Page 1

Service Manual

Model

PD-6

DVD LOCATION RECORDER

<DANGER>

VISIBLE OR INVISIBLE LASER RADIATION WHEN OPEN.

AVOID DIRECT EXPOSURE TO BEAM.

<CAUTION>

• Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous

radiation exposure.

• The use of optical instruments with this product will increase

eye hazard.

Page 2

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

CAUTION:

TO PREVENT ELECTRIC SHOCK, MATCH

WIDE BLADE OF PLUG TO WIDE SLOT,

FULLY INSERT.

CAUTION: TO REDUCE THE RISK OF ELECTRIC SHOCK,

DO NOT REMOVE COVER (OR BACK).

NO USER-SERVICEABLE PARTS INSIDE.

REFER SERVICING TO QUALIFIED SERVICE PERSONNEL.

The lightening flash with arrowhead symbol,

within an equilateral triangle, is intended to

alert the user to the presence of uninsulated

“dangerous voltage” within the product's

enclosure that may be of sufficient magnitude to constitute a risk of electric shock to

persons.

“WARNING”

“TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK,

DO NOT EXPOSE THIS APPLIANCE TO RAIN OR MOISTURE.”

SAFETY INSTRUCTIONS

Read instructions - All the safety and operating instruc-

1.

tions should be read before the appliance is operated.

Retain instructions - The safety and operating instructions

2.

should be retained for future reference.

Heed warnings - All warnings on the appliance and in the

3.

operating instructions should be adhered to.

Follow instructions - All operating and use instructions

4.

should be followed.

Water and Moisture - The appliance should not be used

5.

near water - for example, near a bathtub, washbowl,

kitchen sink, laundry tub, in a wet basement, or near a

swimming pool, and the like.

Carts and Stands - The appliance should be used only

6.

with a cart or stand that is recommended by the manufacturer.

An appliance and cart combination should be moved with

care. Quick stops, excessive force, and uneven surfaces

may cause the appliance and cart combination to overturn.

Wall or Ceiling Mounting - The appliance should be

7.

mounted to a wall or ceiling only as recommended by the

manufacturer.

Ventilation - The appliance should be situated so that its

8.

location or position does not interfere with its proper ventilation. For example, the appliance should not be situated on a bed, sofa, rug, or similar surface that may block

the ventilation openings; or, placed in a built-in installation, such as a bookcase or cabinet that may impede the

flow of air through the ventilation openings.

ATTENTION:

POUR ÉVITER LES CHOCS ÉLECTRIQUES,

INTRODUIRE LA LAME LA PLUS LARGE DE

LA FICHE DANS LA BORNE CORRESPONDANTE DE LA PRISE ET POUSSER

JUSQU' AU FOND.

The exclamation point within an equilateral

triangle is intended to alert the user to the

presence of important operating and maintenance (servicing) instructions in the literature accompanying the appliance.

Heat - The appliance should be situated away from heat

9.

sources such as radiators, heat registers, stoves, or other

appliances (including amplifiers) that produce heat.

Power Sources - The appliance should be connected to a

10.

power supply only of the type described in the operating

instructions or as marked on the appliance.

Grounding or Polarization - The precautions that should

11.

be taken so that the grounding or polarization means of

an appliance is not defeated.

Power Cord Protection - Power supply cords should be

12.

routed so that they are not likely to be walked on or

pinched by items placed upon or against them, paying

particular attention to cords at plugs, convenience receptacles, and the point where they exit from the appliance.

Cleaning - The appliance should be cleaned only as rec-

13.

ommended by the manufacturer.

Nonuse Periods - The power cord of the appliance should

14.

be unplugged from the outlet when left unused for a long

period of time.

Object and Liquid Entry - Care should be taken so that

15.

objects do not fall and liquids are not spilled into the enclosure through openings.

Damage requiring Service - The appliance should be ser-

16.

viced by qualified service personnel when:

The power supply cord or the plug has been damaged;

A.

or

Objects have fallen, or liquid has been spilled into the

B.

appliance; or

The appliance has been exposed to rain; or

C.

The appliance does not appear to operate normally or

D.

exhibits a marked changed in performance; or

The appliance has been dropped, or the enclosure

E.

damaged.

Servicing - The user should not attempt to service the ap-

17.

pliance beyond that described in the operating instructions. All other servicing should be referred to qualified

service personnel.

Page 3

TABLE OF CONTENTS

PD-6 Service Manual

1.

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.

CONTROLS, INDICATORS & CONNECTORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.

SOFTWARE UPDATE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.

SERVICE MENUS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.

ERROR CODE LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.

EXPLODED VIEW, PCB ASSEMBLY & PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . .

7.

CIRCUIT & BLOCK DIAGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.

LOCATION OF IDENTIFICATION / CERTIFICATION LABEL . . . . . . . . . . . . . . . . . .

4

8

11

14

21

22

52

83

NOTES

* Service menus, exploded view, PCB assembly, parts list and circuit diagrams are given in this manual to assist

the service technician in maintaining the Model PD-6.

* The following accessories are supplied with PD-6 as the standard accessories.

PD-6 owner's manual, English : 8288498000

PD-6 owner's manual, Japanese : 8288499000

PD-6 owner’s manual supplement, 1.01, ENG : 8289602000

PD-6 owner’s manual supplement, 1.01, JPN : 8289603000

PD-6 owner’s manual supplement, 1.02, ENG : 8289604000

PD-6 owner’s manual supplement, 1.02, JPN : 8289605000

Shoulder belt assy : 8260374200

DVD-RAM disk, DRMS-V28R 1P : 8266097000

* Following is the packing material for the Model PD-6.

Carton, inner, PD-6 : 8228753000

Carton, outer, PD-6 : 8228932000

Packing, side, L, PD-6 : 8228477001

Packing, side, R, PD-6 : 8228477002

CAUTION

Parts marked with this sign are safety critical components. They must always be replaced with identical

components. Refer to the Fostex Parts List and ensure exact replacement.

3

Page 4

PD-6 Service Manual

1. SPECIFICATIONS

SPECIFICA TION UNIT

0 dBu = 0.775 V r.m.s.

INPUT & OUTPUT

REFERENCE LEVEL -18 dB / -20 dB (default) (Switchable by SETUP mode)

ANALOG INPUT (CH 1 ~ 6)

Connector XLR-3-31 type (Pin 1: GND, Pin 2: HOT , Pin 3: COLD)

Input Impedance 10 kΩ or more

LINE

Input Level - 30 ~ + 4 dBu (± 5 dB)

Maximum Input Level (REF: -20 dB) + 24 dBu (+ 41 dBu (pre fader))

MIC

Input Level - 60 ~ - 26 dBu (± 5 dB)

Maximum Input Level (REF: -20 dB) - 40 dBu (- 23 dBu (pre fader))

ANALOG OUTPUT (TRK 1 ~ 6)

Connector XLR-3-32 type (Pin 1: GND, Pin 2: HOT , Pin 3: COLD)

Load Impedance 10 kΩ or more

Standard Output Level + 4 dBu

Maximum Output Level + 24 dBu

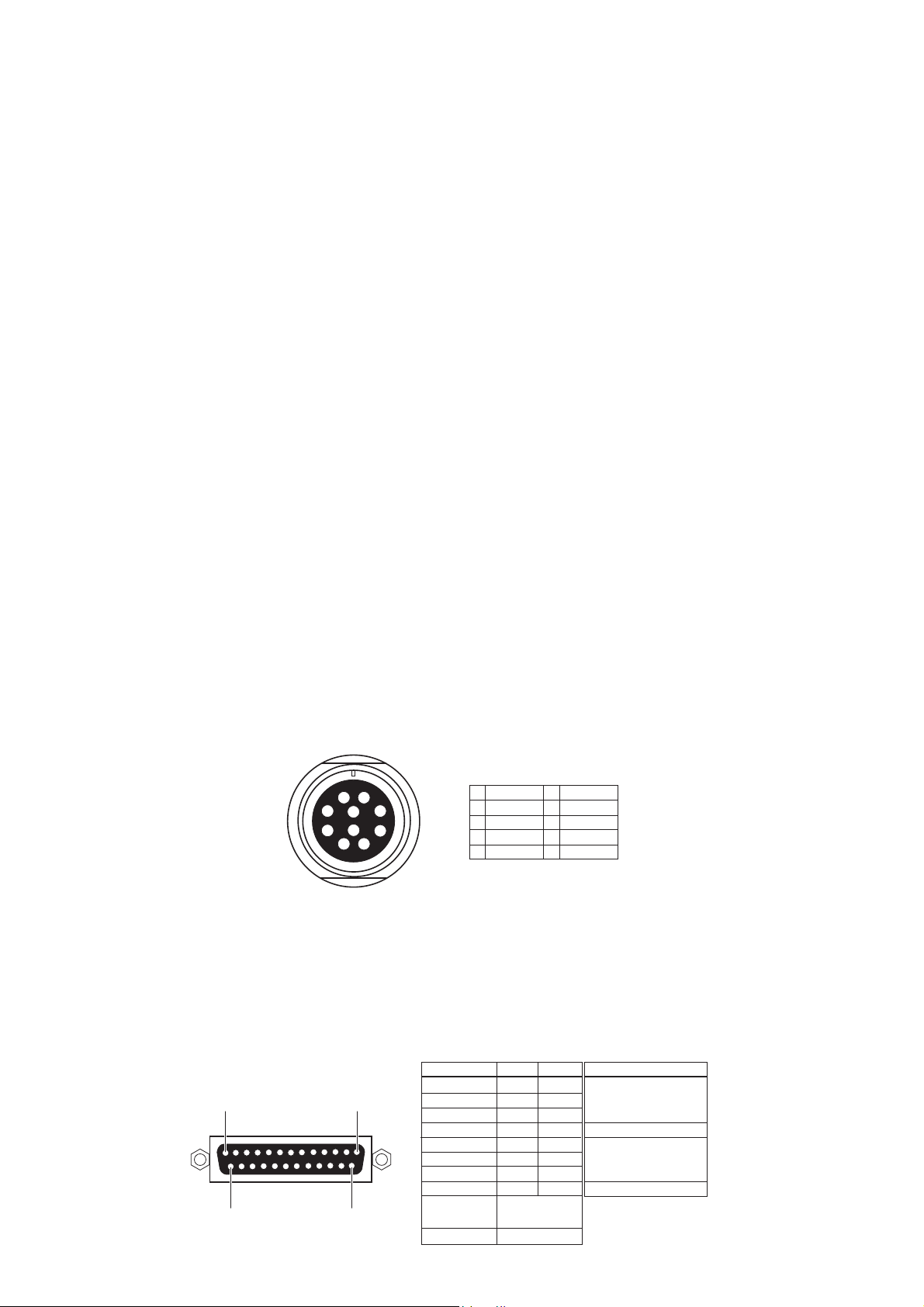

AUX I/O

Connector Hirose RM15TRD-10S, female

Input Balanced audio input for monitoring purpose

Input Impedance 10 kΩ or more

Standard Input Level + 4 dBu

Maximum Input Level + 24 dBu

Output Balanced ST BUSS OUT

Load Impedance 10 kΩ or more

Standard Output Level + 4 dBu / - 10 dBu / - 60 dBu (switchable)

Maximum Output Level + 24 dBu

1

1

8

7

2

9

10

3

465

L OUT +

2

L OUT -

3

R OUT +

4

R OUT -

5

R IN +

10

6

7

8

9

R IN L IN +

L IN GND

GND

DIGIT AL I/O (CH 1 ~ 6)

Connector D-SUB 25-pin

Format

Input Detect either IEC60958 PART 3 (AES/EBU) or IEC60958

PART 2 (S/P DIF) automatically

Output Either IEC60958 PART 3 (AES/EBU) or IEC60958 PART 2

(S/P DIF) is selectable by SETUP menu

Signal

Input 1/2

13

1

1425

Input 3/4

Input 5/6

Input 7/8

Output 1/2

Output 3/4

Output 5/6

Output 7/8

Frame GND

Open

Hot

Cold

1

14

2

15

3

16

4

17

5

18

6

19

7

20

8

21

10, 12, 13, 22,

23, 24, 25

9, 11

Terminal Treatment

Open

GND

4

Page 5

PD-6 Service Manual

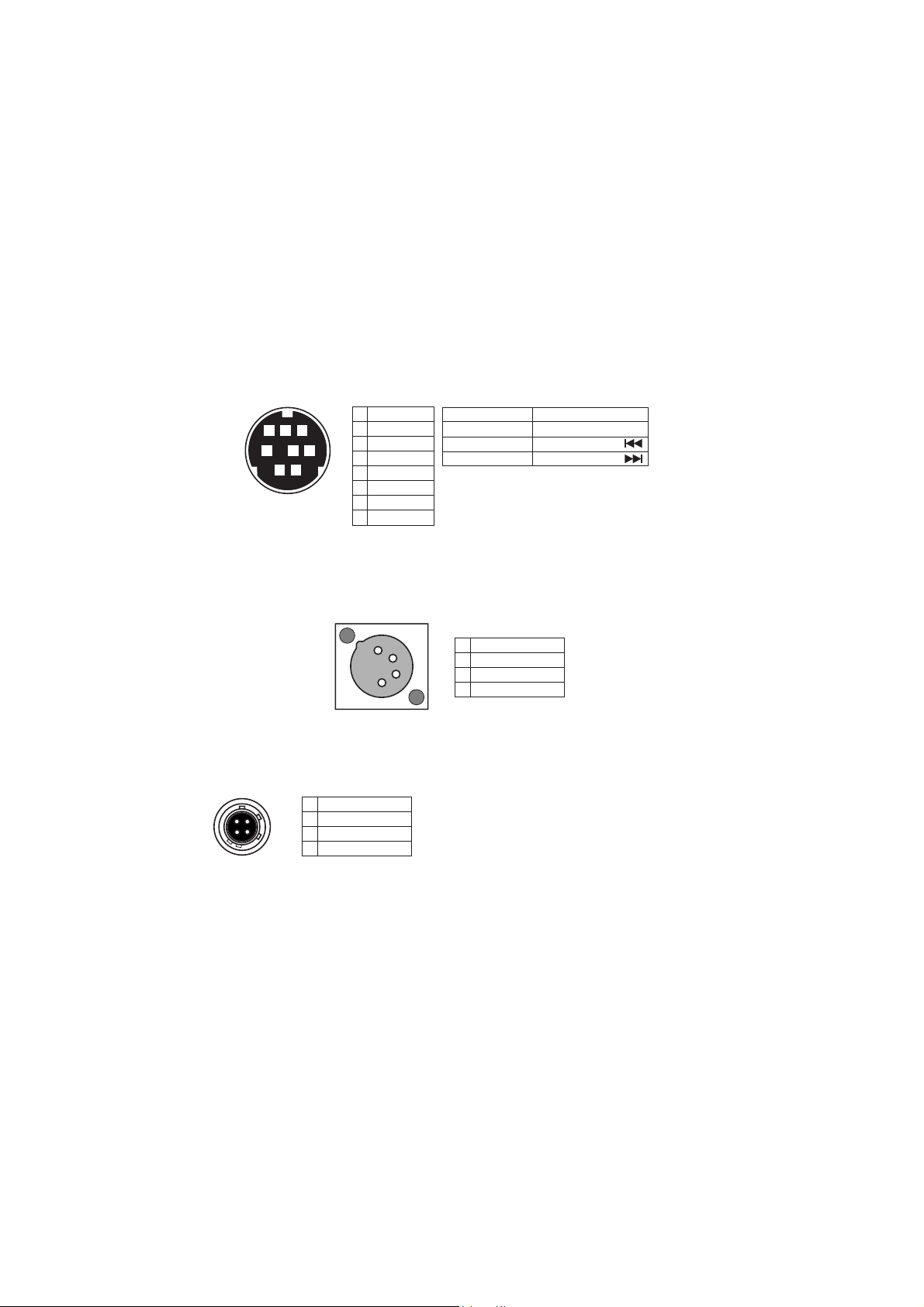

TIME CODE INPUT

Connector XLR-3-31 type (Pin 1: GND, Pin 2: HOT , Pin 3: COLD)

Format SMPTE / EBU

Input Impedance 20 kΩ or more

Standard Input Level 2 V p-p

Minimum Input Level 0.25 V p-p

TIME CODE OUTPUT

Connector XLR-3-32 type (Pin 1: GND, Pin 2: HOT , Pin 3: COLD)

Format SMPTE / EBU

Output Impedance 1 kΩ or less

Standard Output Level 2 V p-p

Load Impedance 600 Ω or more

VIDEO/WORD INPUT

Connector BNC (Automatically switchable)

Standard Input Level TTL level (with 75 Ω terminate switch)

WORD OUTPUT

Connector BNC

Standard Output Level TTL level

AA TON I/O (optional)

Connector LEMO 5-pin connector

Format ASCII I/O & L TC I/O (parallel with TC I/O)

1

1

2

5

4

3

GND

2

LTC OUT

3

ASCII IN-OUT

4

AUDIO TAPE (not compatible)

5

LTC IN

IEEE1394

Format Comply to P1394a Draft 2.0, 4-pin, for PC connection

1

2314

2

3

4

TPB TPB +

TPA TPA +

USB

Connector Series A receptacle, for connecting a USB keyboard only

1

VBUS

2

2314

D -

3

D +

4

GND

PHONES (MONO / MS / SOLO/ PFL / AUX IN /

ST BUS / 1+2 / 1, 3, 5 + 2, 4, 6 / 3, 5 + 4, 6)

Connector ø 6.35 mm stereo phone jack

Load Impedance 32 Ω or more

Maximum Output Level 200 mW at 32 Ω

SPEAKER (with Drip-proof type sheet)

Impedance 4 Ω

Maximum Output Level 720 mW

5

Page 6

PD-6 Service Manual

SLA TE MIC Switch between 1 kHz reference tone and analog input signal.

SLA TE TONE Switch between internal microphone and analog input signal.

LIMITER

Attack Time About 20 msec

Release Time About 150 msec

Threshold Full Scale level - 6 / - 12 dB (Selectable by SETUP mode)

Ratio 1 : 5 / 1 :2 3 (Selectable by SETUP mode)

Link MONO / 1-2 CH / 1-6 CH (Selectable by SETUP mode)

PARALLEL REMOTE

Connector Mini DIN, 8-pin, female

Pin assignment Comply to PD-2 / PD-4. It functions regardless of PANEL

87

2

It can be used for Input / Master fader adjustment.

LOCK key. Connecting a terminal to GND activates a function.

1

PLAY

2

STOP

3

3465

1

REC

4

GND

5

SHIFT

6

REWIND

7

VBATT*

8

FF

SHIFT + STOP

SHIFT + REC

SHIFT + REW

SHIFT + FF

DC + 12 ~ 18 V, MAX 500 mA.

*

DC voltage is output regardless

of PD-6 POWER ON/OFF condition.

CUE

PAUSE

SKIP/CURSOR

SKIP/CURSOR

DC 12 V IN

Connector XLR-4-32 type, male

Pin assignment Comply to PD-2. It functions regardless of P ANEL LOCK key .

4

3

2

1

1

GND

2

NC

3

NC

4

DC +12 ~ 18 V

DC 12 V OUT (x 2)

Connector Hirose HR10-7R-4S, 4-pin, female

Output DC voltage input to DC 12V IN terminal is output.

3

1

42

GND

2

NC

3

NC

4

DC OUT*

DC voltage input to DC IN via protection

*

components are output regardless of

PD-6 POWER ON/OFF condition.

1

RECORD & PLA YBACK

MEDIUM ATAPI (E-IDE) standard 8 cm DVD-RAM drive / disk

RESOLUTION / SAMPLING FREQUENCY 16 bits: 44.1 / 48 kHz

24 bits: 44.1 / 48 / 88.2 / 96 kHz

TRACK MODE

2TRK 44.1 / 48 / 88.2 / 96 kHz

4TRK 44.1 / 48 kHz

5TRK 44.1 / 48 kHz

6TRK 44.1 / 48 kHz

2 + 4TRK 44.1 / 48 kHz

1 + 5TRK 44.1 / 48 kHz

RECORDING TIME (on one side of 8 cm DVD-RAM

disk (about 1.2GB capacity after UDF formatting))

16 bits, 2TRK, 44.1 / 48 kHz About 118 / 108 minutes

24 bits, 2TRK, 44.1 / 48 / 88.2 / 96 kHz About 78 / 72 / 39 / 36 minutes

24 bits, 6TRK, 44.1 / 48 kHz About 26 / 24 minutes

6

Page 7

PD-6 Service Manual

OPERATION

LOCA TE MEMOR Y Cue Point Chunk: 100

EXT / INT BATT key

DISPLAY

DIMENSIONS

WEIGHT

USAGE CONDITION

POWER

INTERNAL NP-1 type battery

EXTERNAL AD-15C

BACKUP BATTERY CR2032 lithium battery (lasting about 3 years)

POWER CONSUMPTION

Black & White LCD (128 x 64 dots)

Bargraph level meter, various time display / mode, setting and

battery remain display

329 (W) x 110 (H) x 245 (D) mm

About 3.4 kg (without NP-1 type battery)

Horizontal / vertical continuous operation

DC 11.5 ~ 18 V (Switchable by INT/EXT SW)

25 W

REGULA TED ENVIRONMENT

ST ANDARD TEMPERA TURE 20 ± 5 °C

ST ANDARD HUMIDITY 65 ± 5 %

ENVIRONMENT AL CONDITION

CHARACTERISTICS GUARANTEED

Temperature 0 ~ + 45 °C

Humidity 30 ~ 70 %

Power Supply Deviation DC 11.5 ~ 18 V

OPERA TION GUARANTEED

Temperature - 10 ~ + 50 °C

Humidity 85 % or less (without water droplet attached)

Power Supply Deviation DC 11.5 ~ 18 V

CHARACTERISTICS

REC / PLA Y FREQUENCY RESPONSE

FS: 44.1 / 48 kHz 20 ~ 20,000 Hz ± 1 dB

FS: 88.2 / 96 kHz 20 ~ 40,000 Hz ± 1 dB

S/N (ADC - DAC, 24 bits, REF: -20 dB, FS; 48 kHz)

(INPUT GAIN: + 4 dBu)

LINE

(INPUT GAIN: -60 dBu, AMP GAIN: 40 dB)

MIC

DYNAMIC RANGE (ADC - DAC, 24 bits, REF: -20 dB,

FS; 48 kHz)

(INPUT GAIN: + 4 dBu)

LINE

THD (ADC - DAC, 24 bits, REF: -20 dB, FS; 48 kHz)

(INPUT GAIN: + 4 dBu)

LINE

(INPUT GAIN: - 60 dBu)

MIC

CLOCK DEVIA TION ± 3 ppm

CHANNEL SEPARATION 90 dB or more at 1 kHz, 0 dB, 24 bits, REF: -0 dB, FS: 48 kHz

PHASE DIFFERENCE 20 ° or less at 20 kHz

CLICK NOISE

Power On/Off - 30 dBVp-p (- 16 dBup-p) or less

SAFETY ST ANDARD

97 dB

84 dB

97 dB

0.008 % or less (at 1 kHz, - 1 dB)

0.010 % or less (at 1 kHz, - 1 dB)

Comply to UES60065, IEC60825-1.

OTHER ST ANDARDS

EMI EN 55011 Class A, EN 61000-3-2/3-3

EMS EN61000-6-1

Specifications and physical appearance are subject to change without notice for product improvement.

7

Page 8

PD-6 Service Manual

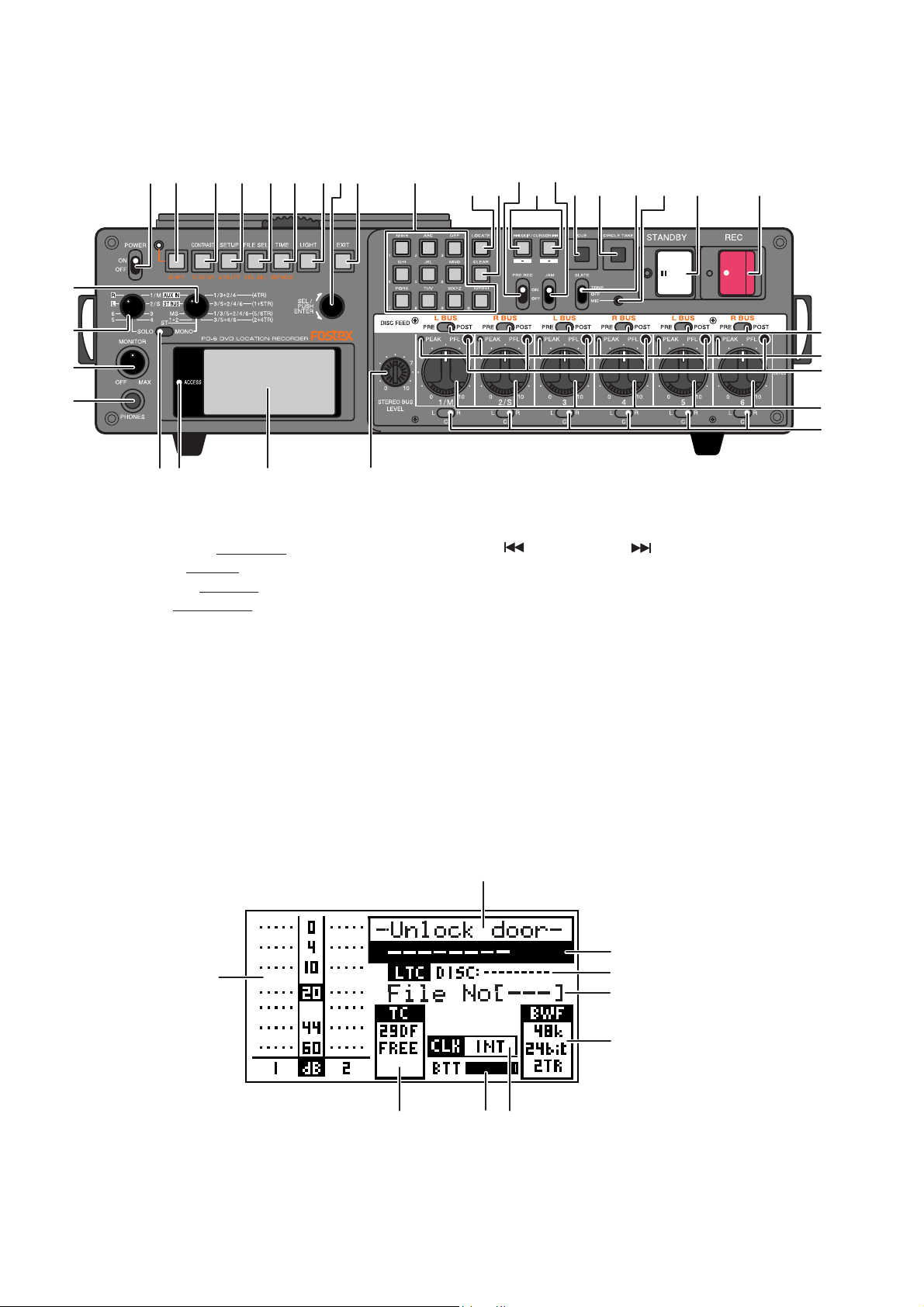

2. CONTROLS, INDICATORS & CONNECTORS

< FRONT PANEL Section >

12 34 56798

16

15

13

12

11 1014

1. [POWER] switch

2. [SHIFT] key / LED

3. [CONTRAST /

4. [SETUP / UTILITY] key

5. [FILE SEL / EDL SEL] key

6. [TIME /

7. [LIGHT] key

8. [EXIT] key

9. [SEL] dial / [ENTER] key

10. LCD display

11. [ACCESS] LED

12. [PHONES] jack

13. [MONITOR] knob

14. [SOLO] monitor select switch

15. Monitor mode select switch

16. [ST/MONO] monitor select switch

17. 10 key

TC SETUP] key

DISP MODE] key

34

17

282027

18 19

18. [LOCATE] key

19. [CLEAR] keys

20. [

21. [CUE] key

22. [CIRCLE TAKE] key

23. [STANDBY] key / Indicator (green)

24. [REC] key / Indicator (red)

25. Slate microphone

26. [SLATE] select switch

27. [JAM] switch

28. [PRE REC] ON/OFF switch

29. [DISK FEED] switch

30. [PEAK] indicator

31. [PFL (Pre Fader Listen)] key

32. [LEVEL] knob

33. [PAN] switch

34. [STEREO BUS LEVEL] knob

21 22 26 23 24

SKIP/CURSOR ] key

25

29

30

31

32

33

< LCD DISPLAY Section >

2

3

1

789

1. Level meter section

2. File name field

3. Time display field

4. Remain field

5. File number field

6. File information field

7. Clock field

8. Battery field

9. TC field

8

4

5

6

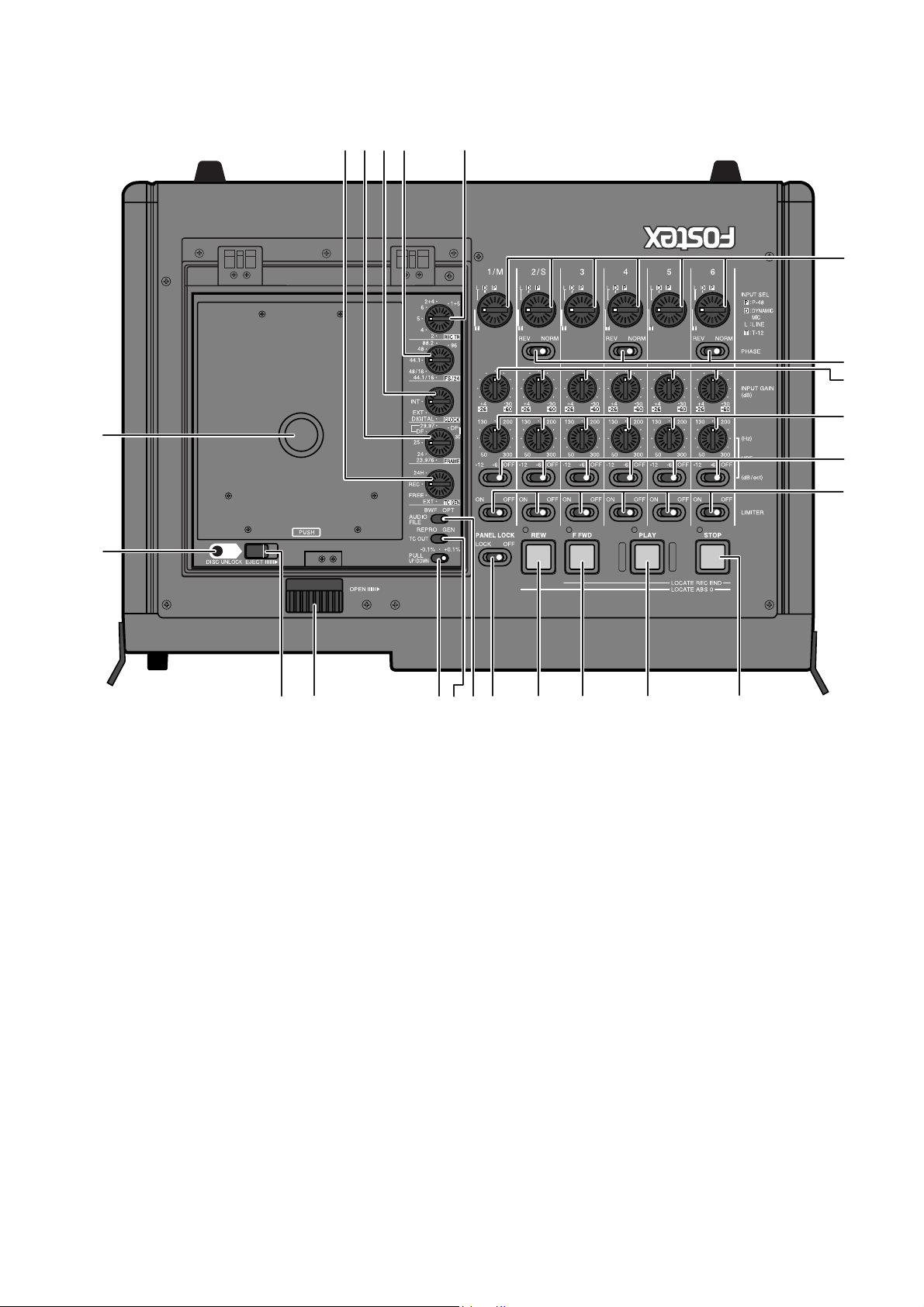

Page 9

< TOP PANEL Section >

78 6910

11

12

54321

23 22 21 20 19

18

17

16

15

14

13

PD-6 Service Manual

1. [TC GEN] switch

2. [FRAME] switch

3. [CLOCK] switch

4. [FS/24] select switch

5. [REC TR] select switch

6. [AUDIO FILE] select switch

7. [TC OUT] switch

8. [PULL UP/DOWN] switch

9. [OPEN] lever

10. [EJECT] lever

11. [DISC UNLOCK] button

12. Disc tray section

13. [INPUT MODE] switch

14. [PHASE] switch

15. [INPUT GAIN] knob

16. [HPF] knob

17. [HPF] switch

18. [LIMITER] switch

19. [STOP] key / Indicator (green)

20. [PLAY] key / Indicator (green)

21. [F FWD] key / Indicator (green)

22. [REW] key / Indicator (green)

23. [PANEL LOCK] switch

9

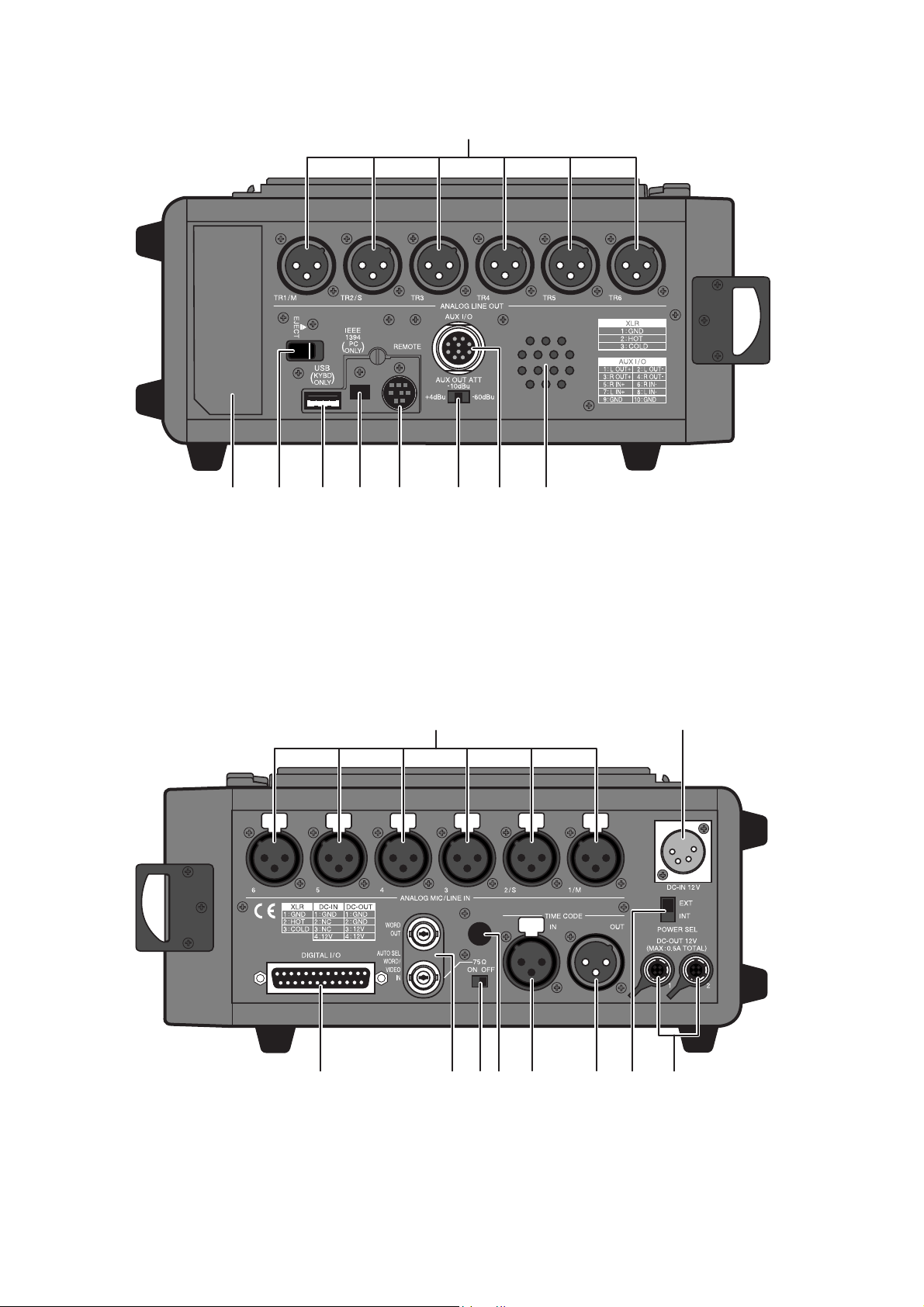

Page 10

PD-6 Service Manual

< SIDE PANEL (left) Section >

1

8 7 6 5 43 29

1. [ANALOG LINE OUT] connectors

2. Internal monitor speaker

3. [AUX I/O] connector

4. [AUX OUT ATT] switch

5. [REMOTE] connector

< SIDE PANEL (right) Section >

6. [IEEE1394] connector

7. [USB] connector

8. [EJECT] lever

9. Battery housing

1

2

10

10

1. [ANALOG MIC/LINE IN] connectors

2. [DC-IN 12V] connector

3. [POWER SEL (INT/EXT)] switch

4. [DC OUT] connector

5. [TIME CODE OUT] connector

8 5 4

6. [TIME CODE IN] connector

7. [WORD IN] terminate switch

8. Blank cap for installing options

9. [WORD/VIDEO IN], [WORD/OUT] connector

10. [DIGITAL I/O] connector–

37 69

Page 11

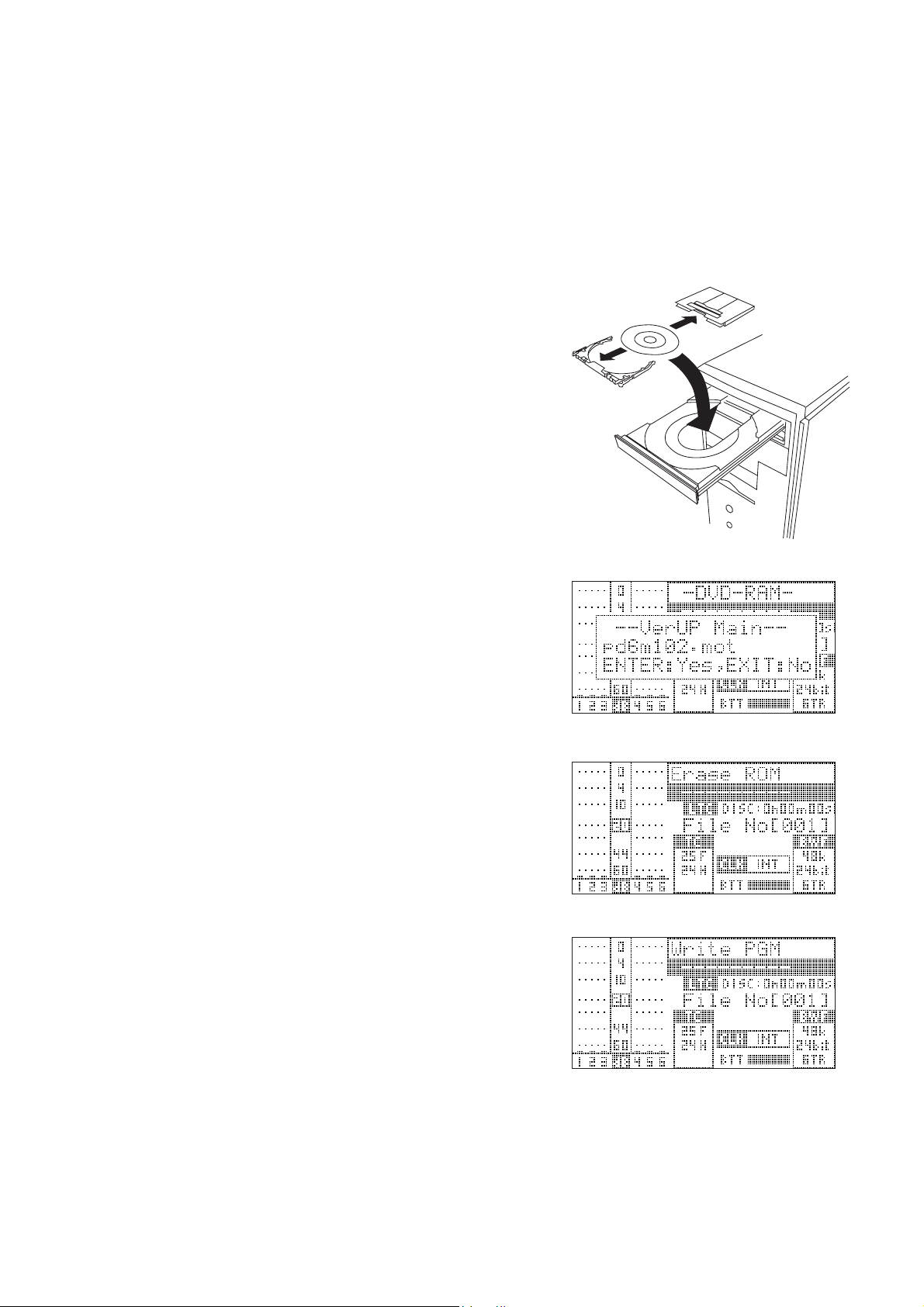

PD-6 Service Manual

3. SOFTWARE UPDATE

The PD-6 software can be updated by placing a software update file in the top directory tree on the 8 cm DVD-RAM

disk formatted by PD-6. There are two ways of copying the software update file from PC to the disk. Read through the

following procedures for proper software update.

3-1. MAIN PCB Software Update Procedures

3-1-1. There is an ATAPI, IEEE1394 or USB DVD-RAM drive exists in your PC environment;

1) Push down 2 pcs. of lock pins located at the lower left side on both

A and B sides of 8 cm DVD-RAM disk by using the tip of a ball

point pen, etc. Then, spin and move the lock pins out and around.

2) Take out the 8 cm DVD-RAM disk out of the cartridge and place

it in the indent of the DVD-RAM drive tray.

3) Extract the WinZip compressed software file “PD6VXXX.zip” and

copy the newly created software update file “pd6mXXX.mot” to

the top directory tree of the DVD-RAM disk. (“XXX” indicates

the software version number. If the software version is V1.02, the

software update file name will be “pd6m102.mot”.)

4) After copying the software, take out the 8cm DVD-RAM disk, put

it back to the cartridge and load it to the PD-6 DVD-RAM drive.

When putting a bare DVD-RAM disk back to the cartridge, be

sure that the side A of the disk conforms with the cartridge’s A

marking.

5) Power on PD-6. In the initialize stage, PD-6 automatically finds

the software update file placed in the top directory tree and is put

into the software update mode. The LCD example on the right

indicates that the PD-6 MAIN software is going to be updated to

V1.02 using the software file “pd6m102.mot”.

6) In the condition that the LCD example on the right is displayed,

press the ENTER key (knob) to update the software.

PD-6 starts updating the MAIN software. The LCD shows “Erase

ROM” (flashing) and then “Write PGM” (flashing).

7) After updating the software is completed, PD-6 is automatically

put initialized, booted up again and is put into the software update

mode. Press the EXIT key. (Depending on the current software

version, there is a case that powering off and then back on PD-6

might be required. Also there is a case that the display contents

differ from those listed in this page.)

8) Confirm the software version by the “Version” SETUP menu explained later.

DVD-RAM cartridge

DVD-RAM Drive

11

Page 12

PD-6 Service Manual

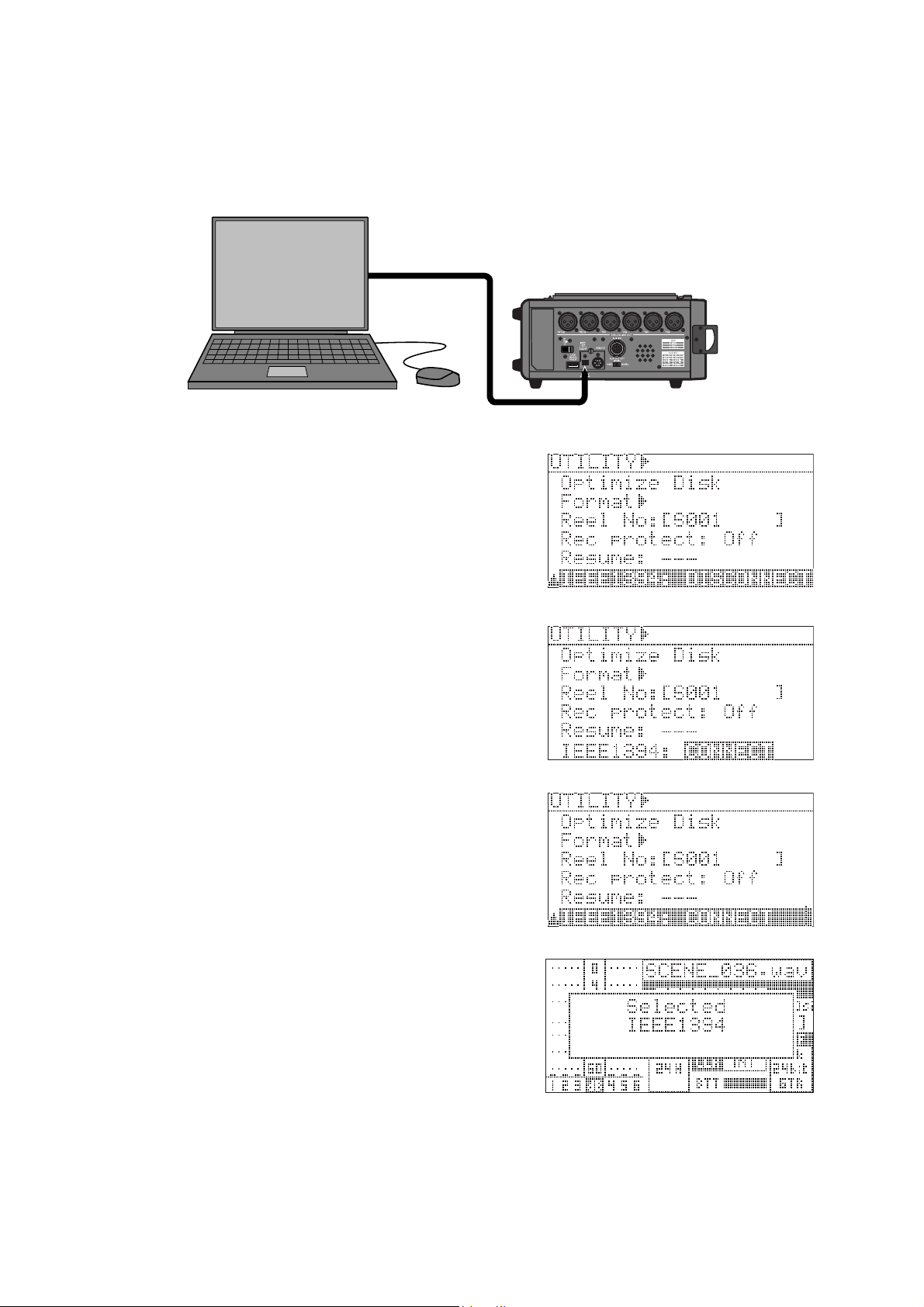

3-1-2. There is no ATAPI, IEEE1394 or USB DVD-RAM drive exists in your PC environment;

NOTE:

As mentioned in the PD-6 owner’s manual, depending on the operating system running on your computer, an

IEEE1394 driver software must be installed in your computer to allow to recognize the UDF formatted PD-6

DVD-RAM disk as a rewritable medium prior to the software update.

1) Select the IEEE1394 Utility menu and press the ENTER knob.

Then, turn the ENTER knob to right to select “CONNECT” and

press the ENTER knob again.

By putting PD-6 into the IEEE1394 mode, all functions are

disabled.

2) Connect the IEEE1394 cable between PC (Desktop PC: 6-pin,

Laptop PC: 4 or 6-pin) and PD-6 (4-pin) IEEE1394 ports.

3) Wait for a while until PC recognizes PD-6 with 8 cm DVD-RAM

disk loaded as an external rewritable removable drive / disk.

4) Extract the WinZip compressed software file “PD6VXXX.zip”

and copy the newly created software update file “pd6mXXX.mot”

to the top directory tree of the DVD-RAM disk. (“XXX” indicates

the software version number.)

5) After copying the software, select PD-6 (FOSTEX FX-FIRE IEEE

1394 SBP2 Device - (*)) and remove it from PC. (*: Drive No. on

your PC)

6) Disconnect the IEEE1394 cable from the PC / PD-6 and turn off

the IEEE1394 mode.

In the initializing stage, PD-6 automatically finds the software

update file placed in the first directory tree and is put into the

software update mode.

7) Press the ENTER key (knob) to update the software.

PD-6 starts updating the MAIN software. The LCD shows “Erase

ROM” (flashing) and then “Write PGM” (flashing).

8) After the software update is completed, power off PD-6 and then

back on. (Depending on the software version, there is a case that

PD-6 is automatically initialized and is booted up.)

9) Confirm the software version by the “Version” SETUP menu.

12

Page 13

PD-6 Service Manual

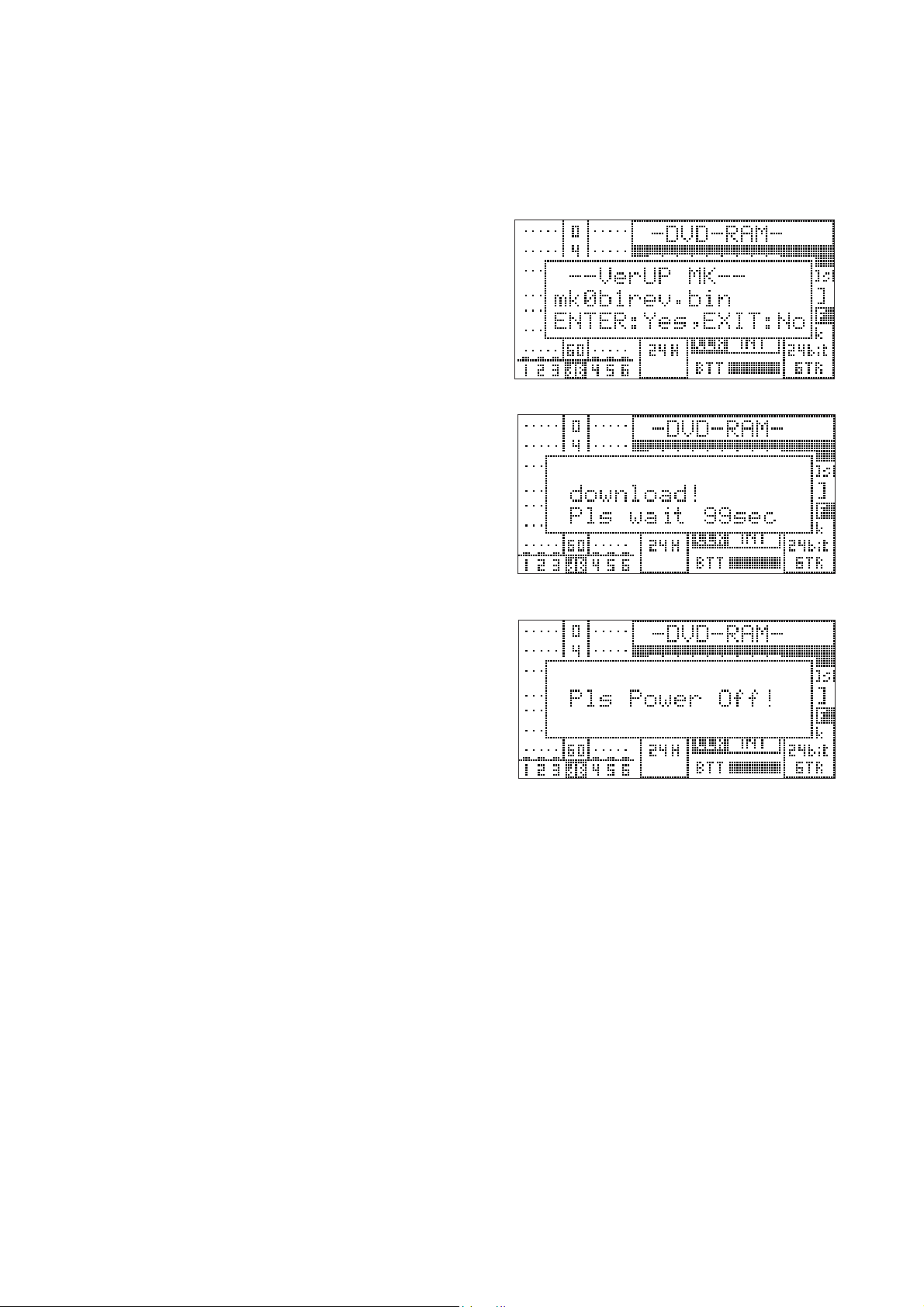

3-2. DVD-RAM Drive Firmware Update Procedures

There are two firmwares for DVD-RAM drive, which can be updated by a similar method explained before. Although

the DVD-RAM drive firmware update will not occur as many times as the MAIN PCB software update, read through

the following explanation for correct update procedures.

1) Copy the DVD-RAM drive firmware update file

“mkXXXrev.bin” to the top directory of the DVD-RAM

disk either by direct software file copy onto a 8 cm DVDRAM bare disk or by putting PD-6 into the IEEE1394

mode and connecting to PC.

2) In the initialize stage, PD-6 automatically finds the

firmware update file in the top directory tree and is put

into the update mode. The example on the right indicates

that there is a firmware update file “mk0b1rev.bin” exists

in the top directory tree.

3) Press the ENTER knob to update the DVD-RAM drive

firmware.

The firmware update remaining time starts counting down.

It will take about 100 seconds (1 minute and 40 seconds)

to complete the firmware update.

4) After the software update is completed, the message “Pls

Power Off!” will appear on the PD-6 LCD. Power off

PD-6 and then back on. (Depending on the software version, there is a case that PD-6 is automatically initialized

and is booted up again.)

5) Select “Reset setup memory” in the SERVICE menu ex-

plained later in this manual, press the ENTER knob and

press the ENTER knob again while “SURE?” is flashing

on the LCD to reset the memory.

6) Confirm the software version by the “Version” SETUP

menu.

13

Page 14

PD-6 Service Manual

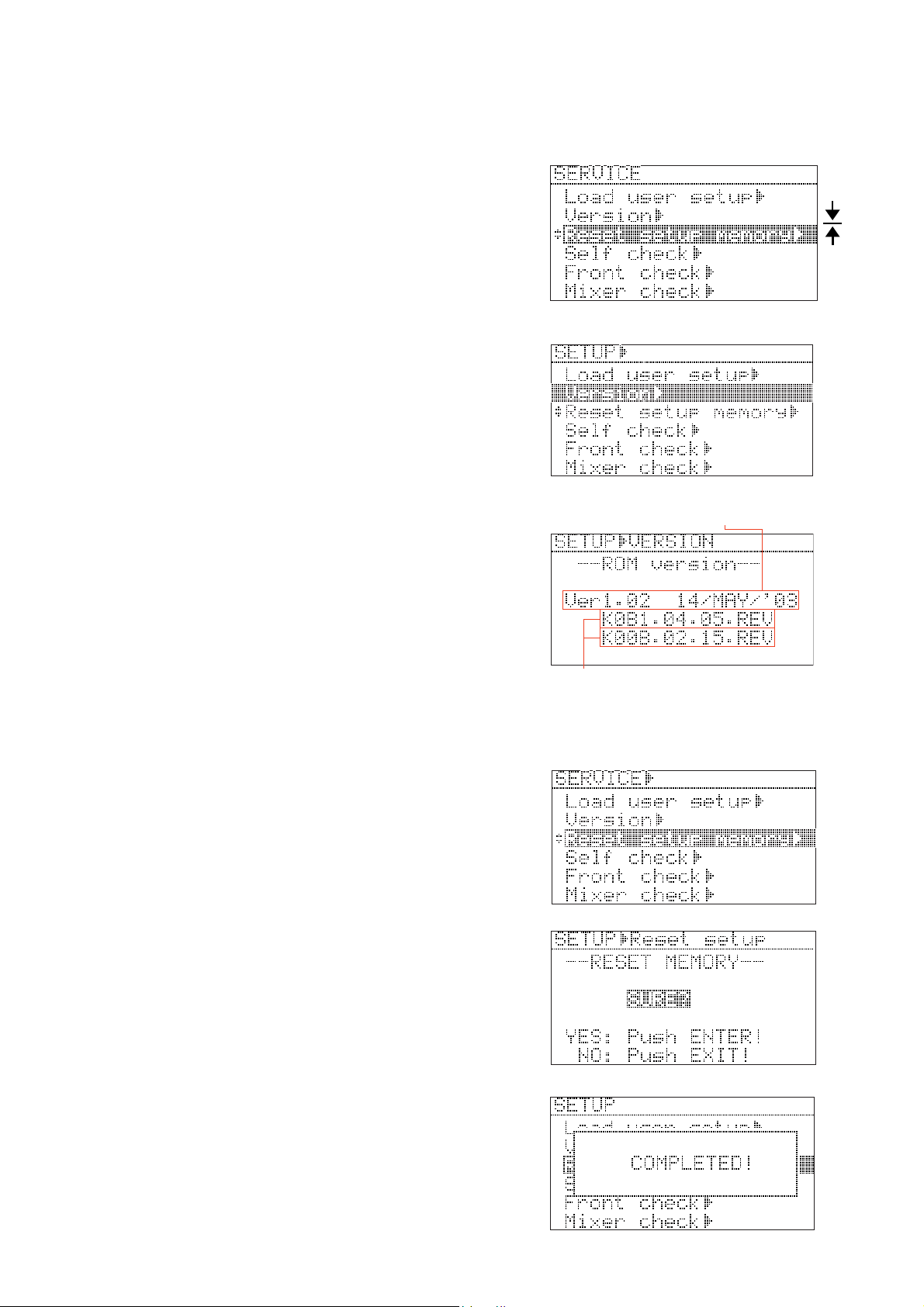

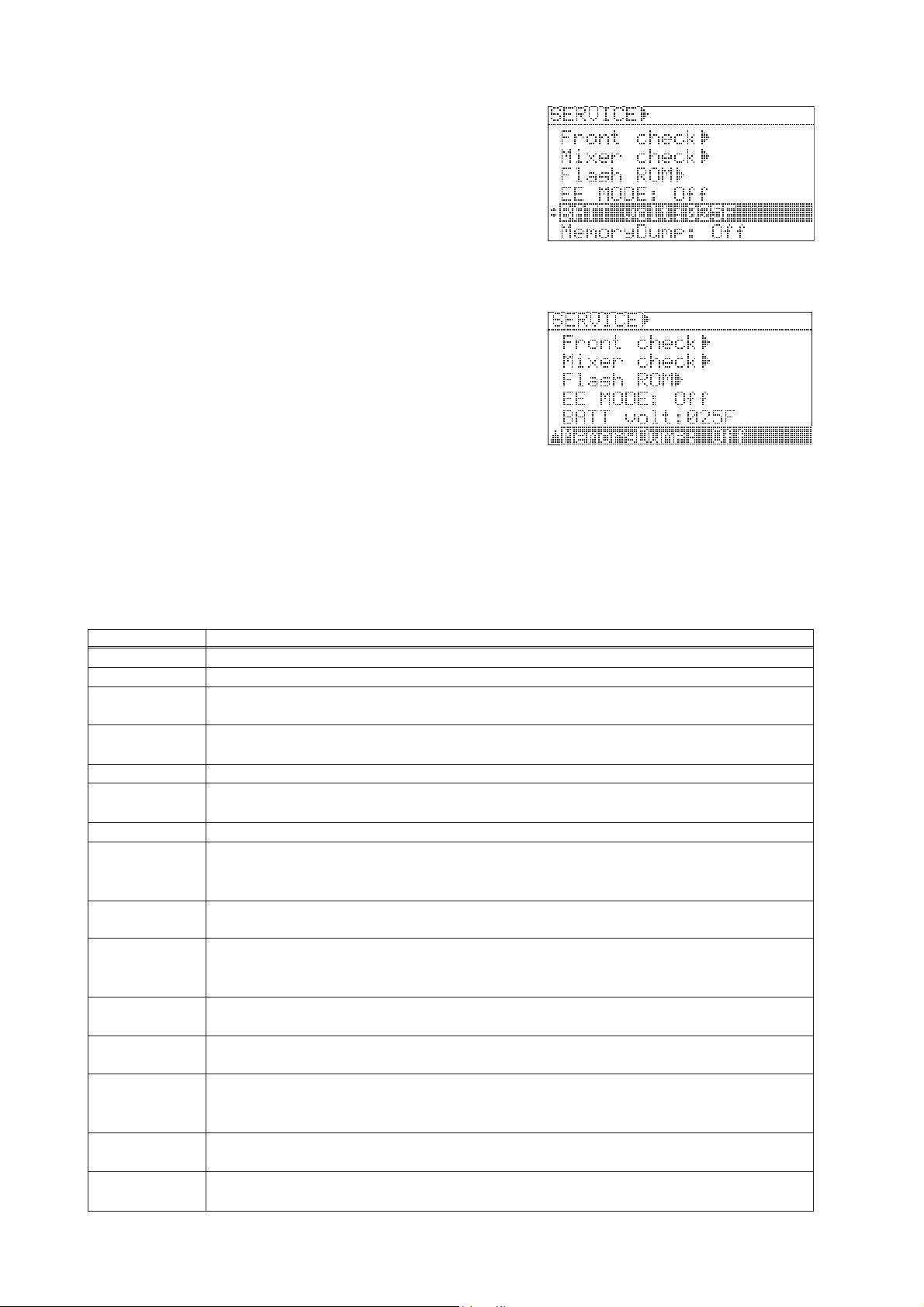

4. SERVICE MENUS

Various Service menus in addition to the normal SETUP menus are

available on PD-6 in order to judge if the unit is working correctly.

4-1. Accessing to Service Menus

1) Power on PD-6.

2) While holding down the STOP key, press the SETUP key.

The Service menus are displayed in addition to the normal menus.

4-2. Software & Firmware Version

Although this is not a Service menu, the PD-6 MAIN software

version as well as the DVD-RAM drive firmware version can be

confirmed. To check, select the “Version” menu and press the

ENTER knob.

There are three versions displayed in the “Version” menu.

The top one (“Ver1.02 14/MAY/’03” on the right example) is the

PD-6 MAIN software version number. The middle one

(“K0B1.04.05.REV” on the right example) and the bottom one

(“K00B.02.15REV on the right example) indicate the DVD-RAM

drive firmware version number.

If the new MAIN software and / or the DVD-RAM drive firmware

are sent from us, check the version number in this menu after updating

the software / firmware.

MAIN software version

and programming date

DVD-RAM drive firmware version

and programming date

MENU

SETUP

MENU

SERVICE

4-3. Reset setup memory

This menu is used for resetting various parameters in the SETUP

menus to the default value such as “Ref.level” to “-20dB” and “Peak

hold” to “3sec”. Also executing the MEMORY RESET is nececsary

after updating the MAIN software.

To reset the setup memory, select the “Reset setup memory” Service

menu and press the ENTER knob. Then, while “SURE?” is flashing,

press the ENTER knob again. After the “Completed!” message

appears for a short while, the LCD returns to the SETUP / SERVICE

menu select display.

CAUTION:

Every time the MAIN software is updated, execute the “Reset setup

memory”.

14

Page 15

PD-6 Service Manual

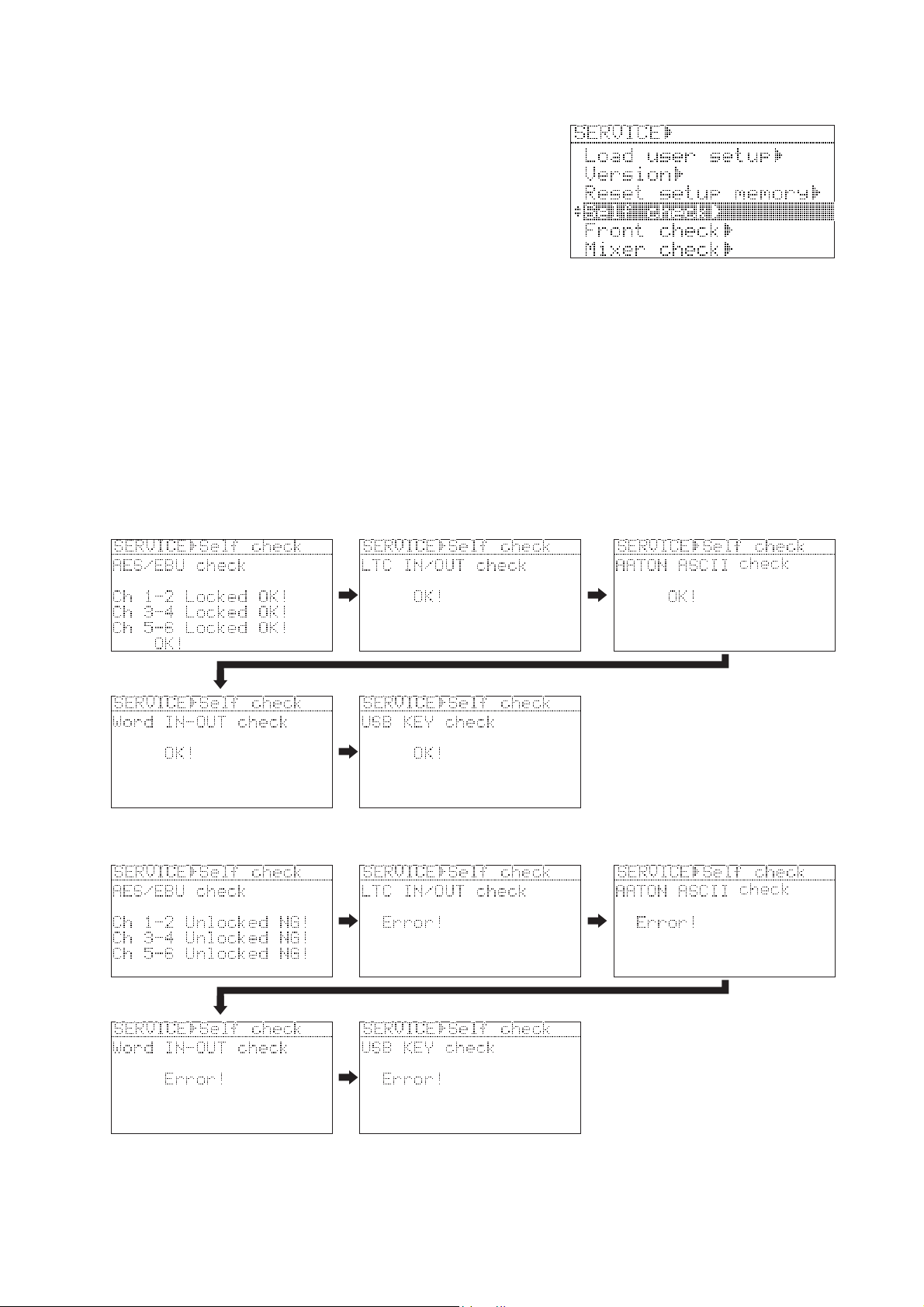

4-4. Self Check

The Self Check Service menu checks if the following circuits works

properly in order.

•AES/EBU IN and OUT circuit

• LTC IN and OUT circuit

• AATON ASCII circuit

• WORD IN and OUT circuit

• USB circuit

Preparation:

Before executing the Self Check menu, the following PD-6 connectors must be connected.

• AES/EBU CH 1-2/3-4/5-6 INPUT and CH 1-2/3-4/5-6 OUTPUT using a D-SUB 25-pin <-> XLR male x 4 / XLR

female x 4 cable such as HOSA DBK-258

• LTC IN and OUT using a XLR male <-> female cable

• WORD IN and OUT using a BNC <-> BNC cable

• USB keyboard

To execute, press the ENTER knob in the condition that “Self Check” is highlighted. PD-6 automatically checks

the above mentioned circuits. In order to skip one or some of the above checking items, press the EXIT key.

• Display example when PD-6 circuit works properly:

• Display example when PD-6 circuit does not work properly:

15

Page 16

PD-6 Service Manual

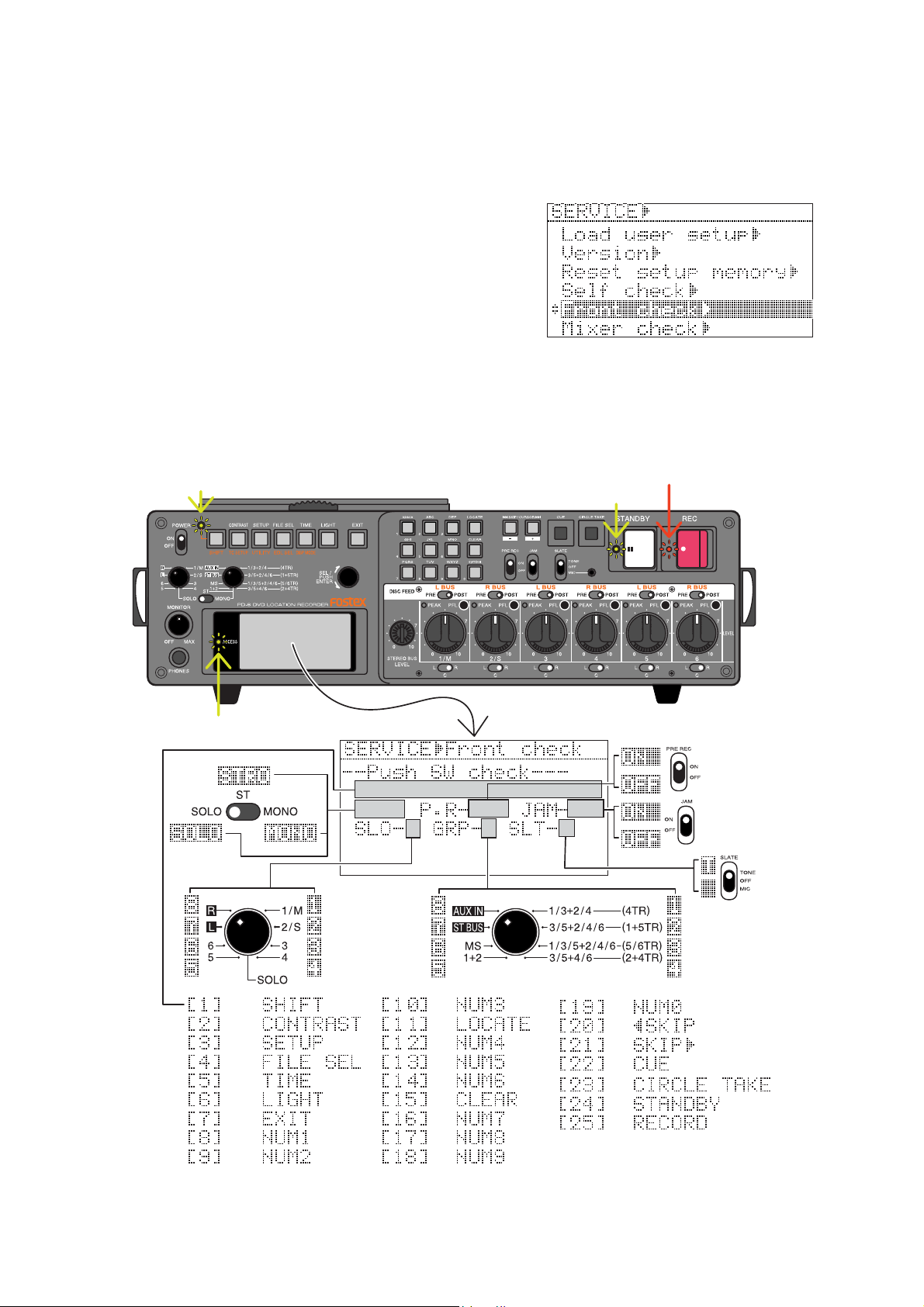

4-5. Front Check

This menu checks if the toggle / rotary / tact switches and LEDs on the PD-6 front panel are correctly working. To

check the switches and LEDs operation on the front panel, select the “Front Check” Service menu and press the

ENTER knob. To get out of this menu, press the ENTER knob again.

• Tact switches (25 pcs. in total)

The switch number 1 through 25 and the corresponding name (i.e.:

[1] SHIFT) are displayed on the LCD every time the tact switch is

pressed.

• Rotary switches (2 pcs. in total)

The number 1 through 8 is displayed on the LCD depending on the

SOLO and MONITOR rotary switch position.

• Toggle switches (4 pcs.)

STRO (stereo) / MONO / SOLO, ON / OFF and T / none (blank) are displayed on the LCD depending on the

SOLO monitor select / PRE REC / JAM / SLATE select toggle SW position respectively.

• LEDs

The REC LED flashes in RED and the STANDBY, SHIFT and ACCESS LEDs flash in GREEN.

Flash in green

Flash in green

Flash in red

Flash in green

16

Page 17

PD-6 Service Manual

Flash in green

Flash in green

Flash in green

Flash in green

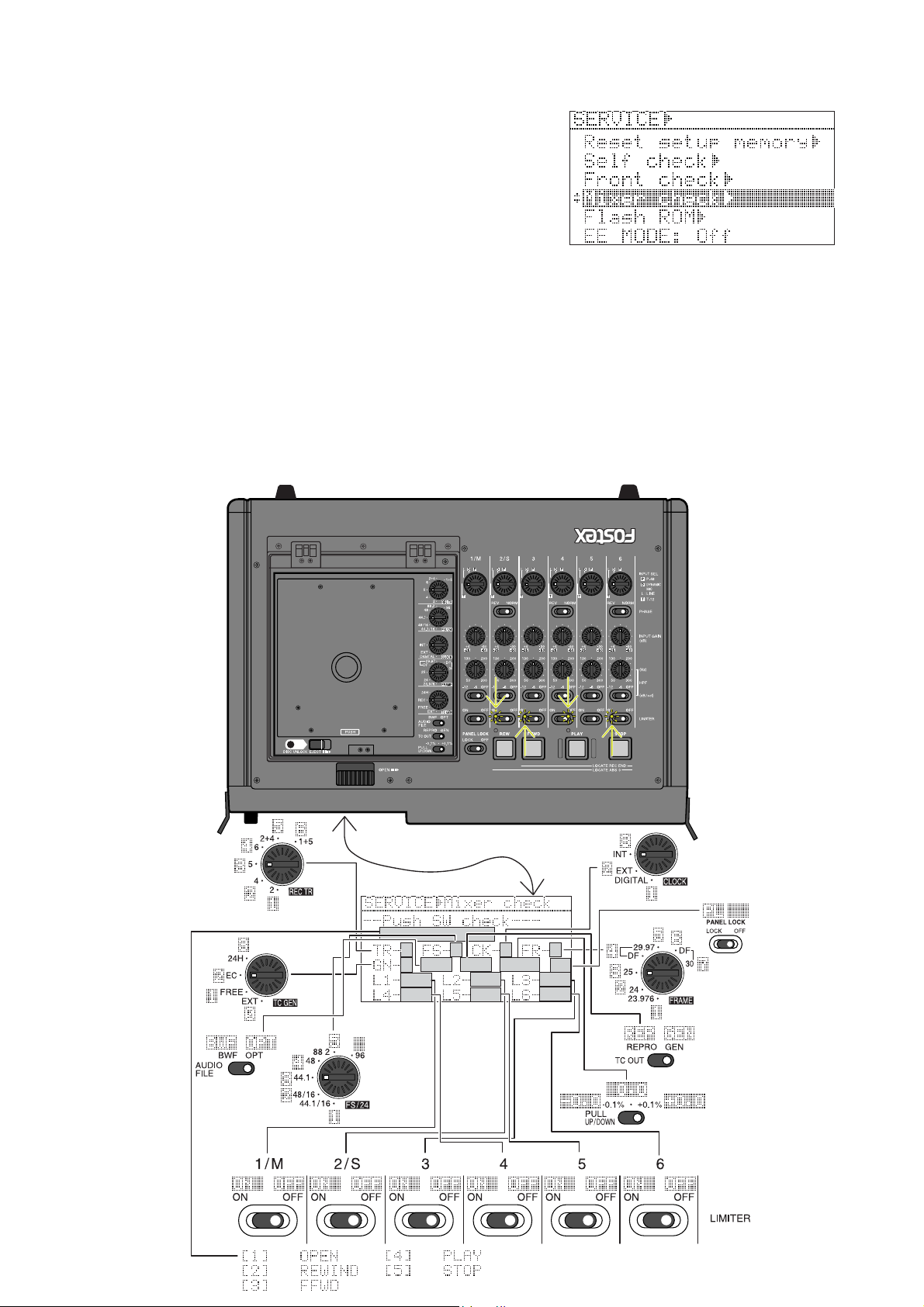

4-6. Mixer Check

This menu checks if the toggle / rotary / tact switches and LEDs on

the PD-6 top panel are correctly working. To check the switches

and LEDs operation on the top panel, select the “Front Check”

Service menu and press the ENTER knob. To get out of this menu,

press the ENTER knob again.

• Tact switches (5 pcs. in total)

The switch number 1 through 5 and the corresponding name (i.e.:

[1] OPEN) are displayed on the LCD every time the tact switch is pressed.

• Rotary switches (5 pcs. in total)

The number is displayed on the LCD depending on the REC TR, FS/24, CLOCK, FRAME and TC GEN rotary

switch position.

• Toggle switch (10 pcs.)

BWF / OPT, REPRO / GEN, -0.1 / 0.0 / +0.1 and ON / OFF are displayed on the LCD depending on the AUDIO

FILE, TC OUT, PULL UP/DOWN, CH1 ~ 6 LIMITER ON/OFF and PANEL LOCK toggle SW position

respectively.

• LEDs

The REWIND, F FWD, PLAY and STOP LEDs flash in GREEN.

Flash in green

Flash in green

Flash in green

Flash in green

17

Page 18

PD-6 Service Manual

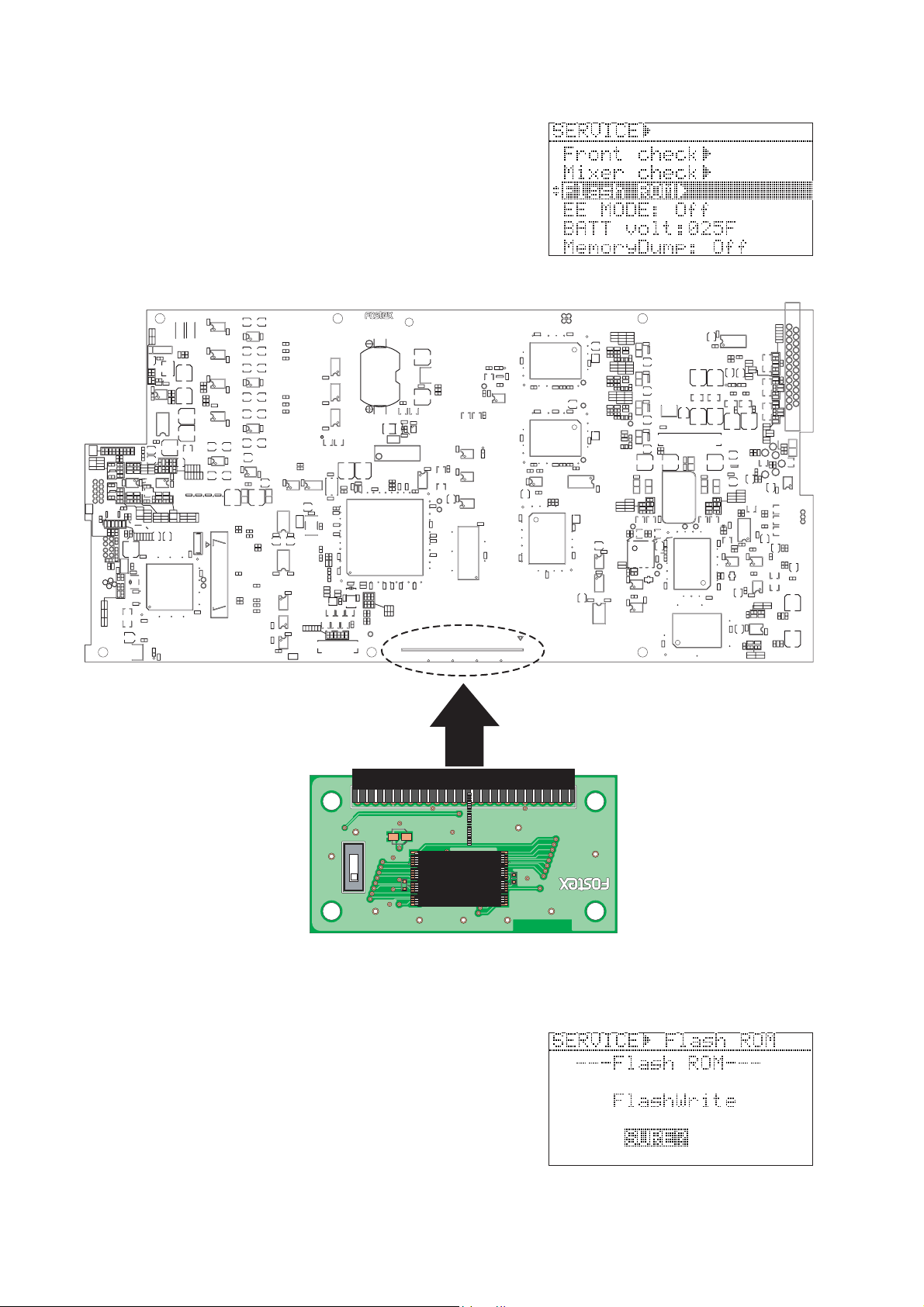

4-7. Flash ROM

There is a Flash ROM Card PCB prepared for the PD-6 MAIN

PCB. The Flash ROM Card PCB (P/N: 8274354000) is used if

something wrong happens during software update (i.e. power

shutdown, blackout). The Flash ROM Card PCB allows to boot up

PD-6, copy the system software in the Flash ROM Card PCB to the

Flash ROM on the PD-6 MAIN PCB using this “Flash ROM”

Service menu. Furthermore, you can rewrite the programming inside

the Flash ROM on the Flash ROM PCB.

U711

C744

1

C746

1

C750

1

U710

1

C809

C734

1

E1152

E1151

C771

+

+

C736+C737

U717U718U719U720

+

J1152

9

9

U712

9

U713

9

C824

8

EXT DRIVE

U703

C745

C706

1

C742

C747C749

C741

U702

1

C740

C739

U701

C772

C702 C704

1

C738

U706

C733

C762

1

R862

+

L701

C825+C826

R1188

W1151

W1153

R1156

R1192

+

+

8

W708

+

W707

+

W706

C723

C722

+

+

8

C703 C705

+

+

C721

C720

+

+

8

C701

+

+

C719

+

C770

5

C763

C766

+

C79

L702

13

U13

W1152

C66

R1175

C90

+

R1158

13

R1157

C89

R1152

C1152

1

R1154

R1155

8

R1153

C1151

1

C62

R1176

W705

W704

W703

R67

R66

U14

1

9

1

8

RED

U19

C76

8

1

1

J5

1

2

1

C64

2

+

C85

U18

1

C87

U1151

U1154

R47

R48

R58

C71

U12

POWER

J902

11

U35

C82

1

11

U24

B1

1

C74

11

U27

C75

1

U37U38

E5

C21+C22

C14

+

11

C50

C24

C29

1234

R17

X1

C15

181

+

C5

R18

C3

C42

X5

C52

R51

C44

34

R19

C17

R68

R69

W1

C10

C12

R20

C18

240

W2

1

C26

C92

C97

C84

C83

C94

R64

C23

R70

D5

D6

R49

R50

R59

D8

D4

D7

19

JTAG

J2

C25

C28

C9

C7

X2

C27

U41

R4

R65

C13

+

15

C20

+

C19

R37

D1

D2

C53

C51

X3

U7

R34

C54

J1

12

8

1

C40

R3

14

7

C96

TMS

TDI

TDO

TCK

1

/TRST

/RESET

/ASEBRK

U29

R2

C38

C49

R8

R25

R33

120

C36

61

U6

C33

60

C35

C37

C39

C47

R12

R13

R11

R6

R7

R5R9R10

49

502

R863

R771

R858

R859

C755

R856

U721

R772

R773

C760

C757

W701

1

+

J702

+

2

C761

R766

C819

C820

R784

+

5

R785

R756

R759

R786

C821

R783

R765

R782

C751

1

R781

U723

C822

R755

+

C773

U716

+

W702

C774

C777

U907

52 13

3

R1184

R1182

C1155

610

U908

64

78

4

1

R1183

R1181

R1185 R1187

C803

R842R843

R819

R820

C789

1

U705

C805

C806

8

R934

R840

R835

R933

Q706

R836

R837

R839

R932

R838

R1189

C937

C939

C940

C941

R1190

C1172

C1160

C1157

+

108

R1177

C1181

C1159

C1156

X1004

2

C1182

C1154

43

1

21

D903 D904

C1164

+

R928

C932

U904

L801

~

L809

R822

R815

R816

Q705

R817

R818R821

51

L910

~

L916

R931

+

+

C804

R807R811

R806

C786C787

8

C796C797

R826

C799

R827R829

C1165+C1166

+

C938

C942

U1152

D905

C930

15

1

U707

R823

D703

R841

20

+

C794

R834

R828

C798 C800

C807C808

C779 C780

C781 C782

R803

R800 R801

J1154

(FIRE-USB1 LOAD)

DGND

D+

D-

C1161

80100

U714

U704

R824

R833

R825

R830

R831 R832

C795

R804

USB

4

1

72

C1162

40

C1163

36

PCB,MAIN,PD-6

U381

C395

D3

U5

E3

E4

C34

C48

C43

C41

R14

1

U3

50

C2

U2

R16

E1

R21

R22

R23

U25

R39

U28

+

C31

28

U10

8

C1

R1

1

U26

U21

U1

R41

C78C11

1

1

C57

1

C60

J3

C196

8

U181

50

U40

D10

8

R1007

U1005

U16

9

C1002

U9

1

C1018

10

U1002

20

C59

C1016

1

EXT ROM

C724

Front Side

C743

1243

U902

R948

+

D918 D919

C951+C952

POWER

R1059

C1094

U1020

L1013

C1086

20

C908

R911

C924

9

C923

R910

C914

R946

R921

C909

R913

C926

C925

R922

R912

R924

C915

1

1

Q904

D906 D909D910D912 D915D916

W903

W904

C905

R905

C918

C917

R918

R1066

L1019

R904

3

C911

C1120

4

C1119

R1065

L1018

2

+

R1070

1

1

R1048

D1006

U1007

+

R1035

C1068

R1031R1032

R1060

8

C1024

R1009

8

C1095

+

C1109

+

R1046

D1007

R1072

U1030

R1052

5

6

C1116

+

R1073

R1074

1

+

D1008

C1089

C1088

R1077

13

D1009D1010D1011

R1076

R1078

U1026

+

C1090

C1112

L1014

R1067

R1039

1

C1091

R1038

8

2H

R1061

R1071

3C

C1079

L1015

1

R1040

5

R1043

C1098

R1047

5

C1099

C1102

R1054

C1113

+

U1028

D1005

1

R1062

G

S4

+

1

D1004

U1029

R1055

R1064

C1103

C1107

R1063

C1115

C1108

L1017

C1118

1

R1069

U1031

G

C

H

C1110

+

C1114

C1117

L1016

R1068

C904

C382

C384

10

30

20

1

C385 C387

R386

C391

R382 R383

R381

R385

C389

L381

C381

C388

R384

+

R387

C285 C287

R282 R283

R281

C397

E381

60

80

R389R390

R391

C396

C181

C182

C183

C195

30

20

R191

60

C197

R1008

8

C1021

+

1

R1004

R1075

100

L1003

R1005

30

50

C1004

1

C185 C187

R182 R183

R181

E281

10

1

100

R187

C184

80

R189R190

L1004

1

9

U1004

C1019

80

R1006

C73

C1006

+

60

C68

1

C1017

U30

9

1

C93

U20

11

+

C65

C63

C67

1

U15

13

R1002

C1008

C1007

C1011

R285

R284

R185

R184

E1001

R1022

C1041 C1044

R1019 R1020

E1002

X1001

C1123

R1037

U1019

R1010

U382

1

R388

C386

+

R286

C291

C289

L281

C288

U282

1

C286

+

R186

C191

L181

C189

C188

U182

1

C186

+

R188 R288

15

C1009

L1001

1

U1032

R1001R1003

1

W902

+

C1005

W901

+

C1049

1

C1054

C1053

L1006

L1007

X1002

R1023

C1046

C1060

U1009

U1010

R1027

U1011

D1001

D1002

2

C1052

U1012

1

R1028

R1024

R1012

3

70

6

C1025

E1006

R1034

E1005

C1022

L1005

C1048

1

U1008

C1030

C1124

1

52

U1034

U1024

C1082

C903

+

1

R903

R947

C947+C950

C949

C948

+

+

U903

1

R943 R944

+

Q9011Q902

Q903

+

+

C931

C929

C935+C936

J901

C1028

11

C1071

+

+

C1055

L1008

C1056

C1032

C1075

C1034

L1011

L1012

R1033

C1064 C1066

U1015

E1003

80

51

64

1

U1016

40

50

D1003

E1004

R1036

C1042

30

U1017

C1026

C1045

20

1

R1011

C1029

1

C1051

100

C1035

90

33

32

19

MAIN PCB

Flash ROM card PCB

50

49

(FLASH)

+

C1

25

C2

INT

S1

EXT

J1

TC58FVT160FT-10

TOSHIBA K29284

Connector J3 Location on MAIN PCB

• Rewriting the Flash ROM Program on Flash ROM Card PCB

NOTE:

In order to rewrite the Flash ROM program on the Flash ROM Card

PCB, PD-6 which works in good order must be prepared.

1) Power off PD-6 and disconnect the power cable from the AC adapter

AD-15C or remove the NP-1 type internal battery.

2) Open up the bottom cover.

3) Set the SW S1 on the Flash ROM PCB to “INT” side and plug it

into the 50-pin connector J3 on the MAIN PCB.

R1

1

U1

PCB,FLASH-ROM CARD

2

1

8252510001

18

Page 19

PD-6 Service Manual

4) Connect the AC cable from the AC adapter AD-15C or insert the

NP-1 type battery.

In this condition, PD-6 is booted up using the software program

inside the Flash ROM on the PD-6 MAIN PCB.

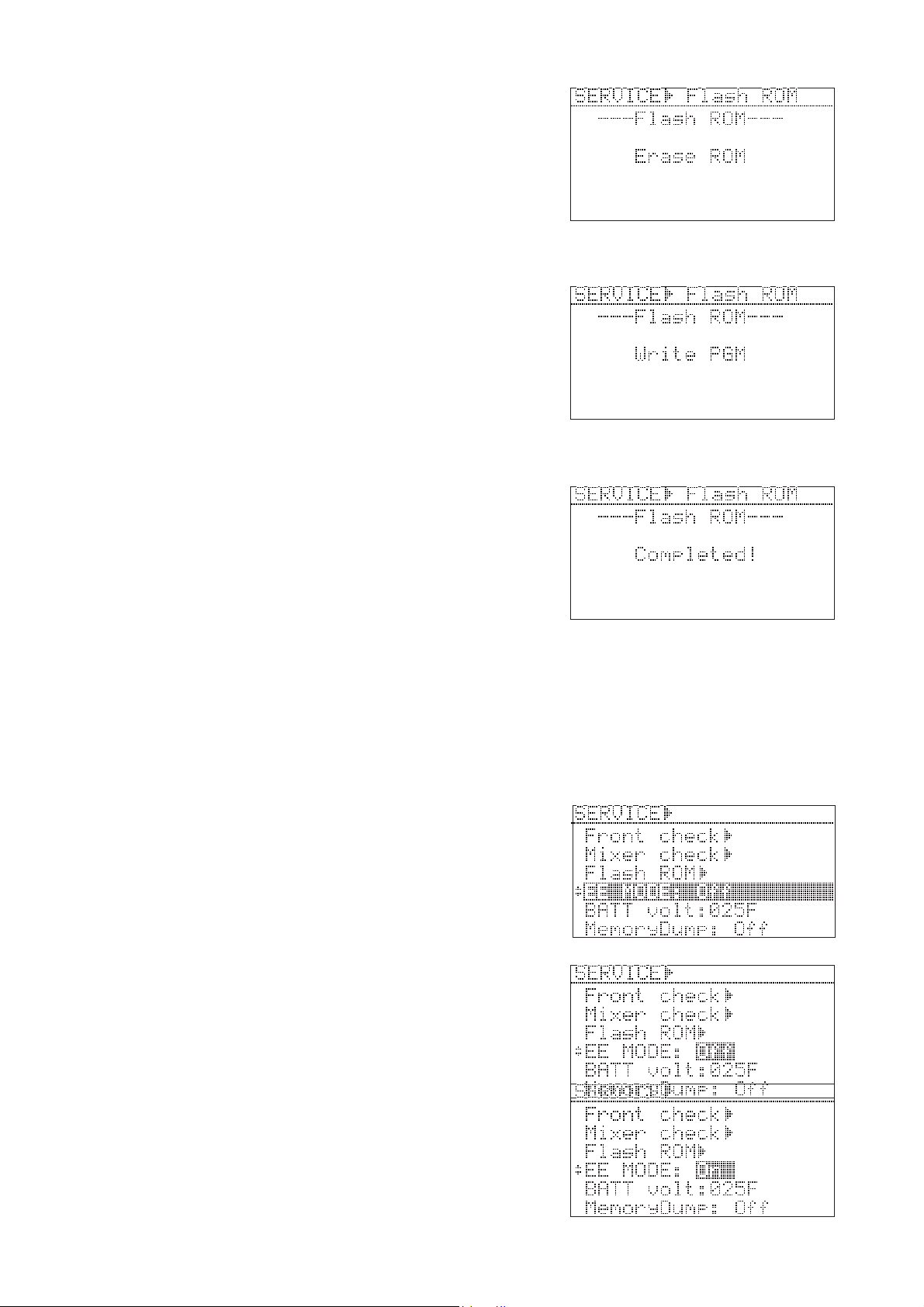

5) Select the “Flash ROM” Service menu and press the “ENTER” knob.

6) While “SURE?” flashes, press the ENTER knob.

“Erase ROM”, “Write PGM” and then “Completed!” will appear

on the PD-6 LCD in order.

7) Press the EXIT key or ENTER knob to go back to the SETUP /

SERVICE menu select display.

With the above procedures, the program inside the Flash ROM on

the PD-6 MAIN PCB is transferred to the Flash ROM on the Flash

ROM Card PCB.

• Rewriting Flash ROM Program on the MAIN PCB

1) Power off PD-6 and disconnect the power cable from the AC adapter

AD-15C or remove the NP-1 type internal battery.

2) Open up the bottom cover.

3) Set the SW S1 on the Flash ROM PCB to “EXT (FLASH)” side

and plug it into the 50-pin connector J3 on the MAIN PCB.

4) Connect the AC cable from the AC adapter AD-15C or insert the

NP-1 type battery.

In this condition, PD-6 is booted up using the software program

inside the Flash ROM on the Flash ROM PCB.

5) Select the “Flash ROM” Service menu and press the “ENTER” knob.

6) While “SURE?” flashes, press the ENTER knob.

“Erase ROM”, “Write PGM” and then “Completed!” will appear

on the PD-6 LCD in order.

7) Press the EXIT key or ENTER knob to go back to the SETUP / SERVICE menu select display.

With the above procedures, the program inside the Flash ROM on the Flash ROM Card PCB is transferred to the

Flash ROM on the PD-6 MAIN PCB.

4-8. EE Mode

By turning on the EE mode, the A-to-D and D-to-A converters

circuitry on PD-6 are directly connected. This menu is used for

measuring the frequency response, S/N and Dynamic Range value

for Quality Control purpose.

• Turning on the EE mode

1) Press the ENTER knob while the EE mode menu is selected.

The default setting “Off” flashes.

2) Rotate the ENTER knob to change the setting to “On” and press the

ENTER knob again.

NOTE:

The EE mode on / off condition will not be battery backed up. Even

if the PD-6 power is turned off with “EE MODE: On” condition,

powering on PD-6 again will initialize the EE mode setting to the

default value (Off condition).

19

Page 20

PD-6 Service Manual

4-9. BATT volt (Battery Voltage)

This menu monitors either the AC adapter DC voltage (POWER

SEL SW setting: EXT, EXT_PWR_DETECT fed to pin-238 (AN6/

PTL6/DA1) of CPU U6 (SH7727)) or the NP-1 type battery DC

voltage (POWER SEL SW setting: INT, INT_BATT_DETECT fed

to pin-239 (AN7/PTL7/DA0) of CPU U6). If the DC voltage is

around 15V, the 4-digit hexadecimal value will be around 0240.

4-10. MemoryDump

This menu is only utilized at our manufacturer and has nothing to

do with servicing PD-6.

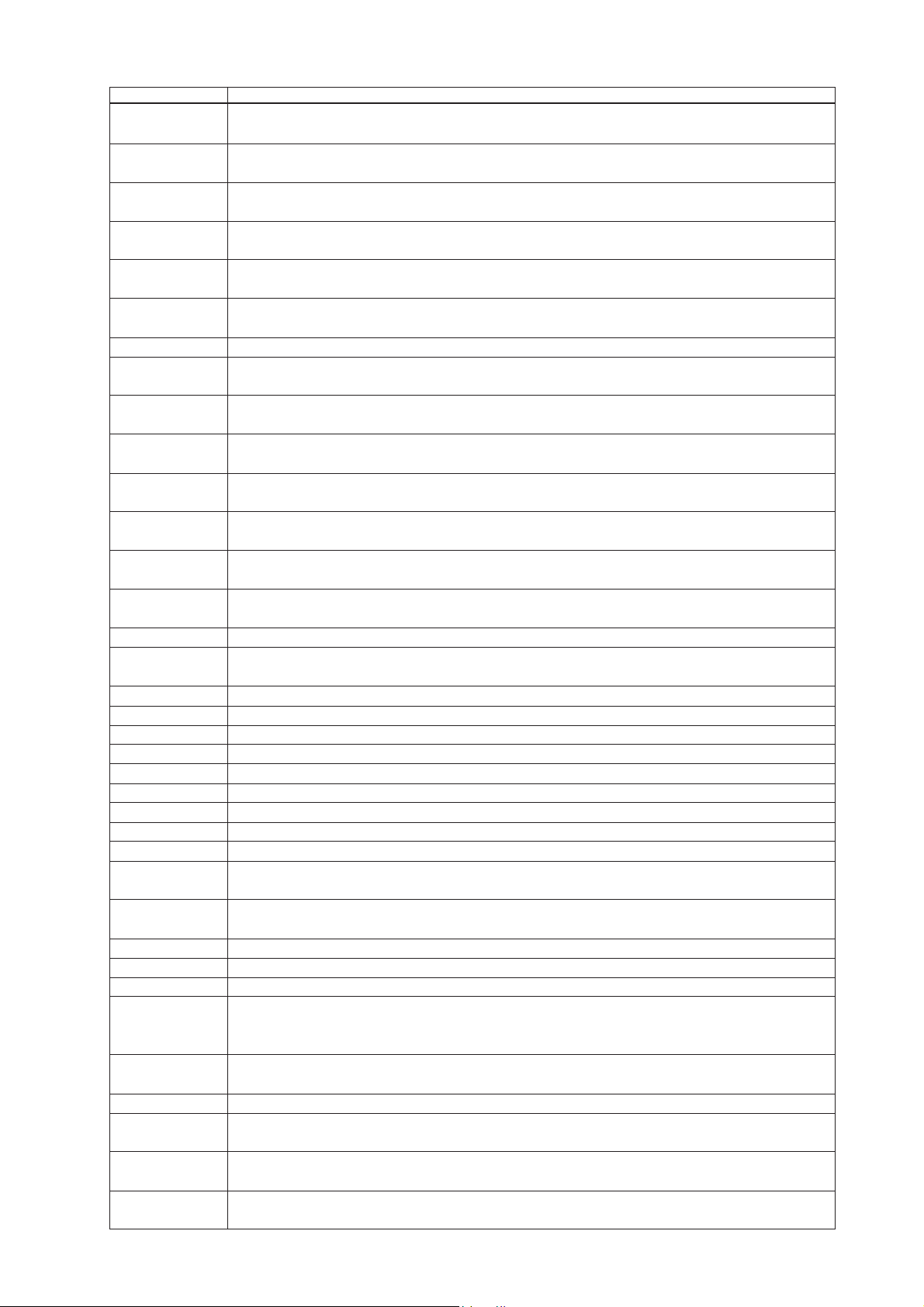

5. ERROR CODE / ALERT LIST

The Table below indicates the error code number and corresponding description. Since the error code list is basically

designed for our engineers to improve the software, the description is quite technical. If you find PD-6 displaying the

error codes, we encourage you to update the software to the latest one first. In case updating the software does not solve

the problem, we would like you to contact us.

Error / Alert

ERROR=0

ERROR=1

ERROR=20

ERROR=21

ERROR=83

TimeOut Read!

Read Error!

Disc Error! Write

Write Error

Event Over!

Diagnoses write!

Rec Timeout Err!

Rec Caution!

File Size Over!

Write Error!

Not defined.

Trying to access the sector address other than the accessible region on disc.

The file size exceeded the specified capacity (2GB or 4GB) while in REC mode. This error code will be

deleted on V1.03 software onwards.

Shortage of capacity while in REC mode occurred. This error code will be deleted on V1.03 software onwards.

Failed to Block-Erase while in the Flash ROM SAVE (writing) mode.

Time-out occurred when reading out data. Drive malfunction, disc failure, dust & dirt on the DVD-RAM

disc.

An error occurred when reading out data. Disc failure, dust & dirt on the DVD-RAM disc.

Time-out occurred when writing in data. After this error message appears, PD-6 initializes the DVD-RAM

drive. Disc failure, dust & dirt on the disc. Changing to a new disc or physical-format a disc is highly

recommended.

An error occurred when writing in data. Disc failure, dust & dirt on the DVD-RAM disc. Changing to a new

disc or physical-format a disc is highly recommended.

Too much disc fragmentation (discontinuous sector region) exceeding the UDF management while recording an audio files. The disc on which editings were executed on PC were used on PD-6. This error rarely

occurs. The cause could be other than PD-6.

An error list information "file name.dia" was created because an error occurred when writing in audio data

on the disc.

A cache buffer overflowed and audio files could not be completed recorded on the disc. Dust & dirt on the

disc, failure sectors forcing the frequent retry of writing in data and / or many alternative sectors are used.

There is a possibility that a cache buffer overflowed and audio files could not be completed recorded on the

disc. Dust & dirt on the disc, failure sectors forcing the frequent retry of writing in data and / or many

alternative sectors are used.

The file size exceeded the specified capacity (2GB or 4GB) while in REC mode. Rarely occurs. It is considered that some sort of system error occurred.

A Verify Error occurred when recording audio files. Dust & dirt of disk, failure sectors. Since alternative

sectors are used, this error rarely occurs.

Description, cause and treatment

20

Page 21

PD-6 Service Manual

Error / Alert

ModifyEntry ERR!

malloc Err!

Reboot!

Erase error!

Write error!

Verify error!

File Open Error!

Disk Error!

RW LVIntegrity

No BWFF Dir.

NewFile Failed!

CheckBackupBA TT!

IllegalDrive!

No DVD Drive!

Song Num. Full!

Wait Emergency!

Out of Zone!

Load error!

BATT Empty!

Void Data!

Illegal Name!

RTC Error!

Illegal REC TR!

Illegal FS or TR!

Fmt. Completed!

No Area!

menu_tb busy

Unlock door!

Panel locked!

Write protected!

HIGH T emperature

PwrOff&ChgDisc!

Post Recording!

New Rec Active!

Selected

IEEE1394

Sys Write Error!

Description, cause and treatment

Modifying audio file UDF Entry failed after recording. Rarely occurs. It is considered that some sort of

system error occurred.

Stands for System Memory Allocation Error. Allocating the system memory failed. Rarely occurs. Some sort

of system error occurred.

The system executes rebooting as the needs arise. The system reboots after the occurrence of "malloc Err!"

or the update of system software.

Erasing data in the Flash ROM when updating the software failed. Rarely occurs. Some sort of system error

occurred.

Writing data into the Flash ROM when updating the software failed. Rarely occurs. Some sort of system

error occurred.

Verifying after the software update data writing on the Flash ROM failed. Rarely occurs. Some sort of

system error occurred.

Opening a particular file failed. A problem exists on the file to be opened.

Indicates a problem on the disc. A disc other than the specified one by the DVD-RAM standards was used or

a problem on the DVD-RAM drive exists.

The UDF Logical Volume Integrity was rewritten. The actual number of directory and unused region do not

correspond with the information written in the UDF Logical Volume Integrity, it is rewritten.

The BWF folder does not exist. The disc formatted by other than PD-6 was used. This does not cause any

problems.

Creating a new audio file when REC mode was initiated failed. Disc failure, malfunction of DVD-RAM

drive.

Check the internal backup lithium battery voltage. The backup lithium battery voltage (CR2032 on the

MAIN PCB) might be too low.

The connected DVD-RAM drive does not correspond with the DVD-RAM specifications. Rarely occurs.

Some sort of system error and / or the drive failure occurred.

The system could not detect the DVD-RAM drive. Rarely occurs. Some sort of system error and / or the

drive failure occurred.

The number of songs exceeded the upper limit of 199. Deleting songs (files) or changing the disk is required.

The system forces the emergency shutdown when recording audio files. Wait for a while for recovery. If it

takes too long to write data in the disc, this message will appear.

The specified time is out of region. The specified time when in Locating, etc. is out of playback region.

Restoring audio files failed. This error rarely occurs. It is considered that some sort of system error occurred.

The NP-1 type battery voltage is too low. Change the battery.

Invalid data was input.

An improper name was input.

The internal Real Time Clock is not working. The internal lithium battery voltage is too low.

An incorrect Fs and REC TR setting is selected. Change the FS and / or REC TR setting.

An incorrect Fs and REC TR setting is selected. Change the FS and / or REC TR setting.

Formatting the disk was correctly completed.

The objective area does not exist. If this error occurs while in the Descriptor Edit mode, there is a possibility

that the recorded file format is not BWF.

The memory table for editing operation is occupied. Rarely occurs. It is considered that some sort of system

error occurred.

The DVD-RAM drive lid is open.

The PANEL LOCK switch on the top panel is at ON.

The Write Protection on the disc is set to ON.

The drive temperature exceeds the upper limit. This message occurs when recording continuously for extended periods of time under extreme hot weather conditions at high bit / sampling rates and maximum track

capability. Take out the unit from the shoulder back if it is in and ventilate.

Power off the disc and replace it with the new one. There is a case that this message is displayed after the

Emergency Stop appears.

PD-6 is executing the post-record when the PRE REC mode is turned on.

REC key is engaged while PD-6 is executing the post-record. After the post-record is completed, PD-6 starts

recording a new file immediately.

The IEEE1394 mode is being turned on and PD-6 works as a IEEE1394 slave device. No controlling is

possible in this mode.

Write Error of the File System section occurred. Retry is possible by pressing the ENTER knob. Dust & dirt

on the disc.

21

Page 22

PD-6 Service Manual

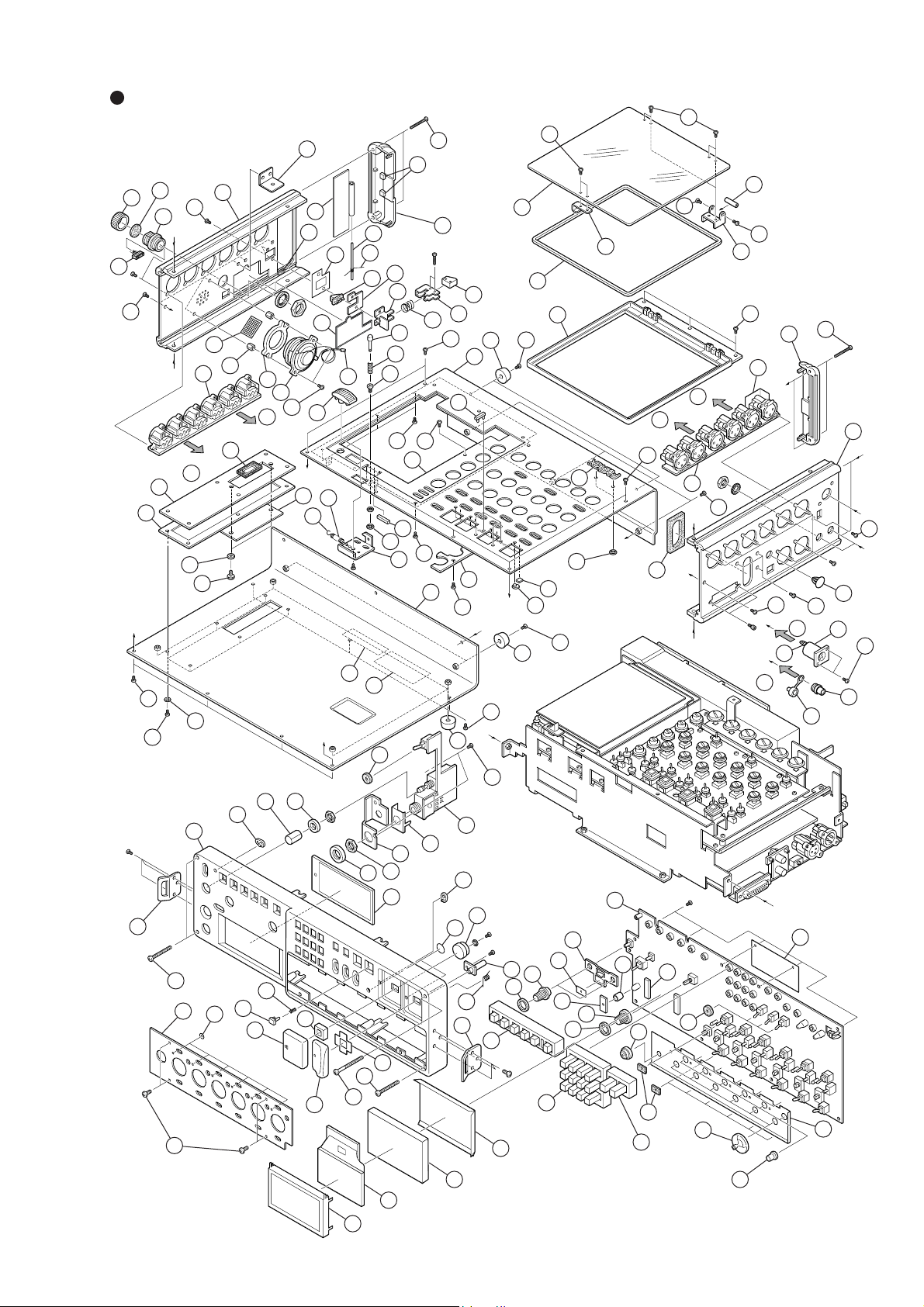

6. EXPLODED VIEW, PCB ASSEMBLY & PARTS LIST

PD-6 OVERALL EXPLODED VIEW 1 Parts List

Ref. No. Part No. Description

1 8221 3900 00 Panel, side, L, PD-6

2 8274 3750 00 PCB assy, XLR OUT, PD-6

3 8221 4290 00 Stopper, eject, battery, B, PD-6

4 8221 4070 00 Stopper, eject, battery, PD-6

5 8221 4060 00 Bracket, eject, battery, PD-6

6 8221 4081 00 Spacer, eject, battery, A

7 8226 2761 00 Knob, lock, PD-6

8 8214 4040 00 Spring, eject, PD-6

9 8204 0830 04 Screw, precision, M 2.6 x 6 BZn

10 8221 4160 00 Bracket, panel, connector, PD-6

11 8278 0170 00 Speaker, C035AS122S11

12 8277 2892 10 Cable assy, 2P, ORG, ZHR/F-WIRE/3,

13 8216 8050 00 Cushion, speaker, PD-6

14 8216 7810 00 Sheet, speaker

15 8204 1160 03 Spacer, speaker, M 2.6 x 10

16 8245 4150 00 Connector, receptacle, 10P,

17 8277 5590 07 Cable assy, 10P, 10-COLORS,

18 8277 5543 15 Cable assy, shield, 2CX3, 9P, BLK,

19 8277 5553 15 Cable assy, shield, 2CX3, 9P, RED,

20 8216 8040 00 Cushion, battery, B, PD-6

21 8260 5930 00 Cushion assy, PD-6

22 8216 8120 00 Sheet, eject, battery, PD-6

23 8221 3910 00 Panel, side, R, PD-6

24 8274 3740 00 PCB assy, XLR IN, PD-6

25 8216 7970 00 Shield, power, PD-6

26 8245 4030 02 Connector, cannon, 4P, male, HA16RA-4P

27 8277 1050 05 Cable assy, separate, 6P, L50

28 8245 4160 00 Connector, receptacle, 4P,

29 8277 5580 05 Cable assy, 4P, BLK, ZH/F-WIRE, L50

30 8207 0142 00 Cap, connector, HR10-7R-C

31 8207 0109 00 Cap

32 8216 7850 00 Packing, panel, BNC, PD-6

33 8277 5553 15 Cable assy, shield, 2CX3, 9P, RED,

34 8277 5543 15 Cable assy, shield, 2CX3, 9P, BLK,

35 8274 3730 00 PCB assy, Front, PD-6

36 8216 7821 00 Sheet, LCD, PD-6

37 8212 7070 00 Plate, reflect, LCD, PD-6

38 8216 7880 00 Spacer, reflect, LCD, PD-6

39 8221 4271 00 Guide, knob, PD-6

40 8216 7790 02 Sheet, toggle, PD-6

41 8226 2750 01 Knob, rotary, C

42 8216 7990 00 Sheet, knob, rotary, PD-6

L100

RM15TRD-10S

ZH/F-WIRE, L70

ZH/F-ZH/F, L150

ZH/F-ZH/F, L150

HR10A-7R-4S

ZH/F-ZH/F,L150

ZH/F-ZH/F, L150

Ref. No. Part No. Description

43 8226 2750 02 Knob, rotary, D

44 8260 5910 00 LCD assy, PD-6

45 8221 4020 00 Bracket, LCD, PD-6

46 8276 8710 03 Tube, UL, 5.3 x 7

47 8216 7930 00 Sheet, LED, PD-6

48 8216 5550 03 Washer, 12 x 2.5 x T2, PD-4

49 8216 7951 00 Cover, PCB, front

50 8216 7790 00 Cushion, toggle, PD-6

51 8212 7061 00 Window, LCD, PD-6

52 8226 1842 12 Button, 6 x 6 x 16.8, N3

53 8214 2700 00 Spring, 8 x 3, 0.2

54 8226 1540 00 Button, tact, PAUSE

55 8216 4080 01 Cushion, search

56 8226 1531 00 Button, REC

57 8216 6260 00 Sheet, slide, PD-4

58 8212 3260 00 Slider, REC

59 8216 3791 00 Cap, button

60 8216 7830 00 Sheet, mic, PD-6

61 8212 2682 00 Lens, LED

62 8214 4020 00 Spring, door, DV40

63 8226 2180 00 Knob, phone, PD-4

64 8260 5920 00 Button, SW assy, PD-6

65 8260 5920 00 Button, SW assy, PD-6

66 8260 5920 00 Button, SW assy, PD-6

67 8274 3710 00 PCB assy, Phones, PD-6

68 8216 3610 00 Shield, phone

69 8216 5550 03 Washer, 12 x 2.5 x T2, PD-4

70 8221 4140 00 Bracket, phones, PD-6

71 8216 5550 01 Washer, 12 x 6 x T4, PD-4

72 8216 5550 02 Washer, 15 x 10 x T4

73 8245 3400 00 Nut, phone jack

74 8216 7980 00 Sheet, front, PD-6

75 8204 0830 03 Precision, M 2.6 x 4 BZn

76 8221 3930 00 Panel, input, volume, PD-6

77 8216 7870 00 Sheet, input, volume, PD-6

78 8204 0730 02 Screw, precision, M 2 x 5 BZn

79 8226 2710 02 Knob, rotary, B

80 8226 2740 01 Knob, input

81 8226 2720 01 Button, push

82 8221 3941 00 Panel, top, A, PD-6

83 8221 3953 00 Panel, top, B, PD-6

84 8212 7080 00 Frame, cover, PD-6

85 8221 4170 00 Stopper, knob, PD-6

86 8204 2460 51 Screw, precision, TB 1.7 x 5 CZn

87 8220 8490 00 Emblem, Fostex

88 8204 0370 01 Ring, CSTW-2

89 8212 3840 01 Protector, REC, BLK

90 8216 8070 00 Tape, 5 x 5 x 0.5

91 8221 3992 00 Lock, cover, B, PD-6

92 8223 3140 00 Shaft, open, PD-6

22

Page 23

PD-6 Service Manual

PD-6 OVERALL EXPLODED VIEW 1

6

5

92

93

86

91

70

122

121

M 2 x 10 BZn

8

78

83

105

86

106

68

123

17

BBT

2.6 x 8

BZn

9

B

F 2.6 x 8 BZn

115

124

16

107

108

9

78

9

A

H

14

2

B

Cable assy (RED)

19

111

110

112

127

113

76

77

78

1

15

13

18

Cable assy (BLK)

To J1152

122

63

61

53

52

54

10

118

20

22

119

120

7

21

94

12

11

9

95

A

109

103

Nut, M4

102

104

BBT 3 x 6 BZn

126

125

D

69

Attached to

71

the jack

73

72

51

55

57

113

114

56

117

9

89

101

60

3

4

82

85

86

67

61

59

62

116

99

9

101

C

J

101

9

H

75

FBT 2.6 x 6 CZn

W 2.6 x 7.5 x 0.5

BPT 2 x 6 CZn

58

42

66

F 2.6 x 8 BZn

36

41

61

98

65

78

90

84

40

47

78

97

78

78

100

96

9

122

117

25

Attached to

the connector

9

Cable assy

F

G

Cable assy

E

128

27

23

E

F

9

G

BBT 2.6 x 8 BZn

31

75

26

9

34

Cable assy

(BLK)

33

Cable assy

(RED)

9

87

J

88

9

32

24

9

C

I

Attached to

the connector

D

29

28

30

B 3 x 6 BZn

39

42

43

35

46

79

38

48

I

74

50

64

80

49

45

44

37

81

23

Page 24

PD-6 Service Manual

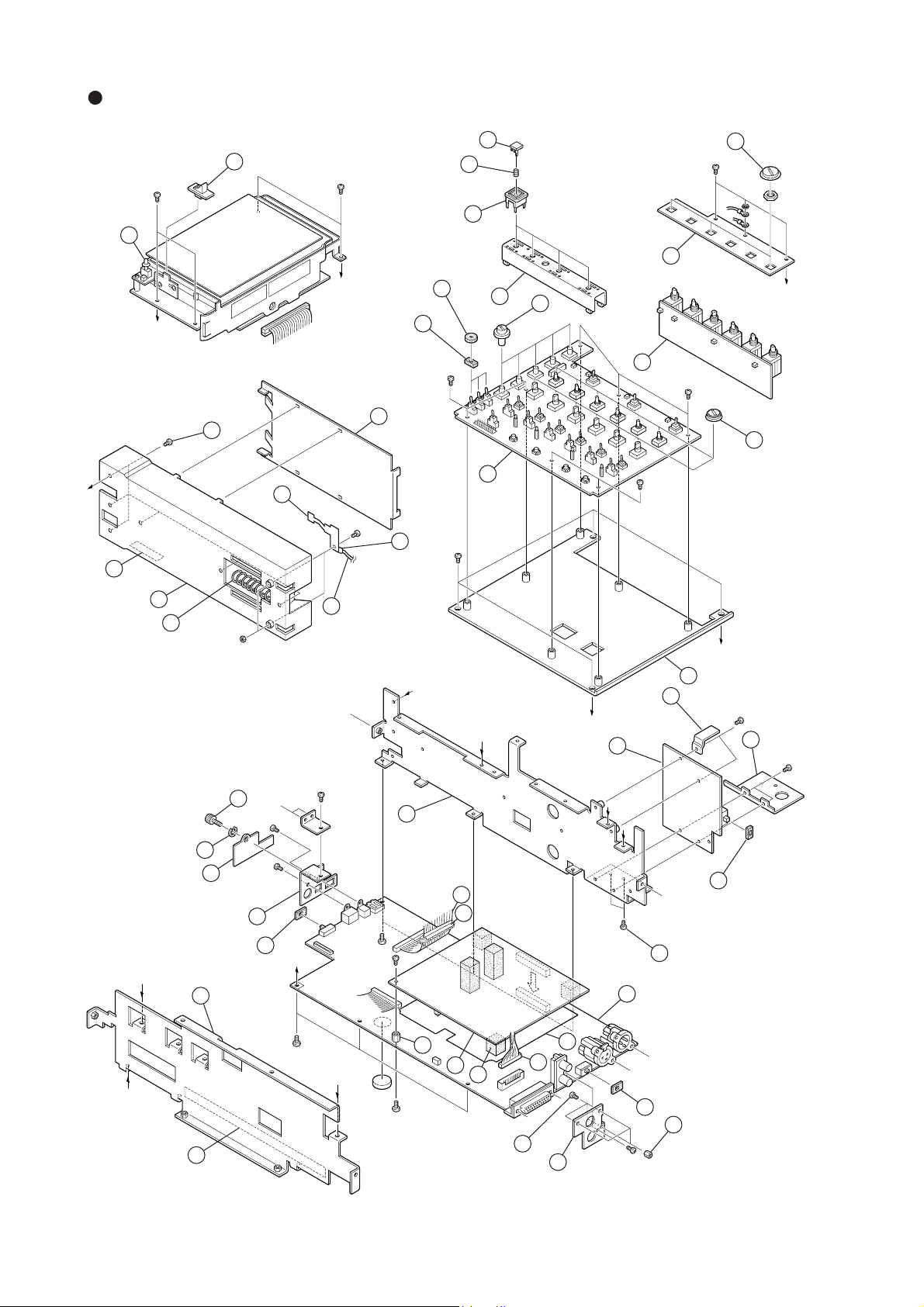

PD-6 OVERALL EXPLODED VIEW 2

B 3 x 6 BZn

40

B 3 x 6 BZn

37

38

B 3 x 6 BZn

33

Attached

to VR

39

41

D

E

Precision

2.6 x 6

36

35

B 3 x 6 BZn

46

21

29

32

28

G

3

B 2 x 3 CZn

5

B 3 x 6 BZn

31

A

30

B 3 x 6 BZn

34

B 3 x 6 BZn

6

1

4

2

N2

45

BBT 3 x 6 BZn

B 3 x 6 BZn

19

G

D

C

22

A

23

B

B

20

B 3 x 6 BZn

24

B 3 x 6 BZn

44

B 3 x 4 BZn

43

25

42

12

13

47

15

Precision

2.6 x 4

10

16

14

8

Precision

2.6 x 6

BBT 3 x 6 BZn

21

7

26

9

11

26

E

B 3 x 6 BZn

F

B 3 x 4 BZn

17

C

F

B 3 x 4 BZn

18

24

Page 25

PD-6 OVERALL EXPLODED VIEW 1 Parts List (continued)

PD-6 Service Manual

Ref. No. Part No. Description

93 8214 4033 00 Spring, cover, PD-6

94 8223 3150 00 Sleeve, open, PD-6

95 8226 2202 00 Knob, lock, PD-4

96 8221 4220 00 Bracket, shaft, cover, PD-6

97 8223 3090 00 Shaft, cover, B

98 8260 5930 00 Cushion assy

99 8212 7041 00 Cover, PD-6

100 8221 3982 00 Lock, cover, A, PD-6

101 8207 0086 01 Foot, rubber, K-15

102 8214 1030 00 Spring, brake

103 8276 9330 15 Tube, UL, SUMI TUBE, 820, F,

D5L15MM

104 8204 2250 03 Washer, RET-RING, E-1.5 ZMB

105 8216 8110 00 Cushion, drive, PD-6

106 8221 3961 00 Panel, bottom, PD-6

107 8221 4260 00 Bracket, cover, EXT, PD-6

108 8216 8000 00 Spacer, cover, EXT, PD-6

109 8221 4250 00 Cover, EXT, PD-6

110 8214 3630 00 Screw, rollet, B, M3

Ref. No. Part No. Description

111 8260 5930 00 Cushion assy, PD-6

112 8204 2440 00 PSW, 2.1 x 4 x 0.5

113 8204 0040 09 Screw, HSB, M 3 x 20 BZn

114 8204 0040 11 Screw, HSB, M 3 x 30 BZn

115 8221 3970 01 Guide, belt, L, PD-6

116 8221 3970 02 Guide, belt, R, PD-6

117 8212 7030 00 Pad, corner, PD-6

118 8221 0872 00 Cover, battery, PD-4

119 8223 3080 00 Shaft, cover, PD-6

120 8214 2911 00 Spring, cover, PD-4

121 8216 8031 00 Cushion, battery, A, PD-6

122 8216 7940 00 Cushion, EXT, PD-6

123 8223 3120 00 Cap, connector, RM15TRD-10S

124 8216 8060 00 Cushion, cap, connector, PD-6

125 N/A Label, serial number

126 8218 8200 00 Label, identification, PD-6

127 8210 0460 00 PANEL, DRESS, PD-6

128 8216 9320 10 Tube, UL, SUMI, 820, F, D4, L10

PD-6 OVERALL EXPLODED VIEW 2 Parts List

Ref. No. Part No. Description

1 8212 4942 00 Case, battery, PD-4

2 8214 3340 00 Spring, battery, PD-4

3 8214 1992 00 Spring, NP-1

4 8277 1050 15 Cable assy, separate, 6P, L150

5 8216 9320 10 Tube, UL, SUMI, 820, F, D4, L10

6 8216 6271 00 Spacer, battery, PD-4

7 8274 3770 00 PCB assy, Main, PD-6

8 8221 4240 00 Panel, BNC, PD-6

9 8204 1160 04 Spacer, M2.6 x 5

10 8204 0830 03 Precision, M 2.6 x 4 BZn

11 8221 4190 00 Panel, conn, PD-6

12 8204 0090 02 Spacer, M 3 x 8

13 8274 3780 00 PCB assy, AD/DA, PD-6

14 8216 7960 00 Shield, ADDA, PD-6

15 8216 8020 00 Cushion, PCB, main, PD-6

16 8277 5630 25 Cable assy, 10P, PH/F-8283/F, L250,

AWG26

17 8221 4100 00 Chassis, front, PD-6

18 8216 8090 00 Sheet, isolation, ADDA, PD-6

19 8221 4110 00 Chassis, rear, PD-6

20 8221 4130 00 Bracket, PCB, input, PD-6

21 8204 0830 04 Screw, precision, M 2.6 x 6 BZn

22 8274 3700 00 PCB assy, Power, PD-6

23 8221 4301 00 Heat sink, power, B, PD-6

Ref. No. Part No. Description

24 8221 4230 00 Heat sink, power, PD-6

25 8216 5370 00 Sheet, SW, PD-4

26 8216 7910 00 Sheet, SW, PD-6

27 8216 8100 00 Cushion, PCB, ADDA, PD-6

28 8274 3690 00 PCB assy, Input amp, PD-6

29 8221 4200 00 Spacer, escutcheon, PD-6

30 8274 3790 00 PCB assy, Input sel, PD-6

31 8221 4120 00 Bracket, PCB, I M, PD-6

32 8226 2710 01 Knob, rotary, A

33 8226 1461 01 Knob, rotary switch, C

34 8226 2800 01 Knob, rotary, B

35 8216 7790 01 Cushion, toggle, B, PD-6

36 8216 5550 03 Washer, 12 x 6 x T4, PD-4

37 8226 1831 08 Button, 11 x 11, N3

38 8214 2700 00 Spring, 8 x 3, 0.2

39 8226 2730 01 Escutcheon, button

40 8226 2761 00 Knob, lock, PD-6

41 8226 2720 01 Button, push

42 8277 4651 15 Cable assy, flat, 50P, P1.0, L150

43 8221 4151 00 Cover, connector, PD-6

44 8204 2250 04 Washer, RET-RING E-2 ZMB

45 8214 3630 00 Screw, rollet, B, M3

46 8221 4180 00 Cover, case, PD-6

47 8216 8250 00 Cushion, core, PD-6

25

Page 26

PD-6 Service Manual

PD-6 OVERALL EXPLODED VIEW 3 Parts List

Ref. No. Part No. Description

1 8221 4310 00 Plate, cover, lock, PD-6

2 8221 4000 00 Bracket, cover, PD-6

3 8204 2450 42 Screw, precision, M 1.7 x 4 BZn

4 8212 7051 00 Window, drive, PD-6

5 8221 4051 00 Bracket, drive, rear, PD-6

6 8204 2460 51 Screw, precision, TB 1.7 x 5 CZn

7 8270 9180 00 DVD-RAM drive assy, PC-2

8 8223 3100 03 Spacer, 5

9 8223 3100 02 Spacer, 4.5

10 8223 3100 01 Spacer, 3.5

11 8221 4041 00 Bracket, drive, front, PD-6

12 8223 3110 00 Shaft, bar, eject, PD-6

13 8221 4030 00 Bar, eject, PD-6

14 8204 2260 00 PSW, 3.1 x 5.4 x 0.13

Ref. No. Part No. Description

15 8204 2250 04 Washer, RET-RING E-2 ZMB

16 8204 0730 02 Screw, precision, M 2 x 5 BZn

17 8274 3900 00 PCB assy, SW-DISC-UNLOCK

18 8277 5660 00 Cable assy, FPC, 70P,

5602/P-5602/P, PD-6

19 8216 8010 00 Cushion, FPC, PD-6

20 8221 4210 00 Bracket, PCB, drive, PD-6

21 8274 3720 00 PCB assy, Drive, PD-6

22 8221 4280 00 Bracket, FPC, PD-6

23 8218 8130 00 Label, laser, caution, PD-6

24 8218 7060 00 Label, push, PD-4

25 8277 5710 06 Cable assy, earth lug, D3-D2,

#22, L60

26 8204 0090 03 Spacer, M3 X 10

PD-6 CABLE ASSY & CONNECTION

Ref. No. Part No. Description Connection

W001 8277 0912 25 Cable assy, 6P, ORG, ZH/F-ZH/F, L250 MAIN J704 <-> PHONES J704

W002 8277 0941 22 Cable assy, 9P, RED, ZH/F-ZH/F, L220 MAIN J902 <-> POWER J805

W003 8277 1050 05 Cable assy, separate, 6P, 50mm DC IN connector <-> POWER J804

W004 8277 1050 15 Cable assy, separate, 6P, 150mm NP-1 Battery section <-> J803

W005 8277 5504 15 Cable assy, SHIELD1CX4, 8P, BLK, ZH/F-ZH/F, L150 INPUT AMP J4 <-> FRONT J1

W006 8277 5514 25 Cable assy, SHIELD1CX4, 8P, RED, ZH/F-ZH/F, L250 MAIN J703 <-> FRONT J3

W007 8277 5503 15 Cable assy, SHIELD1CX3, 6P, BLK, ZH/F-ZH/F, L150 INPUT AMP J5 <-> FRONT J2

W008 8277 5503 10 Cable assy, SHIELD1CX3, 6P, BLK, ZH/F-ZH/F, L100 ADDA2 J2 <-> MAIN J705

W009 8277 5513 10 Cable assy, SHIELD1CX3, 6P, RED, ZH/F-ZH/F, L100 ADDA2 J3 <-> MAIN J706

W010 8277 5502 25 Cable assy, SHIELD1CX2, 4P, BLK, ZH/F-ZH/F, L250 ADDA2 J101 <-> FRONT J101

W011 8277 5512 15 Cable assy, SHIELD1CX2, 4P, RED, ZH/F-ZH/F, L150 ADDA2 J301 <-> FRONT J301

W012 8277 5522 10 Cable assy, SHIELD1CX2, 4P, ORG, ZH/F-ZH/F, L100 ADDA2 J501 <-> FRONT J501

W013 8277 5543 15 Cable assy, SHIELD2CX3, 9P, BLK, ZH/F-ZH/F, L150 XLR OUT J709 <-> ADDA2 J4

W014 8277 5543 15 Cable assy, SHIELD2CX3, 9P, BLK, ZH/F-ZH/F, L150 XLR IN J707 <-> INPUT SEL J701

W015 8277 5553 15 Cable assy, SHIELD2CX3, 9P, RED, ZH/F-ZH/F, L150 XLR OUT J710 <-> ADDA2 J5

W016 8277 5553 15 Cable assy, SHIELD2CX3, 9P, RED, ZH/F-ZH/F, L150 XLR IN J708 <-> INPUT SEL J702

W017 8277 5563 10 Cable assy, SHIELD2CX3, 9P, ORG, ZH/F-ZH/F, L100 MAIN J701 <-> PHONES J703

W018 8277 4651 15 Cable assy, FLAT, 50P, P1.0, L150, CORE DRIVE J902 <-> MAIN J1151

W019 8277 5640 10 Cable assy, FLAT, 20P, P1.0, L100 INPUT AMP J2 <-> FRONT J6

W020 8277 5650 15 Cable assy, FLAT, 34P, P1.0, L150 FRONT J4 <-> MAIN J4

W021 8277 5580 05 Cable assy, 4P, BLK, ZH/F-WIRE, L50 POWER J801 <-> DC OUT connector

W022 8277 5580 05 Cable assy, 4P, BLK, ZH/F-WIRE, L50 POWER J802 <-> DC OUT connector

W023 8277 5590 07 Cable assy, 10P, 10-COLORS, ZH/F-WIRE, L70 AUX I/O connector <-> MAIN J801

W027 8277 5611 25 Cable assy, 11P, PH/F-PH/F, L250, AWG24 MAIN J901 <-> POWER J806

W028 8277 5630 25 Cable assy, 10P, PH/F-8283/F, L250, AWG26 MAIN J908 <-> INPUT AMP J9

W029 8277 2892 10 Cable assy, 2P, ORG, ZHR/F-WIRE/3, L100 Monitor speaker <-> MAIN J702

W030 8277 0870 20 Cable assy, 2P, BLK, ZH/F-ZH/F, L200 SW UNLOCK J801 <-> INPUT AMP J3

W031 8277 5602 30 Cable assy, 2P, PH/F-PH/F, L300, AWG24 POWER J807 <-> DRIVE J903

W032 8277 5710 06 Cable assy, EARTHLUG, D3-D2, #22, L60 DVD-RAM drive <-> Chassis

W033 8277 5720 06 Cable assy, EARTHLUG, D3-D2, DUBLE, #22, L60 DVD-RAM drive <-> Chassis

26

Page 27

PD-6 OVERALL EXPLODED VIEW 3

PD-6 Service Manual

17

B 3 x 6 BZn

24

3

3

4

2

23

1

8

6

3

10

9

9

5

6

25

7

14

13

15

26

12

16

25

11

3

12

20

21

6

18

19

22

16

27

Page 28

PD-6 Service Manual

PD-6 PCB ASSEMBLIES

• Parts Side of ADDA PCB

C5

C6

+

D103

D104

D105

D101

D204

D203

D8

D205

D201

D303

D304

D305

D404

D403

D12

D405

D503 D504 D505

D603

D16

D604

D605

C4

Q2

+

C2

L3

+

+

+

C3

1

1

Q1

+

C1

U6U7 U8

U5

2919

2010

J1 30

MAIN

91

2

W1

U1

C7

15

U3

C12

1

L1L2

Q102

D106

C125

C132

C101

R137

C112

U108

K101

C105

C111

R111

C116

+

U105

R112

C128

C134

+

U101

C102

+

C126

U102

R108

R110

+

D7

Q101

C129

R129

R126 R226

C131

R131

R114

C114

R113

C107

C130

+

C103

1

+

C104

C124R148

1

C138

+

C137

C139

C127

C109

C136

R109

C110

C118 C119

U104

R142

R141

15

C121

R118

C10

+

C151

C152

R156

U4

C17

+

+

C14

C163

C13

+

C122

5

C168

R151

R155

R152

Q152

R173

R153

C155

R170

C154

C162

C161

C158

R168

U151

12

R154

C153

U152

+

+

R164 R264

Q202

C212

D206

+

U109

C232

U205

R212

U208

+

4

5

J101

BLACK RED ORANGE

U206

C204

C224 R348

D202

D102

U106

C239

C238

C202

C227

C205

U202

C236

R107

R209

R210

R211

+

C117

1

W102

W103

C123

C120

C169

U153

Q252

1

R270

C255

U251U252

1

K151

D151

C263

C164

+

+

+

C228

U201

C234

C231

C230

C254

C229

R214

C210

C258

C261

R213

C203

C237

C262

R273

R268

C207

R248

R253

C201

R208

R255

R231

C214

R229

Q201

C225

C226

C208

+

U209

R237

R204R205

C301

R337

C211

C312

+

C332

U308

C311

C305

R311

C316

R342

Q302

D306

R310

R312

C326

R308

U305

U302

+

+

C325

C302

+

C328

C331

C334

C330

R314

R313

C303

C338

C310

U304

C412

C329

U309

C432

R329

R326 R426 R526

R331

C314

C307

U408

1

U301

U406

C304

C324

C339

C337

C336

R309

C318 C319

D402

D302

U306

+

C438

C327

C309

C405

R307

R411

+

1

R341

15

C321

R318

R251

C251

C252

1

C253

C264

+

R252

C352

R256

R254

C363

C351

R356

R351

R352

R353

R354

C353

C354

C362

U352

+

+

R364

R355

C361

+

C358

C322

Q352

R368

R373

C355

C368

U351

12

R370

5

K351

+

C320

D351

C364

U353

C463

+

+

C424

1

+

D406

R412

4

J301

R410

C323

R470

R409

1

U405

C439

C427

U402

C436

C369

U451U452

R464

+

5

C404

C402

C317

W302

W303

Q452

C455

C428

U401

C431

C434

C430

C410

R414

C403

C458

C462

C429

R413

C437

R473

C454

C461

R468

Q402

C407

C401

R448

R408

R453

R455

C512

+

U409

C532

R429

R431

C414

C425

U508

C501

R537

R437

C511

C411

C505

+

R511

R404R405

C426

C408

C516

R542

R541

R518

R451

R452

C451

C551

C552

C452

R556

R456

1

C453

R454

C464

R554

C563

+

+

D506

U505

R512

C528

C531

C534

R514

C530

+

C525

R548

C538

C502

+

C526

U502

R508 R509

R510

+

C510

15

C521

R551

R555

R552

R553

C553

C554

C562

U552

+

R564

R513

C503

U504

C558

C561

C504

+

C522

Q502

C529

C507

C536

Q552

R568

U509

R529

R531

C514

1

U501

C524

D502

C539

+

C537

C527

C509

R507

C518 C519

C520

5

C568

R573

C555

R570

U551

12

K551

+

FRONTFRONTFRONT

U606

D551

C564

U553

C612

C632

U608

C605

1

R611

C663

Q602

D606

+

C629

R613

U601

C637C638

R626

C607

R648

C636

C601

R608

R631

C614

C626

R629

U609

C625

R637

C611

+

R604

4

3

MAIN

+

D602

U506

C624

U605

R612

C628

C631

C634

R614

C630

+

C603

4

5

J501

C604

C639

+

C602

C627

U602

R610

C610

R609

C517

W502

W503

C523

C569

R673

R651

R653

R655

Q652

1

R670

C655

U651

1

U652

+

R664

+

C658

C654

C662

C661

R668

R652

C651

C652

R656

R654

1

C653

C664

+

28

C16

R265

Q151

R169

R165

D153

BLACK

C165

C166

C15

+

+

XLR OUT

Q251

R269

C266

16

MAIN

1

Q351 Q451

C366

R369

C265

J2

9

J4

R365

C365

D353

8251724100

R465

R469

C466

PCB,ADDA2,PD-6

C465

MAIN

J5

C566

Q551

R569

1

J3

1

R565

6

C666

C565

RED

9