Page 1

FD 2000IL

AutoSeal

®

FIRST EDITION

Page 2

Page 3

TABLE OF CONTENTS

SPECIFICATIONS

SETUP

2

Sealer Alignment Base Setup

Sealer Setup

2 - 3

Printer Alignment Base Setup

4

Printer Setup / Printer Setup w/Riser

5

Alignment Stoppers

6

CONTROL PANEL

OPERATION

7

Fold Plate Adjustment

8

Offl ine Print Test

9

Normal Operating Conditions

8

TEST SHEET

TROUBLESHOOTING

Clearing Paper Jams

OPTIONAL CONVEYOR INSTALLATION

Page 4

Page 5

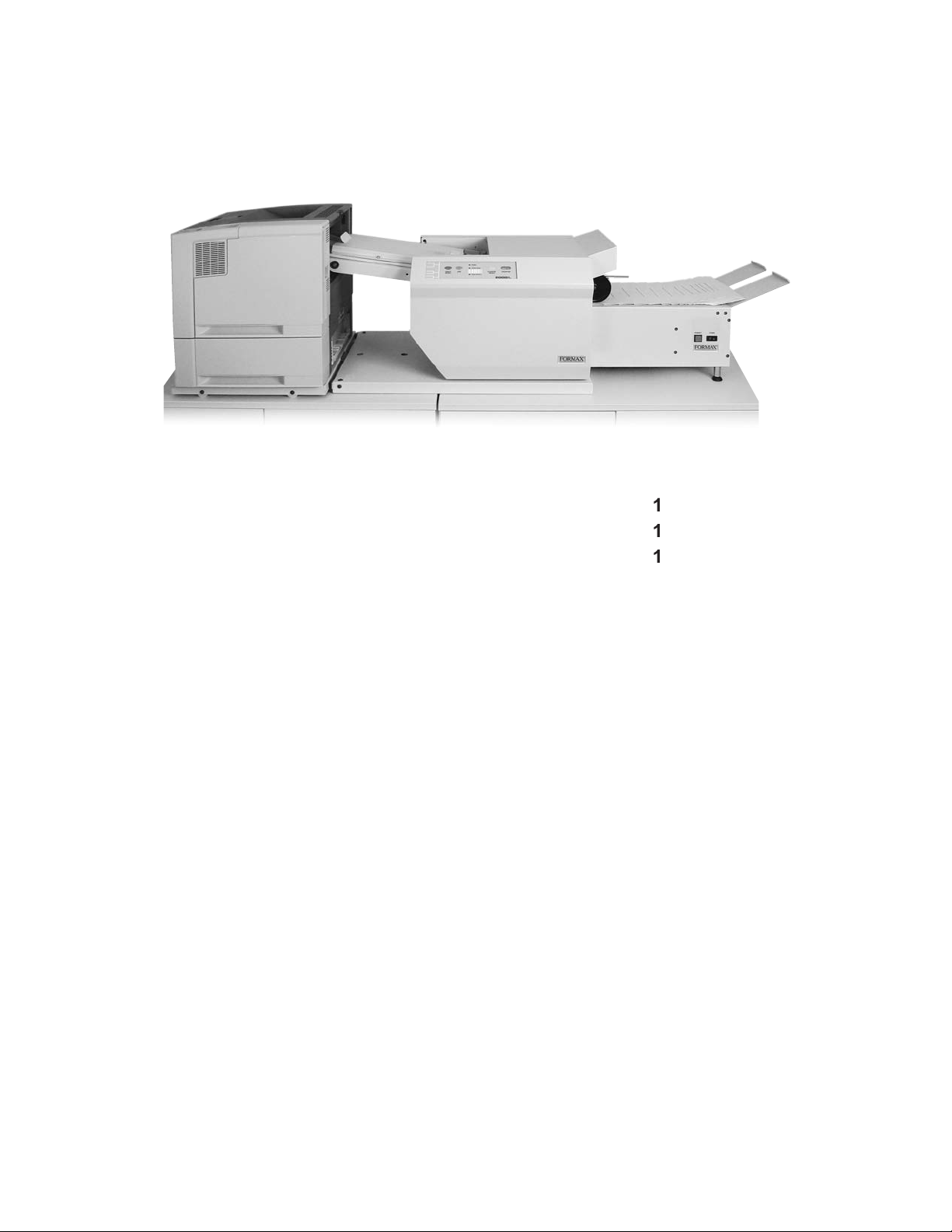

With the Formax FD 2000IL AutoSeal System operators can print, fold and seal all in one streamlined process.

One-piece pressure sensitive forms are loaded into an existing laser printer where they’re printed and fed directly

(requires FD 2000-45IL riser)

w/18” Conveyor:

Page 6

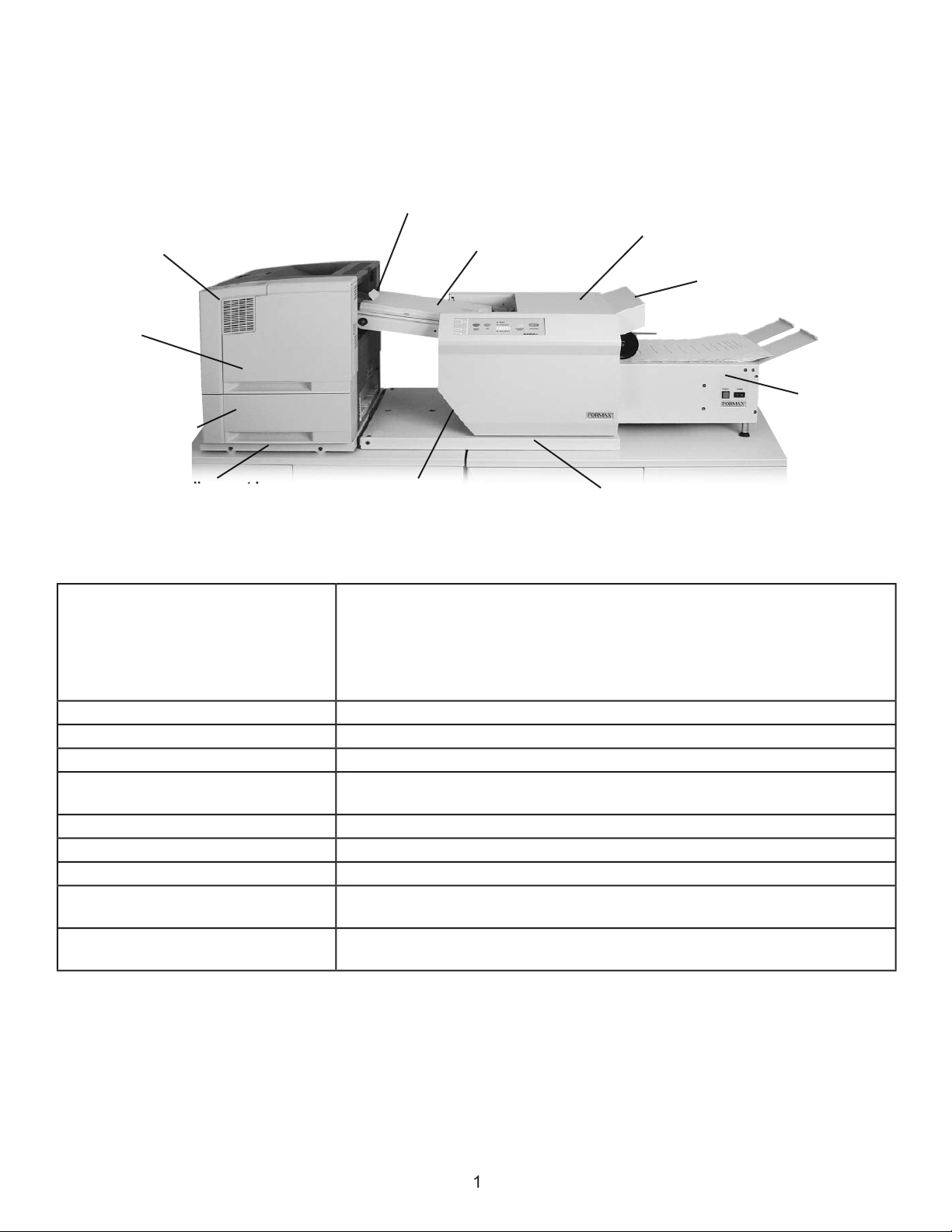

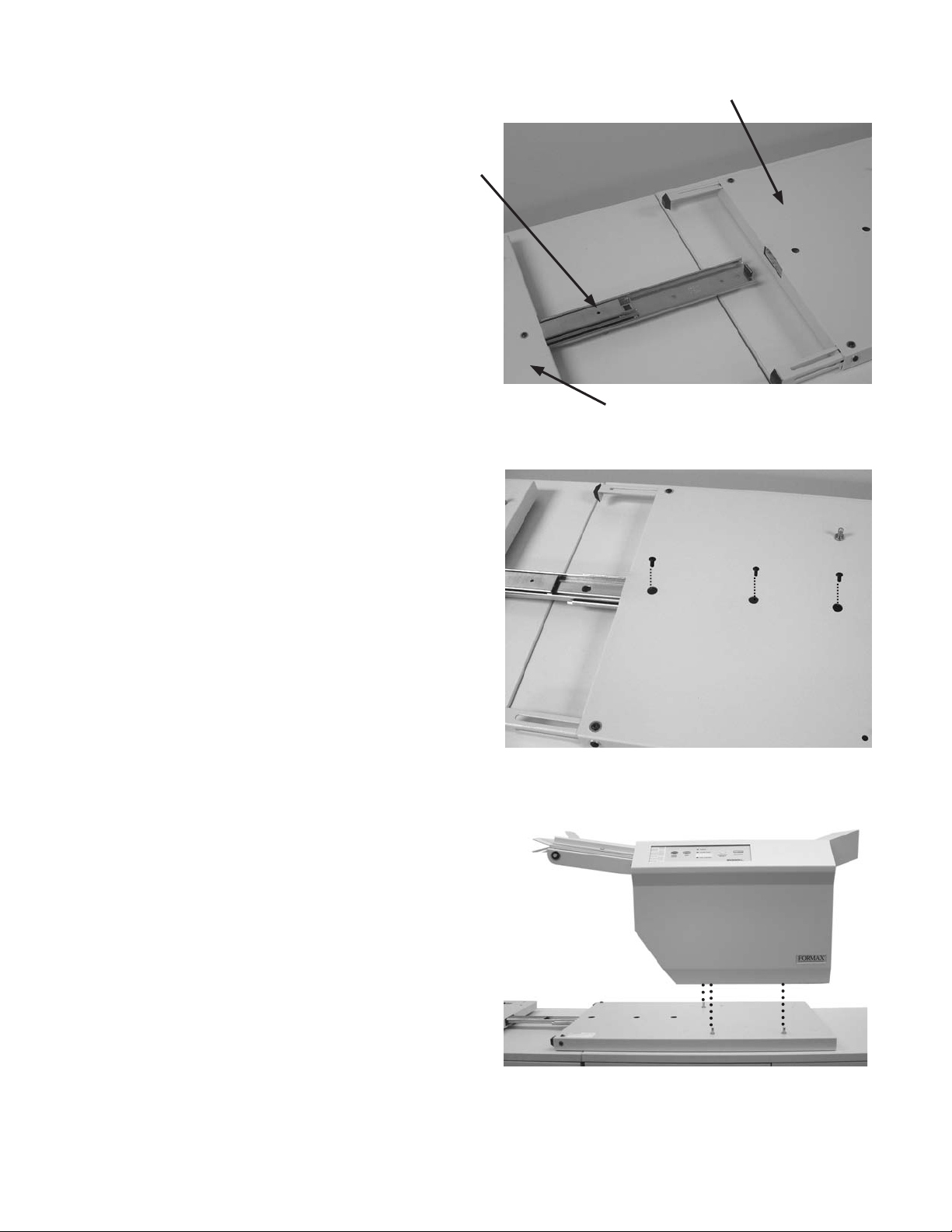

with the holes in the top of the base (Figure 2).

Align third screw hole in the slider with the top

Two people should lift and lower the

Alignment Base, Pressure Sealer Section

Alignment Base, Printer Section

Alignment Base Setup

Page 7

Do not operate the machine without the

Page 8

Alignment pins for use with

Alignment pins for use with

Alignment pins for use with

Alignment pins for use with

Page 9

Refer to page 4 for correct alignment pin

Refer to page 4 for correct alignment pin

Page 10

Alignment base stopper

Alignment Stoppers

Page 11

and reinstall.

Page 12

with the 5 1/4” mark on the fold plate.

The bar should be on the same marks on each side.

Page 13

when the form passes over the photo-eye located at the mouth of the sealer transport deck.

This is

the transport deck to warm up.

Power up the

Printer and Sealer

Load forms into printer face down with glue trailing.

will say “Print Menu

Press the button once to select this option.

Press the button once to select this option.

Power up the

Printer and Sealer

Load forms into printer face down with glue trailing.

button to enter the printer menu. The menu settings

menu.

button once to enter the

menu.

button once. The printer should read

and the menu settings page(s) should print out.

Page 14

Page 15

Page 16

wires.

when the form enters

Page 17

with the correct fold settings. See page 8 for

jammed document. With one hand hold

Adjust rear pin on the printer alignment

Page 18

WARNING:

Turn off machine and unplug cord from its receptacle.

Do not apply excessive force or rollers may be damaged

for

to exit the machine

or the rollers may be

Remove the jammed form, return tool to holder and reinstall the upper fold plate. Reinstall

Press the black button (Fig. 14) near the power cord inlet to reset the breaker if necessary.

A. Clearing paper jams from the steel pressure seal rollers:

WARNING:

Turn off machine and unplug cord from its receptacle.

Press the black button (Fig. 14) near the power cord inlet to reset the breaker if necessary.

Page 19

Assembly

Assembly

Loading...

Loading...