Page 1

Service Manual

Model

FD-4

DIGITAL MULTITRACKER

Page 2

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

CAUTION:

TO PREVENT ELECTRIC SHOCK, MATCH

WIDE BLADE OF PLUG TO WIDE SOLT,

FULLY INSERT.

CAUTION: TO REDUCE THE RISK OF ELECTRIC SHOCK,

DO NOT REMOVE COVER (OR BACK).

NO USER-SERVICEABLE PARTS INSIDE.

REFER SERVICING TO QUALIFIED SERVICE PERSONNEL.

The lightening flash with arrowhead symbol,

within an equilateral triangle, is intended to

alert the user to the presence of uninsulated

“dangerous voltage” within the product's enclosure that may be of sufficient magnitude to

constitute a risk of electric shock to persons.

“WARNING”

“TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK,

DO NOT EXPOSE THIS APPLIANCE TO RAIN OR MOISTURE.”

SAFETY INSTRUCTIONS

1.

Read instructions - All the safety and operating instructions should be read before the appliance is operated.

2.

Retain instructions - The safety and operating instructions

should be retained for future reference.

3.

Heed warnings - All warnings on the appliance and in the

operating instructions should be adhered to.

4.

Follow instructions - All operating and use instructions

should be followed.

5.

Water and Moisture - The appliance should not be used

near water - for example, near a bathtub, washbowl,

kitchen sink, laundry tub, in a wet basement, or near a

swimming pool, and the like.

6.

Carts and Stands - The appliance should be used only

with a cart or stand that is recommended by the manufacturer.

An appliance and cart combination should be moved with

care. Quick stops, excessive force, and uneven surfaces

may cause the appliance and cart combination to overturn.

Wall or Ceiling Mounting - The appliance should be

7.

mounted to a wall or ceiling only as recommended by the

manufacturer.

Ventilation - The appliance should be situated so that its

8.

location or position does not interfere with its proper ventilation. For example, the appliance should not be situated on a bed, sofa, rug, or similar surface that may block

the ventilation openings; or, placed in a built-in installation, such as a bookcase or cabinet that may impede the

flow of air through the ventilation openings.

ATTENTION:

POUR ÉVITER LES CHOCS ÉLECTRIQUES,

INTRODUIRE LA LAME LA PLUS LARGE DE

LA FICHE DANS LA BORNE CORRESPONDANTE DE LA PRISE ET POUSSER

JUSQU' AU FOND.

The exclamation point within an equilateral

triangle is intended to alert the user to the

presence of important operating and maintenance (servicing) instructions in the literature

accompanying the appliance.

Heat - The appliance should be situated away from heat

9.

sources such as radiators, heat registers, stoves, or other

appliances (including amplifiers) that produce heat.

Power Sources - The appliance should be connected to a

10.

power supply only of the type described in the operating

instructions or as marked on the appliance.

Grounding or Polarization - The precautions that should

11.

be taken so that the grounding or polarization means of

an appliance is not defeated.

Power Cord Protection - Power supply cords should be

12.

routed so that they are not likely to be walked on or

pinched by items placed upon or against them, paying

particular attention to cords at plugs, convenience receptacles, and the point where they exit from the appliance.

Cleaning - The appliance should be cleaned only as rec-

13.

ommended by the manufacturer.

Nonuse Periods - The power cord of the appliance should

14.

be unplugged from the outlet when left unused for a long

period of time.

Object and Liquid Entry - Care should be taken so that

15.

objects do not fall and liquids are not spilled into the enclosure through openings.

Damage requiring Service - The appliance should be ser-

16.

viced by qualified service personnel when:

The power supply cord or the plug has been damaged;

A.

or

Objects have fallen, or liquid has been spilled into the

B.

appliance; or

The appliance has been exposed to rain; or

C.

The appliance does not appear to operate normally or

D.

exhibits a marked changed in performance; or

The appliance has been dropped, or the enclosure

E.

damaged.

Servicing - The user should not attempt to service the ap-

17.

pliance beyond that described in the operating instructions. All other servicing should be referred to qualified

service personnel.

Page 3

TABLE OF CONTENTS

FD-4

FD-4

1. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. CONTROLS, INDICATORS AND CONNECTORS . . . . . . . . . . .

3. SOFTWARE UPDATE . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. SERVICE MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5. ERROR CODE LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6. INSTALLING 2.5" INTERNAL HARD DISK DRIVE . . . . . . . . .

7. EXPLODED VIEW, PCB ASSEMBLY AND PARTS LIST . . . . .

8. CIRCUIT DIAGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4

7

11

12

19

20

24

41

NOTES

Service mode, error code list, explode view, PCB assembly, parts list and circuit diagrams are given in this

*

manual to assist the service technician in maintaining the Model FD-4.

The following accessories are supplied with FD-4 as the standard accessories.

*

Owner's manual : 8288414100 (for export model)

: 8288415000 (for domestic model)

Following is the packing material for the Model FD-4.

*

Carton, inner, FD-4 : 8228716000

Packing, side, L, FD-4 : 8228440000

Packing, side, R, FD-4 : 8228441000

CAUTION

Parts marked with this sign are safety critical components. They must always be replaced with identical

!

components. Refer to the Fostex Parts List and ensure exact replacement.

3

Page 4

FD-4

1. SPECIFICATIONS

RECORD & REPRODUCE

Recording Medium External fixed / removable hard disk drive

Standard SCSI-2 or better

Sampling Frequency 32 kHz, 44.1 kHz

Quantization 12-bit nonlinear, 16-bit linear

Emphasis Not available

Recording Time (mono track min.)

Fs: 32 kHz About 33 min. / 100 MB (up to 24 hours) at maximum

Fs: 44.1 kHz About 18 min. / 100 MB (up to 24 hours) at maximum

Number of Tracks

NORMAL / MASTERING MODE 1 6 (4 + 2 additional tracks)

MASTERING MODE 2 4

Number of simultaneous recording tracks 2

Number of simultaneous playback tracks 4

Number of tracks to be pasted at a time 6

Recording Format FDMS-3

Recording Mode NORMAL MODE (Fs: 32 kHz, 4 + 2 tracks, default)

ELECTRICAL (0 dBV = 1 V)

• MIXER SECTION

Reference Input Level

MIC -50, -30 dBV

Impedance 20 kΩ or more

LINE -10 dBV

Impedance 20 kΩ or more

RECORDER IN -10 dBV

Impedance 20 kΩ or more

AUX RTN -20 dBV

Impedance 8 kΩ or more

DATA IN

Connector Square shape optical

Format IEC consumer optical standard IEC 958 Part 3

Reference Output Level

STEREO -10 dBV

Load impedance 10 kΩ or more

AUX SEND -10 dBV

Load Impedance 10 kΩ or more

MONITOR -10 dBV

Load impedance 10 kΩ or more

HEADPHONE 20 mW at maximum (Load: 16 Ω)

DATA OUT

Connector Square shape optical

Format IEC consumer optical standard IEC 958 Part 3

MASTERING MODE 1 (Fs: 44.1 kHz, 4 + 2 tracks)

MASTERING MODE 2 (Fs: 44.1 kHz, 4 tracks)

50 mW at maximum (Load: 50 Ω)

4

Page 5

ELECTRICAL (continued)

SCSI DATA input / output

Connector D-SUB 25-pin

Protocol SCSI-2, unbalanced transfer method

Transfer type Asynchronous

Number of device to be connected 1

Fader / Knob Position at Reference Input / Output

MASTER fader At 8 ~ 9 position (AUX RTN : -20 dBV / 1 kHz, AUX RTN

VR: MAX. Adjust master fader for -10 dBV output at

STEREO OUT.)

MONITOR knob Adjust MONITOR knob for -10 dBV output at MONITOR

OUTPUT. (MON SEL: ST+MON, MON)

INPUT fader At 7 ~ 8 position (INPUT: -10 dBV / 1 kHz, EQ GAIN: 0,

PAN: L (R). Adjust input fader for -10 dBV output at

STEREO OUT.)

Output Level

INPUT (1 ~ 4)

→→

→ AUX SEND -10 dBV +0, -2 dB (INPUT: -10 dBV / 1 kHz, EQ GAIN:

→→

0, PAN: L (R), AUX1, 2 VR: CH MAX, input fader: at 7 ~

8 position.)

INPUT (1 ~ 4)

→→

→ MONITOR -10 dBV ± 1 dB (INPUT: -10 dBV / 1 kHz, EQ GAIN: 0,

→→

PAN: L (R), MON VR: MON MAX, MON PAN: L (R),

input fader: at 7 ~ 8 position.)

Frequency Response

INPUT (1 ~ 4)

→→

→ MONITOR 20 ~ 20 kHz +1, -3 dB (INPUT: -50 dBV)

→→

20 ~ 20 kHz +1, -2 dB (INPUT: -10 dBV)

INPUT (1 ~ 4)

AUX RTN

AUX RTN

→→

→ AUX SEND 20 ~ 20 kHz +1, -2 dB (INPUT: -10 dBV)

→→

→→

→ MONITOR OUT 20 ~ 20 kHz +1, -2 dB (AUX RTN: -20 dBV)

→→

→→

→ PHONES 80 ~ 20 kHz +1, -2 dB (AUX RTN: -20 dBV, at 20 mW /

→→

16 Ω)

EQ Characteristics

High (12 kHz) & Low (80 Hz) +15 dB ± 3 dB at “+15” position

-15 dB ± 3 dB at “-15” position

Mid (200 Hz ~ 5 kHz) +15 dB ± 3 dB at “+15” position

-15 dB ± 3 dB at “-15” position

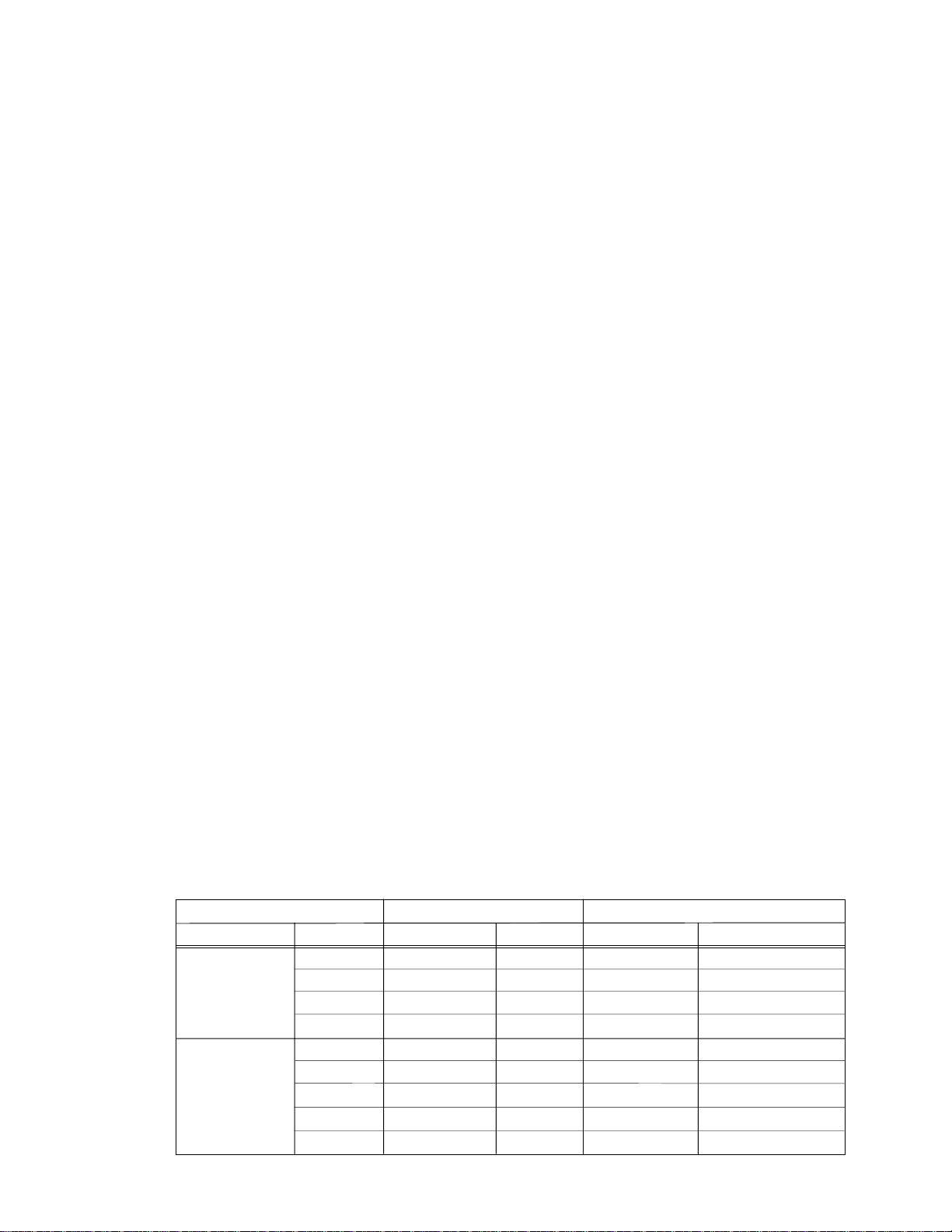

S / N

FD-4

INPUT OUTPUT S / N

INPUT

INPUT Σ4

Residual Noise

LEVEL LEVEL UNWTD. AWTD.

-50 dBV

-38 dBV

-10 dBV

+2 dBV

-50 dBV

-38 dBV

-10 dBV

+2 dBV

VR MIN

AUX SEND

AUX SEND

AUX SEND

AUX SEND

MONITOR

MONITOR

MONITOR

MONITOR

PHONES

-10 dBV

+2 dBV

-10 dBV

+2 dBV

-10 dBV

+2 dBV

-10 dBV

+2 dBV

66 dB or more

78 dB or more

80 dB or more

92 dB or more

63 dB or more

75 dB or more

73 dB or more

85 dB or more

68 dB or more

80 dB or more

82 dB or more

94 dB or more

65 dB or more

77 dB or more

75 dB or more

87 dB or more

-75 dBV or less

5

Page 6

FD-4

ELECTRICAL (continued)

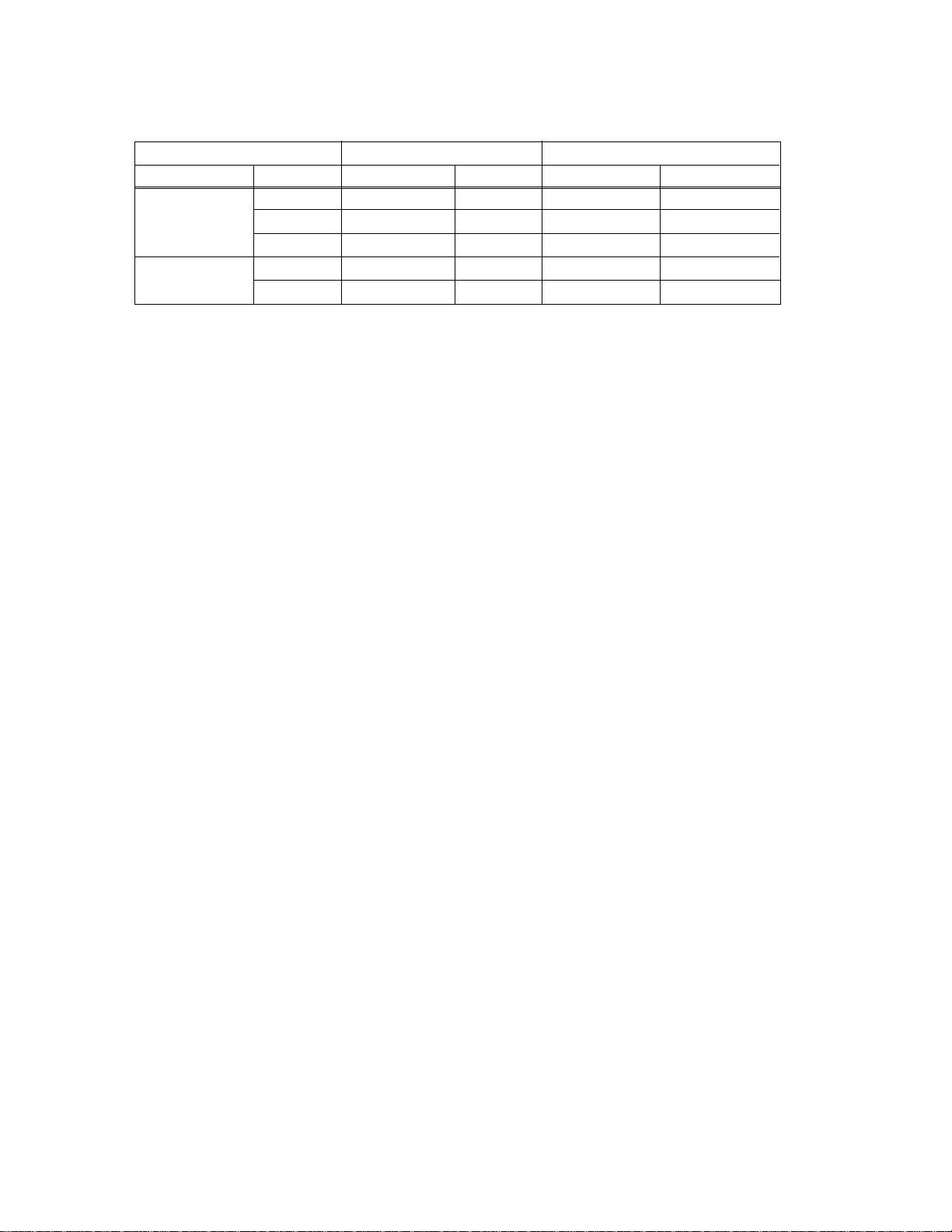

Distortion

INPUT OUTPUT S / N

LEVEL LEVEL UNWTD. AWTD.

INPUT

AUX RTN

-40 dBV

0 dBV

0 dBV

-10 dBV

-10 dBV

MONITOR

MONITOR

AUX SEND

MONITOR

PHONES

0 dBV

0 dBV

0 dBV

0 dBV

20 mW

100 ~ 10 kHz

100 ~ 10 kHz

100 ~ 10 kHz

100 ~ 10 kHz

1 kHz

0.05 % or less

0.05 % or less

0.05 % or less

0.05 % or less

0.10 % or less

Crosstalk 60 dB or more / 1 kHz

Click Noise

Power on / off -20 dBV

Other switching -50 dBV

p-p or less

p-p or less

MIDI Controlling Operation check should be executed using the test mode

with connecting the MIDI IN and OUT terminal.

• RECORDER SECTION

Frequency Response

Fs: 44.1 kHz 20 ~ 20 kHz +1, -2 dB

Fs: 32 kHz 20 ~ 14.5 kHz +1, -2 dB

Full Scale Output Level (Ref: -12dB) +2 dBV ± 1 dB (Fs: 32 kHz / 44.1 kHz)

Dynamic Range 88 dB or more (Fs: 32 kHz / 44.1 kHz)

Total Harmonic Distortion

Fs: 44.1 kHz 0.02 % or less

Fs: 32 kHz 0.08 % or less

Channel Separation 80 dB or more / 1 kHz at max. recording level

(Fs: 32 kHz / 44.1 kHz)

S / N 88 dB or more (A-WTD., Fs: 32 kHz / 44.1 kHz)

Power Consumption

JPN 13 W +5, -20 %

Others 15 W +5, -20 %

Specifications and appearance are subject to change without notice for product improvement.

6

Page 7

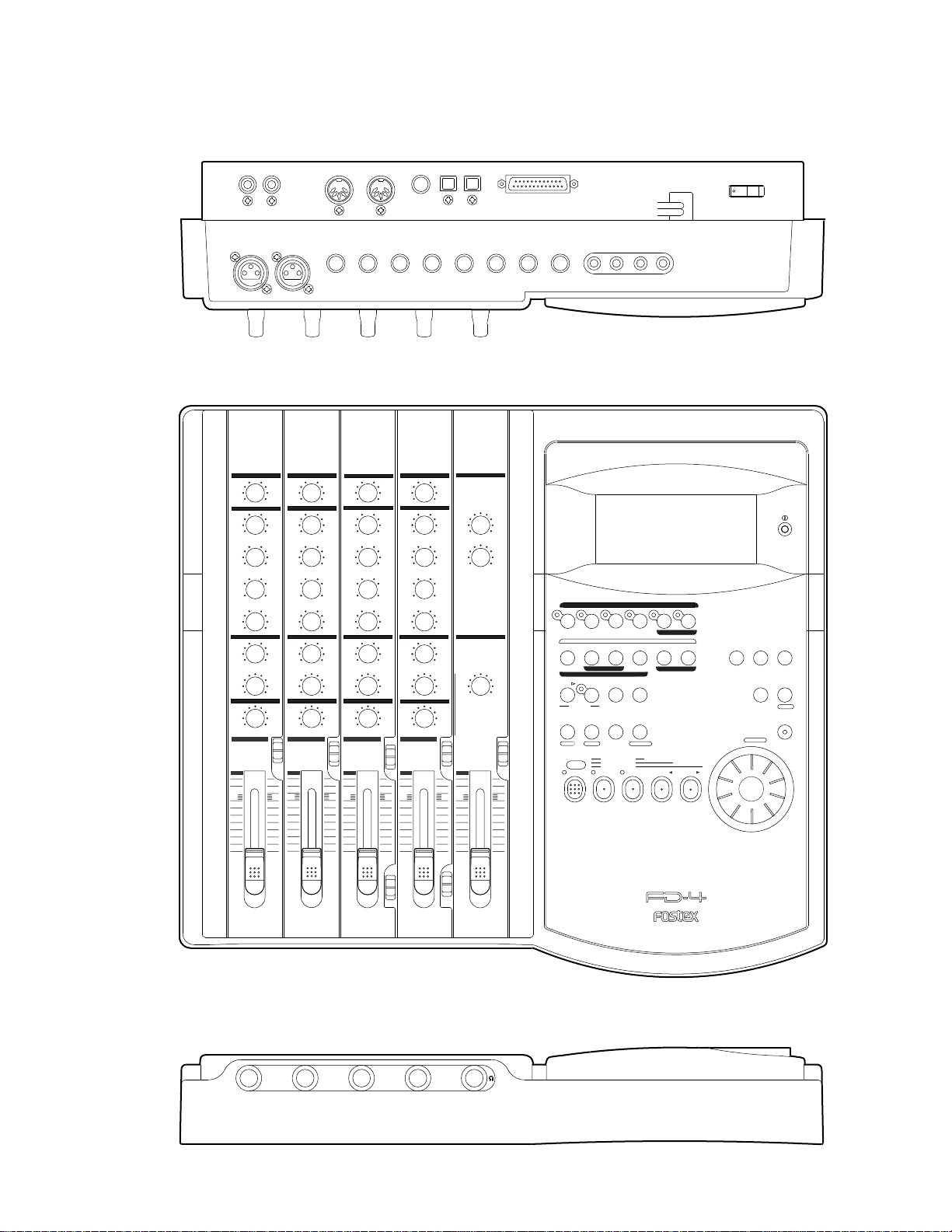

2. CONTROLS, INDICATORS & CONNECTORS

Rear Panel

FD-4

Control Panel

AUX1

HIGH

MID

GAIN

MID

SHIFT

300

200

LOW

PAN

1

10

R

LIN

RECORDER IN

INPUT 3

AUX

AUX2

EQ

HIGH

0

-

+

MID

GAIN

0

-

+

MID

SHIFT

900

300

2k

5k

LOW

0000

-

+

MON MON MON

0

TRK1INPUT

PAN

MON L MON RMON L MON R

PAN PAN PAN

L

R

INPUT SELINPUT SEL INPUT SEL

INPUT

OFF

TRK 1

2 3

10

OUT

MIDI

4 INSERT 3

INPUT 4

AUX

00

AUX1

EQ

0

-

0

-

900

200 5k

-

000

L

INPUT

TRK 2

AUX

0

AUX1

HIGH

MID

GAIN

MID

SHIFT

300

200 5k

LOW

PAN

MON L MON R

10

AUX2

EQ

0

-

+

0

-

+

900

2k

-

+

TRK3INPUT

L

R

INPUT

OFF

TRK 3

AUX2

+

+

2k

+

TRK2INPUT

R

OFF

IN/OUT

OUTIN

DATA

PUNCH

MIDI

R MONO/L

AUX RTN 1

AUX

0

AUX1

AUX2

EQ

HIGH

0

-

+

MID

GAIN

0

-

+

MID

SHIFT

900

2k

300

200 5k

LOW

-

+

MON

TRK4INPUT

PAN

MON L MON R

PAN

L

R

INPUT SEL

INPUT

OFF

TRK 4

4

10

1

2

MON SECTION

MASTER

SELECTOR

L/R

10

DATA

AUX RTN 2

AUX RTN

0

10

010

010

L/R

L/R+MON

MON

SCSI

R MONO/L

2 AUX SEND 1

RECORD TRACK

1/L

START IN OUT

AUTO PUNCH

AUTO RTN

HOLD/ STORE

PGM SEL

VARI

PITCH

SHIFT

P. EDIT

CLIPBOARD PLAY

AUTO

PUNCH

LOCATE REC END

RECORD

AUTO RTN

AUTO PLAY

LOCATE ABS 0

R ST OUT L

4/R3/L2/R

PREVIEW

END IN OUT

UNDO/

REDOEDIT

LOCATE

LOC MEM

R MON OUT L

RL

ADD. TRACK

CLIPBOARD

F FWD/REWIND/PLAYSTOP

POWER

TIME BASE

SETUP

SELDISP SEL

EXIT

EXECUTE

/YES

/NO

EJECT

ACCESS

SHUTTLE

JOG

Front Panel

5

0

5

0

5

0

21

5

0

H

M

L

LEVEL LEVEL

3

5

0

H

M

L

DIGITAL MULTITRACKER

4

7

Page 8

FD-4

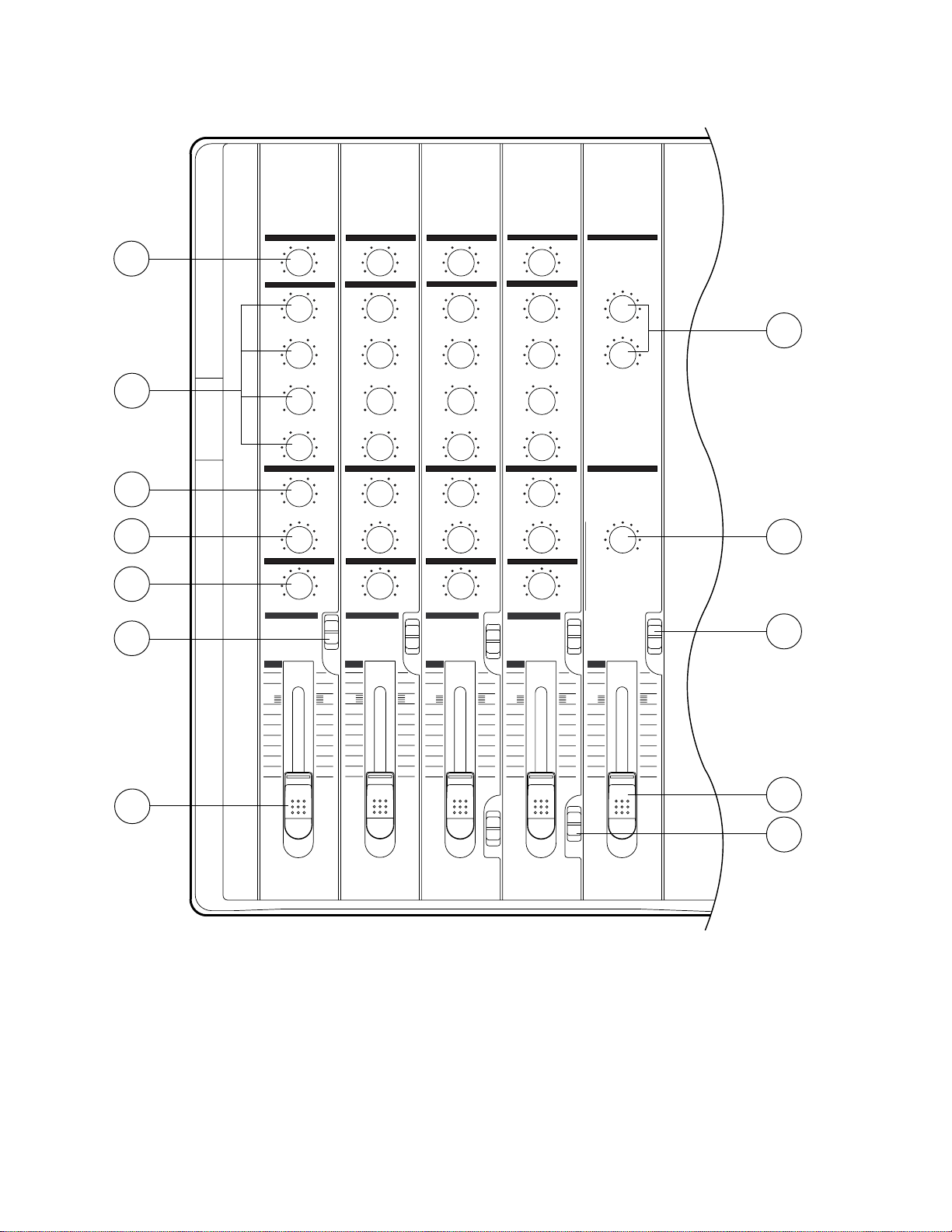

Control Panel (Mixer Section)

7

6

5

4

3

2

AUX1

HIGH

MID

GAIN

MID

SHIFT

300

200 5k

LOW

PAN

MON L MON R

INPUT SEL

4

10

AUX

EQ

-

-

900

-

MON

PAN

L

AUX

AUX1

AUX2

EQ

HIGH

0

-

+

MID

GAIN

0

-

+

MID

SHIFT

900

2k

300

200

5k

LOW

0000

-

+

MON MON MON

0

TRK1INPUT

PAN

PAN PAN PAN

L

R

INPUT

OFF

TRK 1

1

10

AUX

00

AUX1

AUX2

EQ

HIGH

0

-

+

MID

GAIN

0

-

+

MID

SHIFT

900

2k

300

200 5k

LOW

-

+

000

TRK2INPUT

PAN

MON L MON RMON L MON R

L

R

INPUT SELINPUT SEL INPUT SEL

INPUT

OFF

TRK 2

2 3

10

AUX1

HIGH

MID

GAIN

MID

SHIFT

300

200 5k

LOW

PAN

MON L MON R

10

AUX

0

AUX2

EQ

0

-

+

0

-

+

900

2k

-

+

TRK3INPUT

L

R

INPUT

OFF

TRK 3

0

0

0

INPUT

TRK 4

OFF

AUX2

+

+

+

TRK4INPUT

R

AUX RTN

1

0

10

2

010

2k

MON SECTION

MASTER

010

SELECTOR

L/R

L/R+MON

MON

L/R

10

8

9

10

5

0

5

0

1

1. Input faders [1-4]

2. Input select switches

[INPUT SEL (INPUT/OFF/TRK)]

3. Panpot knobs [PAN (L/R)]

4. Monitor panpot knobs [PAN (MON L/MON R)]

5. Monitor level control knob [MON (INPUT/TRK)]

6. Equalizer control knobs [EQ (HIGH/MID/LOW)]

7. AUX send knobs [AUX (AUX 1/AUX 2)]

5

0

5

0

H

M

L

LEVEL LEVEL

5

0

H

M

L

8. AUX return knobs [AUX RTN (1, 2)]

9. Monitor master knob

[MONITOR SECTION (MASTER)]

10. Monitor select switch

[SELECTOR (L/R, L/R+MON, MON)]

11. Master fader [L/R]

12. Input level switches [LEVEL (H/M/L)]

11

12

12

8

Page 9

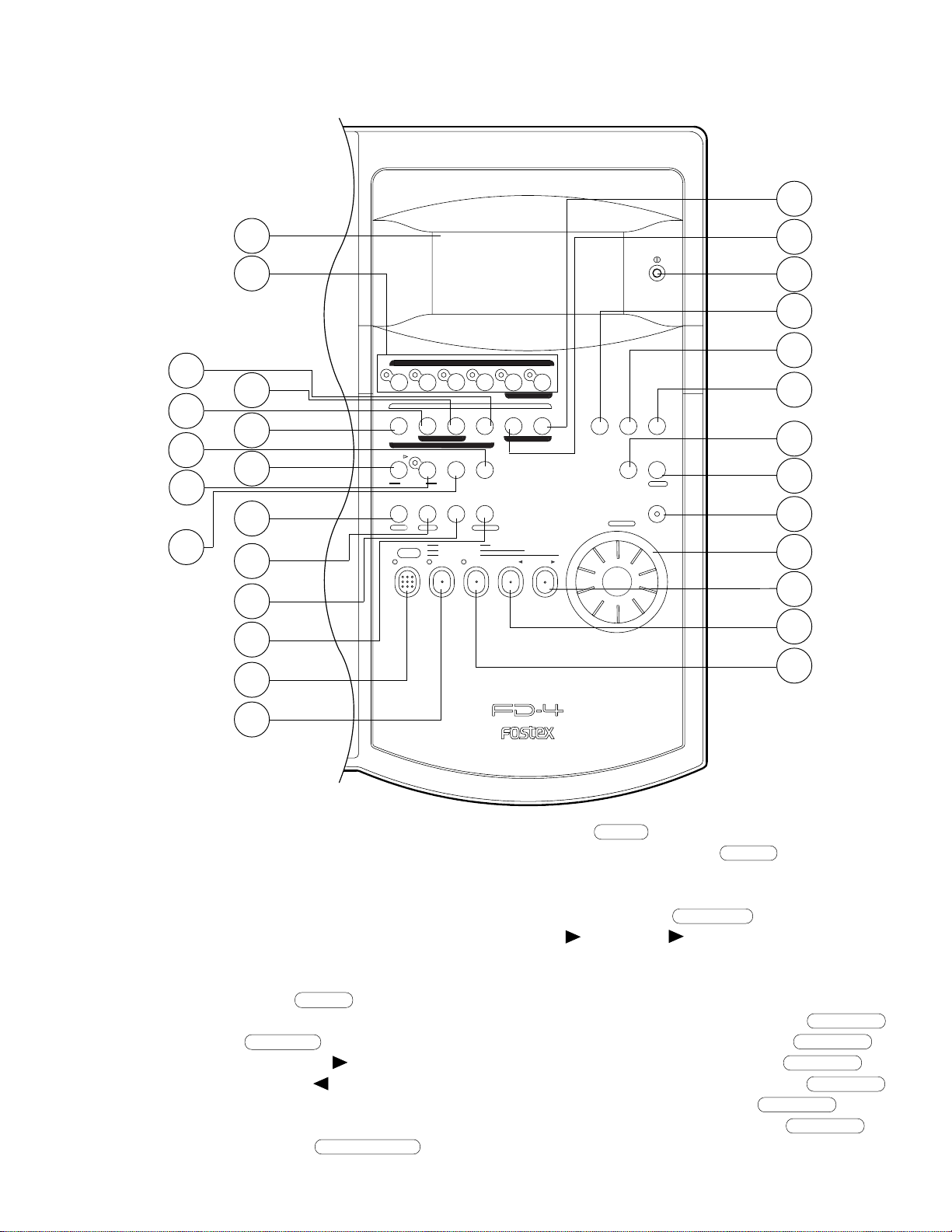

Control Panel (Recorder Section)

FD-4

41

37

38

34

33

35

14

13

39

36

32

28

29

30

31

27

RECORD TRACK

1/L

START IN OUT

AUTO PUNCH

AUTO RTN

HOLD/ STORE

PGM SEL

VARI

PITCH

SHIFT

P. EDIT

CLIPBOARD PLAY

LOCATE ABS 0

AUTO

PUNCH

LOCATE REC END

RECORD

AUTO RTN

AUTO PLAY

PREVIEW

4/R3/L2/R

ADD. TRACK

END IN OUT

CLIPBOARD

UNDO/

REDOEDIT

LOCATE

LOC MEM

40

15

16

17

RL

TIME BASE

SELDISP SEL

SETUP

EXIT

EXECUTE

/YES

/NO

EJECT

ACCESS

SHUTTLE

JOG

F FWD/REWIND/PLAYSTOP

18

19

20

21

22

23

24

25

26

13. Record track select keys

[RECORD TRACK (1/L, 2/R, 3/L, 4/R, L, R)]

14. LCD

15. Contrast adjustment knob

16. Display indication select key

17. Setup key [SETUP]

18. Time Base select key

19. Execute/Yes key [EXECUTE/YES ]

20. Exit/No key [EXIT/NO/ EJECT ]

21. Access LED [ACCESS]

22. JOG dial [JOG/ SHUTTLE ]

23. Fast forward button [F FWD/ ]

24. Rewind button [REWIND/ ]

25. Play button [PLAY]

26. Stop button [STOP]

27. Record button [RECORD/ AUTO PUNCH ]

DIGITAL MULTITRACKER

28. Shift key [ SHIFT ]

29. Vari Pitch key [VARI PITCH/ P.EDIT ]

30. Auto Return/Auto Play mode on/off key

[AUTO RTN/AUTO PLAY]

31. Locate key [LOCATE/ LOC MEM ]

32. Hold/ key [HOLD/ ]

33. Store key [STORE]

34. Undo/Redo key [UNDO/REDO]

35. Edit key [EDIT]

36. Auto Return Start key [AUTO RTN START/ PREVIEW ]

37. Auto Return End key [AUTO RTN END/ PREVIEW ]

38. Auto Punch In key [AUTO PUNCH IN/ PREVIEW ]

39. Auto Punch Out key [AUTO PUNCH OUT/ PREVIEW ]

40. Clipboard In key [CLIPBOARD IN/ PREVIEW ]

41. Clipboard Out key [CLIPBOARD OUT/ PREVIEW ]

9

Page 10

FD-4

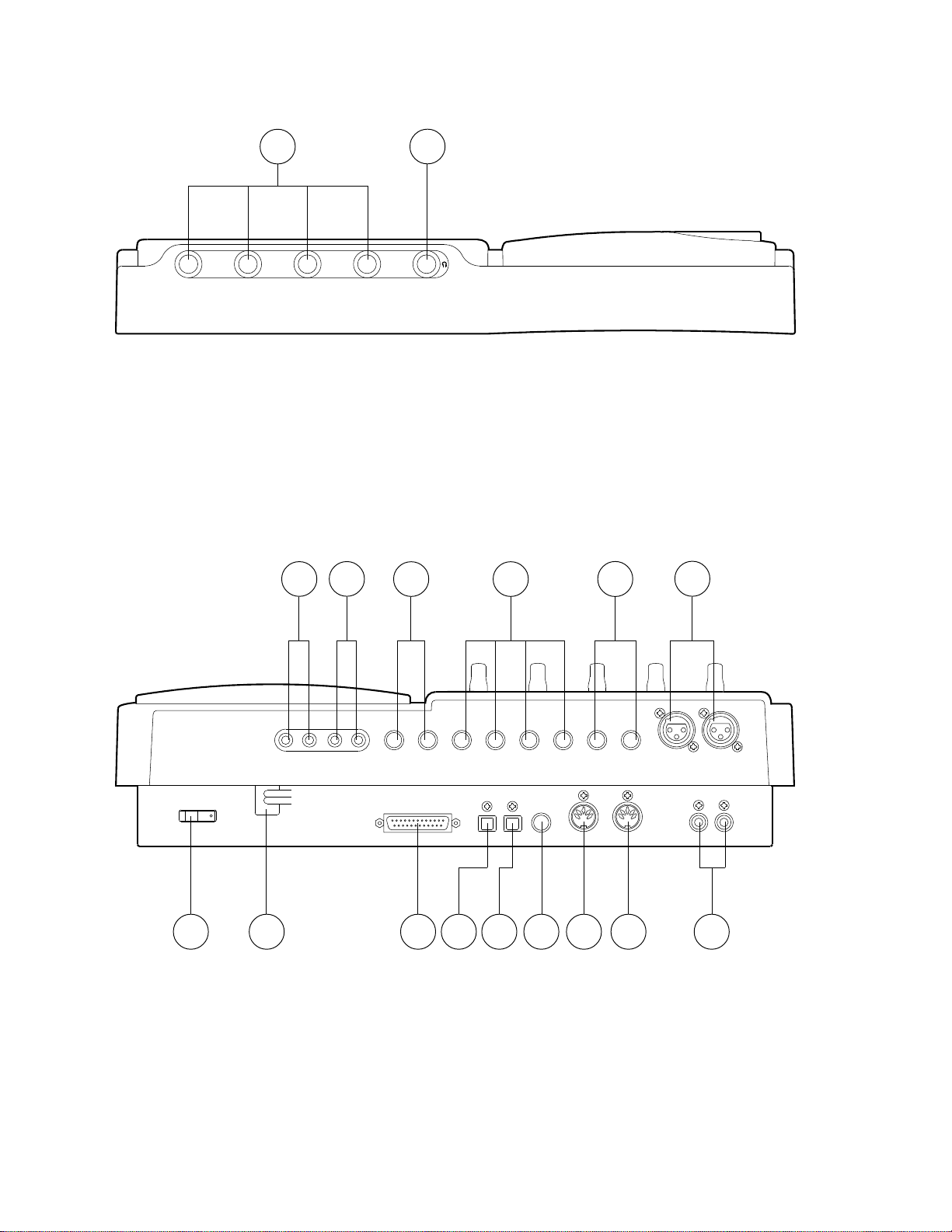

Front Panel

1

21

1. Input jacks [1, 2, 3, 4] (Phone)

2. Headphone jack [PHONES] (TRS Phone)

Rear Panel

1

3

2

2

4

3 4 5

6

R MON OUT L

POWER

R ST OUT L

2 AUX SEND 1

1. Monitor Out jacks [MON OUT L, R] (RCA pin)

2. Stereo Out jacks [ST. OUT L, R] (RCA pin)

3. AUX Send jacks 1, 2 [AUX SEND 1, 2] (Phone)

4. AUX Return jacks 1, 2 [AUX RTN 1, 2] (Phone)

5. Insert jacks 3, 4 [INSERT 3, 4 ] (TRS Phone)

6. Balanced input connectors 3, 4 [INPUT 3, 4]

(Balanced XLR)

7. Recorder in jacks L, R [RECORDER IN L, R]

(RCA pin)

INPUT 3

AUX RTN 2

R MONO/L

12

DATA

11

SCSI

131415

DATA

OUTIN

AUX RTN 1

R MONO/L

PUNCH

IN/OUT

10

MIDI

4 INSERT 3

MIDI

OUT

89

INPUT 4

RECORDER IN

R

7

LIN

8. MIDI OUT jack [MIDI OUT] (DIN 5-pin)

9. MIDI IN jack [MIDI IN] (DIN 5-pin)

10. Punch in/out jack [PUNCH IN/OUT] (Phone)

11. Data output jack [DATA OUT] (OPTICAL)

12. Data input jack [DATA IN] (OPTICAL)

13. SCSI connector [SCSI] (D-SUB 25-pin)

14. Power cable

15. Power switch [ POWER]

10

Page 11

3. SOFTWARE UPDATE

The FD-4 software can be updated through SCSI port. This means that unscrewing and opening up the FD-4 top panel is not

necessary to change the EPROMs on the MAIN PCB assy. Please refer to the following explanation for correct software

updating procedures.

3-1. Method of Sending Software from Fostex Japan

There are two ways of sending the FD-4 updated software.

1.

Updated software in a removable media (e.g. floppy disk, zip disk, etc.) to be sent via airmail

2.

Updated software as an attachment file to be sent via E-mail

3-2. Required Tools

The following tools/equipment are required to update the FD-4 software.

1.

IBM PC compatible computer with SCSI board

2.

Removable type SCSI drive

3.

Cable between the removable type SCSI drive and the SCSI board

4.

Cable between the removable type SCSI drive and the FD-4 (D-SUB 25-pin)

FD-4

3-3. Software Updating Procedures

Presuming that the updated software is correctly sent and is copied into your computer.

Connect the removable type SCSI drive to the SCSI board.

1.

Insert the diskette to the removable type SCSI drive and format it by the computer (IBM PC format).

2.

Copy the updated software file to the removable type SCSI drive (diskette).

3.

Reconnect the removable type SCSI drive to the FD-4 SCSI port.

4.

In order to boot up the FD-4 system software, insert the diskette formatted by the FD-4.

5.

Eject the diskette by pressing the EXIT/NO key while holding down the SHIFT key.

6.

Insert the diskette with updated software file. The FD-4 LCD display shows “No Disk”, “Initial..”, “name of drive (e.g.

7.

ZIP 100)” and “FD4MOT” in order and comes to a standstill at the display below.

DIGITAL

?

SURE

SYNC OUT DRIVE

AUTO A.PUNCH

Pressing the EXECUTE/YES key would update the software. The display shows “Loading!”, “Writing!” and “Initial..”

8.

in order and automatically returns to the above condition again. This indicates that updating the software is completed.

Eject the diskette with updated software file and insert the diskette formatted by the FD-4.

9.

Check the software version by the Service Mode. (For details, please refer to the section “4-2. Software/CPU version”.)

10.

: Blinking

SCSI

CAUTION:

The diskette in which the updated software file is copied must be formatted by IBM PC computer, not by Macintosh.

1.

If something wrong happens while updating the software (e.g. A blackout occurred while updating the software.), the

2.

FD-4 might not be able to boot up the system software inside the Flash ROM. In this case, please refer to the section “4-

8. Flash ROM” (page 17).

11

Page 12

FD-4

4. SERVICE MODE

There are various optional modes available in the FD-4 Service Mode. Please utilize them when servicing the unit.

4-1. Putting FD-4 into Service Mode

The way of putting the FD-4 into Service Mode is as follow.

1)

Connect a SCSI device, insert the diskette formatted by the FD-4 and turn it on.

2)

Turn on the power of FD-4.

3)

While holding down the STOP button and SHIFT key, press the SETUP key.

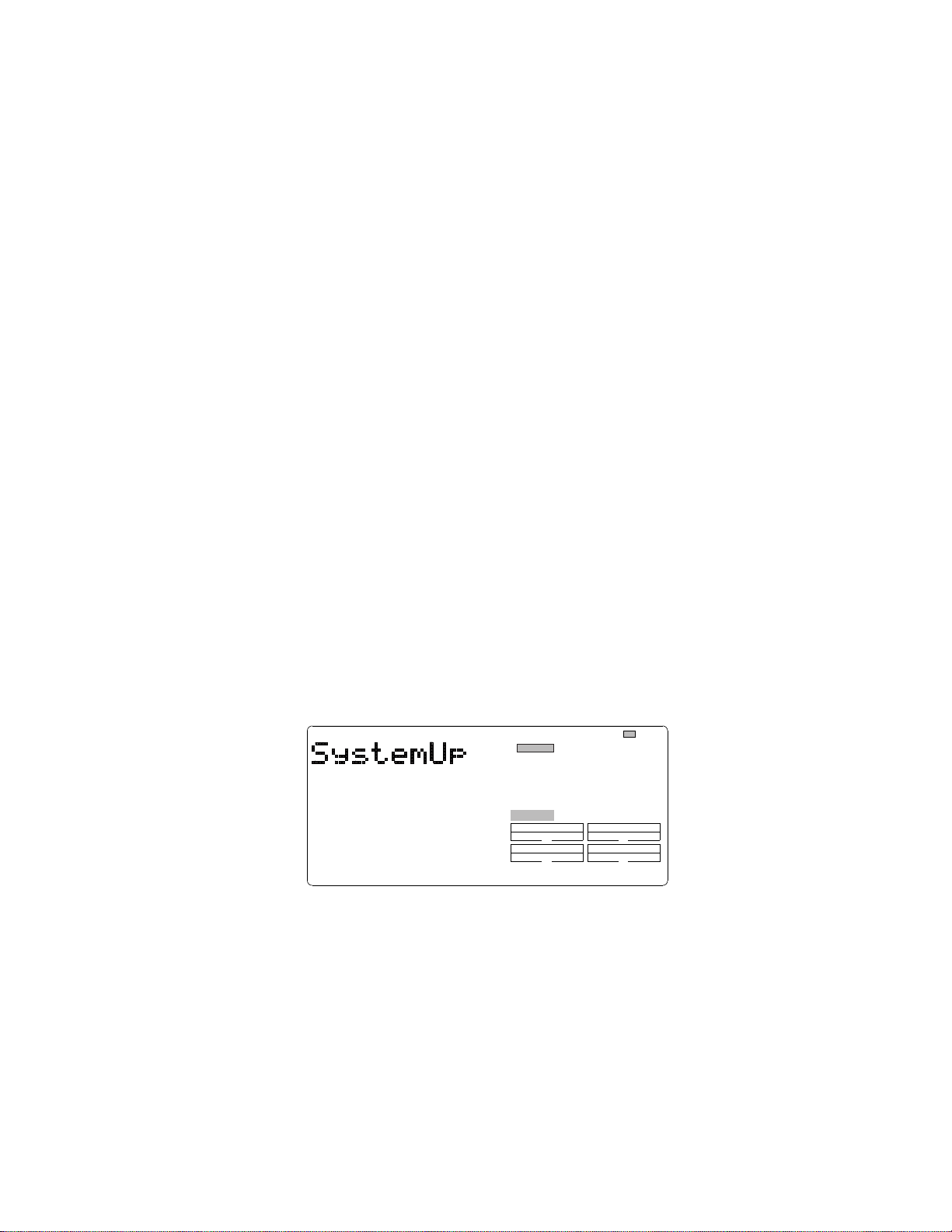

As shown below, by rotating the jog dial C.W. or C.C.W., various optional modes will be displayed in addition to the

general SETUP menus. In order to select a certain optional mode, press the EXECUTE/YES key while its menu is

displayed.

Save PGM?

Load PGM?

DeviceID?

Resolu?

N/A

N/A

Freebloc k?

Digi.out?

C.W.

Digi.in?

NOsEvent?

RecProtct?

SlaveType?

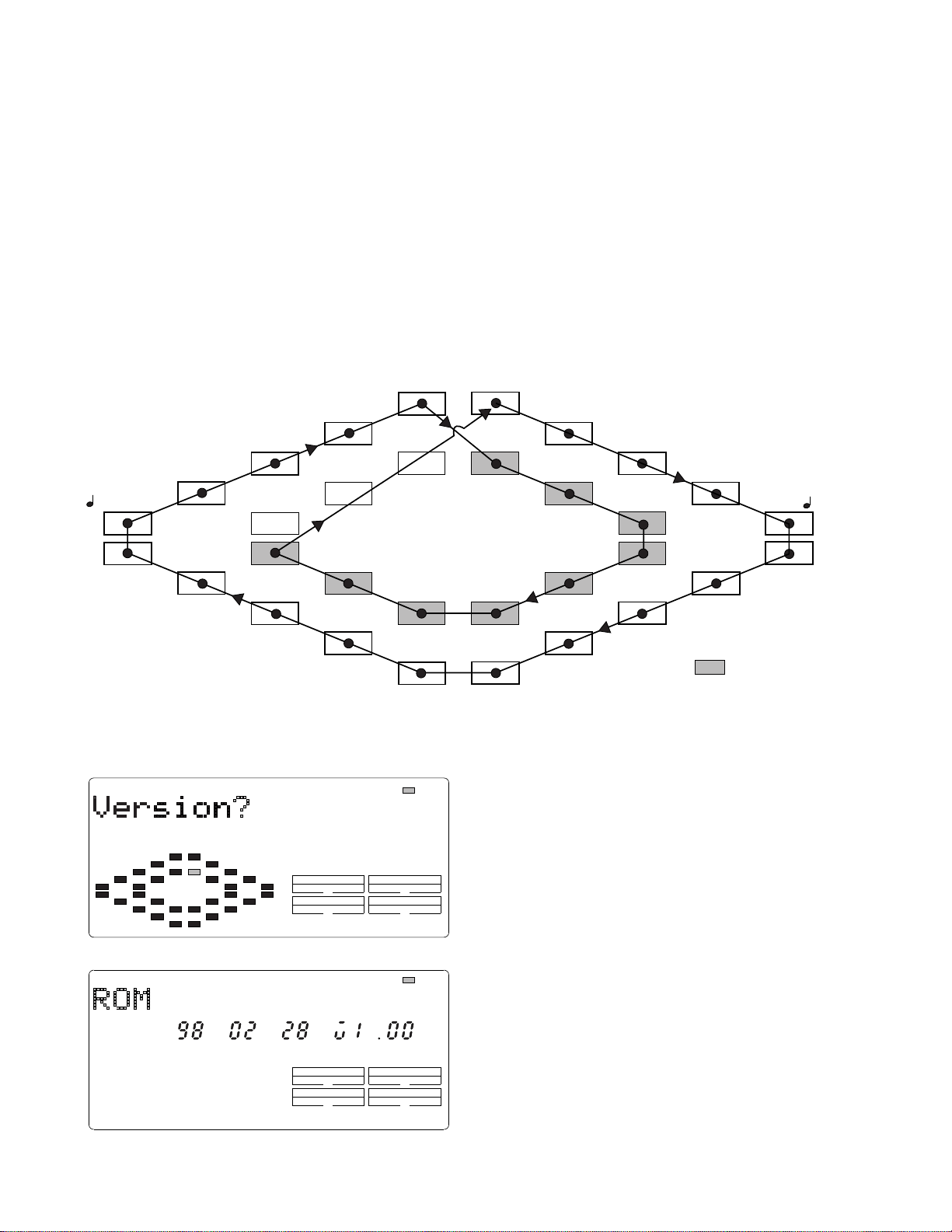

4-2. Flash ROM/CPU version

C.W.

C.W.

Format?

C.W.

N/A

SlaveMode?

: Blinking

Sign.Set?

TempoSet?

Version?

DA Test?

TitleEdit?

C.W.

Del. PGM?

Click ?

Disp.Test?

SelfCheck?

Preroll?

: Service Mode

C.W.

Init.Disk?FlashROM?

MtcOffset?

OfsetMode?

OfsetDisp?

C.W.

FrameRate?

SyncOut?

N/A: Not Available

This mode is used to check the Flash ROM and CPU versions

currently installed in the unit.

12

SYNC OUT DRIVE

CLK

AUTO A.PUNCH

SYNC OUT DRIVE

CLK

AUTO A.PUNCH

SCSI

: Blinking

SCSI

In order to check the version number, press the “EXECUTE/

YES” key while “?” is blinking.

The example on the left indicates that the Flash ROM version

is V1.00 and its programming date is February 28, 1998.

In this condition, by turning the jog dial C.W., the CPU

version can be checked.

Page 13

FD-4

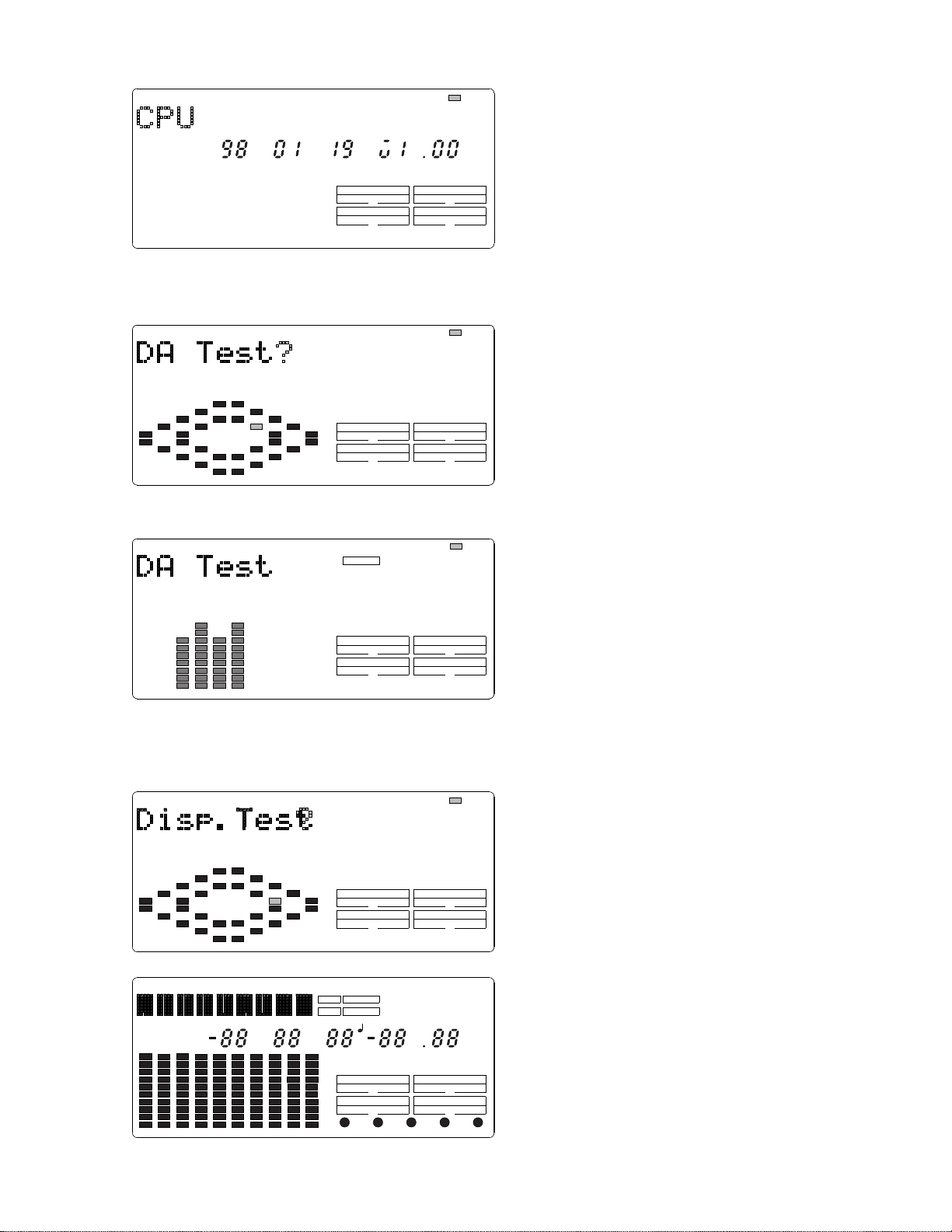

4-3. DA Test

1234 LR

SYNC OUT DRIVE

CLK

AUTO A.PUNCH

SYNC OUT DRIVE

CLK

AUTO A.PUNCH

DIGITAL

32kHz

SYNC OUT DRIVE

CLK

AUTO A.PUNCH

: Blinking

SCSI

: Blinking

SCSI

: Blinking

SCSI

The example on the left indicates that the CPU version is

V1.00 and its programming date is January 19, 1998.

This mode test the signal flow from the DATA INPUT jack

to the D/A converter. A S/P DIF digital signal whose

sampling frequency is the same as the one when formatting

the diskette (MASTERING MODE 1, 2: 44.1kHz,

NORMAL MODE: 32kHz) must be input to the DATA

INPUT jack.

To execute this test, press the EXECUTE/YES key while

“?” is blinking.

If the FD-4 is in a normal condition, “32kHz or 44.1kHz”

and “DIGITAL” will be lit solid. The odd (1 and 3) and

even (2 and 4) channels indicate the L and R input level of

S/P DIF digital signal fed to the DATA INPUT jack

respectively.

If the FD-4 is not in a normal condition, “32kHz or 44.1kHz”

and “DIGITAL” will blink and the bargraph meter will not

indicate any input level.

4-4. Display/Button Test

REMAIN ABS

LOC MTC IN

BAR

SYNC OUT DRIVE

CLK

AUTO A.PUNCH

PLAY RTN

MTC

DIGITAL

MIDI

SLAVE

SMH

VARI PITCH TEMPO PGM

?

SURE COMPLETED

SYNC OUT DRIVE

CLK MTC

AUTO A.PUNCH

PLAY RTN

RHSL TAKE

32kHz 44.1kHz 48kHz

SETUP MTC OFFSET

CLK

DF

IDE SCSI

RHSL TAKE

: Blinking

SCSI

MB

SF

This mode tests if all the segments on the LCD display and

the LEDs on the FD-4 top panel are correctly working or

not.

To execute this test, press the EXECUTE/YES key while

“?” is blinking.

If the FD-4 is in a normal condition, all the segments on the

LCD display will lit solid and the LEDs on the top panel

will start blinking.

F

%

!

If the FD-4 is not in a normal condition, the faulty segments

on the LCD display and/or LEDs on the top panel will remain

unlit.

13

Page 14

FD-4

SYNC OUT DRIVE

CLK

AUTO A.PUNCH

SYNC OUT DRIVE

CLK

AUTO A.PUNCH

SCSI

SCSI

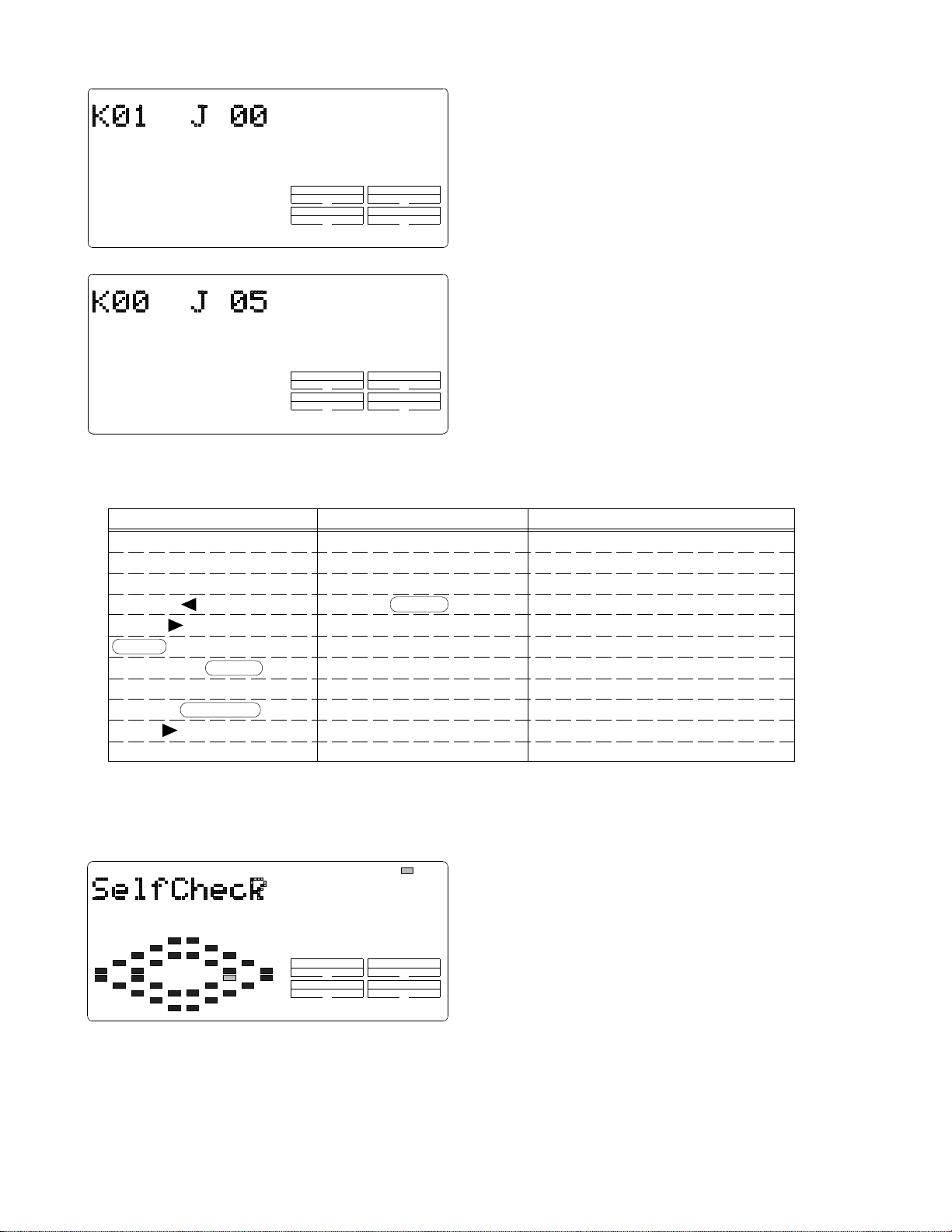

In this condition, if the EXECUTE/YES key is pressed one

more time, the Button Test can be executed.

The Button Test checks if each key/button and jog dial are

working properly or not. The display on the left indicates

that the RECORD button is pressed. (“K” stands for the Key

and “J” the Jog dial.)

The display on the left indicates that the jog dial is turned

C.W.

The table below shows the relationship between the key/

button/jog dial and the corresponding numbers appear on

the LCD display.

In order to quit the Button Test, turn the jog dial C.W. or

C.C.W. further after “J 020” or “J-19” is displayed

respectively.

Key/Button/Jog Dial No.

RECORD K01

STOP K02

PLAY K03

REWIND/ K04

F FWD/ K05

SHIFT K06

VARI PITCH/ P.EDIT K07

AUTO RTN/PLAY K08

LOCATE/ LOC MEM K09

HOLD/ K10

STORE K11

4-5. Self Check

Key/Button/Jog Dial No.

EDIT K12

UNDO/REDO K13

EXECUTE/YES K14

EXIT/NO/ EJECT K15

AUTO RTN START K16

AUTO PUNCH IN K17

AUTO PUNCH OUT K18

AUTO RTN END K19

CLIPBOARD IN K20

CLIPBOARD OUT K21

DISP SEL K22

: Blinking

SYNC OUT DRIVE

CLK

AUTO A.PUNCH

SCSI

Key/Button/Jog Dial No.

SETUP K23

TIME BASE SEL K24

RECORD TRACK 1/L K25

RECORD TRACK 2/R K25

RECORD TRACK 3/L K25

RECORD TRACK 4/R K25

RECORD TRACK 5/L K25

RECORD TRACK 6/R K25

JOG DIAL (C.W.) J 00 ~ 20

JOG DIAL (C.C.W.) J -00 ~ -19

This mode automatically tests the following points in order.

• SCSI bus

• ATA bus

• MIDI in/out circuit

• S/P DIF digital signal (44.1kHz)

• 32kHz digital signal

• Vari-pitch circuit

• A/D and D/A circuit (Input Monitor)

14

Page 15

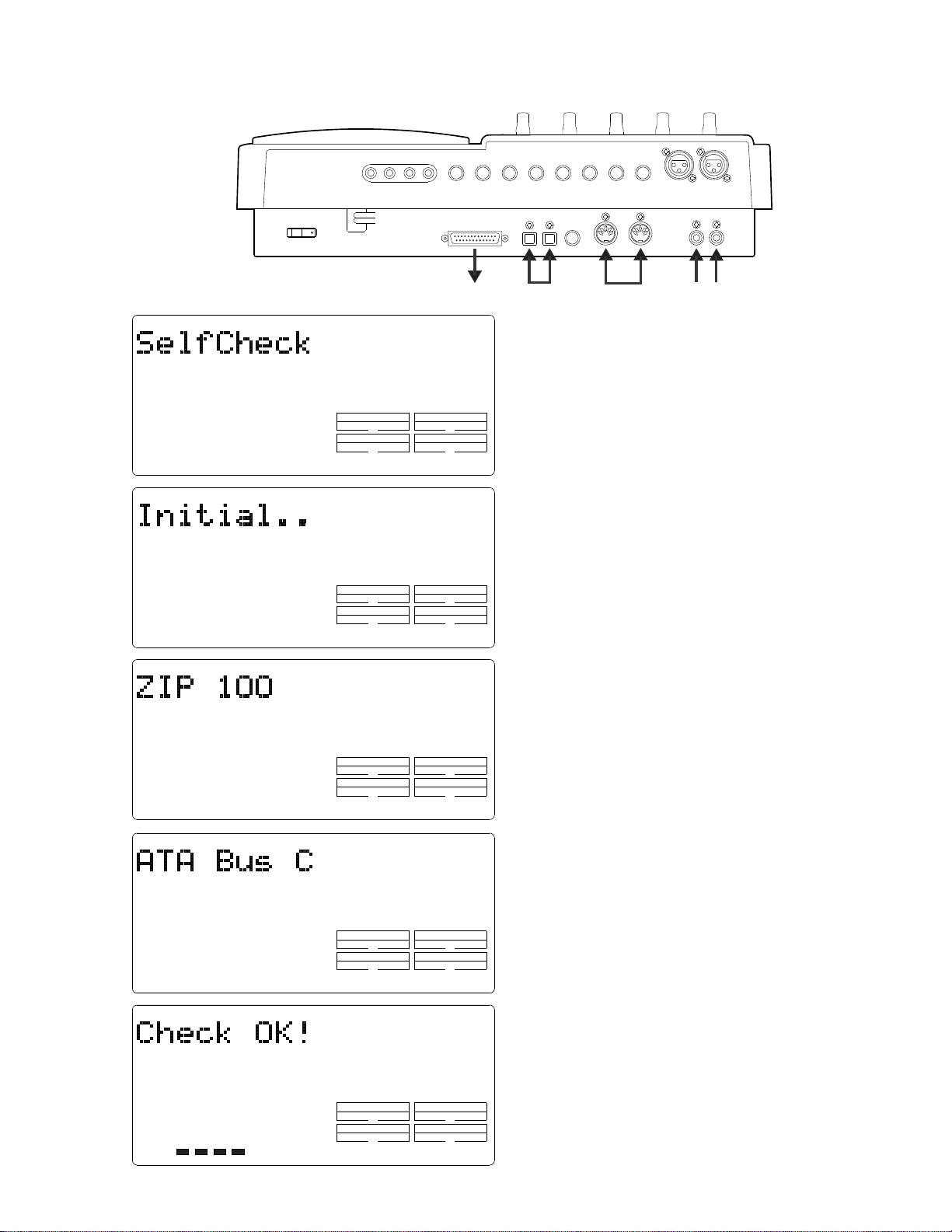

<Cable Connection in “Self Check” Mode>

R MON OUT L

R ST OUT L

2 AUX SEND 1

POWER

SCSI

AUX RTN 2

R MONO/L

DATA

DATA

OUTIN

AUX RTN 1

R MONO/L

PUNCH

IN/OUT

MIDI

4 INSERT 3

FD-4

INPUT 3

INPUT 4

MIDI

OUT

RECORDER IN

R

LIN

SYNC OUT DRIVE

CLK

AUTO A.PUNCH

SYNC OUT DRIVE

CLK

AUTO A.PUNCH

SYNC OUT DRIVE

CLK

AUTO A.PUNCH

External

SCSI Drive

SCSI

SCSI

SCSI

Optical

Cable

MIDI cable

Apply

audio signal.

To start the Self Check mode, press the EXECUTE/YES

key when “?” is blinking (condition indicated in the previous

page).

As shown in the left, “SelfCheck”, “Initial..”, name of

connected SCSI drive (The example in the left shows that

the ZIP drive is connected to the FD-4 SCSI port.) and “ATA

Bus C (Check)” appear on the FD-4 LCD display in order.

Since a 2.5" internal E-IDE hard disk drive is not installed

in the FD-4, the Self Check mode comes to a standstill at

“ATA Bus Check” test.

In order to continue the Self Check mode, press the

EXECUTE/YES key.

If the FD-4 is in a good shape, “Check OK!” will be displayed

and the FD-4 is automatically put into Input Monitor mode

with all the RECORD TRACK LEDs and RECORD LED

flashing after checking the points mentioned in the previous

page. In this condition, if a signal is applied to the FD-4

RECORDER IN (L, R) jacks, its level can be monitored on

the bargraph level meter.

1234 LR

SYNC OUT DRIVE

CLK

AUTO A.PUNCH

SYNC OUT DRIVE

CLK

AUTO A.PUNCH

To quit the Self Check mode, press the EXIT/NO key when

“Check OK!” is displayed.

SCSI

SCSI

15

Page 16

FD-4

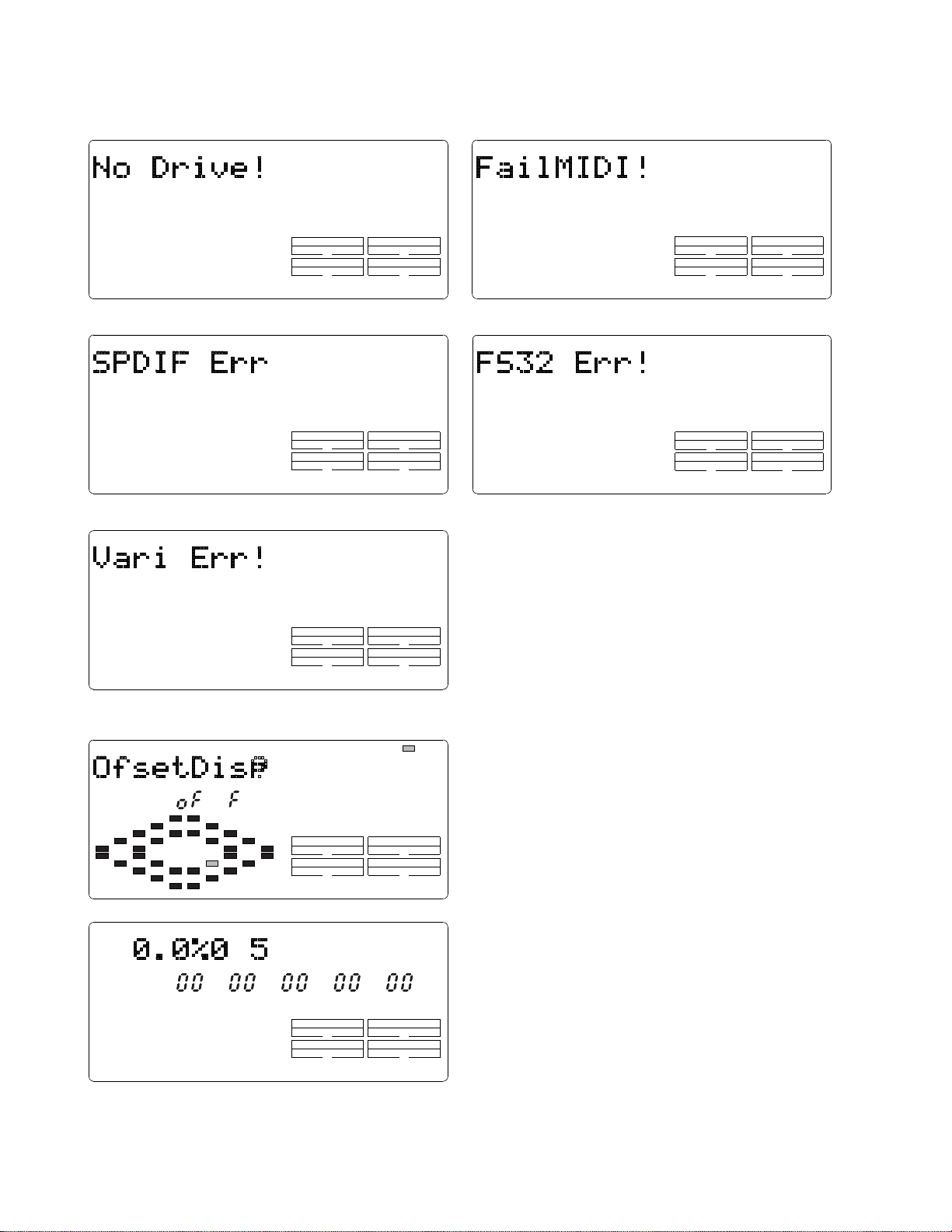

The followings are examples of error message when the FD-4 is not working properly.

• SCSI function

SYNC OUT DRIVE

CLK

AUTO A.PUNCH

• Digital Signal in/out (Fs: 44.1kHz)

SYNC OUT DRIVE

CLK

AUTO A.PUNCH

• Vari-pitch function

44.1kHz

SCSI

SCSI

• MIDI function

SYNC OUT DRIVE

CLK

AUTO A.PUNCH

• Digital Signal in/out (Fs: 32kHz)

SYNC OUT DRIVE

CLK

AUTO A.PUNCH

SCSI

SCSI

4-6. Offset Display

16

VARI PITCH

SYNC OUT DRIVE

CLK

AUTO A.PUNCH

SCSI

: Blinking

This mode determines if the offset value against a master

machine should be displayed or not when the FD-4 is

working as a slave machine.

If you would like to turn ON the offset display, press the

SYNC OUT DRIVE

CLK

AUTO A.PUNCH

SCSI

EXECUTE/YES key while “?” is blinking. (The default

setting is “off”.) Then, turn the jog dial C.W and press the

EXECUTE/YES key.

In order to display the offset value, select the “MTC” by the

OFFSET

SMHDFSF

TIME BASE key and the “REMAINING TIME” as DISP

SEL key.

CAUTION:

SYNC OUT DRIVE

CLK

AUTO A.PUNCH

SCSI

There might be a case that the percentage display does

1.

not indicate “0.0%” exactly when the FD-4 is working as

a slave machine and is synchronizing with a master

machine. This is caused by a difference of internal clock

between both machines but there is nothing wrong with it.

The two-digit numbers displayed in the right of percentage

2.

display (“05” in the left example) is only for software

programming purpose.

Page 17

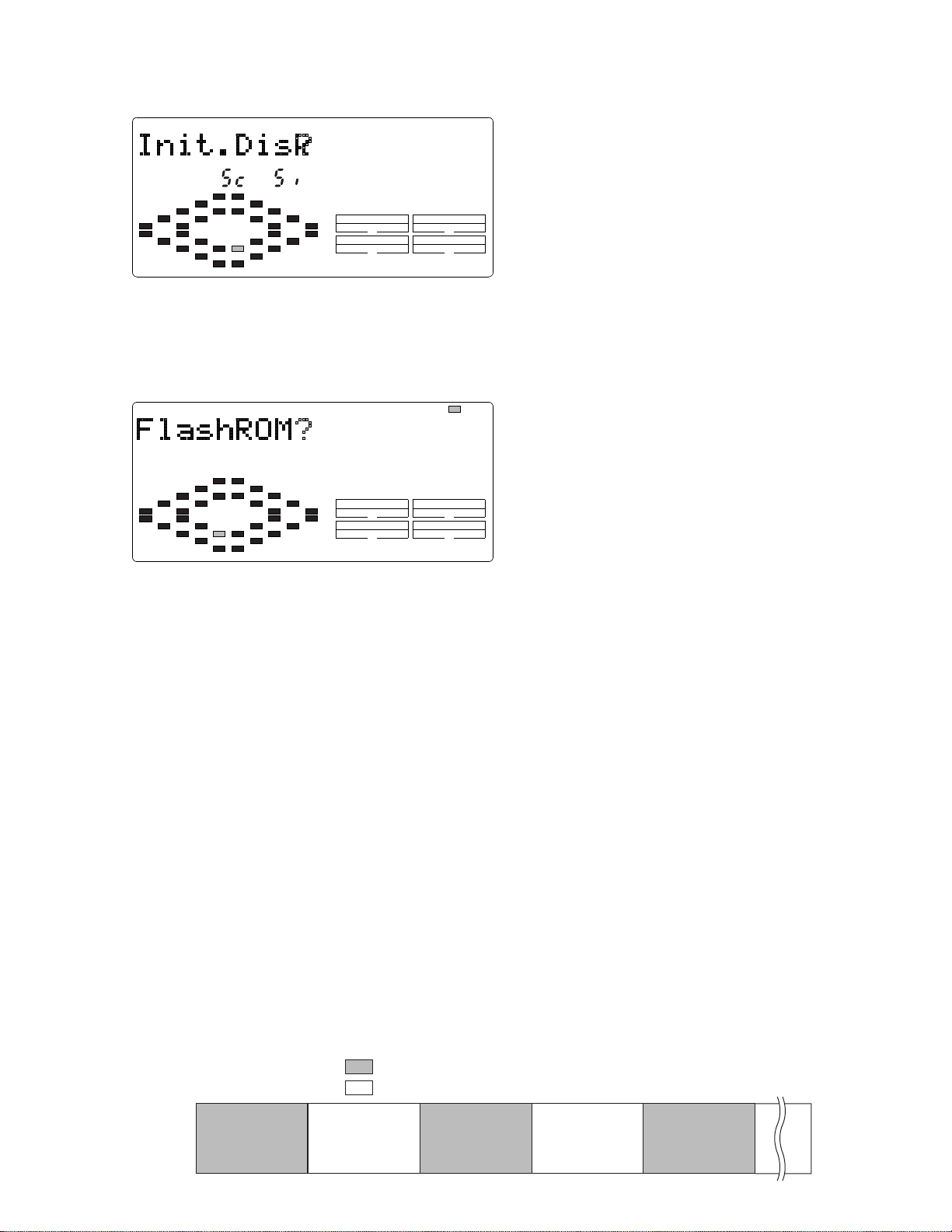

4-7. Initializing Disk

FD-4

This mode initializes an external SCSI device connected to

the SCSI port or a 2.5" internal E-IDE hard disk drive. The

disk drive currently connected can be initialized.

SYNC OUT DRIVE

CLK

AUTO A.PUNCH

SCSI

After pressing the EXECUTE/YES key, “SURE?” will start

blinking in the LCD display. In this condition, pressing the

EXECUTE/YES key one more time would initialize the

selected disk drive.

This mode puts the disk back to the condition originally

formatted and is equal to “Quick Format”.

4-8. Flash ROM

: Blinking

SYNC OUT DRIVE

CLK

AUTO A.PUNCH

SCSI

In this case, the following procedures must be taken.

1.

Turn the switch S1 on the MAIN PCB assy to “EPROM” side.

2.

Mount and solder the EPROM sockets to “U31” and “U32” on the MAIN PCB assy.

3.

Plug the EPROMs into the sockets.

4.

Turn on the power of FD-4.

In this condition, the FD-4 is booted up using the system software inside the EPROMs. The next procedures to take are as

follows.

1.

Put the FD-4 into the Service Mode, select “FlashROM” and press EXECUTE/YES key. (“SURE?” is blinking.)

2.

Press the EXECUTE/YES key one more time to copy the system software from EPROMs to Flash ROM.

3.

Turn the switch S1 to “FLMEM” side.

4.

In order to confirm that the FD-4 is booted up using the system software inside the Flash ROM, turn off the power,

disconnect the EPROMs and turn the power back on again.

5.

After the confirmation, update the system software inside the Flash ROM through SCSI port again.

This mode is used when copying the system software from

EPROMs to Flash ROM.

As mentioned in the section “SOFTWARE UPDATE”, the

FD-4 software inside the Flash ROM can be updated through

SCSI port. However, if something wrong happens when

updating the software (e.g. A blackout occurred while

updating the software.), the FD-4 might not be able to boot

up the system software inside the Flash ROM.

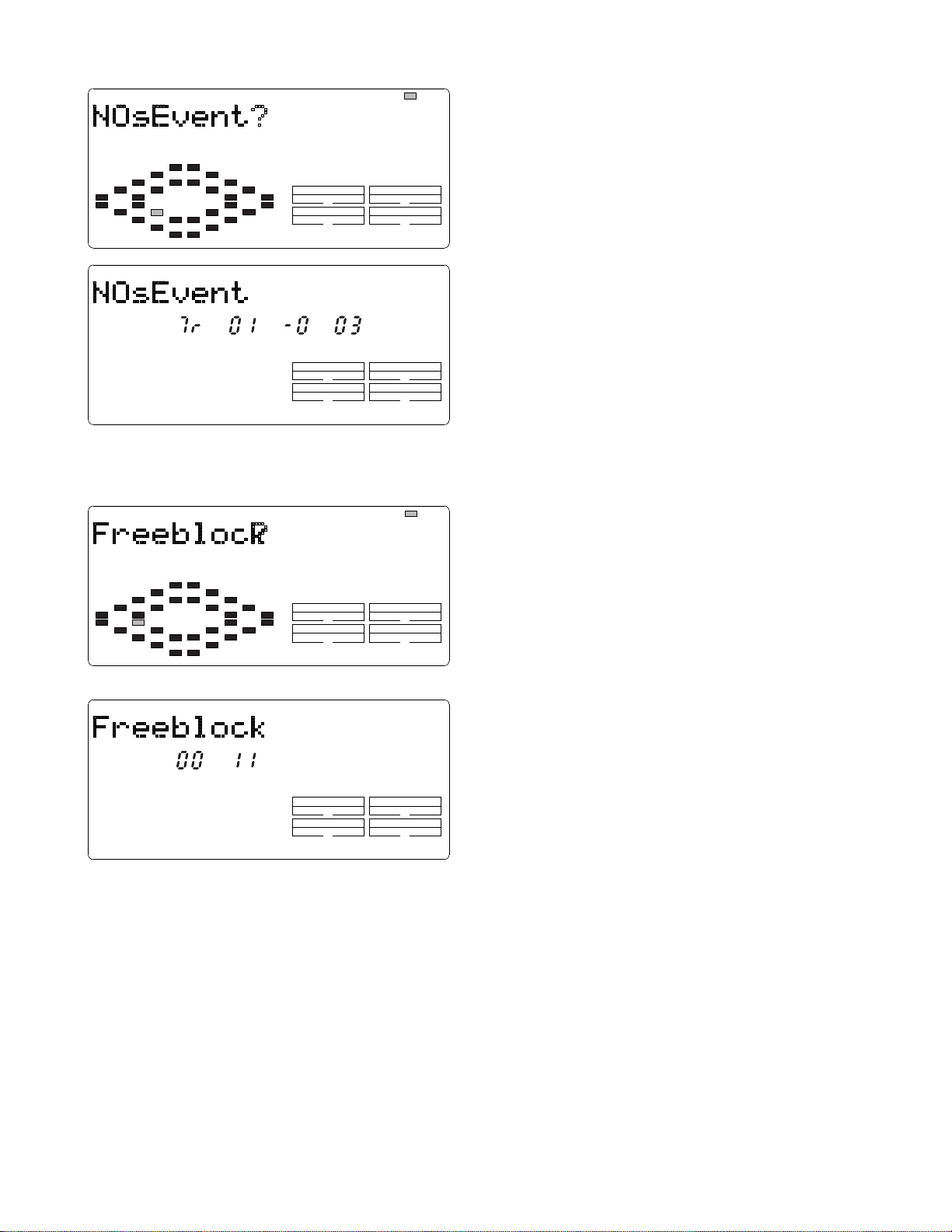

4-9. Event Number

Individual Audio Files are continuously recorded in each track of program on the FD-4. However, the FD-4 disk

management system allows to create a “no signal recorded” section between Audio Files. This “no signal recorded”

section is handled as “Zero File”. As shown in the diagram below, Audio Files and Zero Files will be alternately recorded

on the FD-4 and each Audio File and Zero File are counted as individual “Event”. Thus, the number of events on a certain

track is calculated by summing up these Audio Files and Zero Files. Each track can accommodate up to 512 events but the

FD-4 will not newly record events when the number of events reach 508.

: Recorded part (shortest length: 740msec, Fs=44.1kHz)

ABS 0

Event No.

Audio File 1

123

: Non-recorded part (shortest length: 740msec, Fs=44.1kHz)

Zero File 1

Audio File 2

Zero File 2 Audio File 3

ABS END

45

ABS 23h 59m

17

Page 18

FD-4

4-10. Free Block Check

SETUP

SYNC OUT DRIVE

CLK

AUTO A.PUNCH

SETUP

SYNC OUT DRIVE

CLK MTC

AUTO A.PUNCH

PLAY RTN

IDE SCSI

RHSL TAKE

: Blinking

SCSI

: Blinking

This Service Mode allows to check the Event Number

recorded on each track in one program on the FD-4.

In order to check, press the EXECUTE/YES key while “?”

is blinking.

The example in the left indicates that there are 3 events

created on track 1. By turning the jog dial C.W., you can

check the event number on track 2, 3, 4...

CAUTION:

If a long recording and/or many editing is committed, the

Event Number increases. If the Event Number is getting

closer to its maximum limit (508), please save/load the data

to/from an external DAT recorder or SCSI device. During

save/load procedures, Audio Files can be optimized and as

a result, the Event Number decreases.

This mode is used to check the condition of the diskette

inserted into an external SCSI drive connected to the FD-4.

SYNC OUT DRIVE

CLK

AUTO A.PUNCH

SYNC OUT DRIVE

CLK

AUTO A.PUNCH

SCSI

SCSI

If the Free Block indicates a large number even after

formatting the diskette and no signal is recorded, the diskette

can be judged to be in a bad condition.

18

Page 19

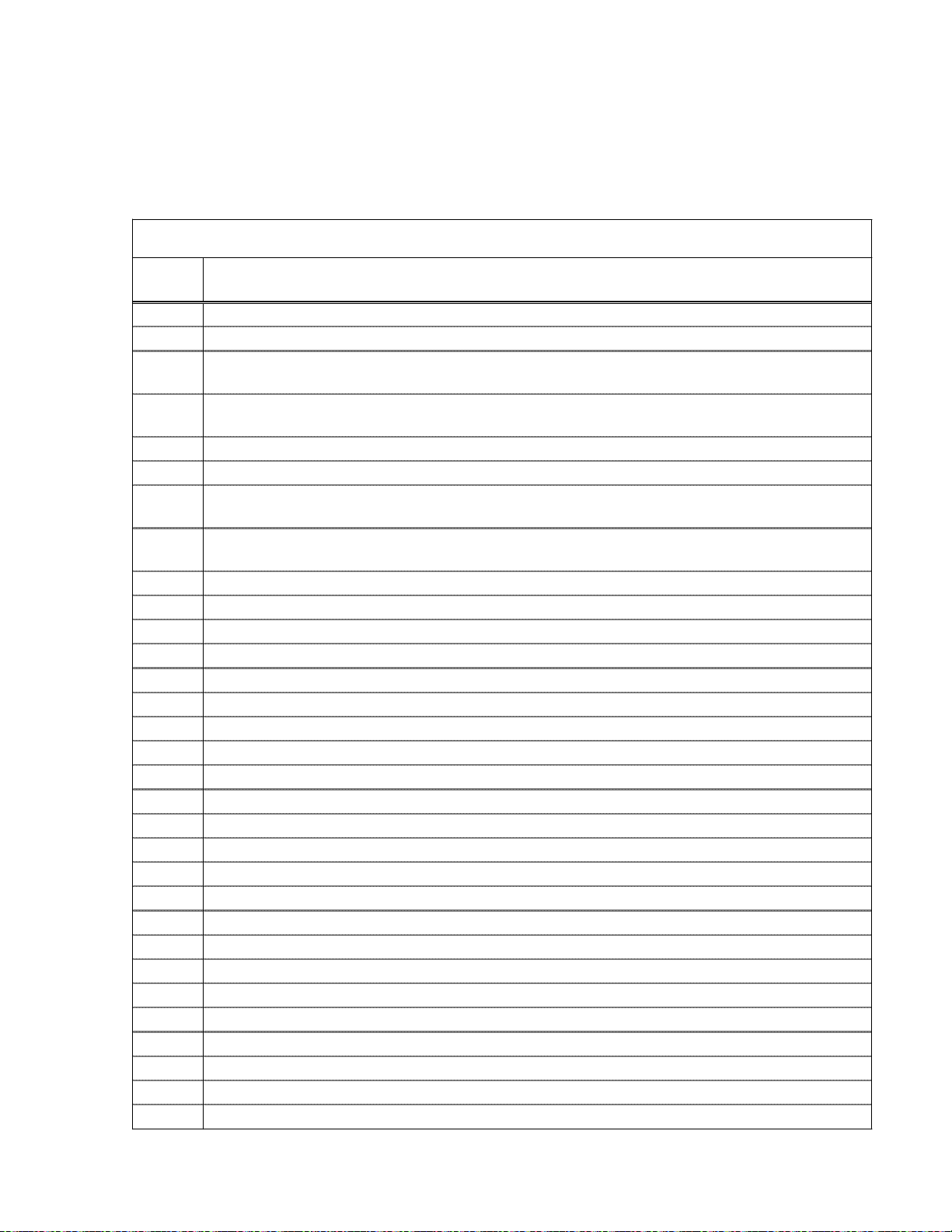

5. ERROR CODE LIST

The chart below indicates the error code number and corresponding description. Since the error code list is basically

designed for our engineers to improve the software, the description is quite technical. If you find the FD-4 with one of the

error codes displayed, we encourage you to update the software first. In case updating the software does not solve the

problem, we would like you to inform us about details.

FD-4 ERROR CO DE LIST

FD-4

ERROR

CODE

1 Audio File address breaks into System File.

3 SCSI drive does not boot up correctly when in SCSI access operation.

9

10

11 Link_pointer indicates larger address (out of region) than Link_File address region in RAM.

12 “Pointer_addre” calculation of Link_Pointer is not correct.

14

15

16 “Pointer_addre” calculation of Link_Pointer during recording/reproducing is not correct.

20 src_cash_load: Improper access of link address occurred while PASTE editing.

21 bak_cash_load: Program link during PASTE/MOVE editing is incorrect.

22 bak_cash_load: Imcompatibility problem occurred on program link during PASTE/MOV E editing.

30 Error when ex ecuting MOVE editing. Improper Link Pointer. Error in “bak_cash_load” function.

31 Error when ex ecuting MOVE editing. Improper Link Pointer. Error in “bak_cash_load” function.

32 Error when ex ecuting MOVE editing. Improper Link Pointer. Error in “bak_cash_load” function.

35 Backup_Save:Error occurred when saving data to SCSI device.

36 Backup_Load: Error occurred when loading data from SCSI device.

38 Displayed in Test Mode only. SCSI device cannot be recognized during initial test.

40 dis_cah_load: Improper access occurred when recording/reproducing.

41 dis_cah_load: Improper access occurred when recording/reproducing.

42 dis_cah_load: Improper access occurred when recording/reproducing.

45 get_non_des_block: Remaining disk capacity is insufficient.

52 non_des_cash_save_sub: Improper access occurred when recording/reproducing.

60 remake_free_block: There was improper access to program management region.

61 remake_free_block: There was improper access to program management region.

62 remake_free_block: Number of manageable events exceeds limit.

63 remake_free_block: There was improper access to program management region.

64 remake_free_block: There is an overlapping section in program management region.

96 There was improper access to program management region.

97 There was improper access to program management region when saving System File.

99 There was improper access when fading in/out.

When saving system region sector, its address is registered in Free_block File during Free block File

checking procedure.

Link_pointer which links Audio File indicates smaller address (out of region) than Link_File address region in

RAM.

Link_Pointer during recording/reproducing indicates smaller address (out of region) than actual Link_File

address region.

Link_Pointer during recording/reproducing indicates larger address (out of region) than actual Link_File

address region.

DESCRIPTION

19

Page 20

FD-4

6. INSTALLING 2.5" INTERNAL HARD DISK DRIVE

The Model 9045 and a 2.5" E-IDE hard disk drive installing procedures are explained below.

Model 9045 Contents

• Bracket, HD, FD-4 (P/N: 8221234000) x 2

• Connector, PI, header, 50P, AMPMOD (P/N: 8245314000) x 1

• Cable, flat, 2P, L150 (P/N: 8276292015) x 1

• Cable assy, flat, 50P, P1.0, AMPMOD, L150 (P/N: 8277465015) x 1

• 14 x screws (P 3 x 4 CZn)

Installing Procedures

Loosen 14 x screws (BBT 3 x 8 BZn) which fix the FD-4 Top Panel section to the Bottom Panel section.

1)

Remove the following cables from the connectors on the MAIN PCB assy.

2)

• 9-pin cable to the J3 (coming from MIXER A PCB assy)

• 9-pin cable to the J7 (coming from DISPLAY PCB assy)

• 7-pin cable to the J10 (coming from MIXER A PCB assy)

Top Panel section

MAIN PCB assy

Bottom Panel section

BBT 3x8 BZn

J10

7-pin

9-pin

J3

9-pin

J7

BBT 3x8 BZn

20

Page 21

Remove the MAIN PCB assy by loosening the following screws.

3)

• 5 x screws (B 3 x 6 CZn) fixing the PCB assy from top

• 6 x screws (BBT 3x8 BZn) fixing the PCB from rear

• 2 x Fix-Stand fixing the D-SUB 25-pin connector

Mount and solder the 50-pin connector and 2-pin cable. (Before soldering, you might need to remove the soldering by

4)

a solder remover.)

FD-4

Connector, PI, header,

50P, AMPMOD

B 3 x 6 CZn

Enlarged View of MAIN PCB assy

Cable, flat, 2P, L150

MAIN PCB assy

BBT 3 x 8 BZn

Fix-Stand

21

Page 22

FD-4

Put back the MAIN PCB assy to the Bottom Panel section by tightening the following screws.

5)

• 5 x screws (B 3 x 6 CZn) fixing the PCB assy from top

• 6 x screws (BBT 3x8 BZn) fixing the PCB from rear

• 2 x Fix-Stand fixing the D-SUB 25-pin connector

Using 4 x screws (P 3 x 4 CZn), fix the HD Bracket to a 2.5" E-IDE hard disk drive.

6)

Using 4 x screws (P 3 x 4 CZn), fix the 2.5" E-IDE hard disk drive/HD bracket to the Bottom Panel section.

7)

(During the above procedures 6) and 7), adjust the tightening position of screws to the HDD and to the bottom panel

so that screws are not bothered from each other.)

B 3 x 4 CZn

2.5" E-IDE

Hard Disk Drive

B 3 x 6

CZn

B 3 x 4 CZn

B 3 x 4 CZn

1

2

49

50

Bracket, HD, FD-4

B 3 x 4 CZn

22

MAIN PCB assy

BBT 3 x 8

BZn

Fix-Stand

Page 23

Connect the 50-pin flat cable between J12 of MAIN PCB assy and the HDD connectors. When connecting, in order to

8)

connect pins straight, do not twist or turn the cable. (Pin-1 of J12 (RED) must go to Pin-1 of HDD connectors.)

Connect the following cables from the connectors on the MAIN PCB assy.

9)

• 9-pin cable to the J3 (coming from MIXER A PCB assy)

• 9-pin cable to the J7 (coming from DISPLAY PCB assy)

• 7-pin cable to the J10 (coming from MIXER A PCB assy)

Tighten 14 x screws (BBT 3 x 8 BZn) which fix the FD-4 Top Panel section to the Bottom Panel section.

10)

FD-4

BBT 3 x 8 BZn

J10

7-pin

J3

9-pin

RED

9-pin

J7

Cable assy, flat, 50P,

P1.0, AMPMOD,

L150

BBT 3 x 8 BZn

23

Page 24

FD-4

7. EXPLODED VIEW, PCB ASSEMBLY AND PARTS LIST

FD-4 OVERALL EXPLODED VIEW & PARTS LIST

Ref. No. Part No. Description

1 82126100 00 Window, LCD, FD-4

2 82126090 00 Panel, top, FD-4

3 82212290 00 Panel, bottom, FD-4

4 82741240 00 PCB assy, XLR, FD-4

5 82166641 00 Shield, mixer, FD-4

6 82262370 00 Button assy, control, FD-4

7 82741220 00 PCB assy, Mixer A, FD-4

8 82262230 01 Knob, volume, C

9 82741360 00 PCB assy, Display, FD-4

10 82741370 00 PCB assy, Main, FD-4

11 82741380 00 PCB assy, Power, FD-4

!

1 2 82040820 00 Plate, mounting, B

1 3 82212270 00 Bracket, jack, FD-4

14 82741230 00 PCB assy, Jack, FD-4

1 5 82262380 00 Knob, jog, FD-4

1 6 82166670 00 Sheet, jog, FD-4

1 7 82261601 03 Knob, slide, N4.5

1 8 8226 2390 0 1 Knob, fader, N4.5

1 9 82070005 00 Cord, holder

2 0 82070120 00 Foot, FF-822

2 1 82768351 00 Cord, power, CSA, non

!

integral, USA/CND

82760030 00 Cord, power, JPN

82760060 00 Cord, power, EUR

82768790 00 Cord, power, BS, 2C, PHE-8,

UK

2 2 82070084 00 Bushing, 2271 (Except CND)

82070084 01 Bushing, 3P31, CND

23 82534620 01 SW, P, Power, SDDJF1-A-2

2 4 82166650 00 Sheet, isolation, power, FD-4

2 5 82166361 00 Cushion, battery, PD-4/FD-4

26 82422340 13 Filter, EMI, ferrite, core,

HF70RH16x28x10

2 7 82769140 06 Tube, UL, black, L60

2 8 82768720 14 Tube, UL, clear, 16, L140

2 9 82763750 09 Cable assy, earth lug, D3,

L90

3 0 82070117 01 Cord holder, CS-1

3 1 82773530 15 Cable assy, earth lug, D3-D3,

#20, L150

Ref. No. Part No. Description

3 2 82773530 20 Cable assy, earth lug, D3-D3,

#20, L200

33 82741390 00 PCB assy, AC In, FD-4

!

3 4 82390007 08 Fuse, 20, TDLY, 0.8A, 250V

!

3 5 82166361 01 Cushion, button, FD-4

24

Page 25

FD-4 OVERALL EXPLODED VIEW

FD-4

25

Page 26

26

FD-4

FD-4 PCB PATTERN DRAWING

• Parts Side of MAIN PCB assy

Page 27

• Foil Side of MAIN PCB assy

27

FD-4

Page 28

FD-4

• MIXER A, JACK and XLR PCB assys

28

Page 29

• DISPLAY PCB assy

FD-4

29

Page 30

30

FD-4

• POWER and AC IN PCB assys

Page 31

FD-4 Parts List

FD-4

• MAIN PCB assy

Ref. No. Part No. Description

82741370 00 PCB Assy, Main, FD-4

B001 8251 5191 00 Plain PCB, Main, FD-4

ICs

Ref. No. Part No. Description

U001, 002 82365403 01 ST, analog, regulator,

NJM78M05DLA

U003, 004 N/A

U005 8236 0818 00 QFP, digital, gate array, ASPI

U006 8236 5610 04 ST, digital, 74HCU04

U007 8236 0828 00 QFP, digital, SCSI, M86604L

U008 8236 0829 00 SOP, digital, SCSI, term,

BH9595FP-Y

U009, 010 82365034 00 ST, digital, VCO, TC9246F

U011 8234 0199 00 Opt., photo coupler, PC900

U012 8236 5600 14 ST, digital, 74HC14

U013 8236 5025 00 ST, analog, reset, NJM2103M

U014 8236 5701 01 ST, digital, driver, DTC114EK

U015 8236 0838 01 QFP, digital, CPU, main,

FD-4, mask, SH7042, F28

U016~019 N/A

U020~023 8236 5704 01 ST, digital, driver, DTA114EK

U024 8236 5600 32 ST, digital, 74HC32

U025~028 N/A

U029 8236 5601 57 ST, digital, 74HC157

U030 8236 0840 11 TSOP, digital, Flash ROM,

M29F400T90, SGS

U031, 032 N/A

U033 8236 0831 00 SOJ, digital, DRAM,

HM5118160AJ-7

U034, 035 N/A

U101, 201 82365050 11 ST, analog, op amp,

NJM2115M (TEI)

U151 8236 5407 00 ST, digital, AD, AK5351

U152, 252 82365408 00 ST, digital, DA, AK4321

U352, 452 N/A

U153, 253 82367207 00 ST, analog, NJM4560M

U353, 453 N/A

U901, 902 82365701 01 ST, digital, driver, DTC114EK

U903 8236 5704 01 ST, digital, driver, DTA114EK

U904 8236 5600 04 ST, digital, 74HC04

DIODEs

Ref. No. Part No. Description

D001 8234 1050 00 VF, SCHOTTKY, EK13

D002 N/A

D003~006 8234 5028 00 ST, DAN202K

D007 8234 7506 00 ST, RB400D

RESISTORs

Ref. No. Part No. Description

R001, 002 8230 5001 01 ST, carbon, 1/10W, 100Ω, 5%

R003, 004 N/A

R005~007 82305001 01 ST, carbon, 1/10W, 100Ω, 5%

R008 8230 5001 03 ST, carbon, 1/10W, 10kΩ, 5%

R009 8230 5005 62 ST, carbon, 1/10W, 5.6kΩ, 5%

R010 8230 5003 32 ST, carbon, 1/10W, 3.3kΩ, 5%

R011 8230 5002 22 ST, carbon, 1/10W, 2.2kΩ, 5%

R012 8230 5001 01 ST, carbon, 1/10W, 100Ω, 5%

R013 8230 5003 31 ST, carbon, 1/10W, 330Ω, 5%

R014 8230 5001 05 ST, carbon, 1/10W, 1MΩ, 5%

R015 8230 5000 00 ST, carbon, 1/10W, 0Ω, 5%

R016 8230 5003 31 ST, carbon, 1/10W, 330Ω, 5%

R017 8230 5001 05 ST, carbon, 1/10W, 1MΩ, 5%

R018 8230 5000 00 ST, carbon, 1/10W, 0Ω, 5%

R019 8230 5004 72 ST, carbon, 1/10W, 4.7kΩ, 5%

R020 N/A

R021~25 8230 5001 01 ST, carbon, 1/10W, 100Ω, 5%

R026, 027 8230 5000 00 ST, carbon, 1/10W, 0Ω, 5%

R028 N/A

R029 8230 5004 72 ST, carbon, 1/10W, 4.7kΩ, 5%

R030 8230 5001 52 ST, carbon, 1/10W, 1.5kΩ, 5%

R031 8230 5001 01 ST, carbon, 1/10W, 100Ω, 5%

R032 8230 5002 24 ST, carbon, 1/10W, 220kΩ, 5%

R033 N/A

R034 8230 5003 31 ST, carbon, 1/10W, 330Ω, 5%

R035 8230 5007 51 ST, carbon, 1/10W, 750Ω, 5%

R036 8230 5001 04 ST, carbon, 1/10W, 100kΩ, 5%

R037, 038 8230 5007 51 ST, carbon, 1/10W, 750Ω, 5%

R039 8230 5002 03 ST, carbon, 1/10W, 20kΩ, 5%

R040 8230 5001 22 ST, carbon, 1/10W, 1.2kΩ, 5%

R041 8230 5005 61 ST, carbon, 1/10W, 560Ω, 5%

R042 8230 5001 22 ST, carbon, 1/10W, 1.2kΩ, 5%

R043, 044 8230 5001 01 ST, carbon, 1/10W, 100Ω, 5%

R045~048 82305001 03 ST, carbon, 1/10W, 10kΩ, 5%

R049 8230 5003 31 ST, carbon, 1/10W, 330Ω, 5%

R050 8230 5001 02 ST, carbon, 1/10W, 1kΩ, 5%

R051 8230 5001 03 ST, carbon, 1/10W, 10kΩ, 5%

R052 8230 5001 01 ST, carbon, 1/10W, 100Ω, 5%

R053, 054 N/A

R061 N/A

R062~065 82305001 01 ST, carbon, 1/10W, 100Ω, 5%

R066 8230 5001 52 ST, carbon, 1/10W, 1.5kΩ, 5%

R067 N/A

R068 8230 5003 31 ST, carbon, 1/10W, 330Ω, 5%

R069 8230 5002 22 ST, carbon, 1/10W, 2.2kΩ, 5%

R070 8230 5003 31 ST, carbon, 1/10W, 330Ω, 5%

R071 8230 5001 03 ST, carbon, 1/10W, 10kΩ, 5%

31

Page 32

FD-4

RESISTORs

Ref. No. Part No. Description

R072 N/A

R073 8230 5000 00 ST, carbon, 1/10W, 0Ω, 5%

R074~076 82305002 21 ST, carbon, 1/10W, 220Ω, 5%

R077 8230 5001 03 ST, carbon, 1/10W, 10kΩ, 5%

R078 8230 5001 01 ST, carbon, 1/10W, 100Ω, 5%

R079~082 82305001 03 ST, carbon, 1/10W, 10kΩ, 5%

R083~086 N/A

R087 8230 5001 03 ST, carbon, 1/10W, 10kΩ, 5%

R088~090 N/A

R091 8230 5001 03 ST, carbon, 1/10W, 10kΩ, 5%

R092~094 N/A

R095, 096 82305001 02 ST, carbon, 1/10W, 1kΩ, 5%

R097 8230 5001 05 ST, carbon, 1/10W, 1MΩ, 5%

R098, 099 N/A

R151 8230 5001 00 ST, carbon, 1/10W, 10Ω, 5%

R152 8230 5001 01 ST, carbon, 1/10W, 100Ω, 5%

R101, 201 82305002 03 ST, carbon, 1/10W, 20kΩ, 5%

R102, 202 82305001 23 ST, carbon, 1/10W, 12kΩ, 5%

R103, 203 82305001 03 ST, carbon, 1/10W, 10kΩ, 5%

R104, 204 82305001 03 ST, carbon, 1/10W, 10kΩ, 5%

R105, 205 82305003 31 ST, carbon, 1/10W, 330Ω, 5%

R106, 206 82305003 31 ST, carbon, 1/10W, 330Ω, 5%

R107, 207 N/A

R108, 208 N/A

R109, 209 82305001 04 ST, carbon, 1/10W, 100kΩ, 5%

R111~411 82305001 03 ST, carbon, 1/10W, 10kΩ, 5%

R511~811 N/A

R112~412 82305001 03 ST, carbon, 1/10W, 10kΩ, 5%

R512~812 N/A

R113~413 82305002 72 ST, carbon, 1/10W, 2.7kΩ, 5%

R513~813 N/A

R114~414 82305001 04 ST, carbon, 1/10W, 100kΩ, 5%

R514~814 N/A

R161, 261 82305001 00 ST, carbon, 1/10W, 10Ω, 5%

R361, 461 N/A

R901 N/A

R902 8230 5001 01 ST, carbon, 1/10W, 100Ω, 5%

R903 8230 5002 21 ST, carbon, 1/10W, 220Ω, 5%

R904, 905 82305001 01 ST, carbon, 1/10W, 100Ω, 5%

R906, 907 8230 5001 03 ST, carbon, 1/10W, 10kΩ, 5%

R908, 909 8230 5001 02 ST, carbon, 1/10W, 1kΩ, 5%

R910, 911 N/A

R912 8230 5001 03 ST, carbon, 1/10W, 10kΩ, 5%

R913 N/A

CAPACITORs

ALU = Electrolytic type

CER = Ceramic type

Ref. No. Part No. Description

C001 N/A

C002 8233 5021 04 ST, CER, 50V, 0.1µF, +80,

CC20F

C003 8232 1431 06 VT, ALU, 16V, 10µF, 20%,

SME-VB

C004 8233 5021 04 ST, CER, 50V, 0.1µF, +80,

CC20F

C005~007 N/A

C008 8233 5021 04 ST, CER, 50V, 0.1µF, +80,

CC20F

C009, 010 8232 1431 06 VT, ALU, 16V, 10µF, 20%,

SME-VB

C011 8233 5021 04 ST, CER, 50V, 0.1µF, +80,

CC20F

C012, 013 N/A

C014 8232 1431 06 VT, ALU, 16V, 10µF, 20%,

SME-VB

C015 8233 5021 04 ST, CER, 50V, 0.1µF, +80,

CC20F

C016, 017 N/A

C018 8233 5021 04 ST, CER, 50V, 0.1µF, +80,

CC20F

C019 N/A

C020 8233 5041 03 ST, CER, 25V, 0.01µF, 10%,

CC20R

C021 8232 1431 06 VT, ALU, 16V, 10µF, 20%,

SME-VB

C022~025 82335041 03 ST, CER, 25V, 0.01µF, 10%,

CC20R

C026 8232 1431 06 VT, ALU, 16V, 10µF, 20%,

SME-VB

C027 8233 5004 71 ST, CER, 50V, 470pF, 5%,

CC20SL

C028 8233 5001 01 ST, CER, 50V, 100pF, 5%,

CC20SL

C029 N/A

C030 8233 5004 71 ST, CER, 50V, 470pF, 5%,

CC20SL

C031, 032 8233 5002 20 ST, CER, 50V, 22pF, 5%,

CC20SL

C033, 034 8233 5041 03 ST, CER, 25V, 0.01µF, 10%,

CC20R

C035, 036 8233 5002 20 ST, CER, 50V, 22pF, 5%,

CC20SL

C037~040 82335041 03 ST, CER, 25V, 0.01µF, 10%,

CC20R

32

Page 33

FD-4

Ref. No. Part No. Description

C041~045 N/A

C046 8232 1431 06 VT, ALU, 16V, 10µF, 20%,

SME-VB

C047 8233 5021 04 ST, CER, 50V, 0.1µF, +80,

CC20F

C048 8232 1431 06 VT, ALU, 16V, 10µF, 20%,

SME-VB

C049~051 82335041 03 ST, CER, 25V, 0.01µF, 10%,

CC20R

C052 8233 5001 50 ST, CER, 50V, 15pF, 5%,

CC20SL

C053~056 N/A

C057 8233 5041 03 ST, CER, 25V, 0.01µF, 10%,

CC20R

C058 8233 5094 74 ST, CER, 25V, 0.47µF, 20%,

KC30E

C059 8232 1431 06 VT, ALU, 16V, 10µF, 20%,

SME-VB

C060 8233 5021 04 ST, CER, 50V, 0.1µF, +80,

CC20F

C061, 062 8233 5041 03 ST, CER, 25V, 0.01µF, 10%,

CC20R

C063 8232 1431 06 VT, ALU, 16V, 10µF, 20%,

SME-VB

C064 8233 5002 21 ST, CER, 50V, 220pF, 5%,

CC20SL

C065 8233 5044 73 ST, CER, 25V, 0.047µF,

10%, CC20R

C066 8233 5041 03 ST, CER, 25V, 0.01µF, 10%,

CC20R

C067 8233 5001 21 ST, CER, 50V, 120pF, 5%,

CC20SL

C068~070 82335021 04 ST, CER, 50V, 0.1µF, +80,

CC20F

C071 8233 5041 03 ST, CER, 25V, 0.01µF, 10%,

CC20R

C072 8232 1461 05 VT, ALU, 50V, 1µF, 20%,

SME-VB

C073 8233 5041 03 ST, CER, 25V, 0.01µF, 10%,

CC20R

C074, 075 8233 5003 30 ST, CER, 50V, 33pF, 5%,

CC20SL

C076 8233 5041 03 ST, CER, 25V, 0.01µF, 10%,

CC20R

C077 8233 5001 01 ST, CER, 50V, 100pF, 5%,

CC20SL

C078 8233 5004 71 ST, CER, 50V, 470pF, 5%,

CC20SL

C079~087 N/A

Ref. No. Part No. Description

C088 8233 5021 04 ST, CER, 50V, 0.1µF, +80,

CC20F

C089, 090 N/A

C091 8232 1431 06 VT, ALU, 16V, 10µF, 20%,

SME-VB

C092 N/A

C093, 094 8233 5041 03 ST, CER, 25V, 0.01µF, 10%,

CC20R

C095 8233 5001 01 ST, CER, 50V, 100pF, 5%,

CC20SL

C096~100 82335041 03 ST, CER, 25V, 0.01µF, 10%,

CC20R

C101~104 N/A

C151 N/A

C152 8233 5041 03 ST, CER, 25V, 0.01µF, 10%,

CC20R

C153 8232 1431 06 VT, ALU, 16V, 10µF, 20%,

SME-VB

C154 8233 5041 03 ST, CER, 25V, 0.01µF, 10%,

CC20R

C155 8233 5021 04 ST, CER, 50V, 0.1µF, +80,

CC20F

C156 8232 1431 06 VT, ALU, 16V, 10µF, 20%,

SME-VB

C157 8233 5041 03 ST, CER, 25V, 0.01µF, 10%,

CC20R

C158, 159 N/A

C101, 201 8232 1431 06 VT, ALU, 16V, 10µF, 20%,

SME-VB

C102, 202 8233 5001 52 ST, CER, 50V, 0.0015µF,

5%, CC20R

C103, 203 8233 5041 03 ST, CER, 25V, 0.01µF, 10%,

CC20R

C104, 204 8233 5041 03 ST, CER, 25V, 0.01µF, 10%,

CC20R

C105, 205 8276 0020 02 Wire, jumper, IPS-1041-2, F5

C106, 206 8276 0020 02 Wire, jumper, IPS-1041-2, F5

C107, 207 N/A

C108, 208 N/A

C111~411 82321431 06 VT, ALU, 16V, 10µF, 20%,

SME-VB

C511~811 N/A

C112~412 82335006 81 ST, CER, 50V, 680pF, 5%,

CC20SL

C512~812 N/A

C113, 213 8233 5041 03 ST, CER, 25V, 0.01µF, 10%,

CC20R

C313, 413 N/A

C114, 214 8233 5041 03 ST, CER, 25V, 0.01µF, 10%,

CC20R

33

Page 34

FD-4

Ref. No. Part No. Description

C314, 414 N/A

C115~815 N/A

C116~416 82321434 76 VT, ALU, 16V, 47µF, 20%,

SME-VB

C516~816 N/A

C161~461 N/A

C162, 262 8233 5041 03 ST, CER, 25V, 0.01µF, 10%,

CC20R

C362, 462 N/A

C163, 263 8232 1434 76 VT, ALU, 16V, 47µF, 20%,

SME-VB

C363, 463 N/A

C164, 264 8233 5041 03 ST, CER, 25V, 0.01µF, 10%,

CC20R

C364, 464 N/A

C165, 265 N/A

C166, 266 8232 1431 06 VT, ALU, 16V, 10µF, 20%,

SME-VB

C366, 466 N/A

C167, 267 8233 5041 03 ST, CER, 25V, 0.01µF, 10%,

CC20R

C367, 467 N/A

C901, 902 N/A

C903 8233 5041 03 ST, CER, 25V, 0.01µF, 10%,

CC20R

C904 8232 1431 06 VT, ALU, 16V, 10µF, 20%,

SME-VB

C905 8233 5041 03 ST, CER, 25V, 0.01µF, 10%,

CC20R

C906 8233 5021 04 ST, CER, 50V, 0.1µF, +80,

CC20F

C907, 908 N/A

C909 8233 5041 03 ST, CER, 25V, 0.01µF, 10%,

CC20R

C910 N/A

C911 8230 5000 00 Resistor, ST, carbon, 1/10W,

0Ω, 5%

C912 8233 5003 30 ST, CER, 50V, 33pF, 5%,

CC20SL

C913 8232 1441 07 VT, ALU, 25V, 100µF, 20%,

SME-VB

MISCELLANEOUS

Ref. No. Part No. Description

E1401 82451580 11 Connector, PI, socket, IC, 32P

E1402 N/A

J001, 002 N/A

J003 82451711 09 Connector, PI, jack, 8283, 9P,

WHT

Ref. No. Part No. Description

J004 82453170 00 Connector, opt., TX178

J005 82453180 00 Connector, opt., RX178

J006 82453120 05 Connector, PL, jack, D-SUB,

25P, 70057-025, EMIFIL

J007 82451711 09 Connector, PI, jack, 8283, 9P,

WHT

J008 82452980 00 Connector, PL, jack, phone,

LGR4609-7000

J009 82454200 00 Connector, jack, DIN5P,

YKF51-5053

J010 82451711 07 Connector, PI, jack, 8283, 7P,

WHT

J011, 012 N/A

J101, 201 8245 2850 00 Connector, PL, jack, RCA,

1P, YKB11-0923, W/S

L001~003 8276 9130 00 Wire, jumper, isolation,

1/4 type

L004 82421962 23 Coil, PVT, 22µH, LF5.0S

L005 N/A

L006 82421962 23 Coil, PVT, 22µH, LF5.0S

L007, 008 82421860 13 Filter, T, EMI,

LFW7B-M3R2T

L009 N/A

L010, 011 82421860 13 Filter, T, EMI,

LFW7B-M3R2T

L012 N/A

L013, 014 82421860 13 Filter, T, EMI,

LFW7B-M3R2T

L015, 016 N/A

L017~021 8242 1860 13 Filter, T, EMI,

LFW7B-M3R2T

L022 N/A

L101~201 8242 1860 13 Filter, T, EMI,

LFW7B-M3R2T

L102~402 8242 1860 13 Filter, T, EMI,

LFW7B-M3R2T

L502~802 N/A

L103~403 8242 1860 13 Filter, T, EMI,

LFW7B-M3R2T

L503~803 N/A

S001 8253 4570 02 Switch, slide, 1-2, non-

shortening, SSSS91

X001 8256 1700 01 Resonator, ST, XTL, 22.579

MHZ, FUP-FBB3AFUJICOM

X002 8256 1700 03 Resonator, ST, XTL,

16.384MHz, FUP-FBB3A

X003 8256 1790 01 Resonator, PT, CER,

7.000MHz, F5, EFOEN

X004 N/A

34

Page 35

FD-4

Ref. No. Part No. Description

Y3301 82165950 00 Shield, RCA

Y3302 N/A

W001, 002 N/A

W003 8276 7320 30 Cable assy, 8P, 8263WHT-

5395, #22, L300

W004~008 N/A

W101, 201 N/A

W102, 202 82305000 00 Resistor, ST, carbon, 1/10W,

0Ω, 5%

• MIXER A PCB assy

Ref. No. Part No. Description

82741220 00 PCB Assy, Mixer A, FD-4

B001 8251 9672 01 Plain PCB, Mixer A, FD-4

ICs

Ref. No. Part No. Description

U001, 002 82360366 00 SIP, analog, NJM2068LD

U003, 004 82360342 02 SIP, analog, NJM4558L

U005 8236 0366 00 SIP, analog, NJM2068LD

U006 8236 0352 03 SIP, analog, NJM4556AL

U301 8236 0342 02 SIP, analog, NJM4558L

U302 8236 0342 02 SIP, analog, NJM4558L

U401 8236 0366 00 SIP, analog, NJM2068LD

U302, 402 82360342 02 SIP, analog, NJM4558L

U503~803 8236 0342 02 SIP, analog, NJM4558L

U510~810 8236 0781 07 PT, digital, driver, DTC143TS

RESISTORs

Ref. No. Part No. Description

R001, 002 8230 1504 79 VT, carbon, 1/2W, 4.7Ω, 5%

R010 8240 2540 00 Pot, PI, SL45, 50kΩAA,

NS-4502GVP, L20

R011~013 82402530 00 Pot, PI, RT12, 30kΩAA,

EVJY00, L20

R150, 250 8230 1388 23 HT, carbon, 1/4W, 82kΩ, 5%

R151, 251 8230 1382 03 HT, carbon, 1/4W, 20kΩ, 5%

R152, 252 8230 1384 73 HT, carbon, 1/4W, 47kΩ, 5%

R153, 253 8230 1381 04 HT, carbon, 1/4W, 100kΩ, 5%

R155, 255 8230 1388 23 HT, carbon, 1/4W, 82kΩ, 5%

R156, 256 8230 1381 03 HT, carbon, 1/4W, 10kΩ, 5%

R157, 257 8230 1381 03 HT, carbon, 1/4W, 10kΩ, 5%

R158, 258 8230 1381 03 HT, carbon, 1/4W, 10kΩ, 5%

R160, 260 8230 1388 23 HT, carbon, 1/4W, 82kΩ, 5%

R161, 261 8230 1381 04 HT, carbon, 1/4W, 100kΩ, 5%

R162, 262 8230 1388 23 HT, carbon, 1/4W, 82kΩ, 5%

R163, 263 8230 1382 03 HT, carbon, 1/4W, 20kΩ, 5%

Ref. No. Part No. Description

R164, 264 8230 1382 04 HT, carbon, 1/4W, 200kΩ, 5%

R165, 265 8230 1381 03 HT, carbon, 1/4W, 10kΩ, 5%

R166, 266 8230 1381 03 HT, carbon, 1/4W, 10kΩ, 5%

R167, 267 8230 1382 00 HT, carbon, 1/4W, 20Ω, 5%

R168, 268 N/A

R170, 270 8230 1381 01 HT, carbon, 1/4W, 100Ω, 5%

R171, 271 8230 1381 01 HT, carbon, 1/4W, 100Ω, 5%

R172, 272 8230 1382 73 HT, carbon, 1/4W, 27kΩ, 5%

R173, 273 8230 1382 73 HT, carbon, 1/4W, 27kΩ, 5%

R501, 601 8230 1381 04 HT, carbon, 1/4W, 100kΩ, 5%

R502, 602 8230 1381 01 HT, carbon, 1/4W, 100Ω, 5%

R503, 603 8230 1381 04 HT, carbon, 1/4W, 100kΩ, 5%

R504, 604 8230 1381 01 HT, carbon, 1/4W, 100Ω, 5%

R701, 801 8230 1381 04 HT, carbon, 1/4W, 100kΩ, 5%

R702, 802 8230 1381 04 HT, carbon, 1/4W, 100kΩ, 5%

R703, 803 8230 1382 04 HT, carbon, 1/4W, 200kΩ, 5%

R704, 804 8230 1382 04 HT, carbon, 1/4W, 200kΩ, 5%

R705, 805 8230 1382 03 HT, carbon, 1/4W, 20kΩ, 5%

R706, 806 8230 1382 03 HT, carbon, 1/4W, 20kΩ, 5%

R707, 807 8230 1382 02 HT, carbon, 1/4W, 2kΩ, 5%

R708, 808 8230 1382 02 HT, carbon, 1/4W, 2kΩ, 5%

R709, 809 8230 1382 04 HT, carbon, 1/4W, 200kΩ, 5%

R710, 810 8230 1382 04 HT, carbon, 1/4W, 200kΩ, 5%

R711, 811 8230 1381 01 HT, carbon, 1/4W, 100Ω, 5%

R512~812 82301382 02 HT, carbon, 1/4W, 2kΩ, 5%

R513~813 82301382 04 HT, carbon, 1/4W, 200kΩ, 5%

R514~814 82301389 12 HT, carbon, 1/4W, 9.1kΩ, 5%

R515~815 82301381 03 HT, carbon, 1/4W, 10kΩ, 5%

R516~816 82301381 03 HT, carbon, 1/4W, 10kΩ, 5%

R517~817 82301381 03 HT, carbon, 1/4W, 10kΩ, 5%

R518~818 82301382 02 HT, carbon, 1/4W, 2kΩ, 5%

R519~819 82301382 02 HT, carbon, 1/4W, 2kΩ, 5%

R520~820 82301381 32 HT, carbon, 1/4W, 1.3kΩ, 5%

R521~821 82301381 32 HT, carbon, 1/4W, 1.3kΩ, 5%

R522~822 82301389 12 HT, carbon, 1/4W, 9.1kΩ, 5%

R523~823 82301389 12 HT, carbon, 1/4W, 9.1kΩ, 5%

R524~824 N/A

R525~825 82301382 73 HT, carbon, 1/4W, 27kΩ, 5%

R526~826 82301382 73 HT, carbon, 1/4W, 27kΩ, 5%

R527~827 82301383 63 HT, carbon, 1/4W, 36kΩ, 5%

R528~828 82301383 63 HT, carbon, 1/4W, 36kΩ, 5%

R529~829 82301382 73 HT, carbon, 1/4W, 27kΩ, 5%

R530~830 82301383 63 HT, carbon, 1/4W, 36kΩ, 5%

R531~831 82301383 63 HT, carbon, 1/4W, 36kΩ, 5%

R532~832 82301382 73 HT, carbon, 1/4W, 27kΩ, 5%

R533~833 82301382 73 HT, carbon, 1/4W, 27kΩ, 5%

R534~834 82301383 63 HT, carbon, 1/4W, 36kΩ, 5%

R535~835 82301383 63 HT, carbon, 1/4W, 36kΩ, 5%

R536~836 82301382 20 HT, carbon, 1/4W, 22Ω, 5%

35

Page 36

FD-4

Ref. No. Part No. Description

R537~837 82301382 20 HT, carbon, 1/4W, 22 Ω, 5%

R540~840 82402500 00 Pot., PI, SL45, 50kΩA,

NS-4502VP, L20

R541~841 82402680 00 Pot., PI, RT09, 10kΩB, CC,

EVUF3A, L20

R542~842 82402700 00 Pot., PI, RT12, 50kΩCC,

EVJY00, L20

R543~843 82402510 00 Pot., PI, RT09, 50kΩB, CC,

EVUF3A, L20

R544~844 82402510 00 Pot., PI, RT09, 50kΩB, CC,

EVUF3A, L20

R545~845 82402510 00 Pot., PI, RT09, 50kΩB, CC,

EVUF3A, L20

R546~846 82402510 00 Pot., PI, RT09, 50kΩB, CC,

EVUF3A, L20

R547~847 82402490 00 Pot., PI, RT12, 100kΩB,

CC CT, EVJ02J, L20

R548~848 82402830 00 Pot., PI, RT12, 20kΩB,

CC CT, EVJ02J, L20

CAPACITORs

ALU = Electrolytic type

CER = Ceramic type

PES=Mylar type

Ref. No. Part No. Description

C001, 002 8232 1431 07 VT, ALU, 16V, 100µF, 20%,

SME-VB

C003~006 82328181 04 VT, CER, 25V, 0.1µF, +80, YF

C007, 008 8232 1432 27 VT, ALU, 16V, 220µF, 20%,

SME-VB

C009 8232 8181 04 VT, CER, 25V, 0.1µF, +80, YF

C140, 240 8232 1424 76 VT, ALU, 10V, 47µF, 20%,

SME-VB

C141, 241 8232 8011 00 VT, CER, 50V, 10pF, 5%, SL

C142, 242 8232 8011 00 VT, CER, 50V, 10pF, 5%, SL

C143, 243 8232 1431 06 VT, ALU, 16V, 10µF, 20%,

SME-VB

C144, 244 8232 8011 00 VT, CER, 50V, 10pF, 5%, SL

C145, 245 8232 8012 20 VT, CER, 50V, 22pF, 5%, SL

C146, 246 8232 1424 76 VT, ALU, 10V, 47µF, 20%,

SME-VB

C150, 250 8232 1424 76 VT, ALU, 10V, 47µF, 20%,

SME-VB

C151, 251 8232 8011 00 VT, CER, 50V, 10pF, 5%, SL

C152, 252 8232 8011 00 VT, CER, 50V, 10pF, 5%, SL

C153, 253 82328011 01 VT, CER, 50V, 100pF, 5%, SL

C154, 254 82328011 01 VT, CER, 50V, 100pF, 5%, SL

C155, 255 8232 1431 06 VT, ALU, 16V, 10µF, 20%,

SME-VB

Ref. No. Part No. Description

C160, 260 8232 1424 76 VT, ALU, 10V, 47µF, 20%,

SME-VB

C161, 261 8232 8011 00 VT, CER, 50V, 10pF, 5%, SL

C162, 262 8232 8011 00 VT, CER, 50V, 10pF, 5%, SL

C163, 263 8232 1424 76 VT, ALU, 10V, 47µF, 20%,

SME-VB

C164, 264 8232 8011 00 VT, CER, 50V, 10pF, 5%, SL

C165, 265 8232 8011 00 VT, CER, 50V, 10pF, 5%, SL

C166, 266 8232 1431 06 VT, ALU, 16V, 10µF, 20%,

SME-VB

C167, 267 8232 1422 27 VT, ALU, 10V, 220µF, 20%,

SME-VB

C170, 270 8232 1424 76 VT, ALU, 10V, 47µF, 20%,

SME-VB

C171, 271 8232 1424 76 VT, ALU, 10V, 47µF, 20%,

SME-VB

C172, 272 8232 8014 71 VT, CER, 50V, 470pF, 5%, SL

C172, 273 8232 8014 71 VT, CER, 50V, 470pF, 5%, SL

C501, 601 8232 8011 01 VT, CER, 50V, 100pF, 5%, SL

C502, 602 8232 1431 06 VT, ALU, 16V, 10µF, 20%,

SME-VB

C503, 603 8232 8011 01 VT, CER, 50V, 100pF, 5%, SL

C504, 604 8232 1424 76 VT, ALU, 10V, 47µF, 20%,

SME-VB

C510~810 82321424 76 VT, ALU, 10V, 47µF, 20%,

SME-VB

C511~811 82328011 01 VT, CER, 50V, 100pF, 5%, SL

C512~812 8232 8011 01 VT, CER, 50V, 100pF, 5%, SL

C513~813 8232 9012 23 VT, PES, 50V, 0.022µF, 5%,

AMZ

C514~814 82329011 03 VT, PES, 50V, 0.01µF, 5%,

AMZ

C515~815 82328011 01 VT, CER, 50V, 100pF, 5%, SL

C516~816 8232 8011 01 VT, CER, 50V, 100pF, 5%, SL

C517~817 8232 9016 82 VT, PES, 50V, 0.0068µF, 5%,

AMZ

C518~818 8232 9016 82 VT, PES, 50V, 0.0068µF, 5%,

AMZ

C519~819 82329011 53 VT, PES, 50V, 0.015µF, 5%,

AMZ

C520~820 82328012 20 VT, CER, 50V, 22pF, 5%, SL

C521~821 82328012 20 VT, CER, 50V, 22pF, 5%, SL

C522~822 82321424 76 VT, ALU, 10V, 47µF, 20%,

SME-VB

C530, 730 8232 8181 04 VT, CER, 25V, 0.1µF, +80, YF

C531, 731 8232 8181 04 VT, CER, 25V, 0.1µF, +80, YF

C532, 732 8232 8181 04 VT, CER, 25V, 0.1µF, +80, YF

C533, 733 8232 8181 04 VT, CER, 25V, 0.1µF, +80, YF

C534~834 82328181 04 VT, CER, 25V, 0.1µF, +80, YF

36

Page 37

FD-4

Ref. No. Part No. Description

C535~835 82328181 04 VT, CER, 25V, 0.1µF, +80, YF

C701, 801 8232 8011 01 VT, CER, 50V, 100pF, 5%, SL

C702, 802 8232 8011 01 VT, CER, 50V, 100pF, 5%, SL

C703, 803 8232 1421 07 VT, ALU, 10V, 100µF, 20%,

SME-VB

C704, 804 8232 1421 07 VT, ALU, 10V, 100µF, 20%,

SME-VB

C705, 805 8232 8011 00 VT, CER, 50V, 10pF, 5%, SL

C706, 806 8232 8011 00 VT, CER, 50V, 10pF, 5%, SL

C707, 807 N/A

C708, 808 8232 1424 76 VT, ALU, 10V, 47µF, 20%,

SME-VB

MISCELLANEOUS

Ref. No. Part No. Description

E601 Wire, jumper, F5

E602 Wire, jumper, F10

E603 Wire, jumper, F15

J001 82452980 00 Connector, PL, jack, phone,

LGR4609-7000

J021 82451711 05 Connector, PI, jack, 8283, 5P,

WHT

J022 82451711 03 Connector, PI, jack, 8283, 3P,

WHT

J023 82451712 03 Connector, PI, jack, 8283, 3P,

RED

J501~801 8245 2980 00 Connector, PL, jack, phone,

LGR4609-7000

S001 82536550 16 SW, PI, slide, 4-3,

non-shortening, SSSF0, L09

S701, 801 82536550 13 Switch, PI, slide, 2-3,

non-shortening, SSSF0, L09

S502~802 8253 6550 13 Switch, PI, slide, 2-3,

non-shortening, SSSF0, L09

W001 8276 7770 20 Cable assy, 7P,

WHTMT/F-MT/BS, L200

W002 8276 7790 30 Cable assy, 9P,

WHTMT/F-MT/BS, L300

W010 8276 7780 20 Cable assy, 8P,

WHTMT/F-MT/BS, L200

W011 8276 7790 20 Cable assy, 9P,

WHTMT/F-MT/BS, L200

W012 8277 4530 40 Cable assy, shiled 2C, 6P,

WHT8283-9073, L400

• JACK PCB assy

Ref. No. Part No. Description

82741230 00 PCB Assy, JACK, FD-4

B001 8251 9672 02 Plain PCB, JACK, FD-4

Ref. No. Part No. Description

Q001~006 8234 1434 03 Transistor, VT, NPN,

2SC2878A/B

R001~006 82301381 02 Resistor, HT, carbon, 1/4W,

1kΩ, 5%

R007~012 82301381 03 Resistor, HT, carbon, 1/4W,

10kΩ, 5%

J010 82451711 08 Connector, PI, jack, 8P, 8283,

WHT

J011 82451711 09 Connector, PI, jack, 9P, 8283,

WHT

J031, 032 8245 2620 01 Connector, PL, jack, RCA,

2P, BLK

J033~040 8245 2980 00 Connector, PL, jack, phone,

LGR4609-7000

L001~006 N/A

E101 Wire, jumper, F5

E102 Wire, jumper, F7.5

E103 Wire, jumper, F10

E104 Wire, jumper, F12.5

• XLR PCB assy

Ref. No. Part No. Description

82741240 00 PCB Assy, XLR, FD-4

B001 8251 9672 03 Plain PCB, XLR, FD-4

Ref. No. Part No. Description

J001, 002 8245 2680 0 3 Connector, PL, XLR 31,

3P, NC3FAH20

J003 82451721 06 Connector, PL, jack, 8283,

6P, WHT

37

Page 38

FD-4

• DISPLAY PCB assy

Ref. No. Part No. Description

82741360 00 PCB Assy, Display, FD-4

B001 8251 5181 00 Plain PCB, Display, FD-4

ICs

Ref. No. Part No. Description

U001 8236 0835 01 QFP, digital, CPU,

FD4-display

U002 N/A

U003 8236 0836 00 QFP, digital, LCD driver,

HD44780U

U004 8256 1760 00 Module, display, LCD, FD-4

U005 N/A

U006 8256 1770 00 Module, jog, SIM-026MT

TRANSISTORs

Ref. No. Part No. Description

Q001, 002 82341008 02 VT, PNP, 2SA1150Y

DIODEs

Ref. No. Part No. Description

D001~008 8234 5007 00 HT, 1SS136

D007, 008 N/A

D009~014 8234 5007 00 HT, 1SS136

D015, 016 N/A

D017, 018 82345007 00 HT, 1SS136

D019, 020 N/A

D021~036 8234 5007 00 HT, 1SS136

D037~040 N/A

D041~046 8234 0100 00 Opt., V, LED, ORG, GL-2HD6

D047, 048 N/A

D049 8234 0100 00 Opt., V, LED, ORG, GL-2HD6

D050, 051 82340191 00 Opt., V, LED, GRN, GL-2EG6

D052 N/A

D053, 054 82340191 00 Opt., V, LED, GRN, GL-2EG6

D055, 056 N/A

RESISTORs

Ref. No. Part No. Description

R001 Wire, jumper, F10

R002~007 82301381 01 HT, carbon, 1/4W, 100Ω, 5%

R008 8230 1381 05 HT, carbon, 1/4W, 1MΩ, 5%

R009 8230 1382 04 HT, carbon, 1/4W, 200kΩ, 5%

R010 Wire, jumper, F5

R011~015 82301381 02 HT, carbon, 1/4W, 1kΩ, 5%

R016 8240 1510 04 Pot., PI, RT09, 5kΩB, L20,

∅4 knob, RK09K113

R017 8230 1381 04 HT, carbon, 1/4W, 100kΩ, 5%

Ref. No. Part No. Description

R018~019 82301381 03 HT, carbon, 1/4W, 10kΩ, 5%

R020 8230 1381 04 HT, carbon, 1/4W, 100kΩ, 5%

R021, 022 8230 1381 03 HT, carbon, 1/4W, 10kΩ, 5%

R023~030 82301382 23 HT, carbon, 1/4W, 22kΩ, 5%

R031~036 82301381 11 HT, carbon, 1/4W, 110Ω, 5%

R037, 038 N/A

R039, 040 8230 1381 02 HT, carbon, 1/4W, 1kΩ, 5%

R041~043 82301388 23 HT, carbon, 1/4W, 82kΩ, 5%

CAPACITORs

ALU = Electrolytic type

CER = Ceramic type

Ref. No. Part No. Description

C001 8232 1431 06 VT, ALU, 16V, 10µF, 20%,

SME-VB

C002 8232 8181 04 VT, CER, 25V, 0.1µF, +80, YF

C003 8232 1451 06 VT, ALU, 35V, 10µF, 20%,

SME-VB

C004 8232 8181 04 VT, CER, 25V, 0.1µF, +80, YF

C005, 006 N/A

C007~009 82328014 71 VT, CER, 50V, 470pF, 5%, SL

C010, 011 8232 8063 30 VT, CER, 50V, 33pF, 5%, NPO

C012 8232 8181 04 VT, CER, 25V, 0.1µF, +80, YF

C013 N/A

C014 8232 8181 04 VT, CER, 25V, 0.1µF, +80, YF

C015, 016 8232 8031 03 VT, CER, 50V, 0.01µF, +80,

YF

MISCELLANEOUS

Ref. No. Part No. Description

E101 N/A

E501 Wire, jumper, F5

E502 Wire, jumper, F7.5

E503 Wire, jumper, F10

E504 Wire, jumper, F12.5

E505 Wire, jumper, F20

E506 Wire, jumper, F30

L001, 002 82391160 00 Lamp, 5V, 75mA

S001~006 8253 1350 02 SW, PT, tact, SOR-112HS

S007, 008 N/A

S009~014 8253 1350 02 SW, PT, tact, SOR-112HS

S015, 016 N/A

S017, 018 82531350 02 SW, PT, tact, SOR-112HS

S019, 020 N/A

S021~036 8253 1350 02 SW, PT, tact, SOR-112HS

S037~040 N/A

W001 8276 7790 55 Cable assy, 9P,

WHTMT/F-MT/BS, L550

W002 N/A

38

Page 39

FD-4

Ref. No. Part No. Description

W003 N/A

X001 8256 1340 03 Resonator, PF, CER,

8.00MHz, F5, EFOEN

Y1001 82070100 10 Spacer, LED, 10

Y1002 82070100 11 Spacer, LED, 11

Y1003 82070100 13 Spacer, LED, 13

Y1004 82070100 14 Spacer, LED, 14

Y1005 N/A

Y1006 8212 6110 00 Plate, reflect, LCD, FD-4

Y1007 82070100 09 Spacer, LED, 9

Y1008 82070100 12 Spacer, LED, 12

• POWER PCB assy

Ref. No. Part No. Description

82741380 00 PCB Assy, Power Supply,

FD-4

B001 8251 9691 01 Plain PCB, Power Supply,

FD-4

ICs

Ref. No. Part No. Description

U001 8236 5410 03 V, analog, power, MIP163

U002 8234 1081 00 Opt., H, photo coupler,

ON3171

U003 8236 0321 05 220, analog, regulator,

7812FA

U004 8236 0348 05 220, analog, regulator,

NJM7912FA

U005 8236 5409 00 VT, analog, regulator,

AN1431T

DIODEs

Ref. No. Part No. Description

D001 8234 1077 00 Stack, 600VAC, 1.5A,

D2SBA60

D002 8234 1079 00 HT, 80V, 0.2A, MA171

D003 8234 1078 00 HT, 600V, 1.0A, D1N60

D004 8234 1080 00 V, 200V, 5.0A, MA649

D005, 006 82341084 00 VT, SCHOTTKY, EK03W

RESISTORs

Ref. No. Part No. Description

R001 8230 1251 04 H, metal, 2W, 100kΩ, 5%,

RSS

R002, 003 8230 1386 29 HT, carbon, 1/4W, 6.2Ω, 5%

R004 8230 1243 30 HT, metal, 1/2W, 33Ω, 5%,

RSS

R005 8230 1387 50 HT, carbon, 1/4W, 75Ω, 5%

Ref. No. Part No. Description

R006 8230 1381 03 HT, carbon, 1/4W, 10kΩ, 5%

R007 8230 1384 71 HT, carbon, 1/4W, 470Ω, 5%

R008, 009 8230 1381 03 HT, carbon, 1/4W, 10kΩ, 5%

CAPACITORs

ALU = Electrolytic type