispense for Japan.

Off

Off

On

Off

Off

Off

Off

Off

Off

Off

Off

P21

Large Fill Pct

P22

Medium Fill Pct

50

100

%

89

Reserved - Do not adjust.

P26

Toggle Rate

1 4

3

2 = Slow, 3 = Med, 4 = Fast)

P27

Display Units

C F

F

Temperature Display Units

Celsius or Fahrenheit

F C C C C C C F C

C

C

P28

Backdoor Type

English

Numeric

English

Displays numeric codes with

English or numeric codes only

Medium (Load)

75

P30

Factor

25

100 % 50

of large load

50

50

50

50

50

50

67

50

50

50

34

P31

Part Number

15 characters maximum. 1st must be 0-9 or F. 2nd must be 0-9, S, ‘.’ or ‘-‘. All others: 0-9, ‘-‘ or ‘.’

P32

Serial Number

P99

Factory Level 3 - Parameter Guide – Page 2

[For Latest Models with BL 2.00; APP 2.12a Chip Software1)]

Factory

Time the basket must remain

GM Exceptions

US-

CAN-

Other

P23

P29

Low Product

Hi Accuracy

Small Fill Pct

Dual Language

Factor

Small (Load)

Exit

50 100 % 90 Reserved - Do not adjust.

50 100 % 88 Reserved - Do not adjust.

25 100 % 67

15 characters maximum. All characters: 0-9 or ‘-‘

Prevents Low Product Warning

Enables high accuracy (but

If Dual Language is enabled,

this sets toggle rate: (1 = Off,

Weight of medium load as

percent of large load

Weight of small load as percent

Exits Level 3, if Entered

67 67 67 67 67 67 80 67 67 67

NOTES: 1) No Main Board Chip Label. Software Vers(ion): BL 2.00; APP 2.12a appears on Lane

Display. [How is this called up?]

2) Country Exceptions Abbreviations: US = North America; EU = Europe; JP = Japan; LA = Latin

America (South & Central); CN = Canada; AP = Asia, Pacific, Middle East & Australia

3) Unit Abbreviation: mS = Milliseconds

Questions? Call Franke Technical Support Group For Your Area. Copyright 2012 Franke, Inc. All rights reserved.

Page 31

F3D3 Series Service Manual Warranty/Section 1.2.1

Franke New Equipment Limited Warranty

Franke Foodservice Systems provides new equipment parts and labor warranties to the original

purchaser, which are equal to or exceed typical foodservice equipment m anufacturers. Special

(extended) warranty coverage may be negotiated with the customer. Extended compressor

warranties may also apply.

To determine if a Franke Frozen French Fry Dispenser is “in warranty”, contact: Franke Technical

Services at the numbers listed in Section 1.2.2 - Service Commitment & Contact Information. Be

prepared to provide the Model and Serial Number from the Manufacturers Data Plate located under

the louvered condenser filter access panel (F3D3 & F3D3S) or the upper right side of the freezer on

(F3D3P & F3D3PS) propane models.

On F3D3 & F3D3S Models On F3D3P & F3D3SP Models

Warranty Exclusions: Certain Franke parts that are expendable by nature and need to be replaced

frequently may not be cov er ed. In addition, Franke is not liable for repairs or damages due to

improper operation, attempted repairs or installation by unauthorized persons, alterations, poor water

quality, owner/operator abuse, fire, flood or acts of God. Fry basket storage racks and drip trays are

not covered by this warranty.

In Addition, this warranty may be voided in the case of:

• Failure to follow Franke instructions for use, care or maintenance

• Removal, alteration or defacing of the Franke-affixed serial number

• Service by a non-authorized service company

Warranty coverage is conditional upon Franke receiving notice of any defect subject to warranty

within thirty (30) days of its original discovery by the Buyer.

Rev. 1. 6/2012

Questions? Call Franke Technical Support Group For Your Area. Copyright 2012 Franke, Inc. All rights reserved.

Page 32

F3D3 Series Service Manual Service Commitment/Section 1.2.2

Contact Information - Americas:

Contact Information- Europe:

Contact Information- Asia, Pacific, Middle East & Africa:

The Franke Ser vice Commitment

Franke Foodservice Systems’ Technical Support Department and its third-party Service Network are

committed to meeting the unique service needs of restaurant operators worldwide. Accordingly, we strive to

provide the following response times to service requests for Franke-manufactured equipment:

1. Provide contact with the customer:

– Within 30 minutes of request for service during normal business hours

– Within 90 minutes after normal business hours (including weekends)

2. Perform service visit:

– The same day for emergency service*

– Within 24 hours for standard service

3. Target a 90% “first trip” fix rate

4. Provide 90-day warranty on the service performed

*An “emergency” is defined as an equipment operating condition that poses an immediate risk to the

safety of restaurant workers or customers.

This response time breakdown applies throughout the week and weekend. Due to varying customer locations,

and varying service agent locations and schedules, response rates may occasionally be extended. In these

situations, Franke Technical Support will work directly with the customer to find mutually acceptable options.

Franke reserves the right to use service agents outside of the Service Network, as needed.

Franke Technical Services

Franke Foodservice Systems

800 Aviation Parkway

Smyrna, TN 37167

United States of America

1-800-5FRANKE (1-800-537-2653); select 5

or

visit: FS-TS.US@Franke.com

Franke Technical Services

Franke Foodservice Systems China Co. Ltd.

318 Yinglang Industrial Zone

Shaping Town, Heshan City

Guangdong Provence, PRC – Postal Code: 5 297 00

Phone: +86 750 841 8476

Fax: +86 750 841 5845

Franke Technical Services

Franke Foodservice Systems GmbH

Jurastrasse 3

79713 Bad Saeckingen

Germany

Switchboard: +49 7761 52 400

Fax: +49 7761 52 408

Rev. 1. 6/2012

Questions? Call Franke Technical Support Group For Your Area. Page 1 Copyright 2012 Franke, Inc. All rights reserved.

Page 33

F3D3 Series Service Manual Troubleshooting Guide / Section 1.3

Use the following Sequence of Operation Questions to help diagnose common service problems.

The Question!

Answer!

What To Check or Do

1. Can the unit be

Check Breaker. OK? Yes = Continue No = Call electrician

Power Outlet OK? Yes = Continue No = Call electrician

Power Cord OK? Yes = Continue No = Replace Power Cord

per Section 2.23

Check power at Power Switch. OK? Yes = Continue to Question 2

No = Replace Power-ON Switch per Section 2.16

Yes!

Go to Question 2!

2. Do the Lane

No power to one lane only? “Push & Hold” touch pad for 4 seconds

Check 24-Volt AC Power Supply; OK? Yes = Continue No =

= Replace Operator Touchpad Panel per Section 2.15

PC Control Board OK? Yes = Continue No = Replace Control

Board per Section 2.20

Yes!

Go to Question 3!

3. Does the

Section 3.6

Section 2.17

Yes!

Go to Question 4!

4. Does the

Is Compressor plugged into terminal box? Yes = Continue No =

Plug it in! Verify Compressor starts.

Check Compressor Relay. OK? Yes = Continue No = Replace

Relay per Section 4.3

Check Compressor Capacitor. OK? Yes = Continue No =

Replace Capacitor per Section 4.3

Check refrigeration system for leak per Sections: 4.4, 4.4A &

4.4B. Yes = Repair leak per Section 4.5. No = Continue

Check Compressor. OK? Yes = Continue No = Replace

Yes!

Go to Question 5!

5. Does the

Check for French fries in hopper? Yes = Continue No = Add

fries to Hopper and attempt to dispense again.

Check for fries bridge inside Hopper? Yes = Clear/disrupt fries

bridge and attempt to dispense again. No = Continue

Is Drum Rotor binding inside Hopper? No = Continue Yes =

Alignment per Section 3.5

Check Drum Rotor Motor. Does it rotate freely? Yes = Continue

No = Replace Drum Rotor Motor per Section 2.5

turned ON?

controls light

up?

compartment

temperature appear

in left lane display?

NO!

NO!

NO!

(required) to turn on each lane. Is word Ready in displays? Yes =

Test & return unit to service; No = Continue

Replace Power Supply for that lane per Section 2.20

Ribbon Cable OK? Yes = Continue No = Replace Ribbon Cable

– Contact Franke Technical Support for P/N & Instructions

Operator’s Touchpad Panel OK? Yes = Return unit to service No

For two lane (F3D3 or F3D3P) Models, See

Temperature Display jumper re-cabling instructions

For single lane (F3D3S or F3D3SP) Models, Check Temperature

Controller Sensor Cable; OK? Yes = Continue No = Replace

Sensor Cable per

for Backup

Refrigeration

System start in two

minutes or less?

Warning: For F3D3P &

F3D3SP Propane

Models, attempt NO

Condenser System

Service! Call Franke.

Machine try to

dispense a load of

fries?

NO!

Condenser Unit per Section 4.7

Yes!

Adjust Drum Rotor Motor per Section 3.4 or Adjust Fry Hopper

Questions? Call Franke Technical Support Group For Your Area. Copyright 2012 Franke, Inc. All rights reserved.

Page 34

F3D3 Series Service Manual Troubleshooting Guide / Section 1.3

NO!

The Question!

Answer!

What To Check or Do

6. Can you simulate

the door?

Check Load Cell calibration per Section 1.9 instructions. OK? Yes

Yes!

Go to Question 7!

7. Can you

Does Control Panel indicate Load Ready? Yes = Continue No =

Yes = Continue No = reassemble Hopper, Drum & Baffle

Check wiring harness from Bump Switch to PC Control Board OK?

Franke Technical Support for P/N & Instructions

Check Bump Switch. OK? Yes = Continue No = Replace

Basket Fill Plunger Switch per Section 2.13

Yes!

The darn thing works. Don’t bother us!

Go to Question 6!

a load by pulling

down on the

product door frame

while it is running

dispense a load by

pushing the bump

switch?

NO!

NO!

= Continue No = Replace Load Cell per Section 2.10

Press and hold LANE OFF/ON button for four seconds. Did Ready

appear in display and basket lights come on within 20 seconds?

Yes =Continue No = connect or replace harness. Contact

Rev. 1 6/2012

Questions? Call Franke Technical Support Group For Your Area. Copyright 2012 Franke, Inc. All rights reserved.

Page 35

F3D3 Series Service Manual Error Message Guide / Section 1.4

Error

Code

Display Window Message

Error Description

Action Required

Ready

Small

Low Product Warning

Add fries to hopper.

01

Err01

Reset

Tare Time Out

See Advanced Troubleshooting

02

Err02

Reset

No Bucket

Check rubber dispense bucket

03

Err03

Reset

Drum Torque Error in Pre-

Empty fries from Hopper and refill.

04A

Err04

Reset

Fill Time Out (with Low

Add fries to hopper.

04B

Err04

Reset

05

Err05

Reset

Drum Torque Error in

Empty fries from Hopper. Test

06

Err06

Reset

Lift Torque Error

All F3D3 Series Frozen French Fries Dispensers have

lane control panels that display unit status and

common Error Messages. The following table lists all

Error Messages and the lane condition or action

required to correct the problem.

---

Low Fry Level

Load Cell Error

Call for Service

No Bucket

Recheck Assembly

Drum Stuck

Empty Hopper & Refill

Hopper Empty

Add Fries

Fry Bridge

Clear Fry Bridge

Pulse Mode

Product Warning ON*)

Fill Time Out (with Low

Product Warning OFF*)

Continue dispensing until Err04A

Message appears.

Section 1.3.

See Load Cell Calibration Section

LCC.

and loading doors.

Press Reset (bottom-right)

touchpad to reset.

Press Reset (bottom-right)

touchpad to reset.

Press Reset (bottom-right)

touchpad to reset.

Clear any fry bridge in hopper.

Press Reset (bottom-right)

touchpad to reset.

Drum Stuck

Empty Hopper

Bucket Lift Error

Call for Service

* When Hopper Level is below Low Product Sensor, display flashes “Low Fry Level” and three LEDs around ‘!’ warning triangle illuminate.

Questions? Call Franke Technical Support Group For Your Area. Page 1 Copyright 2012 Franke, Inc. All rights reserved.

Pulse Mode

rotation of drum.

Press Reset (bottom-right)

touchpad to reset.

Page 36

F3D3 Series Service Manual Error Message Guide / Section 1.4

Continued…

Error

Code

Display Window Message

Error Description

Action Required

07-1

Err07-1

Reset

Sensor Unplugged

Check door-open sensor. If

07-2

Err07-2

Reset

Door Torque Error in

Clear dispense area.

07-3

Err07-3

Door Motor Unplugged

Check 24-volt power to door motor

replace motor.

08

Err08

Reset

Door Torque Error in

Call for Service.

09

Err09

Reset

Complete PN/SN

Enter PN/SN (part number/serial

Doors Stuck

Clear Dispense Area

Doors Stuck

Clear Dispense Area

Doors Stuck

Clear Dispense Area

Reset

Doors Stuck

Call for Service

Forward (Open) Direction

Reverse (Close) Direction

unplugged, plug it in. If faulty,

replace sensor.

Press Reset (bottom-right)

touchpad to reset.

or run Motor Test. (See SM

Section CLPA – Customer Level

Programming Access) If faulty,

Check door open motor for

obstruction.

For Special Models with LON Works Smart Kitchen Package ONLY!

Missing PN/SN

Enter PN/SN

information not available

for LON communications.

number) information, per LON

Installation Instructions

Questions? Call Franke Technical Support Group For Your Area. Page 2 Copyright 2012 Franke, Inc. All rights reserved.

Page 37

F3D3 Series Service Manual Error Message Guide / Section 1.4

Issued 4/2011

Questions? Call Franke Technical Support Group For Your Area. Page 3 Copyright 2012 Franke, Inc. All rights reserved.

Page 38

F3D3 Series Service Manual Parts List & Component Diagrams / Section 1.5

Part Numbers

Key No.

Quantity

Description

120-Volt/60 Hz

230-Volt/50 Hz

1

1 ea.

Back Panel (Service Access)

18005391

18005391

2

1 ea.

Side Access Panel

19003067

19003067

3

1 ea.

Removable Air Inlet (Filter Access Panel)

19003751

19003751

4

1 ea.

Condenser Filter

19003756

19003756

5

2 ea.

Swivel Caster (front) with Brake

562501

562501

6

2 ea.

Swivel Caster (rear)

19000746

19000746

7

1 ea.

Cord Set

19000801

19000826

Access Panels, Filter & Casters (Single Lane Only)

Questions? Call Franke Technical Support Group For Your Area. Page 1 Copyright 2011 Franke, Inc. All rights reserved.

Page 39

F3D3 Series Service Manual Parts List & Component Diagrams / Section 1.5

8

1 ea.

Condensing Unit w/cordset

19003221

19003222

Part Numbers

Key No.

Quantity

Description

120-Volt/60 Hz

230-Volt/50 Hz

9

2 ea.

End Rail (Hopper side support)

18003324

18003324

10

1 ea.

Bucket, Silicone (fries)

19002725

19002725

11

1 ea.

Hopper & Rotor Assembly

12

1 ea.

Baffle, Rubber (for Hopper)

19000247

19000247

13

1 ea.

Removable Bottom (red silicone rubber)

19003754

19003754

14

1 ea.

Wire-form Drip Tray (dispense lane guide)

19004013

19004013

15

1 ea.

Wire Rack, Bottom Fry Basket Support

19003757

19003757

Freezer & Dispensing Loose Component Parts (Single Lane Only)

Questions? Call Franke Technical Support Group For Your Area. Page 2 Copyright 2011 Franke, Inc. All rights reserved.

18004870 18004870

Page 40

F3D3 Series Service Manual Parts List & Component Diagrams / Section 1.5

16

1 ea.

Bottom Drip Tray

19003753

19003753

Part Numbers

Key No.

Quantity

Description

120-Volt/60 Hz

230-Volt/50 Hz

17

1 ea.

Freezer Door Assembly

18004866

18004866

18

1 ea.

Gasket, Freezer Door Case

19003748

19003748

19

1 ea.

Door Hinge, Top (RH)/Bottom (LH)

18002224

18002224

20

2 ea.

Door Bushing, Bronze

3700894

3700894

21

4 ea.

Screw, Flanged

19003057

19003057

Freezer Door Parts (Single Lane Only)

Questions? Call Franke Technical Support Group For Your Area. Page 3 Copyright 2011 Franke, Inc. All rights reserved.

Page 41

F3D3 Series Service Manual Parts List & Component Diagrams / Section 1.5

22

1 ea.

Door Hinge, Bottom (RH)/Top ( LH)

18002225

18002225

Part Numbers

Key No.

Quantity

Description

120-Volt/60 Hz

230-Volt/50 Hz

23

1 ea.

Rotor Drive Sub-Assembly

18003285

18003285

24

1 ea.

Rotor Motor, Gear Reduction

19002708

19002708

25

1 ea.

Retaining Ring, External

19000238

19000238

26

1 ea.

Washer, Sensor Retaining

17002997

17002997

27

1 ea.

Product (present) Sensor

19000384

19000384

Hopper Rotor Drive & Product Sensor (All F3D3 Versions)

Questions? Call Franke Technical Support Group For Your Area. Page 4 Copyright 2011 Franke, Inc. All rights reserved.

Page 42

F3D3 Series Service Manual Parts List & Component Diagrams / Section 1.5

28

1 ea.

Sleeve, Product Sensor

19000383

19000383

29

1 ea.

Heat Wire, 1760 mm, 3 watts/ft.

19003973

19003975

Part Numbers

Key No.

Quantity

Description

120-Volt/60 Hz

230-Volt/50 Hz

30

1 ea.

Touch Pad Overlay

31

1 ea.

Backing Plate, Touch Pad Overlay

19003901

19003901

32

1 ea.

PCB Controller (Master Control Board)

19003899

19003899

33

6 ea.

Standoff, Overlay Mounting (M4 x 18)

19002776

19002776

34

4 ea.

Screw, Overlay Mounting (M4 x 8)

19002745

19002745

35

1 ea.

Rocker Switch, Main Power-ON/OFF

385.151

385.151

36

1 ea.

Front Bezel, Control Panel, w/studs

19004012

19004012

Control Panel & Master Board (All F3D3 Versions)

Questions? Call Franke Technical Support Group For Your Area. Page 5 Copyright 2011 Franke, Inc. All rights reserved.

19003900 19003900

Page 43

F3D3 Series Service Manual Parts List & Component Diagrams / Section 1.5

37

4 ea.

Screws, Front Bezel Mounting

19003058

19003058

38

1 ea.

Heat Wire, 2860 mm, 3 watts/ft.

19003972

19003974

Part Numbers

Key No.

Quantity

Description

120-Volt/60 Hz

230-Volt/50 Hz

39

1 ea.

DIN Rail Mounting Bracket

17017004

17017004

40

4 ea.

Screw, DIN Rail Mounting Bracket

3118101

3118101

41

1 ea.

DIN Rail (35 x 230 mm)

19000366

19000366

42

2 ea.

Screw, DIN Rain Mounting (to Bracket)

19002869

19002869

43

1 ea.

Power Supply, 24V DC SIEMENS

44

1 ea.

Relay, 30A/24V DC DPST - Schneider

19003558

19003558

45

2 ea.

Terminal Block Module

3588201

3588201

46

3 ea.

Terminal Block Module

3588202

3588202

DIN Rail & Mounted Electric Components (Electrical Components All F3D3 Versions)

Questions? Call Franke Technical Support Group For Your Area. Page 6 Copyright 2011 Franke, Inc. All rights reserved.

19003762 19003762

Page 44

F3D3 Series Service Manual Parts List & Component Diagrams / Section 1.5

47

1 ea.

Terminal Block Module

3588203

3588203

48

2 ea.

End Stop Terminal Blocks

3588206

3588206

Part Numbers

Key No.

Quantity

Description

120-Volt/60 Hz

230-Volt/50 Hz

49

1 ea.

Door Lift Assembly

18003834

18003834

50

4 ea.

Flat Washer, Stainless Steel (M6)

19001569

19001569

51

4 ea.

Lock Washer , Stainless Steel (M6)

19001570

19001570

52

4 ea.

Nut , Stainless Steel (M6)

19000492

19000492

60*

1 ea.

Spring, Extension

19000213

19000213

61

1 ea.

Bushing, Bronze (9.4 mm long)

62

1 ea.

Bushing, Bronze (6.3 mm long)

19003680

19003680

63

1 ea.

Bushing, Plastic (5.6 mm)

19003682

19003682

64

1 ea.

Cotter Pin, Brass

19002985

19002985

Automation Assembly & Door Spring Sub-Assembly (All F3D3 Versions)

Questions? Call Franke Technical Support Group For Your Area. Page 7 Copyright 2011 Franke, Inc. All rights reserved.

19003681 19003681

Page 45

F3D3 Series Service Manual Parts List & Component Diagrams / Section 1.5

65

1 ea.

Screw, Stainless Steel (M5x8)

19001582

19001582

Part Numbers

Key No.

Quantity

Description

120-Volt/60 Hz

230-Volt/50 Hz

53

1 ea.

Load Cell

54

1 ea.

Load Cell Base

19000187

19000187

55

1 ea.

Stop Bolt, Load Cell

19002767

19002767

56

1 ea.

Nut, Stop Bolt, Stainless Steel (M6)

19001576

19001576

57

2 ea.

Screw, Cell-to-Base (M6x50)

19001564

19001564

58

4 ea.

Lock Washers (M6)

19001570

19001570

* Break in Key No. sequence is intentional. See Page 8 for Key Nos. 53-59.

Load Cell Assembly (All F3D3 Versions)

Questions? Call Franke Technical Support Group For Your Area. Page 8 Copyright 2011 Franke, Inc. All rights reserved.

19002732 19002732

Page 46

F3D3 Series Service Manual Parts List & Component Diagrams / Section 1.5

59

2 ea.

Screw, Load Cell Mounting (M6x40)

19001580

19001580

Part Numbers

Key No.

Quantity

Description

120-Volt/60 Hz

230-Volt/50 Hz

66

1 ea.

Arm Cam with Internal Flag

18001855

18001855

67

2 ea.

Motor (for Door Open & Lift Motor)

19002708

19002708

68

1 ea.

Optical Sensor with Mounting Bracket

18002665

18002665

69

8 ea.

Lock Washer #10

5046

5046

70

6 ea.

Screw, Motor Mounting - M5 40 mm long

19002765

19002765

Door Open & Lift Motors (All F3D3 Versions)

Questions? Call Franke Technical Support Group For Your Area. Page 9 Copyright 2011 Franke, Inc. All rights reserved.

Page 47

F3D3 Series Service Manual Parts List & Component Diagrams / Section 1.5

71

2 ea.

Screw, Motor Mounting – M5 35 mm long

19002766

19002766

72

1 ea.

Door Lift Shaft

19000198

19000198

Part Numbers

Key No.

Quantity

Description

120-Volt/60 Hz

230-Volt/50 Hz

10

1 ea.

Bucket, Silicone (fries)

19002725

19002725

73

2 ea.

Doors, Product Dispensing w/screws

19003534

19003534

Dispense Doors & Bucket (All F3D3 Versions)

Questions? Call Franke Technical Support Group For Your Area. Page 10 Copyright 2011 Franke, Inc. All rights reserved.

Page 48

F3D3 Series Service Manual Parts List & Component Diagrams / Section 1.5

Part Numbers

Key No.

Quantity

Description

120-Volt/60 Hz

230-Volt/50 Hz

74

1 ea.

Right Dispense Door Shaft

19002738

19002738

75

1 ea.

Left Dispense Door Shaft

19002737

19002737

76

6 ea.

Retaining Ring, external ½”

19000215

19000215

77

2 ea.

Seal, Door Shaft

19000891

19000891

78

2 ea.

Block , Door Rotation

19000193

19000193

79

1 ea.

Link, Door Actuator

19000194

19000194

80

2 ea.

Clevis Pin (4.55 x 38.1)

19000210

19000210

81

1 ea.

Clevis Pin (6.35 x 50.8)

19000211

19000211

82

1 ea.

Clevis Pin (6.35 x 38.1)

19000212

19000212

Door Shafts & Shaft Linkage (All F3D3 Versions)

Questions? Call Franke Technical Support Group For Your Area. Page 11 Copyright 2011 Franke, Inc. All rights reserved.

Page 49

F3D3 Series Service Manual Parts List & Component Diagrams / Section 1.5

83

2 ea.

Spacer

19000214

19000214

84

1 ea.

Cotter Pin, Ring Locking

19000170

19000170

Rev. 1 6/2011

Questions? Call Franke Technical Support Group For Your Area. Page 12 Copyright 2011 Franke, Inc. All rights reserved.

Page 50

F3D3 Series Service Manual El ec tric Sche m atics / Section 1.6

120-Volt Wiring Diagram

Questions? Call Franke Technical Support Group For Your Area. Page 1 Copyright 2012 Franke, Inc. All rights reserved.

Page 51

F3D3 Series Service Manual El ec tric Sche m atics / Section 1.6

230-Volt Wiring Diagram

Questions? Call Franke Technical Support Group For Your Area. Page 2 Copyright 2012 Franke, Inc. All rights reserved.

Page 52

F3D3 Series Service Manual El ec tric Sche m atics / Section 1.6

24-Volt Wiring Diagram (All F3D3S Models)

(Also Covers Dual Lane F3D3 Models)

Questions? Call Franke Technical Support Group For Your Area. Page 3 Copyright 2012 Franke, Inc. All rights reserved.

Page 53

F3D3 Series Service Manual El ec tric Sche m atics / Section 1.6

Danfoss Condensing Unit

Model LCHC0065RC____B Electric Schematic

Rev.1 7/2011

Questions? Call Franke Technical Support Group For Your Area. Page 4 Copyright 2012 Franke, Inc. All rights reserved.

Page 54

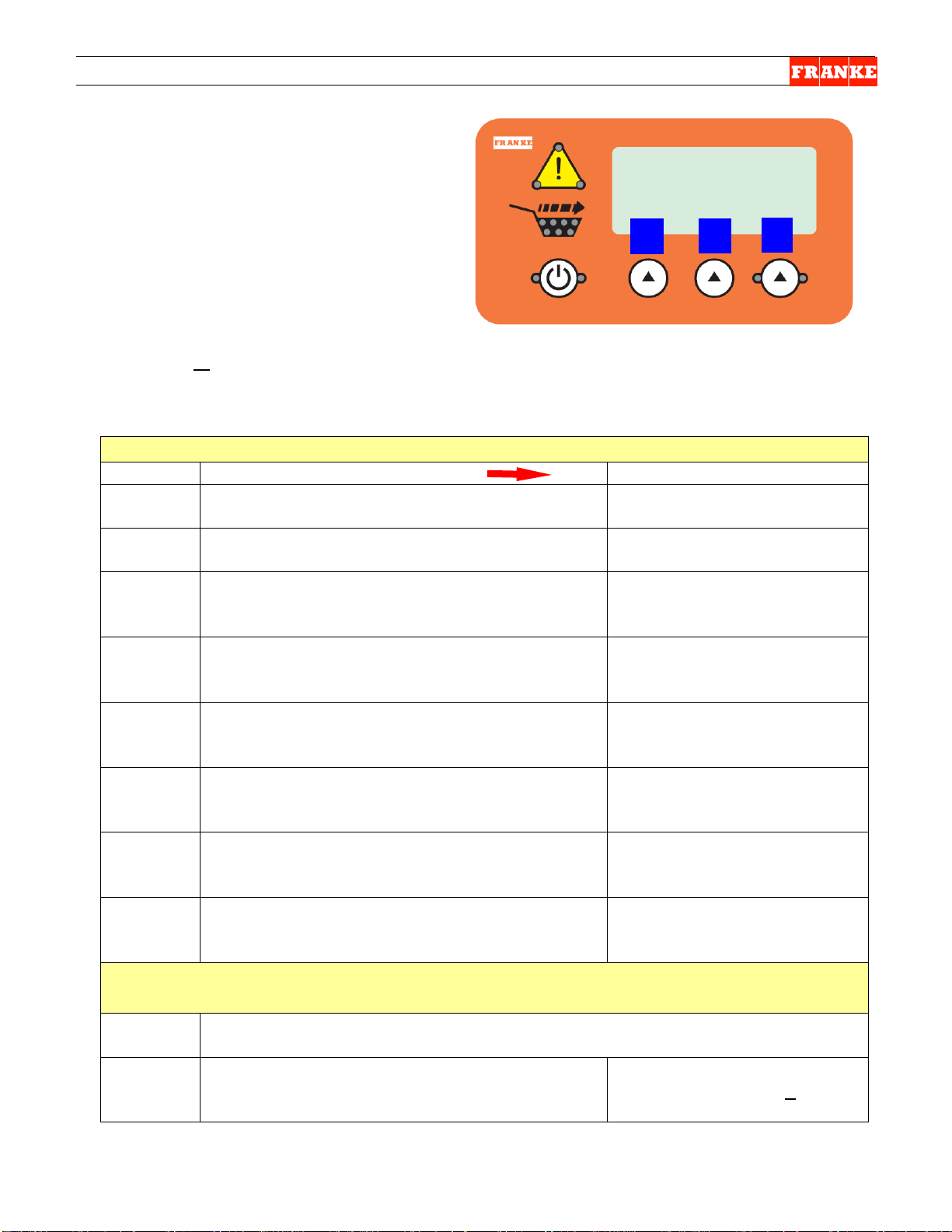

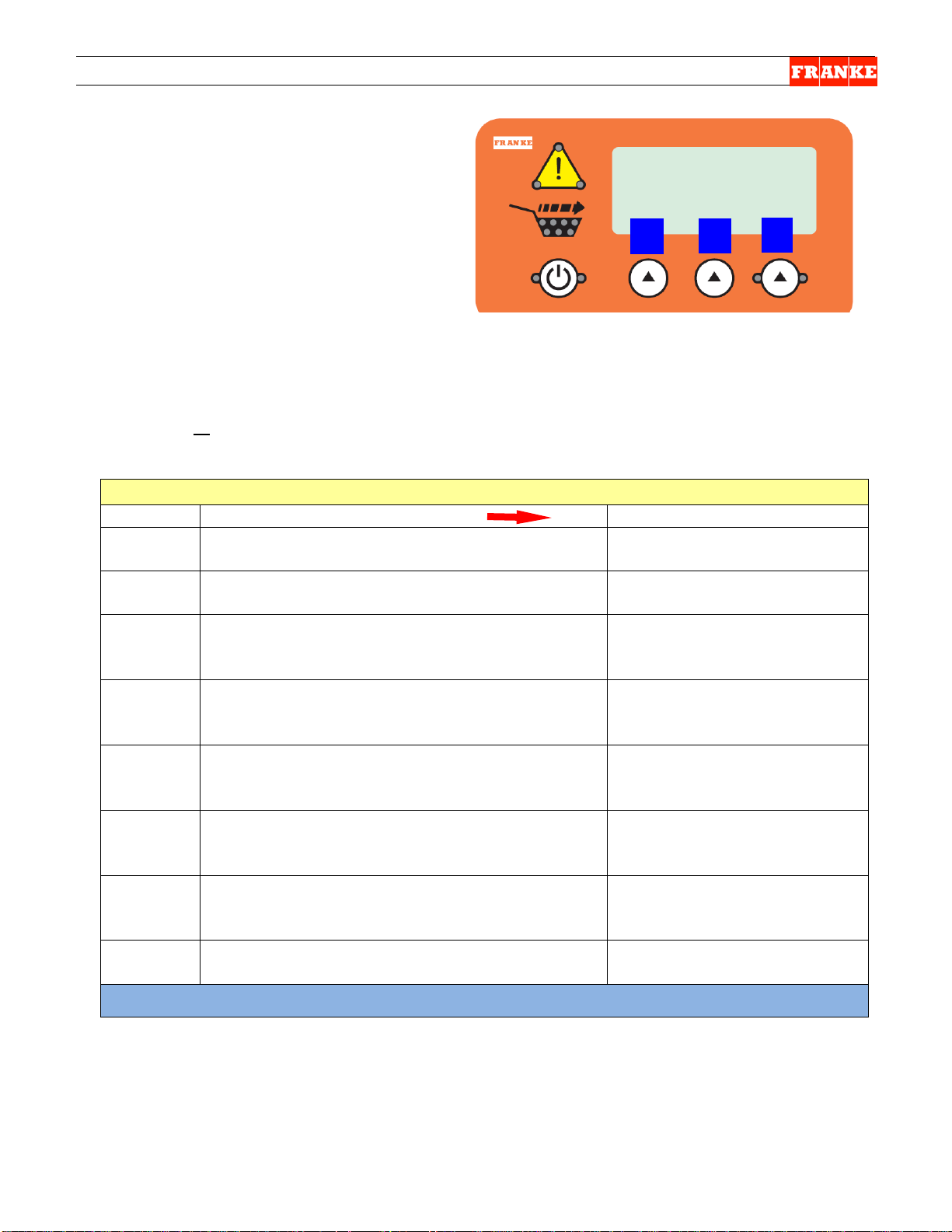

F3D3 Series Service Manual Control Panel Guide / Section 1.7

3 2 1

5 6 7

4

Control Panel Function QUICK-Guide:

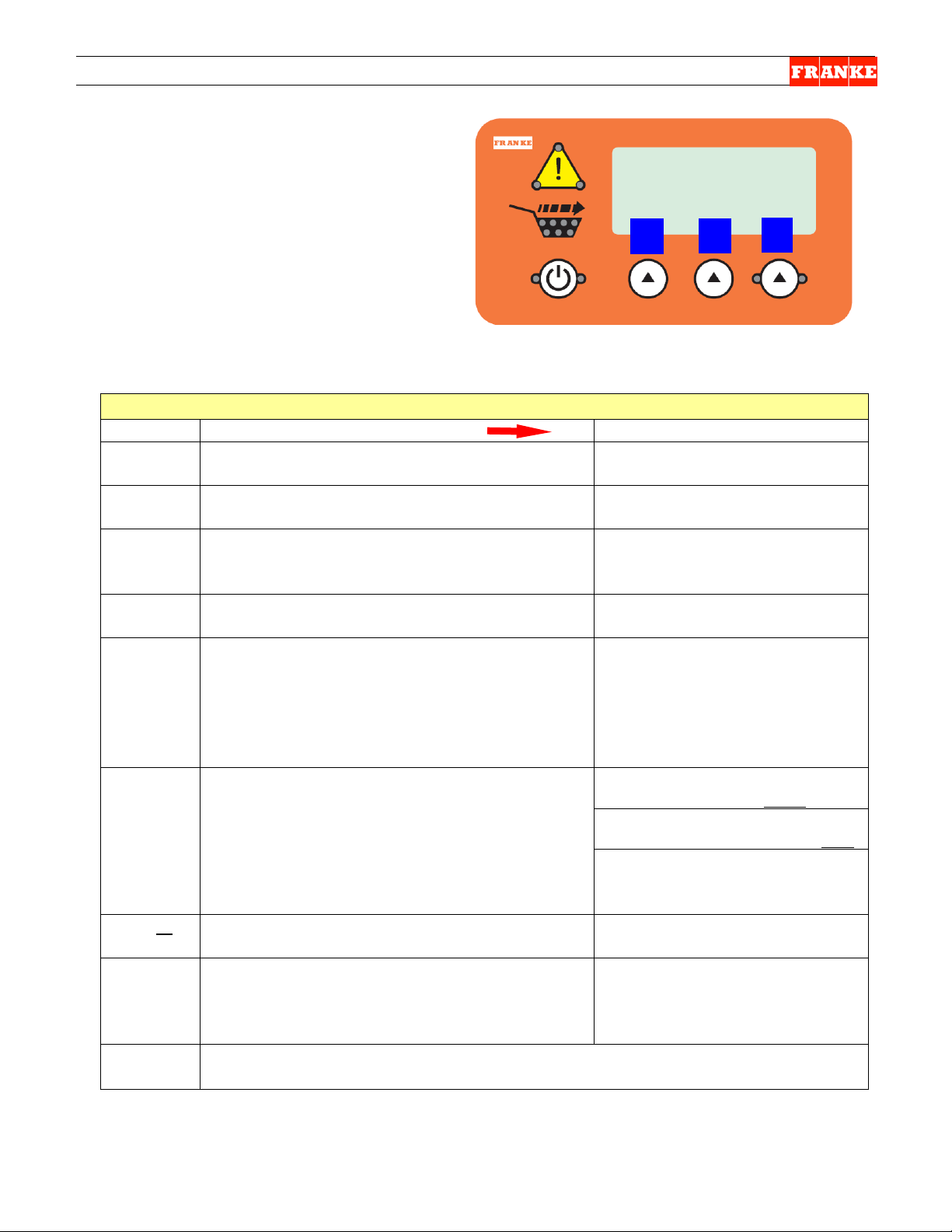

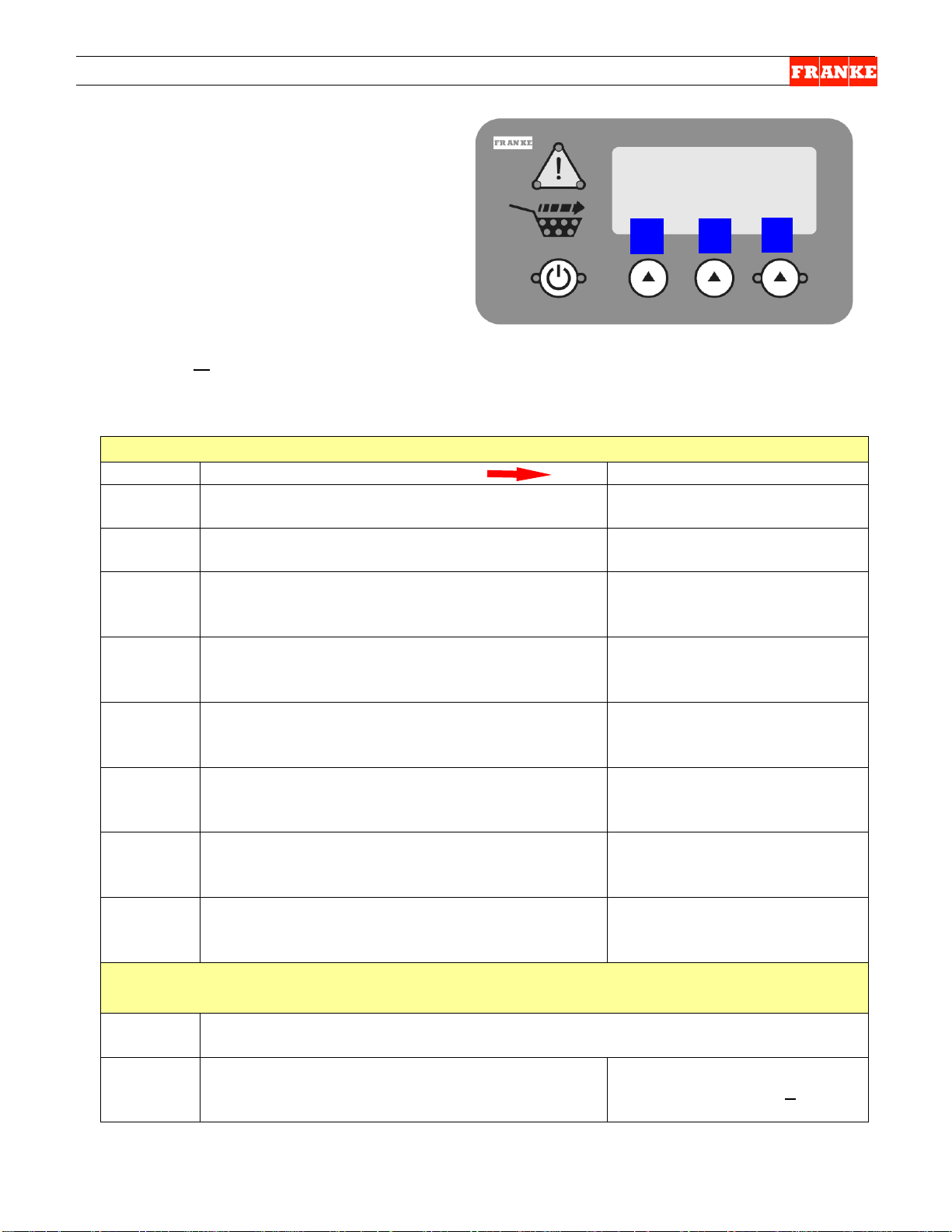

Note: Newer lane

control overlays are

black.

F3D3 Series lane control panel overlays have the following touch pads, indicator lights and display:

1 . Lane POWER Touch Pad (With green right & lef t LED Lights)

Press to turn individual lane ON or OFF:

Press and Hold touch pad for 4 seconds to turn on. Lights will stay on.

Press and Hold touch pad for 4 seconds to turn off. Lights will turn off.

NOTE: Do not turn ON until hopper is filled with fries.

2 . Load READY Graphic (With 7 Green LED lights inside basket icon):

When lights are on, the lane is ready to dispense into a fry basket.

3 . Attention/Warning Graphic (With 3 LED Lights at corners):

This symbol communicates lane status:

No lights on – Unit status OK

Lights ON – Getting low on frozen fries in hopper, but unit will continue to dispense.

Lights Flashing – Error conditi on. See display (4) for error message & SM Section 1.4.

4 . Message Display Window

Displays current freezer operating temperature (in upper-right corner of left display)

Displays Error Messages (Err04, etc.)and possible causes and remedies

Displays unit Setup & Diagnostic Programs with possible actions or decision options.

5-7 Program Decision or Action Touch Pads

Three touch pads are evenly spaced under the Display Screen, which displays options: Inc

(increase) Dec (decrease) OK etc. Use the Action touch pad under the option (Inc/Dec/OK)

to initiate that action.

Rev.1 6/2012

Questions? Call Franke Technical Support Group For Your Area. Copyright 2012 Franke, Inc. All rights reserved.

Page 55

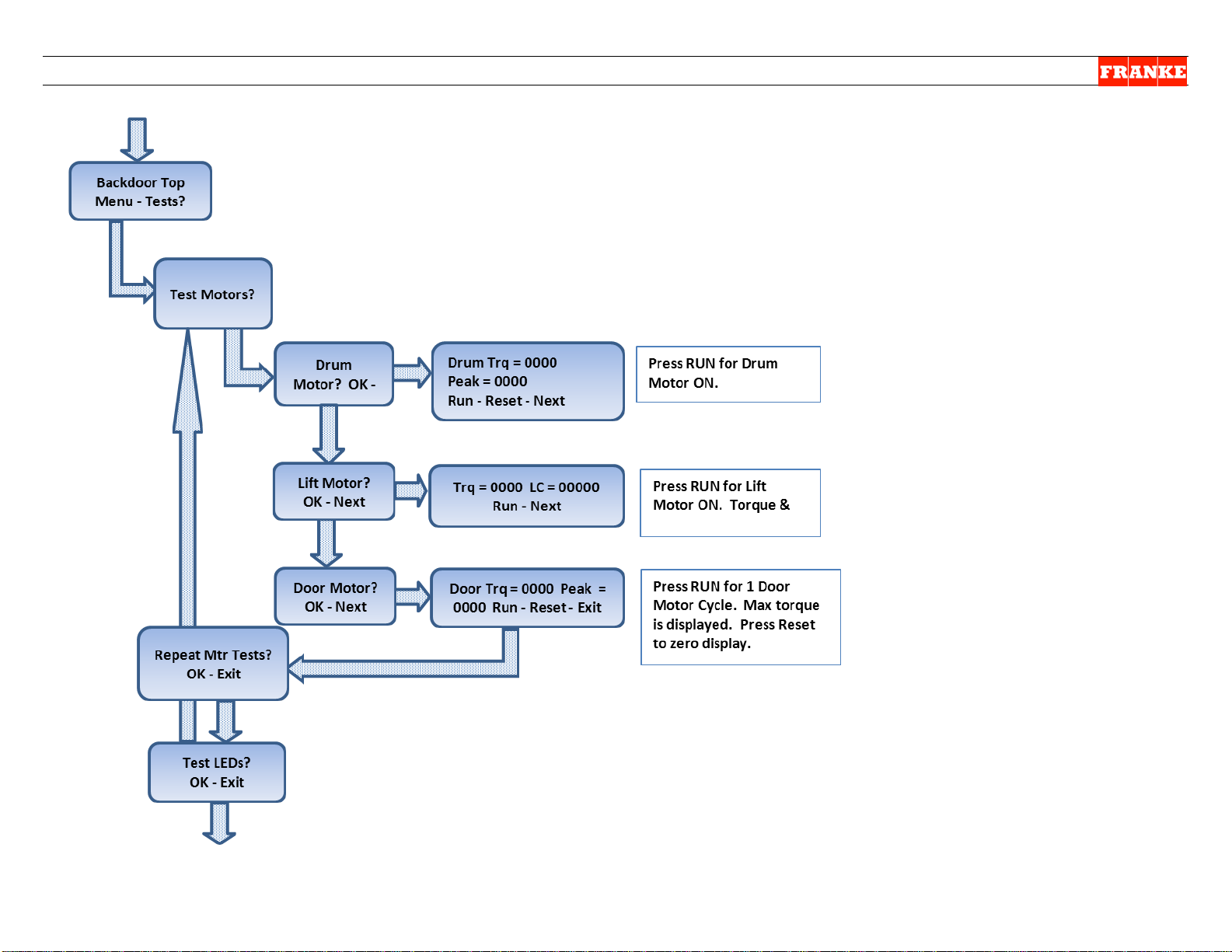

F3D3 Series Service Manual Customer Level Programming / 1.8

To Access Customer Leve l Program ming Functions:

Step

Action Required

Resulting Display

1

From Standby condition use 3rd touchpad and

enter: 3-3-3-3. [Entry code]

Special Mode Select

Cust Fact Exit

Press touchpad 1 = Cust[omer]

See Page 2 Table for language options.

Customer Access

Prev OK Next

Press touchpad 2 = OK [To change language]

Customer Access

Prev OK Next

Press touchpad 2 = OK [To change set temp]

Customer Access

Prev OK Next

Press touchpad 2 = OK [To calibrate load cell]

Customer Access

Prev OK Next

Press touchpad 2 = OK [To test motors]

Customer Access

Prev OK Next

Press touchpad 2 = OK [To view statistics]

Customer Access

Prev OK Next

3F

Press touchpad 2 = OK [To exit]

or Press touchpad 3 = Next [Goes back to Set Language]

See Page 2 Customer Function Guide for Sub-Menus & Options

NOTE: All programming is done using the

1

2

3

Customer Level Access