Replacement Parts

Spare parts are available for your Foredom

®

F

lexade

i

When ordering parts, service or parts lists

be sure to include the model number of

your Flexade.

Description Part No.

Standard Sheath S.86

Neoprene Sheath S.86-N

Inner Shaft S.104

Foredom Grease MS10006

Motor Couplings

1/4″ hole S.92-14

5/16

3/8

1/2

f you wish to do your own service.

″ hole S.92-516

″ hole S.92-38

″ hole S.92-12

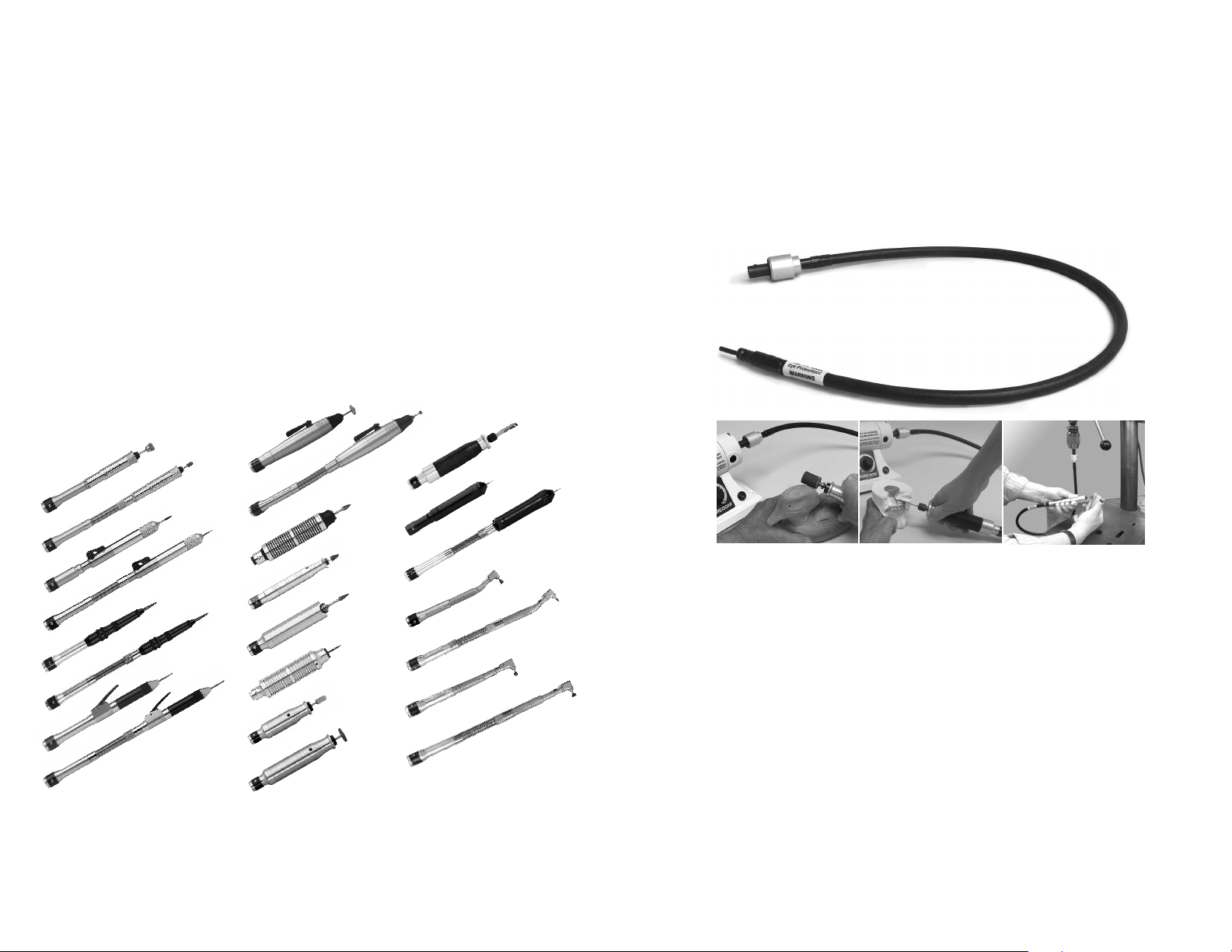

FOREDOM®Handpieces

(burs not included)

H.

20

H.8

H.8D

H.10

H.10D

H.15

H.20D

H.25

H.28

H.30

®

Service

F

actory repairs are done promptly and at

reasonable cost. If you wish, you can send

your equipment directly to the factory

marked “Attention: Service Department”. Be

sure to give your street address and email

address. The equipment should be accompanied by a brief note describing the problem

with the equipment. Estimates will be made

upon request.

For More Information

For more information on Foredom machines,

handpieces or accessories, contact your local

dealer. When no local dealer is available,

write, call or fax: The Foredom Electric Co.

16 Stony Hill Road, Bethel, CT 06801

Phone: 203-792-8622, Fax: 203-796-7861.

You can also visit our website

at www.foredom.com.

H.50

H.52

H.52D

H.55A

H.55D

Owner’s Manual

Assembly, Operation and

Service Manual for

Flexade

For Your Own Safety:

• Read this Owner's Manual before operating your Foredom Power Tool.

• Always wear eye protection while using power tools.

• Always use dust collection, respirator, or face mask to prevent

inhalation of dust particles from workpiece or abrasives.

®

H.15D

H.18

H.18D

H.35

H.56A

H.43T

H.56D

H.44T

®

FOREDOM

The Foredom Electric Company, 16 Stony Hill Road, Bethel, CT 06801

www.foredom.com

Form 1293 n 6/08

®

FOREDOM

www.foredom.com

Printed in U.S.A.

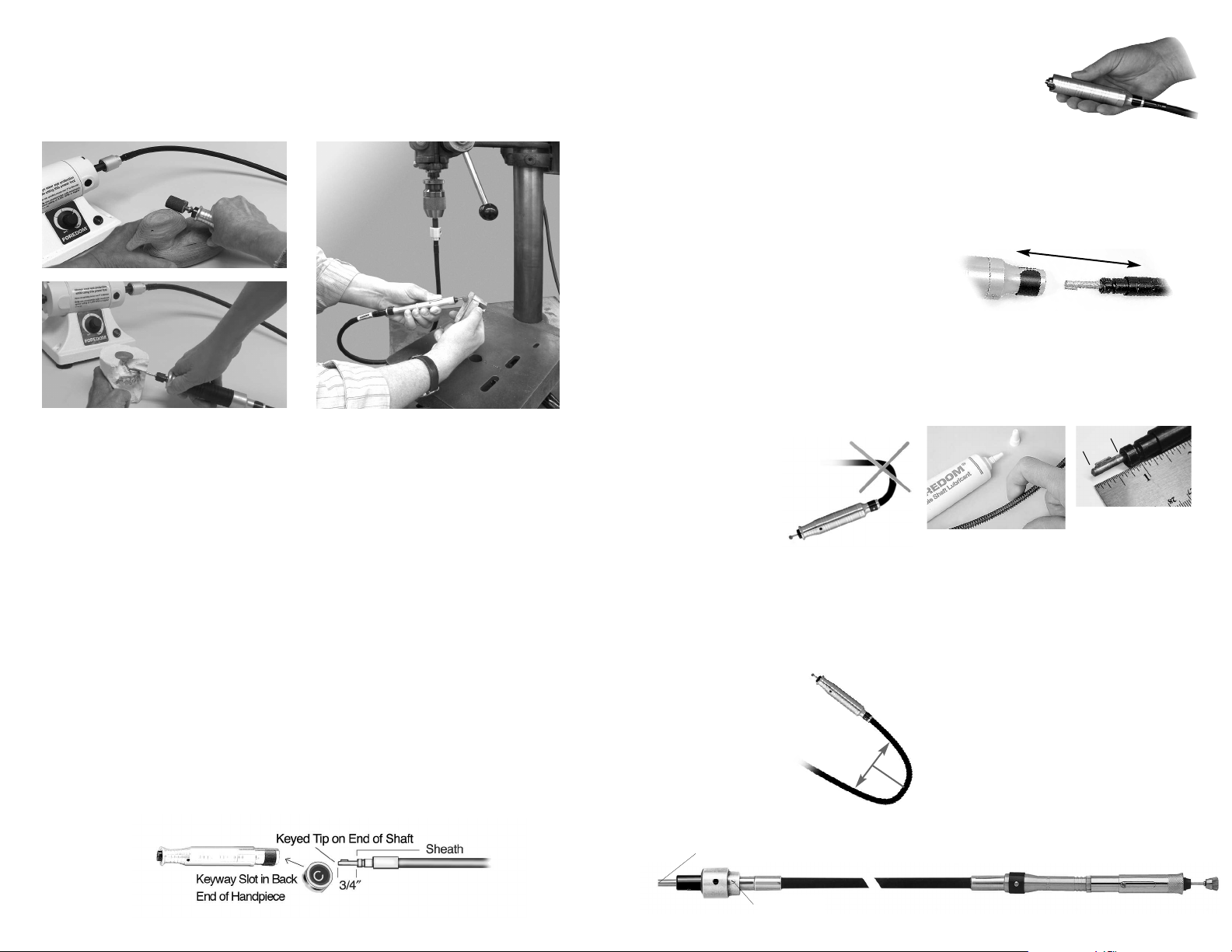

The Foredom Series B Flexade®is suitable for

use with any motor, drill press, or electric drill

which operates between

It is ideal for Foredom’s BL Bench Lathe which

runs at speeds up to 7,000 rpm.

1,500 — 15,000 RPM.

For best performance, the speed should be

3,500 RPM or more.

Only run the motor or other power source

in a forward direction.

Operation

Your Flexade can be used for any small job of

grinding, cutting, polishing, deburring, drilling,

e

tc. Handpieces and accessories for all types

of grinding, deburring, polishing, finishing,

cleaning, and other applications are

available from your Foredom dealer or at

www.foredom.com.

Always turn the flexade

power source off

and wait until

the tool bit or bur

comes to a

complete stop before you

let go of the handpiece.

The Flexade converts the BL Lathe into a flexible

shaft machine. It is shown here with H.44T and

H.50 handpieces that are available separately.

The sheath is flexible, tough, long-lasting and

impervious to oil and grease.

Handpieces are easy to attach and remove, and

can be interchanged with any of Foredom’s 20+

quick disconnect (QD) handpieces. The different

style handpieces for use with your Flexade are

shown on the back of this manual. For more

information visit www.foredom.com.

The B Flexade has a 30

dard or more flexible neoprene sheath. It comes

equipped with a ball bearing 5/16

attaching to a 5/16″ dia. motor shaft. Other

coupling sizes are also available for attaching

to 1/4

″, 3/8″, 1/2″ dia. motor shafts.

″ shaft with either a stan-

″ coupling for

Installation

The Flexade can be attached in a number of

ways. When used with a lathe, motor, or any

The Flexade converts a Drill Press into a flexible

shaft machine. It is shown here with an H.8

handpiece that is available separately.

other rotating shaft, simply attach the coupling to the shaft. Be sure to tighten the set

screw firmly

Flexade should run counterclockwise.

To install your Flexade in a drill press or

electric drill, you need to insert a dowel pin

or short piece (2

Flexade coupling. Tighten the set screw after

inserting. Then insert the exposed part of

the round steel into the drill chuck and close

the chuck. Check to be sure that it rotates

counterclockwise or in the forward direction.

Attach the handpiece by pushing it on the

grooved QD fitting on the shaft. Be sure

that the keyed tip of the flexible shaft is

properly lined up with the keyway slot in the

handpiece by looking into the rear of the

handpiece (see illustration below). If it is

not in line, turn the shaft or handpiece to

the correct position.

. Check the rotation. Your

″) of round steel into the

The best results will be obtained with a fairly

light touch. Heavy pressure will slow down

your tool and, if the motor is actually stalled

because of heavy pressure or snagging, you

may damage the flexible shaft. Let the speed

of the tool do the work. Avoid using too much

pressure. Generally, slower speeds are used for

rougher, heavier work or when greater control

over the accessory is required for precise,

delicate work.

Voltage Decreases

Never operate a power tool during a perceptible power decrease. Turn off tool and unplug

until full power is restored.

Always wear proper eye and

face protection

when operating

a Foredom

Do Not

Do This!

power tool.

Do not bend

shaft and sheath

at tight angle

Shafts and sheaths last longer when they are

used without sharp bends. If used at angles or

loops, wear will occur at the points of greatest

friction. When operating your power tools

careful not to bend the flexible shaft too much

at either the handpiece or

motor shaft connections.

Excessive heat and wear

will occur if the bend

is too great.

Follow these guidelines for trouble-free use:

a 4″ or larger radius, as

shown, should be maintained for

flexade shafts.

dowel pin

Minimum

Operating

Radius

4″

radius

be

4

radius

″

Flexade Lubrication

The flexible shaft should be lubricated after every

50 hours of operation.

To lubricate the shaft, first take off the handpiece.

This is done by giving the handpiece a sharp pull

(shown above). Next, loosen the set screw (see

illustration at bottom of page) and pull the shaft

free of the outer sheath. Apply a VERY light film

of Foredom’s MS10006 grease along the entire

length of the flexible shaft.

3/4″

IMPORTANT

Replace the sheath, being sure that the flexible

shaft tip projects 3/4

handpiece end. When this is correct, tighten

set screw. Run the Flexade slowly for several

minutes. Turn off the power source, wipe any

excess grease from the tip of the flexible shaft

and attach the handpiece.

Handpiece Lubrication

Nearly all of Foredom’s 20+ different interchangeable handpieces have permanently lubricated ball

bearings and

exceptions are handpieces with duplex spring

connections such as the H.8D, H.10D, and H.18D.

The spring connections require oiling approximately every 20 hours of use.

Each Foredom handpiece comes with complete

instructions for use and maintenance. This can

also be downloaded from

″ beyond the sheath at the

should not be lubricated. The

.foredom.com

www

.

set screw

Loading...

Loading...