Page 1

FD/FE 4040 4’ Conveyor

FD/FE 4060 6’ Conveyor

7/2015

OPERATOR MANUAL

Rev 2

Page 2

TABLE OF CONTENTS

SPECIFICATIONS 1

UNPACKING 1

ASSEMBLY 2

Mounting Adjustable Legs 2

Control Panel Module (Optional adjustment) 3

Mounting Accessories 4

MOUNTING OPTIONAL D1000 1K DRYER 8

SETUP & OPERATION 9 - 11

Page 3

SPECIFICATIONS

CONVEYOR

POWER FD: 105/120 VAC 50/60 HZ FE: 240 VAC 50/60 HZ

MAIN FUSE

SECONDARY FUSE FD 4040: 3 AMP FD 4040:

POWER CONSUMPTION

CONVEYOR @ MAX SPEED NO LOAD

CONVEYOR @ MAX SPEED NO LOAD W/ ONE

FAN

CONVEYOR @ MAX SPEED NO LOAD W/ BOTH

FANS

CONVEYOR @ MAX SPEED NO LOAD W/ BOTH

FANS AND DRYER

BELT SPEED VARIABLE 30 TO 350 FT PER MINUTE

FAN C.F.M. 170 C.F.M. EACH

HEIGHT ADJUSTABLE 28” TO 35” FLOOR TO TRANSPORT BELT

LENGTH 65”

WIDTH 14”

DROP TRAY

FD 4040: 10 AMP FE 4040: 7 AMP

FD 4060: 15 AMP FE 4060: 10 AMP

FD 4040: .56 AMP FE 4040:

FD 4060: FE 4060:

FD 4040: .76 AMP FE 4040:

FD 4060: FE 4060:

FD 4040: .96 AMP FE 4040:

FD 4060: FE 4060:

FD 4040: 6.19 AMP FE 4040:

FD 4060: FE 4060:

ADJUSTABLE 5.2’, 7.2”, 9.2” & 11.2” TRANSPORT BELT TO STACKING

SURFACE

WEIGHT 130 LBS (INCLUDES ACCESSORIES)

UNPACKING

INSPECT FOR SHIPPING DAMAGE, MISSING PARTS AND PROPER OPERATION. REPORT SHIPPING DAMAGE

TO THE CARRIER IMMEDIATELY. SAVE THE SHIPPING CARTONS AND MATERIALS IN CASE THEY ARE NEEDED

TO FILE A SHIPPING CLAIM OR FOR FUTURE SHIPPING USE.

1. Check the outside of the carton for visible damage. Make note of any damage on the carrier’s receiving report.

2. Open the carton.

3. Carefully remove the carton contents and inspect the unit for paint and structural damage.

4. Carefully check for missing parts. If damage or missing parts are noted, contact your Sales Representative immediately. Save cartons and packing materials. They may be required to substantiate a damage claim or to return a damaged

unit.

1

Page 4

ASSEMBLY

Mounting Adjustable Legs

Install 2 swivel casters on each of the leg assemblies (Fig 1 item A). Secure casters with hex nuts.

1.

To pre-adjust leg assemblies to proper length, measure the distance from the oor, to the exit surface of the delivery

2.

device (i.e. printer). Loosen the black hand wheels (Fig 1 item B) and adjust leg assembly until overall length,

including casters, is about 7 inches less than the measurement you just obtained. Tighten hand wheels and repeat

procedure for other leg assembly.

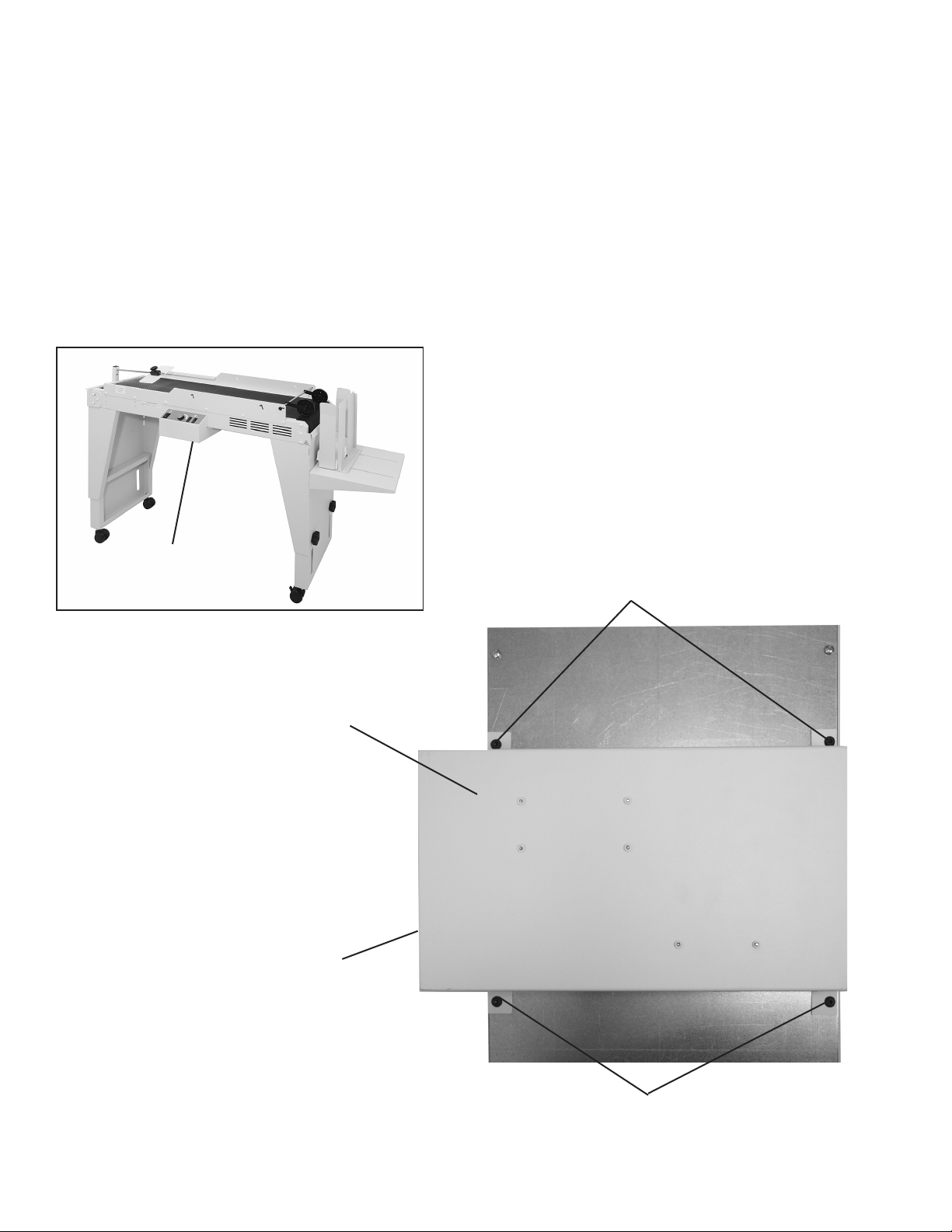

With conveyor laying upside down, install leg assembly. Install two Allen screws to the outer edge of the conveyor

3.

(Fig 2 item C) do not tighten all the way, leave enough space to slide the keyhole, in the top of the leg assembly,

into position (Fig 3 item D). Insert two screws into the two remaining holes, tighten when all screws are in position

(Fig 4). Allen screws are provided in accessory bag.

Assembly Tip (Fig 4): If you have trouble aligning the screw holes in the leg assemblies with the conveyor holes;

loosen the 10 Phillips head screws that secure the bottom plate (Fig 4), to allow the conveyor side frames to ex.

When nished securing leg assemblies to conveyor, be sure to re-tighten these 10 Phillips head screws.

With the legs securely fastened, carefully turn conveyor upright. Note: If conveyor operation direction needs to be

4.

changed, do so before turning upright - see Control Panel Module Optional Adjustment Pg 3.

CAUTION! Two (2) people are required for lifting and turning conveyor.

C

Fig 1

Fig 3

Fig 2

A

D

B

To help align holes, when attaching leg

assemblies, loosen screws that secure

bottom plate.

Fig 4

2

Page 5

Control Panel Module (Optional adjustment)

If the direction of conveyor needs to be changed, a simple adjustment to the control panel module can be made while

the conveyor is in the upside down position.

Remove the four Phillips head screws that hold the control panel module in place (Fig 5 items A).

1.

Rotate the control panel 180 degrees counterclockwise and reattach with the four screws. No electrical connection

2.

adjustments are needed.

With the legs securely fastened and control panel module mounted properly, carefully turn conveyor upright.

3.

CAUTION! Two (2) people are required for lifting and turning conveyor.

Control Panel Module

Conveyor shown going left to right

Control Panel Module

Front of control panel

module

A

Fig 5

A

3

Page 6

Mounting Accessories

Envelope knockdown bracket assembly (Fig 6): To install, temporarily mount the envelope knockdown post (Fig 6

1

item A) in the down position, as shown below. Use thumb screw and securing plate (Fig 6 items B & C) to attach the

post to the bracket.

B

Fig 6

Mount envelope knockdown assembly onto the in-feed of the conveyor (Fig 7 item D) using 6 each white Phillips

2.

head machine screws provided in accessory bag. NOTE: The suction fans are located at the in-feed of the

conveyor. Loosen knockdown post thumb screw (Fig 6 item B) and rotate post 90 degrees into an upright position

(Fig 7).

Mount the outfeed bracket (Fig 7 item E) to the opposite end of the conveyor using the 4 white phillips head

3.

machine screws. Do not completely tighten screws. Continue to step 4 for bracket adjustment.

D

fans

A

C

E

Fig 7

In-feed

Mounting Screws

Out-feed

4

Page 7

CAUTION! This adjustment is necessary to avoid belt damage and eliminate a potential pinch point for safety.

4.

Insert supplied card stock spacer (Fig 8a item A) between the belt and the out-feed bracket to set the spacing

between the bracket and the belt. Move the bracket in or out until a slight drag is felt on the card stock (Fig 8b

item B) and then tighten mounting screws (Fig 8c) . Remove card stock spacer and rotate belt and roller by hand

(Fig 8d) to ensure clearance at all points on the roller and belt. Readjust if belt contacts bracket.

Fig 8a

Mounting screws

Fig 8c

A

Fig 8b

Ensure clearance between belt and bracket

Fig 8d

B

5

Page 8

Mount the side rails to either side of the conveyor with 6 each white Phillips head machine screws provided in

5.

accessory bag. The taller side goes on the out-feed end (Fig 9 items A & B). Note: If the optional D1000 1K dryer

is going to be attached leave the side rail screws loose for mounting the dryer.

B

A

Fig 9

A

Install threaded end of envelope knock down

6.

rod (Fig 10 item B) into hole of envelope knock

B

down post (Fig 10 item C). Install 1 white Phillips

head screw through post and into threaded

screw

rod. Install envelope knock down guide (Fig 10

item A) onto rod, as shown (Fig 10), and secure

using thumb screw.

C

Warning! Be sure the bottom of the envelope

knock down guide does not rub against the belt

or damage to the belt may result.

Install exit wheel assembly (Fig 11 item A)

7.

between rails of conveyor; align with mounting

holes and secure in place with 2 black

thumbscrews provided. The wheels can be

repositioned anywhere along the rod to meet

your specic needs.

Fig 10

A

Fig 11

6

Page 9

Install adjustable height drop tray (Fig 12 item A) into slots in leg assembly (Fig 11 item B).

8.

Install envelope stop plate (Fig 12 item C) onto drop tray using 2 hand wheel nuts provided (Fig 12 item D).

9.

Place envelope side guides (Fig 12 item E), magnetically mounted, onto drop tray.

10.

E

C

C

B

Fig 12

Attach the mounting bracket (Fig 13 item A) to the conveyor. This bracket is used to secure the conveyor to the

11.

A

table that the delivery device (i.e. printer) sits on. See mounting details supplied with the bracket. Do not attach

bracket to table until correct conveyor height has been determined (see page 9).

A

D

Fig 13

7

Page 10

MOUNTING OPTIONAL D1000 1K DRYER

1. Slide mounting rods through holes in dryer (Fig 14a item A).

2. Loosen side rail screws.

3. Loosen side rails (Fig 9 items A & B pg 6), place dryer and rods between rails of conveyor (Fig 14a item A), align

with mounting slots in high or low position (Fig 14b item B) and secure in place with the 4 white Phillips head

screws supplied. Note: Mounting rods, screws and electric components supplied in dryer box.

4. Connect the dryer’s power cord to the receptacle on the back of the dryer (Fig 15a item C) and on the back of the

control panel module (Fig 15b item D). Note: The dryer receptacle is marked on the back of the control panel

module.

CAUTION! Do NOT connect dryer to a separate power source or dryer damage may result. Connect dryer power

cord only to outlet on conveyor, as shown below.

Fig 14a

Fig 15a

Mounting Rods

C

A

Fig 14b

Fig 15b

B

D

8

Page 11

SETUP & OPERATION

Place completed conveyor assembly behind delivery device (i.e. printer) with fans centered on exit end of delivery

1.

device. Attach conveyor mounting bracket to table that the device is sitting on for stability using lag bolts provided,

see mounting details supplied with bracket.

The top of the front guide rail (Fig 16a item A), should be positioned about 1 inch below the exit surface of the

2.

delivery device (i.e. printer). If height adjustment is necessary, have another person support the weight of the

conveyor while you carefully loosen the black hand wheels (Fig 1 item B) and adjust the height of the conveyor leg

assemblies. Retighten to secure in place.

CAUTION! Be careful when performing this procedure. The conveyor is heavy and can cause injury if not properly

supported.

A

Fig 16a - Right angle printer setup Fig 16b - Optional straight-on printer setup

Optional Slide Bar for slow printing speed

If the printer is set at a slow speed, the slide bar (Fig 17a item A) may be needed to feed the envelope onto the

conveyor. Set the slide bar so that the top 1/4 of the envelope rides on the bar (Fig 17b item B). The envelope should

slide across the bar, hit the deector and land on the conveyor in the correct position. To ne tune, move the slide bar

backwards or forwards and adjust the conveyor speed.

A

B

Fig 17a

Fig 17b

9

Page 12

Connect conveyor power cord to a grounded 105/120 VAC, 50/60 Hz electrical source.

3.

Set up delivery device (i.e. printer) for desired media.

4.

The setup of the conveyor (which includes drop tray height, stop plate position, envelope knock down position, belt

5.

speed, and fan combination) is in direct relation to type, size and speed of media being delivered to the conveyor.

Send a test piece of media through delivery device (i.e. printer) to adjust proper distance of envelope knockdown

guide away from exit end of delivery device.

Start (power on) conveyor. Send a few test pieces of media through delivery device. Set conveyor belt speed to

obtain desired gap between pieces of media. Fans can be used to control media movement once it drops onto the

conveyor belt. Set fan controls as desired.

Note: At very low conveyor transport speed settings the transport belt may stall easily, especially when the fans

and/or dryer are being used. Increase the transport speed setting to prevent this condition.

Control Panel

Power Toggle Switch

Speed Control

Fan Toggle Switches

10

Page 13

6. To raise or lower drop tray (Fig 18 item A), insert hooks on drop tray into slots (Fig 18 item B) in leg assembly at

desired height.

7. To move envelope stop plate position (Fig 18 item C), loosen 2 hand wheel nuts (Fig 12 item D), and reposition

stop plate to accommodate the media, then tighten hand wheel nuts.

8. Position envelope side guides (Fig 18 item E), magnetically mounted, at desired location.

9. Send several test pieces of media through delivery device and conveyor to ensure correct set up.

Make adjustments if necessary.

10. The conveyor is now ready for operation.

E

C

B

Fig 18

A

11

Page 14

Loading...

Loading...