Page 1

Installation and operating inst ructions Instrucciones de montaje y uso

DE

EN

FR

ES

IT

Notice de montage et de mise en service Istruzioni per il montaggio e l’uso

EA-Nr.: 7612982185335

FAR-Best.-Nr.: 2000108123

ZA3OP0011

EA-Nr.: 7612982213687

FAR-Best.-Nr.: 2030016282

ZA3OP0022

ZMI_001_2000108123-ZA3OP0011_#SALL_#AQU_#V3.fm / 10.10.17

Page 2

...................................................................................3

Please refer to the graphics in the German Installation and

Operating Instructions.

...................................................................................20

Les graphiques sont disponibles dans la notice de montage et

de mise en service allemande.

...................................................................................38

Por favor, consulte los gráficos en las instrucciones alemanas

de montaje y uso.

...................................................................................56

Per le grafiche fare riferimento alle Istruzioni per il montaggio

e l’uso in tedesco.

EN

FR

ES

IT

Inhaltsverzeichnis35-31.fm

2

Page 3

0English

EN

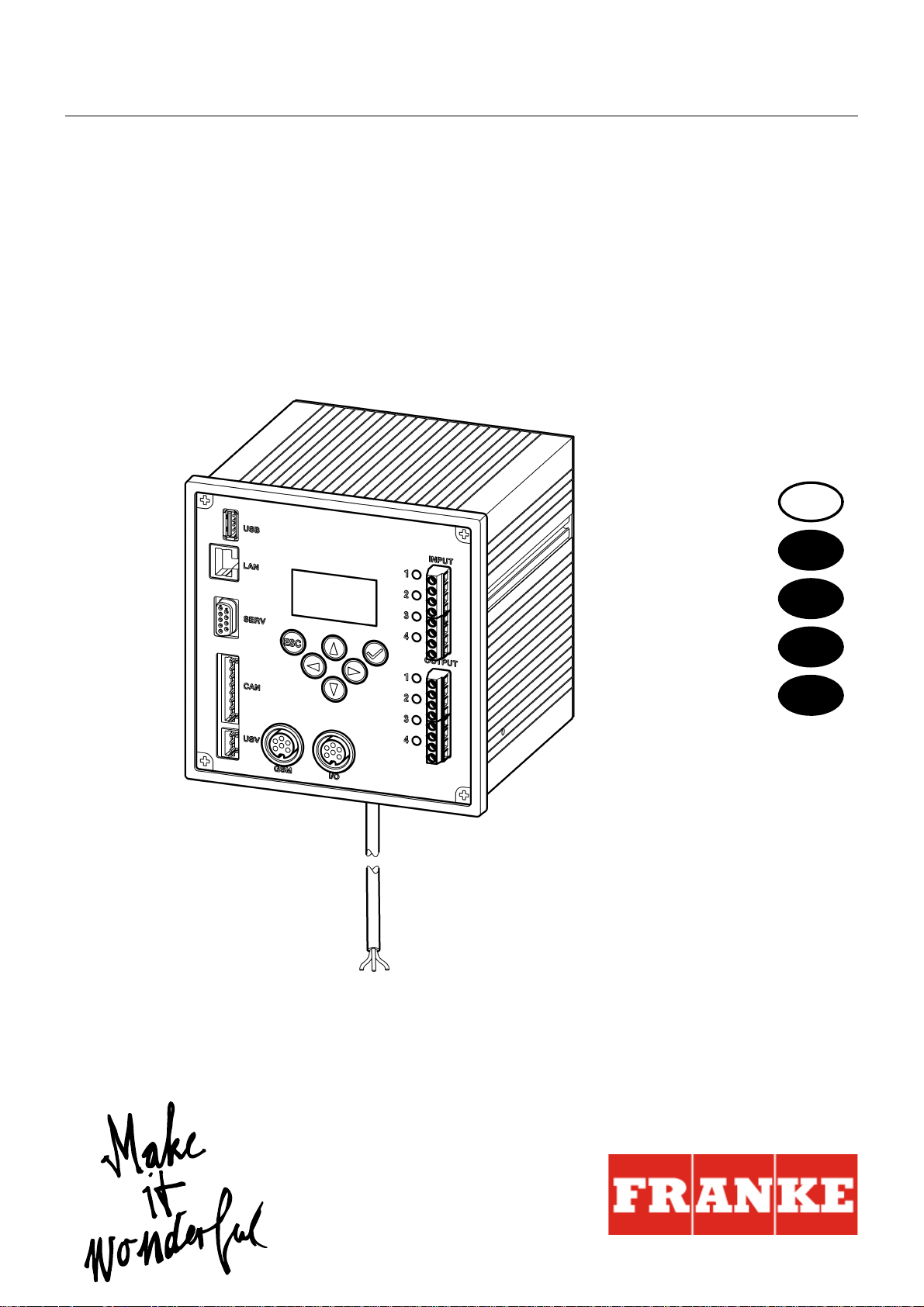

ECC2 Function Controller - A3000 open with

Ethernet Connection, 230 V AC / 24 V DC

2000108123

2030016282 .......................... including BMS data protocols

Please refer to the graphics in the German Installation and Operating Instructions.

Contents

1. Abbreviations and Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2. Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3. Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

4. Important Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Description of Product

5. Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

6. Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

7. Special Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

8. Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

9. Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

10. Pin Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Installation, Function and Commissioning

11. Assembly Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

12. Display with Menu Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

13. Permissions / Passwords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

14. Display for Staff Level. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

15. Settings in Technician Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

16. Start Web Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

17. Connection Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

18. UPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Maintenance

19. Fault Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

20. Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

21. Error Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

ZMI_001_2000108123-ZA3OP0011_#SEN_#AQU_#V3.fm

- 3 -

Page 4

1. Abbreviations and Units

EMC Electromagnetic compatibility

RCD Residual Current Protective Device,

SELV Safety Extra Low Voltage

UPS Uninterruptible power supply

EA No. European Article Number

FAR Order No. Franke Aquarotter Order Number

Conversion 1 mm = 0.03937 inches

All length specifications in the graphics are in mm.

Earth leakage circuit breaker

1 inch = 25.4 mm

2. Key

Warning!

Failure to observe can result in injury or even death.

Caution!

Failure to observe can result in material damage.

☞ Important!

Failure to observe can cause the product to malfunction.

☞ Useful information for optimally handling the product.

3. Warranty

Liability is accepted according to the General Terms and Conditions of Business and

Supply.

Use original replacement parts only!

4. Important Notes

• Installation, commissioning and maintenance are to be performed only by a

qualified technician according to the instructions provided and in accordance with

legal requirements and acknowledged rules of technology.

• All technical connection regulations specified by the local water and electricity

supply utility companies must be complied with.

• All work must be carried out in a de-energised state.

- 4 -

ZMI_001_2000108123-ZA3OP0011_#SEN_#AQU_#V3.fm

Page 5

• Because of the IP20 protective system used, the device must be operated in dry

rooms only.

• Only appliances with protection class III (SELV) may be connected to the unit.

• During the warranty period, the factory-set output voltage 24V may only be

changed by the Franke-Aquarotter customer service department.

• Secure the electric connection with an earth leakage circuit breaker (RCD).

• Proper cooling must be assured. To ensure an unimpeded flow of cooling air, it is

important to maintain a minimum distance of 15 mm to adjacent equipment.

• All rights reserved to make technical alterations.

5. Application

ECC2 Function Controller - A3000 open with Ethernet and CAN bus connection. For

connecting AQUA 3000 open fittings/electronic system modules for the purpose of

supplying power and external control, such as settings for fittings and communication. For mounting on a 35 mm DIN rail in the on-site switch-gear cabinet

(provided by customer), for wall mounting or in an electrical distribution system in

accordance with the applicable VDE regulations.

Functions of integrated digital inputs with LED status display:

– Control for thermal disinfection

– Acknowledgment of collective fault signals

– Switching program modes (e.g. night mode or holiday mode)

Functions of the integrated potential-free digital outputs with LED status display:

– Control for thermal disinfection

– Display of collective fault signals

Storage of statistical data with date and time, can be read via the USB interface in

csv format.

Additional functions can be set via a web browser:

– Switch-off for cleaning

– Triggering hygiene flushing

– Simultaneity suppression

– Sequential controls

– System flushing

– Reduction in flow duration

ZMI_001_2000108123-ZA3OP0011_#SEN_#AQU_#V3.fm

- 5 -

Page 6

6. Technical Specifications

Product group: Primary switched-mode voltage regulator (single

EMC: EN 61000-6-3 (electromagnetic emission)

Electrical safety: EN 60950

Protective system IP 20

Protection class: I

Test voltage: 4.2 kV DC

Dimensions (W x H x D): 144 × 144 × 151 mm

Ambient temperature: -10°C to 60°C / 70°C for 10 min

Cooling: Natural convection

Humidity: 100% relative humidity

phase, primary switched built-in power supply with

Ethernet-CAN coupler)

EN 61000-6-2 (electromagnetic immunity)

There must be no dew formation when the system is

to be commissioned.

Storage temp.: -40°C to 80°C

Long-term storage: To maintain the condensers, apply mains voltage to

the device for at least 5 min. every two years.

Input

Input AC: Rated voltage 100 – 240 V AC / 50 – 60 Hz

Rated current: 0.6 A at 230 V AC

Overvoltage protection: Varistor in the input circuit

Connections: 3 x 1.5 mm²

Output

Output DC (SELV): Rated voltage 24 V DC

Range 22 – 28 V (preset to 24 V)

Rated current: 2.5 A at 24 V DC

Ripple: 150 mVpp (at 20 MHz)

Efficiency: 89 %

Current limitation: from 1.1 × I

Rated

Connections: WAGO 734 Series multi-connector system for max.

1.5 mm²

Digital connections

Connection facilities: Ethernet, USB 2.0, UPS

Connections: WAGO 734 Series multi-connector system for max.

1.5 mm²

- 6 -

ZMI_001_2000108123-ZA3OP0011_#SEN_#AQU_#V3.fm

Page 7

7. Special Features

• Wide range input for AC

• Maintenance free

• Open-circuit proof

• Short-circuit proof

• Protected both on the inside as well as the outside by an internal fuse

• Protected on the outside by an electronic voltage/current controller

• Output voltage adjustable

• in parallel with factory-set default output voltage of 24 V

☞ During the warranty period, the factory-set output voltage 24 V may only be altered

by the customer service department.

• Monitoring by means of an integrated Ethernet-CAN module

• Facility for connecting a UPS

• USB port for offline data transfer to a PC, RJ45 connector for 10/100 Mbit

Standard Ethernet for PC or building network

• Interfaces for optional expansion module (I/O) and wireless module (GSM)

• BMS (building management system) connection possible using protocols BacNet

- IP, KNX - IP and Modbus - TCP

• Visualization and parametrization of the fittings network via integrated display or

web browser

8. Dimensions

9. Connections

1 Port for USB stick (for updates and storing statistical data)

2 RJ45 interface for data communication

(LAN and BMS)

3 Service interface RS232

4 Connection for system lines (operating voltage and CAN bus system; max. 32 fittings)

5 Connector for UPS power supply (optional)

6 Connector for wireless module (optional)

7 Connector for expansion module (optional)

8 Power supply connection

9 Connections for inputs and outputs (supplementary functions)

10 Display with menu buttons (siehe Kapitel 12.)

ZMI_001_2000108123-ZA3OP0011_#SEN_#AQU_#V3.fm

- 7 -

Page 8

Inputs

Input 1 ... Thermal disinfection

Input 2 ... Abort thermal disinfection

Input 3 ... Acknowledge outputs

Input 4 ... Switching program modes

Outputs

Output 1 ... Thermal disinfection active

Output 2 ... Thermal disinfection

Abort (manual)

Output 3 ... Thermal disinfection

Safety abort

Output 4 ... Collective fault message

RD ... red

BU ... blue

WH ... white

BK ... black

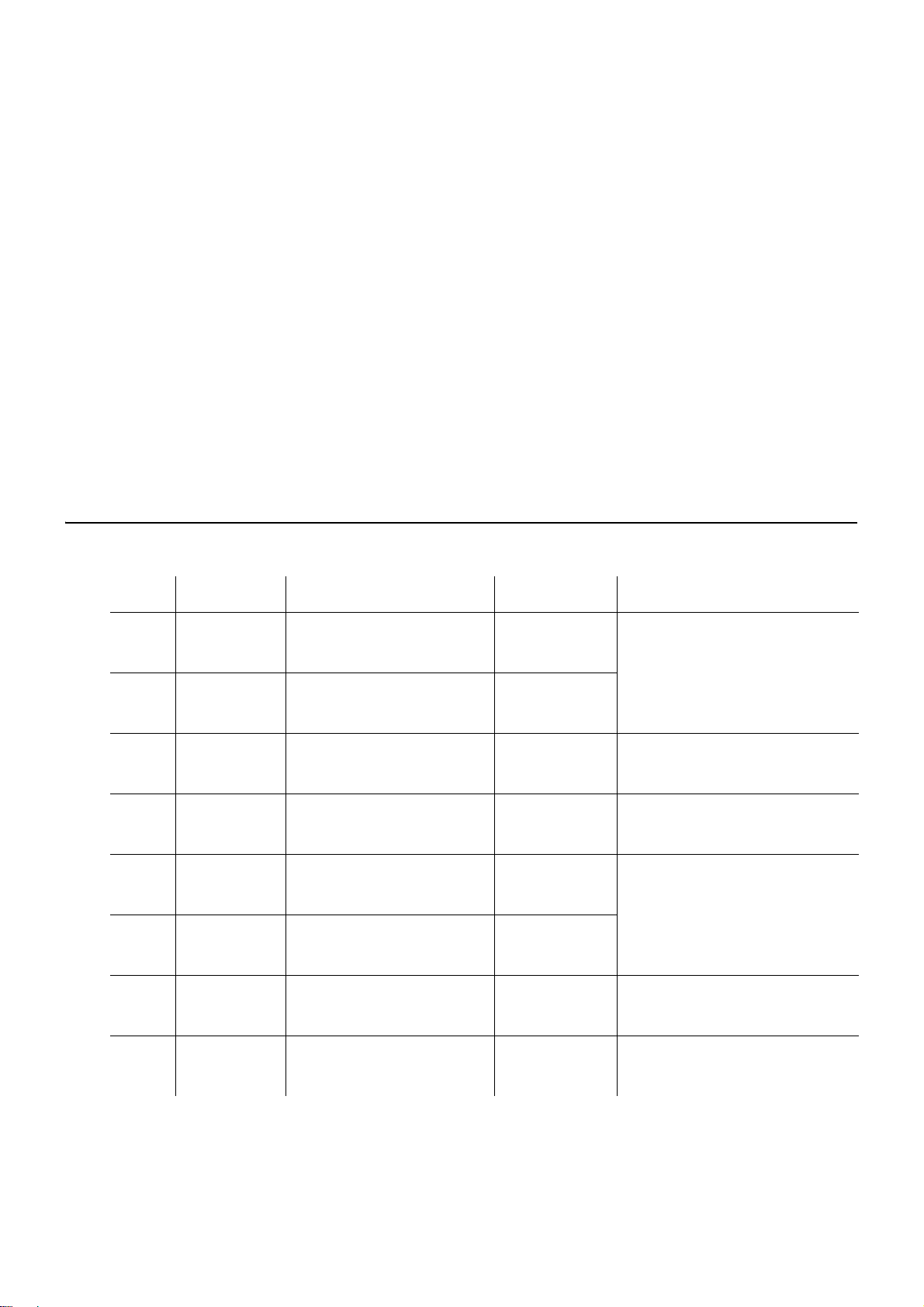

10. Pin Configurations

SELV power supply and data bus (cable system)

Pin Signal Level Color Function

1 Data-L ±0.2 V DC to

BK

±5 V DC

Data bus for bus isle

2 Data-H ±0.2 V DC to

WH

±5 V DC

3 GND 0 V DC BU Reference for bus isle

looped through

4 24 V 24 V DC RD Supply voltage for bus

isle looped through

5 Data-L ±0.2 V DC to

BK

±5 V DC

Data bus for bus isle

6 Data-H ±0.2 V DC to

WH

±5 V DC

7 GND 0 V DC BU Reference for bus isle

looped through

8 24 V 24 V DC RD Supply voltage for bus

isle looped through

- 8 -

ZMI_001_2000108123-ZA3OP0011_#SEN_#AQU_#V3.fm

Page 9

UPS (battery module)

Pin Signal Level Current Function

1 UPS LOW UPS plugged on

HIGH no UPS plugged on

2 GND Reference

3 24 V 24 V DC 2.5 A Supply voltage for bus isle

looped through

Factory settings:

Digital inputs IN1 through IN4 (Input) and

digital outputs OUT1 through OUT2 (Output)

Input 1 - Function:

Start command for thermal disinfection

☞ The contact must be closed at least 5s and no more than 2 minutes

Input 2 - Function:

Abort thermal disinfection

☞ This is triggered with a pulse.

• Thermal disinfection is stopped.

• A safety window of at least 30s passes before the fittings are flushed, and the

system then returns to its normal mode of operation. This process is then

recorded as being "not successful".

• The fittings start the cooling phase.

Input 3 - Function:

Acknowledgment for outputs

☞ This is triggered with a pulse.

• All digital outputs are reset.

Input 4 - Function:

Switching program modes

example for: summer/winter mode, day/night mode or room occupied/not occupied.

☞ The input can be connected with a switch, time switch or GLT contact.

• Functionality depends on the contents of the program ID within the electronic

module.

ZMI_001_2000108123-ZA3OP0011_#SEN_#AQU_#V3.fm

- 9 -

Page 10

Output 1 - Function:

Relay contact 48 VDC/1 A and 240 V AC/2 A

Assigned to thermal disinfection.

☞ Normal functionality: Permanently "ON" for the duration of the thermal disin-

fection process

• Acknowledgement see IN3

Output 2 - Function:

Relay contact 48 VDC/1 A and 240 V AC/2 A

Assigned to thermal disinfection.

☞ Normal functionality: Permanently "ON" when thermal disinfection was aborted

manually.

• Acknowledgement see IN3

Output 3 - Function:

Relay contact 48 VDC/1 A and 240 V AC/2 A

Assigned to thermal disinfection.

☞ Normal functionality: Permanently "ON" when thermal disinfection was aborted

by the system.

• Acknowledgement see IN3

Output 4 - Function:

Relay contact 48 V DC/1 A and 240 V AC/2 A

Assigned to collective fault messaging.

☞ Normal functionality: Permanently "ON" when a fault message is being waved.

• Acknowledgement see IN3

11. Assembly Instructions

☞ When installing several devices, it is essential to ensure an unimpeded flow of

cooling air by maintaining a minimum distance of 15 mm to adjacent parts.

☞ Mount the ECC2 function controller (1) on a rail.

11.1

Snap-lock the lower edge (3) into the rail.

11.2

Push up the ECC2 function controller.

11.3

Snap-lock the upper edge (2) into the rail.

11.4

Connect the system cable (4).

Connecting input and output cables (5)

☞ The maximum cross section of an input/output cable is 1.5 mm².

11.5

Strip off 8 mm of the ends of the input/output cables.

☞ Apply wire-end ferrules to flexible electric cables.

11.6

Connect the input/output cables according to the pin configuration (siehe Kapitel 9.).

- 10 -

ZMI_001_2000108123-ZA3OP0011_#SEN_#AQU_#V3.fm

Page 11

11.7

Connect the desired optional equipment.

11.8

Connect the power cord.

• After the operating voltage has been switched on, the display shows the startup

screen

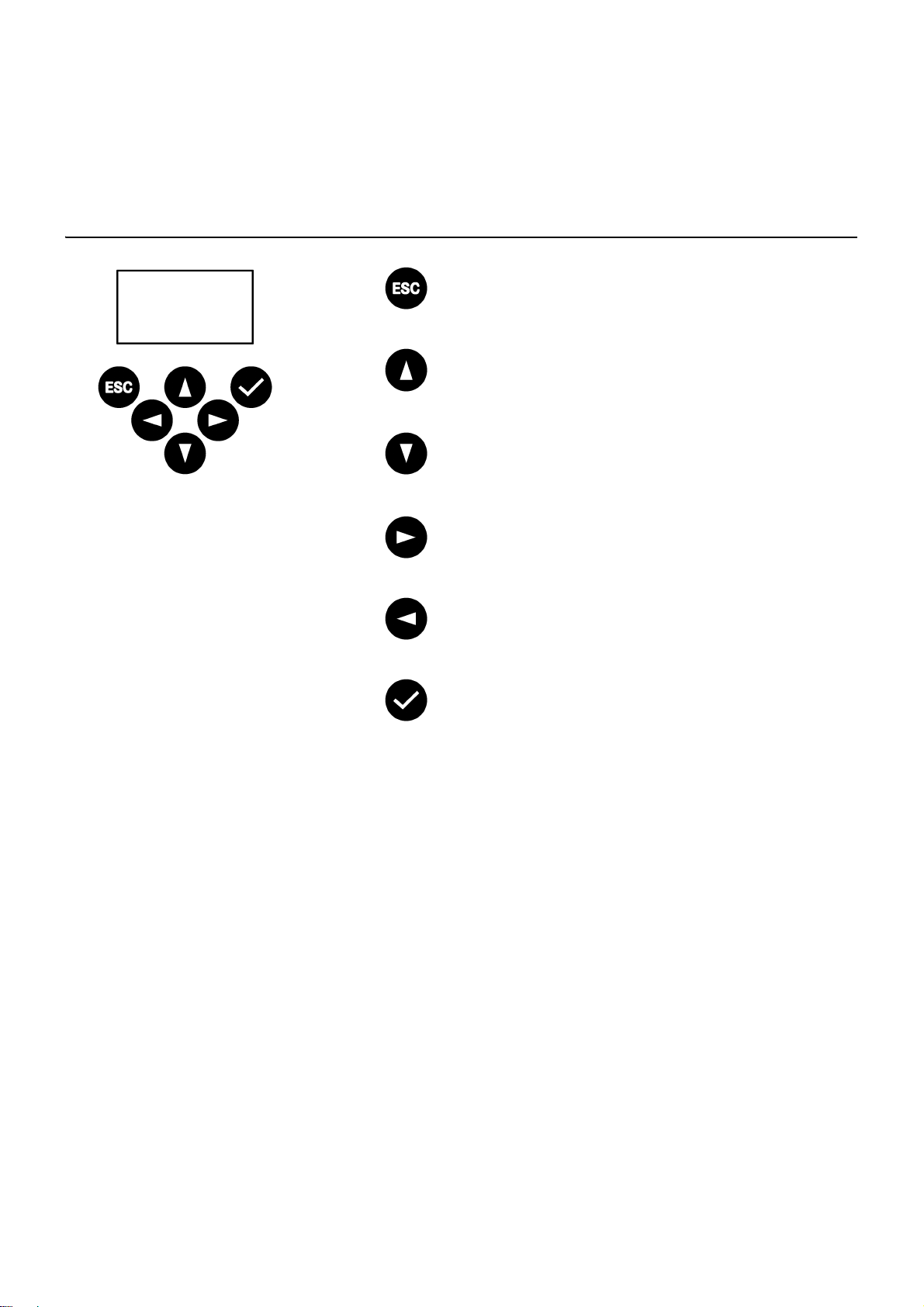

12. Display with Menu Keys

Escape - Aborts each control process and/

or returns to the previous menu level

Cursor up - Navigates upwards line by line

in the menu

Cursor down - Navigates downwards line

by line in the menu

Cursor right - Navigates to the right in the

menu

Cursor left - Navigates to the left in the

menu

Enter - Accepts a value and/or continues

one menu level further

ZMI_001_2000108123-ZA3OP0011_#SEN_#AQU_#V3.fm

- 11 -

Page 12

13. Permissions / Passwords

PIN

0 0 0 0 0

Permission Level

Different permission levels are available for viewing and changing operating

parameters within the multi-function power supply control:

Staff Level No password needed, just for viewing some

parameters

Technician Level Customer/Operator password - Changing all

permissions, saving, etc.

The password consist of a 5-digit numerical code.

Entering passwords (PIN)

13.1

Press key .

13.2

Use keys and to enter the

required digit.

13.3

Use key to jump to the next

location.

☞ When the PIN has been entered successfully the display will show the main menu.

When a wrong number is confirmed with the enter key, the display will remain in

the 'Enter PIN:' status.

Resetting a Permission Level

The permission level must be reset when, for example, the control system must be

immediately protected against unauthorized use after service work was done in the

Technician Level.

☞ If no entries are made in the control panel for more than 4 min., the permission level

is automatically reset.

ZMI_001_2000108123-ZA3OP0011_#SEN_#AQU_#V3.fm

- 12 -

Page 13

14. Display for Staff Level

ECC2 ECC-Name

22/01/2013

14:21

Menu

Page 1

Modules

Fittings

8/10

Page 2 Voltage

24.63V

Page 3 Fault (9)

22.01.2013 13:43 1000

22.01.2013 13:39 1

22.01.2013 13:36 1

21.01.2013 07:50 1

18.01.2013 08:52 1

Page 4 Version

Version x.xx

Page 5 Static IP

IP 10.222.48.226

NM 255.255.0.0

GW 10.222.0.50

DNS

MAC 00-04-A3-87-3D-B5

After the operating voltage has been

switched on, the display shows the startup

screen.

14.1

Use keys and to set the

required page.

Page 1

Shows how many fittings are

connected and in operation.

e.g.: 8 of 10 connected fittings are in

operation

Page 2

Displays the operating voltage for the

valves.

Page 3

Displays

– how many error messages are

stored.

– The last 5 error messages with

date, time and error code

(siehe Kapitel 21.).

Page 4

Shows which version of the system

software is installed on the ECC2

function controller.

Page 5

Shows which device IDs and network

IDs the ECC2 function controller has.

ZMI_001_2000108123-ZA3OP0011_#SEN_#AQU_#V3.fm

- 13 -

Page 14

15. Settings in Technician Level

Main menu

Network config.

Date/time format

Set date/time

Temperature

Restart

OKCancel

Network configuration

IP 010.222.048.222

NM 255.000.000.000

GW 010.222.000.050

DNS 255.000.000.000

OKAbort

select language

Deutsch

Englisch

čeština

Dansk

OKCANCEL

15.1

Enter the PIN (siehe Kapitel 13.).

• The main menu appears.

15.2

Use keys and to select the

desired menu.

15.3

Confirm with key .

• The desired menu opens up.

Network configuration

15.4

Select the "Network Config." menu.

15.5

Use keys and to select the

desired number.

15.6

Use keys and to select the

desired number block.

15.7

Use keys and to enter the

desired number.

15.8

Confirm with key .

• The entries are saved.

• The main menu opens.

or

Press key .

• The entries are not saved.

• The main menu opens.

Select language

15.9

Press and hold key approx. 3

seconds.

15.10

Use keys and to enter the

desired language.

15.11

Confirm with key .

ZMI_001_2000108123-ZA3OP0011_#SEN_#AQU_#V3.fm

- 14 -

Page 15

Date/time formats

Date/time formats

Date DD.MM.YYYY

24H format

Summer time

OKCancel

Set Date/Time

Date 21.01.2013

Time 15:2

1

OKAbort

15.12

Select the "Date/Time" format menu.

15.13

Use keys and to select the

desired format.

15.14

Press key .

15.15

Use keys and to set the

desired format.

15.16

Confirm with key .

• The entries are saved.

• The main menu opens.

or

Press key .

• The entries are not saved.

• The main menu opens.

Set Date/Time

15.17

Select the "Set Date/Time" menu.

15.18

Use keys and to select

between date and time.

15.19

Press key .

15.20

Use keys and to set the

desired date and time.

15.21

Confirm with key .

• The entries are saved.

• The main menu opens.

or

Press key .

• The entries are not saved.

• The main menu opens.

ZMI_001_2000108123-ZA3OP0011_#SEN_#AQU_#V3.fm

- 15 -

Page 16

Temperature/Unit (for electronic group

Temperature/Unit

°C/°F °C

Mixer 1 65.0°C

Mixer 2 65.0°C

Mixer 3 65.0°C

OKAbort

thermostat)

15.22

Select the "Temperature" menu.

15.23

Use keys and to select the

units or the desired mixer.

15.24

Press key .

15.25

Use keys and to set the

desired unit or the desired temperature.

15.26

Confirm with key .

• The entries are saved.

• The main menu opens.

or

Press key .

• The entries are not saved.

• The main menu opens.

Restart ECC2 function controller

15.27

Select the "Restart" menu.

• The ECC2 function controller is

restarted.

16. Start Web Application

16.1

Start a PC in the network.

16.2

Select an Internet browser.

16.3

Enter the IP of the ECC2 function controller in the address bar of the Internet

browser.

16.4

Enter the User and Password.

16.5

Click the "Login" button.

☞ A guide for the Web application is provided in the "Help" menu.

- 16 -

ZMI_001_2000108123-ZA3OP0011_#SEN_#AQU_#V3.fm

Page 17

17. Connection Example

Accessories Order No.

Wireless module . . . . . . . . . . . . . . . . 2000108125

Rod antenna . . . . . . . . . . . . . . . . . . . 2000110895

Wall antenna . . . . . . . . . . . . . . . . . . . 2000110896

Active antenna . . . . . . . . . . . . . . . . . 2000110897

Expansion module . . . . . . . . . . . . . . 2000108124

UPS power supply . . . . . . . . . . . . . . 2000100977

A: max. 200 m system cable or max. 32 fittings with a total performance of max. 60 W

B: Ethernet

C: Terminating resistor

D: Mains 250 V AC

Lead power cord via main switch or fuse

RD ... red

BU ... blue

WH ... white

BK ... black

18. UPS

The ECC function controller automatically detects the presence of any connected

UPS. The UPS is then checked every 25 hours. The ECC checks the function of the

UPS by switching off its own supply voltage for 5 seconds. The system then

operates with power from the UPS. During this time the ECC function controller

measures the voltage. If the voltage is less than 22 V, a corresponding message is

displayed.

19. Fault Correction

Fault Cause Remedy

No output voltage is

present, the display

– Voltage supply interrupted ➯ Restore it

– ECC2 function controller defective ➯ Replace it

does not light

If you are unable to correct a fault or if the fault is not described in the fault correction

section, please inform our customer service department!

20. Accessories

ZMI_001_2000108123-ZA3OP0011_#SEN_#AQU_#V3.fm

- 17 -

Page 18

21. Error Code

Code Meaning

1 System was started

2 System is being shut down.

3Start TD

4 TD completed successfully

5 TD was terminated after an error

100 Start TD Phase 1

110 TD Phase 1 not confirmed by all modules

200 Start TD Phase 2

210 TD Phase 2 not confirmed by all tank modules

211 TD Phase 2 aborted after timeout

300 Start TD Phase 3

310 Rapid heating not confirmed by all EMs

311 TD Phase 3 aborted after timeout

312 TD Phase 3 not confirmed by all masters

313 Rapid heating could not be stopped

400 Start TD Phase 4

410 TD Phase 4 not confirmed by all master modules

411 Master reports safety switch-off

450 Master reports completion (log with temperature)

451 EM reports quick heating terminated

500 Start TD Phase 5 (however only group starts are logged)

501 TD Phase 5 Group 1 started

502 TD Phase 5 Group 2 started

503 TD Phase 5 Group 3 started

504 TD Phase 5 Group 4 started

505 TD Phase 5 Group 5 started

506 TD Phase 5 Group 6 started

507 TD Phase 5 Group 7 started

508 TD Phase 5 Group 8 started

509 TD Phase 5 Reheating time

510 TD Phase 5 not confirmed by all EMs of the group

511 TD Phase 5 aborted after timeout in the group

512 TD Phase 5 tank stop not confirmed

550 TD Phase 5 tank stop started

600 Start TD Phase 6

601 TD Phase 6 Group 1 started

Code Meaning

- 18 -

ZMI_001_2000108123-ZA3OP0011_#SEN_#AQU_#V3.fm

Page 19

602 TD Phase 6 Group 2 started

603 TD Phase 6 Group 3 started

604 TD Phase 6 Group 4 started

605 TD Phase 6 Group 5 started

606 TD Phase 6 Group 6 started

607 TD Phase 6 Group 7 started

608 TD Phase 6 Group 8 started

610 Master has not confirmed Phase 6

611 EMs in current group have not been confirmed Phase 6

620 TD Phase 6 started because of abort

650 TD Phase 6 Cooling of the TD master modules confirmed

651 TD Phase 6 Cooling terminated after safety window

700 TD Phase 7 started (return to normal operation)

710 TD Phase 7 Normal operation not confirmed by all modules

1000 CAN bus error

1001 CAN bus OK

1002 Leakage detected

2036 CAN bus error

2037 Opto-sensor missing

2041 Solenoid valve 1 cable broken

2042 Solenoid valve 1 short circuit

2044 Solenoid valve 2 cable broken

2045 Solenoid valve 2 short circuit

2047 Undervoltage

2061 Temperature sensor 1 cable broken

2062 Temperature sensor 2 cable broken

2068 Opto-sensor missing

2069 Temperature sensor 1 short circuit

2070 Temperature sensor 2 short circuit

2073 Opto-sensor missing

4000 EM not sending data

4001 EM has commenced sending data again

ZMI_001_2000108123-ZA3OP0011_#SEN_#AQU_#V3.fm

- 19 -

Page 20

0Français

FR

Contrôleur de fonctions ECC2 - A3000 ouvert avec

connexion Ethernet, 230 V CA / 24 V CC

2000108123

2030016282 .......................... Protocoles de données inclus

Les graphiques sont disponibles dans la notice de montage et de mise en service

allemande.

Sommaire

1. Abréviations et unités . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2. Explication des symboles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3. Garantie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4. Remarques importantes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Description du produit

5. Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6. Données techniques. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

7. Caractéristiques principales . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

8. Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

9. Raccordements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

10. Affectation des raccords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Montage, fonctionnement et mise en service

11. Montage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

12. Écran avec des touches de menu . . . . . . . . . . . . . . . . . . . . . . . . 29

13. Autorisations/mots de passe. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

14. Affichage niveau Personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

15. Paramètres du niveau Technicien . . . . . . . . . . . . . . . . . . . . . . . . 32

16. Lancer l'appliquant Internet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

17. Exemple de raccordement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

18. ASI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Entretien

19. Élimination de pannes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

20. Accessoires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

21. Code d'erreur . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

ZMI_001_2000108123-ZA3OP0011_#SFR_#AQU_#V3.fm

- 20 -

Page 21

1. Abréviations et unités

CEM Compatibilité électromagnétique

RCD Residual Current Protective Device,

SELV Safety Extra Low Voltage, basse tension de

ASI Alimentation continue en courant

N° EA Numéro d’article européen

N° de comm. FAR Numéro de commande Franke Aquarotter

Conversion 1 mm = 0,03937 pouce

Interrupteur de protection contre les courants de

court-circuit

protection

1 pouce = 25,4 mm

Dans les graphiques, toutes les longueurs sont indiquées en mm.

2. Explication des symboles

Avertissement !

Le non-respect des consignes est susceptible d'induire un danger de mort ou de

provoquer des blessures corporelles.

Attention !

Le non-respect des consignes est susceptible de provoquer des dommages

matériels.

☞ Important !

Le non-respect des consignes est susceptible de provoquer des dysfonctionnements du produit.

☞ Informations utiles pour une utilisation optimale du produit.

3. Garantie

La responsabilité est assumée conformément aux conditions générales de vente et

de livraison.

Utiliser uniquement des pièces de rechange d’origine !

ZMI_001_2000108123-ZA3OP0011_#SFR_#AQU_#V3.fm

- 21 -

Page 22

4. Remarques importantes

• Seul un spécialiste est habilité à effectuer le montage, la mise en service et

l’entretien de l’installation, ces opérations étant effectuées selon les instructions

fournies, conformément aux prescriptions légales et aux règles techniques

reconnues.

• Il convient de respecter les conditions techniques de raccordement des entreprises locales de distribution d’eau et d’énergie.

• Effectuez tous les travaux quand le dispositif est hors tension.

• En raison du type de protection IP 20, le fonctionnement de l’appareil ne doit avoir

lieu que dans des lieux secs.

• Seuls des moyens d’exploitation de la classe de protection III (SELV) peuvent être

raccordés à l’appareil.

• Lors de la période de garantie, la tension de sortie réglée en usine de 24 V ne

peut être modifiée que par le service après-vente clientèle.

• Protéger le raccordement électrique avec un interrupteur de protection contre les

courants de court-circuit (RCD).

• Garantir le refroidissement. Veiller à ce que l’amenée d’air ne soit pas bouchée et

respecter un écart minimal de 15 mm avec les pièces jouxtant l’appareil.

• Sous réserve de modifications.

5. Application

Contrôleur de fonctions ECC2 - A3000 ouvert avec connexion ethernet et bus CAN.

Destiné au raccordement des robinetteries/modules électroniques système AQUA

3000 open pour alimentation en tension et commande externe, comme le réglage

des robinets et la communication. Pour le montage sur un rail normé de 35 mm dans

l'armoire électrique du client, dans un tableau électrique ou dans un distributeur

électrique conformément aux règlements VDE (Association des Électrotechniciens

Allemands).

Fonctions des entrées numériques intégrées avec indication d'état LED :

– Commande d'une désinfection thermique

– Validation de messages d'erreur regroupés

– Commutation des modes de programmes (p. ex. commutation nocturne ou de

vacances)

Fonctions des sorties numériques intégrées sans potentiel avec indication d'état

LED :

– Commande d'une désinfection thermique

– Affichage de messages d'erreur regroupés

- 22 -

ZMI_001_2000108123-ZA3OP0011_#SFR_#AQU_#V3.fm

Page 23

Enregistrement de données statistiques avec date et heure qui peuvent être

appelées en format CSV par voie de l'interface USB.

Fonctions supplémentaires paramétrables moyennant le navigateur Internet :

– Désactivation pour le nettoyage

– Déclenchement de rinçages hygiéniques

– Suppression simultanée

– commandes séquentielles

– Rinçage de l’installation

– Réduction de la durée d'écoulement

6. Données techniques

Groupe de produit : Régulateur à commutation primaire (monophasé,

alimentation intégrée à cycle primaire avec coupleur

Ethernet-CAN)

CEM : EN 61000-6-3 (émissions parasites)

EN 61000-6-3 (résistance aux interférences)

Sécurité électrique : EN60950

Type de protection IP 20

Classe de protection : I

Tension de contrôle : 4,2 kV CC

Dimensions L × H × P : 144×144×151 mm

Température ambiante : -10°C à +60°C / 70°C pour 10 min

Refroidissement : Convection naturelle

Humidité de l’air : 100% humidité relative

Pas de rosée lors de la mise en service.

Température de

-40°C à +80°C

stockage :

Stockage prolongé : Pour le maintien des condensateurs sur l’appareil,

appliquer une tension réseau pendant 5 minutes au

moins tous les deux ans.

Entrée

Entrée CA : Tension de référence 100 – 240 V CA, 50 – 60 Hz

Courant de référence : 0,6 A / 230 V CA

Protection contre les

Varistor dans le circuit d’entrée

surtensions :

Raccords : 3 ×1,5 mm²

ZMI_001_2000108123-ZA3OP0011_#SFR_#AQU_#V3.fm

- 23 -

Page 24

Sortie

Sortie CC (SELV) : Courant de référence 24 V CC

Fourchette 22 – 28 V (préréglage à 24 V)

Courant de référence : 2,5 A à 24 V CC

Ondulation : 150 mVpp (à 20 MHz)

Rendement : 89%

Limitation de courant : à partir de 1,1 × I

Raccords :

Raccordements

numériques

Possibilités de raccordement :

Raccords : Système multifiches WAGO série 734 pour max. 1,5

Système multifiches WAGO série 734 pour max. 1,5 mm²

Ethernet, USB 2.0, USV

mm²

7. Caractéristiques principales

• Large entrée pour courant alternatif

• Sans entretien

• Résiste à la marche à vide

• Résiste aux courts-circuits

• protection côté entrée et sortie par un fusible interne

réf

• Protection côté sortie par une régulation électronique U/I

• Tension de sortie réglable

• Branchement en parallèle possible pour la tension de sortie réglée en usine de

24V

☞ Lors de la période de garantie, la tension de sortie réglée en usine de 24 V ne peut

être modifiée que par le service après-vente clientèle.

• Surveillance par module CAN Ethernet

• Possibilité de raccordement pour une ASI

• Interface USB pour transport de données hors ligne vers le PC, contact RJ45

pour 10/100 Mbit standard Ethernet pour PC ou réseau du bâtiment

• Interfaces pour module d'extension disponible en option (I/O) et module radio

(GSM)

• Raccord GLT par voie des protocoles de données BacNet - IP, KNX - IP et

ModBus - TCP possible

• Visualisation et paramétrage du réseau d'armatures par voie de l'écran intégré ou

du navigateur Internet

ZMI_001_2000108123-ZA3OP0011_#SFR_#AQU_#V3.fm

- 24 -

Page 25

8. Dimensions

9. Raccordements

1 Prise pour clé USB (mises à jour et enregistrement de données statistiques)

2 Interface RJ45 pour la communication de données

(LAN et GLT)

3 Interface de service RS232

4 Branchement des câbles système (tension de service et système bus CAN ; max. 32 robinetteries)

5 Emplacement pour l’alimentation ASI (option)

6 Raccord pour module radio (option)

7 Raccord pour module d'extension (option)

8 Branchement secteur

9 Raccords pour les entrées et les sorties (fonctions supplémentaires)

10 Écran avec des touches de menu (siehe Kapitel 12.)

Entrées

Entrée 1 ... Désinfection thermique

Entrée 2 ... Interrupteur désinfection thermique

Entrée 4 ... Validation des sorties

Entrée 4 ... Commutation des modes de programmes

Sorties

Sortie 1 ... Désinfection thermique active

Sortie 2 ... Désinfection thermique

Interruption (manuelle)

Sortie 3 ... Désinfection thermique

Interruption de sécurité

Sortie 4 ... Messegaes d'erreur regroupés

RD … red (rouge)

BU … blue (bleu)

WH … white (blanc)

BK … black (noir)

ZMI_001_2000108123-ZA3OP0011_#SFR_#AQU_#V3.fm

- 25 -

Page 26

10. Affectation des raccords

Tension d'alimentation SELV et bus de données (câble système)

Broche Signal Niveau Couleur Fonction

1 Data-L ±0,2 V CC à

±5 V CC

2 Data-H ±0,2 V CC à

BK

WH

Bus de données pour

îlot de bus

±5 V CC

3 GND 0 V CC BU Référence pour bloc

bus en boucle

4 24 V 24 V CC RD Tension d’alimen-

tation du bloc bus en

boucle

5 Data-L ±0,2 V CC à

±5 V CC

6 Data-H ±0,2 V CC à

BK

WH

Bus de données pour

îlot de bus

±5 V CC

7 GND 0 V CC BU Référence pour bloc

bus en boucle

8 24 V 24 V CC RD Tension d’alimen-

tation du bloc bus en

boucle

ASI (module de la batterie)

Broche Signal Niveau Courant Fonction

1 ASI LOW ASI raccordée

HIGH pas d’ASI raccordée

2 GND Référence

3 24 V 24 V CC 2,5 A Tension d’alimen-

tation du bloc bus en

boucle

ZMI_001_2000108123-ZA3OP0011_#SFR_#AQU_#V3.fm

- 26 -

Page 27

Réglages d'usine :

Entrées numériques IN1 à In4 (Input) et

sorties numériques OUT1 à OUT2 (Output)

Input 1 - Fonction :

Instruction de démarrage de la désinfection thermique

☞ Le contact doit être fermé pendant au moins 5s et 2 minutes au maximum

Input 2 - Fonction :

Interruption de la désinfection thermique

☞ Déclenchée par une impulsion.

• La désinfection thermique va être interrompue.

• Une fenêtre temporelle de sécurité de 30s minimum s’écoule avant que la robinetterie ne soit rincée et que l’installation ne revienne en mode de fonctionnement

normal. La réalisation est documentée comme « non réussie ».

• Les robinets démarrent la phase de refroidissement.

Input 3 - Fonction :

Validation des sorties

☞ Déclenchée par une impulsion.

• Toutes les sorties numériques sont réinitialisées.

Input 4 - Fonction :

Commutation des modes de programmes

pour p.ex. : heure d’hiver/heure d’été, mode nuit/mode jour ou pièce occupée/pièce

non occupée.

☞

L’entrée peut être raccordée avec un commutateur, une minuterie ou un contact GLT.

• Fonctionnalité dépendante du contenu du programme ID dans les modules électroniques.

Output 1 - Fonction :

Contact de relais 48 V CC/1 A et 240 V CA/2 A

est affecté à la désinfection thermique.

☞

Fonctionnalité normale : « ON » permanent pour la durée de la désinfection thermique

• Validation voir IN3

Output 2 - Fonction :

Contact de relais 48 V CC/1 A et 240 V CA/2 A

est affecté à la désinfection thermique.

☞ Fonctionnalité normale : MARCHE en permanence quand la désinfection

thermique a été interrompue manuellement.

• Validation voir IN3

ZMI_001_2000108123-ZA3OP0011_#SFR_#AQU_#V3.fm

- 27 -

Page 28

Output 3 - Fonction :

Contact de relais 48 V CC/1 A et 240 V CA/2 A

est affecté à la désinfection thermique.

☞ Fonctionnalité normale : MARCHE en permanence quand la désinfection

thermique a été interrompue manuellement.

• Validation voir IN3

Output 4 - Fonction :

Contact de relais 48 V CC/1 A et 240 V CA/2 A

est affecté aux messages d'erreur regroupés.

☞

Fonctionnalité normale : MARCHE en permanence en présence d'un message d'erreur.

• Validation voir IN3

11. Montage

☞ Lors du montage de plusieurs appareils, veiller à ce que l’amenée d’air ne soit pas

bouchée et respecter un écart minimal de 15 mm avec les pièces jouxtant l’appareil.

☞ Fixer le contrôleur de fonctions ECC2 (1) à un rail.

11.1

Engager le bord inférieur (3) dans le rail.

11.2

Pousser le contrôleur de fonctions ECC2 vers le haut.

11.3

Engager le bord supérieur (2) dans le rail.

11.4

Raccorder le câble système (4).

Raccorder le câble d'entrée et de sortie (5)

☞ Le diamètre du câble d'entrée/de sortie peut mesurer 1,5 mm² maximum.

11.5

Isoler les extrémités du câble entrée/de sortie sur 8 mm.

☞ Munir les câbles électriques de manchons d’extrémité.

11.6

Raccorder les câbles d'entrée/de sortie conformément à l’affectation des raccords

(siehe Kapitel 9.).

11.7

Raccorder les appareils disponibles en option selon les besoins.

11.8

Raccordez le câble secteur.

• Après l'activation de la tension de fonctionnement, l'écran affiche l'indication de démarrage

- 28 -

ZMI_001_2000108123-ZA3OP0011_#SFR_#AQU_#V3.fm

Page 29

12. Écran avec des touches de menu

Escape, interrompt tout processus de

commande ou permet de revenir à un

niveau de menu précédent

Curseur Haut, naviguer dans le menu vers

le haut, ligne par ligne

Curseur Bas, naviguer dans le menu vers

le bas, ligne par ligne

Curseur à droite, naviguer dans le menu

Curseur à gauche, naviguer dans le menu

Entrée, valider la valeur ou passer au

niveau du menu suivant

ZMI_001_2000108123-ZA3OP0011_#SFR_#AQU_#V3.fm

- 29 -

Page 30

13. Autorisations/mots de passe

Code personnel

0 0 0 0 0

Niveaux d'autorisation

Pour la consultation et la modification des paramètres de fonctionnement au sein de

la commande du bloc adaptateur multifonction, il existe divers niveaux d'autorisation

:

Niveau Personnel Aucun mot de passe requis, consultation

uniquement de quelques paramètres

Niveau Technicien Mot de passe de client/d'exploitation - modifier,

enregistrer, etc. tous les droits d'accès

Les mot de passe sont composés d'un code

numérique à 5 chiffres.

Entrée du mot de passe (code personnel)

13.1

Appuyer sur la touche .

13.2

Sélectionner les chiffres à l'aide des

touches et .

13.3

Accéder à l'emplacement suivant à

l'aide de la touche .

☞ Après la saisie du code personnel correct, le menu principal s'affiche à l'écran.

L'affichage du menu Saisir PIN reste visible lorsqu'un numéro erroné a été

confirmé au moyen de la Entrée.

Réinitialiser le niveau d'autorisation

Le niveau d'autorisation doit être réinitialisé, par exemple quand la commande du

niveau Technicien doit être protégée d'un accès non autorisé directement après

l'intervention.

☞ Si 4 minutes s'écoulent sans saisie sur le panneau de commande, le niveau d'autori-

sation est réinitialisé automatiquement.

ZMI_001_2000108123-ZA3OP0011_#SFR_#AQU_#V3.fm

- 30 -

Page 31

14. Affichage niveau Personnel

ECC2 Nom ECC

22/01/2013

14:21

Menu

Page 1 Modules

Robinetterie

8/10

Page 2 Tension

24.63V

Page 3 Erreur (9)

22.01.2013 13:43 1000

22.01.2013 13:39 1

22.01.2013 13:36 1

21.01.2013 07:50 1

18.01.2013 08:52 1

Page 4 Version

Version x.xx

Page 5 Static IP

IP 10.222.48.226

NM 255.255.0.0

GW 10.222.0.50

DNS

MAC 00-04-A3-87-3D-B5

Après l'activation de la tension de fonctionnement, l'indication de démarrage est

affichée

14.1

Sélectionner la page à l'aide des

touches et .

Page 1

Montre le nombre de robinets

raccordés et en service.

Par exemple : 8 des 10 robinets

raccordés sont en service

Page 2

Montre la tension de fonctionnement

pour les robinets.

Page 3

montre

– le nombre de messages

d'erreurs enregistrés.

– les 5 derniers messages

d'erreurs avec date, heure et

code d'erreur

(siehe Kapitel 21.).

Page 4

Montre la version du logiciel système

installé sur le contrôleur de fonctions

ECC2.

Page 5

Les identifiants des périphériques et

du réseau du contrôleur de fonctions

ECC2.

ZMI_001_2000108123-ZA3OP0011_#SFR_#AQU_#V3.fm

- 31 -

Page 32

15. Paramètres du niveau Technicien

Menu principal

Config. réseau

Format date/heure

Réglage date/heure

Température

Redémarrage

OKInterruption

Configuration du réseau

IP 010.222.048.222

NM 255.000.000.000

GW 010.222.000.050

DNS 255.000.000.000

OKInterruption

select language

Deutsch

Englisch

čeština

Dansk

OKCANCEL

15.1

Saisir le code personnel

(siehe Kapitel 13.).

• Le menu principal s'affiche.

15.2

Sélectionner le menu à l'aide des

touches et .

15.3

Confirmer à l'aide de la touche .

• Le menu en question s'ouvre.

Configuration du réseau

15.4

Sélectionner le menu Config réseau.

15.5

Sélectionner le numéro à l'aide des

touches et .

15.6

Sélectionner le bloc numérique à

l'aide des touches et .

15.7

Confirmer le numéro à l'aide des

touches et .

15.8

Confirmer à l'aide de la touche .

• La saisie est enregistrée.

• Le menu principal s'ouvre.

ou

Appuyer sur la touche .

• La saisie n'est pas enregistrée.

• Le menu principal s'ouvre.

Réglage de la langue

15.9

Actionner la touche pendant 3

secondes environ.

15.10

Confirmer le language à l'aide des

touches et .

15.11

Confirmer à l'aide de la touche .

ZMI_001_2000108123-ZA3OP0011_#SFR_#AQU_#V3.fm

- 32 -

Page 33

Formats date/heure

Formats date/heure

Date JJ.MM.AAAA

Format 24 heures

Heure d'été

OKInterruption

Régler date/heure

Date 21.01.2013

Heure 15:

21

OKInterruption

15.12

Sélectionner le menu Format Date/

heure.

15.13

Sélectionner le format à l'aide des

touches et .

15.14

Appuyer sur la touche .

15.15

Régler le format à l'aide des touches

et .

15.16

Confirmer à l'aide de la touche .

• La saisie est enregistrée.

• Le menu principal s'ouvre.

ou

Appuyer sur la touche .

• La saisie n'est pas enregistrée.

• Le menu principal s'ouvre.

Régler date/heure

15.17

Sélectionner le menu Réglage Date/

heure.

15.18

Choisir date ou heure à l'aide des

touches et .

15.19

Appuyer sur la touche .

15.20

Régler la date ou l'heure à l'aide des

touches et .

15.21

Confirmer à l'aide de la touche .

• La saisie est enregistrée.

• Le menu principal s'ouvre.

ou

Appuyer sur la touche .

• La saisie n'est pas enregistrée.

• Le menu principal s'ouvre.

ZMI_001_2000108123-ZA3OP0011_#SFR_#AQU_#V3.fm

- 33 -

Page 34

Température/unité (pour thermostat de

Température/unité

°C/°F °C

Mélangeur 1 65,0°C

Mélangeur 2 65,0°C

Mélangeur 3 65,0°C

OKInterruption

groupe électronique)

15.22

Sélectionner le menu Température.

15.23

Sélectionner les unités ou le

mélangeur à l'aide des touches et

.

15.24

Appuyer sur la touche .

15.25

Régler l'unité ou la température à

l'aide des touches et .

15.26

Confirmer à l'aide de la touche .

• La saisie est enregistrée.

• Le menu principal s'ouvre.

ou

Appuyer sur la touche .

• La saisie n'est pas enregistrée.

• Le menu principal s'ouvre.

Redémarrer le contrôleur de fonctions

ECC2

15.27

Sélectionner le menu Redémarrage.

• Le contrôleur de fonctions ECC2

est redémarré.

16. Lancer l'appliquant Internet

16.1

Démarrer un PC du réseau.

16.2

Ouvrir un navigateur Internet.

16.3

Saisir l'IP du contrôleur de fonctions ECC2 dans la ligne d'adresse du navigateur

Internet.

16.4

Saisir identifiant et mot de passe.

16.5

Cliquer sur 'Connexion'.

☞ Vous trouverez des instructions pour l'application Internet sous le point du menu

'Aide'.

- 34 -

ZMI_001_2000108123-ZA3OP0011_#SFR_#AQU_#V3.fm

Page 35

17. Exemple de raccordement

Accessoires N° de comm.

Module radio . . . . . . . . . . . . . . . . . . . 2000108125

Antenne en tige . . . . . . . . . . . . . . . . . 2000110895

Antenne murale. . . . . . . . . . . . . . . . . 2000110896

Antenne active. . . . . . . . . . . . . . . . . . 2000110897

Module d'extension . . . . . . . . . . . . . . 2000108124

Alimentation électrique ASI . . . . . . . . 2000100977

A : câble système de max. 200 m ou max. 32 robinets avec une capacité totale de

max. 60 W

B : Ethernet

C : Résistance de terminaison

D : Secteur 220250 V/CA

Guider le câble secteur sur l'interrupteur principal ou le fusible

RD … red (rouge)

BU … blue (bleu)

WH … white (blanc)

BK … black (noir)

18. ASI

Le contrôleur de fonctions ECC2 reconnaît automatiquement tout ASI raccordé. Un

contrôle de l'ASI a lieu toutes les 25 heures. Le contrôle est réalisé par désactivation

de la tension d'alimentation propre pendant 5 secondes. Le système fonctionne

alors par ASI. La tension est mesurée par le contrôleur de fonctions ECC2. Un

message est affiché quand la tension est inférieure à 22 V.

19. Élimination de pannes

Dysfonctionnement Cause Élimination

Aucune tension de

sortie présente,

l'écran ne s'allume

pas

– Alimentation en tension inter-

rompue

– Contrôleur de fonctions ECC2

défectueux

➯ Rétablir

➯ Remplacer

Veuillez contacter notre service clientèle s'il s'avère impossible de réparer le défaut

ou s'il n'est pas listé dans l'élimination des pannes !

20. Accessoires

ZMI_001_2000108123-ZA3OP0011_#SFR_#AQU_#V3.fm

- 35 -

Page 36

21. Code d'erreur

Code Signification

1 Le système démarre

2 Le système est arrêté

3 Démarrage DT

4 DT terminé avec succès

5 DT terminé après une erreur

100 Démarrage DT phase 1

110 DT phase 1 non confirmé par tous les modules

200 Démarrage DT phase 2

210 DT phase 2 non confirmé par tous les modules de réservoir

211 DT phase 2 interrompu après dépassement du temps imparti

300 Démarrage DT phase 3

310 Chauffage rapide non confirmé par tous les EM.

311 DT phase 3 interrompu après dépassement du temps imparti

312 DT phase 3 non confirmé par tous les modules maîtres

313 Impossible d'arrêter le chauffage rapide

400 Démarrage DT phase 4

410 DT phase 4 non confirmé par tous les modules maîtres

411 Module maître signale une interruption de sécurité

450 Module maître signale la fin des activités (journal avec

température)

451 EM signale la fin du chauffage rapide

500 Démarrage DT phase 5 (uniquement les démarrages de groupes

sont documentés)

501 DT phase 5 groupe 1 démarré

502 DT phase 5 groupe 2 démarré

503 DT phase 5 groupe 3 démarré

504 DT phase 5 groupe 4 démarré

505 DT phase 5 groupe 5 démarré

506 DT phase 5 groupe 6 démarré

507 DT phase 5 groupe 7 démarré

508 DT phase 5 groupe 8 démarré

509 DT phase 5 temps de nouveau réchauffement

510 DT phase 5 non confirmé par tous EM du groupe

511 DT phase 5 interrompu après dépassement du temps imparti au

groupe

512 DT phase 5 arrêt réservoir non actionné

550 DT phase 5 groupe 1 arrêt réservoir démarré

- 36 -

ZMI_001_2000108123-ZA3OP0011_#SFR_#AQU_#V3.fm

Page 37

Code Signification

600 Démarrage DT phase 6

601 DT phase 6 groupe 1 démarré

602 DT phase 6 groupe 2 démarré

603 DT phase 6 groupe 3 démarré

604 DT phase 6 groupe 4 démarré

605 DT phase 6 groupe 5 démarré

606 DT phase 6 groupe 6 démarré

607 DT phase 6 groupe 7 démarré

608 DT phase 6 groupe 8 démarré

610 Phase 6 non confirmée par module maître

611 Phase 6 non confirmée par EM dans groupe actuel

620 DT phase 6 groupe 1 démarré à cause d'interruption

650 DT phase 6 refroidissement des modules maîtres DT confirmé

651 DT phase 6 refroidissement après fenêtre de sécurité terminé

700 DT phase 7 démarré (retour au fonctionnement normal)

710 DT phase 7 fonctionnement normal non confirmé par tous les

modules

1000 Erreur bus CAN

1001 Bus CAN OK

1002 Fuite constatée

2036 Erreur bus CAN

2037 Optosonde manque

2041 Rupture de câble électrovanne 1

2042 Court-circuit électrovanne 1

2044 Rupture de câble électrovanne 2

2045 Court-circuit électrovanne 2

2047 Sous-tension

2061 Rupture de câble sonde de température 1

2062 Rupture de câble sonde de température 2

2068 Optosonde manque

2069 Court-circuit sonde de température 1

2070 Court-circuit sonde de température 2

2073 Optosonde manque

4000 Aucune donnée envoyée par EM

4001 De nouveau des données envoyées par EM

ZMI_001_2000108123-ZA3OP0011_#SFR_#AQU_#V3.fm

- 37 -

Page 38

0Español

ES

Controlador de funciones ECC2 - A3000 open con

conexión Ethernet, 230 V CA / 24 V CC

2000108123

2030016282Incluidos los protocolos de datos GLT

Por favor, consulte los gráficos en las instrucciones alemanas de montaje y uso.

Índice

1. Abreviaturas y unidades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

2. Explicación de los símbolos . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3. Garantía . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4. Advertencias importantes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Descripción del producto

5. Aplicación . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6. Especificaciones técnicas. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

7. Características especiales . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

8. Dimensiones. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

9. Conexiones. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

10. Asignación de conexiones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Montaje, funcionamiento y puesta en servicio

11. Montaje. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

12. Pantalla con teclas de menú . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

13. Autorizaciones/Contraseñas. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

14. Pantalla del nivel Personal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

15. Configuración del nivel Técnico . . . . . . . . . . . . . . . . . . . . . . . . . . 49

16. Iniciar aplicación Web. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

17. Ejemplo de conexión . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

18. SAI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Mantenimiento

19. Resolución de problemas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

20. Accesorios . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

21. Código de error. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

ZMI_001_2000108123-ZA3OP0011_#SES_#AQU_#V3.fm

- 38 -

Page 39

1. Abreviaturas y unidades

CEM Compatibilidad electromagnética

RCD Residual Current Protective Device,

dispositivo de corriente residual

SELV

SAI Sistema de alimentación ininterrumpida

Núm. EA Número de referencia europeo

Núm. ref. FAR Número de pedido de Franke Aquarotter

Conversión 1 mm = 0,03937 pulgadas

Todas las indicaciones de longitud de los gráficos están expresadas en mm.

Safety Extra Low Voltage, tensión baja de protección

1 pulgada = 25,4 mm

2. Explicación de los símbolos

¡Advertencia!

La no observación puede entrañar un riesgo mortal u provocar lesiones personales.

¡Atención!

La no observación puede ocasionar daños materiales.

☞ ¡Importante!

La no observación puede producir errores de funcionamiento en el producto.

☞ Información útil para el manejo óptimo del producto.

3. Garantía

Asumimos responsabilidad conforme a las condiciones generales de entrega y

comerciales.

Utilice únicamente piezas de repuesto originales.

4. Advertencias importantes

• Las operaciones de montaje, puesta en servicio y mantenimiento deben correr a

cargo exclusivamente de un experto que actúe conforme a lo dispuesto en las

instrucciones adjuntas y según las normativas legales y las reglas reconocidas de

la técnica que se encuentren en vigor.

• Observe asimismo las condiciones de conexión de las empresas locales

abastecedoras de agua y energía.

ZMI_001_2000108123-ZA3OP0011_#SES_#AQU_#V3.fm

• Todos los trabajos deben realizarse con la tensión de alimentación desconectada.

- 39 -

Page 40

• Dado que tiene el grado de protección IP 20, el equipo solo puede utilizarse en

espacios secos.

• En el equipo solo pueden conectarse medios de servicio de la clase de protección

III (SELV).

• Durante el período de garantía, la tensión de salida de 24 V ajustada en fábrica

solo puede ser modificada por el servicio de atención al cliente de FrankeAquarotter.

• Proteja la conexión eléctrica con un dispositivo de corriente residual (RCD).

• Asegúrese de que existe una refrigeración adecuada. Para garantizar una

alimentación de aire sin obstáculos, mantenga una distancia mínima de 15 mm

respecto a los componentes vecinos.

• Reservado el derecho de introducir modificaciones.

5. Aplicación

Controlador de funciones ECC2 - A3000 open con conexión Ethernet y de bus CAN.

Para la conexión de guarniciones/módulos electrónicos AQUA 3000 open con el fin

de garantizar una tensión de alimentación y un control externo, como el ajuste de

las guarniciones y la comunicación. Para el montaje en un carril normalizado de 35

mm en el armario de distribución del cliente, para el montaje en pared o en una

distribución eléctrica conforme a las normativas VDE vigentes.

Funciones de las entradas digitales integradas con indicador LED de estado:

– Control de una desinfección térmica

– Confirmación de mensajes de error colectivos

– Conmutación de los modos de programa (por ejemplo, conmutación al modo

nocturno o de vacaciones)

Funciones de las salidas digitales sin potencial integradas con indicador LED de estado:

– Control de una desinfección térmica

– Visualización de mensajes de error colectivos

Almacenamiento de datos estadísticos con fecha y hora, que pueden activarse a

través del puerto USB en formato CSV.

Funciones adicionales ajustables a través de un explorador Web.

– Desconexión de limpieza

– Activación de enjuagues higiénicos

– Supresión de simultaneidades

– Controles subsiguientes

– Enjuague del sistema

– Reducción del tiempo de corriente

- 40 -

ZMI_001_2000108123-ZA3OP0011_#SES_#AQU_#V3.fm

Page 41

6. Especificaciones técnicas

Grupo de productos: Regulador de conmutación primario (monofásico,

CEM: EN 61000-6-3 (emisión de interferencias)

Seguridad eléctrica: EN 60950

Grado de protección IP 20

Clase de protección: I

alimentación incorporada principal de corriente

pulsante y acoplador Ethernet-CAN)

EN 61000-6-2 (inmunidad a las interferencias)

Tensión de comprobación:

Dimensiones (an × al × pr)

4,2 kV CC

144 × 144 × 151 mm

Temperatura ambiente: -10°C a +60°C / 70°C durante 10 min

Refrigeración: convección natural

Humedad relativa del

aire

Temperatura de

100% de humedad relativa

En la puesta en servicio no puede haber condensación.

de -40°C a +80°C

almacenamiento:

Almacenamiento a largo

plazo:

Para mantener los condensadores en el equipo, al

menos cada dos años conecte la tensión de alimen-

tación durante 5 minutos como mínimo.

Entrada

Entrada de CA Tensión de referencia: 100 a 240 V CA / 50 a 60 Hz

Corriente de referencia: 0,6 A a 230 V CA

Protec. frente a sobretensión:

Varistor en el circuito de entrada

Conexiones: 3 ×1,5 mm²

Salida

Salida CC (SELV) Tensión de referencia 24 V CC

Rango 22 a 28 V (predeterminado a 24 V)

Corriente de referencia: 2,5 A a 24 V CC

Ondulación: 150 mVpp (a 20 MHz)

Rendimiento: 89%

Limitación de corriente: a partir de 1,1 × I

Conexiones:

Sist. multiconector WAGO Serie 734 para máx. 1,5 mm²

referencia

Conexiones digitales

Posibilidades de conexión:

Conexiones:

ZMI_001_2000108123-ZA3OP0011_#SES_#AQU_#V3.fm

Ethernet, USB 2.0, SAI

Sist. multiconector WAGO Serie 734 para máx. 1,5 mm²

- 41 -

Page 42

7. Características especiales

• Entrada de rango amplio para corriente alterna

• sin mantenimiento

• resistente a la marcha en vacío

• resistente a los cortocircuitos

• protegido en la entrada y la salida por un fusible interno

• protegido en la salida mediante una regulación electrónica de tensión y corriente

• Tensión de salida ajustable

• conmutable de forma paralela con la tensión de salida de 24 V ajustada en fábrica

☞ Durante el período de garantía, la tensión de salida de 24 V ajustada en fábrica solo

puede ser modificada por el servicio de atención al cliente.

• Supervisión a través del módulo Ethernet-CAN integrado

• Posibilidad de conectar un SAI

• Puerto USB para la transferencia de datos sin conexión hasta el PC, toma RJ45

para Ethernet estándar de 10/100 Mbits para PC o red de edificios

• Puertos para un módulo de ampliación opcional (E/S) y módulo inalámbrico

(GSM)

• Posibilidad de conexión GLT a través de los protocolos de datos BacNet - IP, KNX

- IP y ModBus - TCP

• Visualización y parametrización de la red de guarniciones a través de una

pantalla integrada o de un explorador Web

8. Dimensiones

9. Conexiones

1 Ranura para un lápiz USB (actualizaciones y almacenamiento de los datos estadísticos)

2 Interfaz RJ45 para la comunicación de datos

(LAN y GLT)

3 Interfaz de servicio RS232

4 Conexión de cables de sistema (tensión de servicio y sistema de bus CAN; máx. 32 guarniciones)

5 Conexión para un SAI (opcional)

6 Conexión para un módulo inalámbrico (opcional)

7 Conexión para un módulo de ampliación (opcional)

8 Conexión de red

9 Conexiones para entradas y salidas (funciones adicionales)

10 Pantalla con teclas de menú(siehe Kapitel 12.)

- 42 -

ZMI_001_2000108123-ZA3OP0011_#SES_#AQU_#V3.fm

Page 43

Entradas

Entrada 1 … Desinfección térmica

Entrada 2 … Interrupción de la desinfección térmica

Entrada 3 … Confirmación de salidas

Entrada 4 … Conmutación de los modos de programa

Salidas

Salida 1 … Desinfección térmica activa

Salida 2 … Desinfección térmica

Interrupción (manual)

Salida 3 … Desinfección térmica

Interrupción de seguridad

Salida 4 … Mensajes de error colectivos

RD … red (rojo)

BU … blue (azul)

WH … white (blanco)

BK … black (negro)

10. Asignación de conexiones

Alimentación SELV y bus de datos (cable de sistema)

Pin Señal Nivel Color Función

1 Data-L ±0,2 V CC a

±5 V CC

2 Data-H ±0,2 V CC a

BK

WH

Bus de datos para isla de

bus

±5 V CC

3 GND 0 V CC BU

Referencia para la isla de

bus conectada en bucle

424V 24VCC RD

Tensión de alimentación

para la isla de bus

conectada en bucle

5 Data-L ±0,2 V CC a

±5 V CC

6 Data-H ±0,2 V CC a

BK

WH

Bus de datos para isla de

bus

±5 V CC

7 GND 0 V CC BU

Referencia para la isla de

bus conectada en bucle

824V 24VCC RD

Tensión de alimentación

para la isla de bus

conectada en bucle

ZMI_001_2000108123-ZA3OP0011_#SES_#AQU_#V3.fm

- 43 -

Page 44

SAI (módulo de batería)

Pin Señal Nivel Corriente Función

1SAI LOW

HIGH

2 GND Referencia

324V24VCC 2,5A

Ajustes de fábrica:

Entradas digitales IN1 a IN4 (input) y

salidas digitales OUT1 a OUT2 (output)

Input 1 - Función:

Comando de inicio de la desinfección térmica

SAI acoplado

No se ha acoplado ningún SAI

Tensión de alimentación para la

isla de bus conectada en bucle

☞ El contacto debe estar conectado un mínimo de 5 segundos, pero solo puede

estar conectado 2 minutos como máximo

Input 2 - Función:

Interrupción de la desinfección térmica

☞ Se activa mediante un impulso.

• La desinfección térmica se interrumpe.

• Antes de que las guarniciones se enjuaguen y la instalación pase de nuevo al

funcionamiento normal transcurre un intervalo de seguridad de al menos 30

segundos. La ejecución se documenta como "no correcta".

• Las guarniciones inician la fase de refrigeración.

Input 3 - Función:

Confirmación de las salidas

☞ Se activa mediante un impulso.

• Todas las salidas digitales se restablecen.

Input 4 - Función:

Conmutación de los modos de programa

para, por ejemplo: horario de invierno/de verano, modo diurno/nocturno o sala

ocupada/no ocupada

☞ La entrada puede conectarse con un interruptor, un reloj conmutador o un

contacto GLT.

• La funcionalidad depende del contenido del ID del programa dentro de los

módulos electrónicos.

- 44 -

ZMI_001_2000108123-ZA3OP0011_#SES_#AQU_#V3.fm

Page 45

Output 1 - Función:

Contacto de relé 48 V CC/1 A y 240 V CA/2 A

Está asignado a la desinfección térmica.

☞ Funcionamiento normal: "ON" de forma permanente durante el transcurso de la

desinfección térmica

• Para la confirmación, véase IN3

Output 2 - Función:

Contacto de relé 48 V CC/1 A y 240 V CA/2 A

Está asignado a la desinfección térmica.

☞ Funcionamiento normal: "ON" de forma permanente cuando la desinfección

térmica se ha interrumpido manualmente.

• Para la confirmación, véase IN3

Output 3 - Función:

Contacto de relé 48 V CC/1 A y 240 V CA/2 A

Está asignado a la desinfección térmica.

☞ Funcionamiento normal: "ON" de forma permanente cuando la desinfección

térmica ha sido interrumpida por el sistema.

• Para la confirmación, véase IN3

Output 4 - Función:

Contacto de relé 48 V CC/1 A y 240 V CA/2 A

Está asignado a los mensajes de error colectivos.

☞ Funcionamiento normal: "ON" de forma permanente cuando existe un mensaje

de error.

• Para la confirmación, véase IN3

11. Montaje

☞ Si va a montar varios equipos, mantenga una distancia mínima de 15 mm respecto

a los componentes vecinos para garantizar una alimentación de aire sin obstáculos.

☞ Sujete el controlador de funciones ECC2 (1) en un carril.

11.1

Encaje el borde inferior (3) en el carril.

11.2

Presione el controlador de funciones ECC2 hacia arriba.

11.3

Encaje el borde superior (2) en el carril.

11.4

Conecte el cable de sistema (4).

Conectar cables de entrada y de salida (5)

☞ La sección de los cables de entrada/salida puede ser de 1,5 mm² como máximo.

11.5

Aísle los extremos de los cables de entrada/salida 8 mm.

☞ Acople virolas de cable en los cables eléctricos flexibles.

ZMI_001_2000108123-ZA3OP0011_#SES_#AQU_#V3.fm

- 45 -

Page 46

11.6

Conecte los cables de entrada/salida conforme a la asignación de conexiones

(siehe Kapitel 9.).

11.7

Conecte los equipos opcionales que desee.

11.8

Conecte el cable de alimentación.

• Tras conectar la tensión de servicio, en la pantalla aparece la pantalla de inicio.

12. Pantalla con teclas de menú

Escape - interrumpe todos los procesos o

salta al nivel de menú anterior.

Cursor arriba - se desplaza por el menú

hacia arriba línea a línea.

Cursor abajo - se desplaza por el menú

hacia abajo línea a línea.

Cursor a la derecha - se desplaza por el

menú.

Cursor a la izquierda - se desplaza por el

menú.

Enter - aplica los valores elegidos o pasa

al nivel de menú siguiente.

- 46 -

ZMI_001_2000108123-ZA3OP0011_#SES_#AQU_#V3.fm

Page 47

13. Autorizaciones/Contraseñas

PIN

0 0 0 0 0

Nivel de autorización

Existen diferentes niveles de autorización para ver y modificar los parámetros de

servicio dentro del control multifunción:

Nivel Personal No se necesita ninguna contraseña; solo sirve

para ver algunos parámetros.

Nivel Técnico Contraseña de cliente/propietario: permite

cambiar y almacenar todos los derechos de

acceso, entre otros.

Las contraseña constan de un código numérico

de 5 posiciones.

Introducción de la contraseña (PIN)

13.1

Pulse la tecla .

13.2

Utilice las teclas y para ajustar

el dígito deseado.

13.3

Utilice la tecla para pasar a la

siguiente posición.

☞ Si el PIN se ha introducido correctamente, en la pantalla aparece el menú

principal. Si se ha introducido un número incorrecto y se ha confirmado con la

tecla Enter, en la pantalla sigue apareciendo el mensaje que solicita la introducción del PIN.

Restablecer nivel de autorización

El nivel de autorización debe restablecerse si, por ejemplo, el control debe protegerse frente a un acceso no autorizado después de su uso en el nivel Técnico.

☞ Si no se introduce ningún dato en el panel de mando del control durante más de 4

minutos, el nivel de autorización se restablece automáticamente.

ZMI_001_2000108123-ZA3OP0011_#SES_#AQU_#V3.fm

- 47 -

Page 48

14. Pantalla del nivel Personal

ECC2 ECC-Name

(ECC2 Nombre ECC)

22/01/2013

14:21

Menü

Página 1 Módulos

Guarniciones

8/10

Página 2 Tensión

24.63V

Página 3 Error

(9)

22.01.2013 13:43 1000

22.01.2013 13:39 1

22.01.2013 13:36 1

21.01.2013 07:50 1

Página 4 Versión

Version x.xx

Página 5 IP

estática

IP 10.222.48.226

NM 255.255.0.0

GW 10.222.0.50

DNS

Tras conectar la tensión de servicio,

aparece la pantalla de inicio.

14.1

Utilice las teclas y para ajustar

la página deseada.

Página 1

Muestra el número de guarniciones

que se encuentran conectadas y en

servicio.

Por ejemplo: 8 de 10 guarniciones

conectadas se encuentran en

servicio

Página 2

Muestra la tensión de servicio de las

guarniciones.

Página 3

Muestra

– el número de mensajes de error

que están almacenados

– los últimos 5 mensajes de error

con fecha, hora y código de

error (siehe Kapitel 21.).

Página 4

Muestra la versión de software que

está instalada en el controlador de

funciones ECC2.

Página 5

Muestra las identificaciones de

equipo y de red que tiene el controlador de funciones ECC2.

ZMI_001_2000108123-ZA3OP0011_#SES_#AQU_#V3.fm

- 48 -

Page 49

15. Configuración del nivel Técnico

Menú principal

Config. red

Formato fecha/hora

Definir fecha/hora

Temperatura

Reiniciar

OKCancelar

Configuración de red

IP 010.222.048.222

NM 255.000.000.000

GW 010.222.000.050

DNS 255.000.000.000

OKCancelar

select language

Deutsch

Englisch

čeština

Dansk

OKCANCEL

15.1

Introduzca el PIN (siehe Kapitel 13.).

• Aparece el menú principal.

15.2

Utilice las teclas y para seleccionar el menú principal.

15.3

Confirme su selección con la

tecla .

• El menú deseado se abre.

Configuración de red

15.4

Seleccione el menú "Config. red".

15.5

Utilice las teclas y para seleccionar el número deseado.

15.6

Utilice las teclas y para seleccionar el bloque numérico deseado.

15.7

Utilice las teclas y para ajustar

el número deseado.

15.8

Confirme su selección con la

tecla .

• Los datos introducidos se

guardan.

• Se abre el menú principal.

o

Pulse la tecla .

• Los datos introducidos no se

guardan.

• Se abre el menú principal.

Ajuste del idioma

15.9

Mantenga pulsada la tecla

durante aprox. 3 segundos.

15.10

Utilice las teclas y para ajustar

el idioma deseado.

15.11

Confirme su selección con la

tecla .

ZMI_001_2000108123-ZA3OP0011_#SES_#AQU_#V3.fm

- 49 -

Page 50

Formatos de fecha/hora

Formatos de fecha/hora

Fecha DD/MM/AAAA

Formato de 24 horas

Horario de verano

OKCancelar

Definir fecha/hora

Fecha 21/01/2013

Hora 15:21

OKCancelar

15.12

Seleccione el menú "Formato de

fecha/hora".

15.13

Utilice las teclas y para seleccionar el formato deseado.

15.14

Pulse la tecla .

15.15

Utilice las teclas y para ajustar

el formato deseado.

15.16

Confirme su selección con la

tecla .

• Los datos introducidos se

guardan.

• Se abre el menú principal.

o

Pulse la tecla .

• Los datos introducidos no se

guardan.

• Se abre el menú principal.

Definir fecha/hora

15.17

Seleccione el menú "Definir fecha/

hora".

15.18

Utilice las teclas y para seleccionar entre la fecha y la hora.

15.19

Pulse la tecla .

15.20

Utilice las teclas y para definir

la fecha o la hora deseadas.

15.21

Confirme su selección con la

tecla .

• Los datos introducidos se

guardan.

• Se abre el menú principal.

o

Pulse la tecla .

• Los datos introducidos no se

guardan.

• Se abre el menú principal.

ZMI_001_2000108123-ZA3OP0011_#SES_#AQU_#V3.fm

- 50 -

Page 51

Temperatura/Unidad (para el

Temperatura/Unidad

°C/°F °C

Mezclador 1 65,0°C

Mezclador 2 65,0°C

Mezclador 3 65,0°C

OKCancelar

termostato de grupo electrónico)

15.22

Seleccione el menú "Temperatura".

15.23

Utilice las teclas y para seleccionar las unidades o el mezclador

deseado.

15.24

Pulse la tecla .

15.25

Utilice las teclas y para ajustar

la unidad o la temperatura deseadas.

15.26

Confirme su selección con la

tecla .

• Los datos introducidos se

guardan.

• Se abre el menú principal.

o

Pulse la tecla .

• Los datos introducidos no se

guardan.

• Se abre el menú principal.

Reiniciar controlador de funciones

ECC2

15.27

Seleccione el menú "Reiniciar".

• El controlador de funciones ECC2

se reinicia.

16. Iniciar aplicación Web

16.1

Conecte el PC a una red.

16.2

Abra un explorador de Internet.

16.3

Introduzca la IP del controlador de funciones ECC2 en la línea de dirección del

explorador.

16.4

Introduzca el usuario y la contraseña.

16.5

Haga clic en el botón "Iniciar sesión"