Foredom 350K2 User Manual

®

FOREDOM

Owner’s Manual

for the

AIR TURBINE KIT

General Information

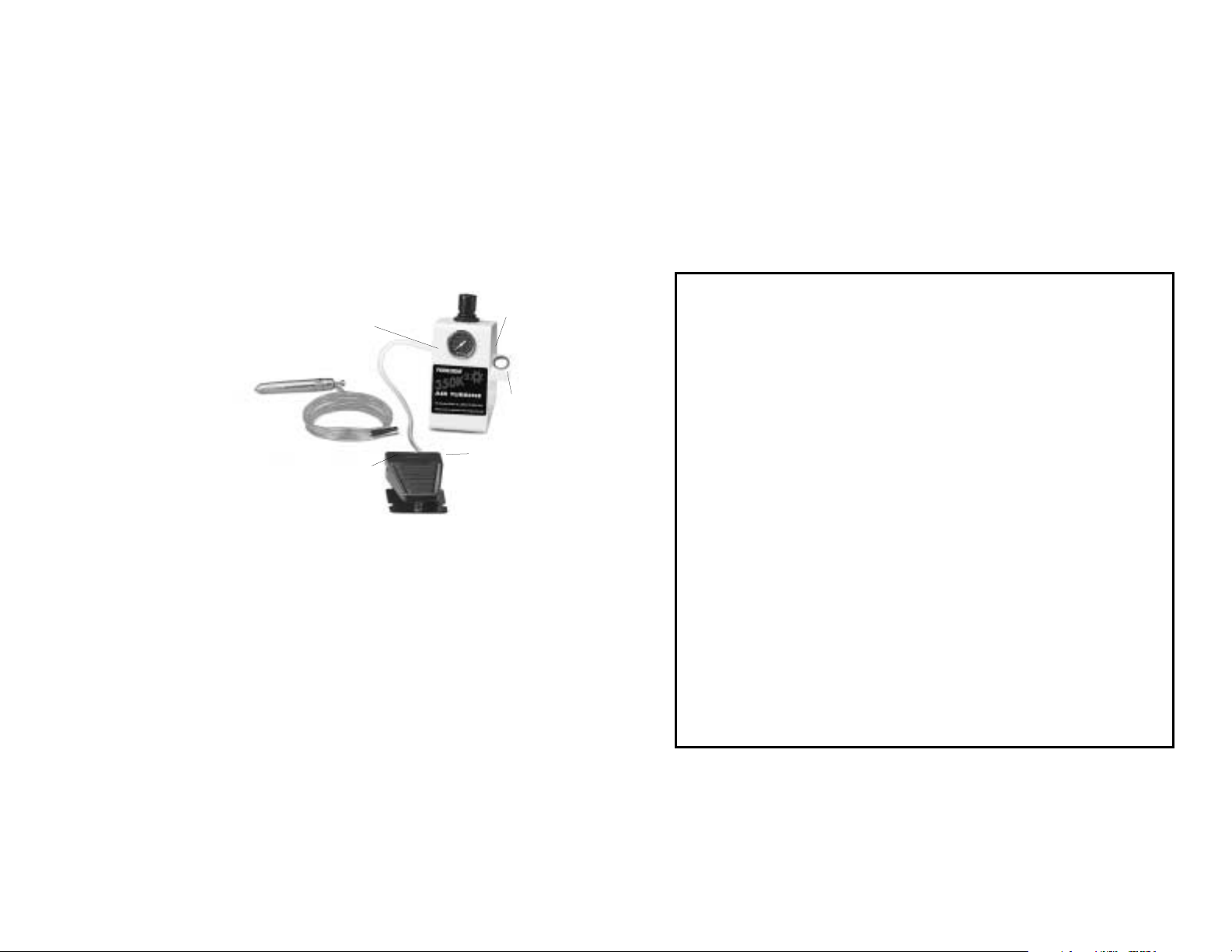

The Foredom®350K2 Air Turbine Kit Contains:

T-35AHandpiece with hose, hose adapter, and instructions

Air Filter/Regulator Push Fittings 3 Assorted Carbide burs

Owner’s Manual 6 Ft. Air Line On/Off Foot Pedal Lubricant

The Foredom 350K2 Air Turbine Handpiece is capable of generating 350,000 RPM

(revolutions per minute). Rotation is accomplished by forcing air at a maximum rate

of 40 P.S.I. (pounds per square inch) across an impeller or turbine which

holds the collet.

The unit generates substantial speed, but little torque, which makes it ideally

suited for operations such as cutting, carving, engraving, texturing, and fine detailing

with carbide or diamond points on materials such as metal, bone, stone, porcelain,

plastics, glass and hard woods.

A delicate touch is required on softer material and woods, or the bur will bury itself

and stall the handpiece– as is the case when too heavy a cut is attempted.

Filtered and regulated air is fed into the handpiece through an on/off foot pedal, or

the air flow can be shut off and on at the regulator. Clean, dry air is an absolute

requirement to the efficient running of this machine, as any foreign particles

generated by or from the air source (compressor) will be thrown into the turbine and

eventually clog and/or damage it.

With proper use and maintenance, the Foredom 350K2 Air Turbine can give a life

time of use. However, if a few simple basics are not observed, like any other fine

instrument or machine, the unit will eventually develop problems that will become

exaggerated if not corrected.

Be sure that the tubing you use to connect the filter/regulator to the air source is

rated for the output pressure of the compressor. The unit requires a minimum of 1.5

C.F.M. (cubic feet per minute) of air at 40 P.S.I. (1/4 HP Compressor) which is also

the recommended operating pressure. If you have purchased a handpiece only, you

must install an industrial filter/separator in the air line. As air is being compressed in

the compressor, heat is generated that causes a temperature differential between

raw air and compressed air that introduces moisture into the system which, in turn,

is forced with the air into the air line feeding the handpiece. Without an in-line

separator/filter, impurities such as moisture or dirt are carried with the air and

forced against the turbine impeller in the handpiece and will damage the turbine.

For Your Own Safety

• Always wear eye protection when

using this and other power tools

• Read this Owner ’s Manual before

operating your Foredom tool

Installation

1. Beginning with the compressor (not included), run a supply hose (not included)

from the compressor to the Filter/Regulator bracket marked “IN”.

2. Insert a length of air line (clear tubing) from the feed nozzle marked “Out” on the

Filter /Regulator to the source nozzle marked “IN” on the Foot Pedal. If necessary

cut the air line to a convenient length. Some applications may require the air line to

be secured along its length with mounting brackets to keep the line out of the way of

other area activities.

3. Insert the free end of the handpiece hose into the air hose adapter (HP91002).

4. Insert the narrow end of the hose adapter hose from the handpiece to the source

nozzle marked “OUT” on the Foot Pedal. To connect the air line hoses push them

directly into the push fittings. Leave sufficient length to allow operator convenience

and movement within the operator’s work area.Using the screw holes in the bracket,

locate the Filter/ Regulator in a permanent position that will allow the operator to read

the pressure gauge with an occasional glance to ensure that it is maintaining the

required 40 PSI. Pressure that is too high can damage the turbine, and too low a

pressure will result in unsatisfactory functioning of the handpiece.

If the compressor introduces any noticeable amount of moisture into the air line,

it will collect in the clear separator cup. Periodically drain the water away by

depressing the air valve on the bottom of the cup.

To keep the Foot Pedal stable and secure, it

is a good idea to mount it either on the floor,

or to a piece of heavy sheet metal or thin

plywood near the operator’s foot. Once a

suitable working location for the components has been found, you may want to

“OUT”

feed

nozzle

Filter

Regulator

“IN”

attach supply

hose from

compressor

(not supplied)

shorten the air lines to a length that will

keep them out of the way.

Handpiece

Operation

• Always wear proper eye protection

when using this and other power tools.

• Never operate the handpiece without a

Air Line

(clear tubing)

“OUT”

nozzle

on foot

pedal

Handpiece

holder

“IN”

nozzle on

foot pedal

Foot Pedal

bur in the collet.

• Always use 1/16″(1.6mm) shank friction grip burs rated for 350,000 RPM.

• Tie back long hair, and avoid wearing jewelry or loose clothing.

• To insert a bur, push the collet release plunger and insert the bur into the collet. Make

sure that the bur is fully inserted into the collet before releasing the collet release

plunger. Bur removal is easy: press the collet release plunger and pull the bur out.

• Develop a light, but sensitive and controlled touch as bur makes contact

with material.

• For accuracy, dexterity, and comfort, hold the handpiece loosely, but with enough

pressure to maintain control.

• Use a suitable dust collection system that will remove not only larger dust

particles, but airborne dust as well from the work area.

• Wear a respirator to prevent the inhalation of dust particles.

• Do not cover exhaust port at the rear of handpiece during use.

• Keep the work area clean and organized.

• Keep children out of the work area and away from any operating or

moving machinery.

• Keep the foot pedal out of the way to avoid accidental starts.

Service:

Factory service is available by sending your 350K2 Air Turbine Handpiece with a

note stating the problem to:

The Foredom Electric Company, 16 Stony Hill Road, Bethel, CT 06801 USA,

Attn.: Service Department.

LIMITED WARRANTY

The Foredom Electric Company warrants the 350K2 Air Turbine to be free of

defects in material or workmanship for a period of 1 year after purchase. The

turbine itself (P/N HP90038) is not covered by this warranty since it is

especially sensitive to pressure and stress variables and the purity of the

compressed air. During the warranty period, the defective product will be

repaired or replaced without charge or, at our option, the purchase price will

be refunded. This warranty does not cover damage caused in transit or by

accident, misuse, or ordinary wear.

ALL IMPLIED WARRANTIES, INCLUDING BUT NOT LIMITED TO

WARRANTIES OF FITNESS AND MERCHANTABILITY, ARE HEREBY

LIMITED IN DURATION TO APERIOD ENDING ONE YEAR FROM DATE OF

PURCHASE, AND WE WILLNOT BE LIABLE OR RESPONSIBLE FOR ANY

SPECIAL OR CONSEQUENTIAL DAMAGES.

Repair or replacement will be made at our option if the product is returned

post-paid to:

The Foredom Electric Company

16 Stony Hill Road

Bethel, CT USA06801

All warranty repairs must be done at the factory at the above address. We will

not pay any shipping or transportation charges. This warranty only covers the

original purchaser of the product.Some states do not allow limitations on how

long an implied warranty lasts, so the above limitations may not apply to you.

This warranty gives you specific legal rights, and you may also have other

rights which vary from state to state.

®

FOREDOM

The Foredom Electric Company

16 Stony Hill Road

Bethel, CT USA06801

www.foredom.com

Form 905 n 9/02 Printed in USA

Loading...

Loading...