Page 1

1400 Quick Setup Guide

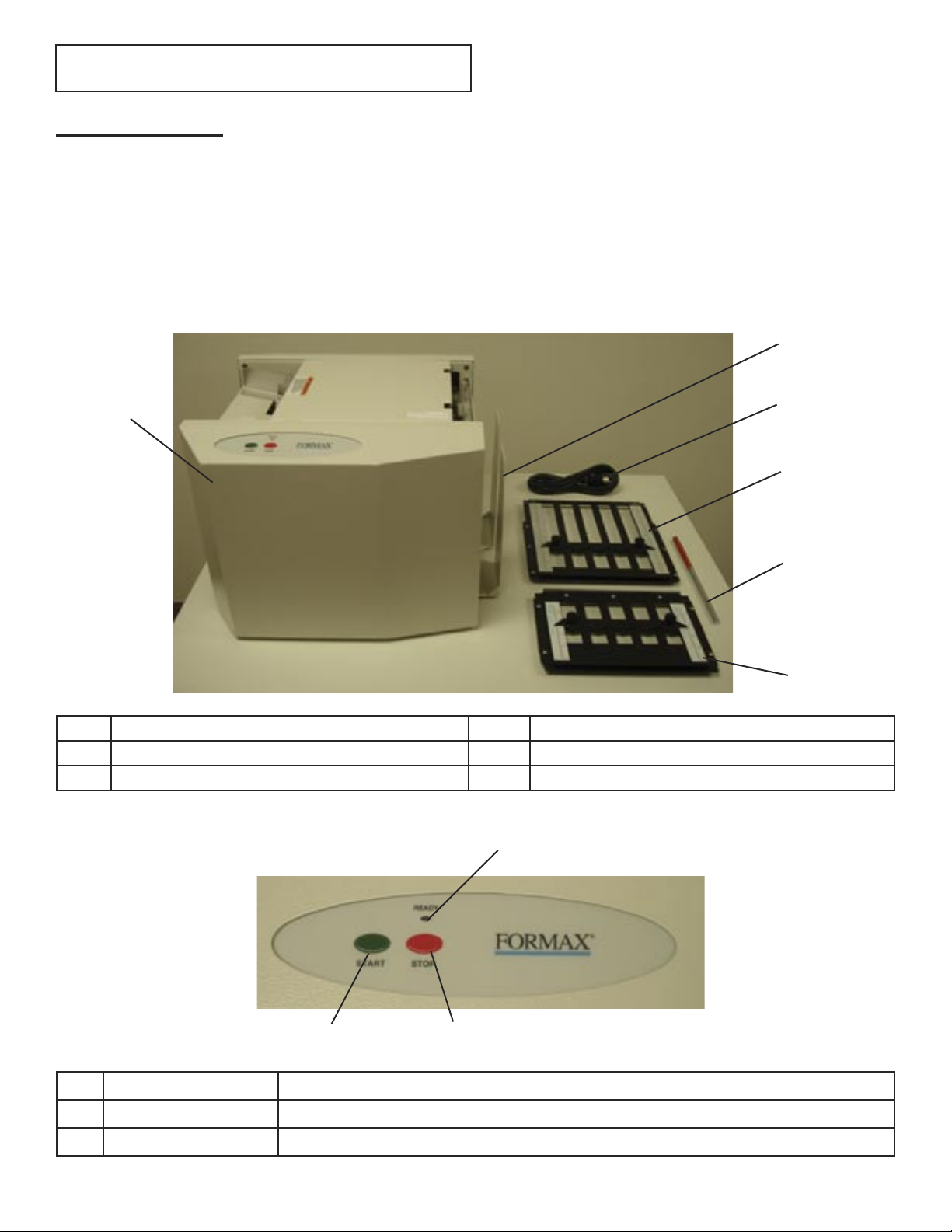

UNPACKING

1. Inspect package for damage.

2. Remove 1400 from box and place on a solid level surface. Caution: Two people are required to

lift machine out of box, as it weighs 81 lbs.

3. Inspect packing to ensure all components are included.

4. Refer to the contact information on the last page if installation or service assistance is needed.

Components

2

1

1 1400 4 Upper Fold Plate

2 Catch Tray 5 Jam Clearing Bar

3 Power Cord 6 Lower Fold Plate (Ships installed)

Control Panel

3

3

4

5

6

1

1 “START” Button Press to start operation

2 “STOP” Button Press to stop operation

3 “READY” Indicator Green indicates the FD 1400 is ready to operate / Blinking Red indicates a fault

2

1

Page 2

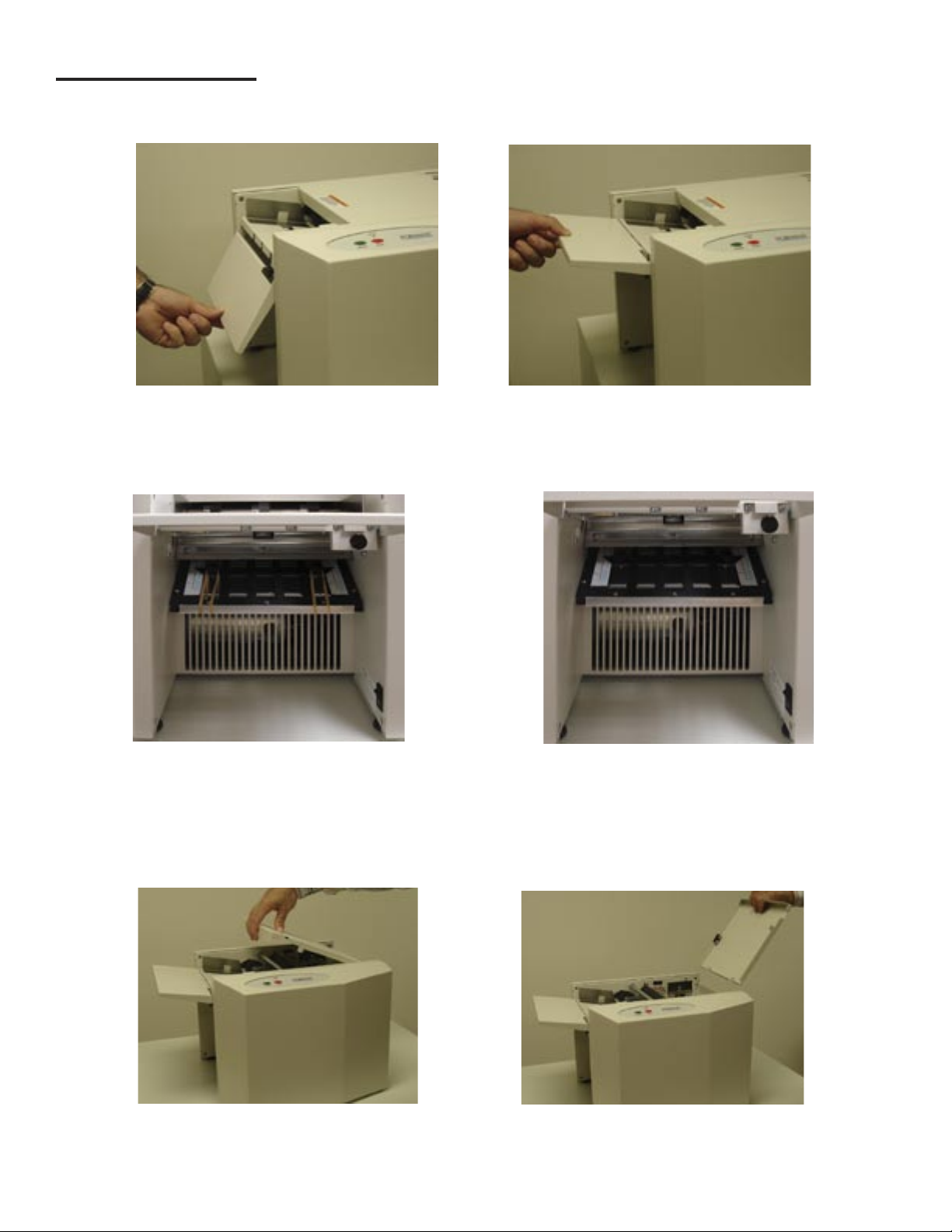

INSTALLATION

1. InFeed Tray Extension

Lift infeed tray extension and lock into place

2. Lower Fold Plate

Remove shipping bands from lower fold plate located under the infeed tray.

3. Upper Fold Plate

Lift top cover and remove

2

Page 3

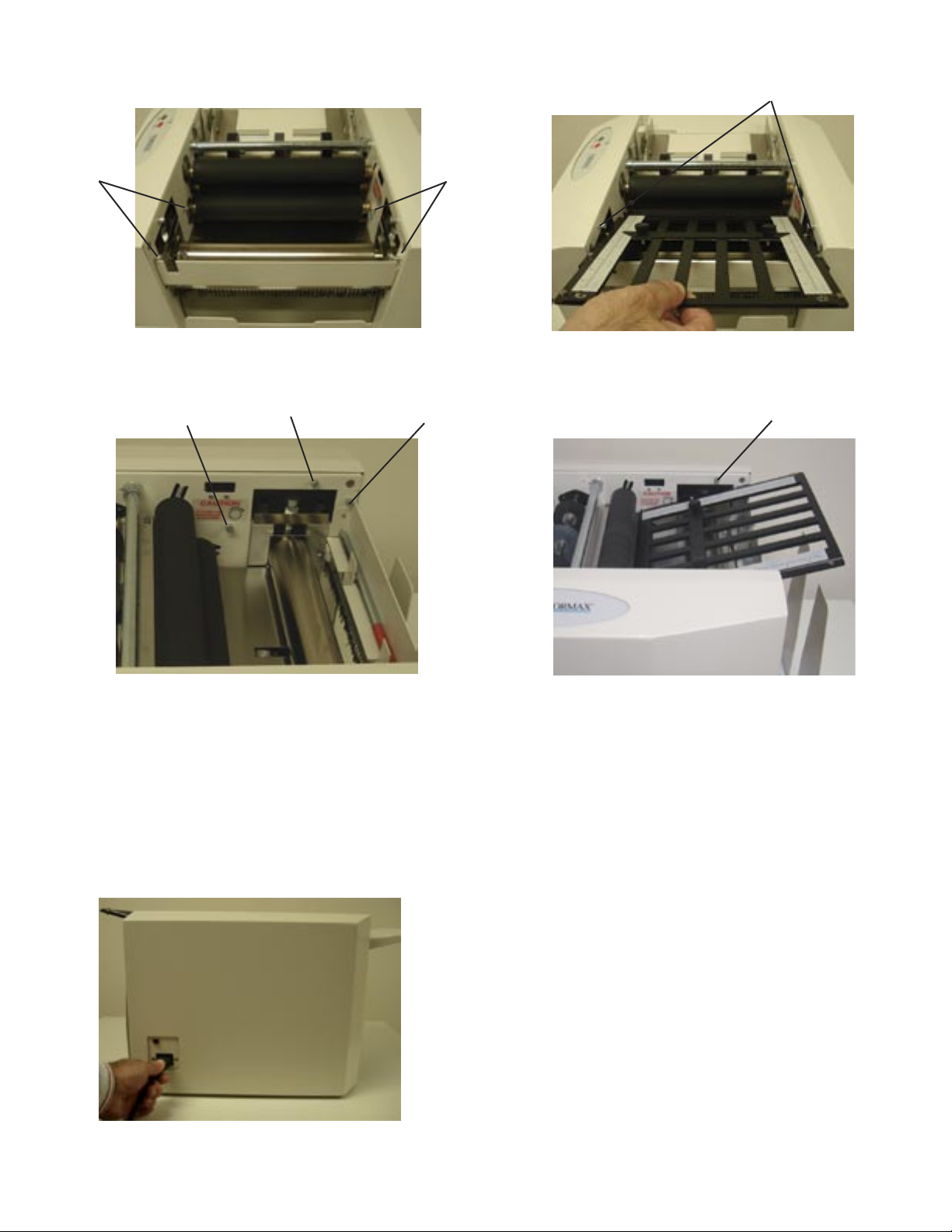

Top View

Top Cover Pins

Fold Plate

Pins

Side View

Fold Plate Pin

Top Cover Pin

Fold Plate

Pins

Fold Plate Pin

Top Cover Pins

a. Slide the upper fold plate under the top cover pins onto the fold plate pins. Push down on the fold plate to

lock it into position.

Note: The fold plate pins are a yellowish color and the top cover pins are a chrome color. Slide the fold plate

under the top cover pins when setting into position.

b. Replace top cover

4. Power Cord

Plug power cord into the receptacle on the backside of the machine.

3

Page 4

DETERMINING FOLD TYPE

Two Standard Folds 11” “Z” & 11” “C”

Refer to Operator Manual for custom fold setup.

Leading glue edge

Glue

Glue

Glue

11” “Z” Fold

11” “Z” Fold

Leading glue edge

Glue

11” “C” Fold

11” “C” Fold

4

Page 5

2. Setting Fold Plates

Fold stop knobs

Fold stop

After determining the fold type of your pressure seal form you will need to set the fold plates.

a. Top Fold Plate: Leave the top fold plate in position, loosen the fold stop knobs and slide the fold stop to the

appropriate fold setting on the fold indicator decals and retighten the fold stop knobs.

b. Bottom Fold Plate: To set the bottom fold remove the bottom fold plate adjust the fold stop and return into

position. Slide lower fold plate onto “Lower fold plate bars” located under the infeed tray.

c. Follow the operating procedure on page 6 to run a few test forms to ensure the folds are correct, if the folds

are off move the fold stops up or down to correct the fold. Use the included test sheets to help line up folds

if needed.

Note: When setting the bottom fold plate for a “half fold” turn the fold plate and insert with the “half fold stop”

leading.

Fold indicator decals

Lower fold plate bars

3. Setting Catch Tray

Lower fold plate

Fold/form size decal

Half fold stop

Edge of the sealer outfeed

Slide the catch tray in or out to align the appropriate fold/form setting on the “Fold/form size decal” with the

edge of the sealer outfeed.

5

Page 6

3. Setting Infeed Side Guides

Infeed Side guides

a. Place a form between the side guides. Adjust the side guides by sliding them left or right so that the form is

snug but still lies flat.

Equal spacing between side frame and guides on both sides

b. Leave equal spacing between the guides and side frame on both sides to help insure that the forms feed

squarely into the pressure sealer.

6

Page 7

OPERATION

1. Power

Switch the power button, located under the infeed tray, to the on position.

2. Loading Forms

Power switch

Feed table lever

a. Remove printed forms from the printer and square them so they are in a neat stack.

b. Press down the feed table lever.

c. Place the neatly stacked forms onto the feed table with the glue edge leading (refer to “Determining Fold

Type” on Pg. 4).

d. Release feed table lever.

3. Starting and Stopping

The green “READY” light will be lit when ready to operate. Press the Green “Start Button” to start and the red

“Stop” button when the feed tray is empty.

7

Page 8

TROUBLESHOOTING

Refer to the “Troubleshooting Section” of the operator manual.

Assistance within the 90 Day Factory Direct Warranty

Please contact Formax Directly for phone support during the first 90 days. Note: The

90 day warranty begins when the machine ships from our factory.

Phone Support: 800-232-5535 Press “0” and ask for FD 1400 technical support.

Hours: Monday - Friday 8AM- 5PM EST

Depot Ship to Address:

Formax

44 Venture Dr

Dover NH 03820

*Machines cannot be shipped to Formax without an RMA#. Shipments will not be accepted without an

authorized Formax RMA#.

Assistance after the 90 Day Factory Direct Warranty

Please contact Intrepid service company for onsite nationwide service. Intrepid offers annual service agreements for your FD 1400 and per trip service at their hourly

rate. Formax strongly recommends that you purchase an annual service agreement

which includes on-site repairs and preventative maintenance as well as rapid on-site

response.

Intrepid Contact Information: 1-800-642-6015

Hours: Monday - Friday 8AM- 5PM

8

Page 9

Leading Edge

Make copies of this page on copy paper for fine tuning folds

Instruction For Lining Up Folds

1. Place a stack of these sheets into the feeder and fold

one (1) or two (2) sheets.

2. Take a folded sheet from the catch tray and lay it on

top of a pressure seal form lining the leading edge of

this sheet up with leading edge of the pressure seal

form.

3.

If the folds on this test sheet do not line up with the

perforated folds on the form, the fold plates need to

be adjusted up or down to make the folds line up.

Refer to Fig. 1 for a “Z” fold and Fig. 2 for a “C” fold.

-

If fold “A” on the test form is right of the perforation on

the pressure seal form move the top fold plate

stop up. If fold ”A” is below move the top fold plate

stop fold stop down.

-

If fold “B” on the test form is right of the perforation

on the pressure seal form move the bottom fold plate

stop down. If fold ”B” is to the left move the bottom

fold plate stop up.

Fold “A” Fold “B”

Fig. 1 “Z” fold Form

Fold “A” Fold “B” Leading Edge

Leading Edge

9

Fig. 2 “C” Fold Form

Loading...

Loading...