Page 1

100-00-1 General Information 100-00-1

SECTION : 100-00 General Information

VEHICLE APPLICATION :

2003.0 BA Falcon

CONTENTS PAGE

DESCRIPTION AND OPERATION

About this Manual .................................................................................................................100-00-3

Introduction ..........................................................................................................................100-00-3

Replacement Parts ...............................................................................................................100-00-3

Special Tools ........................................................................................................................100-00-3

Important Safety Instructions ...............................................................................................100-00-3

Warnings, Cautions and Notes in This Manual ....................................................................100-00-3

How to Use This Manual ......................................................................................................100-00-3

Samples ...............................................................................................................................100-00-4

Health and Safety Precautions .............................................................................................100-00-4

Introduction ..........................................................................................................................100-00-4

Acids and Alkalis ..................................................................................................................100-00-4

Air Bags ................................................................................................................................100-00-4

Air Conditioning Refrigerant .................................................................................................100-00-5

Adhesives and Sealers ........................................................................................................100-00-5

Antifreeze .............................................................................................................................100-00-6

Asbestos ..............................................................................................................................100-00-6

Battery Acids ........................................................................................................................100-00-6

Brake and Clutch Linings and Pads .....................................................................................100-00-6

Brakes Fluids (Polyalkylene Glycols) ...................................................................................100-00-6

Brazing .................................................................................................................................100-00-6

Chemical Materials ...............................................................................................................100-00-6

Chlorofluorocarbons (CFC) ..................................................................................................100-00-7

Clutch Fluids ........................................................................................................................100-00-7

Clutch Linings and Pads ......................................................................................................100-00-7

Corrosion Protection Materials .............................................................................................100-00-7

Cutting ..................................................................................................................................100-00-7

Dewaxing .............................................................................................................................100-00-7

Dusts ....................................................................................................................................100-00-7

Electric Shock ......................................................................................................................100-00-7

Engine Oils ...........................................................................................................................100-00-7

Exhaust Fumes ....................................................................................................................100-00-8

Fibre Insulation .....................................................................................................................100-00-8

Fire .......................................................................................................................................100-00-8

First Aid ................................................................................................................................100-00-8

Fluoroelastomer ...................................................................................................................100-00-8

Foams - Polyurethane ..........................................................................................................100-00-8

Freon ....................................................................................................................................100-00-8

Fuels ....................................................................................................................................100-00-8

Gas Cylinders .......................................................................................................................100-00-9

Gases ...................................................................................................................................100-00-9

Gaskets (Fluoroelastomer) ...................................................................................................100-00-9

General Workshop Tools and Equipment ............................................................................100-00-9

High Pressure Air, Lubrication and Oil Test Equipment ....................................................100-00-10

Halon ..................................................................................................................................100-00-10

Legal Aspects .....................................................................................................................100-00-10

Lubricants and Greases .....................................................................................................100-00-10

Noise ..................................................................................................................................100-00-10

Noise Insulation Materials ..................................................................................................100-00-10

01/2003 2003.0 BA Falcon

Page 2

100-00-2 General Information 100-00-2

(Continued)

O-Rings (Fluoroelastomer) .................................................................................................100-00-10

Paints .................................................................................................................................100-00-10

Pressurized Equipment ......................................................................................................100-00-11

Solder .................................................................................................................................100-00-11

Solvents .............................................................................................................................100-00-11

Sound Insulation ................................................................................................................100-00-11

Suspended Loads ..............................................................................................................100-00-11

Transmission Brake Bands ................................................................................................100-00-11

Underseal ...........................................................................................................................100-00-11

Viton ...................................................................................................................................100-00-11

Welding ..............................................................................................................................100-00-12

Warning Symbols on Vehicles ...........................................................................................100-00-12

White Spirit .........................................................................................................................100-00-13

Standard Workshop Practices ............................................................................................100-00-13

Vehicle in Workshop ..........................................................................................................100-00-13

Alternative Fuel ..................................................................................................................100-00-14

Alternative Fuel — Do’s .....................................................................................................100-00-14

Alternative Fuel — Do Nots ...............................................................................................100-00-14

Towing the Vehicle .............................................................................................................100-00-14

Connecting a Slave Battery Using Jumper Cables ............................................................100-00-14

Component Cleaning .........................................................................................................100-00-15

Calibration of Essential Measuring Equipment ..................................................................100-00-15

Solvents, Sealers and Adhesives .......................................................................................100-00-15

Introduction ........................................................................................................................100-00-15

General Specifications .......................................................................................................100-00-16

Road/Roller Testing ............................................................................................................100-00-16

Pre-Test Checks ................................................................................................................100-00-16

Starting the Engine ............................................................................................................100-00-16

On Road or Roller Test Check: ..........................................................................................100-00-17

Brake Testing .....................................................................................................................100-00-17

01/2003 2003.0 BA Falcon

Page 3

100-00-3 General Information 100-00-3

DESCRIPTION AND OPERATION

About this Manual

Introduction

This manual has been written in a format that is

designed to meet the needs of Ford technicians

worldwide. The objective is to use common formats A warning, caution or note is placed at the beginning

and include similar content in each manual worldwide. of a series of steps if it applies to multiple steps. If the

This manual provides general descriptions for

accomplishing service and repair work with tested,

effective techniques. Following them will help assure

reliability.

Replacement Parts

Ford and Motorcraft parts are made to the same This manual is structured into groups and sections,

exacting standards as the original factory fitted with specific system sections collected together under

components. For this reason, it is recommended that their relevant group.

only genuine Ford or Motorcraft parts are installed

during service or repair.

Special Tools

The Special Tool(s) Table provided at the beginning number of a section number.

of each procedure shows all special tools required to

carry out a repair. Where possible, illustrations are

provided to assist in identifying the special tool

required.

Special tools may be ordered from:

Australia

SPX AUSTRALIA

Tel: +61 (03) 9544 6222

Fax: +61 (03) 9544 5222

Important Safety Instructions

Appropriate service methods and correct repair

procedures are essential for the safe, reliable

operation of all motor vehicles as well as the personal

safety of the individual carrying out the work.

This manual cannot possibly anticipate all such

variations and provide advice or cautions as to each.

Anyone who departs from the instructions provided in

this manual must first establish that he compromises

neither his personal safety nor the vehicle integrity by

his choice of methods, tools or parts.

Warnings, Cautions and Notes in This

Manual

WARNING: Warnings are used to indicate

that failure to follow a procedure correctly may

result in personal injury.

CAUTION: Cautions are used to indicate that

failure to follow a procedure correctly may result

in damage to the vehicle or equipment being

used.

NOTE:

information required to carry out a complete and

satisfactory repair.

As you read through this manual, you will come

across WARNINGS, CAUTIONS and NOTES.

warning, caution or note only applies to one step, it is

placed at the beginning of the specific step (after the

step number).

How to Use This Manual

This manual covers service and repair procedures.

A group covers a specific portion of the vehicle. The

manual is divided into five groups, General

Information, Chassis, Powertrain, Electrical and Body

and Paint. The number of the group is the first

Pages at the start of the manual list all sections

available. Each section has a contents list detailing

General Specifications, Description and Operation

and Service Adjustment and Checks.

If components need to be removed or disassembled

in sequence, the sequence will be identified

numerically in a graphic and the corresponding text

will be numbered accordingly (refer to ‘Samples’).

All left and right-hand references to the vehicle are

taken from a position sitting in the driver seat looking

forward.

All left and right-hand references to the engine are

taken from a position at the flywheel looking towards

the front camshaft pulley.

Where appropriate, instructions will be given for the

use of WDS, diagnostic equipment.

Inspection and Verification

Visual Inspection Charts, Symptom Charts and other

information charts (such as diagnostic routines),

supplement test procedures with technical

specifications, or navigate the user to a specific test

procedure.

Sympton Chart

The symptom chart indicates symptoms, sources and

actions to address a condition.

Pinpoint Tests

For electrical systems, pinpoint test steps are used to

identify the source of a concern in a logical,

step-by-step manner. Pinpoint tests have two

columns: CONDITIONS and

DETAILS/RESULTS/ACTIONS.

The CONDITIONS column is used exclusively for

graphics and icons (with or without captions) and the

DETAILS/RESULTS/ACTIONS column provides

Notes are used to provide additional essential

G17365 en 01/2003 2003.0 BA Falcon

Page 4

100-00-4 General Information 100-00-4

DESCRIPTION AND OPERATION (Continued)

direction to another test step or specific corrective Before using any product the Materials Safety Data

actions. Sheet supplied by the manufacturer or supplier should

The boxed numbers indicate the order in which the

described action is to be performed.

Component Tests

A component test is used when a component is tested

in multiple pinpoint tests, or if a procedure is too

complicated to be formatted within a single page of Used in batteries and cleaning materials.

the pinpoint test.

Graphics throat. Cause burns. Can destroy ordinary protective

Test graphics show the measurement or test to be

performed in a test step. Avoid splashes to the skin, eyes and clothing. Wear

A representative tester graphic is used for voltmeters

and ohmmeters.

If multiple measurements are made in a single

graphic, the test leads are drawn with a solid line until

the test lead splits to indicate the multiple Display Eye Hazard sign.

measurements, at which point dashed lines are used.

Breakout box-type testers are represented by a

double circle test pin. Test pins are labelled with the See also Fire, Chemical Materials

pin number.

Samples

Special Tools and Torque Figures

Any requirement for special tools will picture the tool, panel and side impact Airbags.

showing it in use and with its tool number shown.

Torque settings will be given at the relevant point in

the procedure.

Health and Safety Precautions

Introduction

Many of the procedures associated with vehicle

maintenance and repair involve physical hazards or

other risks to health. This subsection lists,

alphabetically, some of these hazardous operations

and the materials and equipment associated with

them. Precautions necessary to avoid these hazards

are identified.

The list is not exhaustive and all operations and

procedures, and the handling of materials, should be

carried out with health and safety in mind.

be consulted.

Acids and Alkalis

See also Battery Acids.

For example caustic soda, sulphuric acid.

Irritant and corrosive to the skin, eyes, nose and

clothing.

suitable protective impervious apron, gloves and

goggles. Do not breath mists.

Make sure access to eye wash bottles, shower and

soap are readily available for splashing accidents.

Air Bags

Highly flammable, explosive – observe No Smoking

policy.

Used as a safety restraint system mounted in the

steering wheel and passenger side of the instrument

The inflator contains a high-energetic propellant

which, when ignited, produces a VERY HOT GAS

(2500°C).

The gas generant used in air bags is Sodium Azide.

This material is hermetically sealed in the module and

is completely consumed during deployment. No

attempt should be made to open an air bag inflator as

this will lead to the risk of exposure to Sodium Azide.

If a gas generator is ruptured, full protective clothing

should be worn when dealing with the spillage.

After normal deployment, gloves and safety goggles

should be worn during the handling process.

Deployed air bags should be disposed of in a plastic

bag in accordance with local regulations at an

approved chemical waste site.

Following any direct contact with gas generant.

wash affected areas thoroughly with water.

seek medical assistance if necessary.

Air Bags - Do’s

do store modules in an upright position.

do keep modules dry.

do carry modules with the cover side pointing

away from the body.

do place modules with their cover side upwards.

do carefully inspect modules for damage.

do stand to one side when connecting modules.

do make sure all test equipment is properly

calibrated and maintained.

do wash hands after handling deployed air bags.

G17365 en 01/2003 2003.0 BA Falcon

Page 5

100-00-5 General Information 100-00-5

DESCRIPTION AND OPERATION (Continued)

Air Bags - Do Nots

do not store highly flammable material together

with modules or gas generators.

do not store gas generators at temperatures

exceeding 80°C.

do not store modules upside down.

do not attempt to open a gas generator housing.

do not expose gas generators to open flame or

sources of heat.

do not place anything on top of a module cover.

do not use damaged modules.

do not touch a fired module or gas generator for

at least 10 minutes.

do not use any electrical probes on the wiring

circuit.

Air Conditioning Refrigerant

See also Chlorofluorocarbon, Chemical Materials

Highly flammable, combustible – observe No Smoking

policy.

Skin contact may result in frostbite.

Instructions given by the manufacturer must be

followed. Avoid naked lights, wear suitable protective

gloves and goggles.

If refrigerant comes into contact with the skin or eyes,

rinse the affected areas with water immediately. Eyes

should also be rinsed with an appropriate irrigation

solution and should not be rubbed. SEEK MEDICAL

ASSISTANCE IF NECESSARY.

Air Conditioning Refrigerant - Do Nots

do not expose refrigerant bottles to sunlight or

heat.

do not stand refrigerant bottles upright; when

filling, hold them with the valve downwards.

do not expose refrigerant bottles to frost.

do not drop refrigerant bottles.

do not vent refrigerant to atmosphere under any

circumstance.

do not mix refrigerants, for example R12 (Freon)

and R134a.

Adhesives and Sealers

See also Fire, Chemical Materials

Highly flammable, flammable, combustible – observe

No Smoking policy.

Generally should be stored in No Smoking areas.

Cleanliness and tidiness in use should be observed,

for example disposable paper covering benches;

should be dispensed from applicators where possible;

containers, including secondary containers, should be

labelled appropriately.

Solvent-based Adhesives/Sealers - See

Solvents

Follow manufacturers instructions.

Water-based Adhesives/Sealers

Those based on polymer emulsions and rubber

latexes may contain small amounts of volatile toxic

and harmful chemicals. Skin and eye contact should

be avoided and adequate ventilation provided during

use.

Hot Melt Adhesives

In the solid state, they are safe. In the molten state

they may cause burns and health hazards may arise

from the inhalation of toxic fumes.

Use appropriate protective clothing and a

thermostatically controlled heater with a thermal

cut-out and adequate extraction.

Resin-based Adhesives/Sealers, for example

Epoxide and Formaldehyde Resin-based

Mixing should be carried out in well ventilated areas,

as harmful or toxic volatile chemicals may be

released.

Skin contact with uncured resins and hardeners can

result in irritation, dermatitis, and absorption of toxic or

harmful chemicals through the skin. Splashes can

damage the eyes.

Provide adequate ventilation and avoid skin and eye

contact.

Anaerobic, Cyanoacrylate (super-glues) and

other Acrylic Adhesives

Many are irritant, sensitizing or harmful to the skin and

respiratory tract. Some are eye irritants.

Skin and eye contact should be avoided and the

manufacturers instructions followed.

Cyanoacrylate adhesives (super-glues) MUST NOT

contact the skin or eyes. If skin or eye tissue is

bonded, cover with a clean moist pad and SEEK

IMMEDIATE MEDICAL ATTENTION. Do not attempt

to pull tissue apart. Use in well ventilated areas as

vapours can cause irritation to the nose and eyes.

For two-pack systems see Resin-based and

Isocyanate Adhesives/Sealers.

Isocyanate (Polyurethane) Adhesives/Sealers

See also Resin-based Adhesives

Individuals suffering from asthma or respiratory

allergies should not work with or near these materials

as sensitivity reactions can occur.

Over exposure is irritating to the eyes and respiratory

system. Excessive concentrations may produce

effects on the nervous system including drowsiness.

In extreme cases, loss of consciousness may result.

Long term exposure to vapour concentrations may

result in adverse health effects.

G17372 en 01/2003 2003.0 BA Falcon

Page 6

100-00-6 General Information 100-00-6

DESCRIPTION AND OPERATION (Continued)

Prolonged contact with the skin may have a defatting

effect which may lead to skin irritation and in some

cases, dermatitis.

Splashes entering the eye will cause discomfort and

possible damage.

Any spraying should preferably be carried out in

exhaust ventilated booths, removing vapours and

spray droplets from the breathing zone.

Wear appropriate gloves, eye and respiratory

protection.

Antifreeze

See also Fire, Solvents.

For example isopropanol, ethylene glycol, methanol.

Highly flammable, flammable, combustible.

Used in vehicle coolant systems, brake air pressure

systems, screenwash solutions.

Vapours may be given off from coolant antifreeze

(glycol) when heated. Avoid breathing these vapours.

Antifreeze may be absorbed through the skin in toxic

or harmful quantities. Antifreeze, if swallowed, can be

fatal and MEDICAL ATTENTION SHOULD BE

SOUGHT IMMEDIATELY.

These products must not be used in any cooling or

industrial water system which is connected or linked

to general, food preparation or drinking water

supplies.

Asbestos

See also Warning Symbols on Vehicles at the end of

this subsection.

Breathing asbestos dust may cause lung damage or,

in some cases, cancer.

Used in brake and clutch linings, transmission brake cleaned.

bands and gaskets. Ford original production and

genuine replacement items for this model are

asbestos free.

The use of drum cleaning units, vacuum cleaning or inadequate container labelling; fire and explosion

damp wiping is preferred. hazards.

Asbestos dust waste should be dampened, placed in Do wash before job breaks, before eating,

a sealed container and marked for safe disposal. If smoking, drinking or using toilet facilities when

any cutting or drilling is attempted on materials handling chemical materials.

containing asbestos the item should be dampened

and only hand tools or low speed power tools used.

Battery Acids

See also Acids and Alkalis.

Gases released during charging are explosive. Never

use naked flames or allow sparks near charging or

recently charged batteries.

Make sure there is adequate ventilation.

Brake and Clutch Linings and Pads

See Asbestos.

Brakes Fluids (Polyalkylene Glycols)

See also Fire.

Splashes to the skin and eyes are extremely irritating.

Avoid skin and eye contact as far as possible.

Inhalation vapour hazards do not arise at ambient

temperatures because of the very low vapour

pressure.

Brazing

See Welding.

Chemical Materials

See also Legal Aspects.

Chemical materials such as solvents, sealers,

adhesives, paints, resin foams, battery acids,

antifreeze, brake fluids, fuels, oils and grease should

always be used with caution and stored and handled

with care. They may be toxic, harmful, corrosive,

irritant or highly flammable and give rise to hazardous

fumes and dusts.

The effects of excessive exposure to chemicals may

be immediate or delayed; briefly experienced or

permanent; cumulative; superficial; life threatening; or

may reduce life expectancy.

Chemical Materials - Do’s

Do carefully read and observe hazard and

precaution warnings given on material containers

(labels) and in any accompanying leaflets, posters

or other instructions. Material health and safety

data sheets can be obtained from manufacturers.

Do remove chemical materials from the skin and

clothing as soon as practicable after soiling.

Change heavily soiled clothing and have it

Do organise work practices and protective

clothing to avoid soiling of the skin and eyes;

breathing vapours, aerosols, dusts or fumes;

Do keep work areas clean, uncluttered and free of

spills.

Do store chemical materials according to national

and local regulations.

Do keep chemical materials out of the reach of

children.

Chemical Materials - Do Nots

Do not mix chemical materials except under the

manufacturers instructions; some chemicals can

form other toxic or harmful chemicals, give off

toxic or harmful fumes or become explosive when

mixed together.

Do not spray chemical materials, particularly

G17372 en 01/2003 2003.0 BA Falcon

Page 7

100-00-7 General Information 100-00-7

DESCRIPTION AND OPERATION (Continued)

those based on solvents, in confined spaces, for

example when people are inside a vehicle.

Do not apply heat or flame to chemical materials

except under the manufacturers instructions.

Some are highly flammable and some may

release toxic or harmful fumes.

Do not leave containers open. Fumes given off

can build up to toxic, harmful or explosive

concentrations. Some fumes are heavier than air

and will accumulate in confined areas such as

pits.

Do not transfer chemical materials to unlabelled

containers.

Do not clean hands or clothing with chemicals.

Chemicals, particularly solvents and fuels, will dry

skin and may cause irritation leading to dermatitis

or be absorbed through the skin in toxic or

harmful quantities.

Do not use emptied containers for other materials

except when they have been cleaned under

supervised conditions.

Do not sniff or smell chemical materials. Brief

exposure to high concentrations of fumes can be

toxic or harmful.

Chlorofluorocarbons (CFC)

There is concern in the scientific community that

CFCs and Halons are depleting the upper ozone layer

which filters out harmful ultraviolet radiation.

Decreased filtration of ultraviolet radiation may result

in increases in skin cancer, cataracts and immune Make sure that electrical equipment is protected by

system suppression in humans, as well as decreased the correct rated fuse.

productivity of crops and aquatic systems.

CFCs are used primarily as refrigerants in vehicle air equipment which is in any way faulty. The results

conditioning systems and as aerosol propellants. could be fatal.

Halons are used as fire extinguishants.

Ford supports worldwide elimination of CFC usage equipment cannot get trapped and damaged, such as

and it is recommended that Company subsidiaries in a vehicle hoist.

and affiliates should phase out CFC usage as soon as

acceptable substitutes are commercially available.

Clutch Fluids

See Brake fluids.

Clutch Linings and Pads

See Asbestos.

Corrosion Protection Materials

See also Solvents, Fire.

Highly flammable, flammable – observe No Smoking

policy.

These materials are varied and the manufacturers

instructions should be followed. They may contain

solvents, resins or petroleum products. Skin and eye

contact should be avoided. They should only be

sprayed in conditions of adequate ventilation and not

in confined spaces.

Cutting

See Welding.

Dewaxing

See Solvents and Fuels (Kerosene).

Dusts

Powder, dusts or clouds may be irritant, harmful or

toxic. Avoid breathing dusts from powdery chemical

materials or those arising from dry abrasion

operations. Wear respiratory protection if ventilation is

inadequate.

Fine dusts of combustible material can present an

explosion hazard. Avoid explosive limits and sources

of ignition.

Electric Shock

Electric shock can result from the use of faulty

electrical equipment or from the misuse of equipment

in good condition.

Make sure that electrical equipment is maintained in

good condition and frequently tested. Faulty

equipment should be labelled and preferably removed

from the work station.

Make sure that flexes, cables, plugs and sockets are

not frayed, kinked, cut, cracked or otherwise

damaged.

Make sure that electrical equipment and flexes do not

come into contact with water.

Never misuse electrical equipment and never use

Make sure that the cables of mobile electrical

Make sure that the designated electrical workers are

trained in basic First Aid.

In cases of electrocution:

switch off the power supply before approaching

the victim.

if this is not possible push or drag the victim from

the source of electricity using dry non-conductive

material.

commence resuscitation if trained to do so.

SUMMON MEDICAL ASSISTANCE.

Engine Oils

See Lubricants and Grease.

Exhaust Fumes

These contain asphyxiating, harmful and toxic

chemicals and particles such as carbon oxides,

nitrogen oxides, aldehydes, lead and aromatic

G17372 en 01/2003 2003.0 BA Falcon

Page 8

100-00-8 General Information 100-00-8

DESCRIPTION AND OPERATION (Continued)

hydrocarbons. Engines should be run only under

conditions of adequate exhaust extraction or general

ventilation and not in confined spaces.

Gasolene (petrol) engine

There may not be adequate warning of odour or of

irritation before toxic or harmful effects arise. These

may be immediate or delayed.

Diesel engine

Soot, discomfort and irritation usually give adequate

warning of hazardous fume concentrations.

Fibre Insulation

See also Dusts.

Used in noise and sound insulation.

The fibrous nature of surfaces and cut edges can

cause skin irritation. This is usually a physical and not

a chemical effect.

Precautions should be taken to avoid excessive skin

contact through careful organization of work practices

and the use of gloves.

Fire

See also Welding, Foams, Legal Aspects.

Many of the materials found on or associated with the

repair of vehicles are highly flammable. Some give off

toxic or harmful fumes if burnt.

Observe strict fire safety when storing and handling

flammable materials or solvents, particularly near

electrical equipment or welding processes.

Make sure, before using electrical or welding

equipment, that there is no fire hazard present.

Have a suitable fire extinguisher available when using

welding or heating equipment.

First Aid

Apart from meeting any legal requirements it is

desirable for someone in the workshop to be trained

in First Aid procedures.

Splashes in the eye should be flushed carefully with

clean water for at least ten minutes.

Soiled skin should be washed with soap and water.

In case of cold burns, from alternative fuels, place drowsiness and unconsciousness. Small amounts can

affected area in cool to cold water. be fatal to children. Aspiration of liquid into the lungs,

Individuals affected by inhalation of gases and fumes

should be removed to fresh air immediately. If effects Gasolene dries the skin and can cause irritation and

persist, consult a doctor. dermatitis on prolonged or repeated contact. Liquid in

If liquids are swallowed inadvertently, consult a doctor

giving him the information on the container or label. Motor gasolene may contain appreciable quantities of

Do not induce vomiting unless this action is indicated benzene, which is toxic upon inhalation, and the

on the label. concentration of gasolene vapours must be kept very

Fluoroelastomer

See Viton.

Foams - Polyurethane

See also Fire.

Used in sound and noise insulation. Cured foams

used in seat and trim cushioning.

Follow manufacturers instructions.

Unreacted components are irritating and may be

harmful to the skin and eyes. Wear gloves and

goggles.

Individuals with chronic respiratory diseases, asthma,

bronchial medical problems, or histories of allergic

diseases should not work in or near uncured

materials.

The components, vapours or spray mists can cause

direct irritation, sensitivity reactions and may be toxic

or harmful.

Vapours and spray mists must not be inhaled. These

materials must be applied with adequate ventilation

and respiratory protection. Do not remove the

respirator immediately after spraying, wait until the

vapour/mists have cleared.

Burning of the uncured components and the cured

foams can generate toxic and harmful fumes.

Smoking, naked flames or the use of electrical

equipment during foaming operations and until

vapours/mists have cleared should not be allowed.

Any heat cutting of cured foams or partially cured

foams should be conducted with extraction ventilation.

See also the vehicle Body Repair Manual.

Freon

See Air Conditioning Refrigerant.

Fuels

See also, Fire, Legal Aspects, Chemicals and

Solvents.

Avoid skin contact with fuel where possible. Should

contact occur, wash the affected skin with soap and

water.

Gasoline (Petrol)

Highly flammable - observe No Smoking policy.

Swallowing can result in mouth and throat irritation

and absorption from the stomach can result in

through vomiting, is a very serious hazard.

the eye causes severe smarting.

low. High concentrations will cause eye, nose and

throat irritation, nausea, headache, depression and

symptoms of drunkenness. Very high concentrations

will result in rapid loss of consciousness.

G17372 en 01/2003 2003.0 BA Falcon

Page 9

100-00-9 General Information 100-00-9

DESCRIPTION AND OPERATION (Continued)

Make sure there is adequate ventilation when checked for integrity following the specified

handling and using gasolene. Great care must be procedures.

taken to avoid the serious consequences of inhalation

in the event of vapour build up arising from spillages

in confined spaces.

Special precautions apply to cleaning and

maintenance operations on gasolene storage tanks.

Gasolene should not be used as a cleaning agent. It See also Fire.

must not be siphoned by mouth. See First Aid.

Gas-oil (Diesel Fuel)

Combustible.

Gross or prolonged skin contact with high boiling point

gas oils may also cause serious skin disorders

including skin cancer.

Kerosene (Paraffin)

Used also as heating fuel, solvent and cleaning agent.

Flammable - observe No Smoking policy.

Irritation of the mouth and throat may result from

swallowing. The main hazard from swallowing arises if

liquid aspiration into the lungs occurs.

Liquid contact dries the skin and can cause irritation

or dermatitis. Splashes in the eye may be slightly

irritating.

In normal circumstances the low volatility does not

give rise to harmful vapours. Exposure to mists and

vapours from kerosene at elevated temperature

should be avoided (mists may arise in dewaxing).

Avoid skin and eye contact and make sure there is

adequate ventilation.

Alternative Fuel

Highly flammable. Observe “NO SMOKING” signs. maintained in good condition and the correct safety

Make sure there is adequate ventilation when working

on alternative fuelled vehicles. Great care must be Never use tools or equipment for any purpose other

taken to avoid the serious consequences of inhalation than that for which they were designed. Never

in the event of vapour build up in confined spaces. overload equipment such as hoists, jacks, axle and

Inhalation in high concentrations may cause

dizziness, headache, nausea and loss of

co-ordination. Very high concentrations may result in

loss of consciousness.

Contact with liquidified petroleum gas (LPG) or

compressed natural gas (CNG) to skin may cause

cold burns and may cause frost bite.

Long sleeved cotton overalls, steel toe capped safety

boots and rubber neoprene gloves should be worn

during removal and installation of LPG/CNG fuel

system components. Wear a suitable breathing mask when using abrasive

LPG/CNG fuel leaks could cause a fire and be a

hazard to health that can lead to personal injury,

illness or even death. Make sure there is adequate ventilation to control

If a leak is detected, under no circumstances attempt

to seal the leak by tightening the union/connection

until the fuel in the system or component is

depressurised. Once tightened the system should be

If the fuel tank is to be removed for service or repair

the fuel must be evacuated using dedicated

equipment and following the specified procedures.

Gas Cylinders

Gases such as oxygen, acetylene, argon and propane

are normally stored in cylinders at pressures of up to

138 bar (2000 psi) and great care should be taken in

handling these cylinders to avoid mechanical damage

to them or to the valve gear attached. The contents of

each cylinder should be clearly identified by

appropriate markings.

Cylinders should be stored in well ventilated

enclosures, and protected from ice and snow, or

direct sunlight. Fuel gases, for example acetylene and

propane, should not be stored in close proximity to

oxygen cylinders.

Care should be exercised to prevent leaks from gas

cylinders and lines, and to avoid sources of ignition.

Only trained personnel should undertake work

involving gas cylinders.

Gases

See Gas Cylinders.

Gaskets (Fluoroelastomer)

See Viton.

General Workshop Tools and Equipment

It is essential that all tools and equipment are

equipment is used where required.

chassis stands or lifting slings. Damage caused by

overloading is not always immediately apparent and

may result in a fatal failure the next time that the

equipment is used.

Do not use damaged or defective tools or equipment,

particularly high speed equipment such as grinding

wheels. A damaged grinding wheel can disintegrate

without warning and cause serious injury.

Wear suitable eye protection when using grinding,

chiselling or sand blasting equipment.

blasting equipment, working with asbestos-based

materials or using spraying equipment.

dusts, mists and fumes.

G17372 en 01/2003 2003.0 BA Falcon

Page 10

100-00-10 General Information 100-00-10

DESCRIPTION AND OPERATION (Continued)

High Pressure Air, Lubrication and Oil

Test Equipment

See also Lubricants and Greases.

Always keep high pressure equipment in good

condition, and regularly maintained, particularly at

joints and unions.

Never direct a high pressure nozzle, for example

diesel injector, at the skin as the fluid may penetrate

to the underlying tissue, and cause serious injury.

Halon

See CFCs.

Legal Aspects

There are many laws and regulations relating to

health and safety in the use and disposal of materials

and equipment in a workshop.

For a safe working environment and to avoid boilers can be recommended only for units of

environmental pollution, workshops should be familiar, approved design. If in doubt check with the

in detail, with the many health and safety laws and appropriate local authority and manufacturer of

regulations within their country, published by both approved appliances.

national and local authorities.

Lubricants and Greases

Avoid all prolonged and repeated contact with mineral trade. If in doubt, contact the relevant local authority

oils. All lubricants and greases may be irritating to the for advice on disposal facilities.

eyes and skin.

Used Engine Oil

Prolonged and repeated contact with mineral oil will

result in the removal of natural fats from the skin,

leading to dryness, irritation and dermatitis. In

addition, used engine oil contains potentially harmful

contaminants which may cause skin cancer. Adequate

means of skin protection and washing facilities must

be provided.

Do not employ used engine oils as lubricants or for

any application where appreciable skin contact is

likely to occur.

Wash with soap and water to make sure all oil is

removed (skin cleansers and nail brushes will

help). Preparations containing lanoline replace the

natural skin oils which have been removed.

Do not use gasolene (petrol), kerosene (paraffin),

diesel fuel (gas oil), thinners or solvents for

cleaning skin.

If skin disorders develop, obtain medical advice

without delay.

Where practicable, degrease components prior to

handling.

Where there is a risk of eye contact, eye

protection should be worn, for example chemical

goggles or face shields; in addition an eye wash

facility should be provided.

Environmental Precautions

Burning used engine oil in small space heaters or

Dispose of used oil and used oil filters through

authorized waste disposal contractors or licensed

waste disposal sites, or to the waste oil reclamation

It is illegal to pour used oil on to the ground, down

sewers or drains, or into water courses.

Noise

Some operations may produce high noise levels

which could, in time, damage hearing. In these cases,

suitable ear protection must be worn.

Noise Insulation Materials

See Foams, Fibre Insulation.

O-Rings (Fluoroelastomer)

See Viton.

Health Protection Precautions

Paints

Avoid prolonged and repeated contact with oils,

particularly used engine oils.

Wear protective clothing, including impervious

gloves where practicable.

Do not put oily rags into pockets.

Avoid contaminating clothes, particularly

underpants, with oil.

Heavily soiled clothing and oil-impregnated

footwear should not be worn. Overalls must be

cleaned regularly.

First Aid treatment should be obtained Can also contain harmful and toxic unreacted resins

immediately for open cuts and wounds. and resin hardening agents. The manufacturers

Use barrier creams, applying them before each

work period, to help the removal of oil from the

skin.

See also Solvents, Chemical Materials.

Highly flammable, flammable - observe No Smoking

policy

One Pack

Can contain harmful or toxic pigments, driers and

other components as well as solvents. Spraying

should be carried out only with adequate ventilation.

Two Pack

instructions should be followed. See also Resin-based

Adhesives and Isocyanate Adhesives and Sealers

under Adhesives and Sealers.

G17372 en 01/2003 2003.0 BA Falcon

Page 11

100-00-11 General Information 100-00-11

DESCRIPTION AND OPERATION (Continued)

Spraying should preferably be carried out in Avoid splashes to the skin, eyes and clothing. Wear

exhausted ventilated booths removing vapour and protective gloves, goggles and clothing if necessary.

spray mists from the breathing zone. Individuals

working in booths should wear appropriate respiratory

protection. Those doing small scale repair work in the

open workshop should wear air-fed respirators.

Pressurized Equipment

See High Pressure Air, Lubrication and Oil Test

Equipment.

Solder

Solders are mixtures of metals such that the melting

point of the mixture is below that of the constituent

metals (normally lead and tin). Solder application

does not normally give rise to toxic lead fumes,

provided a gas/air flame is used. Oxy-acetylene

flames should not be used, as they are much hotter

and will cause lead fumes to be produced.

Some fumes may be produced by the application of

any flame to surfaces coated with grease, and

inhalation of these should be avoided.

Removal of excess solder should be undertaken with

care, to make sure that fine lead dust is not produced,

which can give toxic effects if inhaled. Respiratory

protection may be necessary.

Solder spillage and filings should be collected and

removed promptly to prevent general air

contamination by lead.

High standards of personal hygiene are necessary in

order to avoid ingestion of lead or inhalation of solder

dust from clothing.

Make sure there is good ventilation when in use,

avoid breathing fumes, vapours and spray mists and

keep containers tightly sealed. Do not use in confined

spaces.

When spraying materials containing solvents, for

example paints, adhesive, coatings, use extraction

ventilation or personal respiratory protection in the

absence of adequate general ventilation.

Do not apply heat or flame except under specific and

detailed manufacturers instructions.

Sound Insulation

See Fibre Insulation, Foams.

Suspended Loads

CAUTION: Never improvise lifting tackle.

There is always a danger when loads are lifted or

suspended. Never work under an unsupported,

suspended or raised load, for example a suspended

engine.

Always make sure that lifting equipment such as

jacks, hoists, axle stands and slings are adequate and

suitable for the job, in good condition and regularly

maintained.

Transmission Brake Bands

See Asbestos.

Underseal

Solvents

See also Chemical Materials, Fuels (Kerosene), Fire.

For example acetone, white spirit, toluene, xylene,

trichloroethane.

Used in cleaning and dewaxing materials, paints,

plastics, resins and thinners.

Some may be highly flammable or flammable.

Skin contact will degrease the skin and may result in

irritation and dermatitis following repeated or

prolonged contact. Some can be absorbed through

the skin in toxic or harmful quantities.

Splashes in the eye may cause severe irritation and

could lead to loss of vision.

Brief exposure of high concentrations of vapours or

mists will cause eye and throat irritation, drowsiness,

dizziness, headaches and, in the worst

circumstances, unconsciousness.

Repeated or prolonged exposure to excessive but

lower concentrations of vapours or mists, for which

there might not be adequate warning indications, can

cause more serious toxic or harmful effects.

Aspiration into the lungs, for example through

vomiting, is the most serious consequence of

swallowing.

See Corrosion Protection.

Viton

In common with many other manufacturers vehicles,

some components fitted to the Ford range have

O-rings, seals or gaskets which contain a material

known as ‘Viton’.

Viton is a fluoroelastomer, that is a synthetic rubber

type which contains Fluorine. It is commonly used for

O-rings, gaskets and seals of all types. Although Viton

is the most well known fluoroelastomer, there are

others, including Fluorel and Tecmoflon.

When used under design conditions fluoroelastomers

are perfectly safe. If, however, they are exposed to

temperatures in excess of 400°C, the material will not

burn, but will decompose, and one of the products

formed is hydrofluoric acid.

This acid is extremely corrosive and may be absorbed

directly, through contact, into the general body

system.

O-rings, seals or gaskets which have been exposed to

very high temperatures will appear charred or as a

black sticky substance.

DO NOT, under any circumstances touch them or the

attached components.

G17372 en 01/2003 2003.0 BA Falcon

Page 12

100-00-12 General Information 100-00-12

DESCRIPTION AND OPERATION (Continued)

Enquiries should be made to determine whether Viton

or any other fluoroelastomer has been used in the

affected O-ring, seal or gasket. If they are of natural

rubber or nitrile there is no hazard. If in doubt, be

cautious as the material may be Viton or any

fluoroelastomer.

If Viton or any other fluoroelastomers have been

used, the affected area should be decontaminated

before the commencement of work.

Disposable heavy duty plastic gloves should be worn

at all times, and the affected area washed down using

wire wool and a limewater (calcium hydroxide)

solution to neutralise the acid before disposing of the

decomposed Viton residue and final cleaning of the

area. After use, the plastic gloves should be discarded

carefully and safely.

Welding

See also Fire, Electric Shock, Gas Cylinders.

Welding processes include Resistance Welding (Spot

Welding), Arc Welding and Gas Welding.

Resistance Welding

This process may cause particles of molten metal to

be emitted at a high velocity, and the eyes and skin

must be protected.

Arc Welding

This process emits a high level of ultra-violet radiation

which may cause arc-eye and skin burns to the

operator and to other persons nearby. Gas-shielded

welding processes are particularly hazardous in this

respect. Personal protection must be worn, and

screens used to shield other people.

CONTACT LENS WEARERS ARE ADVISED TO

REVERT TO ORDINARY SPECTACLES WHEN ARC

WELDING as the arc spectrum is believed to emit

microwaves which dry out the fluid between the lens

and the eye. This may result in blindness when the

lens is removed from the eye.

Metal spatter will also occur, and appropriate eye and

skin protection is necessary.

The heat of the welding arc will produce fumes and

gases from the metals being welded, the rods and

from any applied coatings or contamination on the

surfaces being worked on. These gases and fumes

may be toxic and inhalation of these should be

avoided. The use of extraction ventilation to remove

the fumes from the working area may be necessary

particularly in cases where the general ventilation is

poor, or where considerable welding work is

anticipated. In extreme cases or confined spaces

where adequate ventilation cannot be provided,

air-fed respirators may be necessary.

Gas Welding (and Cutting)

Oxy-acetylene torches may be used for welding and

cutting, and special care must be taken to prevent

leakage of these gases, with consequent risk of fire

and explosion.

The process will produce metal spatter and eye and

skin protection is necessary.

The flame is bright, and eye protection should be

used, but the ultra-violet emission is much less than

that from arc welding, and lighter filters may be used.

The process itself produces few toxic fumes, but such

fumes and gases may be produced from coatings on

the work, particularly during cutting away of damaged

body parts, and inhalation of the fumes should be

avoided.

In brazing, toxic fumes may be produced from the

metals in the brazing rod, and a severe hazard may

arise if brazing rods containing cadmium are used. In

this event particular care must be taken to avoid

inhalation of fumes and expert advice may be

required.

Special precautions must be taken before any welding

or cutting takes place on vessels which have

contained combustible materials, for example boiling

or steaming out of fuel tanks .

Warning Symbols on Vehicles

Decals showing warning symbols will be found on

various vehicle components.

These decals must not be removed. The warnings are

for the attention of owners/operators and persons

carrying out service or repair operations on the

vehicle.

The most commonly found decals are reproduced

below together with an explanation of the warnings.

1. Components or assemblies displaying the caution

triangle and open book symbol advise

consultation of the relevant section of the owners

handbook before touching or attempting

adjustments of any kind.

G17372 en 01/2003 2003.0 BA Falcon

Page 13

100-00-13 General Information 100-00-13

DESCRIPTION AND OPERATION (Continued)

2. Components or assemblies displaying the warning 5. Displaying this symbol (normally in conjunction

triangle with the ‘electrified’ arrow and open book with 5 above) warn of the presence of potentially

symbol give warning of inherent high voltages. explosive matter within the immediate vicinity.

Never touch these with the engine running or the

ignition switched on. See Electric Shock in this

subsection.

3. Components or assemblies displaying this symbol

give warning that the component contains a

corrosive substance. See Acids and Alkalis in this

subsection.

4. Displaying the caution circle with a deleted lighted

match symbol, caution against the use of naked

lights or flames within the immediate vicinity due

to the presence of highly flammable or explosive

liquids or vapours. See Fire in this subsection.

6. Displaying this symbol warn that children should

not be allowed in the immediate vicinity

unsupervised.

White Spirit

See Solvents.

Standard Workshop Practices

Vehicle in Workshop

When working on a vehicle in the workshop always

make sure that:

the parking brake is applied or the wheels are

securely chocked to prevent the vehicle moving

forwards or backwards.

the key is removed from key operated hood locks

before any work is carried out around the front of

the vehicle.

if the engine is to be run, there is adequate

ventilation, or an extraction hose to remove

exhaust fumes.

there is adequate room to raise the vehicle and

remove the wheels, if necessary.

fender covers are always fitted if any work is to be

carried out in the engine compartment.

G17373 en 01/2003 2003.0 BA Falcon

Page 14

100-00-14 General Information 100-00-14

DESCRIPTION AND OPERATION (Continued)

the battery is disconnected if working on the do not work on the fuel lines or system

engine. components unless the alternative fuel has been

evacuated and the pressure in the system is

CAUTION: When electric arc welding on a

vehicle, always disconnect the generator wiring to

prevent the possibility of a surge of current

causing damage to the internal components of the

generator.

If using welding equipment on the vehicle, a

suitable fire extinguisher is readily available.

Alternative Fuel

WARNING: When servicing the fuel system

always follow the recommended procedures.

Failure to follow these instructions may result in

personal injury.

If the odour of liquified petroleum gas (LPG) or

compressed natural gas (CNG) is present in the air in

the workshop, warn all persons in the area to:

extinguish all flames and lighted tobacco.

shut off electrical and air powered equipment.

evacuate the area.

ventilate the area.

contact fire control authorities.

remove the vehicle to a dedicated, ventilated

area.

Alternative Fuel — Do’s

do work on the vehicle in a designated area that

is well ventilated and its access restricted to

qualified personnel only

install new warning labels to their original

locations

if possible always isolate the alternative fuel tank,

run the vehicle on the alternative fuel until it

automatically switches to its normal fuel prior to

taking the vehicle into the workshop/service area

only use tested and approved components and

pipes when repairing or servicing LPG and CNG

systems

reduced to atmospheric, or less

do not use anything other than the specified leak

detector fluid to trace fuel leaks

Be aware of situations that may cause the LPG or

CNG fuel system to vent off fuel, such as:

extremely hot days

parking by a space heater

hoisting a vehicle up near a ceiling heater

Only personnel fully trained to Ford and local

standards are to work on alternative fuel vehicles.

Towing the Vehicle

WARNING: When the vehicle is being towed

the ignition switch must be in position II (steering

lock released and warning lights illuminated).

Only then will the steering, turn signal lamps,

horn and stop lamps be operational. Failure to

follow these instructions may result in personal

injury.

When a vehicle with automatic transmission is towed,

the gear selector must be in position N (Neutral).

Never tow a vehicle with automatic transmission

faster than 30 mph (50 km/h) or further than 30 miles

(50 km). If it is necessary to tow the vehicle a greater

distance, the drive wheels must be lifted clear off the

ground.

Alternatively the vehicle can be transported on a low

loader or a trailer.

Connecting a Slave Battery Using Jumper

Cables

WARNING: If the slave battery has recently

been charged and is gassing, cover the vent plugs

or covers with a damp cloth to reduce the risk of

explosion should arcing occur when connecting

the jumper cables. Failure to follow these

instructions may result in personal injury.

Alternative Fuel — Do Nots

do not vent off LPG fuel

do not use shop air pressure to force LPG fuel

from the fuel tank

do not use paint drying ovens above 40°C for any

alternative fuel vehicles. LPG and CNG fuel tanks

should be removed from the vehicles prior to

being put into paint drying ovens above 40°C

do not modify the system or install new

components with parts not designed for gas

vehicles

do not evacuate fuel tanks unless there is repair

that requires removed of the fuel tank

G17373 en 01/2003 2003.0 BA Falcon

CAUTION: A discharged battery condition

may have been caused by an electrical short

circuit. If this condition exists there will be an

apparently live circuit on the vehicle even when all

normal circuits are switched off. This can cause

arcing when the jumper cables are connected.

CAUTION: While it is not recommended that

the vehicle is jump started, it is recognized that

this may occasionally be the only practical way to

mobilize a vehicle. In such an instance the

discharged battery must be recharged

immediately after jump starting to avoid

permanent damage.

Page 15

100-00-15 General Information 100-00-15

DESCRIPTION AND OPERATION (Continued)

Always make sure that the jumper cables are

adequate for the task. Heavy duty cables must be

used.

Always make sure that the slave battery is of the

same voltage as the vehicle battery. The batteries

must be connected in parallel.

Always make sure that switchable electric circuits

are switched off before connecting jumper cables.

This reduces the risk of arcing occurring when the

final connection is made.

WARNING: Make sure that the ends of the

jumper cables do not touch each other or ground

against the vehicle body at any time while the

cables are attached to the battery. A fully charged

battery, if shorted through jumper cables, can

discharge at a rate well above 1000 amps causing

violent arcing and very rapid heating of the

jumper cables and terminals, and can even cause

the battery to explode. Failure to follow these

instructions may result in personal injury.

Always connect the jumper cables in the following

sequence:

slave battery positive first then vehicle battery

positive

slave battery negative next and then vehicle

ground at least 12 inches (300 mm) from the

battery terminal, for example engine lifting eye

Always reduce the engine speed to idle before

disconnecting the jumper cables.

Before removing the jumper cables from the vehicle

that had the discharged battery, switch on the heater

blower (high) or the heated rear window, to reduce the

voltage peak when the cables are removed.

Always disconnect the jumper cables in the reverse

order to the connecting sequence and do not short

the ends of the cables.

Do not rely on the generator to restore a discharged

battery. For a generator to recharge a battery, it would

take in excess of eight hours continuous driving with

no additional loads placed on the battery.

Component Cleaning

To prevent ingress of dirt, accumulations of loose dirt

and greasy deposits should be removed before

disconnecting or dismantling components or

assemblies.

Components should be thoroughly cleaned before

inspection prior to reassembly.

Cleaning Methods:

dry cleaning

removal of loose dirt with soft or cable brushes

scraping dirt off with a piece of metal or wood

wiping off with a rag

CAUTION: Compressed air is sometimes

‘wet’ so use with caution, especially on hydraulic

systems.

blowing dirt off with compressed air. (Eye

protection must be worn when using this method)

removal of dry dust using vacuum equipment.

This method should always be used to remove

friction lining material dust (asbestos particles)

steam cleaning

WARNING: Most solvents require careful

handling and some are harmful. Refer to Health

and Safety Precautions and to the manufacturers

literature for safety precautions. Failure to follow

these instructions may result in personal injury.

Various solvents are available which are suitable for

component cleaning. Some components such as

brake hydraulic parts and electrical assemblies should

be cleaned only with recommended solvents — refer

to Solvents, Sealers and Adhesives or to the section

of the manual relevant to the component.

Calibration of Essential Measuring

Equipment

WARNING: Failure to follow these

instructions may result in personal injury or

damage to components.

It is of fundamental importance that certain essential

equipment, for example torque wrenches,

multimeters, exhaust gas analysers or rolling roads,

are regularly calibrated in accordance with the

manufacturers instructions.

Solvents, Sealers and Adhesives

Introduction

WARNING: Always handle all solvents,

sealers and adhesives with extreme care. Some

contain chemicals or give off fumes which can be

dangerous to health. Always follow the

manufacturers instructions. If in doubt about any

G17374 en 01/2003 2003.0 BA Falcon

Page 16

100-00-16 General Information 100-00-16

DESCRIPTION AND OPERATION (Continued)

substance, particularly a solvent, DO NOT use it.

CAUTION: If in doubt about the suitability of

any proprietary solvent or sealer for a particular

application, contact the manufacturer of the

product for information regarding storage,

handling and application.

The Health and Safety Precautions subsection refers

to some commonly used chemicals and materials,

hazards associated with their use, and safety

measures to be taken. Some of these chemicals may

be included in the following list either in their own right

or as an ingredient in a sealer or adhesive.

General Specifications

Anti-Seize Compound

Ford Spec.

General SAM-1C-9107A

SAM-1C-9107A

Spark plug threads ESE-M1244-A

Sealers

Application Ford Spec. Manufacturer and Identification

For camshaft bearing caps ESK-M4G260-A Loctite 518

For cylinder block WSK-M4G320-A Hylosil 502

For fitting rear lamp assembly WSK-M4G329-ABC

For transmission housing (80 gram can) Finis Code 6 160 443

Adhesives

Application Ford Spec.

PU for windscreen, side and rear glass Finis Code 6 997 259

Road/Roller Testing

Road or roller testing may be carried out for various

reasons and a procedure detailing pre-test checks,

through engine starting and stopping, pre-driving

checks, on-test checks to final checks on completion

of the test is given overleaf.

Unless complete vehicle performance is being

checked, the full road test procedure need not be

carried out. Instead, those items particularly relevant

to the system/s being checked can be extracted.

Engine oil level

Engine coolant level

Tires, for correct pressure, compatible types and

tread patterns, and wear within limits.

There is sufficient fuel in the tank to complete the

test.

All around the engine, transmission and under the

vehicle for oil, coolant, hydraulic and fuel leaks.

Make a note of any apparent leaks and wipe off

the surrounding areas to make it easier to identify

the extent of the leak on completion of the test.

Pre-Test Checks

Starting the Engine

WARNING: If the brake system hydraulic fluid

level is low, pedal travel is excessive or a

hydraulic leak is found, do not attempt to road

test the vehicle until the reason for the low fluid

level, excessive pedal travel or hydraulic leak is

found and rectified.

It is suggested that pre-test checks, and functional

tests of those systems/circuits which affect the safe

and legal operations of the vehicle, such as brakes,

lights and steering, should always be carried out

before the road or roller test.

G17374 en 01/2003 2003.0 BA Falcon

NOTE:

first 1.5 km (1 mile), do not depress accelerator pedal

beyond half travel until the vehicle has attained a

minimum speed of 25 km/h (15 miles/h). Never

operate at high engine speed or with the accelerator

pedal at full travel whilst the engine is cold.

With the ignition switched off, check:

On initial drive away from cold and within the

The handbrake is applied.

The gear lever is in neutral.

Page 17

100-00-17 General Information 100-00-17

DESCRIPTION AND OPERATION (Continued)

All instrument gauges (except fuel gauge) read

zero.

With the ignition switched on, check:

Ignition controlled warning lights come on.

Engine temperature gauge registers a reading

compatible with the engine temperature.

Fuel gauge registers a reading appropriate to the

fuel level in the tank.

The operation of the handbrake warning light and

fluid level warning indicator light.

On Road or Roller Test Check:

CAUTION: If road testing, check the brake

operation while still travelling at low speed before

continuing with the test. If the brakes pull to one

side, or appear to be otherwise faulty, do not

continue with the road test until the fault has been

found and rectified.

Clutch pedal operation is not stiff or heavy.

Initial gear engagement is smooth and there is no

evidence of clutch drag.

Handbrake control operates smoothly and the

handbrake releases quickly and completely.

Clutch takes up the drive smoothly, without slip or

judder.

Gear changing is smooth, and there are no

abnormal noises or vibrations from the

transmission.

The engine power output is satisfactory, full power

is achieved, acceleration is smooth and pedal

operation not stiff or heavy, and engine speed

returns to idle correctly.

There is no excessive or abnormally colored

smoke from the engine under normal driving,

heavy load or overrun conditions.

Steering operation, including power steering

where fitted, is smooth, accurate, not excessively

heavy or with excessive free play or vibration.

Does not pull to one side and self centres

smoothly after cornering.

Speedometer, oil pressure warning lamp, coolant

temperature gauge and tachometer (where fitted)

register the correct readings or operate correctly.

Switches and controls operate smoothly and

positively, warning or indicator lights operate

correctly and the direction indicator control self

cancels when the steering is returned to the

straight ahead position.

Heating and ventilation systems work correctly

and effectively.

Brake operation and efficiency.

Brake Testing

WARNING: When brake testing, avoid

breathing the smoke or fumes from hot brakes,

this may contain asbestos dust which is

hazardous to health, see Health and Safety

Precautions.

Avoid brake testing on busy roads where it can cause

inconvenience or danger to other road users.

CAUTION: Brake testing which includes

heavy brake applications should not be carried

out with new brake pads/discs or linings/drums

until the components have bedded-in. New brake

friction components will not reach full efficiency

until the bedding-in process is complete.

Test the brakes at several speeds within the normal

operating range using both light and heavy pedal

pressure. Note any tendency to snatch, pull or drag,

and any undue delay in application or release.

Allow the vehicle to coast and note any tendency to

pull to one side, or evidence that the brakes are

binding.

After stopping the vehicle (not immediately after a

period of heavy braking), carefully check the brake

temperature. A disc which feels hot, or appreciably

hotter than the others, indicates that the brake is

binding.

After completion of the test, check for:

Oil, coolant, hydraulic, air and fuel leaks.

Abnormal temperature of any moving components

or assemblies, e.g. wheel hubs, transmission,

axle etc., which might indicate overtightness or

lack of lubrication.

G17375 en 01/2003 2003.0 BA Falcon

Page 18

100-01-1 Identification Codes 100-01-1

SECTION : 100-01 Identification Codes

VEHICLE APPLICATION :

2003.0 BA Falcon

CONTENTS PAGE

DESCRIPTION AND OPERATION

Identification Codes ..............................................................................................................100-01-2

Vehicle Identification Number ..............................................................................................100-01-2

Vehicle Compliance (VC) Label .............................................................................................100-01-5

Emission Decal ....................................................................................................................100-01-6

01/2003 2003.0 BA Falcon

Page 19

100-01-2 Identification Codes 100-01-2

DESCRIPTION AND OPERATION

Identification Codes

Vehicle Identification Number

The vehicle identification number (VIN) is a seventeen-digit combination of letters and numbers. The VIN is

printed on a label located in the engine compartment or on the driver’s side A-pillar as shown. The VIN

number is also found on the vehicle compliance (VC) label located in the same area.

Typical Identification Plate Locations

Identification Label (engine bay)

G86656 en 01/2003 2003.0 BA Falcon

Page 20

100-01-3 Identification Codes 100-01-3

DESCRIPTION AND OPERATION (Continued)

Identification Label (A-pillar)

G86656 en 01/2003 2003.0 BA Falcon

Page 21

100-01-4 Identification Codes 100-01-4

DESCRIPTION AND OPERATION (Continued)

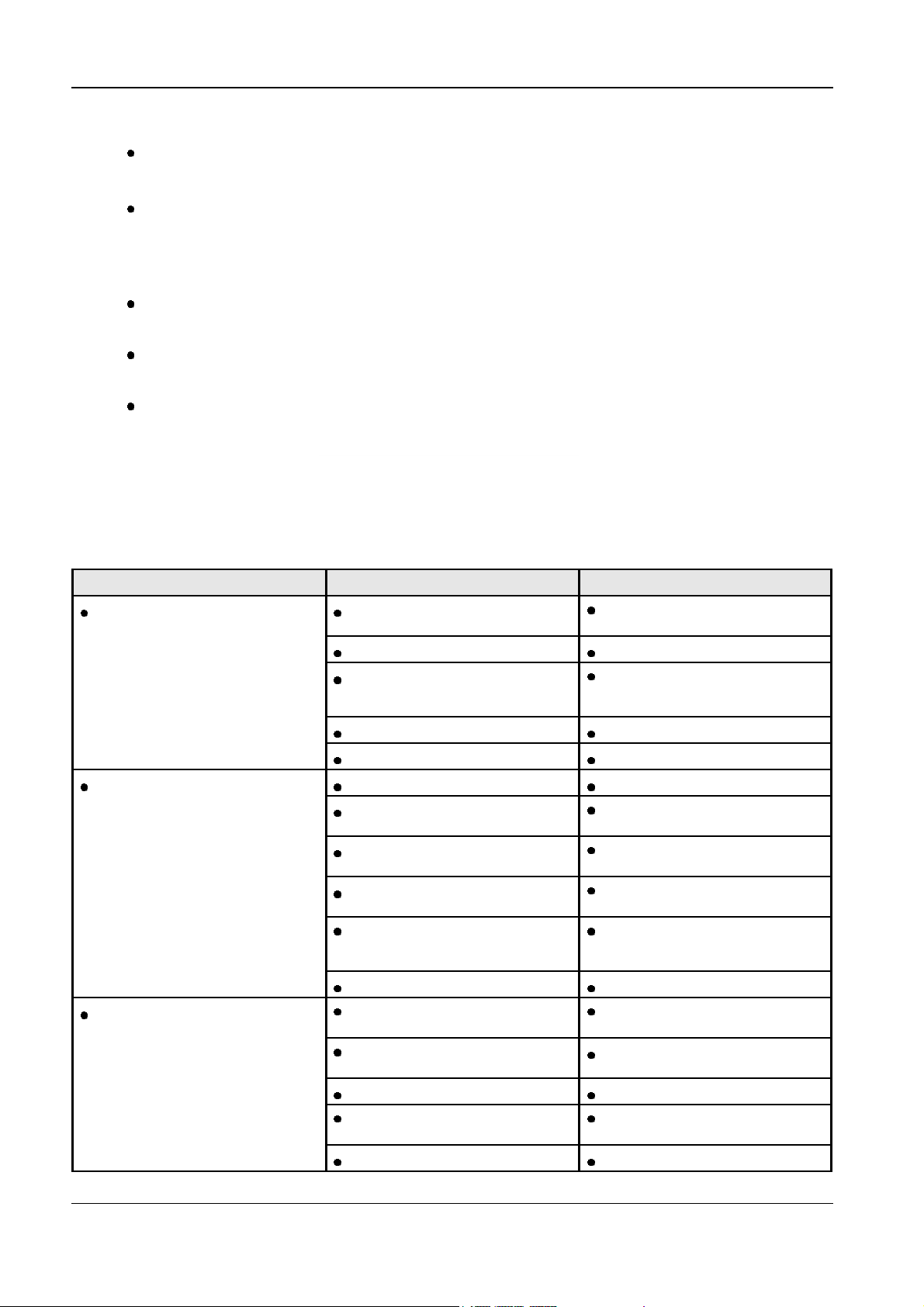

Body Style Code

BODY TYPE CODE

XT Sedan SW

XT Wagon WA

Futura Sedan SW

Futura Wagon WA

XR Sedan SW

XR Ute CM

GT Sedan SW

Fairmont Sedan SW

Fairmont Wagon WA

Fairmont Ghia Sedan SW

Fairlane Ghia LW

LTD LW

XL Ute CM

XLS Ute CM

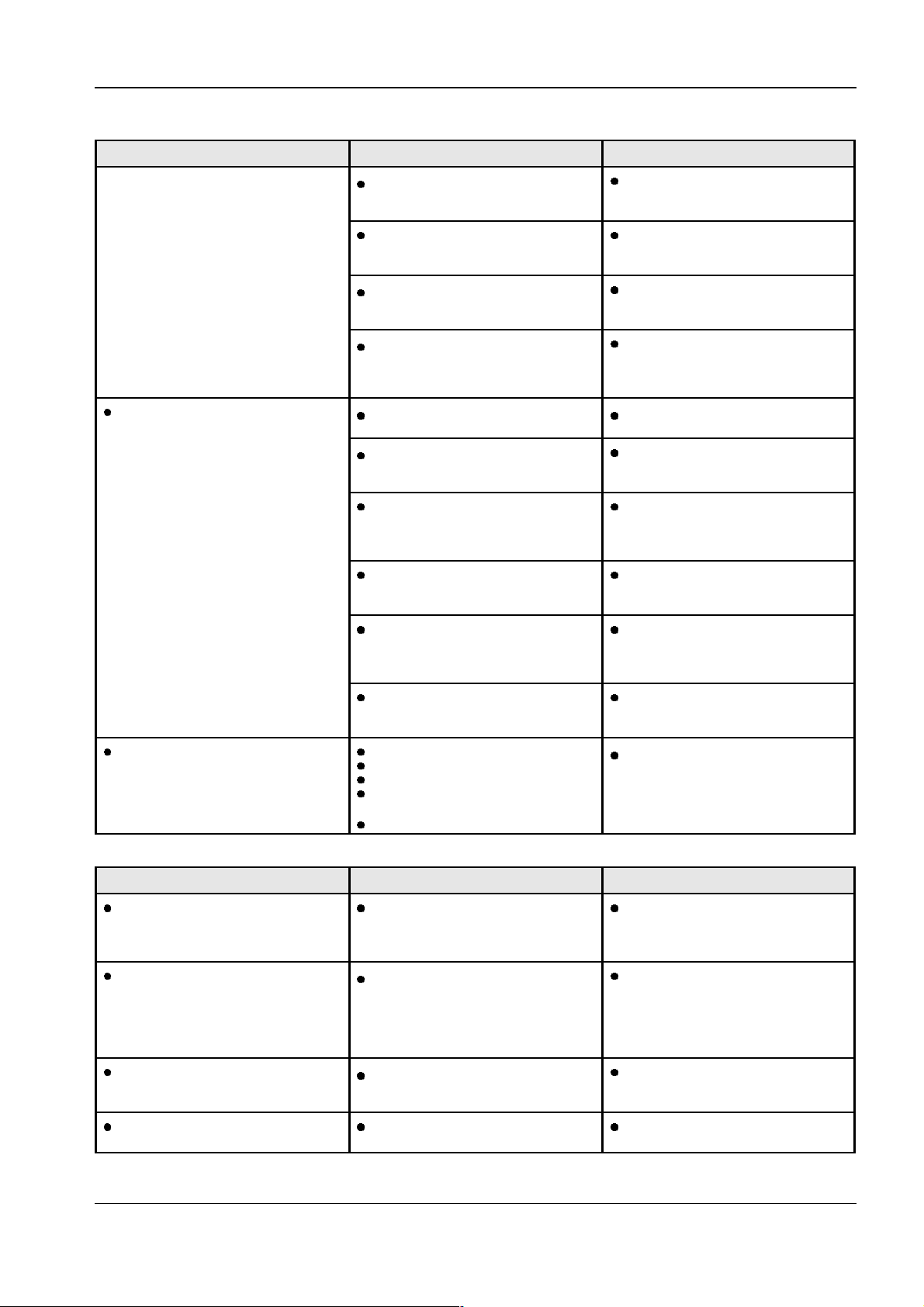

Model Code

Body Type Body Style Model Code

Sedan XT 18333

Wagon XT 18363

Sedan Futura 18334

Wagon Futura 18364

Sedan XR 18335

Sedan FMT 18332

Wagon FMT 18332

Sedan FMT Ghia 18338

Sedan Fairlane Ghia 18349

Sedan LTD 18346

Ute XL Tray 45313

Ute XL SSB 45373

Ute XR Tray 45375