Page 1

Diesel Injection Pump

SERVICE MANUAL

FORD Puma Common Rail System

Functional Parts

OPERATION

February, 2006

00400090E

Page 2

© 2006 DENSO CORPORATION

All Rights Reserved. This book may not be reproduced

or copied, in whole or in part, without the written

permission of the publisher.

Page 3

Table of Contents

Table of Contents

Operation Section

1. ACCESSORY INFORMATION

1.1 Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 Functional Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

2. SUPPLY PUMP

2.1 Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

2.2 Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2.3 Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

3. RAIL

3.1 Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

4. INJECTOR

4.1 Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

4.2 Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

4.3 Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

5. SUPPLY PUMP COMPONENT PARTS

5.1 Feed Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

5.2 SCV (Suction Control Valve) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

5.3 Fuel temperature sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

6. RAIL COMPONENT PARTS

6.1 Rail Pressure Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

6.2 Pressure Limiter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

Page 4

Operation Section

1–1

1. ACCESSORY INFORMATION

1.1 Outline

z This publication details the common rail system for the FORD Puma. This common rail system includes the following DENSO func-

tional parts: supply pump, rail and injectors. Only the functional parts are described here.

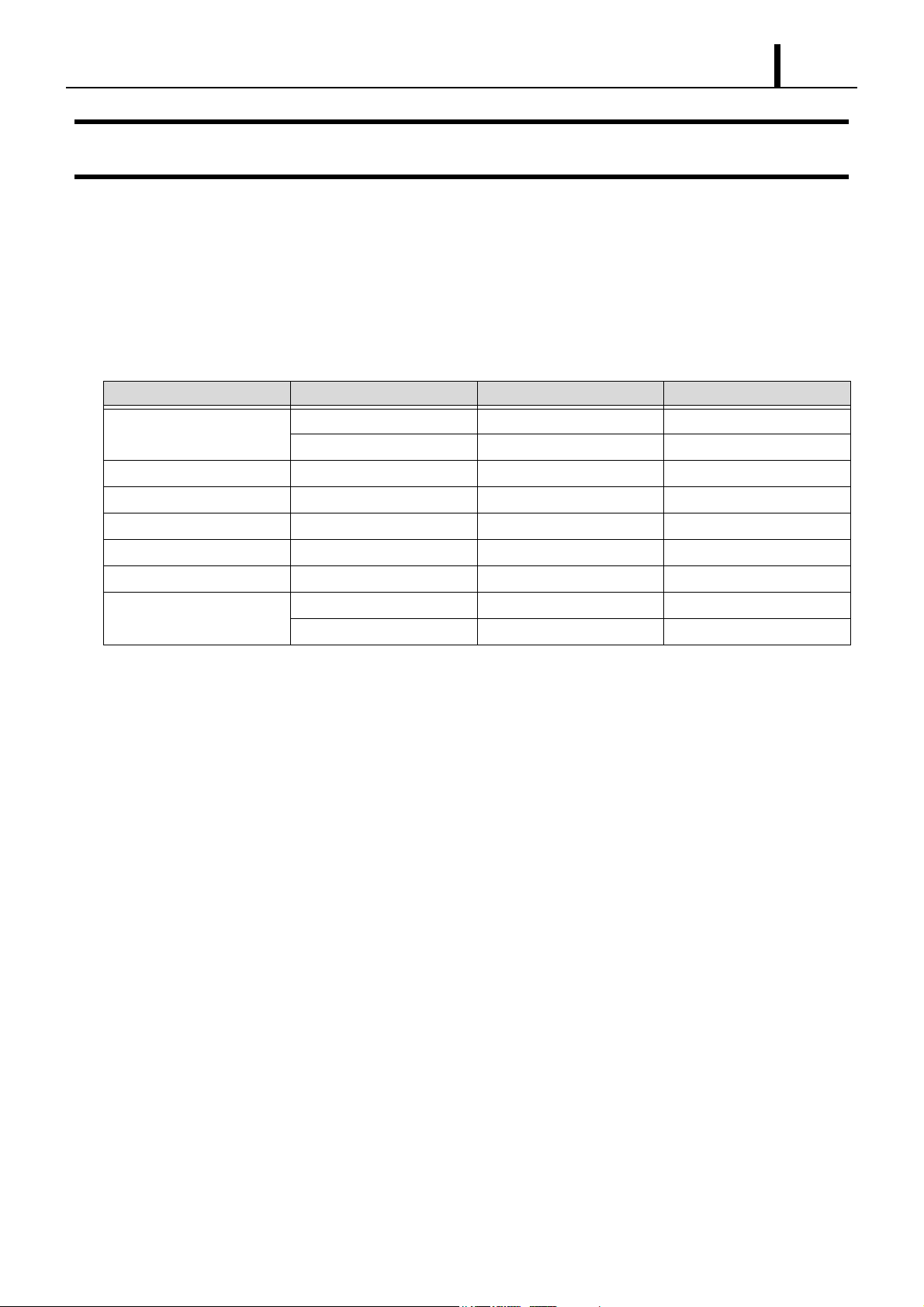

1.2 Functional Parts List

Parts Name DENSO Part Number Manufacturer Parts Number Remarks

Supply pump HU294000-040# 6C1Q-9B395-AB For 2.2L

HU294000-041# 6C1Q-9B395-BB For 2.4L

Fuel temperature sensor 179730-010#

SCV (Suction Control Valve) SM294200-010#

Rail HU095440-073# 6C1Q-9D280-AB

Rail Pressure Sensor HU294390-001#

Pressure Limiter HU095420-033#

Injector HU095000-580# 6C1Q-9K546-AB For low output

HU095000-581# 6C1Q-9K546-BA For high output

Page 5

1–2

Operation Section

2. SUPPLY PUMP

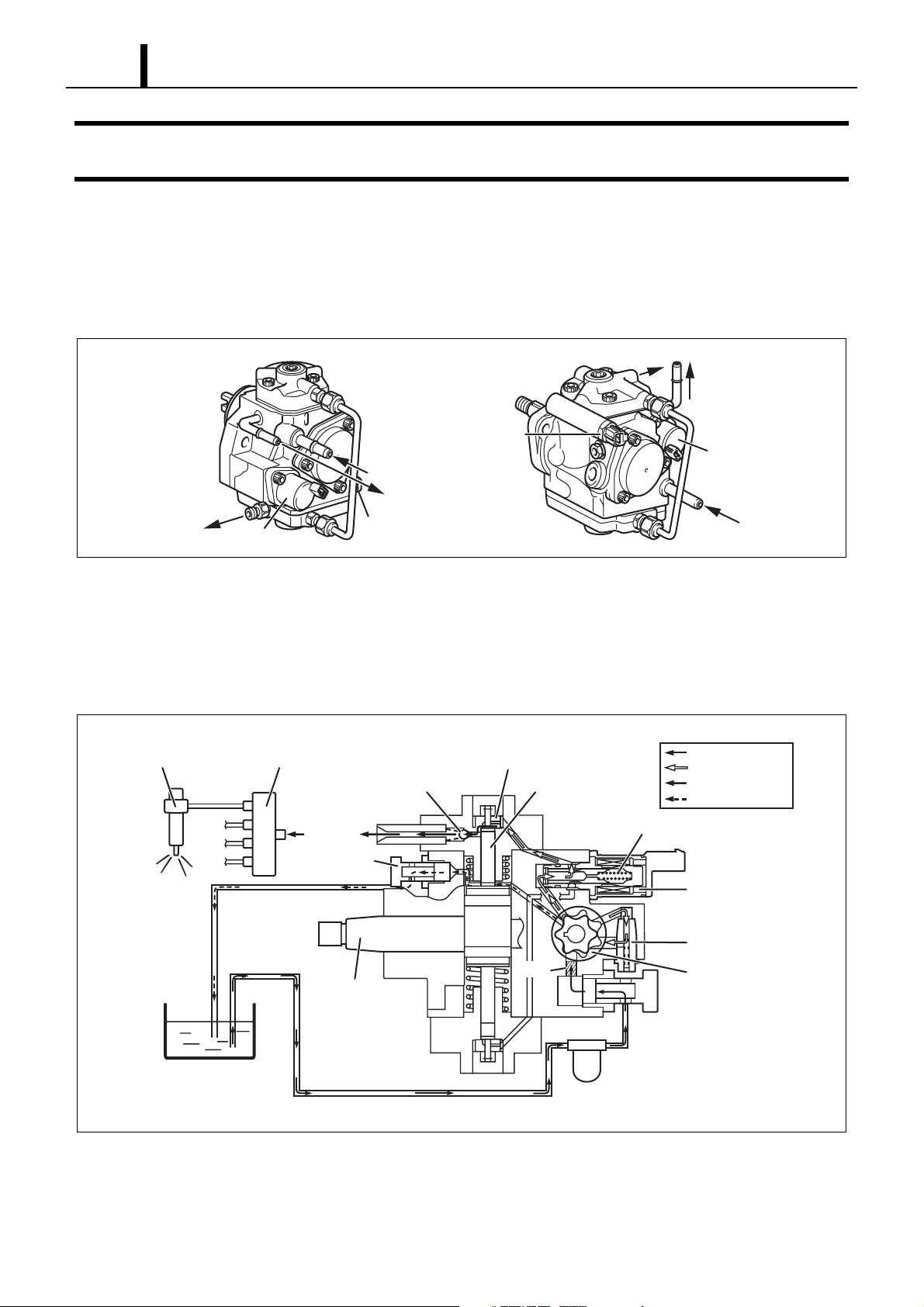

2.1 Outline

z The supply pump consists primarily of the pump body (camshaft (eccentric cam), ring cam, and plungers), SCV (Suction Control

Valve), fuel temperature sensor, and feed pump.

z The two plungers are positioned vertically on the outer ring cam for compactness.

to Rail

Fuel Temperature

from Fuel Tank

Overflow to

Fuel Tank

to Rail

z The engine drives the supply pump at a ratio of 1:2. The supply pump has a built-in feed pump (trochoid type), and draws the fuel

from the fuel tank, sending it to the plunger chamber.

z The internal camshaft drives the two plungers, and they pressurize the fuel sent to the plunger chamber and send it to the rail. The

quantity of fuel supplied to the rail is controlled by the SCV, using signals from the engine ECU. The SCV is a normally open type

(the SCV opens during de-energization).

Injector

SCV

Rail

Fuel Temperature

Sensor

Discharge Valve

Sensor

Intake Valve

Plunger

Overflow to

Fuel Tank

SCV

from Fuel Tank

Q001030E

Intake Pressure

Feed Pressure

High Pressure

Return

Fuel Tank

Fuel Overflow

Return

Camshaft

Filter

Return Spring

SCV

Regulating Valve

Feed Pump

Fuel Inlet

Intake Fuel Filter

Q001019E

Page 6

Operation Section

(1) Supply Pump Internal Fuel Flow

• Fuel drawn from the fuel tank passes through the route in the supply pump as illustrated, and is fed into the rail.

Supply Pump Interior

Regulating Valve

1–3

Feed Pump

Overflow

Fuel Tank

SCV (Suction Control Valve)

Intake Valve

Pumping Portion (Plunger)

2.2 Construction

z The eccentric cam is formed on the camshaft and is attached to the ring cam.

Camshaft

Eccentric Cam

Discharge Valve

Rail

Q000394E

Ring Cam

Q000395E

z As the camshaft rotates, the eccentric cam rotates eccentrically, and the ring cam moves up and down while rotating.

Plunger

Eccentric cam

Drive shaft

Ring cam

QD0727E

Page 7

1–4

Operation Section

z The plunger and the suction valve are mounted on top of the ring cam. The feed pump is connected to the rear of the camshaft.

Plunger A

Ring cam

Feed pump

Plunger B

QD0728E

Page 8

Operation Section

1–5

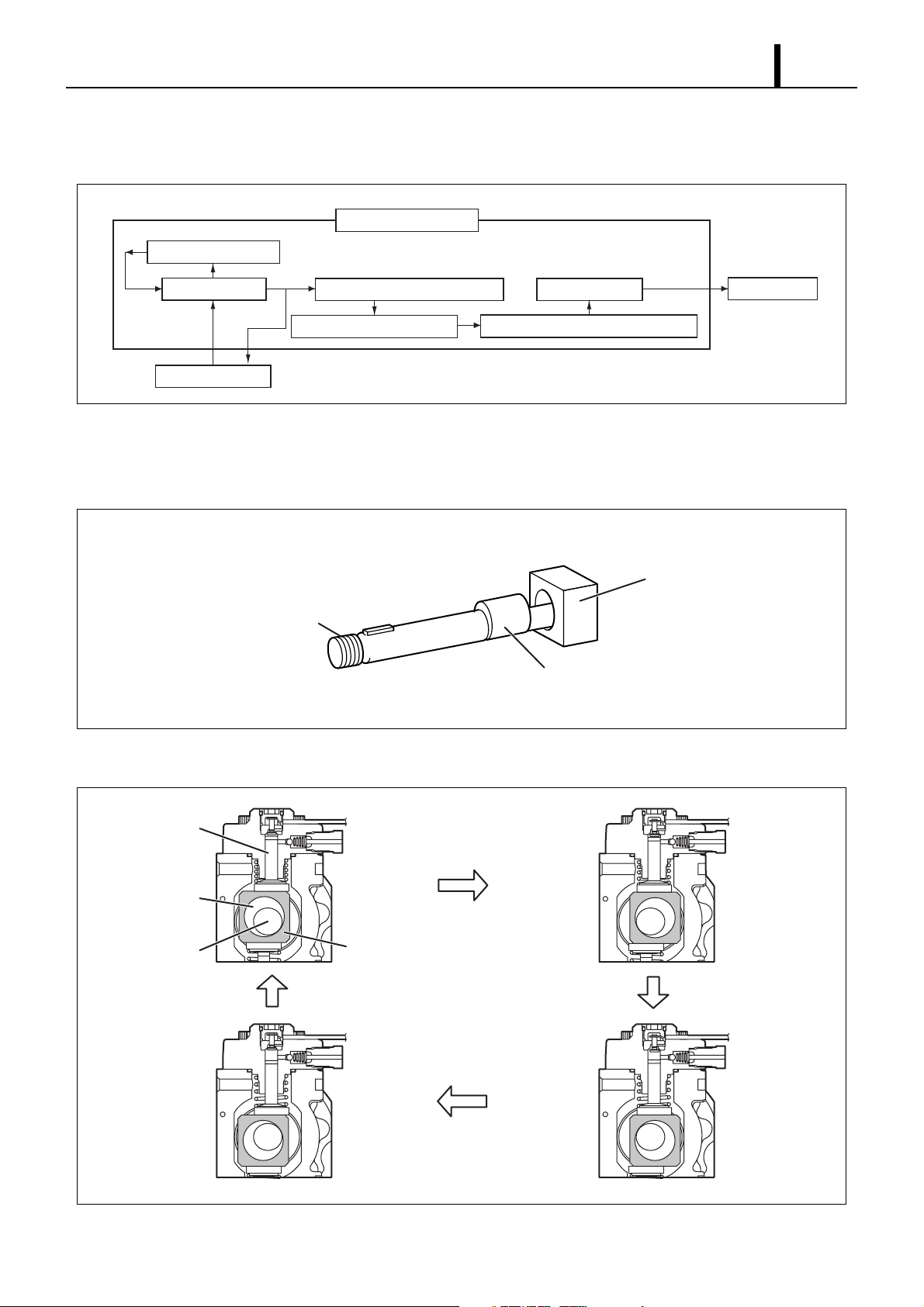

2.3 Operation

z As shown in the illustration below, the rotation of the eccentric cam causes the ring cam to push Plunger A upwards. Due to the spring

force, Plunger B is pulled in the opposite direction to Plunger A. As a result, Plunger B draws in fuel while Plunger A pumps it to the

rail.

Suction valve

Plunger A

SCV

Plunger B

Delivery valve

Plunger A: complete compression

Plunger B: complete intake

Eccentric cam

Ring cam

Plunger A: begin intake

Plunger B: begin compression

Plunger A: begin compression

Plunger B: begin intake

Plunger A: complete intake

Plunger B: complete compression

QD0707E

Page 9

1–6

Operation Section

3. RAIL

3.1 Outline

z The rail stores pressurized fuel that has been delivered from the supply pump and distributes it to each cylinder injector. A pressure

sensor and a pressure limiter are adopted in the rail. The pressure sensor detects the fuel pressure in the rail and sends a signal to the

ECU. The ECU controls the supply pump SCV and the fuel pressure in the rail based on this signal.

Rail Pressure Sensor

To Injector

High-Pressure

Fuel Inlet

Pressure Limiter

Q001054E

Page 10

Operation Section

4. INJECTOR

4.1 Outline

z A compact, energy-saving solenoid-control type TWV (Two-Way Valve) injector has been adopted.

4.2 Construction

16 Base 16 Characters

Sample

1–7

Solenoid Valve

Control Chamber

QR Codes

Sample

Leak Passage

Upper

Side

Pressurized Fuel

(from Rail)

Command Piston

Seat

Pressurized Fuel

Nozzle Spring

Pressure Pin

Filter Orifice Dimensions: φ0.045x2025

Nozzle Needle

Multiple Hole Filter

Q001020E

Page 11

1–8

Operation Section

(1) Injector with QR Codes

QR Code Location

Injection

volume Q

(1)

QR code

Sample

QR Codes

( 9.9mm)

Sample

(2)

(2)

(1)

ID Codes (16 base 16 characters)

Base 16 characters nothing fuel

injection quantity correction

information for market service use.

Sample

Upper

Side

Q001055E

QR Code Correction Points

Pressure parameters

Actuating pulse

Actuating pulse width TQ

TQ

Q001056E

Page 12

Operation Section

1–9

(2) Service Instructions

• When replacing the injectors or the engine ECU, it is necessary to record the ID codes in the ECU using a diagnosis tool (available

from the car manufacturer).

< CAUTION >

If the ID codes for the installed injectors are not registered correctly, engine failure such as rough idling and noise will

result.

Replacing the Injector

"As no correction resistance used, the fuel injection correction data cannot be detected electrically"

Replaced injector

Engine ECU

* Injector ID code must be registered with the engine ECU

Replacing the Engine ECU

"As no correction resistance used, the fuel injection correction data cannot be detected electrically"

Vehicle injectors

Replaced engine ECU

* Injector ID code must be registered with the engine ECU

Q001057E

Q001058E

Page 13

1–10

Operation Section

4.3 Operation

z The TWV (Two-Way Valve) solenoid valve opens and closes the outlet orifice passage to control both the pressure in the control

chamber, and the start and end of injection.

To Fuel

Solenoid

TWV

Outlet Orifice

Actuating

Current

Ta nk

Actuating

Current

Actuating

Current

Inlet Orifice

Control Chamber

Command Piston

Nozzle

Rail

Control

Chamber

Pressure

Injection Rate

Control

Chamber

Pressure

Injection Rate

Control

Chamber

Pressure

Injection Rate

No Injection Injection End of Injection

Q001059E

(1) No injection

• When no current is supplied to the solenoid, the TWV (solenoid valve) is pushed downward by the spring, closing the outlet orifice.

This equalizes the control chamber pressure forcing the command piston down, and the pressure forcing the nozzle needle up. A state

of no injection results because the nozzle needle closes due to the nozzle spring force and the difference in areas to which pressure is

being applied.

(2) Injection

• When current is initially applied to the solenoid, the attraction of the solenoid pulls the TWV (solenoid valve) up, opening the outlet

orifice and allowing fuel to flow out of the control chamber. After the fuel flows out, pressure in the control chamber decreases, pulling

the command piston up. This causes the nozzle needle to rise and injection to start.

(3) Injection Ends

• When current continues to be applied to the solenoid, the nozzle reaches its maximum lift where the injection rate is also at the max-

imum level. When current to the solenoid is turned OFF, the TWV (solenoid valve) falls and closes the orifice. Fuel then flows into

the control chamber via the inlet orifice, increasing pressure and causing the nozzle needle to close immediately and injection to stop.

Page 14

Operation Section

1–11

5. SUPPLY PUMP COMPONENT PARTS

5.1 Feed Pump

z The trochoid type feed pump integrated into the supply pump, draws fuel from the fuel tank and feeds it to the two plungers via the

fuel filter and the SCV (Suction Control Valve). The feed pump is driven by the camshaft. With the rotation of the inner rotor, the feed

pump draws fuel from its suction port and pumps it out through the discharge port. This is done in accordance with the space that

increases and decreases with the movement of the outer and inner rotors.

Outer Rotor

Intake Port

From

Fuel Tank

To

Pump Chamber

Inner Rotor

Discharge

Port

Quantity Decrease

Quantity Increase

Quantity Decrease

(Fuel Discharge)

Quantity Increase

(Fuel Intake)

QD0708E

5.2 SCV (Suction Control Valve)

z A linear solenoid type valve has been adopted. The ECU controls the duty ratio (the duration in which current is applied to the SCV),

in order to control the quantity of fuel that is supplied to the high-pressure plunger.

z The supply pump drive load decreases because intake fuel quantity is controlled to achieve the target rail pressure.

z When current flows to the SCV, the internal armature moves in accordance with the duty ratio. The fuel quantity is regulated by the

cylinder, which moves in connection with the armature to block the fuel passage.

z With the SCV OFF, the return spring pushes the cylinder, completely opening the fuel passage and supplying fuel to the plungers.

(Full quantity intake => full quantity discharge.)

z When the SCV is ON, the return spring contracts and closes the fuel passage.

z By turning the SCV ON/OFF, fuel is supplied in an amount corresponding to the drive duty ratio and then discharged by the plungers.

Valve body

Needle valve Return Spring

Q001060E

Page 15

1–12

Operation Section

(1) When the SCV Energized Duration (Duty ON Time) is Short

• Short duty ON => large valve opening => maximum intake quantity

Feed Pump

Needle valve Large Opening

(2) When the SCV Energized Duration (Duty ON Time) is Long

• Long duty ON => small valve opening => minimum intake quantity

Feed Pump

Q001061E

Needle valve Small Opening

Q001062E

Page 16

Operation Section

(3) Relationship Between the Drive Signal and Current (Magnetomotive Force)

Drive Signal and Current (Magnetomotive Force) Relational Diagram

Low Suction Quantity High Suction Quantity

ON

Voltage

Actuating

OFF

1–13

Current

Average Current Difference

QD0710E

5.3 Fuel temperature sensor

z The fuel temperature sensor is used in rail pressure and injection quantity control. This sensor is installed on the fuel intake side and

utilizes the characteristics of a thermistor in which the electric resistance changes with the temperature in order to detect the fuel tem-

perature.

Initial Resistance Value Characteristics

Temperature

(°C)

Thermistor

Resistance Value

(kΩ)

-30 (25.4)

-20 15.04

+1.29

-1.20

-10 (9.16)

0 (5.74)

10 (3.70)

20

2.45

+0.14

-0.13

30 (1.66)

40 (1.15)

50 (0.811)

60 (0.584)

70 (0.428)

80 0.318±0.008

90 (0.240)

100 (0.1836)

110 0.1417±0.0018

120 (0.1108)

Q001063E

Page 17

1–14

Operation Section

6. RAIL COMPONENT PARTS

6.1 Rail Pressure Sensor

z This sensor detects fuel pressure in the rail and sends a signal to the engine ECU. It is a semi-conductor piezo resistance type pressure

sensor that utilizes the characteristic whereby electrical resistance changes when pressure is applied to a metal diaphragm.

A-VCC = 5V

0 20 100

Rail Pressure (MPa)

160 200

Q001064E

A-VCC PFUEL A-GND

3.56

PFUEL (V)

1.32

4.2

2.6

1.0

0

6.2 Pressure Limiter

z When pressure in the rail is abnormally high, the pressure limiter opens the valve to relieve the pressure. It reopens when pressure in

the rail drops to approximately 200 MPa, and resumes operation when pressure drops to below the specified level. Fuel leaked by the

pressure limiter returns to the fuel tank.

Opening pressure: 200 ± 9MPa

Housing Valve Guide

Valv e

Rail Side

Valve BodySpring

Q001065E

Page 18

Published : February 2006

Edited and published by:

DENSO CORPORATION

Service Department

1-1 Showa-cho, Kariya, Aichi Prefecture, Japan

Loading...

Loading...