Page 1

OPERATOR HANDBOOK

WSG

1068

Gasoline

LIQUEFIED PETROLEUM GAS (LPG)

NATURAL GAS (NG) ENGINES

Part #: 1080050

EDI Revision F

March , 2011

W

Page 2

ARNING:

Page 3

FORD WSG-1068 ENGINES

Gasoline

LIQUEFIED PETROLEUM GAS (LPG)

NATURAL GAS (NG)

Reproduction in any manner, in whole or in part, is prohibited without the

express permission in writing from

Engine Distributors Incorporated

Engine Distributors policy is one of continuous improvement and while every effort is made to

ensure that this publication is up to date and correct in all respects, the right to change prices,

specifications and equipment at any time without notice is reserved. Accordingly this publication is

not to be regarded as a final description of any individual engine.

Page 4

CONTENTS

HEALTH & SAFETY .......................................................................................................... 4

General Guidelines: ................................................................................................ 4

Important Safety Notice........................................................................................... 4

Notes, Cautions, and Warnings .............................................................................. 5

FORWARD ........................................................................................................................ 6

ENGINE IDENTIFICATION................................................................................................ 6

U.S.A. Engine Identification Decal .......................................................................... 7

Non-Certified Engine Decal..................................................................................... 7

Federal Emissions Warranty Statement.................................................................. 8

California Emission Control Warranty Statement.................................................... 8

What Is Covered? .................................................................................................. 10

European Service Identification Plate .................................................................... 11

PARTS AND SERVICE..................................................................................................... 12

SERVICE LITERATURE................................................................................................... 12

WARRANTY REGISTRATION ......................................................................................... 12

BEFORE OPERATING THE ENGINE.............................................................................. .13

OPERATING CONTROLS................................................................. ............................... 13

Ignition or Isolation Switch ..................................................................................... 13

Safety Switch (where fitted) ................................................................................... 14

Power Take-off (where fitted)................................................................................. 14

Throttle Control (where fitted) ................................................................................ 14

INSTRUMENTS................................................................................................................. 15

Ammeter (Where Fitted)......................................................................................... 15

Battery Condition Indicator (Where Fitted)............................................................. 15

Tachometer (Where Fitted) ................................................................................... 15

Hourmeter (Where Fitted) ...................................................................................... 15

Oil Pressure Gauge (Where Fitted)........................................................................ 15

Temperature Gauge (Where Fitted)....................................................................... 16

Malfunction Indicator Light (Where Fitted) ............................................................. 16

Charge Indicator Light (Where Fitted).................................................................... 16

Safety Switch Override Button (Where Fitted) ....................................................... 16

Ignition or Isolation Switch ..................................................................................... 16

Fuel Select Switch (Where Fitted).......................................................................... 16

STARTING THE ENGINE.................................................................................................. 17

Initial Start-up ......................................................................................................... 17

To Start From cold ................................................................................................. 17

To Re-start When Warm ........................................................................................ 17

Page 5

CONTENTS

STOPPING THE ENGINE ................................................................................................ 18

Normal Conditions.................................................................................................. 18

Abnormal Conditions.............................................................................................. 18

RUNNING-IN PROCEDURE ............................................................................................ 18

FUEL RECOMMENDATION............................................................................................. 19

LUBRICATION AND MAINTENANCE.............................................................................. 19

RECOMMENDED MAINTENANCE SCHEDULES........................................................... 20

RECOMMENDED MAINTENANCE OPERATIONS ........................................................ 21

Recommended Lubricants .................................................................................... 21

Used Engine Oils .................................................................................................. 22

Change Engine Oil ............................................................................................... 22

Check Engine Oil Level......................................................................................... 23

Renew Engine Oil Filter ........................................................................................ 23

Ignition System...................................................................................................... 24

Renew Spark Plugs............................................................................................... 24

Electronic Actuator ............................................................................................... 26

Check Condition of Ancillary Drive Belts............................................................... 26

Check Engine Coolant Level................................................................................. 26

Renew Air Cleaner Element.................................................................................. 27

Renew PCV Valve................................................................................................. 27

GENERAL MAINTENANCE INFORMATION .................................................................. 28

Cooling System..................................................................................................... 28

Draining, Flushing and Filling the Cooling System................................................ 30

Engine Lubrication System ................................................................................... 30

Electrical System................................................................................................... 31

Generator ............................................................................................................. 32

Storage.................................................................................................................. 33

ENGINE SYSTEM CHECK.............................................................................................. 34

SPECIFICATIONS .......................................................................................................... 38

TIGHTENING TORQUES................................................................................................ 39

CONVERSION TABLE ....................................................................................... ............40

FORD POWER PRODUCTS SERVICE ......................................................................... 41

Page 6

HEALTH & SAFETY

WARNING: THE FOLLOWING HEALTH AND SAFETY RECOMMENDATIONS SHOULD BE

CAREFULLY OBSERVED.

Carrying out certain operations and handling some substances can be dangerous or harmful to the

operator if the correct safety precautions are not observed. Some such precautions are

recommended at the appropriate points in this book.

While it is important that these recommended safety precautions are observed, care near

machinery is always necessary, and no list can be exhaustive. ALWAYS BE ON YOUR GUARD!

General Guidelines:

The following recommendations are for general guidance:

1. Always wear correctly fitting protective clothing which should be laundered

regularly. Loose or baggy clothing can be extremely dangerous when working on running q

engines or machinery. Clothing which becomes impregnated with oil or other substances

can constitute a health hazard due to prolonged contact with the skin even through

underclothing.

2. So far as practicable, work on or close to engines or machinery only when they are stopped.

If this is not practicable, remember to keep tools, test equipment and all parts of the body

well away from the moving parts of the engine or equipment—fans, drive belts and pulleys

are particularly dangerous. The electric cooling fan used on some installations is actuated

automatically when the coolant reaches a specified temperature. For this reason, care

should be taken to ensure that the ignition/isolating switch is OFF when working in the

vicinity of the fan as an increase in coolant temperature may cause the fan suddenly to

operate.

3. Avoid contact with exhaust pipes, exhaust manifolds and silencers when an engine is, or

has recently been running; these can be very hot and can cause severe burns.

4. Many liquids used in engines or vehicles are harmful if taken internally or splashed into the

eyes. In the event of accidentally swallowing gasoline (petrol), oil, diesel fuel, antifreeze,

battery acid etc., DO NOT ENCOURAGE VOMITING AND OBTAIN QUALIFIED MEDICAL

ASSISTANCE IMMEDIATELY.

Wear protective goggles when handling liquids which are harmful to the eyes these include

ammonia and battery acid. If any of these substances are splashed in the eyes, wash out

thoroughly with clean water and OBTAIN QUALIFIED MEDICAL ASSISTANCE IMMEDIATELY.

Important Safety Notice

Appropriate service methods and proper repair procedures are essential for the safe, reliable

operation of all industrial engines as well as the personal safety of the individual doing the work.

This operator handbook provides general directions for accomplishing service and repair work with

tested, effective techniques. Following them will help assure reliability.

There are numerous variations in procedures, techniques, tools and parts for servicing equipment,

as well as in the skill of the individual doing the work. This manual cannot possibly anticipate all

such variations and provide advice or

the instructions

cautions as to each. Accordingly, anyone who departs from

Page 7

provided in this Manual must first establish that neither personal safety nor equipment integrity are

compromised by the choice of methods, tools or parts.

Notes, Cautions, and Warnings

As you read through the procedures, you will come across NOTES, CAUTIONS, and WARNINGS.

Each one is there for a specific purpose. NOTES gives you added information that will help you to

complete a particular procedure. CAUTIONS are given to prevent you from making an error that

could damage the equipment. WARNINGS remind you to be especially careful in those areas

where carelessness can cause personal injury. The following list contains some general

WARNINGS that you should follow when you work on the equipment.

GENERAL WARNINGS:

• Always wear safety glasses for eye protection.

• Use safety stands whenever a procedure requires you to be under the

equipment.

• Be sure that the ignition switch is always in the OFF position, unless otherwise

required by the procedure.

• Set the parking brake (if equipped) when working on the equipment. If you have

an automatic transmission, set it in PARK REVERSE (engine off) or NEUTRAL

(engine on) unless instructed otherwise for a specific operation. Place wood

blocks (4”x 4” or larger) to the front and rear surfaces of the tires to provide

further restraint from inadvertent equipment movement.

• Operate the engine only in a well ventilated area to avoid the danger of carbon

monoxide.

• Keep yourself and your clothing away from moving parts when the engine is

running, especially the fan belts.

• To prevent serious burns, avoid contact with hot metal parts such as the

radiator, exhaust manifold, tail pipe, catalytic converter and muffler.

• Do not smoke while working on the equipment.

• To reduce the risk of injury, always remove rings, watches, loose hanging

jewelry, and loose clothing before beginning to work on the equipment. Tie long

hair securely behind the head.

• Keep hands and other objects clear of the radiator fan blades. Electric cooling

fans can start to operate at any time by an increase in underhood temperatures,

even though the ignition is in the OFF position. Therefore, care should be taken

to ensure that the electric cooling fan is completely disconnected when working

under the hood.

Page 8

FORWARD

This book contains operating and maintenance instructions for the engine(s) listed on the title

page.

The life of your engine unit and the delivery of the high performance built into it will depend on the

care it receives throughout its life. It is the operator’s responsibility to ensure that the engine is

correctly operated and that the maintenance operations outlined in this book are carried out

regularly after the specified hours of operation have been reached. We consider it to be in your

interests to enlist the aid of an authorized Ford Power Products Distributor not only when repairs

are required but also for regular maintenance. Distributors are listed at the back of this handbook.

Regular maintenance will result in minimal operating costs.

Engines manufactured by Ford Motor Company are available through Ford Power

Products Distributors. When in need of parts or service, contact your local Authorized Distributor.

In overseas territories, in the event of difficulties, communicate directly with the supervising Ford

affiliated Company in your area whose address appears at the end of this book.

Where the terms “Right” or “Left” occur in this publication, they refer to the respective sides of the

engine when viewed from the rear or flywheel end.

Pistons and valves are numbered from the front or timing cover end of the engine commencing at

No. 1.

You may find that your engine assembly includes optional equipment not specifically covered in

the following text. Nevertheless, the maintenance procedures outlined in this book still apply to

your engine

ENGINE IDENTIFICATION

Because Engine Distributors has such a wide range of industrial gasoline and diesel engines manufactured both in the U.S. and overseas - it is important that you have as complete

identification of the engine as possible in order to provide the correct replacement parts. Review

the list of distributors for a distributor in your area. You can obtain a standard parts listing

describing the parts. It remains a distributor function to identify the part number.

The key to identifying the engine is the identification decal mounted on the engine rocker cover.

That decal provides not only the engine serial number, but also the exact model or type,

configuration code and customer name. The combination of that data permits you to isolate the

precise engine, build level and customer so you can determine the correct replacement parts.

Page 9

EDI Engine Identification Decal

An identification Decal is affixed to the valve cover of the engine. The decal contains the engine serial number which

identifies this unit from all others. Use all numbers when seeking information or ordering replacement parts for this

engine.

For handy reference, transfer the data recorded on this decal to a safe place.

Your Warranty Rights and Obligations

The California Air Resources Board, U.S. EPA and Engine Distributors, Inc. are pleased to explain the

emission control system warranty on your new 2010 and subsequent model year emission certified engine

(or brand equipment). New off-road large spark-ignition (LSI) engines must be designed, built and equipped

to meet stringent Federal and State anti-smog standards. Engine Distributors, Inc. warrants that the

emission control system on your engine for the periods of time listed below provided there has been no

abuse, neglect or improper maintenance of your engine.

Your emission control system may include parts such as the carburetor, regulator or fuel-injection system,

ignition system, engine computer unit (ECM), catalytic converter and air induction system. Also included

may be sensors, hoses, belts, connectors and other emission-related assemblies.

Where a warrantable condition exists, Engine Distributors, Inc will repair your LSI engine at no cost to you

including diagnosis, parts, and labor.

Manufacturer’s Warranty Coverage

Standard warranty for any non-emissions related part is two years or 2000 hours. This includes the base

engine and ancillary parts such as the starter and alternator.

The new 2010 model year off-road large spark-ignition engines are warranted for three years or 2500 hours

of service, whichever occurs first from the date the equipment is delivered to the first retail purchaser or

when the equipment is first placed in service. If any emission-related part on the engine is defective, the

part will be repaired or replaced by an authorized Engine Distributors, Inc. dealer. This is your General

Emissions Warranty.

For five years or 3500 hours of service (whichever occurs first) if any emission-related part specially noted

with coverage for five years or 3500 hours is defective, the part will be repaired or replaced by and

authorized Engine Distributors, Inc. dealer. This is your High Priced Parts Emission Warranty.

Page 10

Owner’s Warranty Responsibilities

As the off-road LSI engine owner, you are responsible for the performance of the required maintenance

listed in your owner’s manual. Engine Distributors, Inc. recommends that you retain all records covering

maintenance on your off-road engine, but Engine Distributors, Inc. cannot deny warranty solely for the lack

of receipts or for your failure to ensure the performance of all scheduled maintenance.

As the off-road large spark-ignition engine owner, you should however be aware that Engine Distributors,

Inc. may deny you warranty coverage if your off-road large spark-ignition engine or a part has failed due to

abuse, neglect, improper maintenance or unapproved modifications.

Depending on the model of engine you have purchased, your engine may be designed to operate on LPG,

Gasoline, and/or Natural Gas fuels. Use of any other fuel may result in your engine no longer operating in

compliance with applicable emissions requirements.

You are responsible for initiating the warranty process. Engine Distributors suggests that you present your

off-road large spark-ignition engine to an Engine Distributors, Inc. dealer as soon as a problem exists. The

warranty repairs should be completed by the dealer as expeditiously as possible.

If you have any questions regarding your warranty rights and responsibilities, you should contact Engine

Distributors, Inc. at (800) 220-2700.

What is Covered

Below is a list of the systems that affect emissions on your engine. Emission control components on these

systems are covered by the emissions warranties as applicable.

If failure of one of the components listed below results in failure of another part, both will be covered by this

warranty. For detailed information concerning specific components covered by these emission control

systems warranties, ask your dealer.

General Emissions Warranty Parts List – 3 years or 2,500 hours, whichever comes first

• Fuel Metering System

o Fuel injection system.

o Air/fuel ratio feedback and control system.

o Carburetor system (internal parts and/or pressure regulator or fuel mixer or injection system).

• Air Induction System

o Air intake system.

• Catalyst or Thermal Reactor System

• Positive Crankcase Ventilation (PCV) System.

o PCV Valve.

o Oil Filler Cap.

• Ignition Control System

o Ignition module(s).

o Spark Plugs

• Miscellaneous items Used in Above Systems

o Vacuum, temperature, and time sensitive valves and switches.

o Sensors used for electronic controls.

o Hoses, belts, connectors, assemblies, clamps, fittings, tubing, sealing gaskets or devices,

and mounting hardware.

o Pulleys, belts and idlers.

Page 11

• Emission Related Components (Only Covered if Your Engine was Sold in California)

o Air Induction System

o Fuel System

o Ignition System

o Exhaust Gas Recirculation Systems

o After Treatment Devices

o Crankcase Ventilation Valves

o Sensors

o Electronic Control Units

o Fuel Tank

o Fuel Cap

o Fuel Line

o Fuel Line Fittings

o Clamps

o Pressure Relief Valves

o Control Valves

o Control Solenoids

o Electronic Controls

o Vacuum Control Diaphragms

o Control Cables

o Control Linkages

o Purge Valves

o Vapor Hoses

o Liquid/Vapor Separator

o Carbon Canister

o Canister Mounting Brackets

o Carburetor Purge Port Connector

High Priced Emissions Warranty Parts List – 5 years or 3,500 hours, whichever comes first:

• Press Regulator

• Catalytic Muffler

• Engine Control Module (ECM).

• Intake Manifold

• Exhaust Manifold

• Harness

• Throttle

Page 12

SERVICE LITERATURE

A service manual can be purchased from your EDI distributor. This publication will provide the

necessary servicing and overhaul information for your Ford Power Products engine.

• WSG1068 SERVICE MANUAL - EDI

• WSG1068 PARTS LIST - EDI

BEFORE OPERATING THE ENGINE

1. Before operating a new engine it should be thoroughly inspected to ensure that during

transit and installation it has not suffered damage likely to affect its subsequent operation.

Controls and instruments should be studied carefully in order that their functions are

thoroughly understood.

2. Check that the radiator (where applicable) is full and top off as necessary -- Refer to

“Cooling System” on page 28 for recommended coolant mixtures.

3. In the case of marine/industrial engines, ensure that there is coolant in the degas/expansion

tank (where applicable).

CAUTION: Under no circumstances may the engine be started without liquid in the cooling

system.

4. Check the engine oil level and top up or fill as necessary -- Refer to “Check Engine Oil

Level” on page 23. For the correct type and grade of oil -- Refer to “Recommended

Lubricants” on page 21.

5. Ensure that the battery is fully charged and, if necessary, top up with distilled water.

NOTE: Ensure that ALL wiring ground connections are properly made to a clean point on the

chassis/frame.

6. The engine must be started in accordance with the starting instructions -- Refer

to “STARTING THE ENGINE” on page 17.

OPERATING CONTROLS

Ignition or Isolation Switch

An ignition or isolation switch is usually fitted which connects the engine starter motor and other

electrical equipment to the battery. The switch can be moved to any of the four positions shown by

rotating the key. These positions are:

Page 13

1. Auxiliary Circuits - When moved to this position the auxiliary electrical equipment such as

radios and heater fans, can be operated without also connecting the starting circuit with the

battery.

2. Off - When set to this position, the switch disconnects the auxiliary electrical equipment and

the starting circuit from the battery. The key can be removed from the switch when it is in

this position; this will help to prevent unauthorized operation of the engine.

3. Run - This switch position connects the auxiliary circuits as described previously, and the

alternator is given initial excitation via the battery.

4. Start - In this position, the starter solenoid is energized and the starter motor cranks the

engine. The switch, when released, automatically returns to the RUN position.

Safety Switch (where fitted)

A low oil pressure/high water temperature safety switch may be fitted. This automatically shuts off

the ignition when the oil pressure drops below a pre-set value, or when the water temperature rises

above a pre-set value. A button on the instrument panel is used to override the safety switch when

starting the engine. The safety switch override button must be depressed to start the engine.

NOTE: With EDI GCP safety shut-down incorporated oil pressure below 6 psi and/ or coolant

temperature goes above 250° F, will shut-down ignition system. Corrective action must be taken

and key recycled to restart.

Power Take-off (where fitted)

The power take-off control handle allows engagement and disengagement of the power take-off

clutch. Moving the lever towards the engine engages the clutch and moving the lever away from

the engine disengages the clutch.

When moving the handle to engage the clutch and pick up the load, do so in a smooth manner.

Moving the clutch handle too slowly will cause slippage and wear, while moving it too fast will

cause quick engagement and possible damage to the power take-off, engine or driven equipment.

The normal force required to engage the clutch is 55 lbf (245 N) for the over-centre type and 25 lbf

(110 N) for the spring loaded type.

Throttle Control (where fitted)

The throttle control adjusts engine speed. Initial engine speed adjustment is obtained by pressing

the throttle control release button while pulling the throttle knob out to increase the engine speed or

pushing it in to decrease the engine speed. A final fine speed adjustment is obtained by turning the

throttle control counterclockwise to increase engine speed or clockwise to decrease engine speed.

Page 14

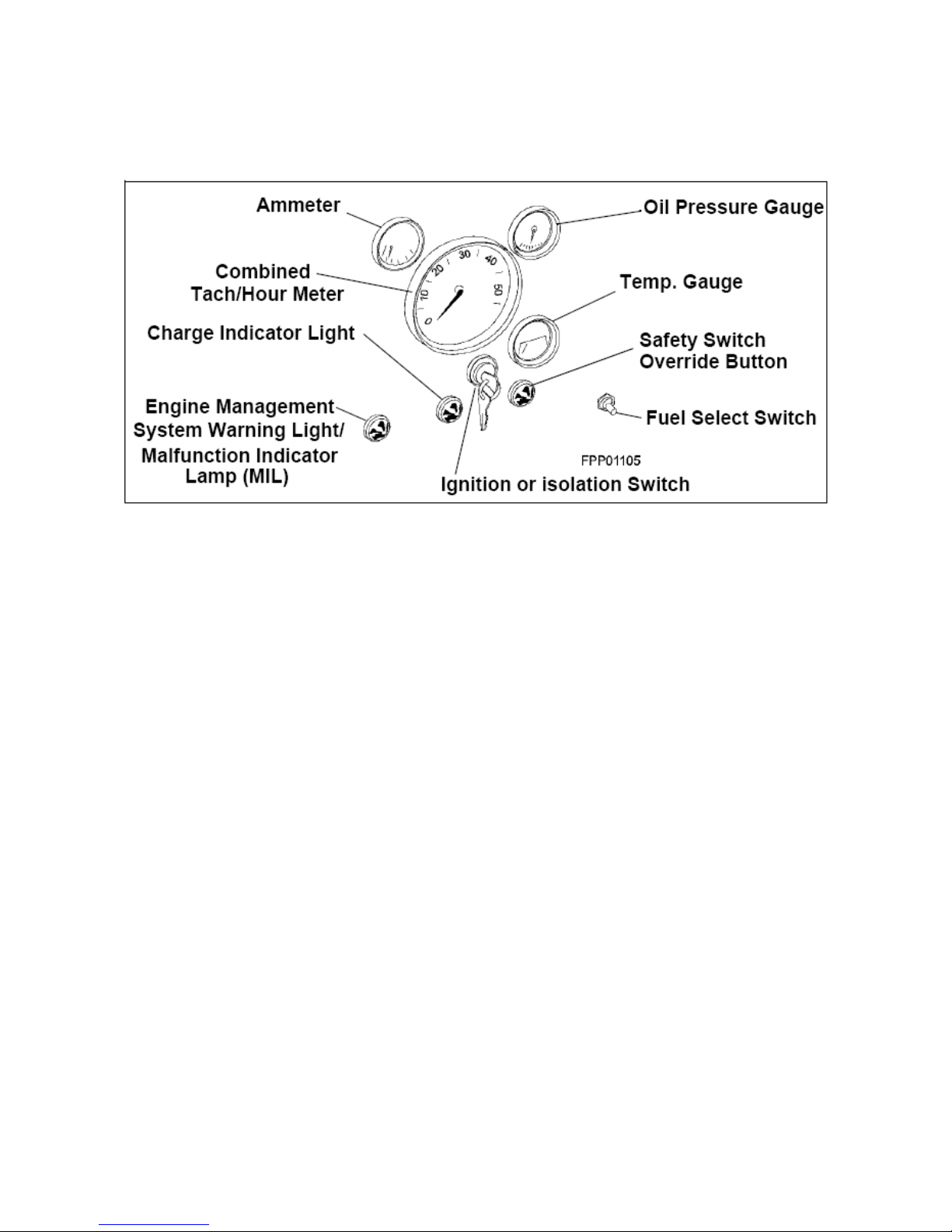

INSTRUMENTS

Your Ford Powered Equipment will have been fitted with instruments selected by the manufacturer.

The types of instruments most likely to be encountered are detailed here. A typical instrument

panel is shown below.

Ammeter (Where Fitted)

This instrument registers the charging current which is being passed to the battery from the

alternator. It also registers a discharge equivalent to the amount of current being used by the

electrical equipment when the alternator is not charging.

Battery Condition Indicator (Where Fitted)

This is sometimes fitted instead of an ammeter and measures the battery voltage thus indicating

the state of charge of the battery.

Tachometer (Where Fitted)

The tachometer indicates the actual engine running speed in crankshaft revolutions per minute.

Hourmeter (Where Fitted)

This instrument records the number of hours of operation which the engine has completed at the

rated rpm. It is frequently combined with the tachometer and is used to determine when an engine

service operation is required. If no hourmeter is fitted, a log should be kept.

Oil Pressure Gauge (Where Fitted)

The oil pressure gauge registers the lubricating system pressure in bar (kgf/cm2 or Ibf/in2) and

should be frequently observed to ensure that the system is functioning correctly.

Temperature Gauge (Where Fitted)

The temperature gauge enables a close check to be kept on the coolant temperatures.

Malfunction Indicator Light (Where Fitted)

Used on all industrial engines. This light will illuminate whenever there is an engine malfunction

such as low oil pressure, high engine temperature, fuel injection system fault. The engine can be

programmed to shut down in the event of a malfunction.

Page 15

Charge Indicator Light (Where Fitted)

If an alternator is fitted to your engine, a charge indicator light will also be fitted. The light will glow

when the isolating switch is in the RUN position with the engine stationary and will therefore serve

as a reminder either to turn the isolating switch to the OFF position or to start the engine. Once the

engine has started, the charge indicator light should cease glowing.

Safety Switch Override Button (Where Fitted)

This must be depressed when starting the engine, as the safety switch operates when the oil

pressure falls due to the engine stopping -- Refer to “Safety Switch (where fitted)” on page 14.

Ignition or Isolation Switch

-- Refer to “Ignition or Isolation Switch” on page 13.

Fuel Select Switch (Where Fitted)

This switch is incorporated for use with dual fuels. Switch must point to selection of fuel being

used.

Page 16

STARTING THE ENGINE

WARNING: ALL INTERNAL COMBUSTION ENGINES GIVE OFF VARIOUS FUMES AND

GASES WHILE RUNNING. DO NOT START OR RUN THE ENGINE IN A CLOSED OR POORLY

VENTILATED BUILDING WHERE THE EXHAUST GASES CAN ACCUMULATE. AVOID

BREATHING THESE GASES AS THEY MAY CONTAIN POISONOUS CARBON MONOXIDE

WHICH CAN ENDANGER YOUR HEALTH OR LIFE IF INHALED STEADILY FOR EVEN A FEW

MINUTES.

Initial Start-up

On initial start-up follow the daily regular maintenance schedule illustration -- Refer

to “RECOMMENDED MAINTENANCE SCHEDULES” on page 20.

To Start From cold

1. Where possible, disconnect the driven equipment, eg, fully depress the clutch

where a manual transmission is fitted. If your unit is equipped with the engine warning light

system, always turn the ignition switch to the ON position to make sure that each warning

light is operating before starting engine.

2. Switch on the ignition and operate the starter motor until the engine fires.

NOTE: Where a safety switch is fitted, the override button must be depressed while

the engine is being cranked.

3. Set the throttle to give a fast idle speed until normal operating temperature is reached

(where fitted).

CAUTION: If the engine stalls or falters in starting, wait 3-4 seconds before re-engaging

starter. This will prevent possible damage to the starter or engine. The starter should not

operate for periods longer than 30 seconds at a time. An interval of at least two minutes

should be observed between such cranking periods to protect the starter from overheating.

To Re-start When Warm

Switch on the ignition and operate the starter motor until the engine starts.

NOTE: Safety shut-down incorporated in the Ignition Performance Module (IPM): Oil pressure

below 6 psi and/or coolant temperature goes above 250°F, will shutdown the ignition system.

NOTE: The IPM will also shut the engine off when engine speed reaches 2250 rpm for Gen-Set

and 4000 rpm for all other applications. Key must be recycled to restart.

NOTE: Where a safety switch is fitted, the override button must be depressed while the engine is

being cranked.

Page 17

STOPPING THE ENGINE

Normal Conditions

Following normal operating conditions, lower the engine speed to idle, disengage the clutch, and

then turn the ignition switch to the OFF position. If the engine has been running under high power,

let it run at fast idle speed a few minutes to cool the engine down.

Abnormal Conditions

Under abnormally overheated conditions, the engine may continue to run after the ignition switch is

turned off. If this case is ever encountered, turn on the ignition switch immediately and allow the

engine to idle until it has cooled enough to stop. If the engine is overheated due to loss of coolant,

it is best to stop the engine immediately, if necessary by applying the load. Add engine oil if

necessary, then after the engine has returned to a normal temperature, add coolant slowly until the

radiator is full.

WARNING: TO REDUCE THE RISK OF INJURY WHEN CHECKING A HOT ENGINE. COVER

THE RADIATOR CAP IN A THICK CLOTH AND TURN IT SLOWLY COUNTERCLOCKWISE TO

THE FIRST STOP. AFTER THE PRESSURE HAS BEEN COMPLETELY RELEASED, PRESS

THE CAP DOWNWARD AND FINISH REMOVING THE CAP.

The above instructions also apply to engines that stop due to operation of the low oil pressure/high

water temperature safety switch. However, if the engine stops due to low oil pressure, do not

restart until the cause has been determined and corrected -- Refer to “Recommended Lubricants”

on page 21.

RUNNING-IN PROCEDURE

A new or reconditioned engine must not be run at high speeds or on full load for the first 25 hours.

The load and speed may be increased to a maximum over this period. After the first 50 hours

running, carry out the maintenance operations listed

-- Refer to “RECOMMENDED MAINTENANCE SCHEDULES” on page 20.

Check the instruments frequently and keep the coolant and oil filled to their recommended levels.

Page 18

FUEL RECOMMENDATION

This engine is designed to operate on dry fuel such as LPG Grade HD5 or NG (1050 BTU/ft^3).

CAUTION: Use of fuels rated lower than the grades specified above may cause persistent,

heavy spark knock, which can lead to engine damage. If your engine knocks heavily, or if

you hear continuous spark knock while maintaining constant operating speeds, consult

your distributor or another qualified technician.

LUBRICATION AND MAINTENANCE

The importance of correct lubrication, periodic inspection and adjustment cannot be overemphasized. It will determine, to a very large extent, the service the engine will give. Detailed

instructions regarding this maintenance are given in the following pages.

Your Authorized EDI Distributor listed in the back section of this manual, will be pleased to carry

out this regular maintenance for you. The various maintenance operations are listed -- Refer to

“RECOMMENDED MAINTENANCE SCHEDULES” on page 20.

When carrying out any of the following maintenance operations, any fault or malfunction should be

reported immediately to the supervisor or person responsible for engine overhaul or repair.

The following Maintenance Schedules give the maximum recommended service periods. Since

operating conditions can vary, it may be advisable to carry out some operations, for example,

changing the engine oil, at an interim period. Your operating experience is the best guide for

determining this time.

Page 19

RECOMMENDED MAINTENANCE

*It is recommended that this operation is carried out by an authorized Ford Distributor. Depending

upon the quality of the fuel used, it may be necessary to renew the filter element more frequently.

** PCV Valve inspection and Spark Plug replacement are recommended at the interval(s)

described. Spark plug cleaning/replacement at these intervals will ensure maximum engine

performance, fuel economy, and emissions. Failure to complete recommended maintenance does

not disqualify your engine from any emissions related warranty coverage’s

Page 20

RECOMMENDED MAINTENANCE OPERATIONS

Recommended Lubricants

CAUTION: Do not use supplemental oil additives or other engine treatments. They are

unnecessary and could, under certain conditions, lead to engine damage which is not

covered by Ford warranty.

Lubricating oil cleanliness is vital for the successful operation of your engine. The oil should be

stored under the cleanest possible conditions. When changing or topping-up engine oil use only

clean receptacles. Do not allow the oil to come into contact with rubber hoses on the engine.

CAUTION: Use Ford/Motorcraft “Formula E” SAE 5W20 engine oil or equivalent that meets Ford

Specification ESEM2C153-C(API Classification – SJ).

If SJ oils are not available, SH oils are acceptable.

Use only engine oil displaying the American

Petroleum Institute Certification Mark on the front of

the container, or API specification SH, or SJ.

NOTE: Ford Power Products industrial engines are designed to perform with engine oils that are

licensed by the American Petroleum Institute (API), and oils carrying the most current API

classification should be used. API classifications are broken into two categories, gasoline and

diesel engines. API’s classification is designated by a two letter system. The first letter, the prefix,

designates gasoline or diesel. An “S’’ designates gasoline and a “C’’ designates diesel. The

second letter in the system designates the level of the classification. It should be noted that

alternative fuel engines fall into the “gasoline’’ API category.

Gasoline engines that are converted for LPG or Natural Gas applications must use

oils labeled SH and/or SJ. Do not use oils that are specifically formulated for Diesel

Engines only. CC or CD classification, even when labeled Heavy Duty or for

Natural Gas Engines, are not acceptable. The use of SAE 5W-20 is recommended

for all temperatures:

Page 21

Used Engine Oils

WARNING: PROLONGED AND REPEATED CONTACT MAY CAUSE SERIOUS SKIN

DISORDERS INCLUDING DERMATITIS AND SKIN CANCER.

WARNING: AVOID EXCESSIVE CONTACT—WASH THOROUGHLY AFTER CONTACT. KEEP

OUT OF THE REACH OF CHILDREN.

WARNING: PROTECT THE ENVIRONMENT: IT IS ILLEGAL TO POLLUTE DRAINS, WATER

COURSES OR SOIL. USE AUTHORIZED FACILITIES FOR DISPOSAL. IF IN DOUBT,

CONTACT YOUR LOCAL AUTHORITY FOR ADVICE.

WARNING: DO NOT HANDLE A HOT OIL FILTER WITH BARE HANDS. CONTINUOUS

CONTACT WITH USED MOTOR OIL HAS CAUSED SKIN CANCER IN LABORATORY MICE.

PROTECT YOUR SKIN BY WASHING WITH SOAP AND WATER IMMEDIATELY AFTER

CONTACT.

Change Engine Oil

1. Warm the engine to normal operating temperature.

2. Make sure that the equipment is standing level and that the engine is stopped.

3. Obtain a sufficiently large draining pan to accommodate the engine oil -- Refer to “Service Oil fill

capacity (including filter):” on page 38.

4. Remove the oil filler cap from the rocker cover, remove the drain plug from the oil pan and drain

the oil into the draining pan.

NOTE: Modern high performance oils have a cleaning action on the engine which may turn the oil

dark, but does not necessarily indicate inadequate oil changes.

5. Replace and tighten the drain plug, then fill the engine via the filler neck in the rocker cover with

the correct quantity of oil -- Refer to “SPECIFICATIONS” on page 38.

6. Replace the oil filler cap and run the engine for no more than 30 seconds.

7. Check the oil level as described in the following section.

Page 22

Check Engine Oil Level

1. Make sure the equipment is standing level and

that the engine is stopped.

2. Pull out the dipstick and wipe it with a clean rag.

3. Insert the dipstick fully and again remove it. At no

time should the level of the oil fall below the lower

mark on the dipstick.

4. If necessary, top up to the dipstick higher mark

with an approved type and grade of oil.

5. Replace the dipstick, ensuring that it is fully

inserted into its tube to maintain a sealed crankcase

condition

Renew Engine Oil Filter

CAUTION: The original oil filter is not available for service. Use the recommended

Motorcraft FL-820S.

Your engine is equipped with a Motorcraft oil filter. A

filter of this quality should be used throughout the life

of the engine. It is designed to protect your engine by

filtering harmful abrasive and sludgy particles

without clogging up or blocking the flow of the oil to

vital engine parts. This filter is especially designed for

use in engines built by Ford to give successful

operation with the recommended oil filter change

intervals. Contact your nearest EDI

Distributor/Dealer listed in the back section

to obtain the correct filter. Before commencing, place a

drain pan beneath the filter to catch any spilt oil.

1. Using a suitable strap wrench, unscrew the oil filter

canister.

2. Thoroughly clean oil filter housing face.

3. Partly pre-fill the new filter with clean engine oil of the correct type and grade. Apply a thin film of

clean engine oil to the oil filter sealing ring.

4. Screw on new oil filter canister until sealing ring abuts the filter head and tighten a further 1/2

turn. Do NOT use a strap wrench or similar tool to tighten the filter canister.

5. Run engine and check for any leaks from oil filter.

6. Stop engine, allow oil to settle and top up as necessary.

Page 23

Ignition System

The 6.8L engine is equipped with a coil-on-plug ignition system. Rather than a

remotely mounted coil with secondary ignition wires, this system has a separate

ignition coil mounted on each spark plug. Operation of the coils is controlled by the

engine computer module (GCP), which computes ignition timing based on inputs from

engine sensors.

Renew Spark Plugs

WARNING: THE IGNITION SYSTEM COMMONLY CARRIES VOLTAGES IN EXCESS OF

30,000 VOLTS. PLEASE USE CAUTION.

CAUTION: Do not pull directly on the lead as this could cause the wire connection

inside the boot to become separated.

NOTE: To remove spark plugs you must first remove coils.

1. Disconnect the ignition coil wire connectors.

2. Remove the hold down screw then the coil.

NOTE: For fuel rail clearance rotate coils 45° clockwise and lift out.

3. After loosening each spark plug one or two turns with a proper spark plug spanner, clean the

area around each spark plug port with compressed air then remove the spark plugs.

WARNING: PROTECTIVE GOGGLES MUST BE WORN TO PROTECT THE

EYES WHEN USING COMPRESSED AIR.

Page 24

4. Check the gaps of the new spark plugs with a feeler

gauge, and, where necessary, bend the outer

ground extension to achieve the specified gap.

5. Use a proper spark plug spanner to avoid damaging

the insulators, screw the new spark plugs into the

cylinder head and tighten them to the specified

torque value listed under specification of this manual.

NOTE: Do not over tighten spark plugs as the gap may

change considerably due to the distortion of the plug

outer shell.

6. Coat the inside of each spark plug boot with silicone

dielectric compound D7AZ-1 9A33 1-A (USA) or equivalent,

using a small nscrewdriver blade.

7. Install the plug coils and tighten hold down bolt to 5-7 Nm (44-62 in-lb).

NOTE: Coils are interchangeable.

8. Reconnect ignition coil wire connectors.

Page 25

Electronic Actuator

In the event that your engine is equipped with an electronic actuator, any

necessary adjustment should be made by your Power Products Distributor listed at

the back of this manual. The adjusting procedure requires the use of tools which

are not readily available to consumers

Check Condition of Ancillary Drive Belts

WARNING: ENGINE SHOULD BE STOPPED AND ANY REMOTE STARTER

DISABLED BEFORE CHECKING BELTS.

The serpentine ancillary belt used to drive the generator and water pump, is tensioned

automatically and does not require adjustment.

The belts should be visually inspected for signs of wear or damage. It should be renewed if

necessary. Refer to Service Manual.

NOTE: May be purchased from your local Ford Power Product Distributor listed on the back of this

handbook.

Check Engine Coolant Level

WARNING: TO REDUCE THE RISK OF INJURY WHEN CHECKING A HOT ENGINE. COVER

THE RADIATOR CAP WITH A THICK CLOTH AND TURN IT SLOWLY COUNTER-CLOCKWISE

TO THE FIRST STOP. AFTER THE PRESSURE HAS BEEN COMPLETELY RELEASED,

PRESS DOWNWARD AND FINISH REMOVING CAP. FAILURE TO FOLLOW THESE

INSTRUCTIONS COULD RESULT IN DAMAGE TO THE COOLING SYSTEM OR ENGINE AND/

OR PERSONAL INJURY.

CAUTION: Do not add coolant to an engine that has become overheated until the engine

cools. Adding coolant to an extremely hot engine can result in a cracked block or cylinder

head.

1. Allow the engine to cool down to 40°C (110°F).

2. Turn the radiator expansion/degas tank filler cap through 90° in a counterclockwise direction.

Pause to allow any pressure to drop, then turn cap fully counterclockwise and remove it.

3. The quantity of coolant in the expansion/degas tank is a direct indication of the coolant level in

the complete system. The acceptable level of coolant in the expansion/degas tank is shown by the

level indicators moulded into the tank wall. Top up as necessary with a mixture of plain water and

antifreeze -- Refer to “Cooling System” on page 28 for information on mixing antifreeze solutions.

NOTE: It is essential that only the correct type of antifreeze is used -- Refer to “Cooling System” on

page 28.

4. Replace the filter cap and turn down tightly

.

Page 26

Renew Air Cleaner Element

Your air cleaner filters air entering the engine induction system and acts as a silencer and a flame

arrester. Air that contains dirt and grit produces an abrasive fuel mixture, and can cause severe

damage to the cylinder walls and piston rings. Damage to the cylinder walls and piston rings will

cause high oil consumption and short engine life. A restricted or dirty air cleaner will also cause a

rich fuel mixture. Thus, it is extremely important that the air cleaner be serviced at recommended

intervals.

CAUTION: Service the air cleaner more frequently under severe dust conditions to prevent

engine damage.

1. Release the air cleaner lid retaining hardware.

2. Lift the air cleaner lid clear of the air cleaner body, then remove the air cleaner element and

discard it.

3. Wipe the inside of the air cleaner body and lid clean, using a lint-free rag.

4. Insert the new element, ensuring that it fits properly and install air cleaner lid.

Renew PCV Valve

1. Detach the hose, from the top of the

PCV valve located at the top rear of right

valve cover and from the intake manifold.

2. Withdraw the PCV valve from the valve

cover grommet.

3. Discard the PCV valve and the ‘O’ ring.

4. Thoroughly clean the inside and outside

of the hose.

5. Insert the new PCV valve, complete

with a new ‘O’ ring.

6. Re-connect the hose to the PCV valve

and to the intake manifold.

Page 27

GENERAL MAINTENANCE INFORMATION

The following section outlines some aspects of general maintenance which will be of value to the

operator.

Cooling System

To obtain maximum engine service life, its operating temperature must be maintained by an

efficient cooling system.

CAUTION: Under no circumstances should the engine be started without liquid

in the cooling system. This may cause permanent damage to the engine.

Inspect the exterior of the radiator for obstructions, remove all bugs, dirt or foreign material with a

soft brush or cloth.

Use care to avoid damaging the fins. If available, use low pressure compressed air or a stream of

water in the opposite direction to normal airflow. Check all hoses and connections for leaks. If any

of the hoses are cracked, frayed, or feel spongy, they should be replaced.

CAUTION: Never use a cold coolant mixture to top-up the radiator or degas tank of a hot

engine if the coolant level is very low; this could cause serious engine damage.

The radiator or degas tank is equipped with a pressure cap. It is dangerous to

remove this when the system is very hot.

WARNING: NEVER REMOVE THE PRESSURE RELIEF CAP WHILE THE ENGINE IS

OPERATING OR WHEN THE COOLING SYSTEM IS HOT. MAY CAUSE PERSONAL INJURY

OR DAMAGE TO COOLING SYSTEM OR ENGINE. TO REDUCE THE RISK OF HAVING

SCALDING HOT COOLANT OR STEAM BLOW OUT OF THE DEGAS BOTTLE WHEN

REMOVING THE PRESSURE RELIEF CAP, WAIT UNTIL THE ENGINE HAS COOLED DOWN

TO AT LEAST 40°C (110°F).

1. Wrap a thick cloth around the pressure relief cap and turn it slowly one-half turn

counterclockwise. Stepping back while the pressure is released from the cooling system.

2. When you are sure all the pressure has been released, (still with a cloth) turn counterclockwise

and remove the pressure relief cap.

In territories where freezing conditions may occur, the coolant should consist of a mixture of 50%

plain water and 50% Motorcraft Super Plus 2000 coolant. This

antifreeze contains additional corrosion inhibitors designed to provide lasting protection for the

engine.

Only this antifreeze, or proprietary antifreeze meeting Ford specification WSSM97B44D or Ford specification ESE-M97B44-A should be used when topping-up or re-filling the cooling

system.

Motorcraft Super Plus 2000 coolant has long life characteristics and if the concentration is kept to a

maximum of 50% it will provide adequate frost protection and inhibiting for the life of the engine.

Page 28

NOTE: If a major component of the cooling system is renewed such as the radiator, water pump

etc., the system should be flushed and re-filled with a 50% solution of Motorcraft Super Plus 2000

coolant and clean water.

In territories where the ambient temperature is such that no protection against freezing is required,

it is recommended that a 25% concentration of Motorcraft Super Plus 2000 coolant is used. This

will protect water pumps, core plugs, thermostat housings and radiators against corrosion for the

life of the engine and raise boiling point when used at this concentration. See previous Note on

renewing cooling system components.

The antifreeze concentration in a cooling system can be determined by using a

suitable hydrometer.

• A reading of 1080 represents a 50% antifreeze concentration.

• A reading of 1040 represents a 25% antifreeze concentration.

• A reading of 1000 represents plain water.

WARNING: ANTIFREEZE CONTAINS MONO ETHYLENE GLYCOL AND OTHER

CONSTITUENTS WHICH ARE TOXIC IF TAKEN INTERNALLY AND CAN BE ABSORBED IN

TOXIC AMOUNTS ON REPEATED OR PROLONGED SKIN CONTACT. PERSONS USING

ANTIFREEZE ARE RECOMMENDED TO ADHERE TO THE FOLLOWING PRECAUTIONS:

• ANTIFREEZE MUST NEVER BE TAKEN INTERNALLY. IF ANTIFREEZE IS

SWALLOWED ACCIDENTALLY, MEDICAL ADVICE SHOULD BE SOUGHT

IMMEDIATELY.

• PRECAUTIONS SHOULD BE TAKEN TO AVOID SKIN CONTACT WITH

ANTIFREEZE. IN THE EVENT OF ACCIDENTAL SPILLAGE ONTO THE

SKIN, ANTIFREEZE SHOULD BE WASHED OFF AS SOON AS

PRACTICABLE. IF CLOTHING IS SPLASHED WITH ANTIFREEZE, IT

SHOULD BE REMOVED AND WASHED BEFORE BEING WORN AGAIN, TO

AVOID PROLONGED SKIN CONTACT.

• FOR REGULAR AND FREQUENT HANDLING OF ANTIFREEZE,

PROTECTIVE CLOTHING (PLASTIC OR RUBBER GLOVES, BOOTS AND

IMPERVIOUS OVERALLS OR APRONS) MUST BE USED TO MINIMIZE

SKIN CONTACT.

Page 29

Draining, Flushing and Filling the Cooling System

WARNING: NEVER REMOVE THE PRESSURE

RELIEF CAP WHILE THE ENGINE IS

OPERATING OR WHEN THE COOLING SYSTEM

IS HOT. MAY CAUSE PERSONAL

INJURY OR DAMAGE TO COOLING SYSTEM OR

ENGINE. TO REDUCE THE RISK OF HAVING

SCALDING HOT COOLANT OR STEAM BLOW

OUT OF THE DEGAS BOTTLE WHEN REMOVING

THE PRESSURE RELIEF

CAP, WAIT UNTIL THE ENGINE HAS COOLED

DOWN TO AT LEAST 40°C (110°F).

1. Wrap a thick cloth around the pressure relief cap and turn it slowly one-half turn

counterclockwise. Stepping back while the pressure is released from the cooling system.

2. When you are sure all the pressure has been released, (still with a cloth) turn counterclockwise

and remove the pressure relief cap.

3. Remove the radiator expansion/ degas tank filler cap, then open the radiator drain cock, where

fitted, or detach the bottom radiator hose.

4. Flush the system with water using a hose until clean water emerges and allow all water to drain

out. Close the drain cock (or replace the bottom radiator hose). Recover all old antifreeze and

dispose of properly. Contact your local municipal government for the proper disposal.

5. Fill the system with the correct coolant mixture via the expansion/degas tank filler neck. Fill the

system slowly, to avoid air locks, up to the ‘maximum’ mark on the degas tank.

6. Run engine and check hose connections for leaks. Check, and, if necessary, top up the coolant

in the radiator or degas tank.

Engine Lubrication System

The lubrication system should be maintained

regularly -- Refer to “RECOMMENDED

MAINTENANCE SCHEDULES” on page 20,

with the correct grade of lubricant as specified

in the maintenance summary -- Refer to

“Recommended Lubricants” on page 21. The

system is of the force feed type, the lubricating

oil being circulated to the engine bearings

under pressure by an oil pump driven from the

camshaft drive chain belt.

The dipstick provides some guide to the

condition of the oil. An additive type of oil keeps

soot in suspension, and even a small amount

of soot causes the oil to darken rapidly.

However, if the dipstick is found to be heavily

coated with sludge, then obviously the oil should be changed.

Page 30

Electrical System

A NEGATIVE EARTH (NEGATIVE GROUND) SYSTEM IS USED.

GCP - Power Distribution Box

Fuse Amps Circuits protected

1 10 Battery Voltage to EPR

2 5 Ignition Voltage to GCP and Relays

3 10 Battery Voltage to GCP

4 15 Fuel pump

5 15 Battery Voltage out of Power Relay

6 10 Alternator

Generator

This is mounted on a bracket at the front of the engine and is driven from the crankshaft by a

serpentine belt.

The charging rate is adjusted automatically by the built-in regulator to provide sufficient electric

current to keep the battery fully charged under normal operating conditions.

The generator requires no lubrication or maintenance.

WARNING: IT IS ESSENTIAL THAT THE WIRING CONNECTIONS TO THE GENERATOR ARE

NOT REMOVED WHILE THE ENGINE IS RUNNING, AS THIS WILL RESULT IN DAMAGE TO

THE REGULATOR OR PERSONAL INJURY.

Page 31

Storage

Storage - One Month

• While the engine is running, treat upper cylinders by spraying engine fogging agent (from

your local aftermarket supplier) into the air intake for about two minutes. Open throttle for

short burst of speed, shut off engine and allow it to come to a stop while continuing to spray

into air intake.

• Leave spark plugs in holes or seal spark plug holes with suitable threaded metal plugs and

cover all openings into engine with dust-proof caps or shields (suitable non-hygroscopic

material).

• If engine is less transmission, spray flywheel and ring gear with mixture of one part

recommended engine oil, and one part Stoddard Solvent or equivalent.

• Check coolant protection. Store indoors in dry area.

Storage - Indefinite Period

• Drain crankcase completely and refill with recommended engine oil, (SAE 10) or equivalent.

• Run engine and treat upper cylinders by spraying fogging agent into the air intake for about

two minutes. Open throttle for short burst of speed, shut off engine and allow it to come to a

stop while continuing to spray into air intake.

• Check coolant protection

• Disconnect and remove battery.

• Clean exterior surface of engine.

• Leave spark plugs in holes or seal spark plug holes with suitable threaded metal plugs.

• Seal all openings in engine and accessories with non-hygroscopic material. Mask off all

areas to be used for electrical contacts.

• Make sure all surfaces are dry, then spray all taped openings, all engine accessories

including ignition wiring, and all exterior surfaces of engine with Insulation Compound.

• If engines are equipped with automotive type clutch, block clutch in slightly disengaged

position so that lining and pressure plates are not in contact.

Page 32

ENGINE SYSTEM CHECK

GCP System Check

NOTE: Most items listed in the possible cause column may not set a diagnostic fault indicator or

illuminate the MIL light.

NOTE: EDI engines are used in many different applications and equipment. When performing any

system diagnosis be aware of any OEM inputs or equipment monitoring devices that may have an

effect on the engine’s performance or any of the engine’s operating systems.

Engine Performance - No Load

Page 33

Engine Performance - While Under Load

Page 34

Page 35

Engine Concerns

Page 36

SPECIFICATIONS

Page 37

TIGHTENING TORQUES

Page 38

CONVERSION TABLE

Page 39

EDI Distributors

Europe

Page 40

New Zealand

North America - Canada

Page 41

North America - United States

Page 42

North America - United States (Continued)

Page 43

Page 44

Page 45

Page 46

Loading...

Loading...