Foredom Double Motor Hanger User Manual

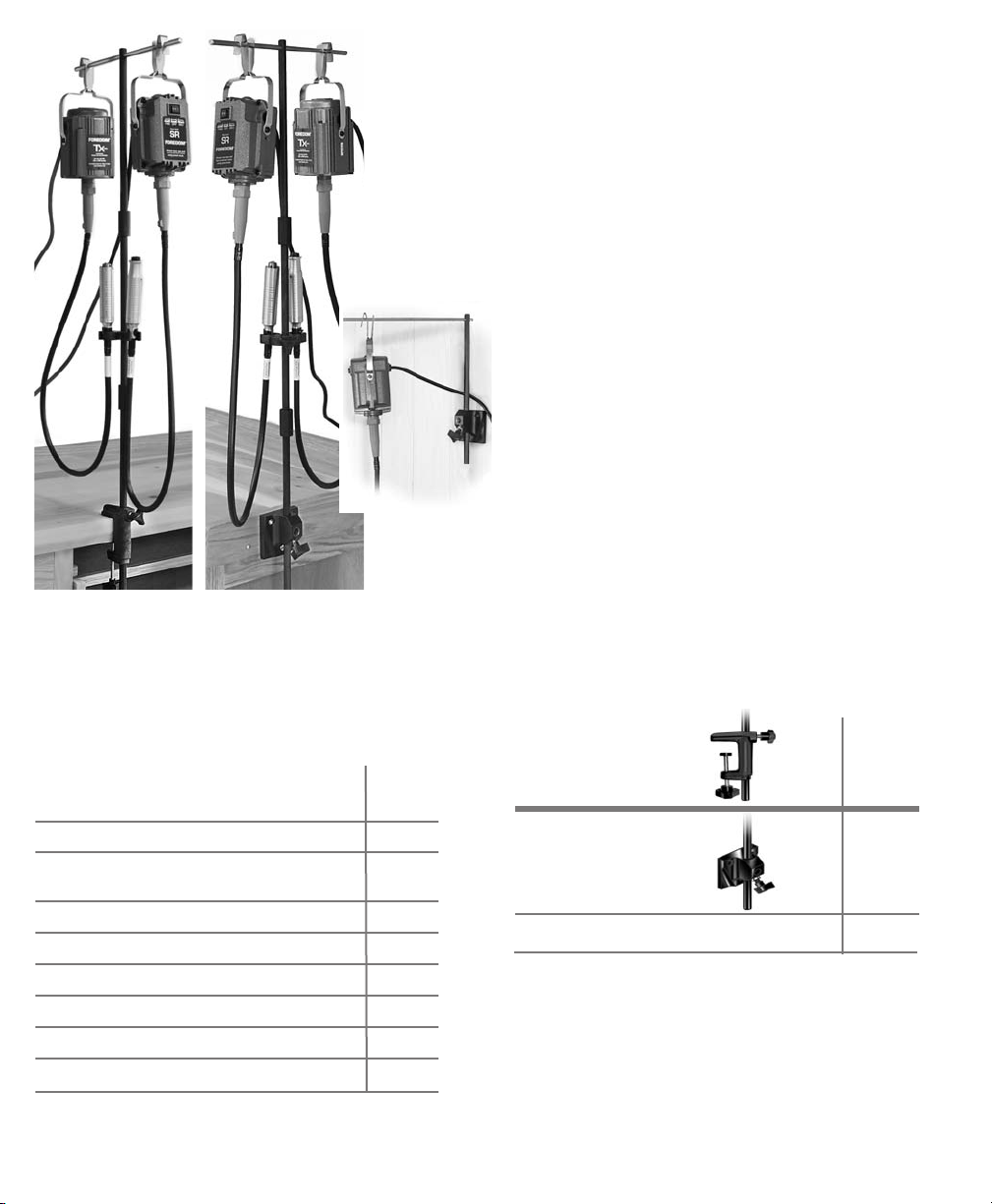

Wall Mount

set-up

with MAMH-2

using the

MAMH-1

with MABC-1 Clamp

attaches to bench

MAMH-2

with MABC-2 Base

screws or bolts to bench

or attaches to wall

MABC-2 Base

attaches to wall

for hanging

one motor

Replacement Parts for

MAMH-1

Part No. Description

UA10658 Safety Hook 2

UA10661 Hanger Rod (horizontal) 1

UA110-5 Set Screws, (10−32 x 1/4″) 5

hexagon socket cup point

UA10682 Coupling 2

UA10683 Top Rod 12

UA10685 Middle Rod 12

UA10686 Bottom Rod 17″ long 1

UA115 3/32″ Hex Key 1

MAHR-2 Handpiece Rest 1

or

MAMH-2

Quantity

Included

1

⁄4″ long with cross hole 1

1

⁄4″ long 1

1/13 F-10687 Printed in USA

®

FOREDOM

D

ouble Motor Hanger

Safety Instructions

Before using your Foredom power tool, please read safety

instructions. They are for your protection and should always be

followed to reduce the risk of personal injury or damage to the tool.

• Always wear proper eye and face protection. Wear safety glasses or

face shields whenever you operate a Foredom or any power tool to

prevent serious eye or face injuries.

• Secure the work piece or item that you are working on in a vise or

other work holding device. Holding it with your hand can result in

serious hand injury.

• Always use a proper dust collection system or wear a respirator

to prevent the inhalation of dust particles, polishing compounds, or

other debris into the lungs.

• Do not wear loose fitting clothing or jewelry. Loose clothing or

jewelry can become entangled in the rotating accessory. Do not wear

items such as neckties, necklaces, or bracelets when operating power

tools. Be sure to tie back or secure long hair.

• Secure hang up motor to motor hanger. Flexible shaft power

tools can “jump” at start up or vibrate during operation. The

tool should be properly secured to prevent it from vibrating

off of the motor hanger or work bench.

• Never operate any accessory at speeds above its maximum rated

speed. When properly used, all of Foredom’s accessories can be operated at the speed ratings listed in the Foredom Accessory Catalog or

specified on kits and packages. Always find out the manufacturer’s

speed rating before using accessories other than those from Foredom.

Quantity

Part No. Description

For MAMH-1

MABC-1 Clamp Mount 1

For MAMH-2

MABC-2 Base Mount 1

HP103117 Wrench for Base Mount MABC-2 1

Three wood screws are required to attach the

MABC-2 Base to a wall or workbench. Use wood screws

long enough to securely hold the base, motor hanger,

and motor.

Foredom Electric Company

16 Stony Hill Road, Bethel, CT 06801 USA • Tel: 203-792-8622

Fax: 203-796-7861

• Email: customerservice@blackstoneind.com

www.foredom.net

Included

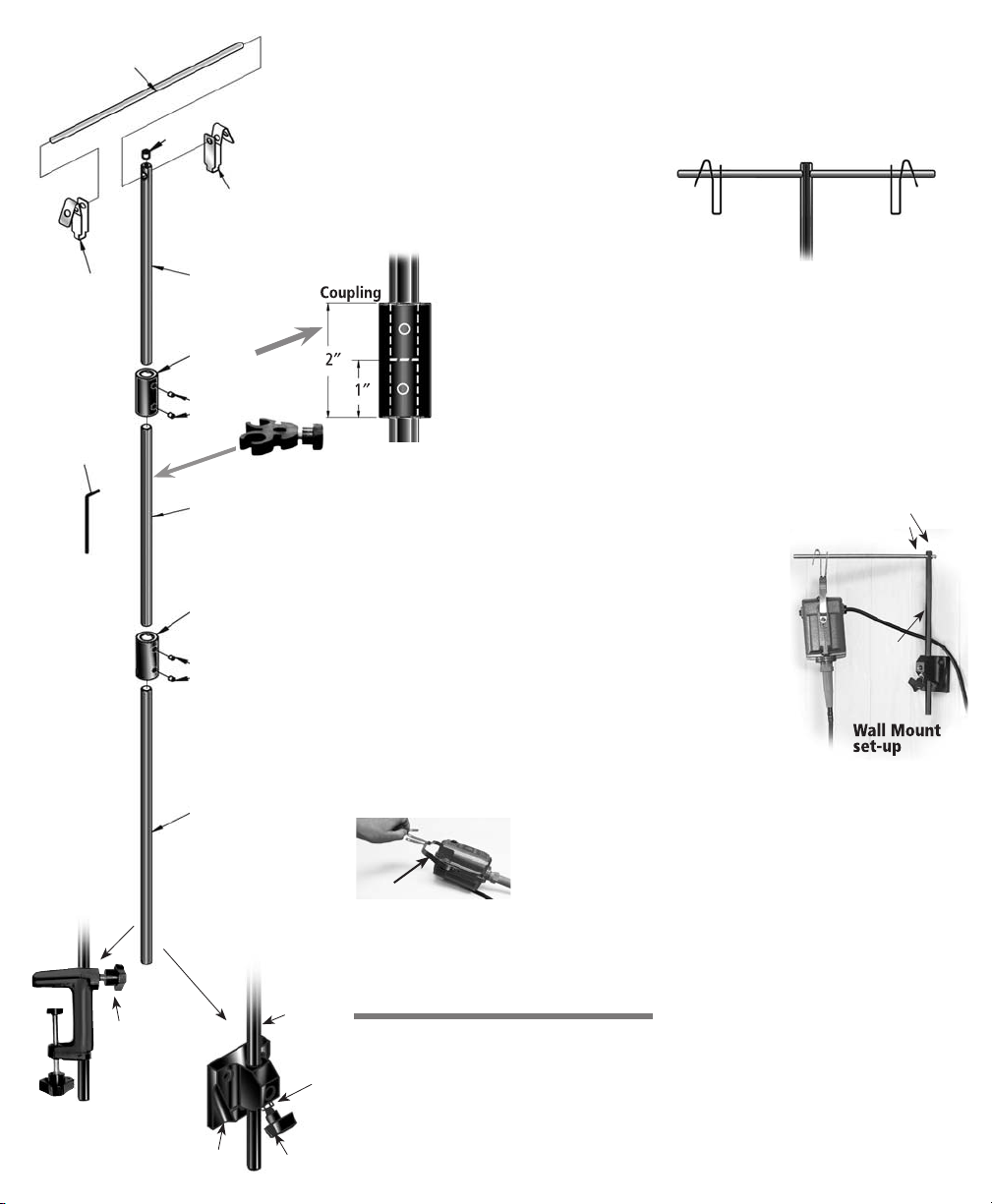

Hanger Rod

UA10661

Safety

Hook

3/32″

Hex Key

UA115

MABC-1

Bench Clamp

attaches to

bench top

Threaded

Knob

Set

Screw

or

MABC-2

Base

screws or

bolts to

bench top

or side

Base

Mount

Safety

Hook

UA10658

Top Rod with

cross hole

(121⁄4″ long)

UA10683

Coupling

UA10682

Set

Screws

Middle

Rod

(12

long)

UA10685

Coupling

Set Screws

UA110

Bottom Rod

(17″ long)

UA10686

Bottom end of Rod

inserts into MABC-1

Bench Clamp or

MABC-2 Base

1

⁄4″

Handpiece rest

MAHR-2 slides

onto Middle

rod before

couplings are

attached

Upright

Rod

1/2″ Hex

Jam Nut

Threaded

Knob

Follow Instructions below to assemble your

MAMH-1 or MAMH-2 Double Motor Hanger

1. Before you can hang up your flex shaft

motor, decide where you want the motor

hanger to be. If you are right handed it will

probably be on your right, and if you are left

handed it will probably be on your left.

Depending on which you have, attach either

the MABC-1 Bench Clamp or MABC-2 Base

to your work bench very securely. Both

mounts have knobs for adjusting

the height of the motor hanger.

2. Slide the handpiece rest

MAHR-2 onto the Middle

and tighten it enough so that it

does not slide around. You will

want to adjust its position on the

rod according to your needs once

the motor is hanging.

3. Assemble the rods in the order

shown in the drawing at left.

Insert the rods half way into the couplings.

4. Use the Hex Key to securely tighten

both Set Screws in each of the two

Couplings. When the three rods are

properly joined by the Couplings it should

feel like one solid steel bar and should

not flex or wobble at all.

5. Insert the Hanger Rod through the Top Rod

with cross hole so that the Hanger Rod is

centered and securely tighten the Set Screw

into the end of the Top Rod with cross hole

using the Hex Key.

6. Slide the assembled hanger rods into either

mount that you have installed on your work

bench at a comfortable height for you to reach

and tighten adjusting knob.

Make sure the

vertical hanger rod extends at least 1/4″

below the end of either the MABC-1

Bench Clamp or MABC-2 Base.

Safety Hook

7. Slip a Safety Hook

through the motor

bale so that the

circular holes in the

Safety Hook are at

the top.

8. Slide Safety Hook holding motor onto the

Hanger Rod with the hooks positioned as

shown at top right side of this page.

Using the MABC-2 Base

1. Position the assembled Motor Hanger at

desired height.

2. Tighten the Threaded Knob firmly against

the Rod.

3. Tighten the Jam Nut firmly against the Base

using a 1/2″ wrench.

Rod

Check www.foredom.net for

MAMH-1 and MAMH-2

instruction videos!

9. Use the Threaded Mounting Knobs to raise

or lower the height of the Motor Hanger.

Keep a distance of 25″–29″ between the

benchtop and the bottom surface of the

motor. Turn motor on to be sure it is installed

properly. A second motor can also be

mounted on the hanger.

IMPORTANT:

height to avoid sharp angles and bends in

your shaft and sheath. Excessive heat or

wear will occur if the curve is less than

a

4″ radius.

Be sure to position motor

Mounting a

MAMH-2

Motor

Hanger

on a wall

1. Attach the

MABC-2 Base

Mount to a wall

stud* or other

very sturdy vertical

wooden structure.

Be sure the

wood screws are

firmly fastened

into solid wood.

2. Use only the Top Rod with cross hole for

the hanger rod. Insert the Hanger Rod and

tighten this connection with a set screw.

3. Insert the vertical Top Rod through the Base

Mount and tighten both the Threaded Knob

firmly against the Rod and the Jam Nut firmly

against the Base using a 1/2″ wrench.

4. Adjust the Hanger Rod to hold a single

motor and you’ve got a wall-mounted

motor hanger!

To find the wall stud: tap on the wall with

*

your knuckle.

frame of a wall.

Move sideways along the wall, still tapping,

and listen for a solid sound. Studs are usually

placed 16″– 24″ apart, but may be located

differently in older buildings.

If you don’t trust your ear, use an electronic

or magnetic stud finder, available at

hardware stores.

Wall Studs are the inside

Set Screw here

Hanger Rod

Top Rod

with cross

hole

Loading...

Loading...