FOREDOM SR Series 1/6 HP Owner's Manual

Owner’s Manual

for 1/6 HP

Series SR

Flexible Shaft

Power Tools

2-Year Warranty

See Insert with Special

Instructions for Square Drive

Heavy Duty Series SRH Models

For Your Own Safety

•

Please read this Assembly, Operation,

and Service Manual before operating your

Foredom power tool.

•

Always wear eye protection while using

power tools.

•

Only use accessories rated for use

at 18,000 RPM or higher.

FOREDOM

®

Visit www.foredom.net

to view videos on this product

Form 1268 n 7/16

Printed in USA

Contents

Safety Instructions 2–4

Series SR Motors and Speed Controls 4-7

Assembly Instructions 5–6

Assembly and Adjustment of Shaft, Sheath & Handpiece 5

Connecting Foot Controls 6

Connecting Table Top Dial Speed Controls 6

Operation – General Guidelines 7

Foredom Handpieces and Rotary Accessories 8–10

Attaching Accessories to Handpieces 9

Handpiece Lubrication 10

General Accessory Recommendations 11–12

Maintenance Procedures 13–14

Routine Motor Cleaning and Lubrication 13

Replacement of Worn Shafts and Sheaths 14

Replacement of Motor Brushes 14

Repair Service 15

Recommended Spare Parts and Supplies 15

Motor Hangers 15

Limited Warranty 16

Contact Information 16

Safety Instructions

Before using your Foredom power tool, please

read safety instructions. They are for your protec-

tion and should always be followed to reduce the

risk of personal injury or damage to the tool.

•Always wear proper eye and face protection.

Wear safety glasses or face shields whenever you

operate a Foredom or any power tool to prevent

serious eye or face injuries.

•Secure the work piece or item that you are

working on in a vise or other work holding device.

Holding it with your hand can result in serious

hand injury.

•Always use a proper dust collection system or

wear a respirator to prevent the inhalation of

dust particles, polishing compounds, or other

debris into the lungs.

•Do not wear loose fitting clothing or jewelry.

Loose clothing or jewelry can become entangled

in the rotating accessory. Do not wear items such

as neckties, necklaces, or bracelets when operat-

ing power tools. Be sure to tie back or secure

long hair.

•Secure the power tool to motor hanger or

work surface. Flexible shaft power tools can

“jump” at start up or vibrate during opera tion. The tool should be properly secured in

order to prevent it from vibrating off of the

motor hanger, work bench or wall.

•Never use any accessory at speeds above

its maximum rated speed. When properly

used, all of Foredom’s accessories can be

operated at the speed ratings listed in the

Foredom Accessory Catalog or specified

on kits and packaging. Always find out the

manufacturer’s speed rating before using ac cessories other than those from Foredom.

•For added safety and comfort while using

this power tool for carving or other applica tions, it is recommended that you wear a heavy

canvas or leather apron. It will protect you

from dust, debris and chips as well as help

prevent injury if the handpiece slips off the

workpiece. It will also help prevent loose

clothing from getting caught in a rotating

cutter, bur or other accessory.

How-To Videos on

www.foredom.net

Click on our homepage

Video Library Link where

Foredom’s National Sales Manager shows you the

basics of using and maintaining

flex shaft machines.

Click to View:

1. Intro & Proper Set-up

2. Safety Guidelines

3. Handpieces & Accessories

4. Shaft and Sheath Maintenance

– Grease and Replace

5. Motor Maintenance– Remove

Dust, Replace Motor Brushes

There are many other productrelated videos throughout

our website.

We suggest that you take the time

to watch these since they help to

clarify product features and uses.

Visit Foredom on

www.youtube.com

2

• Never wear open shoes or sandals. Use

footwear that is tough enough to protect

your feet from falling tools.

•Never use or continue to use any accessory

which appears to be damaged, loose,

vibrating, or out of balance. Inspect each

accessory for cracks or flaws before using

it. Avoid knots, imperfections in wood

or metal objects like nails, which could dam age or catch the accessory.

•Always insert the shank or arbor of an

accessory or mandrel into the collet or

chuck of the handpiece as far as possible in

order to provide proper support and tighten

the collet or chuck securely.

•Never use excessive side pressure which

may bend or break the shank or arbor of an

accessory. Let the speed of the accessory

do the work.

•Do not stall the motor by jamming or using

excessive pressure on the accessory. This

can result in damage to the motor or

flexible shaft.

•Never operate the motor with the outer

sheath removed from the flexible shaft.

•Always disconnect the power cord before

servicing the motor or removing the flexible

shaft or sheath.

•Never operate your power tool during a

perceptible power decrease. Turn power tool

off and do not use until power is fully restored.

•Use proper grounding procedures. This tool

should be grounded while in use to protect the

operator from electric shock. The tool is

equipped with an approved 3-conductor cord

and a 3-prong grounding type plug to fit the

proper grounding receptacle. The green (or

green and yellow) conductor in the cord is the

grounding wire. Never connect the green (or

green and yellow) wire to a live terminal. If

your unit is for use on less than 150 volts, it

has a plug that looks like sketch A below. An

adapter (sketches B and C) can be used for

connecting plugs as shown in sketch A to

2-prong receptacles. The green colored rigid

ear, lug, etc., extending from the adapter must

be connected to a permanent ground such as

a properly grounded outlet box. Some juris-

dictions, including Canada, prohibit the use

of 3 to 2 prong adapters. Where prohibited,

they should not be used. Use only 3-wire

extension cords that have 3-prong grounding

type plugs and 3-pole type plugs and 3-pole

receptacles that accept the tool’s plug. Always

disconnect the power cord before servicing

the tool. Never use in an area where

flammable vapors are present.

Never change motor direction while the motor is running.

Changing direction while motor is running can damage the motor or

flexible shaft or lead to premature wear. To turn motor off, remove foot from

foot pedal speed control, or turn dial speed control to “off” position, and set

rocker switch to “off” (center) position on motor.

3

OFF – no rotation.

FORWARD – counterclockwise shaft rotation.

Forward is going to be the most commonly

used setting. Right-handed people will get

the most control in the forward direction.

At Foredom we define motor rotation this way:

Forward motor rotation means that the motor

is turning an accessory (bur, bit, drill, cutter,

etc.) counterclockwise when holding the

handpiece upright in your hand and you are

looking down on to the front of the accessory.

When the handpiece/accessory is applied to

the workpiece, your viewpoint changes to the

back end of the handpiece and accessory and

the forward rotation direction can be

described as clockwise.

Forward Motor Rotation

• ONLY use Chisel or Hammer handpieces or

Angle Grinder attachment for H.30

®

hand piece in Forward Rotation. Using Chisel or

Hammer handpieces or Angle Grinder

attachment in reverse can damage the hand piece, attachment, flexible shaft, or motor

and may cause injury.

• Use the forward motor direction ONLY for

fluted burs, drills and cutters. Most will cut

efficiently only when turning in this direction.

• Many mandrels have right-hand threaded

arbor screws which will unscrew in the

reverse direction.

• Dust and debris flies away from the user

when operated in forward in the left hand.

•Whetheryouarerightorlefthandedor

REVERSE – clockwise shaft rotation.

Advantages of Reverse Rotation

•Left-handeduserswillhavebettercontrolin

the reverse direction.

•Forrighthandeduse,dustanddebrisies

away in reverse.

•Alternatingmotordirectionhelpstoextend

the life of mounted abrasive points, buffs,

brushes, sanding bands, and Typhoon

®

burs.

•Reversehelpswithaccomplishingsymmetri-

cal grinding and carving techniques.

•Reverseisgoodfor“backingout”stuck

drill bits.

•Alternatingmotordirectionmakesiteasier

and faster to polish metals.

•Besuretouseamandrelwithaleft-hand

threaded arbor screw.

Never change motor direction while the motor is running.

Foredom® 1/6 HP Series SR Power Tools run at speeds up to 18,000 rpm

You have purchased a fine quality power tool which will perform a wide variety of tasks difficult

to do with any other kind of power tool. Foredom power tools are manufactured to high standards

of precision and performance and with proper use and regular maintenance will give you years of

trouble-free performance. This manual contains instructions for the assembly, operation, and

servicing of Foredom’s 1/6 HP Series SR motors.

operate in forward or reverse, precautions

taken against dust and debris are always

necessary and important.

•Always securely tighten chuck nut or chuck

jaws of handpiece with wrench or chuck

key so that it will not come loose in the

reverse or forward operating directions.

4

M.SR Hang-Up Style

M.SRB Bench Style

M.SRM Bench Style

with built-in control

A complete Series SR flexible shaft power tool consists of a motor, flexible shaft and

sheath, speed control (foot or manual) and a handpiece. If you purchased a motor and control, a

handpiece will also be needed to operate the machine. Locate and identify all components, parts

and accessories you purchased before discarding the packing list and packing materials that

came with your power tool.

Please follow these directions to assemble

and adjust the shaft and sheath.

To check the shaft and sheath you

must first remove the handpiece

which is easy to do.

To remove:

1. First make sure your power

tool is unplugged. Simply pull the

handpiece off the shaft and sheath with

a firm grip.

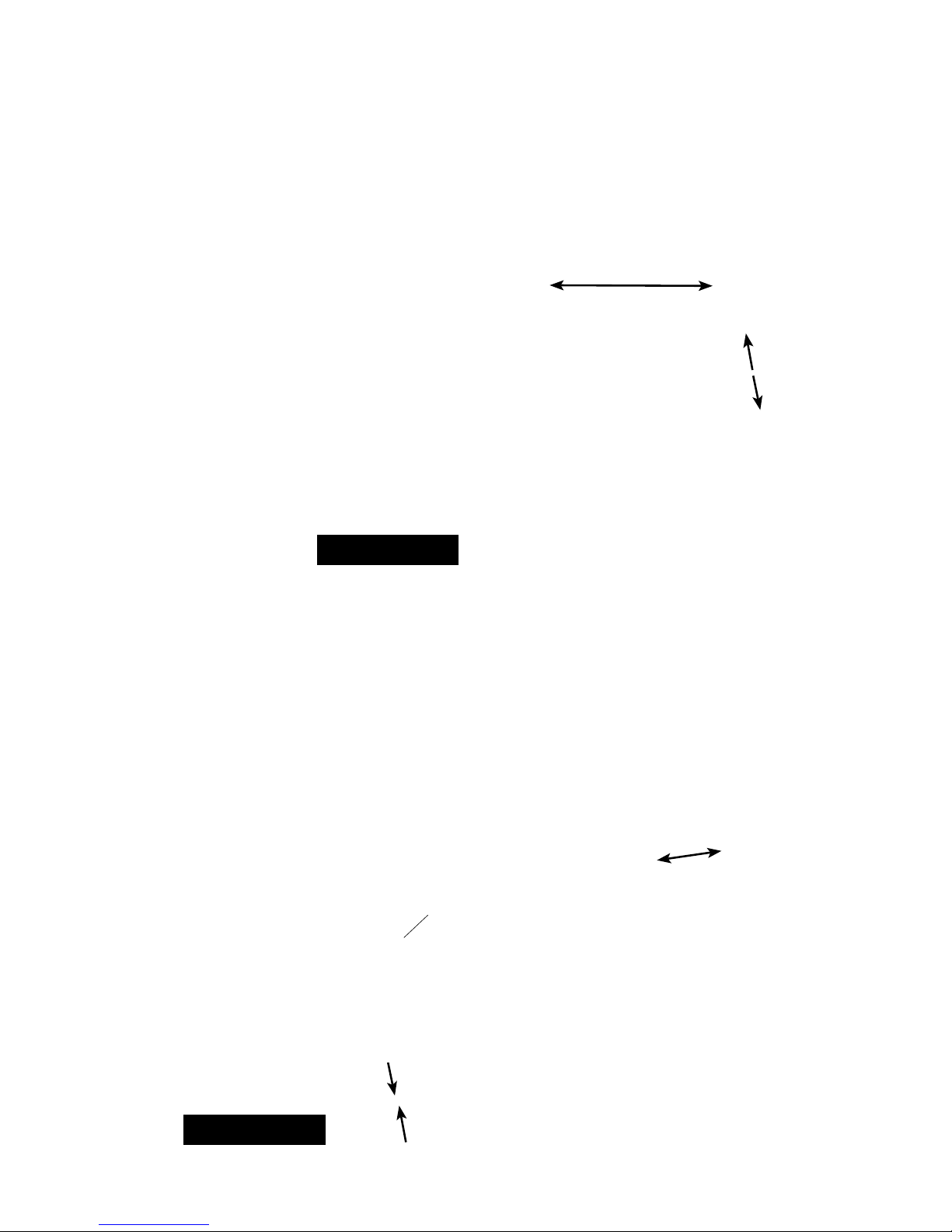

2. With the handpiece removed, place the entire

unit on a flat surface with the shaft and sheath

extended straight. Loosen the set screw on the

motor connector. Adjust the exposed tip (hand-

piece end) of the flexible shaft so that it

extends 3/4″ (19mm) beyond the sheath. This

is done by moving the sheath in or out of the

motor connector (motor end). Shown below.

3. When the correct adjustment is made,

re-tighten the set screw in the motor connector

and re-attach handpiece onto the shafting.

Assembly Instructions

Always make sure your power tool is

unplugged during assembly!

After identifying all the components of your

power tool, assemble it in the following manner:

Assembly and Adjustment of Flexible

Inner Shaft, Outer Sheath, & Handpiece

Proper assembly and adjustment of the key tip

flexible shaft and sheath are critical for the

correct operation of your Foredom power tool.

The exposed tip

(handpiece end

of the flexible

shaft with handpiece removed)

must extend 3/4″

(19mm) beyond

the sheath.

Important Note: The shaft and sheath should

be checked and adjusted (if necessary) even

if you received them assembled and

attached to the motor!

To Re-attach Handpiece: while holding the black

colored metal outer sheath tip facing upward, turn

on the motor so that it is running at about half

speed and then turn it off. While the inner key tip is

still rotating, grip the handpiece and push it onto the

sheath tip with one firm motion until it snaps into

place (shown at right). This procedure will align the

key tip into the keyway slot (as shown at left). To

verify this, insert and tighten an accessory into

collet or chuck, turn on motor to low speed and

observe that the accessory rotates smoothly.

keyway

slot

inside,

back end of

handpiece

key tip end of

shaft

metal

sheath tip

IMPORTANT!

IMPORTANT!

5

Loading...

Loading...