Page 1

FortiSwitch-1000

Version 4.0 MR1

Install Guide

Page 2

FortiSwitch-1000 Install Guide

Version 4.0 MR1

Revision 2

October 27, 2009

© Copyright 2009 Fortinet, Inc. All rights reserved. No part of this publication including text, examples, diagrams

or illustrations may be reproduced, transmitted, or translated in any form or by any means, electronic, mechanical,

manual, optical or otherwise, for any purpose, without prior written permission of Fortinet, Inc.

Trademarks

Dynamic Threat Prevention System (DTPS), APSecure, FortiASIC, FortiBIOS, FortiBridge, FortiClient, FortiGate®,

FortiGate Unified Threat Management System, FortiGuard®, FortiGuard-Antispam, FortiGuard-Antivirus,

FortiGuard-Intrusion, FortiGuard-Web, FortiLog, FortiAnalyzer, FortiManager, Fortinet®, FortiOS, FortiPartner,

FortiProtect, FortiReporter, FortiResponse, FortiShield, FortiVoIP, and FortiWiFi are trademarks of Fortinet, Inc. in

the United States and/or other countries. The names of actual companies and products mentioned herein may be

the trademarks of their respective owners.

Regulatory compliance

FCC Class A Part 15 CSA/CUS

CAUTION: Risk of Explosion if Battery is replaced by an Incorrect Type. Dispose of Used Batteries According to

the Instructions.

Page 3

Table of Contents

1 Introduction .................................................................................................................................................... 6

1.1 Scope...................................................................................................................................................... 6

1.2 Audience................................................................................................................................................. 6

1.3 Registering your Fortinet product ........................................................................................................... 6

1.4 Customer Service and Technical Support.............................................................................................. 6

1.5 Training................................................................................................................................................... 7

1.6 Fortinet Documentation .......................................................................................................................... 7

2 Switch Overview............................................................................................................................................. 8

2.1 Front of Chassis ..................................................................................................................................... 8

2.2 Back of Chassis...................................................................................................................................... 9

2.3 Management Card................................................................................................................................ 10

2.4 Line Card (CX4).................................................................................................................................... 11

2.5 Line Card (XFP).................................................................................................................................... 11

2.6 Fan Tray ............................................................................................................................................... 12

2.7 Power Supply ....................................................................................................................................... 13

3 Site Preparation............................................................................................................................................ 14

3.1 Safety Considerations .......................................................................................................................... 14

3.2 Environmental Considerations.............................................................................................................. 14

3.3 Rack Requirements .............................................................................................................................. 14

3.3.1 Switch Dimensions and Weight .................................................................................................. 14

3.4 Power Requirements and Redundancy................................................................................................ 14

3.4.1 Power Overview.......................................................................................................................... 14

3.4.2 Feed-Level Redundancy............................................................................................................. 15

3.4.3 Circuit Breaker-Level Redundancy ............................................................................................. 15

3.4.4 Power Supply-Level Redundancy............................................................................................... 15

4 Unpacking and Mounting the Switch ......................................................................................................... 17

4.1 Unpacking the Switch ........................................................................................................................... 17

4.1.1 Prepare Rack .............................................................................................................................. 17

4.1.2 Remove Cover ............................................................................................................................ 17

4.1.3 Lift Switch Free from Crate Base ................................................................................................ 17

4.2 Mounting the Switch ............................................................................................................................. 18

4.2.1 Position and Attach the Switch ................................................................................................... 18

4.2.2 Establish Ground and Connect to AC Power.............................................................................. 18

– 3 –

Page 4

4.3 XFP Pluggable Transceivers ................................................................................................................ 18

4.3.1 Further Considerations in Handling XFP Transceivers............................................................... 18

5 Configuring the IP Address and Default Gateway.................................................................................... 19

5.1 Initial Switch Configuration ................................................................................................................... 19

5.1.1 Connecting to the Serial Port ...................................................................................................... 19

5.2 Management and IP Addressing Options............................................................................................. 19

5.2.1 Inband vs. Out-of-Band Management......................................................................................... 19

5.2.2 DHCP vs. Static IP Addressing................................................................................................... 20

5.3 IP Address Configuration...................................................................................................................... 20

5.3.1 Configuring an IP Address via DHCP ......................................................................................... 20

5.3.2 Manually Configuring a Static IP Address .................................................................................. 20

6 Appendix 1: LED States............................................................................................................................... 22

7 Appendix 2: Updating the System Image .................................................................................................. 25

7.1 Image Update Procedure ..................................................................................................................... 25

7.1.1 Download Image ......................................................................................................................... 25

7.1.2 Load Images onto Switch............................................................................................................ 25

7.1.3 Set System Images..................................................................................................................... 25

7.1.4 Reload System............................................................................................................................ 26

8 Appendix 3: Regulatory Compliance and Safety Considerations .......................................................... 27

8.1 Agency Approvals................................................................................................................................. 27

8.1.1 Safety .......................................................................................................................................... 27

8.1.2 EMI.............................................................................................................................................. 27

8.1.3 Immunity...................................................................................................................................... 27

8.2 EMC Compliance Statements .............................................................................................................. 28

8.2.1 United States............................................................................................................................... 28

8.2.2 European Union .......................................................................................................................... 28

8.2.3 Canada........................................................................................................................................ 28

8.3 General Safety Guidelines.................................................................................................................... 28

8.3.1 Installation Environment.............................................................................................................. 28

8.3.2 Mechanical .................................................................................................................................. 28

8.3.3 Electrical Rating .......................................................................................................................... 29

8.3.4 Grounding ................................................................................................................................... 29

8.3.5 Metallic Interfaces ....................................................................................................................... 29

8.3.6 Fuse Replacement...................................................................................................................... 29

8.3.7 LASER Safety ............................................................................................................................. 29

8.3.8 Restricted Access Location......................................................................................................... 29

8.3.9 Power .......................................................................................................................................... 30

– 4 –

Page 5

8.3.10 Supply and Chassis Ground Wiring.......................................................................................... 30

8.4 General Operational and Maintenance Guidelines .............................................................................. 30

8.4.1 Electrical Safety .......................................................................................................................... 30

8.4.2 ESD............................................................................................................................................. 31

– 5 –

Page 6

1 Introduction

1.1 Scope

This document describes the process of installing the FortiSwitch-1000 unit, up to and including

the configuration of the management IP address and default gateway. Additional information

regarding FortiSwitch-1000 can be found in the following documents:

FortiSwitch-1000 Configuration Guide Configuration procedures for the FortiSwitch-1000 unit

FortiSwitch-1000 CLI Reference Full description of the FortiSwitch-1000 CLI commands

1.2 Audience

This guide is intended for use by “service personnel” as defined in section 1.1 of IEC 60950:

trained and experienced technicians aware of the hazards involved in Ethernet switch installation

and maintenance and capable of minimizing the related dangers to themselves and others. Only

such service personnel should undertake the installation or servicing of the FortiSwitch-1000 unit.

1.3 Registering your Fortinet product

Before you begin, take a moment to register your Fortinet product at the Fortinet Technical

Support web site, https://support.fortinet.com.

Many Fortinet

Antivirus and other FortiGuard services, require product registration.

For more information, see the Fortinet Knowledge Center article Registration Frequently Asked

Que

stions.

customer services, such as firmware updates, technical support, and FortiGuard

1.4 Customer Service and Technical Support

Fortinet Technical Support provides services designed to make sure that your Fortinet products

install quickly, configure easily, and operate reliably in your network.

To learn about the technical support services that Fortinet provides, visit the Fortinet Technical

Support web site at https://support.fortinet.com.

You can d

providing your configuration file, a network diagram, and other specific information. For a list of

required information, see the Fortinet Knowledge Center article What does Fortinet Technical

Suppo

ramatically improve the time that it takes to resolve your technical support ticket by

rt require in order to best assist the customer?

– 6 –

Page 7

1.5 Training

Fortinet Training Services provides classes that orient you quickly to your new equipment, and

certifications to verify your knowledge level. Fortinet provides a variety of training programs to

serve the needs of our customers and partners world-wide.

To learn about the training services that Fortinet provides, visit the Fortinet Training Services web

site at http://campus.training.fortinet.com, or email the

1.6 Fortinet Documentation

The Fortinet Technical Documentation web site, http://docs.fortinet.com, provides the most up-todate versions of Fortinet publications, as well as additional technical documentation such as

technical notes.

In addition to the Fortinet Technical Documentation web site, you can find Fortinet technical

documentation on the Fortinet Tools and Documentation CD, and on the Fortinet Knowledge

Center.

1.6.1.1 Fortinet Tools & Documentation CD

m at training@fortinet.com.

Many Fortinet publications are available on the Fortinet Tools and Documentation CD shipped

with your Fortinet product. The documents on this CD are current at shipping time. For current

versions of Fortinet documentation, visit the Fortinet Technical Documentation web site,

http://docs.fortinet.com.

1.6.1.2 Fortinet Knowledge Base

The Fortinet Knowledge Base provides additional Fortinet technical documentation, such as

troubleshooting and how-to-articles, examples, FAQs, technical notes, a glossary, and more. Visit

the Fortinet Knowledge Base at http://kb.fortinet.com.

1.6.1.3 Comments on FortiMail technical documentation

Please send information about any errors or omissions in this or any Fortinet technical document

to techdoc@fortinet.com.

Please

send information about any errors or omissions in this document to techdoc@fortinet.com.

– 7 –

Page 8

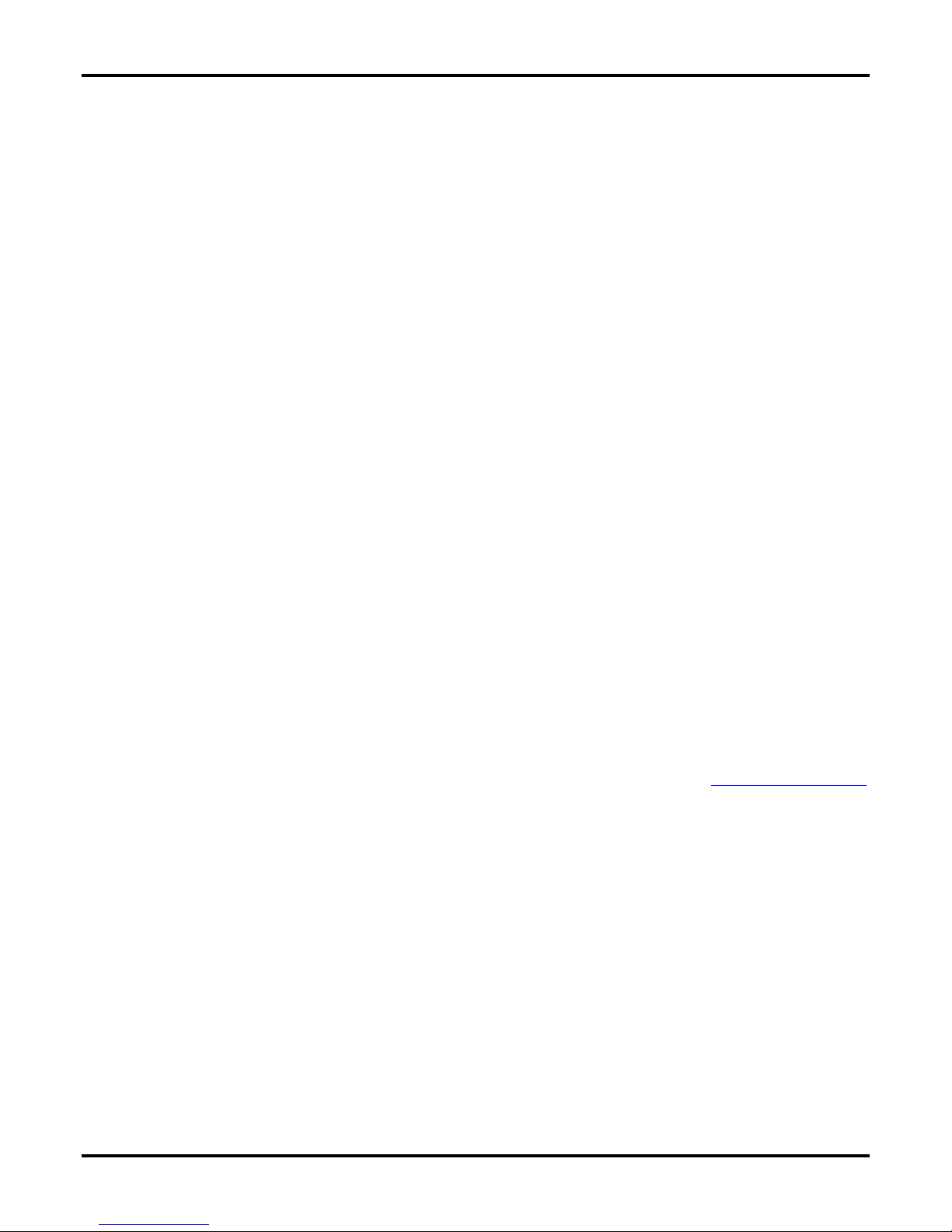

2 Switch Overview

2.1 Front of Chassis

Fully loaded FortiSwitch-1000 chassis with dual management cards and a combination of XFP

line cards and CX4 line cards.

– 8 –

Page 9

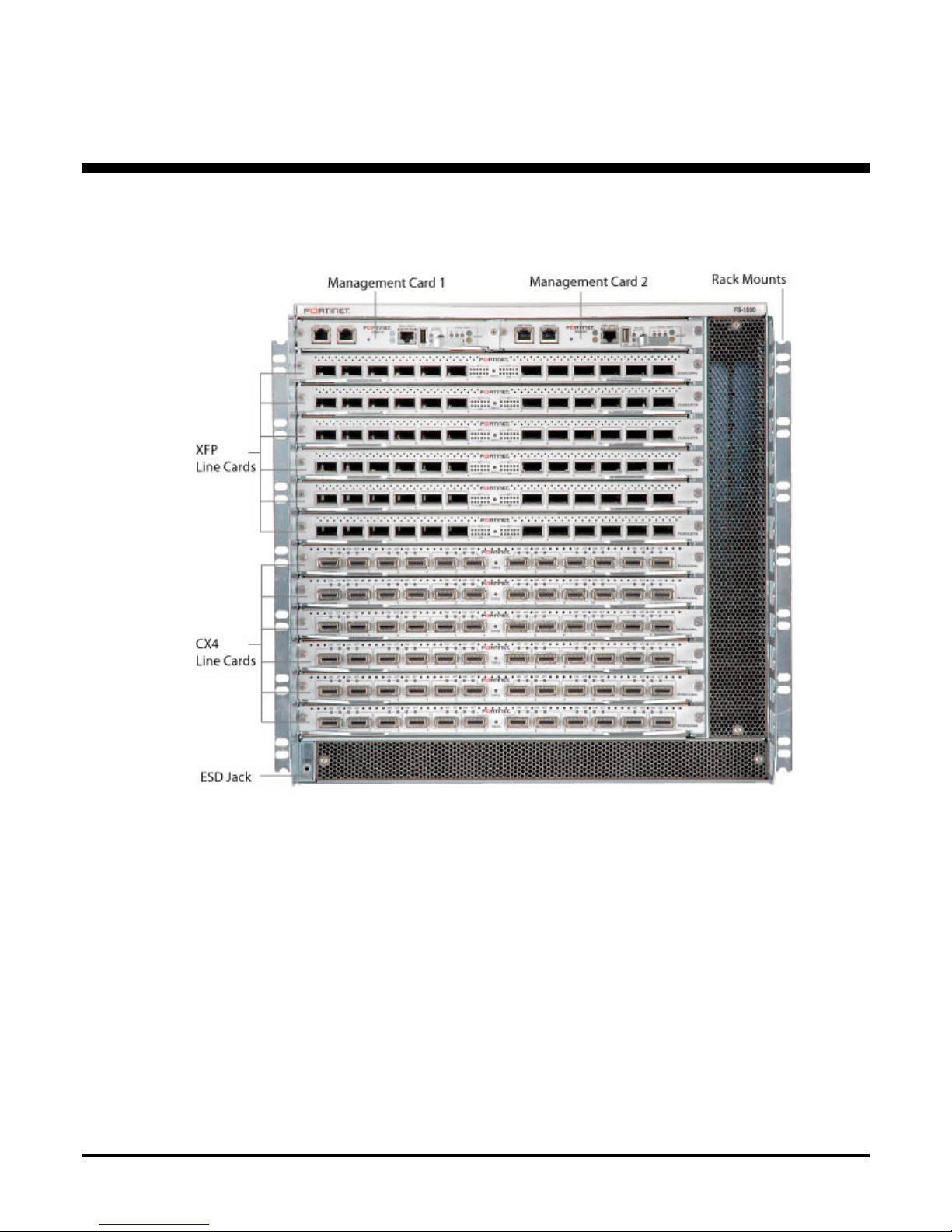

2.2 Back of Chassis

The back of the FortiSwitch-1000 with the full complement of six power supplies installed. Note

orientation of fan trays and power supplies. The three power supplies on the left are installed

with the release lever side down; the three power supplies on the right are installed with the

release lever side up. Ensure that each supply is correctly oriented.

– 9 –

Page 10

2.3 Management Card

Management Network Port: Ethernet port for out-of-band management of the switch. To

configure the switch via the management network port, an IP address must be configured on the

port by accessing the switch through the serial port or connecting the switch to a network with a

DHCP server.

Config Ethernet Port: This port is reserved for future functionality.

Reset Switch: Recessed switch used to force a reset of the management card without physically

removing the card from the chassis.

Serial Console Port: RS-232 serial port used for direct configuration of the management card by

connection to a laptop or other external control device. The settings for the serial connection are

an initialized baud-rate of 115200, 8 bit, no parity, and no flow control. The table below shows

the pinout of the serial console port connector:

Pin Signal Direction

1 NC Not Connected

2 DTR Output from card

3 TXD Output from card

4 GND

5 GND

6 RXD Input to card

7 DSR Input to card

8 NC Not Connected

External USB Port, Activity Indicator and Stop Switch: These three elements are reserved for

future external USB functionality and are not currently supported. Note: the stop button in this

grouping is currently unsupported and does not reset the management card. To reset the

management card, use the recessed reset switch.

LEDs: For full description of LED states, see Appendix 1: LED States on page 22.

– 10 –

Page 11

2.4 Line Card (CX4)

FS-10G12-CX4 / FS-10G12-CX4-A

Line card with CX4 ports; ports can support either powered (active) cables or passive copper

cables. “Link up” indicators and link activity indicators are located next to each port. For full

description of LED states, see Appendix 1: LED States on page 22.

2.5 Line Card (XFP)

FS-10G12-XFP / FS-10G12-XFP-A

Line card with XFP optical ports, optical transceivers installed; ports can support either SR (FSXFP-10G-SR) or LR (FS-XFP-10G-LR) optical transceivers. The indicator LEDs are identical in

function to those on the CX4 line card, but aggregated in a central panel. For full description of

LED states, see Appendix 1: LED States on page 22.

– 11 –

Page 12

2.6 Fan Tray

FS-1000-FANTRAY

Fan tray, showing release tab and handle for use in removing fan tray in case of a fan failure. For

full description of LED states, see Appendix 1: LED States on page 22.

– 12 –

Page 13

2.7 Power Supply

FS-1000-PWR850

850 watt power supply unit, showing release tab and handle for use in removing power supply in

case of a failure requiring unit replacement (indicated by a solid amber light). For full description

of LED states, see Appendix 1: LED States on page 22. To remov

green release tab toward the center of the unit, then pull on the black handle.

e power supply unit, press the

– 13 –

Page 14

3 Site Preparation

3.1 Safety Considerations

Please see “Appendix 3: Regulatory Compliance and Safety Considerations” on page 27 for

regulatory and safety information.

3.2 Environmental Considerations

The maximum recommended ambient temperature for the FortiSwitch-1000 during operation is

40 degrees C. Please note, though, that in a multi-unit rack assembly, temperatures in the rack

environment can be greater than room ambient: room temperatures below 40 degrees C are

often required.

Rack assembly must be configured to avoid blockage of intake and exhaust registers; a minimum

of 6 inches of clearance is required from the front and rear of the FortiSwitch-1000 to ensure

adequate air flow through the system.

3.3 Rack Requirements

The FortiSwitch-1000 chassis is 19" rack-mountable and occupies 10RU (rack units) of rack

space. It is shipped with rack mounts installed appropriately for front mounting, and includes

additional screw holes to accommodate mid-mounting.

Ensure that adequate racking is available to safely support the chassis with 6" clearance in front

and in back for airflow and cabling. Install chassis supports or shelving in rack before removing

chassis from packing crate.

3.3.1 Switch Dimensions and Weight

Height: 44.45 cm (17.50 inches)

Depth: 71.12 cm (28 inches)

Width: 43.82 cm (17.25 inches)

Weight: 56 to 85.5 Kg (125 to 188.5 lbs) depending on configuration; a fully-loaded chassis with

12 XFP line cards weighs approximately 85.5 Kg (188.5 lbs).

3.4 Power Requirements and Redundancy

3.4.1 Power Overview

Please consult “Power” on page 30 before connecting the switch to an AC power source. Fortinet

recommends using 200 to 240 V AC power to accommodate future upgrades which may require

higher power consumption.

– 14 –

Page 15

Each power supply shipped with the FortiSwitch-1000 provides a maximum of 850 W DC power.

To calculate the power draw and circuit breaker requirements for the switch as a whole, limit the

AC current per power supply to 8A for 100-180VAC and 5A for 200-240VAC.

3.4.1.1 Peak Input AC Current per Power Supply

At 120 V AC: 12 A

At 240 V AC: 6 A

3.4.2 Feed-Level Redundancy

For the highest level of power redundancy, the switch must be connected to two independent

sources of AC power. In addition to the primary AC power source, this requires a second feed

from a different power substation or an in-house generator or other grid-independent source of

dependable AC power. Connecting three 850W power supplies to each of the two independent

AC feeds (attached to separate circuit breakers) can provide feed-level redundancy for a subset

of possible switch configurations (those for which N=3 or below – consult “Power Supply-Level

undancy” below).

Red

3.4.3 Circuit Breaker-Level Redundancy

If feed-level redundancy is impossible or unnecessary for your installation, Fortinet recommends

establishing circuit breaker-level redundancy by putting each pair of power supplies on a separate

circuit-breaker. For configurations where N=4 or below, this allows six power supplies to provide

uninterrupted power to the switch in the event that a single power cord is disconnected or a single

circuit-breaker is tripped.

3.4.4 Power Supply-Level Redundancy

The minimum recommended level of redundancy is provided by ensuring the presence of N+1

power supplies as detailed in the chart below. Assuming constant AC power from the power strip,

this provides uninterrupted power to the switch in the event that a single power supply fails.

The following chart shows the maximum number of line cards supported by various numbers of

power supplies. Recommended minimum power supply configuration is N+1, where N is equal to

the minimum number of power supply units required to power the chassis for a given

configuration.

850 W Power

Supplies Required

N=1

N=2

N=3

N=4

CX4 Line Cards

Using Passive

Cables

Maximum Number of Line Cards Supported

CX4 Line

Cards Using

Active Cables

0 0 0 0

4 3 3 3

10 7 7 6

12 12 11 10

XFP Line

Cards, SR

Modules

XFP Line

Cards, LR

Modules

– 15 –

Page 16

N=5

N=6

12 12 12 12

12 12 12 12

– 16 –

Page 17

4 Unpacking and Mounting the Switch

4.1 Unpacking the Switch

NOTE: Prior to touching or handling the switch or any of its components, ensure that the

equipment is protected against all forms of electrostatic discharge (ESD). Personnel must ground

themselves before handling the switch or its components, and Fortinet recommends that all cards

should be handled using anti-static bags.

4.1.1 Prepare Rack

The packing crate in which the FortiSwitch-1000 is shipped is the safest place to store the switch

while preparing for installation. Ensure that chassis supports or shelving are properly installed

and secured before removing the switch from its crate; if third party or aftermarket shelving is

unavailable, Fortinet recommends use of the support brackets included in the shipping crate.

4.1.1.1 Support Brackets

Support brackets are shipped with the FortiSwitch-1000 to facilitate the mounting of the switch,

packed in the gap above the crate base (see below). They are designed to support the weight of

the chassis during mounting, and are attached at the front and rear of the shelving space (not on

the sides).

4.1.2 Remove Cover

The crate cover is held in place by four hinged clasps; unfasten them by turning the handle

counterclockwise to disengage the clasp, then pulling the clasp away from the crate cover. Once

the clasps are unfastened, lift the cover straight up until it is clear of the chassis and set it aside.

4.1.3 Lift Switch Free from Crate Base

Fortinet strongly recommends using a mechanical lift to install the switch in the rack. Before a lift

can be used, though, the switch must be manually lifted to free it from the crate base. Lift the

– 17 –

Page 18

switch straight up to clear the lip on the base, then position it to be mechanically lifted into

position in the rack.

CAUTION: There are sharp metal components inside the chassis; be sure to wear adequate

hand protection and grip carefully. A fully-loaded switch weighs over 188 lbs.; Fortinet

recommends removing components as needed to reduce weight before lifting and using a

minimum of four people to manually lift the switch. If you remove cards from the switch, take

necessary precautions to protect them against electrostatic discharge (ESD) as described above.

4.2 Mounting the Switch

4.2.1 Position and Attach the Switch

Use a mechanical lift to position the switch on the chassis supports or shelving. Align the rackmount holes with the rail holes, insert mounting screws and tighten.

4.2.2 Establish Ground and Connect to AC Power

Before connecting the power supplies to AC power, establish the ground for the switch by

connecting a grounding wire to the grounding attachment point located on the back of the chassis

and connecting the other end to an appropriate grounding attachment point in your facility. The

grounding attachment holes accommodate 1/4"-20 thread screws and are spaced for a dual hole

ground lug on 5/8" centers.

Use only copper conductors for supply and ground wiring.

4.3 XFP Pluggable Transceivers

The pluggable transceivers supplied with XFP line cards are Class 1 LASER devices. They are

theoretically eye-safe without protection, but Fortinet strongly recommends avoiding looking into

the transceivers or into the end of an attached fiber optic cable when the switch is powered. For

further safety information, please consult “LASER Safety” on page 29.

4.3.1 Further Considerations in Handling XFP Transceivers

The transceivers are very sensitive to static shock damage. Always take adequate precautions

against ESD when handling transceivers.

Never try to force a transceiver out once it is inserted into the line card; transceivers have a

release button or lever which must be actuated before attempting to remove the transceiver.

– 18 –

Page 19

5 Configuring the IP Address and

Default Gateway

In order to configure or otherwise manage the FortiSwitch-1000 without the use of a console

directly attached to the serial console port, an IP address must first be configured on the

management card of the switch to allow access via telnet or SSH session.

5.1 Initial Switch Configuration

5.1.1 Connecting to the Serial Port

Until inband or out-of-band management has been established, initial configuration of the switch

must be performed via the serial port (see the management card illustration on page 10). The

serial cable provided with the switch can connect to a standard DB9 serial port on an older PC;

newer computers may require a USB-serial converter (not included).

The settings for the serial connection are an initialized baud-rate of 115200, 8 bit, no parity, and

no flow control. The table below shows the pinout of the serial console port connector:

Pin Signal Direction

1 NC Not Connected

2 DTR Output from card

3 TXD Output from card

4 GND

5 GND

6 RXD Input to card

7 DSR Input to card

8 NC Not Connected

5.2 Management and IP Addressing Options

5.2.1 Inband vs. Out-of-Band Management

The FortiSwitch-1000 may be managed inband or out-of-band, with out-of-band management

typically being performed via the management network port on the management card. Fortinet

recommends use of out-of-band management to allow uninterrupted access to the switch in the

event of a broadcast storm.

– 19 –

Page 20

5.2.2 DHCP vs. Static IP Addressing

The FortiSwitch-1000 is configured to seek an IP address via DHCP by default, but a static IP

address can also easily be manually configured on the switch. If the network administrator

wishes to always access the switch by a consistent IP address, in switches with dual

management cards Fortinet recommends manually configuring the same static management IP

address on both cards. Because only one management card is active at a time, the duplicate

address does not cause an addressing conflict, and in the event of a switchover to the standby

management card the switch may still be accessed using the same IP address, even if the switch

is then rebooted with the second management card remaining active.

5.2.2.1 Management Card Switchover

During a switchover (when the standby management card becomes the active card without

rebooting, through either failover or use of the switchover command), the IP address of the

newly active card will depend on the configuration of the second management card.

Static (Manually Configured): If the IP addresses of both management cards are fixed, then the

standby card will take over the IP address of the active card when they switch roles; the IP

address remains the same even if the cards have different static IP addresses. On reboot,

however, the second management card will be reset to its manually configured, fixed IP address.

If the operator wishes to guarantee access to the switch by a single IP address under all

circumstances, both management cards should be configured with the same static IP address.

Dynamic (DHCP): If the IP addresses of both management cards are assigned dynamically by

DHCP, then the standby card will take the next available IP address from the DHCP server in the

event of a switchover. The management IP address for the switch will therefore be different after

switchover.

5.3 IP Address Configuration

5.3.1 Configuring an IP Address via DHCP

5.3.1.1 Setting the IP Address

By default, each FortiSwitch-1000 management card will attempt to acquire an IP address

automatically via DHCP once the switch is running and a network cable is plugged into the

management network port of the management card. If the management network port of the

active management card is connected to a network which includes a functioning DHCP server, an

IP address for the management network port should be automatically configured on the active

management card.

5.3.1.2 Finding the Assigned IP Address

If the DHCP-assigned management IP address for the management card cannot be easily

deduced from the network, it can be found through the CLI:

Log into the switch (see “Logging in to the Switch” below).

Type sho

service port, including the management IP address.

w mgmt-ip service-port to display configuration information for the management

5.3.2 Manually Configuring a Static IP Address

The process below assumes that the operator is configuring the switch for out-of-band

management. Inband management is disabled on the switch by default; information on

– 20 –

Page 21

configuring inband management can be found in the CLI Command Reference Guide under in

section 4.2.16 (“mgmt-ip inband”).

5.3.2.1 Logging in to the Switch

The switch is factory configured with a single administrator-level login account. To log in to the

switch for the first time with administrative privileges:

1. Ensure that the switch has been turned on and allowed to boot up.

2. Connect a console to the active management card via the serial console port (see

“Management Card” on page 10). The settings for the serial connection are an initialized baudrate of 1152

3. Type admin for the user name, and enter for the password (the default account has no

associated password).

00, 8 bit, no parity, and no flow control.

5.3.2.2 Setting the IP Address, Netmask and Gateway

Once logged in to the CLI, use the following steps to enter static IP address details for the

management network port:

Type enable to enter Enable Mode.

Type config to enter Config Mode.

Type mgmt-ip service-port ip <ip_address><netmask><gateway> where <ip_address> is the

static IP address you wish to configure on the active management card’s management network

port for out-of-band management of the switch.

5.3.2.3 Configuring an IP Address on the Second Management Card

When configuring IP addresses statically on a switch with dual management cards, the second

card can be configured with the same IP address as the first. Once the above steps have been

followed to log into the switch and configure an IP address on the first management card, follow

the following steps to configure the second card:

From Enable Mode, type switchover. This transfers switch management to the secondary

management card and allows its direct configuration.

Type config to enter Config Mode.

Type mgmt-ip service-port ip <ip_address><netmask><gateway> where <ip_address> is the

static IP address you wish to configure on the secondary management card’s management

network port for out-of-band management of the switch. Because the management cards never

operate simultaneously, this may be the same IP address as for the primary management card.

Type switchover again to return control of the switch to the primary management card.

Note: the same result can be achieved by copying the entire configuration of the active

management card to the standby management card.

– 21 –

Page 22

6 Appendix 1: LED States

LED State Meaning State Meaning Notes

Mgmt Card

ACT In current versions of the

FortiSwitch, the ACT light is always

off. Future functionality will use

this light to indicate state and

activity of the external USB card.

ACT

MGR

MC green All installed management

FC green All fabric cards are running

LC green All line cards are running

PWR green All power supplies

FAN green All fans are running

green This is the active

management card.

cards up and running.

normally.

normally.

powered and running

normally.

normally.

off This is the

yellow One or both

yellow One or more

yellow One or more line

yellow One or more

off One or more fans

standby

management

card.

management

cards are not up

and running.

fabric cards are

not running

normally.

cards are not

running normally.

power supplies

not running

normally.

not running

normally.

In a system with only one

management card the MC light

indicates the state of that card.

If the management card's FC light

is yellow, check the LEDs on the

individual fabric cards to identify

the source of the problem.

If the management card's LC light

is yellow, check the LEDs on the

individual line cards to identify the

source of the problem.

If the management card's PWR

light is yellow, check the LEDs on

the individual power supplies to

identify the source of the problem.

If the management card's FAN

light is off, check the LEDs on the

individual fan trays to identify the

source of the problem.

– 22 –

Page 23

LED State Meaning State Meaning Notes

(Mgmt Card, cont.)

ENV green All thermal

yellow One or more

sensors within

range.

SUMMARY

(green)

on All is well. The

SUMMARY light is

Summary lights are mutually

green if everything

else is green.

SUMMARY

(yellow)

LNK green Connection is

on Something is

wrong.

off The link is not up.

made, synched

and ready.

ACT blinking

Activity on the link. off No traffic present. Green ACT LED will be constantly

green

STATUS green Line card

yellow Line card not

functioning

normally.

thermal sensors

out of range.

Line Card

functioning

normally.

exclusive; one is on, the other is

off; if both are off, it usually means

no power is being supplied to the

system.

on at high data rates.

Check here to see which line card

is the problem if the management

card LC LED is yellow.

STATUS green Fabric card

functioning

normally.

(LED) green All fans in tray

running normally.

Fabric Card

yellow Fabric card not

functioning

normally.

Fan Tray

yellow One or more fans

in tray not running

normally.

Check here to see which fabric

card is the problem if the

management card FC LED is

yellow.

– 23 –

Page 24

LED State Meaning State Meaning Notes

Power

Supply

(LED)

solid

green

Main output (12V

DC) is available

from this unit.

blinking

green

AC power is

present; standby

output (3.3V DC) is

on, main output is

off.

off No AC power is

being supplied to

the unit.

solid

amber

Unit has failed

and must be

replaced due to

fan failure,

overtemperature

protection (OTP),

or standby output

overcurrent or

undervoltage

protection

(OCP/UVP).

blinking

amber

Main output

failure due to

OCP, OVP or

UVP.

– 24 –

Page 25

7 Appendix 2: Updating the System

Image

The software image of the most recent approved GA software at ship time is provided on a USB

flash drive already installed in the management card, so installation of an updated system image

is only necessary if you need features which are not available in the shipped version of the

software.

7.1 Image Update Procedure

7.1.1 Download Image

Contact Fortinet Technical Support to download the appropriate system images to a local FTP or

TFTP server on your network. Fortinet recommends installing the images onto the switch from a

local server on your network to reduce the number of hops in the final installation process and

ensure higher data integrity in the images.

Note: there are separate system images for management, line and fabric cards; all system

images in use on a single chassis must be from the same software build, so be sure to update all

three at the same time.

7.1.2 Load Images onto Switch

If using FTP, type the ftp command in File Mode to open a connection to the local FTP server

onto which you’ve downloaded the images and copy the images to the switch using standard FTP

commands.

If using TFTP, use the tftp get command to copy the images from the local TFTP server onto

which you’ve downloaded the images as follows:

1. Access the CLI with admin privileges, and type enable to access Enable Mode.

2. Type file to access File Mode.

3. To load each image from your TFTP server, type tftp get

<ip_address>:/<file_path>/<file_name> [target_file] where <ip_address>:/<file_path> is the IP

address and file path of the local FTP server location of the new image file, <file_name> is the

name of the new image and <target_file> is the file name on the FortiSwitch-1000 management

card.

4. Repeat step three for each of the remaining images. Be sure to update your system with

system images from the same build for the management card, fabric cards and line cards.

7.1.3 Set System Images

Set the newly downloaded images as the system images for all cards by using the system image

command.

1. From File Mode, type system image mgmt all <file_name> (where <file_name> is the name

of the new management card system image) to set the system image for both management cards.

(In a non-redundant chassis, use system image mgmt 1 instead.)

– 25 –

Page 26

2. Type system image fabric all <file_name> (where <file_name> is the name of the new fabric

card system image) to set the system image for all fabric cards.

3. Type system image line all <file_name> (where <file_name> is the name of the new line card

system image) to set the system image for all line cards.

7.1.4 Reload System

Finish the process by resetting the switch.

1. From File Mode, type exit to access Enable Mode.

2. Type reload to reset the switch without power cycling. This command terminates all network

connections and loads the settings from the startup-config file.

– 26 –

Page 27

8 Appendix 3: Regulatory Compliance

and Safety Considerations

8.1 Agency Approvals

8.1.1 Safety

UL 60950-1 / CSA 22.2 No. 60950-1; Safety of Information Technology Equipment

EN / IEC 60950-1; Safety of Information Technology Equipment

EN 60825-1 - Safety of Laser Products - Part 1; Equipment Classification. Requirements and

User's Guide

EN 60825-2; Safety of Laser Products - Part 2; Safety of Optical Fiber Communication Systems

8.1.2 EMI

FCC Part 15 Class A

ICES-003 Class A

EN 300 386 Class A

EN 55022 Class A

VCCI Class A

EN 61000-3-2

EN 61000-3-3

8.1.3 Immunity

EN 300 386

EN 55024

EN 61000-4-2; Electrostatic Discharge (ESD) Immunity

EN 61000-4-3; Radiated RF Immunity

EN 61000-4-4; Electrical fast Transients (EFT) Immunity

EN 61000-4-5; Electrical Surge Immunity

EN 61000-4-6; Conducted Immunity

EN 61000-4-8; Magnetic Field Immunity

EN 61000-4-11; Power Voltage Dips Immunity

– 27 –

Page 28

8.2 EMC Compliance Statements

8.2.1 United States

This equipment has been tested and found to comply with the limits for Class A digital devices,

pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed and used

in accordance with the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at their own

expense. Changes or modifications to this equipment not expressly approved by the party

responsible for compliance to FCC part 15 could void the user's authority to operate the

equipment.

8.2.2 European Union

This is a Class A product. In a domestic environment this product may cause radio interference in

which case the user may be required to take adequate measures.

8.2.3 Canada

This Class A digital apparatus complies with Canadian ICES-003. Cet appareil numérique de la

classe A est conforme à la norme NMB-003 du Canada.

8.3 General Safety Guidelines

8.3.1 Installation Environment

The maximum recommended ambient temperature for the FortiSwitch-1000 during operation is

40 degrees C.

Since a chassis can be installed into a multi-unit rack assembly, the operating ambient

temperature of the rack environment may be greater than room ambient. Therefore, consideration

should be given to installing the equipment in an environment compatible with the maximum

recommended ambient temperature of 40 deg C.

Installation of the chassis in a rack assembly should be such that the amount of air flow required

for safe operation of the equipment is not compromised (that is, no blockage of intake or exhaust

registers). A minimum of 6 inches of clearance is required from the front and rear of the

FortiSwitch-1000 to ensure adequate air flow through system.

8.3.2 Mechanical

Mounting of the FortiSwitch-1000 in the rack assembly should be such that a hazardous condition

is not achieved due to uneven mechanical loading.

– 28 –

Page 29

8.3.3 Electrical Rating

The FortiSwitch-1000’s electrical ratings should be considered when connecting to the power

supply circuits. Consideration must be given to the effect that overloading of circuits may have on

overcurrent protection and supply wiring.

8.3.4 Grounding

Reliable earthing (grounding) of the FortiSwitch-1000 chassis through the protective earthing

terminal(s) should be maintained.

8.3.5 Metallic Interfaces

FortiSwitch-1000 metallic interfaces are suitable for connection to intrabuilding or non-exposed

wiring or cabling only.

8.3.6 Fuse Replacement

Although FortiSwitch-1000 field-replaceable units (cards, power supplies and fan trays) are

provided with fuses and holders, Fortinet does not recommend replacement of damaged or blown

fuses. It is recommended instead that the entire FRU be returned to Fortinet for

repair/replacement if found to be non-functional.

8.3.7 LASER Safety

CLASS 1 LASER PRODUCT: FortiSwitch-1000 circuit boards may be equipped with optical

communication transmitters which have been evaluated and found to be in compliance with

requirements found within 21 CFR (FDA-CDRH) and EN 60825-1 for Class 1 laser devices.

WARNING: While Class 1 laser products are considered to be “eye safe” without the need for

additional protection, when working around the circuit boards, the following general safety

guidelines should be observed to reduce the risk of eye injury:

Do not look or stare into unterminated optical fiber ports or at fibers that are connected to a

source.

Do not examine unterminated optical fiber ports or optical fibers that are connected to a source

with optical instruments. The use of optical instruments (e.g. magnifying glass) with this product

may increase eye hazard.

Adjustments/settings, maintenance, operational parameters and procedures other than those

specified and allowed herein and on the rating plate of the FortiSwitch-1000 may result in

increased eye hazard.

Do not attempt to perform any repair or maintenance on optical communications components.

Repairs and maintenance outside that which is allowed herein must be performed only by an

authorized repair facility.

8.3.8 Restricted Access Location

The FortiSwitch-1000 is intended to be installed only in a RESTRICTED ACCESS LOCATION.

A RESTRICTED ACCESS LOCATION is defined as an area where access can be gained only by

SERVICE PERSONNEL who have been instructed about the reasons for the restrictions applied

to the location and about any precautions that must be taken.

– 29 –

Page 30

RESTRICTED ACCESS LOCATIONS can be accessed only through the use of a tool or lock and

key or other means of security, and are controlled by the authority responsible for the location.

SERVICE PERSONNEL are defined as persons having appropriate technical training and

experience necessary to be aware of hazards to which they are exposed in performing a task and

of measures to minimize the danger to themselves or other persons.

8.3.9 Power

Each chassis has a maximum of six AC power supply connections. A minimum of 5 power

supplies and 3 separate branch circuits are required when input voltage range is 100-180 VAC.

A minimum of 5 power supplies and 2 branch circuits are required when input voltage range is

200-240 VAC. Each branch circuit over-current protection must be Listed 20 Amp for North

America or European Union (EU) Installation. A readily accessible disconnect device that is

suitably approved and rated should be incorporated in the facility wiring. All power connections

must be removed to completely de-energize the unit.

Before conducting non-operational work or maintenance on the FortiSwitch-1000, completely

remove all power from the unit. The circuit breakers feeding the chassis, when opened, will deenergize circuitry beyond the breakers.

When performing work/maintenance on the FortiSwitch-1000 during operation, SERVICE

PERSONNEL should use caution as there are Hazardous Energy levels present within the

chassis.

8.3.10 Supply and Chassis Ground Wiring

Use only copper conductors for supply and ground wiring.

The power supplies are designed to accept UL/CSA rated power cords with IEC 60320 C13 plugs.

Specific conductor size and type should be in accordance with NEC/CEC requirements.

8.4 General Operational and Maintenance

Guidelines

The following guidelines are designed to help ensure the safety of the people working on or

around the FortiSwitch-1000 (such as technicians or installers) and are also designed to protect

the routing equipment.

Installation of the FortiSwitch-1000 should be performed only by a qualified technician.

Do not wear conductive items such as watches, bracelets, rings, or other jewelry when working

with the FortiSwitch-1000.

The installation area should be kept dust-free at all times.

Never attempt to lift an object that may be too heavy.

Keep tools and other equipment out of walkways where people could trip on them.

8.4.1 Electrical Safety

WARNING: Disconnect all power supplies before performing non-operational servicing.

The FortiSwitch-1000 is designed to be upgraded while the system is operational. Performing

upgrades on the FortiSwitch-1000 therefore entails working with live voltage. The following

– 30 –

Page 31

guidelines are designed to help ensure the safety of technicians working with the equipment,

prevent occurrences of electric shock, and to mitigate the risk of damaging the equipment:

Know the location of the emergency power-off switch at the facility before work on the

FortiSwitch-1000 begins. The readily accessible disconnect device shall be incorporated in the

building installation wiring.

Never work alone when connecting power cables to the FortiSwitch-1000.

Examine all equipment and components for possible hazards, such as moistness, loose cabling,

or improper grounding.

Never install damaged equipment.

Never assume a circuit is disconnected from the power source. Always verify that a circuit has

been disconnected before work begins.

8.4.2 ESD

The FortiSwitch-1000 is sensitive to electrostatic discharge (ESD). It is important to take the

necessary precautions before working on a system. The following guidelines will help reduce the

risk of an ESD event damaging the electronics of a system:

Make sure the chassis is properly grounded before handling any electronic components (the

FortiSwitch-1000 is provided with attachment points on the rear of the chassis for the connection

of a grounding cable).

Always wear an ESD-preventative wrist strap.

Make sure the wrist strap makes adequate contact with your skin. An ESD wrist strap tester is

recommended.

Make sure the other end of the wrist strap is connected to one of the standard ESD jacks on the

front or rear of the chassis.

– 31 –

Loading...

Loading...