Page 1

FORMAX

FD 332

Document Folder

â

Operator Manual

First Edition

1

Page 2

2

Page 3

Introduction

Thank you very much for purchasing the FD 332 Document Folder. This machine

enables users to achieve greater efficiency at work by releasing them from

paper-folding that has manually been performed in the past. Please read the

Operation Manual carefully before using this machine.

Contents

Introduction .............................................................................. 1

Contents ................................................................................... 1

(1) Specifications ....................................................................... 2

(2) Accessories .......................................................................... 3

(3) Description of Parts ............................................................... 4

(4) Designation and Functions of Operation Panel........................... 5

(5) Preparation .......................................................................... 6

(6) Operation Procedure.............................................................. 7

Switching the Power on ......................................................... 7

Setting Fold Plate Positions .................................................... 7

Test Folding ......................................................................... 8

Fold Feed Angle/Skew Adjustment .......................................... 8

Continuous Folding ............................................................... 8

Batch Counting .................................................................... 9

Clearing a Paper Jam .......................................................... 10

Cross Folding ..................................................................... 10

Fine Adjustments for Table 1................................................ 12

Fine Adjustments for Table 2................................................ 13

(7) Daily maintenance .............................................................. 14

(8) Trouble shooting ................................................................. 15

3

Page 4

(1) Specifications

Model FD332

Paper size

Paper quality

Fold type

Fold

dimensions

Paper feed

system

Max. stacking

capacity

Folding speed 10500 sheets/hr (11” Half Fold)

3.5” x 5.0” to 11” x 17”

Smaller size is for single fold only.

High-quality paper, high-quality paper for stencil printing,

medium-quality paper

Single, Letter, Zigzag, Double, Parallel Fold-out

Other special folding twice.

Maximum

Table 1: 13”

Table 2: 9 ½”

Minimum

Table 1: 2”

Table 2: 1 ½”

Three-roller paper feed system

500 sheets 20#

Operation

method

Available

functions

Power

Consumption

Pressing digital keys

Fold skew adjustment, paper jam detection, four digit counter, auxiliary

paper guide for cross folding and Jam map indication

75 W

4

Page 5

Additional

functions:

Skew adjustment memory, paper jam detector, four-digit counter with

addition/subtraction modes, and automatic paper size detector

Auxiliary paper guide for cross fold

A perforator can be installed (optional)

Dimensions

Net weight 80lb

W 29 ½” x D 21 ½” x H 21” (during use)

W 22” x D 21 ½” x H 21” (during storage)

(2) Accessories

Make sure that the following accessories are included in the package after opening

it. Contact your sales agency immediately if there are missing accessories.

Accessories Qty Illustration

Tab le 1

1

Table 2 1

Power cable 1

Paper support guides

(right and left)

Machine cover 1

Operation Manual 1

2

5

Page 6

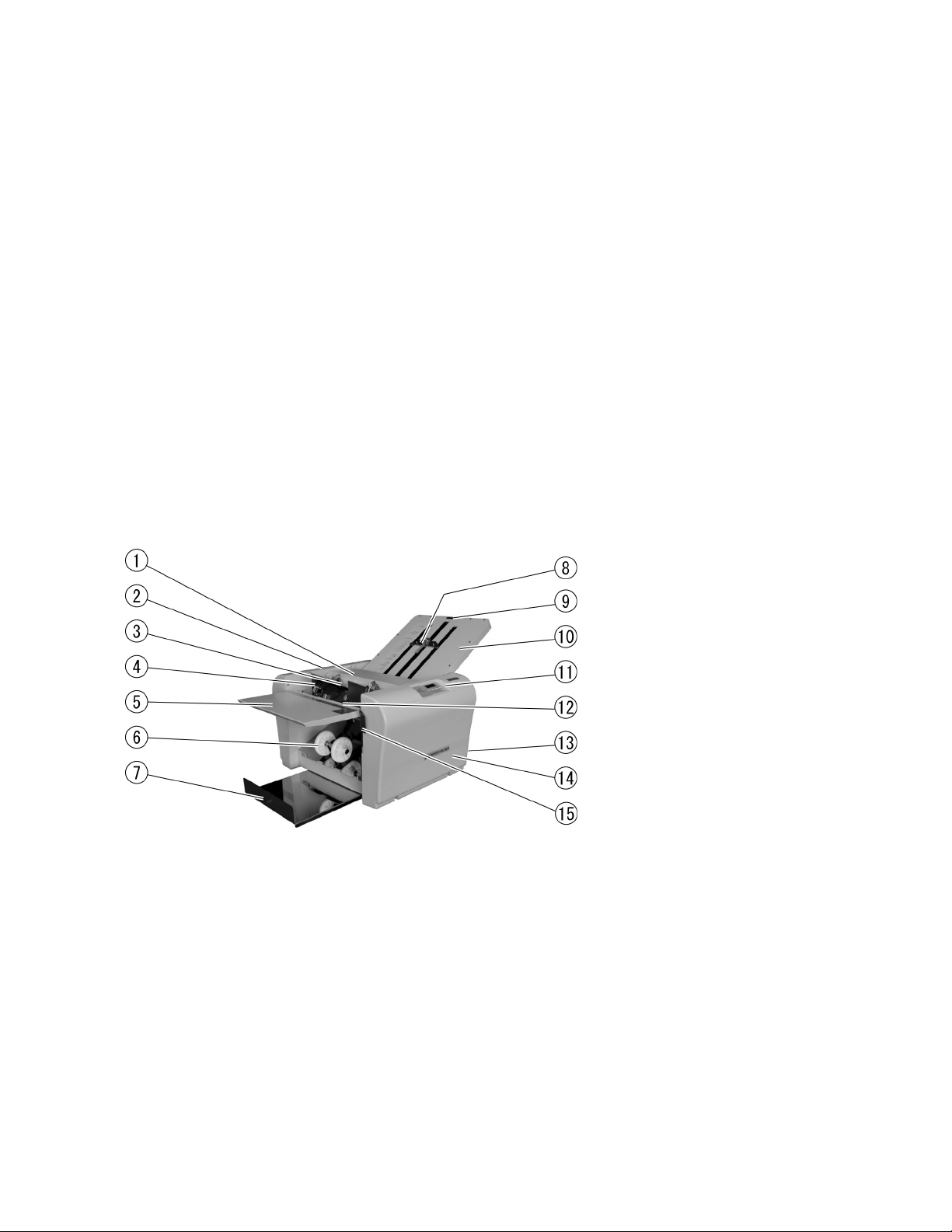

(3) Description of Parts

6

Page 7

Number Name Number Name

1 Roller cover 10 Table 1

2 Left side cover 11 Control panel

3 Paper feed roller 12 Paper feed table

4 Paper guide 13 Table 2

5 Auxiliary feed table 14 Right side cover

6 Paper eject roller 15 Paper feed table lever

7 Paper stacking table 16 Power source switch

8 Stopper plate 17 Inlet

9 Fold position adjustment knob 18 Circuit breaker

(4)Designation and Functions of Operation Panel

7

Page 8

No. Designation/Indication Function

1

2

3

4

5

6

Test key Test folding of two sheets is performed.

Start/Stop key

Clear/Reset key

Numerical key Used for batch counting.

Counter The number of sheets folded.

Check lamp

Operation starts and if pushed again,

The machine stops.

Clearing the indication of the counter

/ resetting an error.

Comes on when paper stock runs short, or indicates a

place where paper feed trouble occurs.

8

Page 9

(5)Preparation

Install Table 1 and 2:

Insert Table 1 on the studs indicated by (a) and (b) as shown

in the picture to the right.

Insert Table 2 on the studs indicated by (c) and (d) as shown

in the picture to the right.

Note:

When setting Table 1, be sure to put its

stopper plate at the center position.

Caution:

Be sure that both Table 1 and 2 properly fit in the positions

of the studs (a), (b), (c) and (d). If they are improperly set,

it may cause an incorrect collation, or the tables may fall out of

the machine.

Setting Paper:

Lift the auxiliary table and pull the paper

stacking table out.

Raise the paper feed table lever.

9

Page 10

Set the paper guide for the appropriate paper size.

Neatly stack the paper on the feed table with its

printed side facing up. (its printed side down in case of fold-out)

Lower the paper feed table lever to set the paper.

Note:

If the paper does not come in contact with the paper feed roller, remove and reinsert.

Curled or wrinkled paper, may cause trouble. Correct it before use.

In case of printed paper, use it only after the ink is dry, otherwise the paper feed rubber

roller, paper separator, fold roller, and other parts of the unit will be stained with ink,

causing trouble.

Setting the paper discharge roller:

The discharge roller should be moved to the proper position

that suits the paper size.

Note:

Refer to the “Roller position indication” label. If ejection

is not performed properly, set to a different position.

Example:

Set the roller to position one when using 8 ½” x 11” paper.

(6)Operation Procedure

10

Roller position indication label

Page 11

Switching the Power on:

Insert the power plug into the outlet.

Set the POWER to ON position.

Note:

Remove the power plug from the outlet after use.

Setting Fold Plate Table Position

Pull the half-nut lever to move the stopper plate to the

desired position on table 1 and 2. Align the arrow on the

stopper plate with the desired fold marks on the tables and

release the half-nut and the stopper plate will be locked in

position.

Test Folding

Press the Test key to feed two sheets of paper.

Check if the paper has been folded correctly by

examining the second of the two folded sheets.

If the fold position is not correct, refer to

“Fine Adjustments” pages 11 & 12

Half nut lever

11

Page 12

Fold Feed Angle/Skew Adjustment:

Turn the feed angle adjustment knob to the right

if the lower side of the folded paper slants to the right.

Turn the knob to the left of the lower side slants to

the left.

Note:

In cases other than single fold, put the folded

paper face down on Table 1 to make a feed angle

adjustment.

Continuous Folding:

Press the Start/Stop key. The machine starts to

fold the sheets continuously.

Press the Start/Stop again, while the machine

is in operation, to stop feeding.

Batch Counting:

As a sheet is folded the number indicated decreases

by one.

12

Page 13

Press the appropriate numerical key to select the

number of forms to be folded.

Example: press the number “10” key twice to select

twenty.

Note:

The batch counting number is cancelled

when the POWER is set to OFF.

Under the following conditions the machine will automatically stop feeding:

(Press the Clear/Reset key to reset after the error has been corrected)

Numerical Key

Conditions

1. When the Start/Stop key is pressed while there is no stock.

2. When the Start/Stop key is pressed while the paper feed lever is at

the upper position.

3. When the stock runs short while folding in the Batch Counting Mode.

1. When paper feed slip occurs

2. When paper jam occurs at Table 1 and Table 2

1. When paper stack table is full.

2. When paper jam occurs at the paper discharge.

Indication on Control panel

Clearing a Paper Jam:

13

Page 14

Should a paper jam occur, set the POWER to the OFF position immediately and remove the

jammed sheets. When the jammed paper is stuck around the fold roller or other parts, it can be

easily removed by detaching the Table 1 and 2 from the unit.

Note:

When the roller cover is opened, the machine will stop operation instantly.

Cross Folding:

Cross folding refers to performing the double

parallel, letter, or other types of folds for the

sheets of paper folded using the single fold

method.

Example:

11”x 17” folded in half and then letter folded to fit

into a standard # 10 envelope.

14

Page 15

Note:

The maximum weight of paper that can be used for

cross folding is 28#.

This requirement, however, varies according to the

following conditions:

Paper type; Paper size;

Whether grains run lengthways or sideways;

Temperature and relative humidity;

Printing condition.

The folding position may be displaced to a greater

extent than when the paper is folded using a

regular fold method, or a corner of the folded

paper may be folded inside as indicated in the

figure. These, however, do not mean that the

machine has broken down.

Note:

Press the crease hard using the hand. Do not

stack too many sheets of paper on the paper feed

table.

Fine Adjustments for Table 1

Fold type Plane (A)

Single

fold

Gate

fold

Table 1 is not used

Long

Short

15

Direction to turn the Table 1

fine adjustment knob

Page 16

Letter

fold

Zigzag

fold

Long

Short

Long

Short

Double

Long

parallel

fold

Short

Long

Fold-ou

t

Short

Fine Adjustments for Table 2

Fold type Plane (B)

Direction to turn the Table 2 fine

adjustment knob

Single

fold

Gate

fold

Long

Short

Long

16

Page 17

Letter

fold

Zigzag

fold

Short

Long

Short

Long

Short

Double

parallel

Long

fold

Short

Long

Fold-ou

t

Short

(4) Daily Maintenance

1 Before cleaning the machine, be sure to set POWER is in the OFF position and pull the

power plug from the outlet.

2 When the unit is not in use, put its cover in place to prevent dust, paper chips, etc. to

accumulating on the paper fold rollers.

3 If paper chips, ink, etc. are accumulated on the paper fold rollers; it may cause trouble

such as wrinkles, or improper folding. To prevent from it, clean them periodically.

17

Page 18

4 If paper chips, ink, etc. are accumulated on the paper feed rubber roller and the paper

separator, paper feed performance deteriorates and the machine becomes liable to paper

jam or slip. Clean the rollers periodically to reduce down time.

5 If black marks occur that correspond with the location of the paper-feed tires, the feed tires

need to be cleaned.

6 Consumable products: Paper feed rubber roller, rubber brake, and paper feed separator.

18

Page 19

g

(5) Trouble Shooting

Trouble Possible Cause Measures

The paper does

not feed properly

The machine does

not operate even

after the Start/Stop

key is pressed.

Paper sticks just after it is

printed

Stains on the paper separator

Stains on the paper feed rubber

roller.

The paper separator is worn out.

The volume of the paper stacked

on the paper feed table is not

enough.

Paper jam inside the unit.

Paper sticks just after it is

printed

Jog the paper sufficiently or feed the paper

after it is dry.

Clean the paper feed separator using

approved cleaner.

Clean the paper chips or ink on the paper

feed roller with approved cleaner.

Replace the paper separator with a new

one.

If the volume on the paper feed table is not

enough, it does not feed since the paper

detection lever is installed.

Stack 20 sheets or more.

Detach Table 1 and 2 and remove the paper

in the unit.

Jog the paper sufficiently or feed the paper

after it is dry.

Wrinkles appear on

the paper.

Improper fold

position

Stains on the paper separator

Stains on the paper feed roller

Stains on four paper fold rollers

Table 1 and 2 are not properly

set.

Paper jam in Table 1 and 2

The total length of the paper is not

standard size.

19

Clean the paper separator usin

approved cleaner.

Clean the paper chips or ink on the paper

feed roller with the approved cleaner.

Clean the stain on four fold rollers using

approved cleaner.

Reset properly.

Detach Table 1 and 2 and remove the

jammed paper out.

Measure the total length of the paper and adjust

using the fine adjustment knob

the

Page 20

Drawing paper

13# or lighter

cannot be folded.

The surface of four fold rollers

are stained with paper chips or

ink (slippery situation)

Low room temperature

Clean away the stain on four fold rollers

using the approved cleaner.

The paper gets stiff and hard to fold at the

low room temperature in winter. Perform

folding after leaving the paper as it is for 3

to 4 hours at the temperature of 53 to 67°F.

20

Loading...

Loading...