Page 1

FD 6100

Folder/Inserter

OPERATOR MANUAL

FIRST EDITION

Page 2

INTRODUCTION

Your folding and inserting machine enables you to fold documents, insert them into envelopes and seal the envelope flaps.

Small inserts business reply envelopes (BRE) can be added to

folded large format documents, or can be inserted individually,

without folding.

This user-friendly machine operates automatically and efficiently.

It makes short work of dispatching invoices, mass mailings,

payrolls, daily mail, etc.

The information contained in this guide will help you to get the

best use and productivity from your machine.

Its main features are:

- Two automatic feeder trays for large format documents (letter

up to legal)

- An automatic feeder tray for small inserts BRE.

- Easy vertical loading of the trays

- User-friendly, intuitive interface with memory enabling each

user to record and save details of the most frequent jobs.

- Automatic adjustment of the size of the folds.

- Automatic doubles document detection fitted to all feed trays, to

ensuring the security of the contents of the envelope.

- Small footprint enabling the machine to fit neatly into any office

environment.

4125603C/B

10/10/2003

1

SI30-0008-1/B

Page 3

4125603C/B

10/10/2003

2

Page 4

4125603C/B

10/10/2003

This manual cannot be reproduced, registered or transmitted

by any electronic, mechanical or other means, partly or wholly,

without permission of your vendor/reseller.

3

Page 5

OFFICIAL STANDARDS

In order to comply with standards EN60950 and UL1950, this

equipment must be connected to standard installation of the

construction industry. In order to protect the internal wiring, protection against 5A current surges is required. This equipment

complies with norm 55022, Class A.

INSTALLATION

This equipment must be installed close to a grounded electrical

AC outlet, and the plug must be protected with a 16A fuse.

ATTENTION

UNDER NO CIRCUMSTANCES SHOULD AN ATTEMPT BE

MADE TO REMOVE THE COVERS OF THE MACHINE SINCE

THEY PROTECT LIVE ELECTRICAL PARTS.

WARNING: moving parts. Keep fingers, jewelry or loose

clothing away.

4125603C/B

10/10/2003

4

Page 6

TABLE OF CONTENTS

SECTION A: GENERAL PRESENTATION ........... 9

1. MACHINE .......................................................................... 11

2. CONTROL PANEL ...........................................................12

3. OPENING THE MACHINE AND INTERNAL VIEW .........13

SECTION B: FUNCTIONS.................................... 15

1. INSTALLATION AND START-UP.......................................... 17

1.1 Installing the machine ............................................ 17

1.2 Installation and initial start-up ................................ 19

1.3 Entering the unlocking code .................................... 19

1.4 Selecting the language ........................................... 20

1.5 Filling the moistening tray ....................................... 21

1.6 Double Detection Tray C ........................................ 22

4125603C/B

10/10/2003

2. USING THE MACHINE ......................................................... 23

2.1 User Mode ............................................................. 23

2.1.1 Stored job selection....................................... 24

2.1.2 Table of stored jobs ....................................... 24

2.1.3 Starting a job ................................................. 26

2.1.4 Modifying a job .............................................. 26

2.1.5 Locking and unlocking a job .......................... 30

2.1.6 Counter ......................................................... 31

5

Page 7

2.2 Advanced Functions .............................................. 32

2.2.1 Changing the language ................................. 33

2.2.2 Settings for envelope formats and

special documents ......................................... 33

2.2.3 Double Document detection activation/

desactivation (Tray C) .................................... 38

2.3 Other Advanced functions ....................................... 38

2.3.1 Double Document Detection Activation/

Deactivation for trays A and B. ....................... 38

2.3.2 Displaying Job Adjustments ........................... 39

3. LOADING DOCUMENTS ......................................................40

3.1 Loading documents (trays A and B in

automatic mode) .................................................... 40

3.2 Loading documents in manual mode (tray A) ........ 42

3.3 Loading envelopes ................................................ 43

3.4 Loading small inserts and reply

envelopes (tray C) ................................................. 45

4125603C/B

10/10/2003

SECTION C: HELP AND ADVICE ........................ 47

1. HELP GUIDE ......................................................................... 49

1.1 Error messages ..................................................... 49

1.2 Symptoms and remedies ....................................... 55

6

Page 8

2. JAM CLEARING ................................................................... 60

2.1 Clearing the feeders (tray A and B) ....................... 60

2.2 Unjamming the document path.............................. 61

2.3 Unblocking path of small inserts (tray C) ............... 61

2.4 Clearing the envelope tray ..................................... 62

3. CLEANING ............................................................................ 63

3.1 Cleaning the rollers ................................................. 63

3.1.1 Internal rollers ................................................ 64

3.1.2 Envelope Tray Rollers .................................... 65

3.1.3 Tray C Rollers ................................................ 65

3.1.4 A/B Feeder Rollers ........................................ 66

3.2 Cleaning/Replacing moistening brushes ................. 67

3.3 Cleaning the covers of the machine ........................ 67

SPECIFICATIONS ...............................................69

4125603C/B

10/10/2003

7

Page 9

Symbols used

Indicates necessary information

Indicates potential problem area

Indicates an idea or interesting point

Illustration through an example

4125603C/B

10/10/2003

8

Page 10

SECTION A: GENERAL PRESENTATION

1. MACHINE .......................................................................... 11

2. CONTROL PANEL ...........................................................12

3. OPENING THE MACHINE AND INTERNAL VIEW .........13

4125603C/B

10/10/2003

9

Page 11

123 4 5

8

6

17

4125603C/B

10/10/2003

10911 16151415

10

General presentation

7

12 13

Page 12

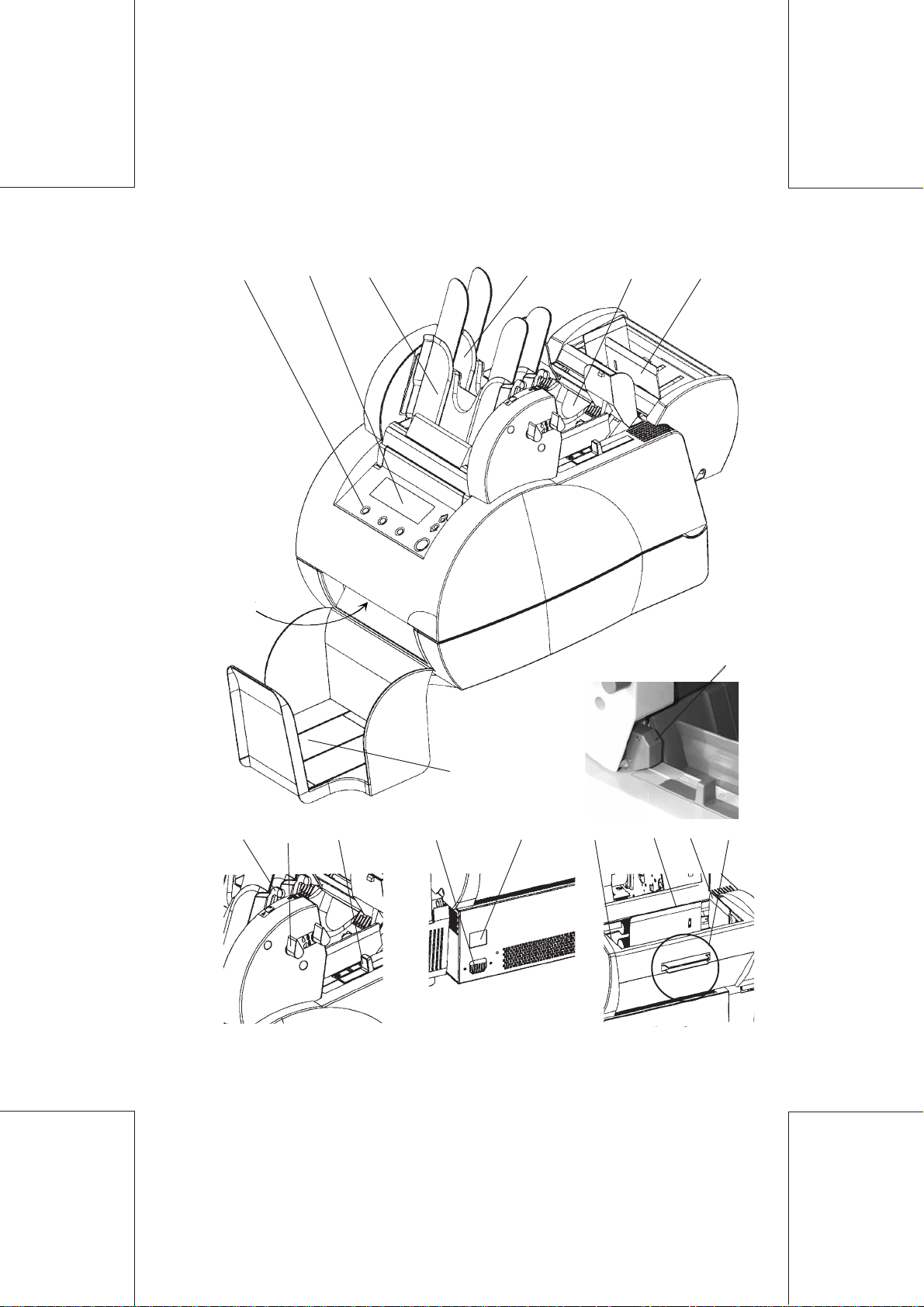

1. MACHINE

1 Control panel

2 Display

3 Tray A (document feeder)

4 Tray B (document feeder)

5 Envelope tray

6 Tray C (small insert or reply envelope feeder)

7 Catch tray

8 Opening handle of the machine

9 Paper side guide locking levers (trays A and B)

10 Locking levers for trays A and B

11 Locking mechanism for envelope guides

12 Power supply socket

13 On/off switch

14 Tray C guides (small inserts)

15 Lateral guides

16 Tray C Opening handle (small inserts)

17 Connector for document feeders

4125603C/B

10/10/2003

General presentation

11

Page 13

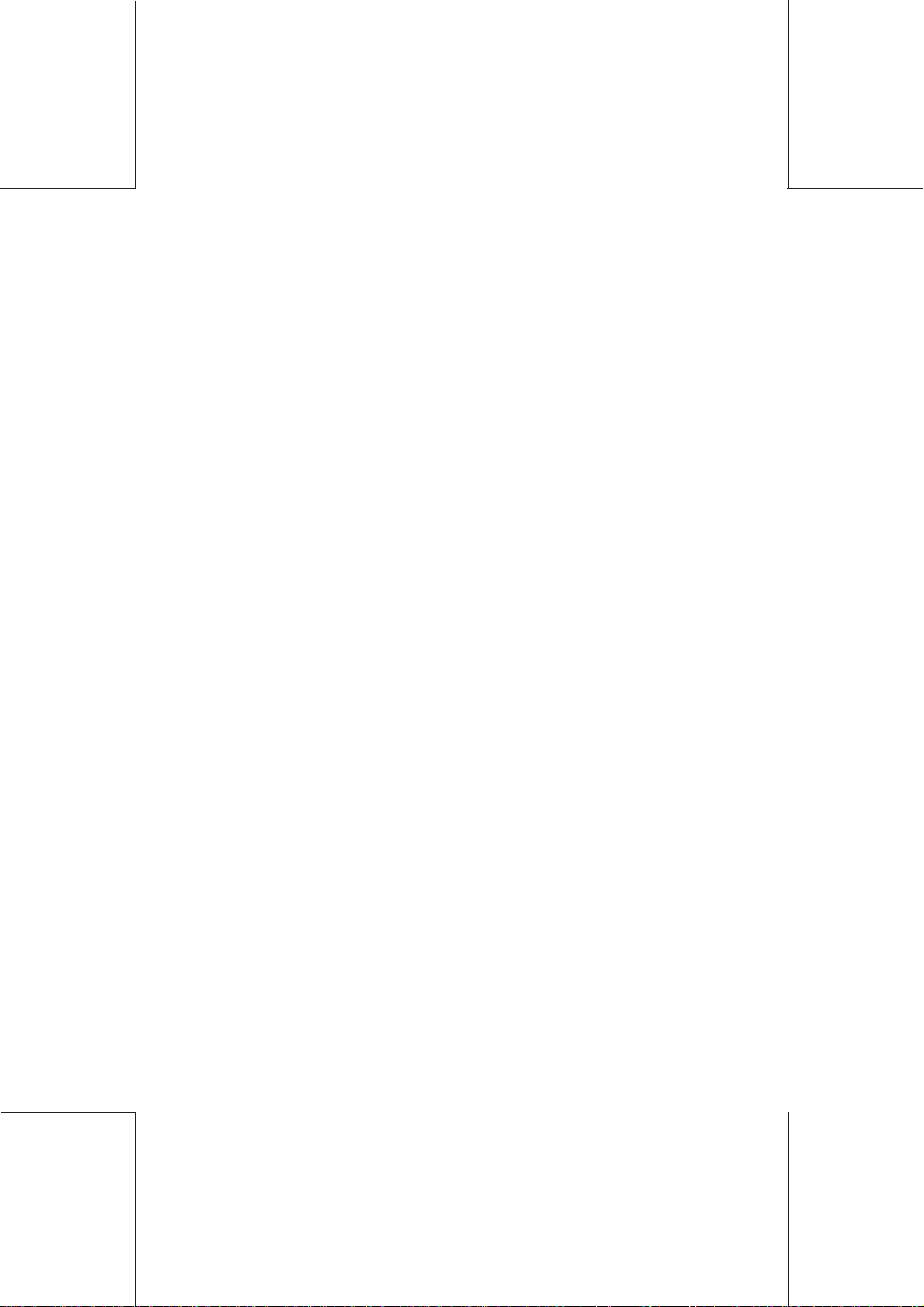

2. CONTROL PANEL

Display panel

Selection

key

Save to

memory

key

Cancellation

key

Control keys

Start and

stop key

4125603C/B

10/10/2003

12

General presentation

Page 14

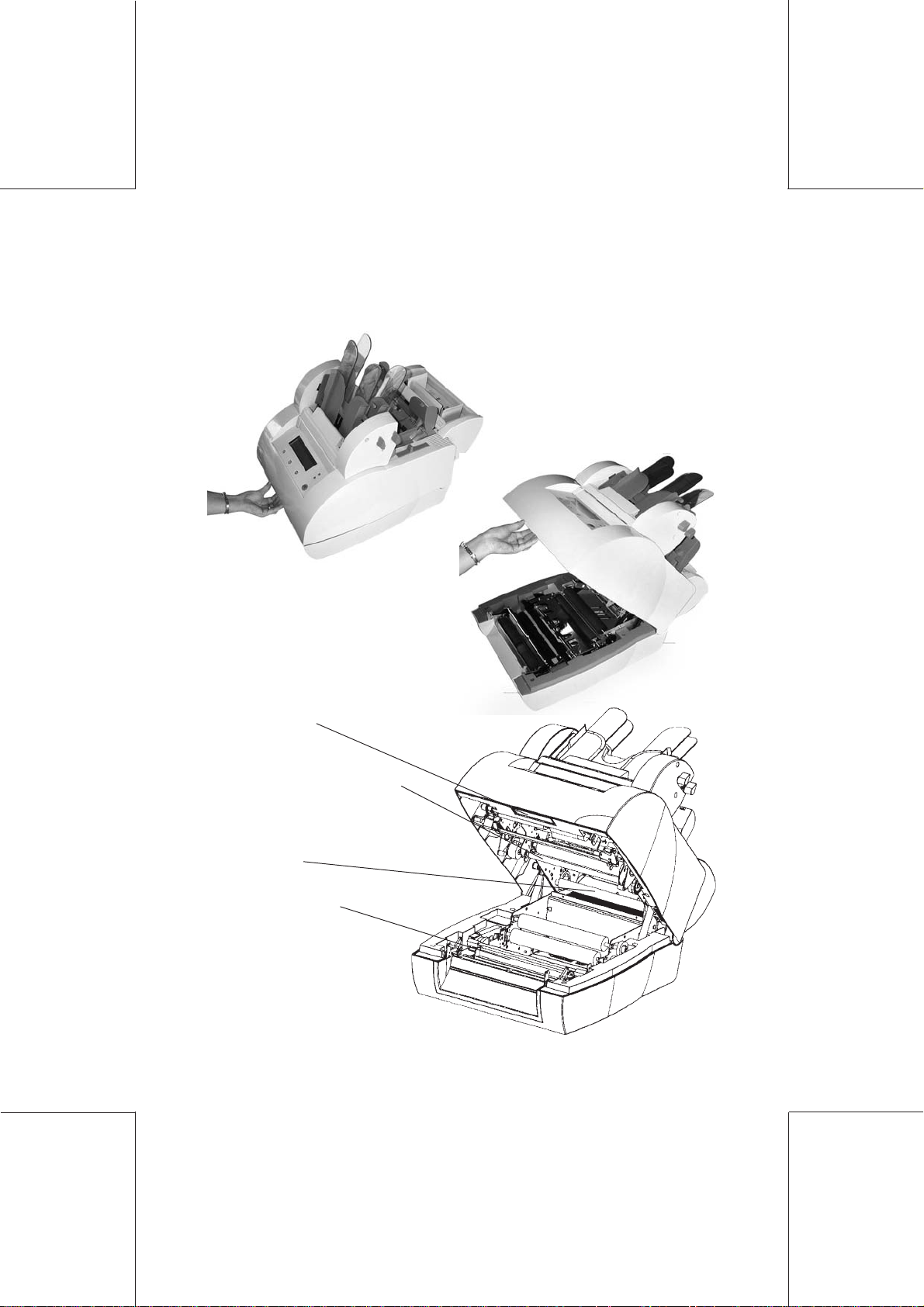

3. OPENING THE MACHINE AND INTERNAL VIEW

To open the machine:

Squeeze the handle

on the front.

Lift the lid of the machine

upwards.

Opening handle of

the machine

4125603C/B

10/10/2003

Envelope exit roller (E)

Shutter (7)

Moistening tray

General presentation

13

Page 15

4125603C/B

10/10/2003

14

Page 16

SECTION B: FUNCTIONS

1. INSTALLATION AND START-UP......................................... 17

1.1 Installing the machine .............................................. 17

1.2 Installation and initial start-up .................................. 19

1.3 Entering the unlocking code .................................... 19

1.4 Selecting the language ........................................... 20

1.5 Filling the moistening tray ....................................... 21

1.6 Double detection tray C .......................................... 22

2. USING THE MACHINE ......................................................... 23

2.1 User Mode ............................................................. 23

2.1.1 Stored job selection....................................... 24

2.1.2 Table of stored jobs ....................................... 24

2.1.3 Starting a job ................................................. 26

2.1.4 Modifying a job .............................................. 26

2.1.5 Locking and unlocking a job .......................... 30

2.1.6 Counter ......................................................... 31

2.2 Advanced Functions .............................................. 32

2.2.1 Changing the language ................................. 33

2.2.2 Settings for envelope formats and

special do-cuments ....................................... 33

2.2.3 Double Document Detection Activation/

Desactivation (tray C) .................................... 38

2.3 Other Advanced functions ....................................... 38

2.3.1 Double Document Detection Activation/

Deactivation for trays A and B. ....................... 38

2.3.2 Displaying Job Adjustments ........................... 39

4125603C/B

10/10/2003

15

Page 17

3. LOADING DOCUMENTS..................................................... 40

3.1 Loading documents (trays A and B in

automatic mode) .................................................... 40

3.2 Loading documents in manual mode (tray A) .......... 42

3.3 Loading envelopes ................................................. 43

3.4 Loading small inserts and reply

envelopes (tray C) .................................................. 45

4125603C/B

10/10/2003

16

Page 18

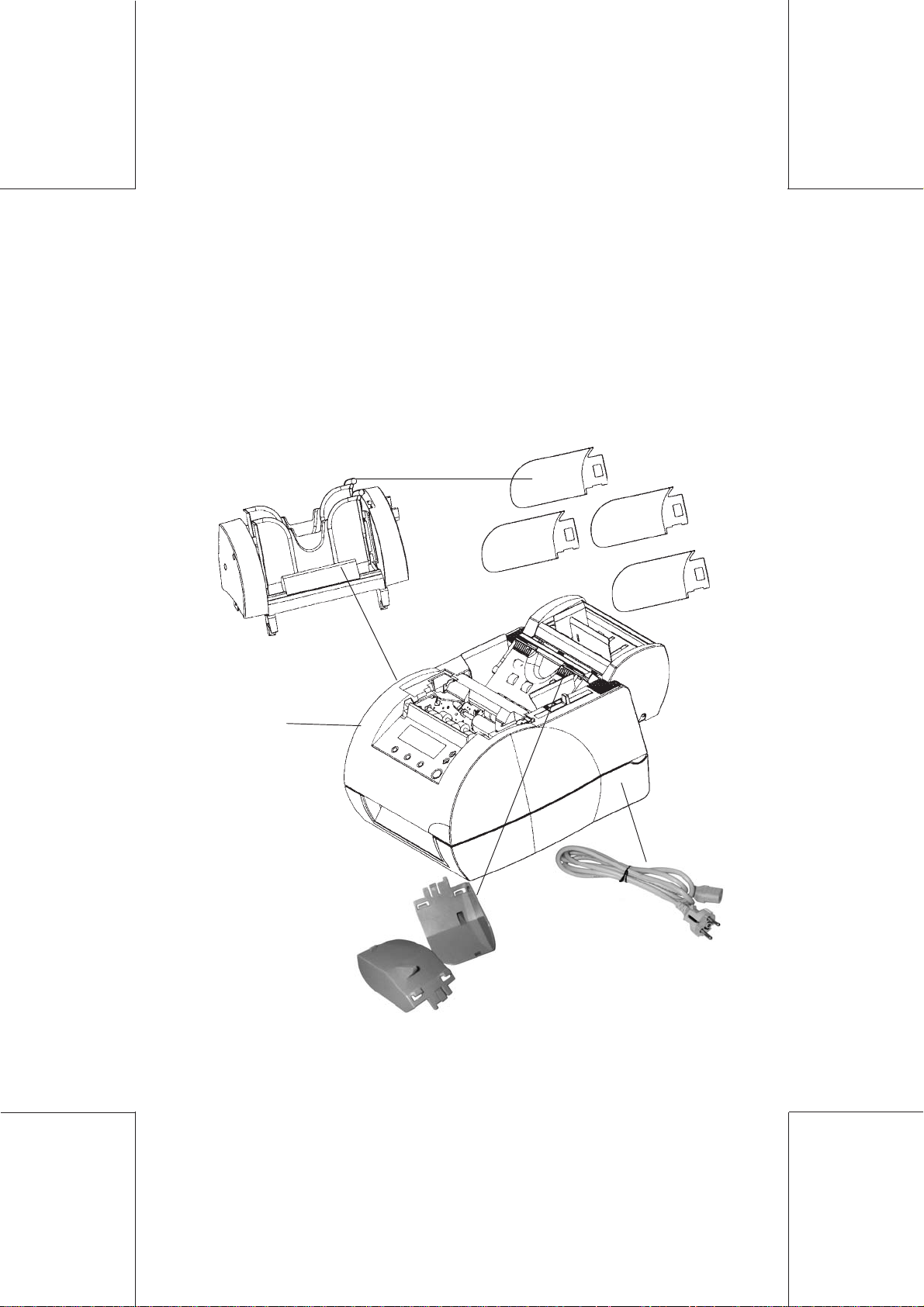

1. INSTALLATION AND START-UP

1.1 Installing the machine

Upon receiving the machine, check the content according to

the list below :

Four transparent

document-holders

Document feeders

Trays A and B

Base

4125603C/B

10/10/2003

1 power cord

2 rear guides for

envelope tray

Installation and start-up

17

Page 19

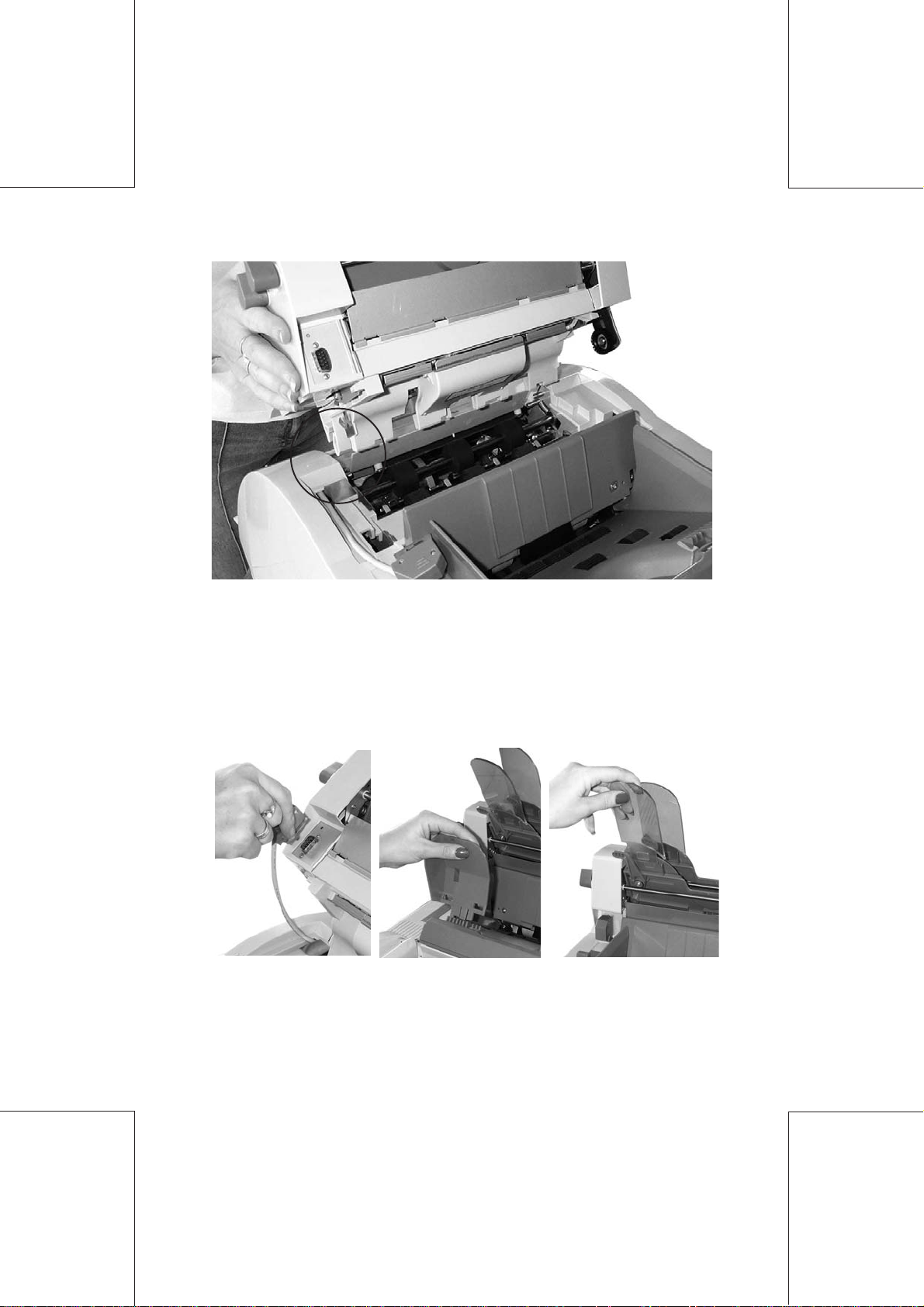

Install the document feeder by inserting its 2 plastic lugs into their

respective slit, located on the base of the machine.

Hold the feeder

towards you, plug

the connector to the

A/B Feeder socket,

then replace the

feeder properly on

Clip the guides onto

the back of

envelope tray : be

careful regarding

the position

Clip-on the transparent document

holders on trays A

and B.

the base.

Connect the power cord to the machine on main and press the

switch : The initialization screen will be displayed for a few

seconds.

18

Installation and start-up

4125603C/B

10/10/2003

Page 20

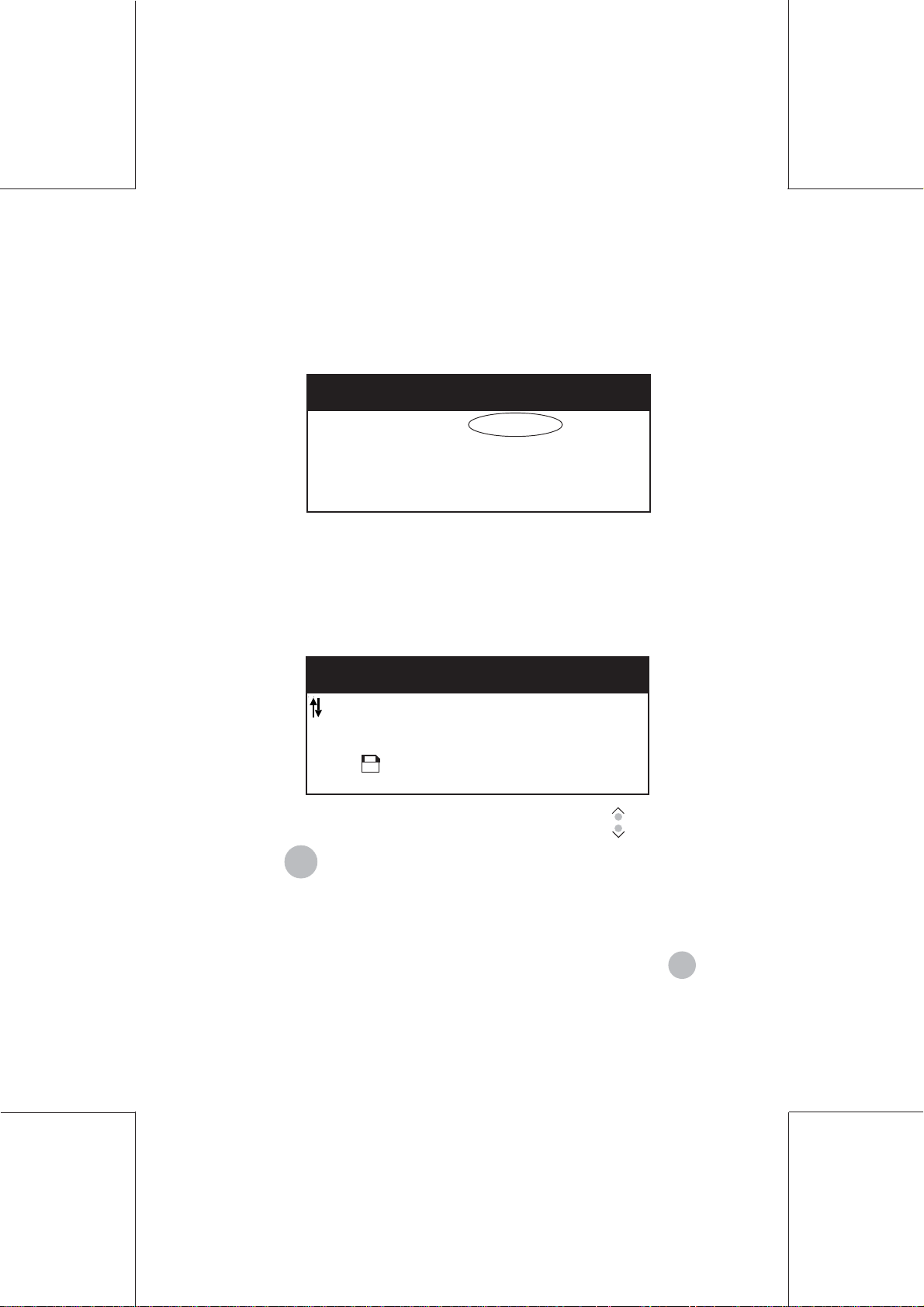

1.2 Installation and initial start-up

When the machine is powered up, the initialization screen will

be displayed for a few seconds. The number displayed is the

total number of cycles the machine has performed, all tasks

included.

INITIALIZATION IN PROGRESS

Total number of cycles : 1234567

(press ESC during

initialization to change the

machine setup)

INITIALIZATION IN PROGRESS

1.3 Entering the unlocking code

This screen will automatically appear at the final step of the

installation procedure.

Enter the code number appearing in section J of your quick startup guide as follows:

INITIALIZATION IN PROGRESS

1. Select a number between 0 and 9, using the keys

2. Press

START

STOP

AUTHORIZATION CODE SET UP

: Select number

START-STOP : Validate number

ESC : exit

Press to confirm

Code : 0000000000

.

to select the number and the cursor should move

automatically to the next position.

3. Repeat these two operations until you have finished entering

(10 digits).

4. If you make a mistake when entering your code, press

ESC

to

delete and start again from the beginning.

Installation and start-up

19

4125603C/B

10/10/2003

Page 21

ESC

ESC

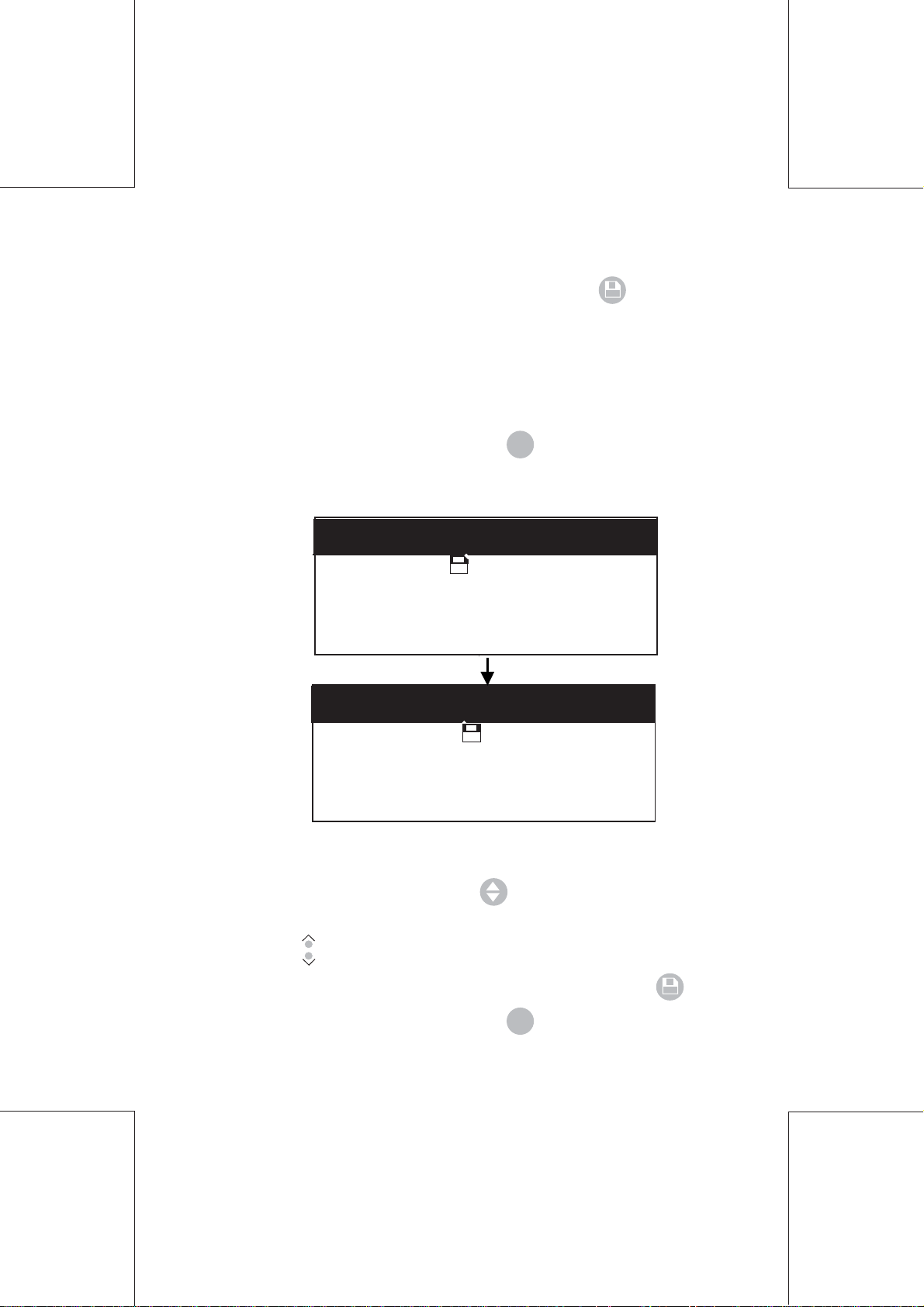

5. Once your code is enter correctly, press

to store it.

1.4 Selecting the language

The default configuration of your machine is English.

To modify the language:

- If the machine is switched on, switch it off then on again.

- During the initialization phase press

to display the following

screen:

INITIALIZATION IN PROGRESS

Language : ENGLISH

Set : Env. / Doc.

Double Det. Bin C : DISABLE

INITIALIZATION IN PROGRESS

Numéro Machine : 0000000000

Appuyer sur pour continuer

Langue : FRANCAIS

Personnalisation : Env. / Doc.

Det. Double Bac C : DEVALIDER

MACHINE SETUP

Serial Number : 0000000000

Press to confirm

CONFIGURATION MACHINE

- Upon entering this screen, the "language" line indicates the

language used.

- Select this line by pressing the key.

4125603C/B

10/10/2003

- Scroll until you have reached the desired language to select,

using the

- Complete the operation by saving the changes with

- Or by cancelling the changes with

20

Installation and start-up

keys.

.

.

Page 22

1.5 Filling the moistening tray

The moistening tray is a device that enables the machine to

moisten the glue on the envelope flap so that it can be sealed.

This screen appears each time the machine is started up and

remains active for several seconds.

INITIALIZATION IN PROGRESS

Do not do this if you have already done

CHECK WATER LEVEL

Refill water

To fill the moistening tray

1. Open the machine

11

1

11

11

1

11

2. Remove carefully the

moistening tray by its blue handles.

3. Remove the strip of 3 stoppers

and fill the tank with water through

the 3 holes.Ensure the brushes

are properly impregnated with

water

4. Replace the moistening tray

in the machine, with the blue

handles towards you.

5. Close the machine

22

44

2

4

22

44

33

3

33

Installation and start-up

21

4125603C/B

10/10/2003

Page 23

1.6 Double Document Detection Tray C

This option is deactivated by default.

This function enables the machine to detect the presence of two

small inserts passing simultaneously through the insertion circuit.

To activate it, select this function, using

it, using the

key.

INITIALIZATION IN PROGRESS

Language : ENGLISH

Set : Env. / Doc.

Double Det. Bin C : DISABLE

MACHINE SETUP

Serial Number : 0000000000

Press to confirm

and enable/disable

4125603C/B

10/10/2003

22

Installation and start-up

Page 24

2. USING THE MACHINE

To use the machine, the following must be specified:

- type of document

- type of envelope

- feeder trays being trays

This information is saved by the machine as a "job",

corresponding to a specific application. There are nine (9) jobs

which can be stored in memory for later recall.

Fill the tray or trays concerned, depending on the task to be

performed (see section entitled “loading documents”).

2.1 User Mode

When the user menu appears, the machine is ready for use.

READY : START to process a job

or to select line to modify

Counter : 1 2 3 4

Job number : 02

Feeder : AUTO A+B+C

Document : LETTER 11"

Envelope : # 10 SEAL

Address height : +0 mm

4125603C/B

10/10/2003

Selection area Modification area

Using the machine

23

Page 25

2.1.1 Stored job selection

When first entering this screen, no line is active.

Pressing the key activates the "Counter" line, and each

time this key is pressed, the next line will be selected.

Use the

keys to select the job number desired

(The machine is delivered with 9 pre-stored jobs )

READY : START to process a job

or to select line to modify

Counter : 1 2 3 4

Job number : 02

Feeder : AUTO A+B+C

Document : LETTER 11"

Envelope : # 10 SEAL

Address height : +0 mm

2.1.2 Table of stored jobs

In the pre-stored jobs, the default envelope format

is # 10 SEAL. The machine defines automatically

the folding parameters to fit the size of the envelope

chosen.

A pre-stored job will certainly suit your needs. If

not, please consult the section entitled “Modifying

a job”.

4125603C/B

10/10/2003

Job

number

Job 1

Job 2

AUTO

AUTO

A+B+C

24

Using the machine

Trays

A+B

Document Functions

LETTER 11"

LETTER 11"

The 2 trays function together

The 3 trays function together

Page 26

Job 3

AUTO A

LETTER 11"

Trays A and B function

alternately, when one tray is

empty, the machine switches

automatically to the other

Job 4

Job 5

Job 6

Job 7

Job 8

Job 9

AUTO

A+C

AUTO

A

AUTO

A+C

MANUAL

A

MANUAL

A+B

MANUAL

A+C

LETTER 11"

LEGAL 14"

LEGAL 14"

LETTER 11"

LETTER 11"

LETTER 11"

Trays A and B function

alternately, and tray C

functions simultaneously with

whichever tray is operational.

Trays A and B function

alternately, when one tray is

empty, the machine switches

automatically to the other

Trays A and B function

alternately, and tray C functions

simultaneously with whichever

tray is operational.

Tray A functions alone in

manual AutoStart mode. Documents are inserted manually in

tray A.

Tray A functions alone in

manual AutoStart mode and

Tray B is on automatic.

Documents are inserted

manually in tray A.One document from Tray B is added to

the bundle in tray A.

Tray A functions alone in

manual AutoStart mode and

tray C is on Automatic. One

document from tray C is added

to the bundle in tray A.

4125603C/B

10/10/2003

Envelope # 10 : ~ 105 mm

Using the machine

25

Page 27

2.1.3 Starting a job

START

STOP

- Select the line "Job number", with the key.

- Choose a job number with

.

- Load the appropriate trays with your documents.

START

- Press the

key to start the cycle.

STOP

The cycle can be interrupted at any time by pressing the

START

key again.

STOP

An on-line help message is displayed on the

screen

for each job.

If the job selected uses the "Manual" (AutoStart)

function it is not necessary to press the

START

STOP

key.

Tray A starts automatically when inserting a

sheet of paper.

2.1.4 Modifying a job

Jobs already in the memory can be modified:

- Select the line "Job number", with the

key.

- Choose the job number to be modified with

4125603C/B

10/10/2003

- Make the necessary changes, including selection of

trays, document format and envelope format.

- Launch the cycle by pressing the

key.

As long as the icon is flashing, the changes have not

been finalized. Press to save them to the memory.

START

STOP

26

Using the machine

To test the settings quickly, press

machine will perform a single cycle.

twice: the

Page 28

Selecting trays :

To change the tray operating mode in a job.

- Select the "Tray" line using the key

- Select the desired function using the keys

.

.

Tray functions available:

AUTO A+B

AUTO A

AUTO A+B+C

AUTO A+C

AUTO C

MANUAL A

MANUAL A+B

MANUAL A+C

MANUAL A+B+C

Trays A and B enable the insertion of large format documents,

of the LETTER 11" type, that are to be folded. They accept

documents measuring from 11" to 14".

Press to choose feeders

or START to process a job

Counter : 1 2 3 4

or to select line to modify

Job number : 02

Feeder : AUTO A+B+C

Document : LETTER 11"

Envelope : # 10 SEAL

Address height : +0 mm

The largest document format will be taken

into account for folding purposes.

4125603C/B

10/10/2003

Auto: Automatic operating mode, starts after pres-

sing the key

START

STOP

.

The envelope by envelope operating mode starts

with "Autostart" mode (manual insertion of a

sheet of paper or bundle of up to five sheets).

Using the machine

27

Page 29

Selection of document format

To change the format of the main document in a job

- Select the "Document" line using the key .

- Select the desired format using the

keys.

Document formats available

LETTER 11", LEGAL 14"

Press to select format

or START to process a job

Counter : 1 2 3 4

or to select line to modify

Job number : 02

Feeder : AUTO A+B+C

Document : LETTER 11"

Envelope : # 10 SEAL

Address height : +0 mm

Envelope selection

To change the envelope format in a job.

- Select the "Envelope" line using the key .

- Select the desired format using the keys

Envelope formats available

#10 SEAL

#10 NO SEAL

SPECIAL SEAL (see "Advanced functions")

SPECIAL NO SEAL (see "Advanced functions")

C-FOLD ONLY

.

4125603C/B

10/10/2003

28

Using the machine

Press to select format and mode

or START to process a job

Counter : 1 2 3 4

or to select line to modify

Job number : 02

Feeder : AUTO A+B+C

Document : LETTER 11"

Envelope : # 10 SEAL

Address height : +0 mm

Envelope # 10 : ~ 105 mm

Page 30

Changing the height of the address

START

STOP

This setting enables adjustment of the fold position to have the

printed address seen through the envelope window.

- Select the line "Address Height" using the key .

- Change the setting using the keys .

- Perform a test run by pressing the

key twice.

- Once you have the correct setting, start the cycle by pressing the

START

key once.

STOP

Press to move adress in

or START to process a job

Counter : 1 2 3 4

or to select line to modify

Job number : 02

Feeder : AUTO A+B+C

Document : LETTER 11"

Envelope : # 10 SEAL

Address height : +0 mm

The

Mr P. Robert

1, Rue des arbres

75020 PARIS

key moves it upwards

in the window

4125603C/B

10/10/2003

Place the document

in tray A, face up with

the address at the top.

Mr P. Robert

1, Rue des arbres

75020 PARIS

The

key moves it down-

wards in the window

Using the machine

29

Page 31

2.1.5 Locking and unlocking a job

To protect a job, no line should be selected.

If not press

to deselect.

ESC

To lock a job:

- Complete any changes to the settings using the key

ESC

- Keep this key pressed,

- Save to memory using the key ,

- A key-shaped symbol will appear next to the number

of the amended job.

Only the job in progress can be amended (the one with the

current number).

READY : START to process a job

or to select line to modify

Counter : 1 2 3 4

Job number : 02

Feeder : AUTO A+B+C

Document : LETTER 11"

Envelope : # 10 SEAL

Address height : +0 mm

To unlock a job:

- Press the key

ESC

,

,

4125603C/B

10/10/2003

- Keep this key pressed,

- Validate and save the unlocking using the key

- The job is then unprotected, and the key-shaped symbol

beside the job number will disappear.

READY : START to process a job

or to select line to modify

Counter : 1 2 3 4

Job number : 02

Feeder : AUTO A+B+C

Document : LETTER 11"

30

Using the machine

Envelope : # 10 SEAL

Address height : +0 mm

,

Page 32

2.1.6 Counter

The machine has 2 counters.

- The first one can be read on the initialization screen when

the machine is switched on. It indicates the total number

of cycles performed, all jobs included, since the machine

was used for the very first time. It cannot be changed.

- The second counter, which displays on the main screen,

is a meter that monitors activity and it can be returned to

zero. It indicates the total number of cycles performed on

all jobs inclusive since it was last returned to zero.

To return a job meter to zero:

- Select the line "Counter" using the key

- Return it to zero using the keys

Press to reset by zero

or START to process a job

Counter : 1 2 3 4

Job number : 02

Feeder : AUTO A+B+C

Document : LETTER 11"

Envelope : # 10 SEAL

Address height : +0 mm

Press to reset by zero

or START to process a job

Counter : 0000

Job number : 02

Feeder : AUTO A+B+C

Document : LETTER 11"

Envelope : # 10 SEAL

Address height : +0 mm

.

.

4125603C/B

10/10/2003

Using the machine

31

Page 33

2.2 Advanced Functions

ESC

To enter the advanced functions mode:

- During initialization, press the key

The following screen will appear:

INITIALIZATION IN PROGRESS

Language : ENGLISH

Set : Env. / Doc.

Double Det. Bin C : DISABLE

MACHINE SETUP

Serial Number : 0000000000

Press to confirm

4125603C/B

10/10/2003

32

Page 34

2.2.1 Changing the language

The machine’s user default language is set to English. This

can be changed by holding down the

ESC

key while switching

the machine ON from the switch located at the back of the

machine.

1. Select the "language" line using the

2. Use the

3. Press

4. Press

keys to change the language setting,

to store changes,

to return to the user menu.

ESC

INITIALIZATION IN PROGRESS

Language : ENGLISH

Set : Env. / Doc.

Double Det. Bin C : DISABLE

INITIALIZATION IN PROGRESS

Numéro Machine : 0000000000

Appuyer sur pour continuer

Langue : FRANCAIS

Personnalisation : Env. / Doc.

Det. Double Bac C : DEVALIDER

MACHINE SETUP

Serial Number : 0000000000

Press to confirm

CONFIGURATION MACHINE

key,

4125603C/B

10/10/2003

2.2.2 Settings for envelope formats and special documents

This menu allows adjustment for:

- format, size and position of the envelopes,

- position for moistening the glue on the flap,

- Special document formats.

Using the machine

33

Page 35

To perform these adjustments :

INITIALIZATION IN PROGRESS

Language : ENGLISH

Set : Env. / Doc.

Double Det. Bin C : ENABLE

- Select the line "SET. ENV / DOC" using the key

- Enter the manual adjustment menu using the key

SELECT THE ENVELOPE FORMAT

Set Standard envelope :

Set Special envelope :

Set Special document :

- Select the line you want to change, using the key

MACHINE SETUP

Serial Number : 0000000000

Press to confirm

,

,

Press to confirm

,

- Enter the manual adjustment sub-menu using the key ,

STANDARD ENVELOPE SETUP

4125603C/B

10/10/2003

Press to confirm

Envelope height : 105 mmmmSet

Envelope stop position : + 0 mm

Moistening position : 13 mm

- Select the line to be modified, using the key

- Adjust the value using the keys

- Store the adjustment by pressing

- Press

34

to return to previous menu.

ESC

Using the machine

Page 36

Changing the size:

Indicate the height of the envelope or document in millimeters

x mm

x mm

Correcting the stop position of the envelope:

You can correct the position of the envelope in order to insert

folded leaflets correctly. If the settings are incorrect, the envelope

may not be sealed correctly.

Set too high

Set too low

Correcting the moistening position:

This setting makes it possible to adjust the area to be moistened

on the envelope flap.

It may be necessary to adapt the moistening

to the shape of the flap or the thickness of the envelope in order to

ensure optimal adhesion.

Moistening area

Moistening limit

Moistening

position

Using the machine

35

4125603C/B

10/10/2003

Page 37

The settings indicated on the following screens

are the machine’s default settings.

Manual adjustment of standard envelopes

STANDARD ENVELOPE SETUP

Press to confirm

Envelope height : 105 mmmmSet

Envelope position : + 0 mm

Moistening position : 13 mm

Size: 105 mm to 125 mm, manually adjustable

(105, 108, 110, 114, 115, 120 and 125 mm)

Position correction: +7 mm to -8 mm, manually adjustable

(in 1 mm increments)

Moistening position:

13 mm to 45 mm, manually adjustable

(in 1 mm increments)

Manual adjustment of special envelopes

4125603C/B

10/10/2003

SPECIAL ENVELOPE SETUP

Press to confirm

Envelope height : 105 mmmmSet

Envelope position : + 0 mm

Moistening position : 18 mm

Size: 105 mm to 165 mm, manually adjustable

(in 1 mm increments)

Position correction: +7 mm to -8 mm, manually adjustable

(in 1 mm increments)

Moistening position: 13 mm to 45 mm, manually adjustable

(in 1 mm increments)

36

Using the machine

Page 38

Manual adjustment of special documents

SPECIAL DOCUMENT HEIGHT

SETUP

Press to confirm

Size : 178 mm

Size: 177 mm to 356 mm, manually adjustable

(in 1 mm increments)

4125603C/B

10/10/2003

Using the machine

37

Page 39

2.2.3 Double document detection activation/

ESC

desactivation (tray C)

To activate this mode:

- Select the line "Double Det. Bin C", using .

- Activate or deactivate using the keys

- Cancel any changes using the key

ESC

.

- Save changes to memory with the key .

- Exit the mode using the key

INITIALIZATION IN PROGRESS

Language : ENGLISH

Set : Env. / Doc.

Double Det. Bin C : ENABLE

MACHINE SETUP

Serial Number : 0000000000

Press to confirm

mode.

2.3 Other Advanced functions

2.3.1 Double Document Detection Activation/

Deactivation for trays A and B.

The double document detection is activated by

default on both trays A and B. To deactivate it,

use a stylus or paperclip to press a small button

located near the feeder socket. A message will

appear on the control panel screen.

4125603C/B

10/10/2003

38

Page 40

2.3.2 Displaying Job Adjustments

To access this screen:

- You should be in user mode.

- Press the

key and keep it pressed

ESC

- Press the key

The following screen will appear.

INFORMATION

Press ESC to exit

Fold A : 089 mm

Fold B : 097 mm

Envelope height : 105 mm

Counter : 12345

- Exit this screen using the

key to return to user mode.

ESC

4125603C/B

10/10/2003

C-fold

Double parallel fold

Using the machine

39

Page 41

3. LOADING DOCUMENTS

3.1 Loading documents (trays A and B in automatic

mode)

Documents are loaded vertically in the natural direction

of reading. The document containing the address must

always face the user. When both feeders feed

simultaneously (2 documents), the address document

must be in tray A.

1. Release the blue locking levers

Tray B

Lever in locked position.

Tray A

Lever in released position.

4125603C/B

10/10/2003

2. Adjust the lateral guides to the width of the document.

Guide for Trays A and B

in locked position.

40

Loading documents

Guide for Tray A

in unlocked position.

Page 42

3. Adjust the stack of paper by jogging it on a flat surface.

Insert the documents vertically,

facing the user. When feeding 2 documents, the sheet containing the

address must always be loaded into

tray A.

4. Lock the lateral guides and the blue locking levers.

Automatic feeding

- Avoid mixing documents of different sizes and

weights (thickness) in the same tray.

- In case of documents particularly difficult to

handle (uneven, smooth, rough or sticky), use

half of the capacity of the feeder

4125603C/B

10/10/2003

Curled documents:

Some laser printers curl the paper excessively.

We recommend flattening the printed paper

manually before inserting it into the machine.

If the job consists of a single document, tray A

and tray B can be loaded : the second tray will

start automatically when the first one is empty.

Loading documents

41

Page 43

3.2 Loading documents in manual mode (tray A)

Before selecting manual mode, remove any document previously

loaded in tray A.

Check and adjust the lateral guides if necessary.

Insert a document or a set of documents manually into tray A to start

the cycle.

4125603C/B

10/10/2003

Maximum 5 documents of 20 lbs bond (or 3 documents

of 24 lbs bond paper) can be folded and inserted at one

time.

42

Loading documents

Page 44

3.3 Loading envelopes

1. Unlock the lever backward

(to the

position)

"locked" position : forward

"unlocked" position : backward

2. Adjust the lateral envelope guides

3.Place the envelopes in the

envelope tray. The flap should

be closed, facing downwards and

towards the back of the machine.

4125603C/B

10/10/2003

Maximum capacity of the feeder : 65 envelopes

Loading documents

43

Page 45

4. Adjust the lateral guides to the

size of the envelopes, without

squeezing them.

Bottom of the envelope

Top of the envelope

5. Lock the lever forward

44

Loading documents

(in position

It is not necessary to adjust the guides each time

envelopes are loaded, as long as the same type

of envelope is being used.

).

4125603C/B

10/10/2003

Page 46

3.4 Loading small inserts and reply envelopes (tray C)

Slide the lateral envelope guides apart.

Take the stack of small inserts

or reply envelopes and jog it

on a flat surface.

4125603C/B

10/10/2003

Tip the pressure pad backward and holding it there,

insert the stack of small inserts

or reply envelopes into the

tray.

In the case of envelopes, the

flap should be closed, facing

upwards and towards the

user.

Loading documents

45

Page 47

Release the pressure pad

and bring the guides together

against the small inserts or

reply envelopes, without

squeezing them.

4125603C/B

10/10/2003

46

Page 48

SECTION C: HELP AND ADVICE

1. HELP GUIDE ........................................................................ 49

1.1 Error messages ..................................................... 49

1.2 Symptoms and Remedies ...................................... 55

2. JAM CLEARING ................................................................... 60

2.1 Clearing the feeders (trays A and B) ....................... 60

2.2 Unjamming the document path ................................ 61

2.3 Unblocking path of small inserts (tray C) ................. 61

2.4 Clearing the envelope tray ...................................... 62

3. CLEANING ............................................................................63

3.1 Cleaning the rollers ................................................. 63

3.1.1 Internal rollers ................................................ 64

3.1.2 Envelope Tray Rollers .................................... 65

3.1.3 Tray C Rollers ................................................ 65

3.1.4 A/B Feeder Rollers ........................................ 66

3.2 Cleaning/Replacing moistening brushes ................. 67

3.3 Cleaning the covers of the machine ........................ 67

SPECIFICATIONS ...............................................69

47

4125603C/B

10/10/2003

Page 49

4125603C/B

10/10/2003

48

Page 50

1. HELP GUIDE

1.1 Error messages

Screen message

CHECK THE

ENVELOPE TRAY

CHECK THE

DOCUMENT PATH

CHECK THE

CONNECTION OF

THE PAPER TRAYS

Probable

Cause(s)

• No envelope in the

holder.

• No envelope fed up by

the machine.

• Envelope distorted.

• Envelope crumpled

during its progress

through the

machine.

• The document or

envelope did not go out

of the tray:

• document is outside

the specification or

distorted.

• Paper overload.

Paper tray connector

disconnected (Trays A

and B).

Remedy

Reinsert envelopes.

Adjust the guides on tray E,

check that the envelope

path is clear (open the machine if necessary) then

START

or

press

STOP

the menu.

Open the machine, remove

paper and envelopes from

areas 1 to 8 or open shutter

7 then close the machine to

return to the menu.

Reconnect the connector,

open the machine, remove

paper and envelopes from

areas 1 to 8 and close the

machine again. Switch it off,

then on again.

to return to

ESC

4125603C/B

10/10/2003

CLOSE THE

MACHINE

Machine open or not

properly closed.

Close the machine in order

to continue.

Help guide

49

Page 51

Screen message

Probable

Cause(s)

Remedy

DOUBLE

DOCUMENT

DETECTION IN

TRAYS A-B

DOUBLE

DOCUMENT

DETECTION IN

TRAY C

SWITCH

THE MACHINE

OFF AND THEN

ON AGAIN

• Stuck Documents

• Document outside

the specification

• Stuck Documents

• Document outside the

specification

A/B Feeder Socket

disconnected

• Release the blue locking

levers, take out the documents.

• Separate the documents

stuck together. Replace

them in the trays, lock the

levers and press

START

STOP

or

ESC

to return to the menu.

• Open the machine and

remove the document from

the machine. Check its

thickness

• Take out the stack from

Tray C and separate documents stuck together.

START

Press

STOP

or

to return

ESC

to the menu.

• Switch off the machine,

reconnect the socket

and switch on.

• Open the machine,

remove the documents

and envelopes from

areas 1 to 8 and close it

again.

4125603C/B

10/10/2003

OPEN THE

MACHINE AND

CLOSE IT AGAIN

50

Help guide

The machine was

unable to run through

its normal cycle.

• Open the machine,

remove the documents and

envelopes from areas 1 to 8

and close it again.

Page 52

Screen message

Probable

Cause(s)

Remedy

KEYBOARD FAULT

CHECK THE

REAR GUIDE

OF THE

ENVELOPE TRAY

CHECK THE

ENVELOPE PATH

When powered up,

one or more keys on

the keyboard are

depressed.

Envelope size does not

match the position of

the rear guide.

Double envelope

detected.

Envelope jammed in

the machine.

Check if one key is not

stuck.

• Adjust the rear guide of the

envelope tray (tray E)

according to the size of the

envelopes

• Open the machine and

check that the envelope

path is clear.

Open the machine and check

the envelope path

.

4125603C/B

10/10/2003

CHECK THE

WATER TANK

This message is only

a reminder.

Open the machine, check the

water level and fill up the

reservoir if necessary. (See

Chapter "Filling the

moistening tray")

Help guide

51

Page 53

Screen message

Probable

Cause(s)

Remedy

REMOVE THE

DOCUMENTS

FROM THE ENTRY

OF TRAYS A + B

NO DOCUMENT

IN THE TRAY(S)

CHECK THAT DO-

CUMENTS ARE

MOVING

CORRECTLY OUT

OF TRAYS A,B

REMOVE

DOCUMENTS

FROM TRAY A

Document(s) jammed

in the entry of the

feeder A (and/or B)

stopping the cycle.

The machine has not

detected a document

in any tray.

Document jammed in

entry A (and/or B),

preventing the cycle

from running its

course.

The documents in tray

A do not match the job

selected.

Open the entry of the

tray, using the lever,

remove the jammed

document and return

the lever to its locked

position then press

ESC

to return to the

or

START

STOP

menu.

Insert documents in

tray(s) A, B or C.

Open the entry of the

tray, using the lever,

remove the jammed

document and return

the lever to its locked

position then press

to return to the

or

ESC

START

STOP

menu.

Open the entry to tray

A using the lever.

Remove the documents and return the

lever to its locked po-

sition then press

or

to return to the

ESC

START

STOP

menu.

4125603C/B

10/10/2003

52

Help guide

Page 54

START

STOP

Screen message

Probable

Cause(s)

Remedy

DOUBLE

DETECTION,

CHECK

CONTENTS OF

ENVELOPE

CHECK PAPER

PATH OF TRAY C

CHECK THAT DO-

CUMENTS ARE

MOVING

CORRECTLY OUT

OF TRAY C

Stuck Documents

Document outside the

specification or detector

failure.

. Document outside the

specification or

distorted.

. Paper overload.

Document stopped in

insert path (entry C),

preventing the cycle from

completing.

Ensure the remaining documents are not stuck.

Check the contents of the

envelope. If the envelope

does not contain a double

document, remove the documents from the trays, jog

them and put them back in

the trays or switch off the

double detection, then press

or

to return to the

ESC

menu.

Apply the clearing

procedure described in the

chapter "Clearing small

insert path (tray C)"

. Check the document position in the tray C.

.Apply the clearing

procedures described in

the chapters " Clearing

small insert path (tray C)"

and "Clearing document

path".

4125603C/B

10/10/2003

CLOSE TRAY C

. Insert Path is open

. Tray C is open

or improperly closed.

Close path and tray then

START

ESC

to return to

STOP

or

press

the menu.

Help guide

53

Page 55

Screen message

OPEN

THEN CLOSE

THE MACHINE

Probable

Cause(s)

The machine was unable

to run through its normal

cycle.

Remedy

Open the machine, remove

the documents if any are

jammed inside and close

the machine again.

JOB DEFECT

Er3

Minor defect, it has

become impossible to

use this job.

Select another job from the

list.

4125603C/B

10/10/2003

54

Help guide

Page 56

1.2 Symptoms and remedies

Machine jammed

CAUSES

REMEDIES

1/ The authorization code

was not entered.

1/ Enter the

authorization code, see

“Installation and Startup” section.

Envelope not closed or improperly closed

CAUSES

1/ Inadequate moistening

REMEDIES

1/ See Remedy insufficient

moistening

2/ Wrong job selection

2/ Select "SEAL" in the line

"ENVELOPE"

3/ Document/small insert

non-compliant or incompatible

4/ Job non-compliant with

3/ Check document

compliance with job or check

machine specifications

4/ Check job content

documents used

5/ Documents incorrectly

inserted

5/. Check settings of lateral

guides for documents, small

inserts and envelopes . Clean

selection and folding rollers if

necessary, see chapter

"Cleaning the rollers"

4125603C/B

10/10/2003

The content of the letter is wet

CAUSES

1/ Wrong moistening

REMEDIES

1/ See section "Advanced

settings

Functions","Setting

envelope and special

document formats"

Help guide

55

Page 57

2/ Exit roller wet

Faulty fold

2/ Wipe the exit roller, see

section "Cleaning the

rollers"

CAUSES

1/ Side-guides incorrectly

locked or unlocked

REMEDIES

1/

Adjust the document, small

insert and envelope guides,

see "Loading the document"

2/ See the chapter

2/ Dirty rollers

"Cleaning the rollers"

3/ Lock the A/B Feeder

3/ Trays A and/or B

blue levers

incorrectly locked

Keyboard fault

CAUSE

1/ One or more keys stuck

REMEDY

1/ Check to see whether a

key is stuck

Rate slowdown and irregular functioning

CAUSES

1/ Side-guides too tight

against the paper

REMEDIES

1/ Adjust the document,

small insert or envelope

side-guides, see

"Loading the documents"

4125603C/B

10/10/2003

2/ Documents or small

inserts wrong size or not

straight and flat

3/ Dirty rollers

56

Help guide

2/ Check the specifications

or, if necessary, adjust/

correct the shape of the

documents.

3/ Clean the rollers, see

"Cleaning the rollers"

Page 58

4/ Document, small insert

or envelope trays

overloaded

4/ Load fewer documents in

the trays- see

specification

5/ Trays incorrectly locked

5/ Lock the trays

Address incorrectly positioned in the window

CAUSE

1/ Fold in wrong place

REMEDY

1/ Adjust the height of the

address in your job.

Shifted documents in trays A and B

CAUSES

1/

Dirty selection rollers

2/ Tray A or B lateral gui-

des too tight

REMEDIES

1/ See "Cleaning the rollers"

2/ Adjust the lateral guides,

see "Loading the documents"

3/ Trays A and/or B

incorrectly locked

3/ Lock the A/B Feeder blue

levers

4125603C/B

10/10/2003

Double Documents not detected

CAUSE

1/ Mixed documents of

REMEDY

1/ Process different types of

different types or out of

specification documents

2/ Double detection not

2/ Activate Double

activated

paper separately or see

specifications

detection, see "Other

advanced functions"

Help guide

57

Page 59

Documents ejected above/below envelope

CAUSE

1/ Envelopes incorrectly

loaded

2/ Envelope out of

specification

Insufficient moistening

CAUSE

1/ Moistening tray empty

2/ Wrong envelope selection,

open/closed

3/ Dirty moistening brushes

4/ Worn moistening brushes

REMEDY

1/ Correctly position the

envelopes in their tray, see

"Loading the envelopes"

2/ See specification

REMEDY

1/ Fill the moistening tray, see

"Installation and Start-up"

2/ Select "SEAL" in the line

"ENVELOPE"

3/ Clean the brushes, see

Section "Cleaning"

4/ Replace the moistening

brushes, see Section

"Cleaning"

4125603C/B

10/10/2003

5/ Envelope out of

specification

6/ Poor quality envelope

7/ Wrong moistening settings

Jamming

CAUSES

1/ Wrong job selected for

application

58

Help guide

5/ Check the specifications

6/

Check quality of seal by

sealing the envelope

manually

7/ See section "Advanced

Functions"

REMEDIES

1/ Select the job

corresponding to your

documents/application

Page 60

2/ Type or size of fold

unsuited to envelope

2/ See Specifications

3/ Documents or envelopes

outside the specifications

or distorted

4/ Dirty rollers

5/ Lateral guides incorrectly

adjusted and/or

incorrectly locked

6/ Too many documents

inserted simultaneously

7/ Envelopes incorrectly

loaded

8/ Small inserts incorrectly

loaded

9/ Faulty closure of small

insert path

3/ See Specifications

4/See Section "Cleaning the

rollers"

5/ See Section "Loading the

documents"

6/ See specifications

7/ Position the envelopes

correctly in the tray, see

section “Loading

Envelopes”

8/ Position the small inserts

correctly in the tray, see

section "Loading the

documents

9/ Close the small insert

path, see section

"Unblocking path of small

inserts"

4125603C/B

10/10/2003

10/ Unspecified error

10/ Switch the machine off;

clear the documents and

envelopes jammed inside

the machine; switch the

machine on again.

Help guide

59

Page 61

2. JAM CLEARING

2.1 Clearing the feeders (tray A and B)

Switch off the machine.

Tip the feeder forward

and unplug the connector.

Take out the feeder from

the base.

Remove the jammed

document through the

lower part of the feeder.

4125603C/B

10/10/2003

After unjamming, place the

feeder back on the base and

plug in the feeder connector.

60

Jam clearing

Page 62

2.2 Unjamming the document path

88

8

88

EE

E

EE

Open the machine, remove any

documents in areas 1 to 8 and

behind the shutter 7 (to release

the jammed documents, turn

blue flywheel or roller E).

77

7

77

2.3 Unblocking path of small inserts (tray C)

Pinch the opening control

located at the back of tray C:

it will then tip backward.

In the back part of the base,

squeeze the two plates

together and raise the

assembly. The small inserts

path will then become accessible. Remove the

jammed small inserts. Close

by pressing firmly in the center

until the tray locks into place.

Jam clearing

61

4125603C/B

10/10/2003

Page 63

2.4 Clearing the envelope tray

In case of Envelope jamming, perform the following procedure:

- Open the machine, take out the jammed envelope(s) through

the internal paper path.

- if some envelopes are still jammed, close the machine, remove

the envelope stack and take out the last envelope squeezed by

the rollers. For this last envelope, push up the separation plates

while pulling the envelope.

4125603C/B

10/10/2003

62

Jam clearing

Page 64

3. CLEANING

3.1 Cleaning the rollers

The cleaning of the rollers offers the following benefits:

- Improved paper take-up from the document, small insert and

envelope trays,

- Reduced risk of paper jams,

- Preserves the roller material.

To ensure optimal working of the machine, we recommend to

clean all rollers at the same time. This operation will take

approximately ten minutes (time required for the rollers to dry)

It is necessary to remove all the documents from all the trays

(including envelopes) before starting.

4125603C/B

10/10/2003

Cleaning

63

Page 65

3.1.1 Internal rollers

- Open the machine

- Use a cleaning product recommended by your vendor/

reseller and apply it with a lint-free cloth.

Wipe each rubber roller while turning it manually.

Rollers to

be cleaned

4125603C/B

10/10/2003

64

- Close the machine

Cleaning

Page 66

3.1.2 Envelope Tray Rollers

Use a cleaning product recommended by your vendor/reseller

and apply it with a lint-free cloth.

Wipe each rubber roller while turning it manually.

3.1.3 Tray C Rollers

Use a cleaning product recommended by your vendor/reseller

and apply it with a lint-free cloth. The rollers identified by a

yellow arrow (rear view with tray C lowered) are the ones to

be cleaned.

Wipe each rubber roller while turning it manually.

4125603C/B

10/10/2003

Cleaning

65

Page 67

3.1.4 A/B Feeder Rollers

- Power up the machine

- Select feed method "AUTO 1"

- Impregnate 25 mm of the lower part of a 24 lbs bond sheet of

paper with the cleaning product supplied by your service provider.

- Place the sheet of paper in the tray, with the strip impregnated

with the cleaning product at the bottom.

- While holding the sheet with your hand, press the start key

several times, so that the rollers can rub against the sheet. Then

release the sheet so it can engage in the machine, pressing the

START

STOP

key.

- If necessary, you can

repeat the operation

using a new sheet.

- To complete the

cleaning process,

insert two or three

clean, blank sheets in

the normal way, before

resuming normal

documentprocessing.

4125603C/B

10/10/2003

66

Cleaning

Page 68

3.2 Cleaning/Replacing moistening brushes

1. Open the machine

2. Remove the moistening tray by holding it with the

blue handles.

3. Remove the 3 brushes

4. Clean them with a thin trickle of water

5. If these brushes are worn, replace them with new

ones.

6. Put back the brushes in the tray

7. Fill the tray with water and make sure brushes

are properly impregnated

8. Insert the moistening tray in its location (with blue

handles frontwards)

9. Close the machine

3.3 Cleaning the casing of the machine

Clean with a damp cloth and a slightly soapy solu

tion.

4125603C/B

10/10/2003

Cleaning

67

Page 69

4125603C/B

10/10/2003

68

Page 70

SPECIFICATIONS

Feeder (Trays A and B)

Standard documents

A4 (210 x 297mm), LETTER US (8

LEGAL (8

Width 5

Height 3

Coated paper* 24 lbs to 32 lbs

Printed matter, listing paper,

photocopies, offset 20 lbs to 32 lbs

1/2"

x 14")

Other dimensions

In 1 mm increments

Paper quality

In automatic mode

24 lbs to 40 lbs

In manual mode (tray A)

in automatic and manual mode

5/8

1/8"

7/8

" to 8

" (142 to 226 mm)

to 14" (80 to 356 mm)

1/2"

x 11")

4125603C/B

10/10/2003

Capacity of trays

Standard paper 100 sheets weighing 20 lbs

In case of documents particularly difficult to handle (uneven, smooth,

rough or sticky), use half the capacity of the feeder

*perform a test.

Use of this paper requires frequent cleaning of all the

rollers.

Specifications

69

Page 71

Tray B

Size

Width 5

Height 3

5/8

1/8"

" to 8

7/8

" (142 to 226 mm)

to 14" (80 to 356 mm)

Paper quality

Coated paper* 24 lbs to 32 lbs

In automatic mode

Printed matter, listing paper,

photocopies, offset 20 lbs to 24 lbs

in automatic and manual mode

*perform a test.

Use of this paper requires frequent cleaning of all the

rollers.

The insert should always be positioned behind the main

document so that it cannot be seen through the window of

the envelope.

4125603C/B

10/10/2003

70

Specifications

Page 72

Tray C

(enclosed small format documents)

Size

Width 5

Height 3

5/8

1/8"

" to 8

to 5

7/8

" (142 to 226 mm)

7/8"

(80 to 150 mm)

Paper quality

Printed matter, listing paper,

Photocopy paper 24 lbs to 32 lbs

Offset paper, Bristol board,

*Coated paper 24 lbs to 65 lbs

*Coated paper

pre-folded 24 lbs to 45 lbs

Reply envelope 20 lbs to 24 lbs

With or without window

*perform a test.

Use of this paper requires frequent cleaning of the traction

rollers.

4125603C/B

10/10/2003

Capacity of tray 100 reply envelopes

200 inserts of 65 lbs

Specifications

71

Page 73

Envelope Tray

Size

Width 8

Height 3

6/8

1/2

" to 9

" to 4

1/2

" (224 mm to 240 mm)

7/8

" (90 mm to 125 mm)

Folding and insertion capacity

C fold Up to 5 sheets 20 lbs

Up to 3 sheets 24 lbs to 32 lbs

Double parallel fold Up to 3 sheets 20 lbs (hand feed

only)

Up to 2 sheets 24 lbs to 32 lbs

Insertion without folding 1 small insert

Maximal insertion capacity : Up to 5 sheets

72

Specifications

20 lbs to 65 lbs

20 lbs (hand feed)

4125603C/B

10/10/2003

Page 74

USER'S GUIDE

FOLDING

AND

INSERTING MACHINE

4125603C/B

10/10/2003

Page 75

4125603C/B

10/10/2003

4125603C/B - 10/10/2003

Loading...

Loading...