Other Service and Repair

All other service and repairs should only be

done by a qualified repair person or shop. Your

dealer can help you select one or you can send

your Foredom equipment to the Bethel, CT

factory. Factory repairs are done promptly and

at reasonable cost. Send the equipment marked

“Attention: Service Department”. Be sure to

include your street address, email address, and

phone number. The equipment should be

accompanied by a brief note describing the

problem with the equipment. Estimates will

be made upon request.

LIMITED WARRANTY

Foredom warrants the M.PGX Motor (excluding flexible shaft and sheath) and the C.EMGX Dial

Speed Control

purchase, the

after purchase. During the warranty period the defective product will be repaired or

days

replaced without charge or at our option, the purchase price will be refunded. This warranty

does not cover damage caused in transit or by accident, misuse, or ordinary wear.

ALL IMPLIED WARRANTIES, INCLUDING BUT NOT LIMITED TO WARRANTIES OF FITNESS

AND MERCHANTABILITY, ARE HEREBY LIMITED IN DURATION TO THE PERIOD MENTIONED

ABOVE FROM DA

ANY SPECIAL OR CONSEQUENTIAL DAMAGES.

Repair or replacement will be made at our option if the product is returned post-paid to:

All warranty repairs must be done at the factory at the above address. We will not pay any

shipping or transportation charges.

since it is especially sensitive to the pressure and stress variables of each individual operator.

This warranty only covers the original purchaser of the product. Some states do not allow

limitations on how long an implied warranty lasts or the exclusion or limitation of incidental

or consequential damages so the above limitations may not apply to you. This warranty gives

you specific legal rights, and you may also have other rights which vary from state to state.

to be free of defects in material or workmanship for a period of 2 years after

C.FCGX Foot Switch for 1 year after purchase, and the H.9D Handpiece for 90

TE OF PURCHASE, AND WE WILL NOT BE LIABLE OR RESPONSIBLE FOR

The Foredom Electric Company

16 Stony Hill Road

Bethel, CT 06801

The HP76 Duplex Spring is not covered by this warranty

Storage

Store your Foredom power tools in a dry, clean,

dust-free area and out of the reach of children.

Please retain your proof of purchase

for warranty repairs.

Contact Information

For more information on Foredom machines,

handpieces or accessories, contact your local

dealer. When no local dealer is available, write,

call, fax or visit on-line:

The Foredom Electric Company

16 Stony Hill Road, Bethel, CT 06801

Tel.: (203) 792-8622 Fax: (203) 796-7861

Email: customerservice@blackstoneind.com

www.foredom.net

Owner’s Manual

Assembly, Operation and Service for the

PowerGraver® Kit

2-Year Warranty

For Your Own Safety

• Please read this Assembly, Operation, and Service Manual

before operating your Foredom power tool.

• Always wear eye protection while using power tools.

FOREDOM

®

The Foredom Electric Company • Bethel, CT USA 06801 • www.foredom.net

Form 1297 n 6/11

®

FOREDOM

www.foredom.net

Printed in U.S.A.

P

Contents

age

Specifications 2

Safety Instructions 2

The Complete PowerGraver®Kit 3-4

Assembly Instructions 4

Assembly and Adjustment of Handpiece 4-5

Connecting Speed Control and Foot Switch 5

Operation 5

Stroke/Speed Adjustment 5

Installing Accessories

Changing Collets 6

Adjusting Impact of Hammer 6

5-6

Maintenance 6

Routine Cleaning and Lubrication

of Flexible Shaft 6

Replacement of Worn Shaft and Sheath 7

Replacement of Motor Brushes 7

Handpiece Lubrication 7

Other Service and Repair 8

Storage 8

For More Information 8

Limited Warranty 8

Specifications

M.PGX Motor: 125 Volt DC; Ball Bearing

Permanent Magnet Motor, Operable Speed

Range: 500 – 2,800 RPM.

PGX-1 is for use with 115Volt AC.

PGX-2 is for use with 230Volt AC.

C.EMGX Dial Control: Variable speed

manually operated electronic control.

EMGX-1 is for use with 115Volt AC.

EMGX-2 is for use with 230Volt AC.

Shaft/Sheath: Shaft S-93 is 39″ long, and

″ in diameter

.150

S-76N is 36

Optional FCGX Foot Switch: On/Off foot-

operated switching. (115V or 230V AC

Current)

Safety Instructions

Before using your Foredom®power tool,

please read all these safety instructions.

They are for your protection and should always

be followed to reduce the risk of

personal injury or damage to the tool.

• Always wear proper eye and face

protection.

should be worn whenever you operate a

Foredom or any power tool to prevent

serious eye or face injuries.

2

Visit

www.foredom.net

How-To Videos

FOREDOM BASICS

Foredom's National Sales

Manager, walks you through

the "Basics" of using and

maintaining flexible shaft

machines. Downloadable

mini series of .wmv files each

under 5 minutes.

Click to View:

1. Introduction and

Proper Set-up

2. Safety Guidelines

3. Handpieces and

Accessories

4. Maintenance of Shafts

and Sheaths – Grease

and Replace

5. Motor Maintenance–

Remove Dust, Replace

Motor Brushes

. Flexible Neoprene Sheath

1

⁄4″ long.

Safety glasses or face shields

Always make sure your power tool

is unplugged during maintenance!

Replacing Worn Shafts and Sheaths

Shafts and sheaths last longer when they are not

used at sharp angles or loops, since wear occurs at

the points of greatest friction. There is no way to

avoid ultimate wear, and under normal conditions a

flexible shaft machine may require several replacement shafts and sheaths during its lifetime.

To expose the inner shaft follow steps 1, 2, and 3

on the previous page.

Next, remove motor connector

with 1

″ open end or adjustable

wrench.

Motor connector has a

left hand thread and must be

turned clockwise (right)

for removal.

Loosen set screw on the flexible shaft motor

coupling and slide shaft off the motor shaft.

Installation of New Shaft

1. After removing old shaft, loosen set screw on

the new flexible shaft motor coupling and slide

coupling onto motor shaft.

2. Tighten set screw

securely onto the flat of

the motor shaft.

3. Grease shaft prior to

putting on the sheath.

(See lubrication

instructions on page 6.)

4. Slide motor connector back up over the shaft

and tighten to the left (counterclockwise).

5. Slide sheath over flexible shaft with plain fitting directed toward the motor and into the motor

connector. (Each end of the sheath has a metal

fitting. One is plain, the other fits the handpiece.)

6. Adjust the shaft as

shown at top right side

of page and tighten

sheath set screw in

motor connector.

Connector Aligning T

ab

set screw

motor

coupling

Oil Hole

Duplex Spring Cover

motor

shaft

Shaft and Sheath Adjustment:

P

lace the entire unit on

a flat surface with shaft

a

nd sheath extended

Adjust the

straight.

exposed tip of the

flexible shaft at the handpiece

end so that it extends 3/4

the sheath

is done by moving the sheath in or out of the

motor connector. When he correct adjustment is

made, tighten the screw in the motor connector.

, as shown at bottom of page 6. This

″ (19mm) beyond

Replacement of Motor Brushes

New Motor Brush

Motor Brush that

needs replacement

The motor brushes (MP319P) should be

checked for wear periodically. When new, they are

approximately 3/4

when they have worn to 1/4

disconnect motor power cord and unscrew the

brush caps. Be sure that the contour of the

brushes match the contour of the armature when

replacing them. Be sure to replace both motor

brushes even if one of them is less worn than the

other.To remove dirt and dust buildup, when motor

brushes are checked or replaced, compressed air

should be blown through the motor.

″ long. They should be replaced

″. To remove brushes,

Handpiece Lubrication

The H.9D Handpiece requires lubrication

approximately every 40 hours of use. Use oiler

provided to apply

hole located on the barrel of the handpiece under

the palm rest and into the hole on the rear of the

duplex spring connection. To remove palm rest,

loosen set screw.

drops of oil.

two drops of oil into the oiling

Do not apply more than two

Replacement Fuse

The C.EMGX Dial Speed Control may require

CP10543 Replacement Fuse for either 115V AC or

230V AC.

Palm Rest

Impact Adjusting Ring

7

Set Screw

Tool Holder

Chuck Nut

Wrench Flats

Oil Hole

Maintenance Procedures

Always make sure your power tool

is unplugged during maintenance!

It is very important to routinely clean your

Foredom

(NOT the motor), especially in areas that

generate a lot of dust.

Dirt and improper lubrication are the most

common causes of poor operation and

excessive wear.

Always disconnect power tool before

cleaning or servicing.

Note: The M.PGX has permanently

lubricated ball bearings and does not

require additional lubrication.

Routine Cleaning of Motors

Foredom Motors need air circulation through the

motor housing to remove waste heat and cool the

windings. Inlet and outlet slots provide the means

for air flow. However, saw dust and conductive

debris (like metal filings or gold dust) can enter in

through these slots. If not cleaned regularly, dust

can collect, making a bridge between parts,

causing an electrical short.

In high dust environments, Foredom

recommends cleaning the motor every

40 hours of use.

To remove dirt and dust buildup, motor brushes

should be removed, cleaned and replaced, and air

should be blown through the motor.

Routine Cleaning and

Lubrication of Flexible Inner Shaft

The shaft should be checked, wiped clean, and

re-lubricated with grease every 50 hours of use.

With every 200 hours of use, the shaft should be

thoroughly cleaned with solvent and lubricated.

Use Foredom flex shaft grease (p/n MS10006) or

high quality white lubricating grease.

®

Power Tool and lubricate the shaft

Exposing the Inner Shaft

1.Remove handpiece

(see page 4).

2. Loosen set

screw on motor

connector.

3. Slide outer

sheath out of motor

connector and wipe

shaft clean.

4. Apply a very light

coating of lubrication

to shaft starting at the

top and working

downward to about

one inch from the handpiece end. Apply grease

with your finger tip or small brush. Don’t overdo,

apply a light film of grease. Once the machine is

running, the shaft itself will spread the grease. If

too much grease is applied, the excess will work

its way into the handpiece and will make the

handpiece run hot. For this reason, apply a bit

less near the handpiece end of the shaft.

Never operate the motor with the outer

sheath removed from the flexible shaft.

5. Replace and adjust

sheath so that shaft

key tip extends 3/4

(19mm) from sheath.

Retighten the set

screw in motor connector.

6. Clean outside of sheath by wiping with

a cloth.

7. Hang and run the motor for about 10 minutes

before attaching the handpiece to allow enough

time for the grease to warm up, spread and

drain off. Wipe off any excess grease at tip end

of sheath.

8. Re-attach handpiece.

6

″

IMPORTANT!

• Always use dust collection, respirator,

or face mask to prevent inhalation of

dust particles from workpiece

or abrasives.

• Never use or continue to use a graver or

accessory which appears to be damaged.

Inspect each graver for cracks or flaws

before using it.

• Always insert the shank or arbor of an

accessory or mandrel into the collet of

the handpiece as far as possible in order

to provide proper support and tighten the

collet securely.

• Never use excessive side pressures

which may tend to bend or break the

shank or arbor of an accessory. Let the

impact of the hammer do the work.

• Do not stall the motor by jamming or

using excessive pressure on the accessory.

This can result in damage to the motor or

flexible shaft.

• Never operate the motor with the outer

sheath removed from the flexible shaft.

• Always disconnect the power cord

before servicing the motor or removing

the flexible shaft or sheath.

• Never operate your power tool during a

perceptible power decrease. Turn power

tool off and do not use until power is

fully restored.

Accessories

Collets:

HP602 (1/16″),

HP603 (3/32″), 604 (1/8″)

and HP605 (3mm)

Gravers: A-G91 #52 Round

A-G92 #3 Onglette

A-G93 #2 Bevel

A-G94 #40 Flat

10215 Carbide Stylus

10177P Anvil Point

se proper grounding procedures.

• U

should be grounded while in use to protect

the operator from electric shock. The tool is

equipped with an approved 3-conductor cord

and a 3-prong grounding type plug to fit the

proper grounding receptacle. The green (or

green and yellow) conductor in the cord is

the grounding wire. Never connect the green

(or green and yellow) wire to a live terminal.

If your unit is for use on less than 150 volts,

it has a plug that looks like sketch A in the

diagram below. An adapter (sketches B and

C) can be used for connecting plugs as

shown below to 2-prong receptacles. The

green colored rigid ear, lug, etc., extending

from the adapter must be connected to a

permanent ground such as a properly

grounded outlet box.

Some jurisdictions,

This tool

including Canada, prohibit the use of 3 to

2 prong adapters. Where prohibited, they

should not be used.

extension cords that have 3-prong grounding

type plugs and 3-pole receptacles that accept

the tool's plug. Always disconnect the power

cord before servicing the machine. Never use

in an area where flammable vapors are present.

Use only 3-wire

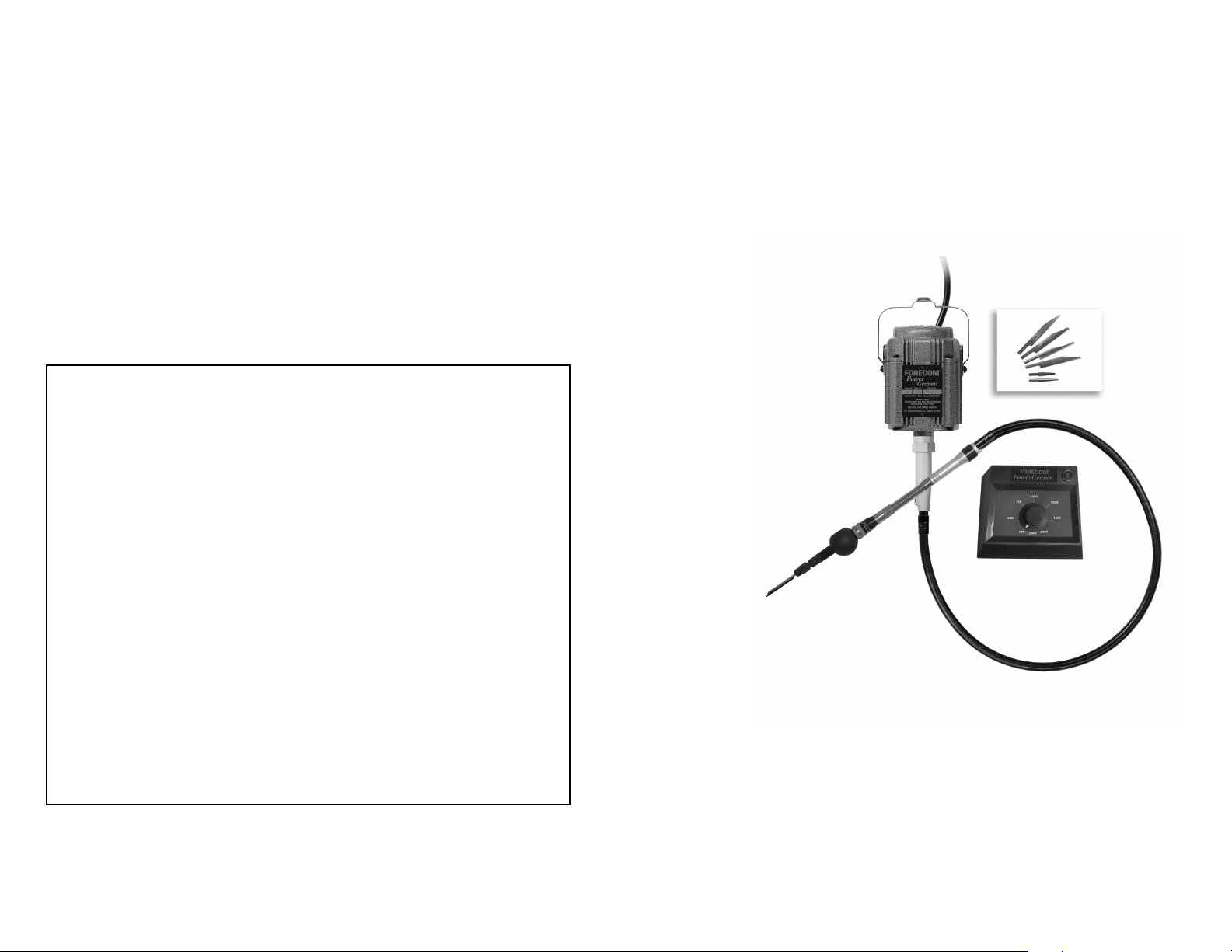

The PowerGraver® Kit

The Foredom®PowerGraver is a complete

power tool used to perform a wide variety of

tasks such as engraving, stone setting, bright

cutting, bead raising, and other applications

requiring the use of a graver or a hammering

effect. Foredom power tools are manufactured to

high standards of precision and with proper use

and regular maintenance will give you years of

trouble-free performance.

The Foredom PowerGraver Kit K.2293

a permanent magnet DC motor, flexible shaft with

neoprene sheath, dedicated handpiece with palm

rest, variable speed dial control, and accessories

listed at left.

3

consists of

The Foredom PowerGraver Kit K.2293

includes collet changing wrenches, handpiece

oil, flexible shaft grease, 32-minute instructional

DVD and booklet.

also

Assembly Instructions

Always make sure your power tool is

unplugged during assembly.

The PowerGraver ships with the shaft and

sheath assembled, however,

be sure that the tip of the shaft extends

″ beyond the end of the sheath. If it

3⁄4

IMPORTANT!

exposed tip of the flexible shaft so that it

extends 3/4

This is done by loosening the set screw in the

motor connector and moving the sheath in or

out of the motor connector. When the correct

adjustment is made, tighten the set screw in

the connector. See photo on bottom of page 6.

Connecting the Handpiece:

Unlike other Foredom Handpieces, the H.9D

handpiece has a tab on the end where it connects to the shaft and sheath (see drawing).

The tab slides over the flattened edge on the

sheath.

sheaths.

be attached to the PowerGraver shaft for

slow speed jobs.

″ beyond the sheath, as shown.

flattened edge of sheath

tab

The H.9D will not fit other Foredom

However, other handpieces can

please check to

needs to be

adjusted, place the

entire unit on a flat

surface with shaft

and sheath

extended straight.

Adjust the

Locate and identify all components before

discarding the packing list and materials that

came with your PowerGraver.

An optional on/off foot switch is available.

1. In addition to aligning the outer tab, the

keyed tip at the end of the flexible shaft must be

lined up with the keyway inside the end of the

handpiece. Do this by looking into the rear of

the handpiece before pushing it on. If it is not in

line, turn the key tip or the handpiece to the

correct position while being sure to also align

the outer tab with the flat outer edge of the

shaft.

Both connections must be properly

aligned and they move or turn independently

of eachother.

from the flexible shaft. To

the handpiece off the shaft and sheath with a

firm grip.

2. Install the Palm Rest. Slide the larger

opening over the front of the handpiece and

place it as close to the impact adjustment ring

as possible. Rotate the palm rest to the most

comfortable position and tighten set screw with

a small flat-head screwdriver. Use of the palm

rest is a matter of personal preference. You may

find that the palm rest is more appropriate for

some applications than others.

1

⁄8″

The handpiece is easy to remove

remove, simply pull

Grind corners of shank

1″

to dimension shown for

snug fit into collet.

Installing Accessories

The PowerGraver can take standard gravers and

other accessories with 1/16

(2.35mm), 1/8″ (3.18mm) and 3mm diameter

shanks. Choose the correct accessor

particular application. We recommend that you

grind and trim standard graver shanks to the

dimension illustrated above.

4

(1.6mm), 3/32

″

y for your

To install an accessory, insert one wrench into

the wrench flats of handpiece. Insert other

wrench into wrench flats of chuck nut. Loosen

chuck nut. Insert accessory as far as possible

into the collet. Tighten chuck nut. Test for a

secure hold by pulling on accessory. Remove

wrenches. To release an accessory, follow the

same steps.

Changing Collets

The H.9D handpiece has collets to fit four

different shank sizes: 1/16

3mm. To use the correct collet size for the

shank of the accessory you are using, it is

sometimes necessary to change a collet. The

″, 3/32″, 1/8″ and

collet holds the accessory securely in the

handpiece. Unscrew the chuck nut and slip out

collet. Slip in new collet and screw the chuck

nut back into place.

Chuck Nut

Palm Rest

Impact

Adjustment Ring

Adjusting Impact of Hammer

The impact of the stroke is adjusted by rotating

the knurled ring on the handpiece clockwise

towards the chuck nut for a lighter impact –

and counterclockwise towards the back for a

heavier impact.

Connecting Motor and Control

1. Connect male plug of motor to female

cord of Dial Control.

2. Connect male cord of Dial Control into wall

outlet or into female cord of Optional On/Off

Foot Switch.

Motor

Variable

Speed

Dial

Control

3. Plug the Optional On/Off Foot Switch into

an electrical outlet.

Plug into wall outlet

On/Off

Foot

Switch

Optional

Plug

into wall

outlet or

Optional

Foot

Switch

Operation

Read all safety instructions on pages 2 and 3

before using your Foredom PowerGraver.

Wear proper eye and face protection to protect yourself from injuries caused by flying

debris or chips from the work being done.

Your Foredom motor may be operated in a vertical or horizontal position. If the motor is hung

″

up above a workbench, be sure to

fasten it securely.

Do Not Bend the Flexible Shaft at a T

Angle.

Shafts and sheaths last longer when

they are used without sharp bends. If used at

angles or loops, wear will occur at the points of

greatest friction.

ight

Do Not Force the Tool. Let the speed of

the tool do the work. Avoid using too

much pressure.

Stroke/Speed Adjustment

The strokes per minute are determined by

motor speed, which can be varied from 500 to

2,800 strokes. Set the speed desired with the

knob on the V

speed and impact can be adjusted while the

motor is running. The On/Off Foot Switch will

turn the motor on or off at the speed set on the

speed control.

5

ariable Speed Dial Control. Both

Loading...

Loading...