Page 1

FD 4400

High-Volume

EDITION

Page 2

Blank

Page 3

Burster Unpack and Assembly

Pump Installation

Controls

Length Set-up Procedure

Squaring Feed Table

Vacuum Feed Sheet Separator

Horizontal Separator Adjustment

Feeding Paper

Bleeder Valve (Vacuum Adjustment)

TROUBLESHOOTING

Page 4

Page 5

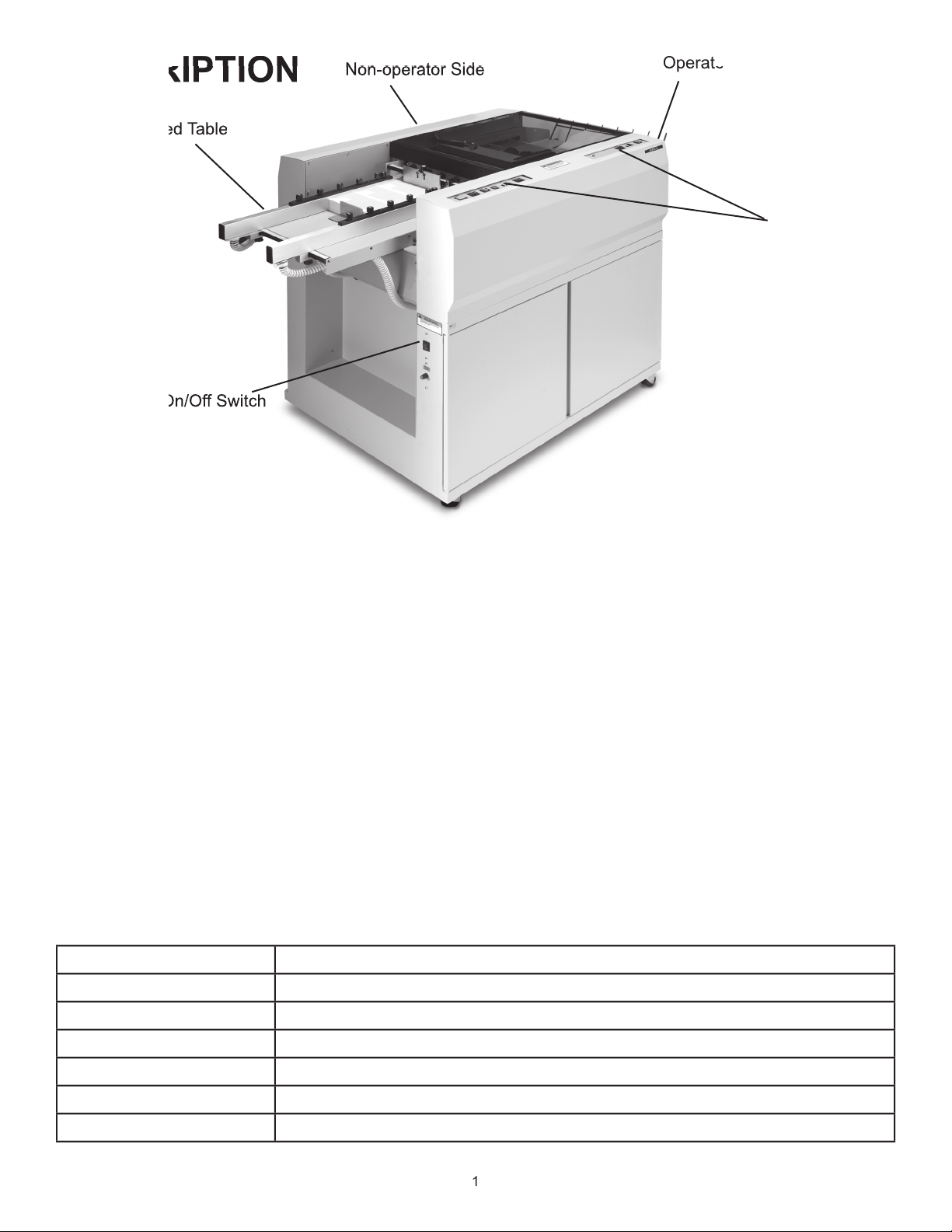

Air-Feed Table

The FD 4400 High-Volume Cut-Sheet Burster

A bottom-feed air system is utilized to allow operators to continually load forms to maximize effi ciency and

throughput.

The Conveyor

The o

Variable, up to 30,000/hour (11”)

42” H x 33” W x 64.5” - 72” L

Weight:

Approx. 500 lbs.

Page 6

Assembly

Lifting should not be attempted by less

than four people.

wooden pallet. Remove cardboard box.

4. Remove (4) foam blocks.

table.

9. Add 1/4-20 x 1 1/2 locating screws (included),

to underside of table, screwing up into burster

frame.

t

wo people should unpack and install

the base.

the rear and the vacuum is toward the front of the

the

to the right side of the base

th the mounting holes in the fl oor and

fans as shown in Fig. 3. Insert mounting bolts and

Vacuum

Page 7

Vacuum Hose

feed thru the

of

the burster).

feed up

of

the burster).

four

screws

A

table into place

the metal fi ngers under the blind roller and

4. Reset the table on infeed cover and align the holes

the cover

Page 8

-deck

screws

Page 9

Turns burster on and off

Jog Switch

Advances forms forward or backward at infeed and outfeed

4

4

2

Page 10

Length Set-up Procedure

Length Scale

Alignment Mark

2

to burst when perforation is just under tear points.

to position them at any location along tear bar. Tear

vertically along the length of the form. (Illust. 1)

Page 11

Vacuum Feed Sheet Separator

The sheet separator will need adjusting for the

weight of paper you are bursting. Ideal adjustment

will feed only one sheet without marking the paper

to the condition of the paper and the environmental

Adjustment Procedure

the sucker

wheel.

feature allows for quick and easy adjustment if

feeder table (Fig 14).

The rear scale will line up with the inside edge of the

4. Position the operator side guide so it is just touching

the sheet but not pushing it. The side guide must be

tuning the overall squareness.

Adjusting Knob

4

Table

Page 12

fl oat the bottom of the paper stack approximately

from the separator.

4. The vacuum advance knob is located on the side

4. Adjust separator assembly so that the plate is 1/16”

forward of the 12 o’clock position, measure from the

feed side of the plate.

Vacuum Advance

Air Blast Control

Air Blast

New Pic

Page 13

Turn the speed control to ½ or full speed. Place

your thumb on the back of the stack to keep paper

from feeding. Press the power button, the sucker

wheel will start to turn. Reduce the

thumb to feed only 3 to 4 sheets. Press your thumb

There is a bleeder valve on the vacuum pump, (Fig 20),

which allows for vacuum adjustment from completely

valve are half open for 20# stock, and closed for 80#

this can be opened slightly to “relieve” some of the

vacuum and stop the double feeding.

20

Tips

two stop buttons. Opening safety cover or lifting jam

thumbwheel is turned down.

4. Perforations vary in strength. If forms are bursting

Page 14

to a non-standard or defective form.

TROUBLE

Are the safety covers lowered?

turned on, plugged in, wall

wall outlet has power.

Are outfeed stacker nip rollers

to eliminate curl.

Page 15

forms

Tear bar in high position.

Tear points not adjusted properly

Tough form perforations.

Adjust tear points

Adjust tear points

Won’t burst properly.

Tear point not set correctly.

Tear bar not set correctly.

Adjust tear points

Adjust tear bar position

Tighten setscrew, call for service.

Adjust wheels left or right so they are

Page 16

Loading...

Loading...