Page 1

670 Series

Bursters

OPERATOR MANUAL

SECOND EDITION

Page 2

Page 3

TABLE OF CONTENTS

DESCRIPTION

Function 1

Model Numbers 1

Accessory Model Numbers 1

Specifications 2

INSTALLATION

Unpacking and Set-up 2

OPERATION

General 3

Safety 3

Control/Feature & Function 5

Form Set-up Procedure With And

Without Tractors 6

Form Set-up Procedure With Imprinter 9

Normal Loading 9

Operating Hints 10

Troubleshooting 11

Vertical Folder 13

Merger/Burster 14

Page 4

Page 5

DESCRIPTION

FUNCTION

BURSTER

Moore 676/680 Burster bursts (breaks apart) single

and multi-part continuous forms and feeds them

sequentially onto the stacker.

SEQUENCE STACKER

Sequence stacker allows continuous runs of

forms without stopping burster to unload stacker

Web belts carry forms from burster output onto a

slanted grill where they are partially jogged for

removal.

SLITTER/TRIM CHOPPER

Slitter/trim chopper operates like the slitter unit

but also chops trim into short pieces, 4 to 5

inches long. The advantage in using the trim.

chopper is that it compacts trim in the

wastebasket.

SLITTER

Slitter enables the operator to remove trim at

same speed forms are being burst.

IMPRINTER

Imprinter unit enables operator to print

signatures at same speed forms are being

burst.

POWER DROP STACKER

Optional power drop stacker collects forms in

one neat stack without need for operator

intervention at ouffeed end of the machine

during processing of each box of forms. The

power drop stacker has automatic, presetable,

shutoff.

BURSTER TABLE

Burster table has casters which allows

freedom of movement. Enclosed in the table

is a wastebasket to catch trim while slitting.

MODEL NUMBERS

FD 676 Burster/Tractor Feed/Slitters/Base

FD 680 Burster/Imprinter/Tractor Feed/Slitters/

CENTER SLITTER

Makes a mid-form cut in forms as they are

burst.

Base

OPTIONAL ACCESSORIES

FD680-06 Imprint Module (8”)

FD630-22 Tri-Color Ink Roller FD680-07 Imprint Module (8-1/2”)

FD630-31 Violet Ink Roller FD680-08 Imprint Module (10”)

FD630-32 Green Ink Roller FD680-09 Imprint Module (11”)

FD630-33 Red Ink Roller FD680-10 Imprint Module (12”)

FD670-10 Power on-off Key Lock FD680-11 Imprint Module (14”)

FD670-18 Last Form Switch FD680-14 Imprint Module (10-1/2”)

FD670-19 Last Form Timed Out FD680-15 Imprint Module (7-1/4”)

FD670-24 Photo Cell Counter FD680-21 Signature Saddle (6”)

FD670-40 Extra Wide Slitter L. FD680-22 Signature Saddle (6-1/2”)

FD670-42 Extra Wide Slitter R. FD680-23 Signature Saddle (6FD670-44 Vertical Folder FD680-24 Signature Saddle (7”)

FD670-70 Margin Trim Chopper FD680-25 Signature Saddle (7-113”)

FD670-77 Center Slitter FD680-26 Signature Saddle (8”)

FD670-80 Power Slacker (17”) FD680-27 Signature Saddle (8FD670-87 Stacker Control Wheel Assy. FD680-28 Signature Saddle (10”)

FD670-88 Infeed Static Eliminator FD680-29 Signature Saddle (11 “)

FD680-01 Imprint Module (6”) FD680-30 Signature Saddle (12”)

FD680-02 Imprint Module (6-1/2”) FD680-31 Signature Saddle (14”)

FD680-03 Imprint Module (6-2/3”)

FD680-04 Imprint Module (7”)

FD680-05 Imprint Module ( 7-1/3”)

2/3”)

1/2”)

1

Page 6

SPECIFICATIONS

FORM SPECIFICATIONS

Variable Speed 30-500 ft/mm (4.6-154 m/mm)

Capacity 1-8 pan forms

Maximum Depth 17 inches (43 cm)

Minimum depth 2 3/4 inches (7cm)

Maximum Width Before Slitting 19 1/4 inches (49cm)

Maximum Width After Slitting 17 inches (43cm)

Form Types Carbon or Carbonless

Form Weights 10 lb. to 140 Ib.

Size-Model FD 676/680

Height 43”(109cm)

Width 31 “(79cm)

Length 56” to 68 1/4”

Actual 142cm to 173cm

Weight 330 lbs(149kg)

INSTALLATION

UNPACKING AND SET-UP

Do not destroy shipping cartons or materials until

machine has been inspected for damage, missing

parts, and proper operation.

1. Remove bands which hold cardboard box to

wooden pallet. Remove cardboard box.

2. Remove burster top supports.

3. Remove (4) carriage bolts: (2) on infeed end of

burster and (2) outfeed end. Hint: Leave carriage

bolts in place on center burster support,

4. Remove (4) foam blocks.

5. With allen wrench supplied, unfasten four

retaining bolts which hold machine to the board

immediately below it.

NOTE: Center burster support is not fastened to

burster.

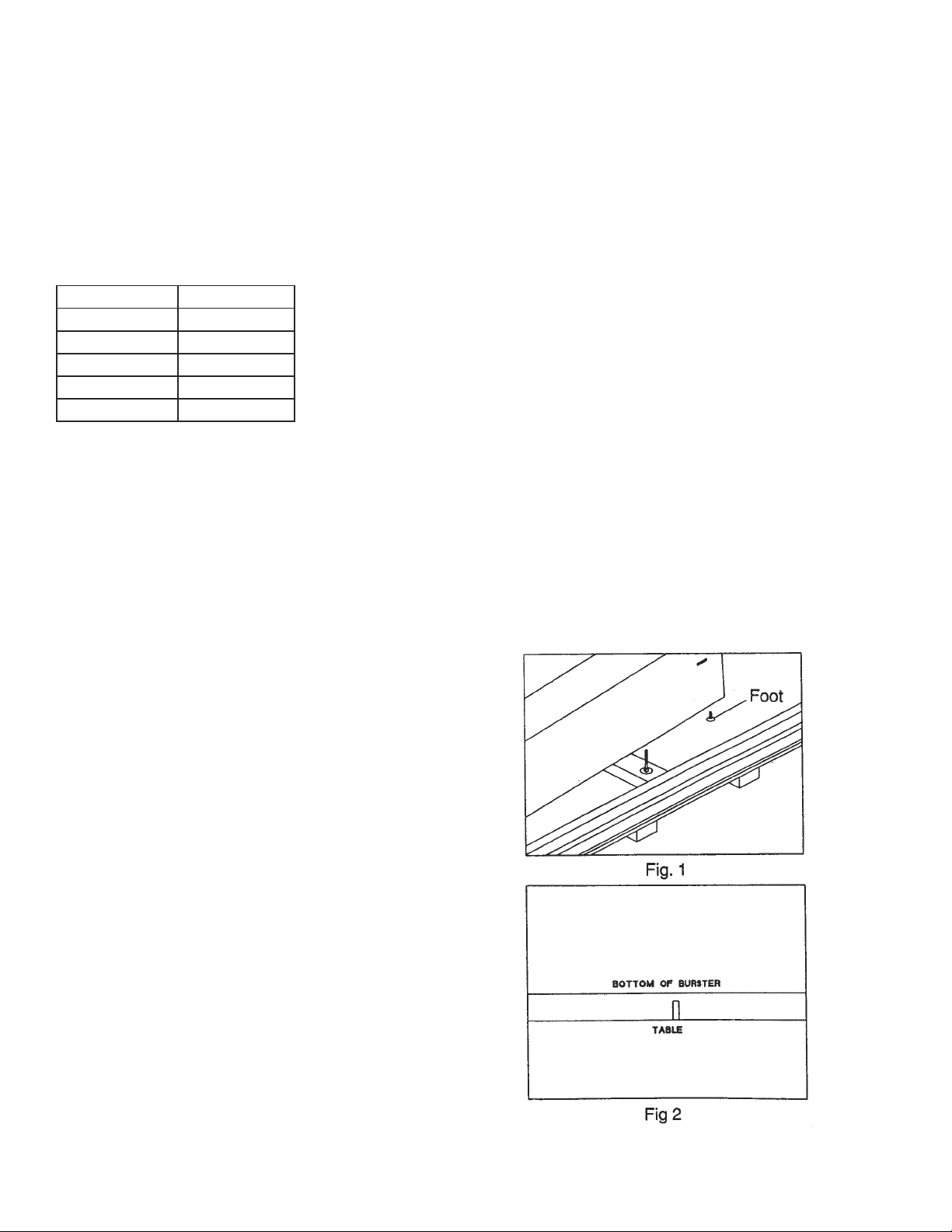

6. Add burster feet to burster. (Fig. 1)

7. Remove burster table from its carton.

NOTE: Location of holes on top of table.

CAUTION: Lifting should not be attempted by

less

than four people.

9. Add 1/4-20 x 1 1/2 locating screws, (included),

to underside of table, screwing up into burster

frame.

8. Set burster on table, lining up holes in table with

holes in burster frame. (Fig.2)

NOTE: Burster will line up evenly on all sides of the

table.

2

Page 7

OPERATION

0 POWER I JOG START STOP MACHINE FORM

SPEED LENGTH

000000000

INTERLOCK RESET NORMAL/ STACKER STACKER

ENABLE VARIABLE SPEED CLEAR

Optional

SAFETY

GENERAL

This section describes controls, features, and normal

operating procedures for this identifies and describes

control devices of machine. Familiarity with these

devices is very important in order to operate this

machine properly.

This section describes built-in safety devices to

protect operator, but these devices do not replace

good operator practices.

-Do not touch any moving parts

-Keep fingers, long hair, jewelry, ties and loose

clothing away from any moving parts.

-Refer servicing to qualified personnel.

3

Page 8

WEDGER

EDGE SLITTERS

SLITTER

ADJUSTMENT SCREW

8 PIN TRACTOR DR.

URGE ROLLER

MAGNETIC STOP

FORM LENGTH SCALE

FIG. 5

URGE ROLLER

CENTER PAPER

GUIDE

LEFT PAPER GUIDE

8 PIN TRACTOR OP.

RIGHT PAPER

GUIDE

OPTIONAL

STACKER GRILL

STACKER ADJUSTMENT

RACK

STACKER WHEEL

ASSEMBLY

FIG. 6

4

Page 9

CONTROLS AND FEATURES

Refer to Figures on previous page for

locations of controls and indicators below.

CONTROL / FEATURE FUNCTION

On/Off Switch Controls power to Burster. Indicator light

lets operator know that power is on.

Start Button Starts Burster

Stop Button Stops Burster

Machine Speed Thumb Wheel Varies Burster Speed

Paper Guides Prevents side to side movement of form while

it is entering Burster during friction feeding.

Jog Switch Enables operator to advance or retract forms

during initial loading.

Interlock Light Lets operator know that jam has occurred at

outfeed end of Burster or that safety covers

are not properly closed.

Stacker Clear Button Clears Stacker at a fast speed.

Stacker Speed Thumb Wheel Varies Stacker speed in variable position.

Stacker Switch Sets mode of Stacker, either normal or variable.

Stacker Wheel Indicator Aids the operator in setting Stacker wheels for

proper form length.

Urge Roller Assists vertical stacking of forms on Stacker grill.

Stacker Grill Provides a surface for forms to vertically stack.

Jam Detector Grill Guides forms onto stacker belts. In event of a j am,

it activates jam detection switch.

Stacker Wheel Assembly Guides forms out of Burster onto stacker belts.

Keeps forms properly aligned.

Stacker Adjustment Rack Holds stacker wheel assembly and enables stacker

wheel assembly to be adjusted.

Form Length Scale Indicator mark to set form length.

Form Length Switch To set form length.

Last Form Switch (Optional) Shuts Machine off after last form leaves the

tractor.

Last Form Defeat Switch Defeats last form switch optlon,(located on

tractor).

the side frame just above the right side

5

Page 10

FORM SET-UP PROCEDURE WITH

AND WITHOUT TRACTORS

1.Turn on machine. Measure form length using form

length scale on sequence stacker. (Fig. 6)

2- Press form length switch to align alignment mark

with form length on form length scale. (Fig. 4)

3. Place form stack on pull down tray on front of

table.

4.If friction feeding use left, right and center paper

guides. If feeding with tractors, use center paper

guide only. (Fig. 7

)

5. Center leading edge of form at i nfeed end of

machine so that outer edges of form extend equally

beyond guide straps on each side. If you find that the

edges come within 1/4” of the guide straps, offset form

in either direction to avoid this condition. (Fig. 5)

NOTE: For friction feeding omit steps 6-10.

6. Position tractors to proper form width by releasing

thumbscrews on top of tractors and sliding tractors to

proper width. Raise tractor gates

7. Lay margin holes of form over feed pins. (Fig. 8)

NOTE: Do not stretch form too tightly between

pins should be centered in margin holes.

8. Close tractor gates and lock tractors by tightening

thumbscrews.

9. If using edge slitters, position alignment mark where

you wish to slit. (Fig. 5)

10. 1f slitting, be sure that slitter blades are

engaged. This is accomplished by rotating wedger

in a counterclockwise direction as far as they will go

without force. (Fig. 5)

11. Lock edge slitters in place by tightening

thumbscrews clockwise. (Fig. 5)

NOTE: If you do not want to slit, push edge slitters

away from form and tighten thumbscrews.

12. By pressing jog switch in forward position,

advance form through feed rollers until snap rollers

grab the form.

13. 1f necessary, adjust form length so that form starts

to burst when perforation is just under tear points.

NOTE: Tear points can be moved to allow operator

to position them at any location along tear bar. Tear

points should be set between perforations that run

vertically the length of the form. (Fig. 10)

pins;

6

Page 11

14. Tear bar is adjustable to accommodate

characteristics of various forms. To adjust height bar

must be pushed to compress spring and lift out. Rotate

180 degrees (turned over) and replaced making sure

that square end of bar locks into brackets. (Fig. 9,

shown in HIGH position)

15. Set stacker wheel assembly so that stacker

wheels come to rest on proper form length indicated

on sequence stacker. (Fig. 6)

NOTE: When running forms at high speed, move

stacker wheels one notch furthertoward stacker grill

on stacker wheel adjustment rack. This will avoid jams

at jam grill.

16. Jog first form into sequence stacker to make

sure that sequence stacker wheels are just ahead of

leading edge of form.

17. Close safety covers. Machine is now ready to

burst. Press start button and adjust machine to

desired speed.

.

7

Page 12

8

Page 13

FORM SET-UP PROCEDURES

WITH IMPRINTER

NOTE: It is recommended that numbered forms or

checks fed into imprinter should be last form first, right

side up.

1. Center leading edge of form at infeed end of

machine so that outer edges of form extend equally

beyond guide straps on each side. If you find that

edges come within about 1/4” of guide straps, offset

form in either direction to avoid this condition.

2. If form length is 3 1/2”, 7”, 10 1/2” or 14”, rollers

must be timed. Time rollers by activating jog switch

until timing marks on the rollers are vertical and in view

in cutouts in feed and snap roller covers.

3. Position tractors by releasing and sliding to proper

form width. Raise tractor gates. Place forms on feed

pins as shown in (Fig. 8). Close tractor gates and

secure in position.

4. Loosen thumbscrews on ink roller unit and slide unit

10. Move timing collar so that mark on collar aligns

with mark on side frame. Tighten setscrews. (Fig. 11)

11. Remove forms from tractors. Install signature

patches on imprint cylinder. (Fig. 12)

12. Move ink roller directly over signature patch on

imprint cylinder. Jog forward, if necessary, so that

imprint cylinder turns to a point where signature patch

should touch ink roller. Adjust ink roll thumbscrews so

ink roll turns when signature patch makes contact.

For darker impression, turn adjustment thumbscrews

clockwise. (Fig. 19)

NOTE: The signature saddle has been factory adjusted

to fit a .092 thick signature patch. If adjustment is

required to lower or raise the height of signature

saddle for a different signature patch thickness,

release imprinter side plates from their locked

positions. Pull back latch finger to release plates. (Fig.

11. Loosen side setscrews to free top setscrew Turn

top setscrew in at half-turn increments until required

height is reached. Tighten side setscrews and slide

imprinter module back into position.

away from signature area on form. (Fig. 12)

5. Loosen setscrew on plate cylinder. if setscrews are

not in view, rotate free wheeling cylinder until they are

in view.) Horizontally align plate cylinder with signature

area on form. Tighten setscrews. (Fig. 12)

6. Loosen setscrews on imprint cylinder. (if setscrews

are not in view, use jog switch to bring them into view.

Fig. 11)

7. With no signature saddles on imprint cylinder, move

forms forward so signature area is centered over plate

cylinder shaft.

8. Center signature cylinder over signature area

(NOTE: Setscrews should be facing you.) and center

signature plate locator pins directly over imprint area

on form. Tighten setscrews.

9. Advance forms forward so that next horizontal

perforation aligns at top edge of plastic tractor or

alignment mark on metal tractor. (Fig. 11)

NORMAL LOADING

NOTE: Imprinter must be timed each time you load a

different form into Burster for imprinting.

1. Jog machine forward until timing collar mark is

aligned with side panel mark. (Fig. 11)

2. Place forms to leading edge of plastic tractors.

On metal tractors place forms leading edge to timing

mark.

3. Advance (jog) forms forward through imprint area.

Stop leading edge of form in front of slitters.

4. Move slitters to trim proper amount of trim

and engage slitter blades by turning wedgers

counterclockwise. Lock down slitters.

5. Advance forms through slitters and check for

proper slitting. Advance on through to Tear Bar.

9

Page 14

6. Set up tear bar as before. (Fig. 9) bar, vary form length setting up to 1/2”

ahead or behind actual form size setting,

7. Set up Stacker Wheel Assembly as and/or put tear bar in low position.

before. (Fig. 6)

5. Multiple part forms with hard glued

8. Jog first form into Sequence Stacker edging can be burst by positioning tear

to make sure that stacker wheels are bar over glued edge.

just ahead of leading edge of form. Put

urge roller in place. 6. Stacker wheel should not stop the

form until form clears snap rollers.

9. Close Safety covers. Machine is now

ready to burst and imprint. Press start 7. Carbonized forms will generally stack

Button and adjust machine speed to better when run with coated side up.

speed desired.

OPERATING HINTS

1. To stop the machine just push on either one of

two stop buttons. Opening safety cover or lifting jam

detection grill will also stop machine.

2. To restart machine start button must be pressed.

CAUTION: Machine will restart at same speed that it

was running at unless speed control thumbwheel is

turned down.

3. Some paper has a natural curve. Sometimes this

curve tends to catch air and sail. If this occurs, try

running them upside down.

4. Perforations vary in strength. If forms are bursting

hard, tearing, or breaking behind tear

TROUBLESHOOTING

Feeding, bursting, and stacking problems are usually

due to improper adjustment of machine to forms of

due to a non-standard or defective form.

Most problems fall into one of three categories,

Electrical, Mechanical, or Form Flow. Electrical

troubles are USUALLY obvious because machine will

not run or respond in a normal manner to its controls.

Mechanical problems are usually accompanied

by noise, slippage, tearing, or binds. If a form flow

problem is present, jamming, mis-stacking, or

intermittent form damage will occur. Problem should

be diagnosed to one of three categories, before

proceeding to pinpoint problem. Best approach is a

logical elimination of possible malfunctions.

10

Page 15

SYMPTOM PROBLEM CAUSE

Burster will not run. Power light on. Safety cover not closed.

Jam detection grill not activating switch.

Last form switch activated (no forms in tractors).

Faulty interlock switch.

Faulty run switch.

Faulty stop switch.

Faulty last form switch.

Faulty jam detection switch.

Faulty cover switch.

Faulty brake resistor.

Faulty speed control.

Faulty motor brush(s) (worn out or stuck).

Faulty motor.

Loose wire.

Faulty mechanical crimp on quick disconnect.

Faulty power-on/power-off key lock.

Burster will not run. No power light Line plug loose or pulled out.

Blown fuse.

Defective power cord.

No line voltage.

Defective on-off switch.

Forms creep to one side. Infeed quides not set property.

Roller tension not uniform across roller.

Burster stalls or tears forms. Tear bar in high position.

Burster not running fast enough.

Incorrect form length setting.

Tear points not adjusted properly across face of form.

Tough form perforations.

Improper stacking. Stacker wheels positioned to close or to far from.

Outfeed.

Stacker wheels not directly over belts.

Stacker wheels binding on axle.

Edge of form not under roller.

Stacker grill not adjusted property.

Static.

Sequence stacker at wrong speed. In variable.

Sequence stacker not running.

Poor slitting. Slitter blades not making contact with one another.

Worn blades.

Edge slitters difficult to slide. Foreign material on shaft.

Burr on shaft.

Blade Slitter Assy. dirty.

Poor cuts on trim chopper. Roller tension not correctly set.

Worn blade.

11

Page 16

SYMPTOM PROBABLE CAUSE

Stacker does not run but Burster does. Broken belt

Loose stacker drive gear/tbroken drive pin.

Faulty stacker motor.

Faulty stacker motor speed control

Faulty stacker switch.

Rollers don’t rotate/machine runs. Broken drive belt, Loose pulley.

Won’t burst properly. Incorrect roller tension.

Carriage not properly positioned.

Tear point not set correctly.

Tear bar not set correctly.

Forms pull out of tractors. Roller timing off.

Incorrect form length setting.

Incorrect feed roller tension.

Tractor drive pulley bound up.

Tractors binding internally.

Tractor pins not centered in margin holes.

Dull slitter blades.

Tractor timing is off.

Uneven inking. Ink roller not adjusted properly.

Ink roller needs replacing.

Signature patch not installed properly.

Patch worn out.

Ink roll not spinning freely.

Signature position moves. Incorrect check length for print cylinder.

Form not in tractors.

Print cylinder loose.

Print cylinder timing incorrect.

Signature patch not positioned correctly.

Large variations in trim accuracy. Paper not centered to slitter feed.

Margin slitter setscrew not tightened down.

Snap roller carriage will NOT move. Defective switch or motor.

Broken carriage drive chain.

Loose setscrew on carriage advance shaft or on motor.

Obstruction on rack.

Obstruction at the pivot arm.

Loop forming between the slitter and Obstruction between the infeed and snap rollers.

the infeed roller. Broken flow strap.

Bent infeed finger.

Tear bar in low position.

Too many tear points.

Need Anti-tenting bracket.

12

Page 17

VERTICAL FOLDER

SET-UP

FUNCTION

Vertical folder provides means for folding two-wide

forms side-to-side prior to their entry into burster.

SET-UP PROCEDURE

1. Place forms on floor at infeed end of burster.

2. Thread forms through folding bale. (Fig. 13) If you

are going to imprint, arrange forms so that side to be

imprinted is facing down.

3. Folding bale should line up with infeed guides so

edge of the form is in a straight line. (Fig. 13)

4. Position the infeed brush to the side of the forms

opposite tractor being used. (Fig. 13)

5. Center perforation of forms in a straight line from

floor to infeed brush.

13

Page 18

MERGER-BURSTER

SET-UP

FUNCTION

FD589 Merger/Burster

Center slits continuous forms and allows forms to be

merged into burster for slitting, imprinting, bursting

and stacking.

SET-UP PROCEDURE

1. Set forms in tractor. (see page 6, Fig. 8)

2. Adjust center slitter to the middle of the

forms. (Fig. 15)

3. Jog forward and guide forms through paper guides

to second set of tractors. Allowing forms to merge

together. (Fig. 16)

4. Adjust slitters to location that forms are to be

trimmed and proceed with form set-up procedure

starting on page 6.

14

Loading...

Loading...