Foredom 5 High Speed User Manual

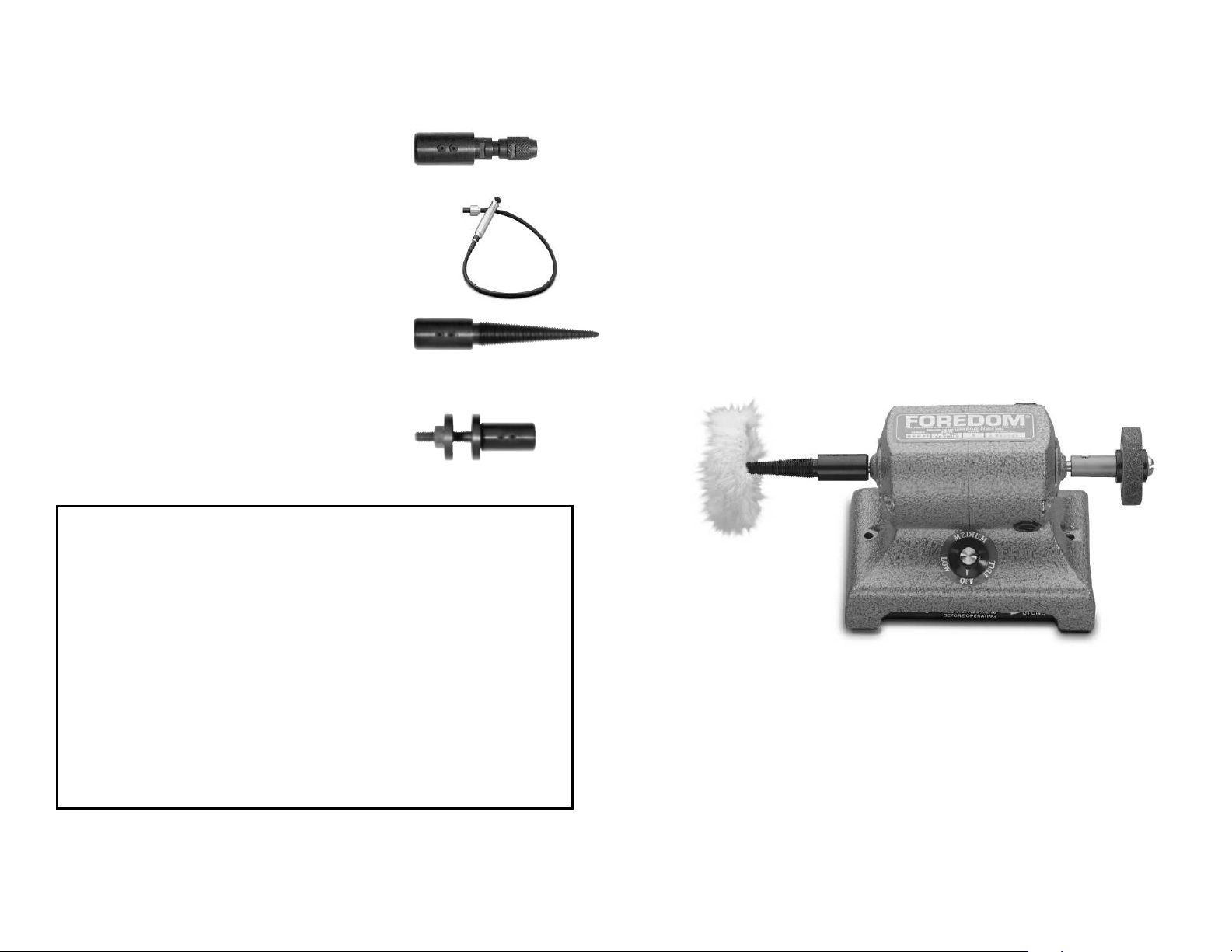

Optional Accessories c

Collet Holder, Flexade®and Tapered Spindle

Use on right hand side of bench grinder only.

Collet Holder (Part No. CHA-1) – Holds all No. 600

series collets in 1/32

a 3/32

″ collet. Fits 1/4″ diameter straight motor shafts.

ontinued

″ to 1/8″ and 3mm sizes. Includes

®

FOREDOM

Owner’s Manual

Flexade®(Part No. BO-14) – detachable flexible shaft which

converts your bench grinder into a flexible shaft machine

when used with any Foredom handpiece

catalog for description of handpieces.

Tapered Spindle (Part No. TM-4) – Precision spindle

suitable for use with cotton, felt, or chamois buffs with

shellac hardened or lead centers. Also used with inside

ring buffs on wooden mandrels. Fits 1/4

straight motor shafts. For use on right side of grinder.

Wheel Mandrel (Part No. WM-3) – Holds rubber bonded

abrasive wheels, sanding drums, brushes, and other

accessories with 1/4

maximum speeds of 15,000 RPM or higher. Use WM-3

on left side of grinder.

The Foredom Electric Co. warrants its product to be free of defects in material or workmanship

for a period of one year after purchase. During the warranty period, the defective product will

be repaired or replaced without charge or, at our option, the purchase price will be refunded.

This warranty does not cover damage caused in transit or by accident, misuse, or ordinary

wear. ALL IMPLIED WARRANTIES, INCLUDING BUT NOT

FITNESS

ENDING ONE YEAR FROM DATE OF PURCHASE, AND WE WILL NOT BE LIABLE OR

RESPONSIBLE FOR ANY SPECIAL OR CONSEQUENTIAL

AND MERCHANTABILITY, ARE HEREBY LIMITED IN DURATION TO A PERIOD

″ mounting holes and rated for

LIMITED WARRANTY

. See the Foredom

″ diameter

LIMITED

DAMAGES.

TO WARRANTIES OF

for the

High Speed

Bench Grinder

Models No. 1 and 5

Repair or replacement will be made at our option if the product is returned post-paid to:

The Foredom Electric Company

16 Stony Hill Road

Bethel, CT USA 06801

All warranty repairs must be done at the factory at the above address. We will not pay any shipping or transportation charges. This warranty only covers the original purchaser of the product.

Some states do not allow limitations on how long an implied warranty lasts, so the above

limitations may not apply to you. This warranty gives you specific legal rights, and you may also

have other rights which vary from state to state.

®

FOREDOM

The Foredom Electric Co.

16 Stony Hill Road, Bethel, CT 06801 • website: www.foredom.co m

Form 1227E n 5/02 Printed in USA

For your Own Safety:

• Read Owner’s Manual before operating

your Foredom power tool.

• Always wear eye protection while using power tools.

Always check to be sure that accessories are tight

•

on their shafts before you turn on the motor.

• Always use dust collection, respirator, or face mask

to prevent inhalation of dust particles from

workpiece or abrasives.

Installation

Your Foredom High Speed Bench Grinder can be used almost anywhere, but the

motor should not be enclosed or confined so as to restrict air circulation. Two

holes are provided in the base casting if you wish to fasten your grinder to your

bench. Be sure the switch/speed control knob is in the off position (turned

counterclockwise as far as it will go) before you plug in the power cord. Check

the nameplate of your grinder to be sure the motor voltage matches the voltage

you are using. Attach the tapered spindle TM-3 and wheel mandrel, which come

with the No. 1 and No. 5 Bench Grinder, to the left and right motor shafts. Make

sure that the set screws are on the flat part of the motor shaft as close to the

motor as possible; and that the set screws are tight.

The High Speed Bench Grinder Models No. 1 and 5

come with the following accessories:

Tapered Spindle (Part No. TM-3) – Precision spindle suitable for use

with cotton, felt, or chamois buffs with shellac hardened or lead centers

on left side of grinder. Also used with inside ring buffs on wooden

mandrels. Fits 1/4

tapered spindle for use on right side of motor.

Cotton Buff (Part No. CB-1) – 21/2″ diameter buff for polishing and

buffing. May be used with jeweler’s rouge, tripoli, etc. It must be used on

the TM-3 tapered spindle on the left side of the grinder. Maximum speed

rating: 25,000 RPM.

″ diameter straight motor shafts. Optional TM-4 is

Operation

The Model No. 1 Grinder produces no load speed up to 15,000 RPM, controlled

by an electronic speed control which is manually adjusted. The on/off switch and

speed control are operated by the knob on the front of the motor base. To shut

the motor off, turn the knob counterclockwise as far as it will go. You will hear the

switch click as it goes into the off position. The Model No. 5 Grinder is similar to

the No. 1 except the speed is adjusted by a foot control. This model does not

have an off/on switch. Please keep in mind that both grinders accomplish their

work through high speed rather than high torque; therefore you should use the

lightest pressure possible. With a light touch you will avoid unnecessary tool

marks, rapid wear of the tool, and overheating of the motor.

Service

Your Foredom High Speed Bench Grinder is equipped with a ball bearing motor,

and requires no lubrication. However, we recommend that you keep a spare set

of motor brushes, Part No. 229P. The motor brushes should be checked periodically for wear. When new they are approximately 1/2″ long. They should be

replaced when they have worn to 1/4

the brush caps. When replacing them, be sure that the contour of the brush

matches the armature. The motor and base should be kept as clean and free of

dust, grease, and dirt as possible.

The electronic control mounted in the base of the Model No. 1 High Speed Bench

Grinder contains a specially designed electronic circuit, and service on this

component should be performed only by the factory. Factory repairs are made

promptly and at reasonable cost. If it is not convenient to arrange for service

through your dealer, you may send your equipment directly to the factory marked:

“Attention: Service Department.” Estimates on repairs are given promptly when

requested.

data on the nameplate located on the motor.

Important: When ordering spare parts, please be sure to give all the

Always Wear Eye Protection While Using Bench Grinder.

″. To remove the brushes, simply unscrew

Aluminum Oxide Grinding Stone on Wheel Arbor (Part No. 10072) –

3

/4″ diameter 80 grit stone for general grinding, sharpening edged tools,

1

etc. Maximum speed rating: 17,000 RPM.

Optional Accessories

Only use accessories rated for 15,000 RPM or higher. The following are

available from Foredom.

Felt Buff (Part No. W305) – 2″ diameter buff ideal for polishing gem

stones, metals, etc. Maximum speed rating: 25,000 RPM.

Rubber Bonded Abrasive Wheel (Part No. W306) – 11/2″ diameter

wheel available in coarse, medium, or fine grit. Excellent for rust,

corrosion, and scratch removal, and preparation of all metal surfaces

for polishing and buffing. Maximum speed rating: 17,000 RPM.

Steel Wire Brush (Part No. W302) – 2″ diameter brush with .008″ thick

wire for cleaning, brushing, and texturing metal surfaces. Can be

operated at high speed. Maximum speed rating: 20,000 RPM.

Tampico Fiber Brush (Part No. W303) – 2″ diameter brush with an

unusual ability to hold abrasive compounds. Good for wet cleaning, chip

removal, dulling a satin finish, or fine burr removal. Maximum speed

rating: 20,000 RPM.

010

Nylon Brush (Part No. W304) – 2″ diameter brush with

filaments that resist attack by most acids and alkalis, heat, and

abrasion. Excellent for wet scrubbing, cleaning, and slurry abrasive

finishing. It is also used extensively for fabric scrubbing, glass and bottle

cleaning, and plastic burr removal. Max. speed rating: 20,000 RPM.

.

″ thick

Loading...

Loading...