Follett VU155 Service Manual

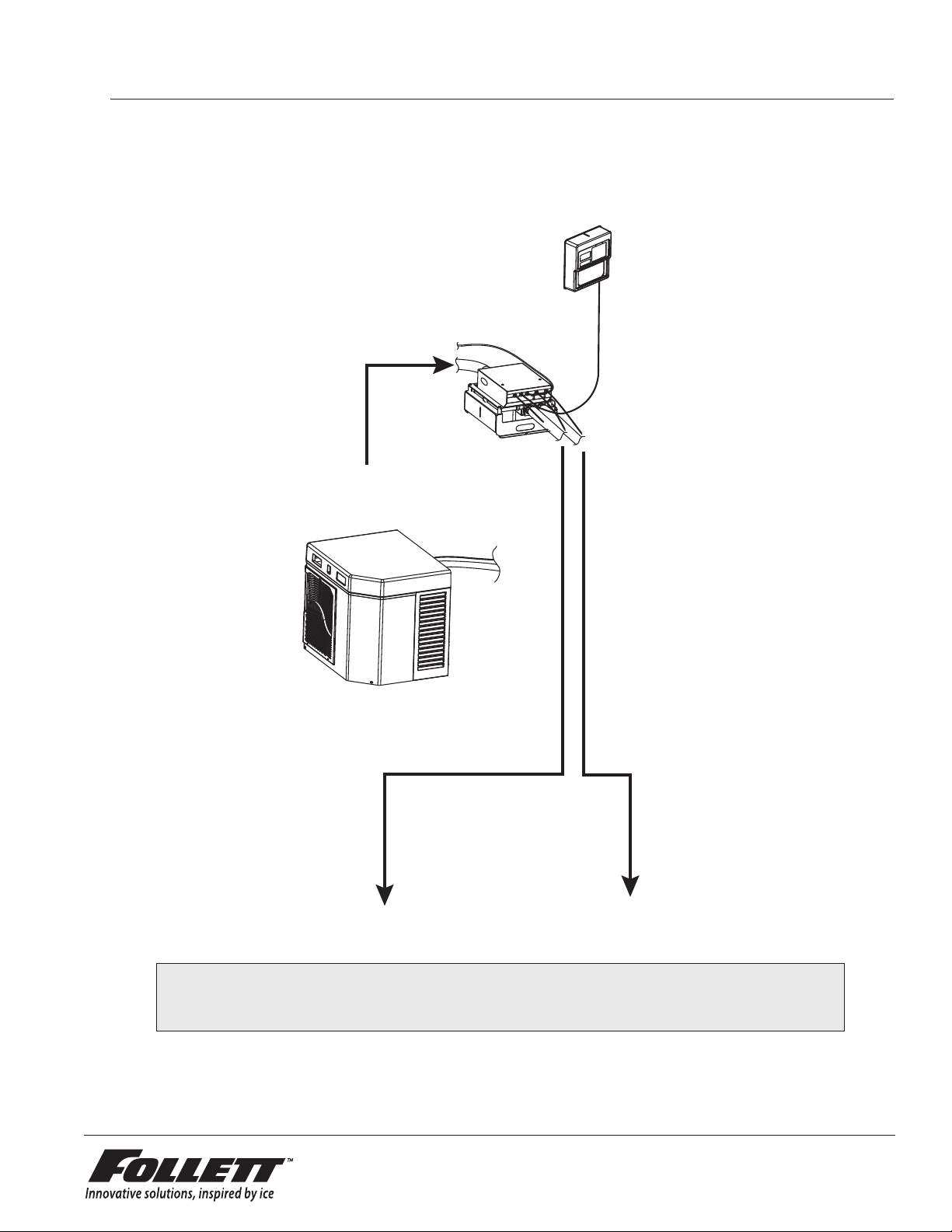

Ice Manager™ Diverter Valve System

Order parts online

www.follettice.com

(1) Horizon

Chewblet® Icemaker

(purchased separately)

™

Operation and Service Manual

After Serial Number C43650

Ice Manager

Control Panel

Ice Manager

Diverter Valve

(2) ice storage units

(purchased separately)

Any combination of bins or dispensers

Lane 2

Lane 1

Following installation, please forward this manual

to the appropriate operations person.

801 Church lane • Easton, PA 18040, USA

Toll free (800) 523-9361 • (610) 252-7301

Fax (610) 250-0696 • www.follettice.com

00195776R01

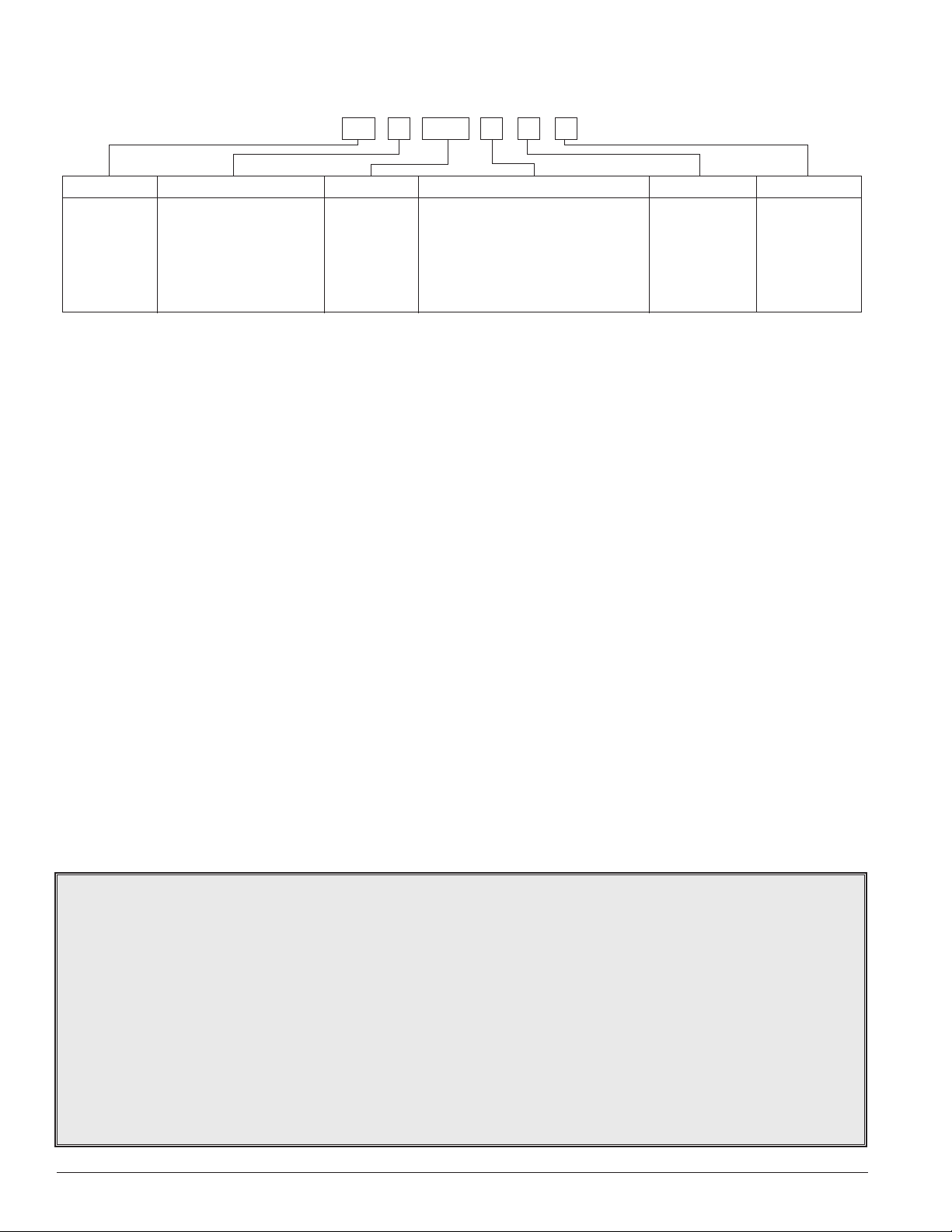

Horizon 1000 & 1400 Series Icemaker Model Number Configurations

for use with Ice Manager Diverter Valve System

A M SC 1000HC

Icemaker Voltage Series Condenser

HC Horizon

Chewblet

† Ice Manager Diverter Valve Systems can be used to fill any two of these bins or dispensers with a single ice machine.

C 208-230/60/1

(self-contained only)

D Low side 115/60/1

Condensing unit

208-230/60/1

(remote condensing only)

E 230/50/1

(self-contained only)

1000 up to

1036 lbs

(471kg)

1400 up to

1450 lbs

(658kg)

A Air-cooled, self-contained

W Water-cooled, self-contained

R Air-cooled, remote condensing unit

N Air-cooled, no condensing unit for

connection to parallel rack system

Application Configuration

M Ice Manager

†

S Satellite-fill™

diverter valve

system

Follett Corporation

Equipment Return Policy

Follett equipment may be returned for credit under the following conditions:

1. The equipment is new and unused.

2. A return authorization number has been issued by customer service within 30 days after shipment.

3. Follett receives the equipment at the factory in Easton, PA within 30 days after issuance of the return authorization number.

4. The equipment must be returned in Follett packaging. If the packaging has been damaged or discarded, Follett will forward, at the customer’s expense,

new packaging.

Note: Return freight charges are the responsibility of the customer. If equipment is returned and is damaged because of improper packaging, Follett

Corporation will not be held responsible.

Credit will be issued when:

The equipment has been inspected by Follett and deemed suitable to be returned to stock.

Note: A 15% restocking charge will be deducted from the credit. If the cost to return the product to stock exceeds 15%, the actual cost will be deducted.

2 Ice Manager Diverter Valve System Operation and Service Manual

Table of contents

Welcome to Follett

Before you begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Speci cations

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Plumbing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Temperature requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Operation

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Audible alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Cleaning and preventive maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Preventive maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Weekly exterior care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Cleaning and sanitizing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Service

System components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

System operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Control logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Auto mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Manual mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Diverter valve module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Control board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Divert gearmotor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Divert paddle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Ice Manager diverter valve wiring diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Membrane switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

LCD screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Audible alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Ultrasonic sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Ice level set points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

To view ice levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

To view set points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

To change set points for 23" or 30" drop-ins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Troubleshooting

Ice shortage with audible alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Ice shortage without audible alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Service Parts

Diverter valve module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Sensor distribution unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Drop-in Ice Manager application kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Follett Vision™ VU155 Ice Manager kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Follett Vision™ VU300 Ice Manager kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Ice Manager Diverter Valve System Operation and Service Manual 3

Welcome to Follett

Follett equipment enjoys a well-deserved reputation for excellent performance, long-term reliability and

outstanding after-the-sale support. To ensure that this equipment delivers the same degree of service, we ask

that you review the installation manual (provided as a separate document) before beginning to install the unit.

Our instructions are designed to help you achieve a trouble-free installation. Should you have any questions or

require technical help at any time, please call our technical service group at (800) 523-9361 or (610) 252-7301.

Before you begin

After uncrating and removing all packing material, inspect the equipment for concealed shipping damage. If

damage is found, notify the shipper immediately and contact Follett Corporation so that we can help in the ling

of a claim, if necessary.

CAUTION

• Warranty does not cover exterior or outside installations.

• Moving parts. Do not operate with front cover removed.

• Hot parts. Do not operate with cover removed.

• To reduce risk of shock, disconnect power before servicing.

• Most icemaker cleaners contain citric or phosphoric acid, which can cause skin irritation. Read caution label

on product and follow instructions carefully.

• Ice is slippery. Maintain counters and oors around dispenser in a clean and ice-free condition.

• Ice is food. Follow recommended cleaning instructions to maintain cleanliness of delivered ice.

4 Ice Manager Diverter Valve System Operation and Service Manual

Speci cations

Electrical

115V, 60Hz, 1ph, 1.5 amps.

8' (2.4m) cord with NEMA 5-15 plug provided. If local code requires hard-wiring, separate disconnects also required.

Plumbing

Drain line – 15' (4.6m) 3/8" nylon tubing, supplied

Temperature requirements

Ice Manager components, including ice transport tube, must be operated in ambient temperatures between 40 F and

120 F (5 C and 49 C). Relative humidity not to exceed 55%.

Dimensions

Diverter Valve with Mounting Bracket Control Panel

Front View Side View Front View Side View

17.5"

(445mm)

13.625"

(346mm)

LANE 2

LANE 1

12"

(305mm)

3.75"

(96mm)

10.375"

(264mm)

16"

(407mm)

12.5"

(318mm)

3/8" NPT

barbed drain fitting

Ice Manager Diverter Valve System Operation and Service Manual 5

Operation

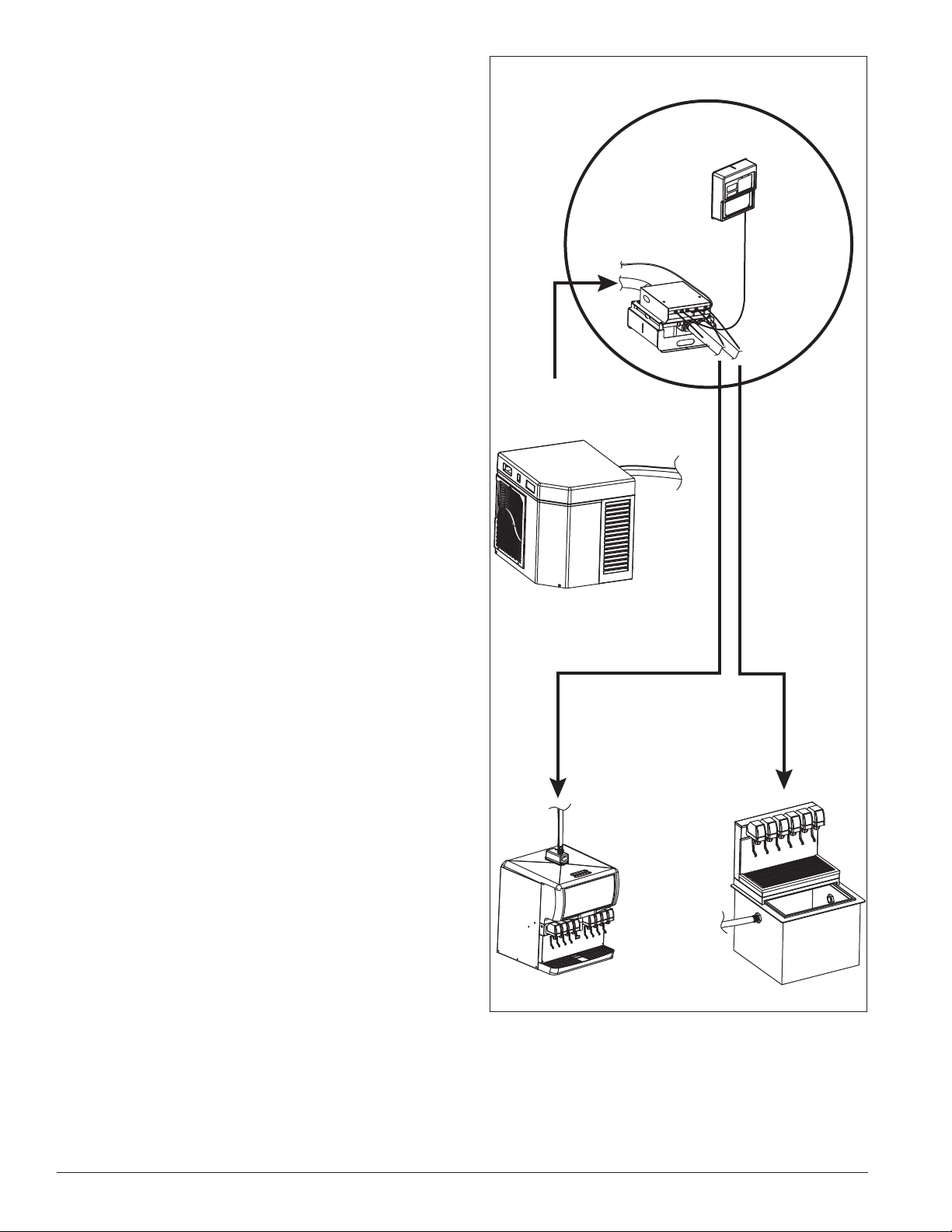

Ice Manager

Diverter Valve

(1) Horizon

™

Chewblet® Icemaker

(purchased separately)

(2) ice storage units

(purchased separately)

Any combination of bins or dispensers

Ice Manager

Control Panel

ICE MANAGER SYSTEM

Lane 2

Lane 1

General information

The Ice Manger diverter valve system is designed

to direct ice from one Horizon icemaker to two ice

storage units. AUTO is the standard operating mode.

When selected, ice is directed to the lane 1 storage

unit until it reaches the MIN (minimum) set-point.

Ice is then directed to the lane 2 storage unit and

will continue to ll this lane until the FULL level is

achieved. If at any time the ice level in lane 1 storage

unit goes below the MIN set-point, ice will be directed

back to lane 1 until the MIN level is satis ed. When

lane 2 reaches its FULL level, ice will be directed back

to lane 1. When both lanes reach their FULL level, the

Horizon icemaker will shut off. After a 15-minute delay,

the icemaker will be ready to start as soon as the ice

level in either of the storage units drops below the

FULL set-point.

Audible alarm

In the event a system error occurs that could cause

ice shortages, the audible alarm will be turned ON

accompanied by an appropriate error message on the

LED screen. To silence the alarm, press any of the

push buttons on the control panel. This will silence

the alarm for 4 hours, however the error message

displayed on the LED screen will remain until the

problem is addressed. After 4 hrs, if the error has not

been addressed, the audible alarm will resume.

Placing the system in MANUAL MODE will also

prevent the alarm from sounding. The error message

on the LED screen will still ash, but the alarm will not

resume.

See troubleshooting guide on page 26 for causes.

6 Ice Manager Diverter Valve System Operation and Service Manual

Cleaning and preventive maintenance

LO WATER

C

L

E

A

N

Preventive maintenance

Periodic cleaning of Follett’s Ice Manager diverter valve system is required to ensure peak performance and delivery

of clean, sanitary ice. Cleaning of the Ice Manager system, in most cases, should be performed by your facility’s

maintenance staff or a Follett authorized service agent. Regardless of who performs the cleaning, it is the operator’s

responsibility to see that this cleaning is performed every 6 months or more often if conditions dictate. Service

problems resulting from lack of preventive maintenance will not be covered under the Follett warranty.

Weekly exterior care

The exterior of the diverter valve and control panel may be cleaned with a soft cloth and mild detergent. The

icemaker exterior may be cleaned with a stainless cleaner such as 3M Stainless Steel Cleaner & Polish or

equivalent.

Note: Do not use bleach to sanitize or clean the icemaker or diverter valve.

WARNING

• Wear rubber gloves and safety goggles (and/or face shield) when handling icemaker cleaner or sanitizer

CAUTION

• Use only Follett approved SafeCLEAN™ cleaner (item# 00132001) and NU-CALGON IMS-II SANITIZER.

• Do not mix cleaner and sanitizer solutions together

• DO NOT USE BLEACH

• It is a violation of Federal law to use these solutions in a manner inconsistent with their labeling

• Read and understand all labels printed on packaging before use

Note: Complete procedure for cleaning and sanitizing MUST be followed in order shown. Ice must be collected for

10 minutes from each lane before putting icemaker and Ice Manager system back into service.

Cleaning and sanitizing

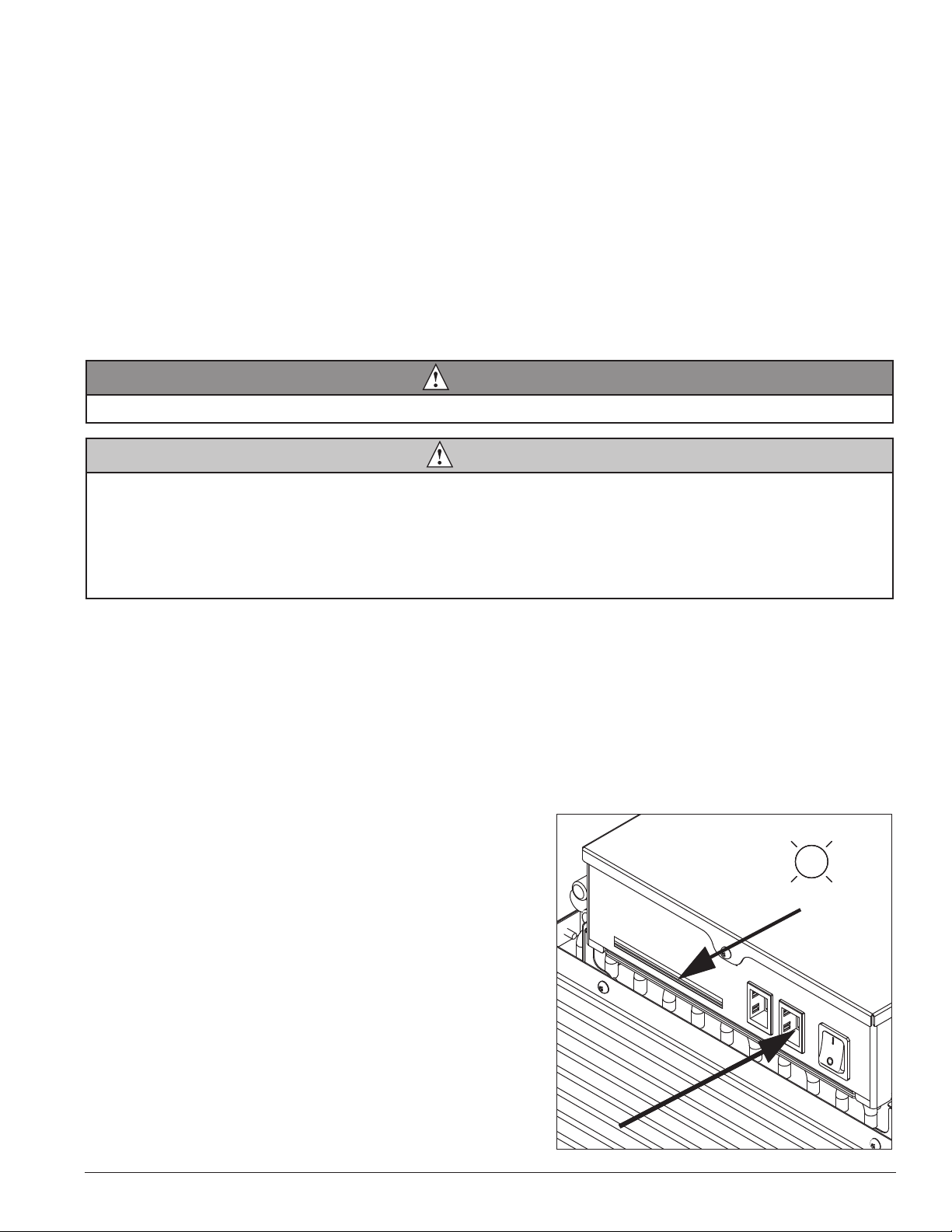

1. To clean icemaker – Remove icemaker cover. Press

the CLEAN button. The machine will drain. Wait for

the LO WATER light to come on (Fig. 1).

Fig. 1

Ice Manager Diverter Valve System Operation and Service Manual 7

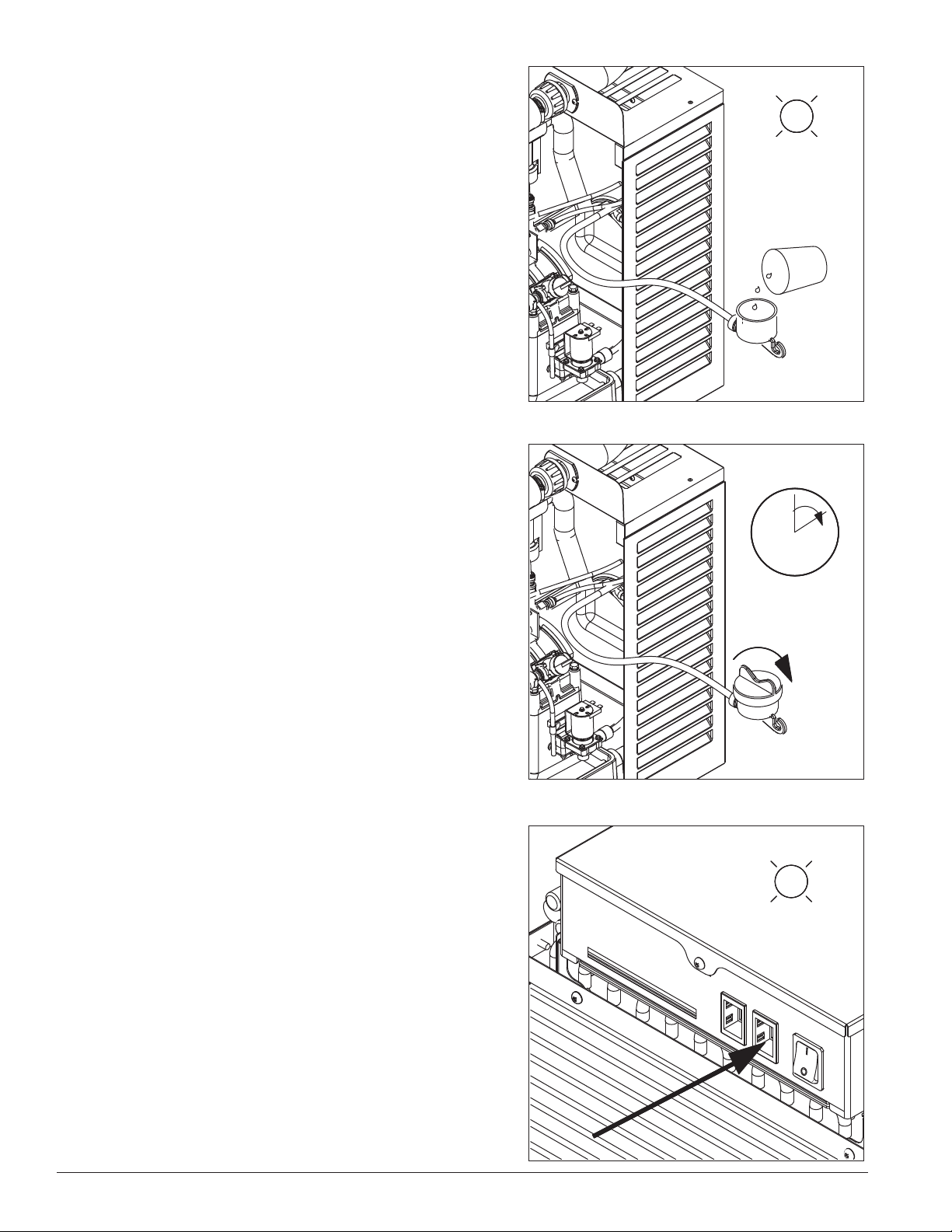

2. Mix 1 gallon (3.8L) 120 F (49 C) water and

HI WATER

12

LO WATER

N

A

E

L

C

one 7 ounce (198g) packet of Follett SafeCLEAN

icemaker cleaner (item# 00132001). Locate cleaning

cup. Fill until HI WATER light comes on (Fig. 2).

Note: Do not use bleach to sanitize or clean the

icemaker.

3. Replace cover on cleaning cup. Wait until icemaker

restarts. Machine will clean, then ush 3 times in

approximately 12 minutes (Fig. 3).

Fig. 2

Fig. 3

Fig. 4

4. To sanitize icemaker – Press CLEAN button. The

icemaker will drain. Wait for LO WATER light to

come on (Fig. 4).

8 Ice Manager Diverter Valve System Operation and Service Manual

HI WATER

12

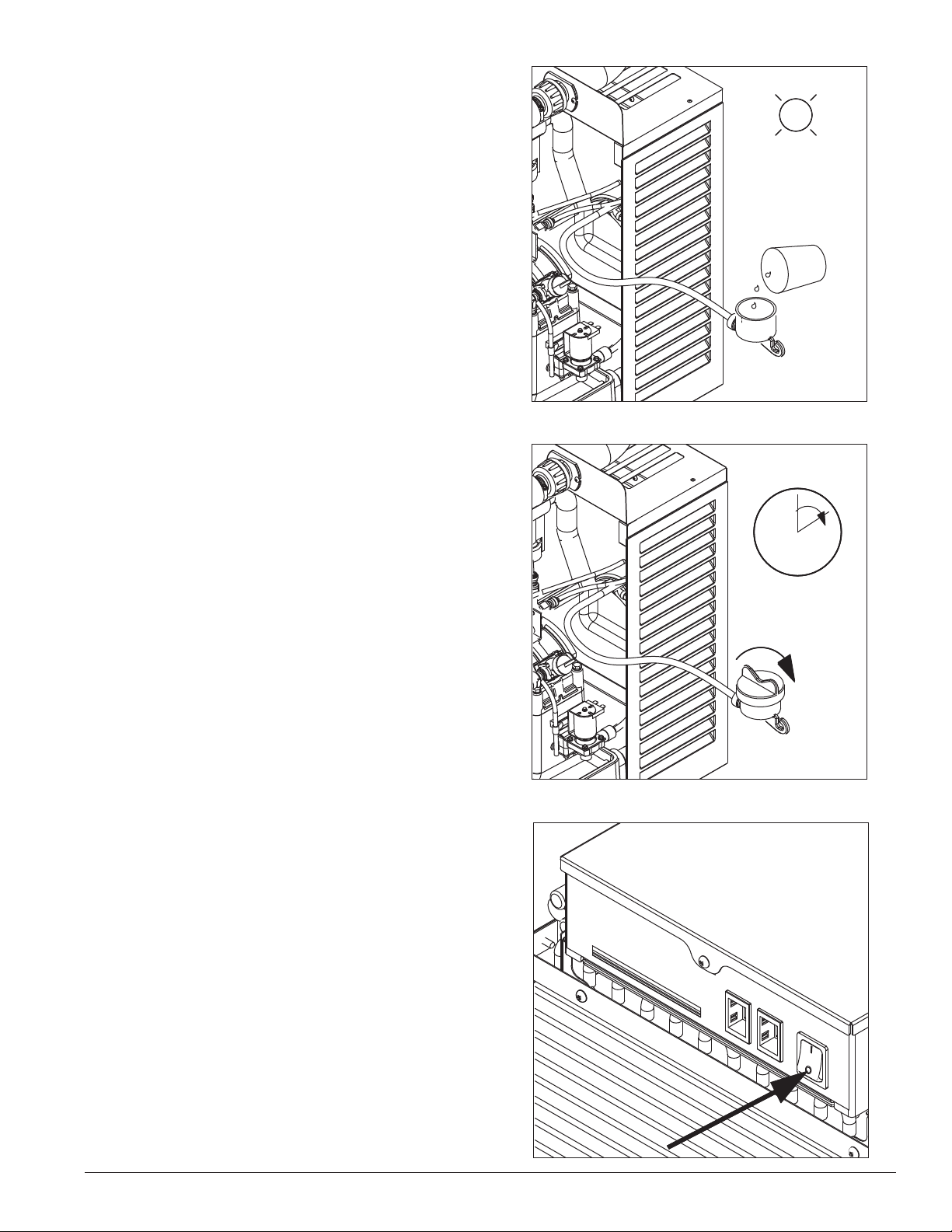

5. Mix 1 gallon 120 F (49 C) water and 1.6 ounces

(48ml) NU-CALGON IMS-II SANITIZER. Fill until

HI WATER light comes on (Fig. 5).

Note: Do not use bleach to sanitize or clean the

icemaker.

6. Replace cover on cleaning cup. Wait until icemaker

restarts. Machine will sanitize, then ush 3 times in

approximately 12 minutes (Fig. 6).

Fig. 5

Fig. 6

Fig. 7

7. To sanitize diverter valve – Press icemaker

power switch OFF (Fig. 7).

Ice Manager Diverter Valve System Operation and Service Manual 9

Mode

select

Auto

Icemaker

Manual

ON

ON

ON

Lane 1

Lane 2

Fig. 8

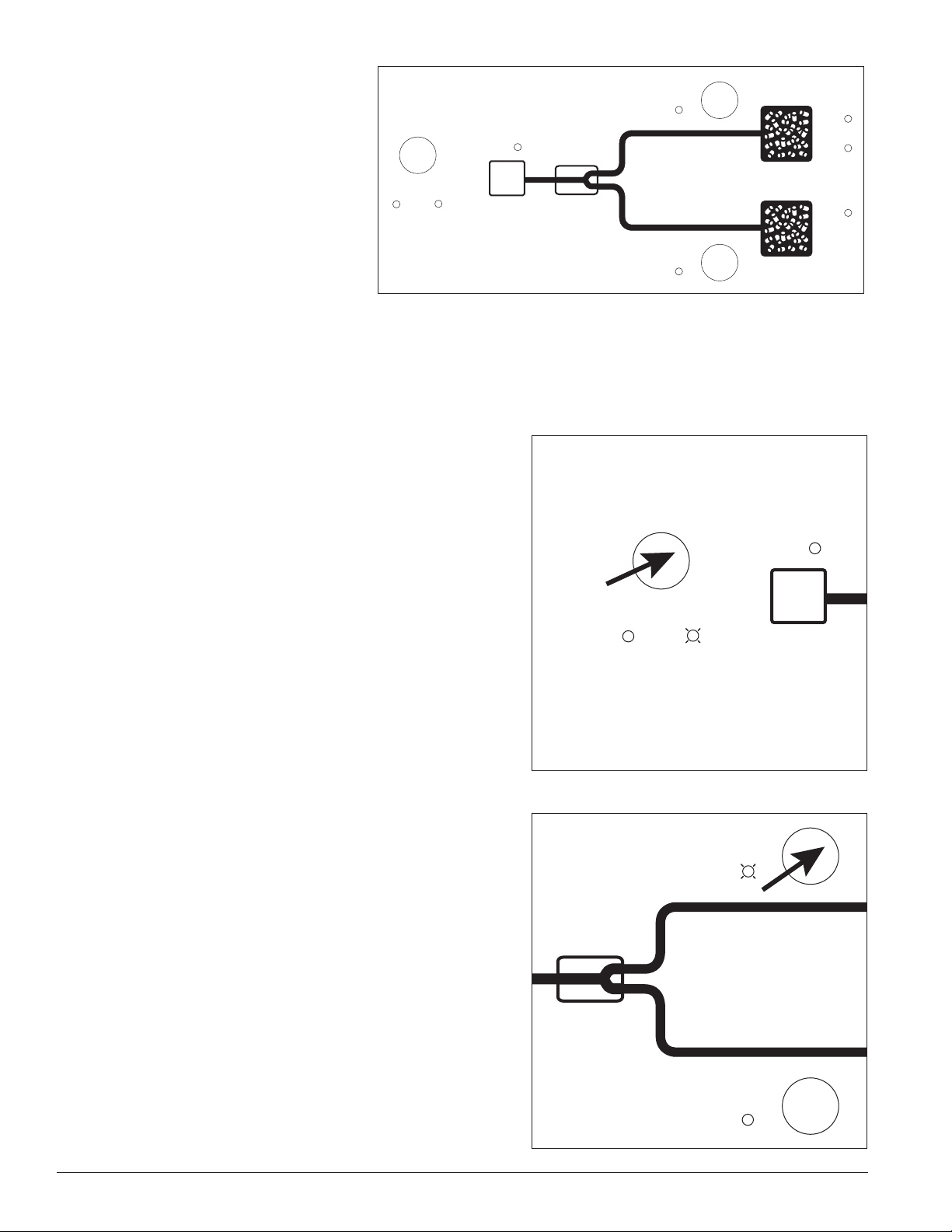

8. Locate Ice Manager control panel.

(Fig. 8)

Mode

select

Auto

Manual

9. To sanitize lanes 1 and 2, diverter valve must be in

manual mode. Press the MODE SELECT button on

the Ice Manager control panel (Fig. 9). Manual light

will come on. If auto light comes on, press MODE

SELECT button again.

Icemaker

ON

Fig. 9

Lane 1

ON

Lane 2

ON

Full

Min

Full

Fig. 10

10. To sanitize lane 1 – Press LANE 1 button

(Fig. 10). Lane 1 light will come on.

10 Ice Manager Diverter Valve System Operation and Service Manual

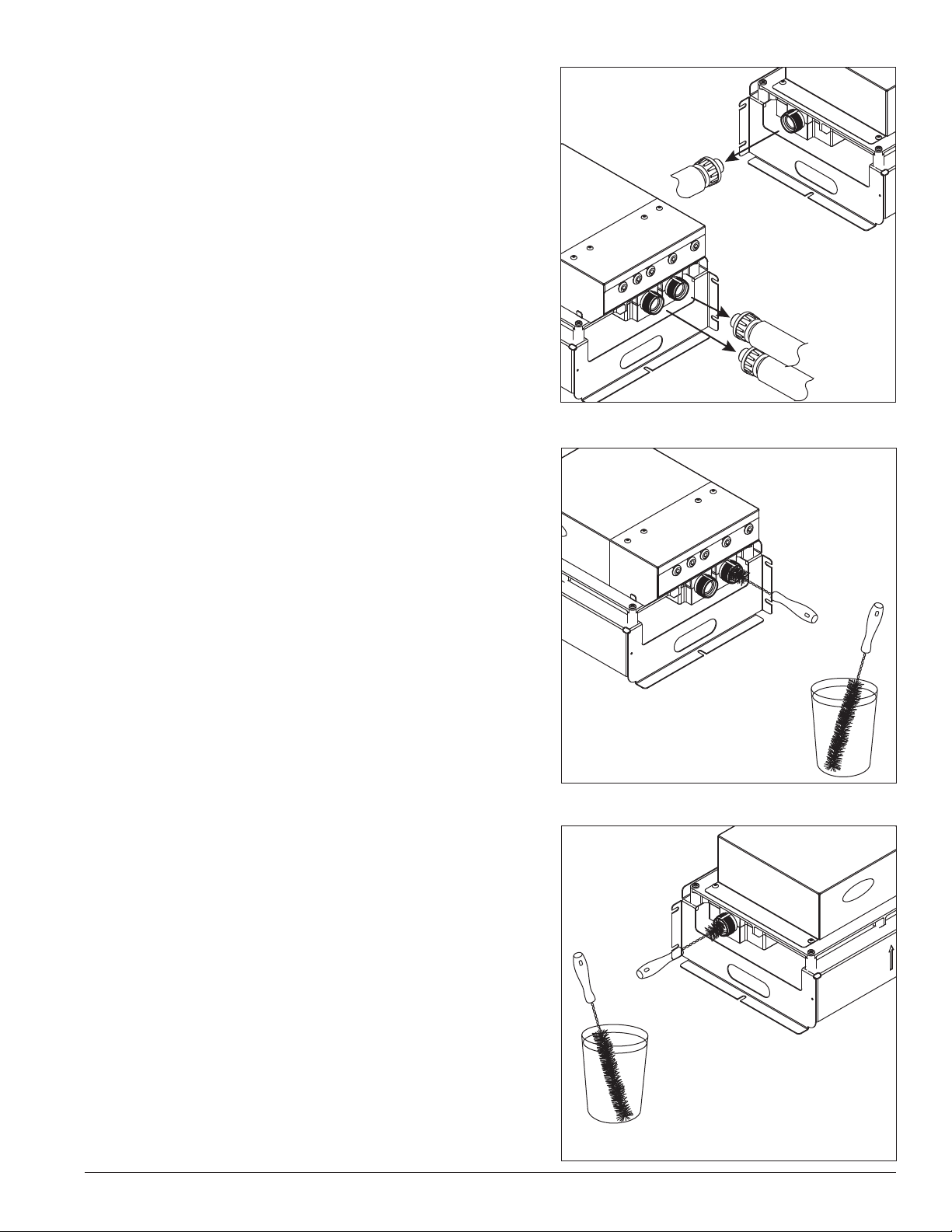

11. Disconnect ice transport tubes from diverter valve

1

3

2

unit. Be sure to note lane 1 (Fig. 11.1), lane 2

(Fig. 11.2) and inlet (Fig. 11.3) ice transport tube

connections to avoid confusion when reattaching.

12. Mix 1 gallon 120F (49C) water and 1.6 oz (48ml)

NU-CALGON IMS-II SANITIZER.

Fig. 11

Fig. 12

Note: Do not use bleach to sanitize or clean the

diverter valve.

Soak supplied brush in sanitizer solution and scrub

inside of the diverter valve lane 1 for at least 60

seconds, re-wetting the brush with sanitizer as

needed (Fig. 12).

13. Re-wet brush with sanitizer and scrub diverter

valve inlet for at least 60 seconds, re-wetting the

brush with sanitizer as needed (Fig. 13).

Fig. 13

Ice Manager Diverter Valve System Operation and Service Manual 11

Loading...

Loading...