Page 1

FD 125

Large-Format Card Cutter

9/2012

OPERATOR MANUAL

Page 2

Page 2

Page 3

Page 3

Table of Contents

SAFETY PRECAUTIONS ........................................................................................................................................................ 4

Introduction ........................................................................................................................................................................ 5

Specifications ...................................................................................................................................................................... 5

Accessories ......................................................................................................................................................................... 5

Major Components and Assemblies ................................................................................................................................... 6

Control Panel ...................................................................................................................................................................... 8

Installation .......................................................................................................................................................................... 9

Setting Up Procedure ......................................................................................................................................................... 9

The Job selection .............................................................................................................................................................. 11

Registration Mark Position ............................................................................................................................................... 15

Selecting a job ................................................................................................................................................................... 15

Batch Count function ........................................................................................................................................................ 16

User Define Job ................................................................................................................................................................. 17

Cut mark ........................................................................................................................................................................... 18

Turbo and normal Mode .................................................................................................................................................. 18

Paper weight ..................................................................................................................................................................... 18

Reset Counter ................................................................................................................................................................... 19

Clear Jam .......................................................................................................................................................................... 19

Troubleshooting ............................................................................................................................................................... 20

Optional Slitter Cassette ................................................................................................................................................... 20

Optional Conveyor ............................................................................................................................................................ 21

Page 4

Page 4

SAFETY PRECAUTIONS

Always pull the power supply plug out of its outlet before removing jammed

paper.

Do not use supply voltage other than the specified voltage.

Do not insert pins, wire or other foreign objects into the machine. Do not allow

any liquid to get into the machine through its openings or gaps in its structure.

Do not modify the machine. Do not remove any of the covers from the machine..

Keep this unit and the power cord away from heaters and heater vents. Excessive heat could

melt the cover or power cord covering, and result in a fire or an electrical shock.

Do not put fingers inside during operation.

Keep away long hair, ties, jewelry and loose clothing.

Install this unit on a level, stable stand or floor, with sufficient space around it.

Do not install this unit in a location where there is excessive humidity or where contact with

water is possible.

Disconnect the power plug from the power outlet before attempting to move this unit. Failure to

do so could result in power cord damage, a fire or an electrical shock.

Always observe the cautions and warnings given below to prevent personal injury or property damage.

Page 5

Page 5

INTRODUCTION

Paper Size

LT, LG, LD, 12 x 18 and 13 x 19

Paper Weight

120 ~ 350 gsm

Feeder Capacity

120 sheets (300gsm)

Receiving Tray

250 business Card x 3

Speed

Up to 240 business cards/min

Based on 55x90mm in A3

Accuracy

± 0.2 mm

Dimension -- With Conveyor

W/O Conveyor

98.5 X 53.5 X 101.5CM (38.8x21.1 x 40”)

48.5 X 53.5 X 101.5CM (19.1 x 21.1 x 40”)

Net Weight –With Conveyor

W/O Conveyor

70.8Kgs ( 156 lbs)

61.2Kgs (135 lbs)

Power

110/220V Selectable, 50/60Hz, 1.2A

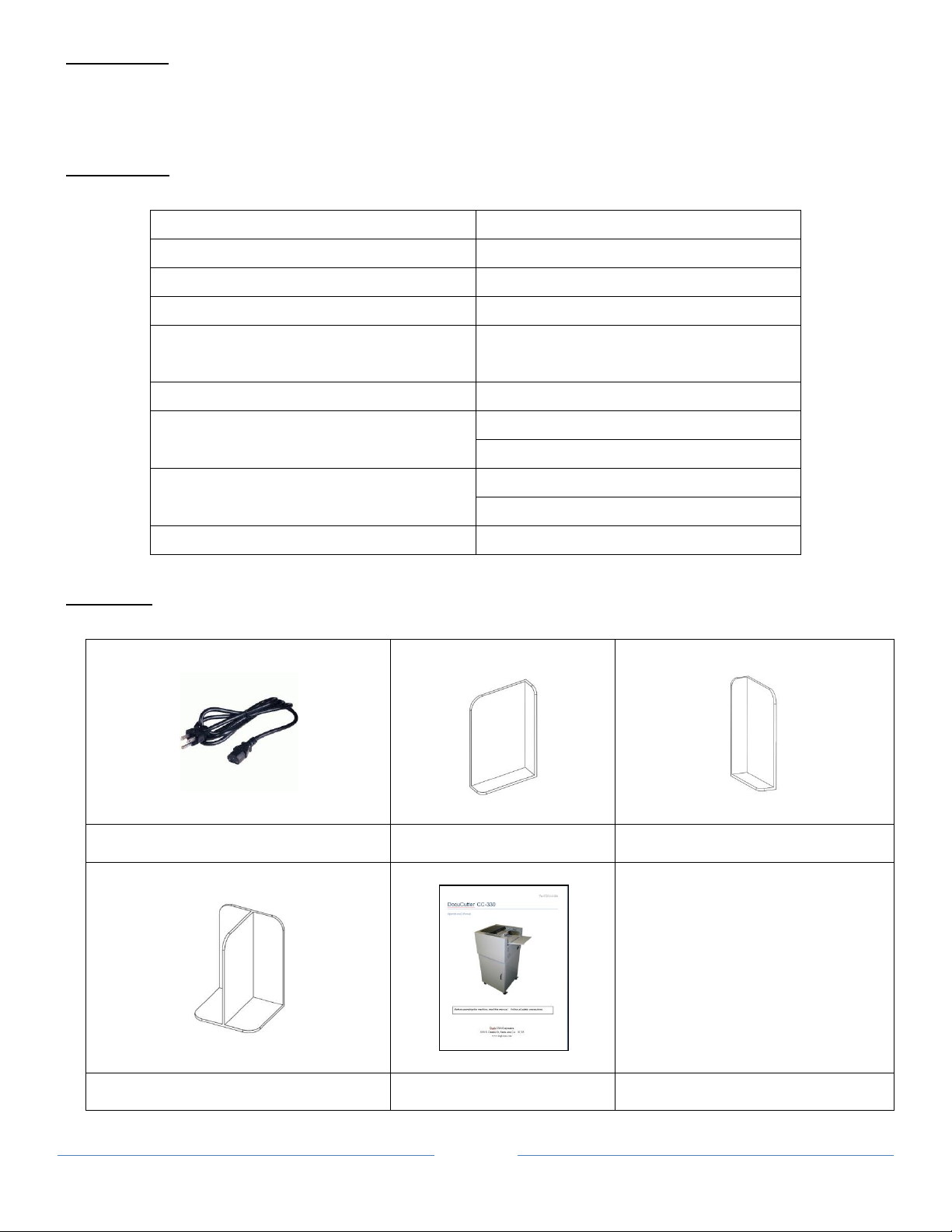

Power Cord

Right Stacking Guide

Left Stacking Guide

Center Stacking Guides X 2

Operation Manual

The FD 125 is designed to easily and accurately cut business cards, photos and postcard cutting in one pass.

SPECIFICATIONS

ACCESSORIES

Make sure all accessories provided with the machine.

Page 6

Page 6

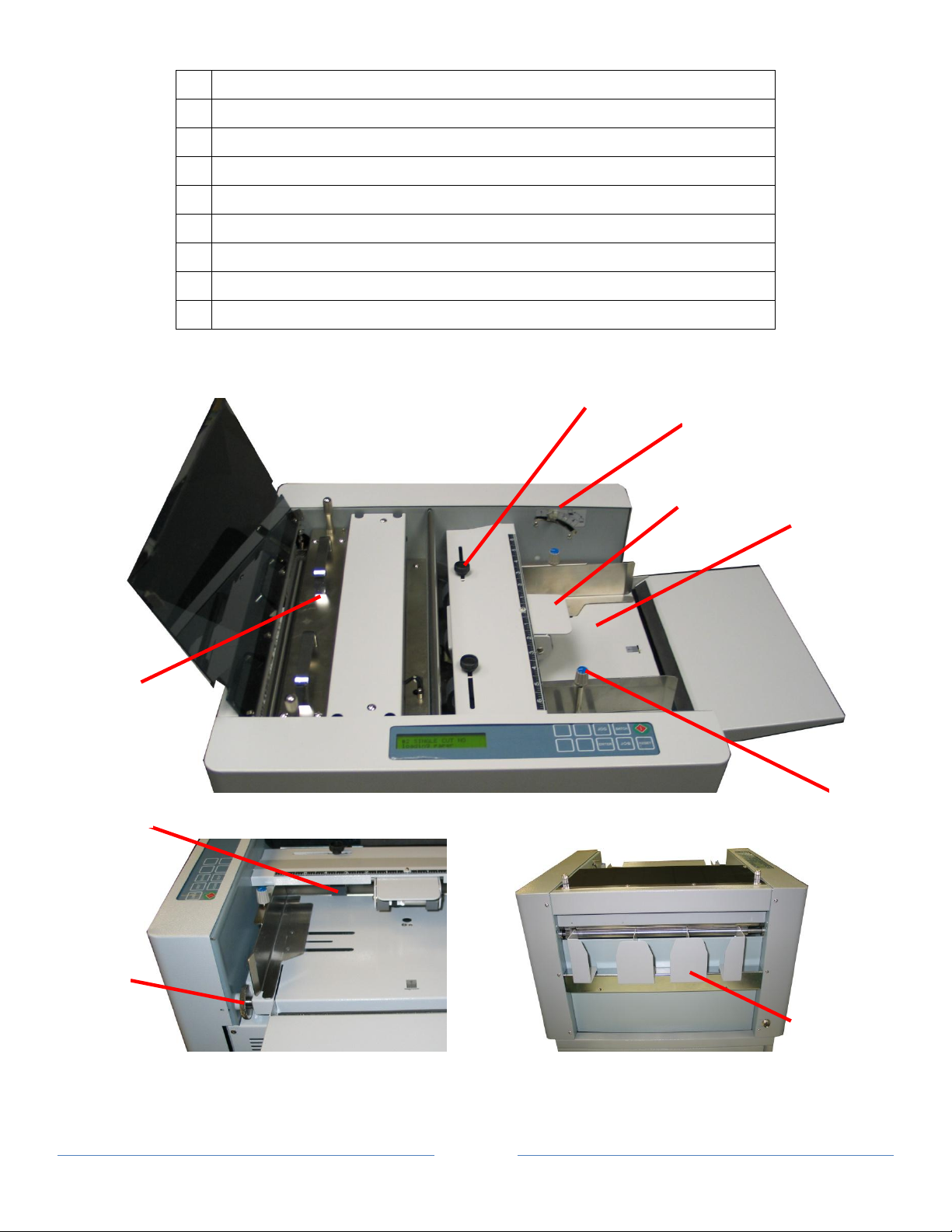

MAJOR COMPONENTS AND ASSEMBLIES

1

Power Switch

2

Control Panel

3

Extended Tray

4

Top Cover

5

Waste Compartment Door

6

Machine Stand

1

3

4

5

2

6

Page 7

Page 7

7

Stack Tray

8

Auxiliary Roller

9

Side Guide Adjustment Knob

10

Feed Tray Pressure Adjustment

11

Feed Rollers Adjustment Knob

12

Feed Rollers

13

Slitter Cassette

14

Slitting Registration Adjustment

15

Stacking Guides

7

8

12

9

13

11

10

14

15

Page 8

Page 8

CONTROL PANEL

Keys

Function

Start and Stop the cutter

Change job

Toggle between “Normal Mode” and “Turbo Mode” (Paper Weight Setting Mode)

Select batch count

Pre-feed (Mark Reader Calibration Mode)

Jog forward

Confirm job and batch count setting.

Jog backward

Reset counter (use with “RESET” button simultaneously)

Save settings

Hold (4s) paper weight setting mode

Reset counter (use with “ENTER” Button simultaneously)

Enter program mode

Change paper weight

Set top margin

Set finished length

Increment settings by 0.1 mm when pressed.

Decrement settings by 0.1mm when pressed (Mark Reader Calibration Mode).

Page 9

Page 9

INSTALLATION

on the stand to the holes on the base plate of the machine.

Stack Tray

Power Cord

1

To set the width of paper, loosen thumbscrew knob on

the side guide and slide to position. Use scales as

reference point.

2

Fan paper before loading. This will reduce static and

toner adhesion due to printing. For best result, the

paper stack should be flat.

Thumbscrew

Scales

guides

Pins

1. CUTTER INSTALLATION

Note: No tool is required for installation.

Stand

Place the machine on the stand. Make sure to align the pins

The door of the stand should face the operator side.

Place the left guide, center guides and right guide as shown.

Left

guide

Right

guide

Use caution when plugging in power cord. Attach power cord

to the machine and plug the other end into the wall outlet.

SETTING UP PROCEDURE

Center

knobs

Paper feed guides

Page 10

Page 10

3

Push the feed tray down and load the paper. Readjust

paper guides if needed.

4

Adjust tray pressure. For thinner paper, the number

should be higher. For heavier paper the number should

be lower.

5

Use slitter registration adjustment knob to compensate

for printing registration. The knob will allow ± 2mm of

6

7

Adjust feed rollers so they are about 0.5” away from the

edge on each side of the paper.

adjustment left and right.

Auxiliary roller is for hard-to-feed paper. To use auxiliary

roller, load paper, then push the rollers down onto paper.

Page 11

Page 11

JOB SELECTION

Slitters

Slit Size

Gutter Size

Number of rows

Default Size

Standard Slitter

3.5”

0.25” 3 3.5”

8.5” to 11”

None 1 11”

4” to 6”

0.25” 2 6”

Layouts

Job #

Applications

Display

Paper Size

Finished Size

Layouts

Gutter

Margin

Slitters

A

1

Full Bleed

Business Cards

Business

Card

12”X18”

2” x3.5”

24 up

0.2 in

(5.08 mm)

0.35”

(8.9 mm)

Standard Slitter

B 2 Business card

Business

Card

12”X17”

2” x3.5”

24 up

None

0.75”

(19.1 mm)

Standard Slitter

C 3 Brochure

Brochure

12”X18”

8.5” x 11”

2 up

0.25 in

(6.35 mm)

0.5”

(12.7 mm)

(11 in.)

D

Insert/Greeting

Cards

12”X18”

3.5” x 8.5”

6 up

0.25 in

(6.35 mm)

0.5”

(12.7 mm)

Standard Slitter

E 4 Photo

Photo

12”X18”

8” x 10”

2 up

1.25 in

(31.75 mm)

0.5”

(12.7 mm)

(10 in.)

F

Insert/Greeting

Cards

12”X18”

3.5” x 8”

6 up

1.25 in

(31.75 mm)

0.5”

(12.7 mm)

Standard Slitter

G 5 Postcard

Postcard

12”X18”

5.5” x 8.5”

3 up

0.375 in

(9.525 mm)

0.5”

(12.7 mm)

(8.5 in.)

H 6 Postcard

Postcard

12”X18”

5” x 7”

4 up

3.25 in

(82.55 mm)

0.5”

(12.7 mm)

(5 in.)

I 7 Postcard/Photo

Postcard

13”X19”

4” x 6

8 up

0.5 in

(12.7 mm)

0.5”

(12.7 mm)

(6 in.)

J

8-13

Custom

Program

Postcard

(Program)

12”x18”

3.5”x5”

9 up

0.875 in

(22.2 mm)

1.00”

(25.4 mm)

Standard Slitter

K

Brochure

12”X18”

11” x 17”

1 up

None

0.75”

(19.1 mm)

(11 in.)

L

Postcard

13”X19”

6” x 9”

4 up

0.25 in

(6.35 mm)

0.5”

(12.7 mm)

(6 in.)

The FD 125 offers 7 different programmed jobs from (1 to 7) and 6 programmable jobs (8 to 13).

The standard cassette has a slit size of 3.5” x 3 rows for business cards. Optional cassettes are available.

See below to select the proper slitter and program for your application.

Slitters

Optional Cassette 1

Optional Cassette 2

Applications

Option Slitter 1

Option Slitter 1

Option Slitter 1

Option Slitter 2

Option Slitter 2

Option Slitter 1

Option Slitter 2

Page 12

Page 12

Job Layout

A B

C D

Page 13

Page 13

E F

G H

Page 14

Page 14

I J

K L

Page 15

Page 15

REGISTRATION MARK POSITION

Actions

Display Example

1

Turn on the power. Previous job will appear.

2

Press

01 → 02 → 03 → 04 … 13

3

Press to select job

4

Press to start operation.

#01BUSINESS CARD

NM 2”x3.5” W/G 23

#04 PHOTO

NM 8”x10 W/G 23

#04 PHOTO

NM 8”x10 W/G 23

#04 PHOTO

NM 8”x10 W/G 23

1st Cut

Margin

Center

Feed

Registration mark will compensate for print shifting. See below for registration mark position.

SELECTING A JOB

until the desired job is displayed.

Page 16

Page 16

BATCH COUNT FUNCTION

Actions

Display Example

1

Press

appears. The batch count will increment by 10 every time

Batch → 10 → 20 → 30 → 40 → 50

2

Press to select batch count.

3

Press to start operation.

#04 PHOTO

NM 8”x10 W/G 23

#04 PHOTO

NM 8”x10 W/G 50

#04 PHOTO

NM 8”x10 W/G 50

Batch count function is used to automatically stop the machine after a set number of sheets has been fed.

until the desired batch count number

the button is pressed. Set “OFF” for no batch count.

Page 17

Page 17

Actions

Display Examples

1

Turn on the power. Previous job will appear.

2

Press

01 → 02 → 03 → 04 … 13

3

Press to select job.

4

Hold for 4 seconds. “Edit” will appear indicating

5

Hold and press to increment or to

6

Hold and press to increment or to

7

Hold and press to increment or to

8

Press to save settings.

#10L000.0M00.0G00.0

NM 89

#10L000.0M00.0G00.0

(E) 89

#10L000.0M00.0G00.0

(E) 89

#10L127.0M00.0G00.0

(E) 89

#10L127.0M12.7G00.0

(E) 89

#10L127.0M12.7G06.0

(E) 89

#10L127.0M12.7G06.0

NM 89

#04 PHOTO

NM 8”x10” W/G 50

USER DEFINED JOBS

Only jobs #8 – 13 can be programmed.

until the desired job is displayed.

machine is in “Program Mode”.

decrement change to finished length in mm.

decrement change to top margin in mm

decrement change to gutter length in mm

Page 18

Page 18

CUT MARK

Setting

Paper Weight

1, 2

120 – 210 (gsm)

3

211 – 300 (gsm)

4, 5

301 – 350 (gsm) (Normal Mode)

The purpose of the cut mark is to compensate horizontal cut due to image shifting during printing.

Hold and press to enable or disable cut mark. This will toggle “M” for mark and “NM” for no mark on the

display.

TURBO AND NORMAL MODE

1. Hold for 4 seconds.

2. Press to select “Normal Mode” or “Turbo Mode (Default)”.

3. Press to save settings.

# Paper weight above 300 gsm set it to “Normal Mode”

PAPER WEIGHT

Adjust paper weight settings if paper is skewing or misfeeding.Set 1 or 2 for lighter paper and 4 or 5 for heavier paper.

1. Hold for 4 seconds.

2. Press to select settings 1-5. Use table below for references.

3. Press to save settings.

Page 19

Page 19

RESET COUNTER

Hold and simultaneously to reset counter to 0.

CLEAR JAM

If a jam occurs in the machine follow these steps to clear it.

1. Press and pull out jammed paper toward feeding tray.

2. Press to move the jammed piece toward the exit.

3. If necessary, depending on location of the jam, open the corresponding cover or covers. If jam persists, refer to

“Error Message and Trouble Shooting” page 20.

4. After clearing the jam, press to clear all errors.

Page 20

Page 20

TROUBLESHOOTING

Error

Troubleshooting

Out of paper

1. Adjust the feed tray tension

jam sensor 2

1. Remove the paper jam by pulling toward stacking tray.

2. Adjust the feed hopper tension, if double feed happens

jam sensor 3

1. Use JOG key to clear the jam

2. Adjust feed hopper tension, if double feed happens

check top cover

Put the top cover in position

check rear cover

Put the rear cover in position

Call for service

Error message cannot reset

1. Lift Top Cover

4. Replace with the desired slitter cassette.

turning them clockwise.

Thumbscrews

Lift Handles

Disfeed

FinishĞĚ cardƐ not clean and neat

>ŽĂĚĨeed tray

2. Side guideƐ too tight. Adjust side guideƐ.

3. Fan the paper and reload the paper into ĨĞĞĚƚƌĂLJ

Check covers and ĐŚĞĐŬĨŽƌpaper jam

OPTIONAL SLITTER CASSETTE

Optional slitters enable the &ϭϮϱ to have more range of applications. Follow the stepƐ below to replace optional slitter

cassette.

2. Remove thumbscrewƐ by turning counter-clockwise on

both sideƐ of the slitter cassette.

3. Using both hands, lift ŽƵƚthe slitter cassette.

5. Secure the slitter cassette with the thumbscrewƐ by

Page 21

Page 21

OPTIONAL CONVEYOR

1 x Conveyor

1 x Ramp

1 x Stacking Rollers Assembly

1 x Interface Cable

1 x Stand Support

4 x Studs

4 x Socket Cap Screws (M6x12)

6 x Lock Washers (M6)

4 X Shoulder Washers

4 x Machine Screws (M4 x 12)

2 x Spacer

2 x Machine Screws (M5 x 35)

2 X Hex Bolt (M6 x 30)

4 x Washers (M6)

2 X Hex Nuts (M6)

2 Thumbscrews (M4 x 12)

Accessories List

Page 22

Page 22

2. Remove the chrome bracket.

3. Install the 4 studs as shown using 4 Socket Cap Screws

(M6x12) and 4 Lock Washers (M6).

4. Hook the conveyor onto the studs.

5. Use 2 spacers and Machine Screws (M5 x 35) to secure

the conveyor on the left and right side located below the

conveyor.

6. Plug interface cable to conveyor and machine.

Side Covers

Chrome Bracket

Shoulder Washers

Left Side Spacer

Right Side Spacer

1. Remove the side coversĂŶĚŵĂŐŶĞƚŝĐƐƚĂĐŬŝŶŐŐƵŝĚĞƐ.

7. Fasten 4 Machine Screws (M4 x 12) and 4 shoulder

washers ƚŽ the ŽƉƉŽƐŝƚĞend of the conveyor.

Page 23

Page 23

8. Install the ramp using the key holes.

9. Install Stack Rollers assembly using 2 thumbscrews as

shown onto conveyor rails. Adjust roller distance

depending on paper finish size for better stacking.

10. Install stand support using 2 Hex Bolt (M6 x 30), 4

washers (M6), 2 Lock Washer (M6) and 2 Nuts (M6) and

secure stand support to the stand.

Conveyor Rails

Thumbscrews

Loading...

Loading...