FOREDOM 500, 500L, 500-2, 500L-2 Setup, Operation & Maintenance Manual

Replacement of Handpiece Pads: When install-

ing or replacing the Handpiece Pad Holder be

sure that the Adjustment Sleeve is tight. The

plunger shaft should extend at least 1/16″ beyond

the adjustment sleeve when the Plunger Shaft is

in its uppermost (withdrawn) position.

The rubber holder has a screw and locking nut for

attaching it to the plunger shaft. Screw the Pad

Holder into the plunger shaft and tighten the lock

nut with a 3/8″ wrench. Replacement pads can be

held in the holder with double faced pressure

sensitive tape.

Replacement of Motor Brushes: Be sure to

unplug motor before re plac ing motor brushes.

The motor brushes should be replaced when they

have worn down to 1/4″. To remove the brushes,

unscrew the brush caps on either side of motor.

Be sure to replace both motor brushes even if one

of them seems less worn than the other.

Replacement of Shafts and Sheaths: Shafts and

sheaths will last the longest when they are used as

straight as possible and when the shaft is cleaned

and lubricated regularly. There is no way to avoid

ultimate wear. A Massager may require several

replacement shafts and sheaths during its lifetime. Always keep a spare shaft on hand.

Repair Service:

Other service or repairs should

be done by a competent repair person or you can

return your Foredom equipment to the factory. If

you wish, send your Massager directly to the factory marked "Attention: Repair De part ment".

Enclose the item(s), a packing list, information

regarding the problem or repairs required, and your

contact information including daytime phone

number, email and mailing address. Estimates of

repair cost will be made upon request. If the cost

(labor plus parts) is more than fifty percent of the

price for a new replacement we will contact you and

recommend a trade-in offer.

For More Information

For more information on Foredom machines,

handpieces or ac ces so ries, contact your local

dealer. When no local dealer is available you

can also visit our website at www.foredom.net

for Foredom replacement parts.

Other contact information:

Email:

customerservice@blackstoneind.com

Foredom Electric Company

16 Stony Hill Road, Bethel, CT 06801

Phone: 203-792-8622

Fax: 203-796-7861

Form 1232 N-IH 9/17 Printed in USA

Massager

Models:

500

500L

500-2

500L-2

IMPORTANT!

Read Manual before operating this tool.

FOREDOM

®

www.foredom.net

Set-up, Assembly and

Maintenance Manual

Please retain your proof of purchase

for warranty repairs.

Recommended Spare Parts:

39″ Long Shaft S-93

36

1

⁄4″ Long Neoprene Sheath to use

with 39″ Long Shaft S-77N

Replacement Pad HP10254

Motor Brushes MP319P (Pair)

Foredom Flexible Shaft Grease MS10006

Optional Parts / Accessories:

66″ Long Shaft S-93-66

63

1

⁄4″ Long Sheath to use with

66″ Long Shaft S-77-66

Holder with Pad HP10255

Pad Holder HP10253

Pack of 6 Pads HP10254B

LIMITED WARRANTY

Warranty period is 2 years for motors, 90 days for handpieces, and 1 year for controls and switches.

Blackstone Industries, LLC d/b/a The Foredom Electric Company warrants, to the original purchaser only, that its

products will be free from defects in material or workmanship for the applicable period of time indicated above

following the purchase date. During the warranty period, the defective product will be repaired or replaced with

out charge or, at our sole option, the purchase price will be refunded. This warranty does not cover damage

caused in transit or by accident, misuse or ordinary wear.

ALL IMPLIED WARRANTIES INCLUDING, WITHOUT LIMITATION, IMPLIED WARRANTIES OF FITNESS FOR A

PARTICULAR PURPOSE AND MERCHANTABILITY, ARE LIMITED IN DURATION TO THE APPLICABLE

WARRANTY PERIOD. IN NO EVENT WILL WE BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL

DAMAGES. Some states do not allow limitations on how long an implied warranty lasts or the exclusion or

limitation of incidental or consequential damages, so the above limitations or exclusion may not apply to you.

At our sole option, repair, replacement or refund will be made if the product is returned postage prepaid to:

Foredom Electric Company 16 Stony Hill Road Bethel, Connecticut 06801

All warranty repairs must be done at our factory at the above address. We will not pay any shipping or transpor

-

tation charges. Armatures, bearings, shafts, sheaths and duplex springs are not covered by this warranty.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

Operation

For the best performance, safety, and

maximum life, please follow these

general suggestions:

1. Try to avoid using the Massager with

sharp bends or loops in the flexible shaft.

This will reduce wear of the flexible shaft

and the sheath lining.

2. Never deliberately stall the motor or slow

it down near the stalling point by bearing

down too hard on the handpiece.

3. The Massager comes with a dial control

built into the base. Strokes can be varied

from 0 to 4,400 per minute with the turn

of the dial.

Maintenance and

Assembly

These simple maintenance procedures

should be done by the user:

1. Cleaning and lubrication of flexible shaft

and handpiece.

2. Replacement of motor brushes.

3. Replacement of worn shafts

and sheaths.

4. Replacement of handpiece pads.

Keep the Massager as free of dust and

dirt as possible. Never allow oil or

grease to accumulate on exposed

surfaces as this tends to collect dirt.

Lubrication

The motor has permanently lubricated bear ings and does not require lubrication.

The flexible shaft should be cleaned and

lubricated once every 100 hours of use.

Expose the shaft by removing the handpiece

and then the sheath by loosening the set

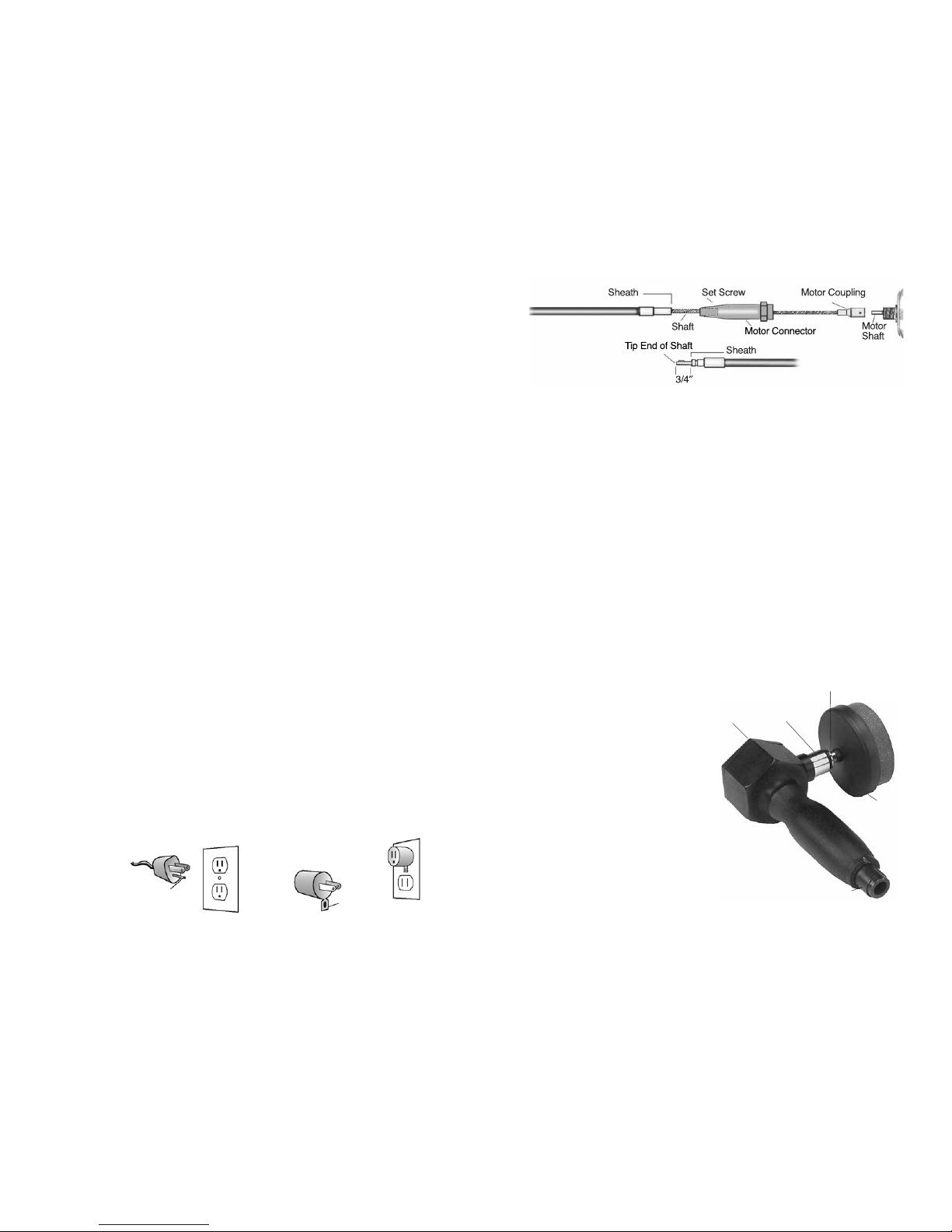

screw in the motor connector (see Figure 1)

and sliding it off the shaft. Apply a light film

of Foredom flexible shaft grease (MS10006)

along the entire length of the shaft after wip ing off the old grease with a piece of cloth.

Replace the sheath by sliding it over the shaft

and tightening the set screw. Be sure to

follow the Adjustment Instructions below.

Shaft Replacement

1. Remove the motor connector. Left hand

thread, turn right. (See Figure 1)

2. Loosen the set screw on the old flexible shaft

motor coupling and slide the shaft coupling

off the motor shaft. (See Figure 1.) Tighten

the set screw of the new shaft onto the flat

on the motor shaft.

3. Put the motor connector back on the motor

by sliding it up the flexible shaft and tighten ing. Grease shaft as described above.

4. Now slide the sheath over the flexible shaft

with the plain sheath fitting (not the grooved

fitting) going toward the motor and into the

motor connection.

Adjustment of Shaft and Sheath

Before attaching handpiece, shaft and sheath

adjustment must be carefully checked. Place

the entire unit on a flat surface with shaft and

sheath extended straight. Adjust the exposed

tip of the flexible shaft so that it extends 3/4″

beyond the sheath, as shown above. This is

done by moving the sheath in or out of the

motor connector. When the correct ad just-

Front

Plate

Set Screw

Adjustment

Sleeve

Plunger Shaft

Handpiece

Pad Holder

Figure 1

Figure 2

Set Up

Check the voltage of your power before plugging in the motor. It should match the voltage

shown on the motor nameplate. Models 500

and 500L are for use on 115 Volt AC power.

Models 500-2 and 500L-2 are for use on 230

Volt AC power.

Note: The Massager Handpiece comes

attached to the motor. If you need to remove

the handpiece (when cleaning, for example),

loosen the set screw and just pull away from

the shaft and sheath with a strong motion. To

reattach, push the hand piece onto the shaft

tip and sheath fitting while motor is running

slowly. Be sure that the catch ball in the end

of the handpiece toward the sheath goes into

the groove in the sheath tip so that the handpiece will be held securely onto the sheath.

ment is made, tighten the screw in the motor

connector. The handpiece can now be reattached

as described in the Note: under “Set Up”.

H.60 Massager

Handpiece Maintenance

The handpiece should be cleaned and lubricated

once every 100 hours of use. Remove the Front

Plate to expose the ec cen tric cam and plunger

shaft. Flush out the old grease with a solvent and

regreasewith a tea spoon ful of Foredom grease,

being sure that all the moving parts are thoroughly lubricated. After regreasing, run the handpiece slowly for a few minutes to fully distribute

grease. The Ad just ment Sleeve retains a grease

seal and should be tightened to prevent leakage

of grease.

• Use proper grounding procedures. This tool

should be grounded while in use to protect

the operator from electric shock. The tool is

equipped with an approved 3-conductor cord

and a 3-prong grounding type plug to fit the

proper grounding receptacle. The green (or

green and yellow) conductor in the cord is the

grounding wire. Never connect the green (or

green and yellow) wire to a live terminal. If

your unit is for use on less than 150 volts, it

has a plug that looks like sketch A below. An

adapter (sketches B and C) can be used for

connecting plugs as shown in sketch A to

2-prong receptacles. The green colored rigid

ear, lug, etc., extending from the adapter must

be connected to a permanent ground such as

a properly grounded outlet box.

Some jurisdictions, including Canada,

prohibit the use of 3 to 2 prong adapters.

Where prohibited, they should not be used.

Use only 3-wire extension cords that have 3-

prong grounding type plugs and 3-pole type

plugs and 3-pole receptacles that accept the

tool’s plug. Always disconnect the power cord

before servicing the tool.

Replace a worn

cord immediately.

Models 500-2 and 500L-2 are equipped

with power plugs suitable for use in the

country for which they are intended.

Loading...

Loading...