Page 1

FD 4170

Cut Sheet Burster

4/2010

OPERATOR MANUAL

FIRST EDITION

Page 2

Page 3

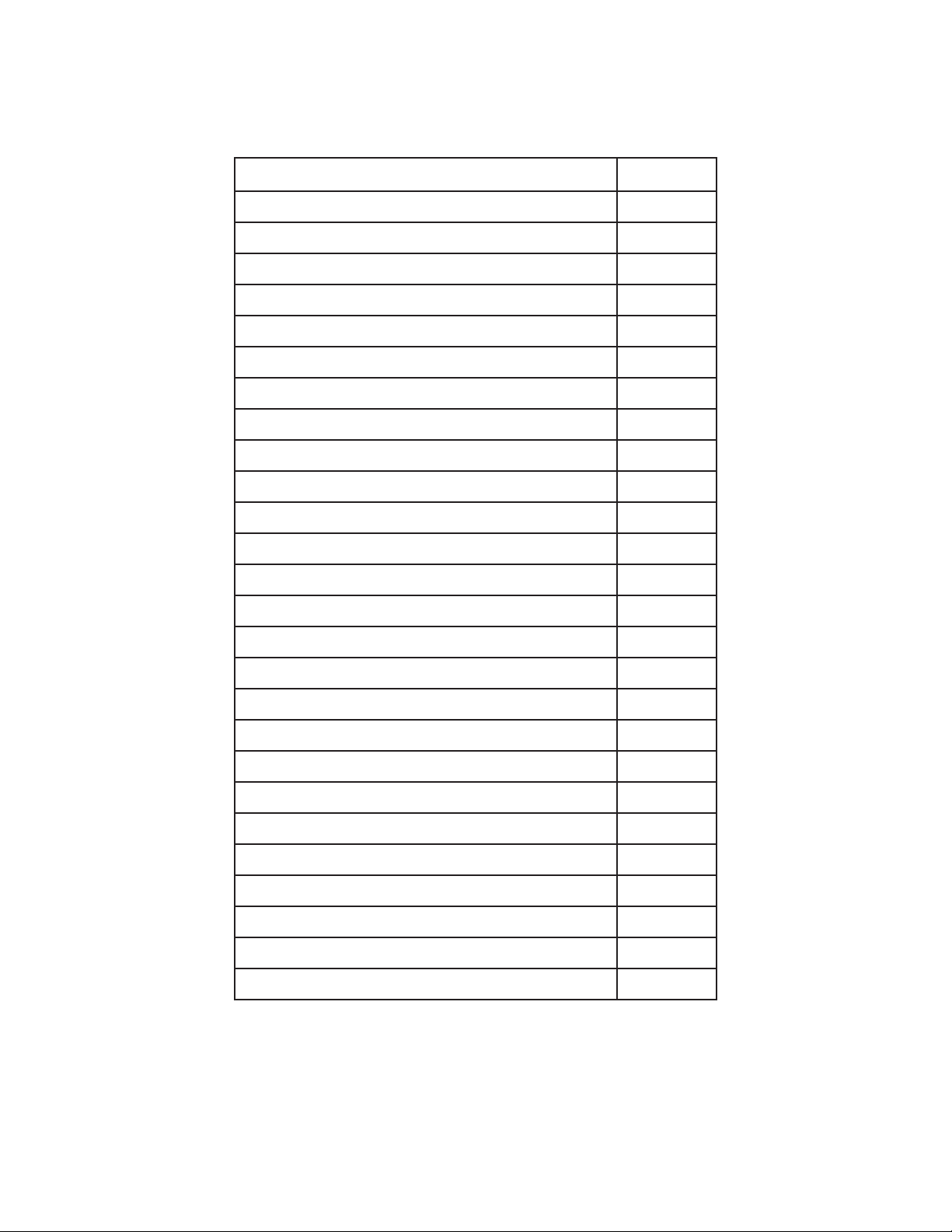

TABLE OF CONTENTS

TOPIC PAGE

SPECIFICATIONS 1

UNPACKING & SET-UP 1

INPUT SIDE 2

OUTPUT SIDE 3

OUTPUT CONVEYOR (OPTIONAL) 3

CONTROL PANEL 4

POWERING UP 4

ADJUSTING PROCESSING SPEED 4

LCD DISPLAYS FOR SET-UP & OPERATION 5

STEPS OF SET-UP & OPERATION 6

MANUAL SETTING 7

EXAMPLES OF CUT SIZES 7

LOADING PAPER 8

PREPARATION BEFORE OPERATION 9

COUNTER DISPLAY & RESET 10

PRESET MODE 10

PRESET TABLES 11

PRESET SELECTION SETTING 11

TO INPUT FIXED PRESET 12

TO CANCEL FIXED PRESET 12

TO INPUT FREE SIZE PRESET 13

TO CANCEL FREE SIZE PRESET 13

OPTIONAL CONVEYOR OPERATION 14

TROUBLE-SHOOTING 14

ERROR DISPLAY GUIDE 15

CLEARING ERROR MESSAGES 16 - 21

Page 4

Page 5

SPECIFICATIONS

■ Preparation Before Using Machine

1. Remove the setscrew from the right side of the

paper stacker, and insert the axis into the holes

of the machine frame on the both sides.

Then install the paper stacker with the setscrew

removed.

■ Preparation Before Using Machine

1. Remove the setscrew from the right side of the

paper stacker, and insert the axis into the holes

of the machine frame on the both sides.

Then install the paper stacker with the setscrew

removed.

2. Remove the thumb screws in the circles and

attach the columns on the right and left hooks,

and fasten thumb screws.

Speed: 5-level speed adjustment: 42, 64, 89, 114, 140 sheets/minute

Feed Tray Capacity: Up to 400 sheets

Paper Size: 5” - 17” H x 4” - 11” W

Paper must not have staples, clips, adhesive or holes.

Paper Weight: 13# bond - 110# index (58 - 175 gsm)

Min./Max. Burst Length: 2.5” - 9.9”

Dimensions: 32” L x 9” H x 16” D

Weight: 56 lbs.

Voltage: 120V, 60 Hz

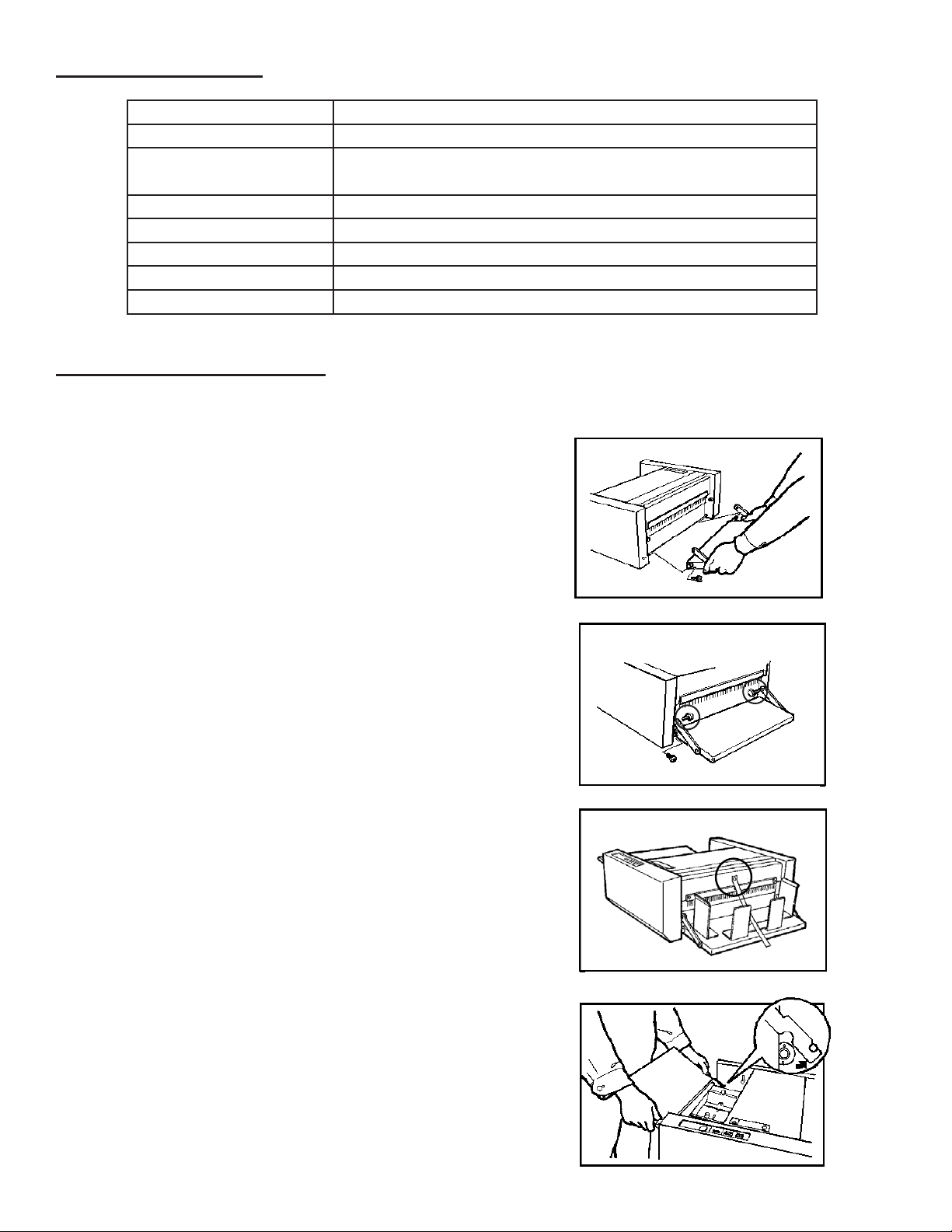

UNPACKING & SET-UP

Check package for shipping damage. If there is shipping damage, do not discard the box.

1. Facing the output side, remove the setscrew from the

right side of the paper stacker, and insert the axis into

the holes of the machine frame on both sides. Then

install the paper stacker with the setscrew removed.

2. Remove the thumb screws (in the circles) and attach

the columns on the right and left hooks, then fasten the

thumb screws.

3. Remove the screw (see circled area, right) and install

the paper holding plate attachment. Set the paper stopper and paper guides as shown in the picture.

4. Insert the edge of the support tray into the right and left

columns of the paper infeed tray. Then set the support

tray downward.

1

Page 6

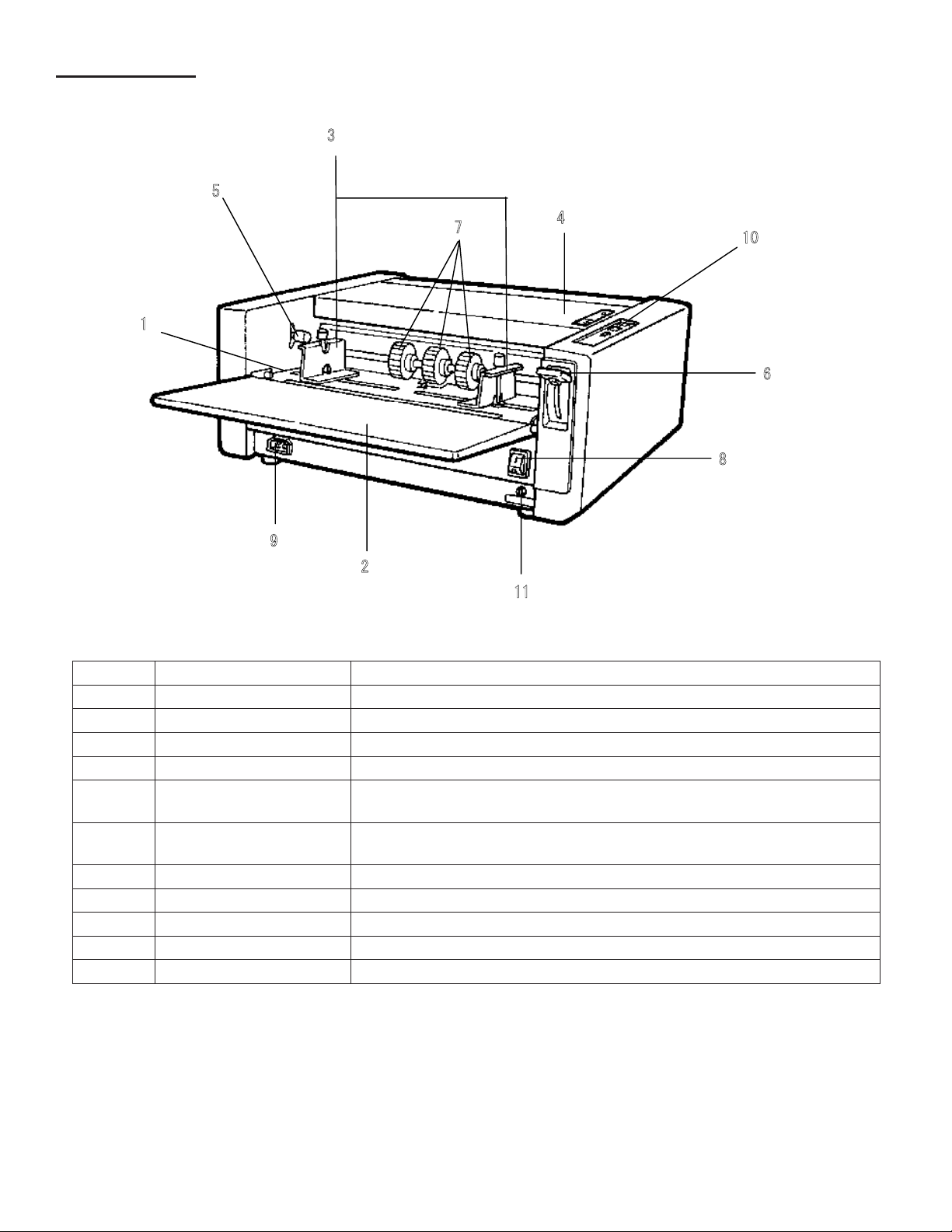

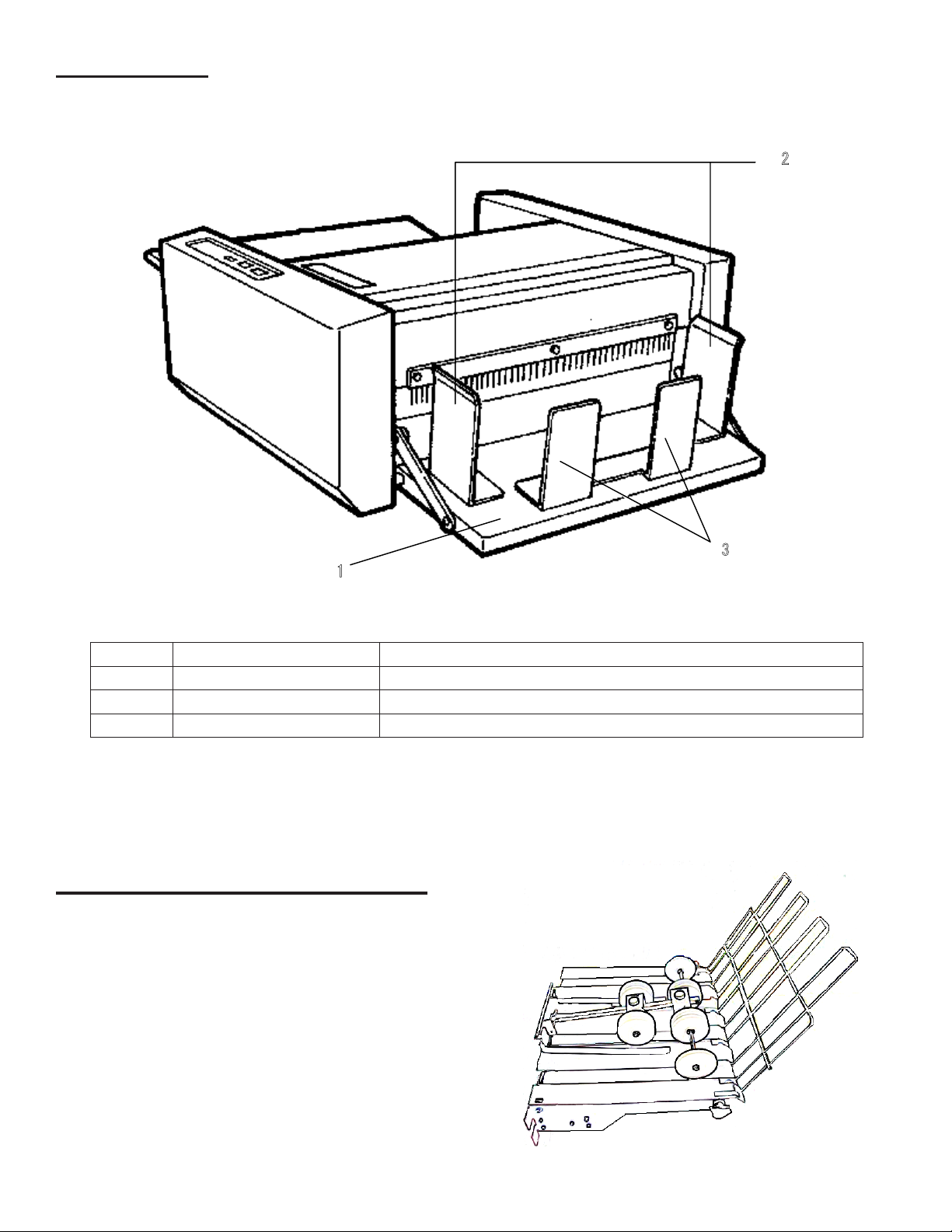

■ Part Names and Their Functions

● Appearance (front side)

INPUT SIDE

5

1

9

3

7

2

4

0

1

6

8

1

1

Number Description Function

1 Paper Feed Tray

2 Support Tray Open this tray prior to operating to support paper.

3 Paper Feed Guides Align and center paper according to width.

4 Safety Cover Must be closed during operation. Burster will not operate with cover open.

5 Paper Feed Pressure

Adjusting Lever

6 Paper Feed Tray

Up/Down Lever

7 Paper Feed Rubber Roller Feeds paper into the bursting area.

8 Power Switch Toggles between ON (I) and OFF (O).

9 Power Cord Inlet Insert power cord here.

10 Control Panel Refer to Control Panel on page 4.

11 Circuit Breaker Shuts down machine in case of overload.

Adjusts paper feed pressure according to paper thickness. Standard setting is “Normal Paper.”

Moves the paper feed tray up and down.

2

Page 7

● Appearance (exit side)

OUPUT SIDE

1

3

2

Number Description Function

1 Stacker Burst forms stack here upon exiting.

2 Paper Guide Should be set according to the width of the burst forms.

3 Paper Stopper Should be set according to the length of the burst forms.

OUTPUT CONVEYOR (optional)

With the optional Output Conveyor, burst forms can be

easily removed while the burster is still operating.

3

Page 8

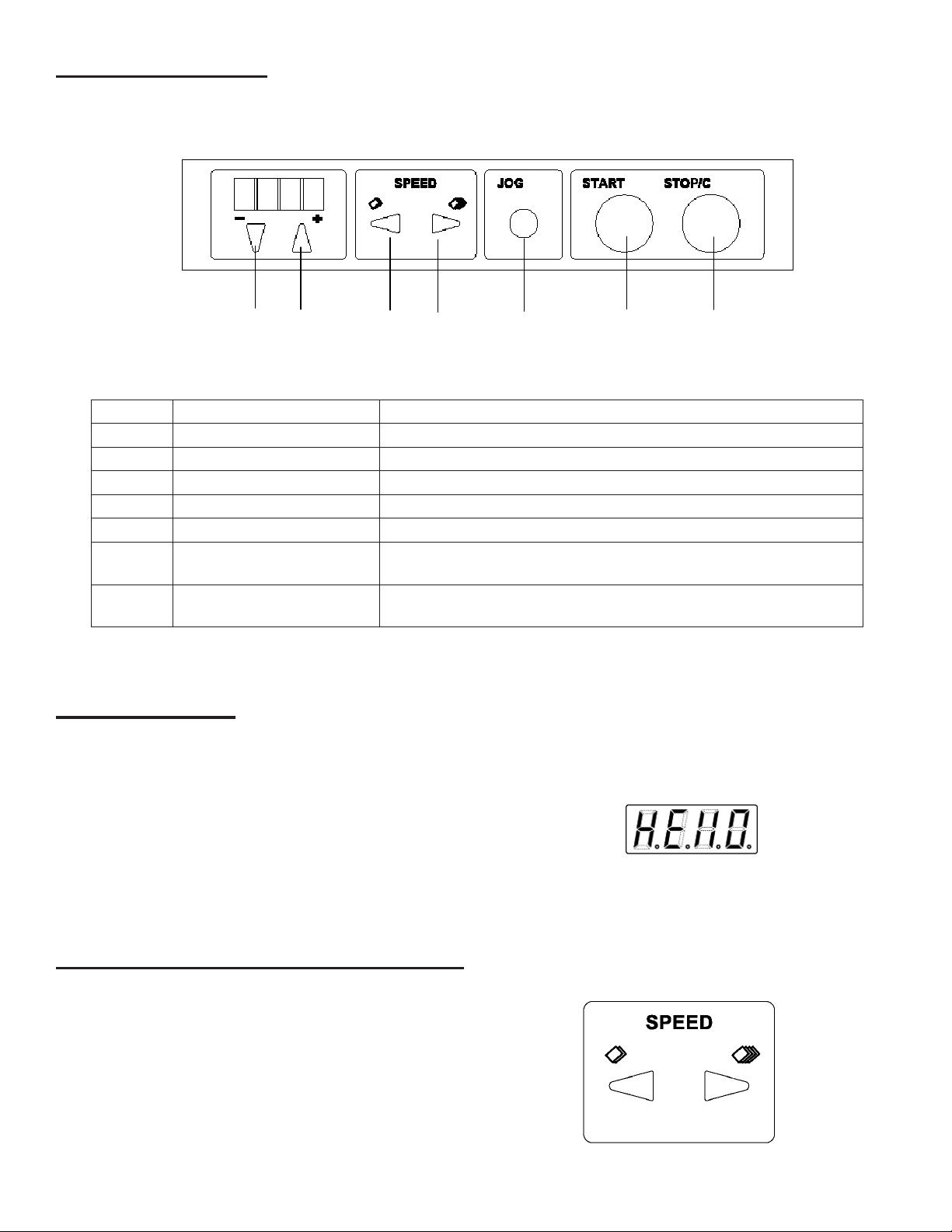

● Operation Panel

CONTROL PANEL

Number Description Function

1 “-” Button Use to decrease cut size on LCD display

2 “+” Button Use to increase cut size on LCD display

3 Decrease Speed Button Decreases processing speed, also used to select Presets

4 Increase Speed Button Increases processing speed, also used to select Presets

5 JOG Button Press this to process one sheet of paper

6 START Button Press to start operation. NOTE: This button is inoperative when an

7 STOP/C Button Press to stop operation. NOTE: When this button is pressed after a

1 2 3 4 5 6 7

error is displayed, or no paper is in the infeed tray.

paper jam is cleared, the indicator will be reset.

POWERING UP

1. Plug power cord into inlet on Infeed Side of burster.

Plug into wall outlet with appropriate power capacity.

2. Press power switch to the “I” position.

3. When the power is turned on, “HEll0” appears in the

LCD area of the control panel.

4. To turn off power, press switch to “O” position.

ADJUSTING PROCESSING SPEED

To adjust between speed levels, press either of the speed

buttons. Speeds include 42, 64, 89, 114, or 140 sheets per

minute.

To decrease speed, press the left SPEED button.

To increase speed, press the right SPEED button.

4

Page 9

LCD DISPLAYS FOR SET-UP AND OPERATION

Selection)

Selection)

Displays preset fixed cut size.

Selection)

Selection)

Displays preset fixed cut size.

Selection)

Displays preset cut size.

Selection)

Displays preset fixed cut size.

Selection)

Displays preset cut size.

Selection)

Displays preset fixed cut size.

Selection)

Displays preset cut size.

Registration)

Registration)

Displays fixed cut size for preset registration/cancel.

registration)

Displays fixed cut size for preset registration/cancel.

key)

Registration)

Displays fixed cut size for preset registration/cancel.

registration)

Registration)

Displays fixed cut size for preset registration/cancel.

registration)

Displays fixed cut size for preset registration/cancel.

Display for Start

Appears when the power is turned on.

Display for Stand-by Status

Appears when Manual Setting is selected.

Appears when Preset Selection Setting is chosen (Fixed Preset Selection).

Displays pre-set xed cut size.

Appears when Preset Selection Setting is chosen (Free Size Preset Selection).

Displays pre-set cut size.

Displays counter (appears by pressing the STOP/C button).

Display for Pre-Set Mode

Display for Bursting

Displays cut speed, Speed 1 - 5 (appears by pressing one of the SPEED buttons).

Displays independent operation of optional unit (appears by pressing the

STOP/C button and JOG button simultaneously).

Appears when preset registration/cancel is executed (Fixed Preset Registration).

Displays xed cut size for preset registration/cancel.

Appears when preset registration/cancel is executed (Free Preset Registration).

Displays xed cut size for preset registration/cancel.

Counter

Bursting speed: Speed 1 -5 (appears by pressing one of the SPEED buttons).

5

Page 10

STEPS OF SETUP AND OPERATION

■ Procedure of Use

(pg 7)

(p.19) Manual Setting: Standard mode inputting cut size on a case-by-case basis

(pg 11)

(p.24) Preset Selection Setting: Convenient function registering frequently used cut size

Manual Setting and Preset Selection Setting cannot be selected simultaneously.

When cut size is registered in Preset Mode (p.25), Preset Selection Setting is automatically

selected.

When you desire to return the setting to manual setting, cancel all preset registrations.

Refer to “■ Fixed Preset Registration/Cancel” or “■ Free Size Preset Registration/Cancel”

on pages 27 - 28 for canceling preset registration.

12-13

■ Preparation Before Using Machine (p.17)

Unpacking & Set-up (page 1)

■ Turning On the Power (p.18)

in advance and easily retrieving the registered cut size

(pg 10)

(page 4)

Register desired size in

Preset Mode. (p.25)

Manual Setting (p.19) Preset Selection Setting (p.24)

Preparation Before Operation (Setting paper stacker, Speed adjustment) (p.22)

(pg 7) (pg 11)

Loading Paper (page 8)

Setting Paper (p.21)

Start operation.

(pg 10)

(pages 1-4)

6

Page 11

● Setting example

MANUAL SETTING

Manual Setting is a standard mode in which each cut size is input individually for each project.

NOTE: When cut size is input as Preset Setting, “Preset Selection Setting” is automatically selected. “Manual Setting” and

“Preset Selection Setting” cannot be selected simultaneously. Cancel all preset inputs to change “Preset Selection Setting” to “Manual Setting.” Refer to Fixed Preset Input/Cancel or Free Size Preset Input/Cancel on pages 12-13 for more

information.

1. Turn on power. Machine is in stand-by mode. Previous cut size will be shown in LCD display.

2. Input cut size.

The value of each digit is increased by pressing the “+” button, decreased by pressing the “-” button.

Refer to the Cut Size Chart below. Abbreviate the value for cut size to the rst decimal place.

NOTE: Setting range is 0, 2.5-9.9 inches. When cut size is set to 0, the paper is fed without bursting.

3. Refer to Preparation Before Operation on page 9.

EXAMPLES OF CUT SIZES

When setting cut size, abbreviate to the rst decimal place.

Paper size Number of

cuts

8.5” x 11” Vertical

8.5” x 11” Horizontal

8.5” x 14” Vertical

11” x 17” Horizontal

2 8.5” x 5.5” 5.5

3 8.5” x 3.67” 3.6

4 8.5” x 2.75” 2.7

2 11” x 4.25" 4.2

3 11” x 2.83” 2.8

2 8.5” x 7.0” 7.0

3 8.5” x 4.67” 4.6

4 8.5” x 3.5” 3.5

5 8.5” x 2.8” 2.8

2 11” x 8.5” 8.5

3 11” x 5.67” 5.6

4 11” x 4.25” 4.2

5 11” x 3.4” 3.4

6 11” x 2.83” 2.8

Finished size (inch) Set value of cut size

(Truncate to first decimal

place)

7

Page 12

LOADING PAPER

1. Fan the sheets to loosen, which will decrease static

electricity and reduce the chance of a paper jam or

misfeed.

2. Lower the up/down lever on the paper feed tray and

place the paper on the tray. Adjust the paper feed

guides on both sides, then tighten the setscrews.

3. Adjust the paper feed pressure adjustment lever to the

thickness of the paper. Usually it is set to “NORMAL.”

If the paper cannot be fed, set the pressure adjust lever

to “HEAVY.”

If double feeding occurs, set the lever to “LIGHT.”

4. Raise the up/down lever.

8

Page 13

Ex.: Speed 1

PREPARATION BEFORE OPERATION

■ Preparation Before Operation

1.Set bursting speed.

Ex.: Speed 1

Setting range: Speed 1 - 5

Speed

Number of sheet processed

[sheet/min.]

(A4 vertical)

1 / JOG 40

2 60

3 84

4 107

5 130

2.Feed the paper by pressing the JOG key to

perform test cut.

* If test cut does not succeed, check the cut size

setting.

3.Adjust the paper stopper and the paper guides

wider by approx. 0.12 inch than burst paper with a

hand.

■ Preparation Before Operation

1.Set bursting speed.

Ex.: Speed 1

Setting range: Speed 1 - 5

Number of sheet processed

Ex.: Speed 1

Ex.: Speed 1

1. Set bursting speed

Number of sheets

Speed

1 / JOG 40

2 60

3 84

4 107

5 130

2. Feed paper by pressing the JOG button to perform a

test cut. If test cut is incorrect, check cut size setting.

processed

[sheet/min.]

(sheets per minute)

(A4 vertical)

Ex.: Speed 1

3. On output side, adjust paper stopper and paper guides

to approximately 0.12 inch wider than the burst paper.

4. Start operation by pressing the START button. Machine

automatically stops after processing.

5. The counter will appear in the LCD display during

processing. The value of the counter is from 0 - 9999.

After 9999, counter will return to 0.

9

Page 14

COUNTER DISPLAY AND RESET

Ex.: Speed 1

Counter Display

1. To display the number of cut sheets after a previous reset, press and hold the STOP/C button in stand-by mode.

2. The counter display disappears by releasing the STOP/C button.

Counter Reset

To reset the counter, press both the STOP/C button and

the “-” button and hold for three seconds or more.

PRESET MODE

Preset Mode is different from Standard Mode and can register cut size selected in Preset Selection Setting in advance.

Registering Preset Mode

1. Turn on power while pressing the STOP/C button on the control panel.

2. To select Preset # press either the speed up or down button. See Preset Table on the following page.

Speed up button: Increases the value of the Preset number.

Speed down button: Decreases the value of the Preset number.

3. Preset is saved by pressing the “+” button and cancelled by pressing the “-” button.

Preset Setting is not available at factory setting.

4. Save/Cancel information is stored by pressing the JOG button.

5. To quit Preset Mode, turn power off and on, or press the STOP/C button for more than 3 seconds. This will make the

Preset Setting available.

10

Page 15

PRESET TABLES

zFixed preset list

No. Display Paper size Number

of cuts

Finished size

(inch)

Cut size

0 “11-2” 2 8.5” x 5.5” 5.5

1 “11-3” 3 8.5” x 3.67” 3.6

2 “11-4”

8.5” x 11” Vertical

4 8.5” x 2.75” 2.7

3 “14-2” 2 8.5” x 7.0” 7.0

4 “14-3” 3 8.5” x 4.67” 4.6

5 “14-4” 4 8.5” x 3.5” 3.5

6 “14-5”

8.5” x 14” Vertical

5 8.5” x 2.8” 2.8

7 “17-2” 2 11” x 8.5” 8.5

8 “17-3” 3 11” x 5.67” 5.6

9 “17-4” 4 11” x 4.25” 4.2

10 “17-5” 5 11” x 3.4” 3.4

11 “17-6”

11” x 17” Vertical

6 11” x 2.83” 2.8

12 “PASS” ----- 0 ----- 0

zFixed preset list

No. Display Paper size Number

0 “11-2” 2 8.5” x 5.5” 5.5

1 “11-3” 3 8.5” x 3.67” 3.6

2 “11-4”

3 “14-2” 2 8.5” x 7.0” 7.0

4 “14-3” 3 8.5” x 4.67” 4.6

5 “14-4” 4 8.5” x 3.5” 3.5

6 “14-5”

7 “17-2” 2 11” x 8.5” 8.5

8 “17-3” 3 11” x 5.67” 5.6

9 “17-4” 4 11” x 4.25” 4.2

10 “17-5” 5 11” x 3.4” 3.4

11 “17-6”

12 “PASS” ----- 0 ----- 0

8.5” x 11” Vertical

8.5” x 14” Vertical

11” x 17” Vertical

of cuts

4 8.5” x 2.75” 2.7

5 8.5” x 2.8” 2.8

6 11” x 2.83” 2.8

Finished size

(inch)

Cut size

zFree size preset list

No. Display Cut size input range

13 “0. *.*”

14 “1. *.*”

15 “2. *.*”

16 “3. *.*”

17 “4. *.*”

18 “5. *.*”

19 “6. *.*”

20 “7. *.*”

21 “8. *.*”

22 “9. *.*”

0, 2.5 - 9.9 inches

When “0” is displayed, preset is cancelled.

PRESET SELECTION SETTING

Frequently used cut sizes can be stored into memory and recalled easily. Preset Selection Setting is available only in

Preset Mode.

NOTE: When cut size is already registered, Preset Selection Setting is automatically selected.

Manual Setting and Preset Selection Setting cannot be selected simultaneously.

Cancel all preset registrations in order to change to Manual Setting.

1. Turn on power. Machine will be in stand-by mode.

2. To choose Fixed Preset or Free Size Preset, use the

“+” and “-” buttons.

+ button increases the Preset #

- button decreases the Preset #

(Non-preset number is not displayed.)

When the machine is turned off and turned on again,

the previous setting is displayed.

3. Select Preset cut size and follow “Preparation Before

Operation” steps on page 9.

11

Page 16

TO INPUT FIXED PRESET

Lights up

* The display blinks while registration is in process. Do not turn off the power.

Lights up

* The display blinks while registration is in process. Do not turn off the power.

Lights up

Example: No. 0 8.5” x 11” Vertical 2-cut

1. Select preset No. 0 by pressing the speed up or speed down button.

* The display blinks before being accepted.

2. Press the “+” button to accept the preset.

To add more presets, repeat steps 1 and 2.

Blinking

3. Fixed/Free Size Preset Setting is saved by pressing the JOG button.

* The display blinks while being accepted. Do not turn off power during this stage.

Lights up

TO CANCEL FIXED PRESET

Example: No. 0 8.5” x 11” Vertical 2-cut

1. Select preset No. 0 by pressing the speed up or speed down button.

2. Press the “-” button to cancel the preset.

To cancel more presets, repeat steps 1 and 2.

3. Fixed/Free Size Preset Setting is cancelled all at once by pressing the JOG button.

* The display blinks while being accepted. Do not turn off power during this stage.

12

Page 17

TO INPUT FREE SIZE PRESET

Lights up

* The display blinks while registration is in process. Do not turn off the power.

Lights up

* The display blinks while registration is in process. Do not turn off the power.

* The display blinks while registration is in process. Do not turn off the power.

Example: No. 13 5.5”

1. Select preset No. 13 by pressing the speed up or speed down button.

2. Input the cut size by pressing the “+” and the “-” buttons.

To add more presets, repeat steps 1 and 2.

Lights up

3. Fixed/Free Size Preset Setting is saved by pressing the JOG button.

* The display blinks while being accepted. Do not turn off power during this stage.

TO CANCEL FREE SIZE PRESET

Example: No. 13

1. Select preset No. 13 by pressing the speed up or speed down button.

2. Set cut size to “0”.

To cancel more presets, repeat steps 1 and 2.

Blinking

3. Fixed/Free Size Preset Setting is cancelled all at once by pressing the JOG button.

* The display blinks while being accepted. Do not turn off power during this stage.

NOTES: When cut size is 2.5 - 9.9 inches: preset is available.

When cut size is 0: preset is cancelled.

To choose non-cut process (just feeding): choose “PASS” in xed preset.

13

Page 18

OPTIONAL CONVEYOR OPERATION

this unit even while the machine is in process of

bursting.

simultaneously.

The optional Output Conveyor can be installed in the paper outfeed of the FD 4170.

The conveyor can be operated independently by following these steps:

1. Turn on power to place burster in Stand-by mode.

2. Start operation by holding down the STOP/C button

and JOG button simultaneously.

LCD operation

3. Independent operation mode nishes by releasing the

JOG button.

TROUBLE-SHOOTING

TROUBLE REMEDY

Power will not turn on, even after pressing “I” side of

power switch

Machine does not operate or stops even after

pressing the START button

Check that power cable is properly connected to the

machine and an appropriate wall outlet

Check the LCD display for an error message. Refer

to Error Displays (on following pages), then complete

the action required.

14

Page 19

ERROR DISPLAY GUIDE

■ Error Display

* 2 error displays appear in turn.

After removing the jammed paper, press the STOP/C key

ess the STOP/C key to clear the

e machine and then turn it on after

Display Status and Solutions

[ FEEd ]→[ Err. ]

[ OPEn ]

[ SEt ]→[ PAPE. ]

Status: Paper jam in the paper feed part

Solutions: Check the paper feed tray and remove jammed paper.

to clear the error display.

Details:

Status: Safety cover is open.

Solutions: Close the safety cover.

Details:

Status: No paper is set.

Solutions: There is no paper in the paper feed tray. Place the paper

Refer to the How to deal with “[ FEEd. ]→[ Err. ]” on

16

page 32.

Refer to the How to deal with “[ OPEn ]” on page 33.

in the paper feed tray or press the STOP/C key.

16

[ PAPE. ]→[ LEFt ]

[ Cut ]→[ Err. ]

[ PASS ]→[ Err. ]

[ Err.1 ]

[ Err.5 ]

Others

Details:

Status: Paper remains inside the machine (cut part).

Solutions: Remove the paper and pr

Details:

Status: Cut error

Solutions: Remove the paper in the cut part or paper ejection part

Details:

Status: Paper jam in the paper ejection part

Solutions: Remove the paper in the cut part or paper ejection part

Details:

Status: Main motor lock (Paper remains in the cut part or paper

Solutions: Remove the paper and press the STOP/C key.

Details:

Status: Overload

Solutions: Turn off the power to the machine and leave it for over 3

Solutions: Turn off the power to th

Refer to the How to deal with “[ SEt ]→[ PAPE. ]” on

17

page 33.

error display.

Refer to the How to deal with “[ PAPE. ]→[ LEFt ]” on

18

page 34.

and, press the STOP/C key to clear the error display.

Refer to the How to deal with “[ Cut ]→[ Err. ]” on page

18

34.

and, press the STOP/C key to clear error display.

Refer to the How to deal with “[ PASS ]→[ Err. ]”

18

page 34.

ejection part.)

Refer to the How to deal with “[ Err.1 ]” on page 35.

hours.

a few seconds. If the same error message is displayed,

note the error content and contact our service person.

on

19

15

Page 20

CLEARING ERROR MESSAGES

■ Clearing Error and How to Deal with Trouble

How to deal with “[ FEEd. ]→[ Err. ]”

● Paper feed part

1. Remove the jammed paper at the entrance of

the machine.

WARNING

Be sure to remove the power plug

from the outlet when working near

movable parts due to paper jam and

so on.

2. Press the STOP/C key to clear the error display.

■ Clearing Error and How to Deal with Trouble

clear the error display.

How to deal with “[ FEEd. ]→[ Err. ]”

● Paper feed part

1. Remove the jammed paper at the entrance of

the machine.

Be sure to remove the power plug

from the outlet when working near

movable parts due to paper jam and

so on.

2. Press the STOP/C key to

● When misfeed has occurred:

1. Adjust the paper feed pressure adjusting lever.

* When double feed has occurred

→ Move the lever to “LIGHT”.

* When paper cannot be fed

→ Move the lever to “HEAVY”.

How to deal with [ OPEn ]

1. Close the safety cover.

* The error display disappears by closing the

safety cover.

WARNING

16

Page 21

How to deal with [ OPEn ]

1. Close the safety cover.

* The error display disappears by closing the

safety cover.

How to deal with [ SEt ]→[ PAPE. ]

ay up/down lever upwards.

1. Move the paper feed tray up/down lever

downwards to place the paper on the paper

feed tray.

2. Move the paper feed tr

* The error display disappears by setting the

paper or pressing the STOP/C key.

17

Page 22

How to deal with [ PAPE. ]→[ LEFt ]

How to deal with [ Cut ]→[ Err. ]

How to deal with[ PASS ]→[ Err. ]

1. Press the “O” side of the power switch to turn

off the power and remove the power plug from

the outlet.

WARNING

Be sure to remove the power plug

from the outlet when working near

movable parts due to paper jam and

so on.

2. Open the safety cover and remove the jammed

paper with tweezers.

* If the paper cannot be removed with tweezers,

do not try to remove it forcefully.

Follow the “● Removing paper using the JOG

key“ on page 36.

20

3. Close the safety cover. Connect the power

plug to the outlet and press the “I” side of the

power switch to turn on the power.

* If “[ PAPE. ]→[ LEFT ]” still appears even after

removing the paper, follow the “● Cleaning

sensor part“ on page 37.

21

18

Page 23

How to deal with [ Err.1 ]

* If an excessive load is applied to the machine

during operation due to paper jam and so on,

the breaker works for safety and the machine

stops.

If this happens, follow the procedures below.

power switch to turn off

ining inside the machine

there is no paper inside the machine

How to deal with [ Err.1 ]

If an excessive load is applied to the burster during operation due to paper jam, etc, the circuit breaker will

shut down the machine. If that happens, follow the instructions below.

1. Press the “O” side of the

the power.

Be sure to remove the power plug

from the outlet when working near

movable parts due to paper jam and

so on.

WARNING

2. Remove the paper rema

if there is any.

3. Confirm that

and press down the breaker button sticking out.

4. Press the “I” side of the power switch to turn on

the power. Now, the machine can restart.

If the burster still does not start, contact your Service

Technician.

19

Page 24

● Removing paper using the JOG key

1. Close the safety cover.

2. Remove the paper from the paper feed tray.

3. Pull out the paper with a hand while feeding

it by holding down the JOG key.

[ IMPORTANT ]

Note for operating the JOG key

NOTE: To use the JOG button, be sure to close the

safety cover. Press the JOG button while watching the

Be sure to close the safety cover.

jammed paper as the jam may get worse.

Press the JOG key while observing the status of

paper jam because paper jam sometimes gets

worse.

WARNING

The driving part contains driving

parts. Care should be taken when

working in it.

4. Set the paper again.

5. Clear the error display by pressing the STOP/C

key.

20

Page 25

● Cleaning sensor part

1. Press the “O” side of the power switch to turn off

the power and remove the power plug from the

outlet.

WARNING

Be sure to remove the power plug

from the outlet when working near

movable parts due to paper jam and

so on.

2. Open the safety cover. Spray the sensor part

Open the safety cover. Spray the sensor with canned

air, or gently clean with a cotton swab to remove paper

with air spray which is available in the market or

dust residue.

gently clean it with a cotton swab to remove paper

powder.

3. Close the safety cover. Insert the power plug

into the outlet and then press the “I” side of the

power switch to turn on the power.

Sensor part

If the burster still does not start, contact your Service

Technician.

21

Loading...

Loading...