Follett U300 Service Manual

Operation, Service and Parts Manual

Service Number A23719 to B22204

U300/UD300 Series Ice Dispensers

208782R02

801 Church Lane • PO Box D, Easton, PA 18044, USA

Toll free (800) 523-9361 • (888)2-FOLLETT

(610) 252-7301 • Fax (610) 250-0696 • www.follettice.com

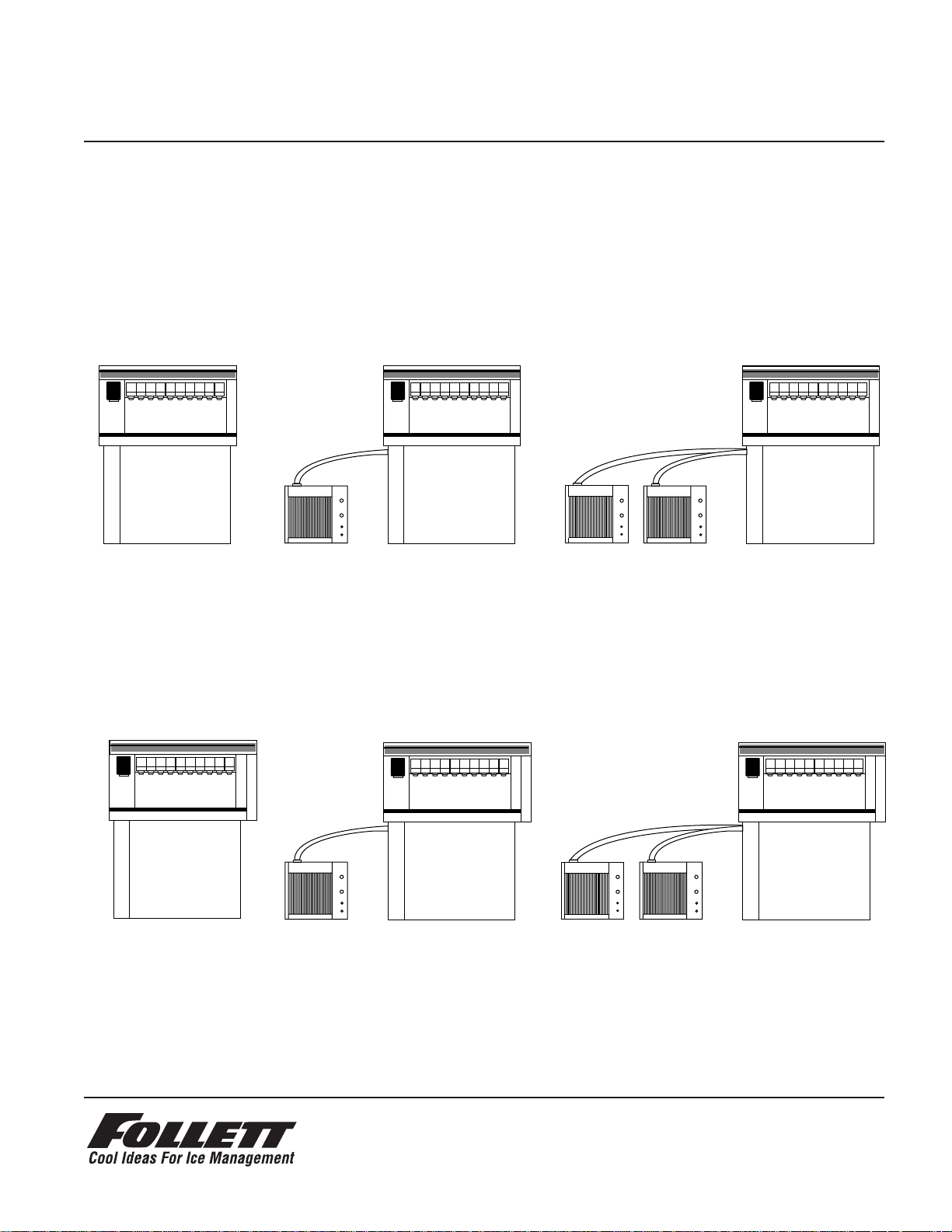

Model UD300

Model U300

Model U300B

Model U300R400A/W

Model U300BR400A/W

Model U300R800A/W

Model U300BR800A/W

Model UD300R400A/W Model UD300R800A/W

Order parts online

www.follettice.com

Single-sided dispensers

Dual-sided dispensers

Welcome to Follett

Follett ice dispensers enjoy a well-deserved reputation for excellent performance, long-term reliability and

outstanding after-the-sale support. To ensure that this dispenser delivers that same degree of service, we ask

that you take a moment to review this manual before using the dispenser. Should you have any questions or

require technical help at any point, please call our technical service group at (800) 523-9361 or

(888) 2-FOLLETT or (610) 252-7301.

Before you begin

Check your paperwork to determine which model you have. Following is an explanation of the different model

numbers in the U300 series.

U300BR400A

Condenser type – A = air-cooled, W = water-cooled

Remote icemaker(s) capacity and refrigerant – 400 = 400 lbs (181kg)/day, R404A

800 = 800 lbs (363kg)/day, R404A

absence of = manual fill unit

B = integral beverage cooling. Absence of a B = no integral beverage cooling.

Approximate storage capacity in lbs

Configuration – U = undercounter single-sided, UD = undercounter dual-sided

Important cautions

• Storage area of dispenser contains mechanical, moving parts. Keep hands and arms clear of this

area at all times. If access to this area is required, power to unit must be disconnected first.

• Follett manual load units accommodate most cube/cubelet ices up to 1" square and Follett

compressed nugget ice. Crushed, flake, bagged or congealed ice cannot be used. Use of these ices

can jam dispenser and void warranty. Separate any “waffle-like” sections of cubes before adding to

dispenser. If you have questions concerning your ice type, call Follett’s customer service group at

(800) 523-9361 or (888) 2-FOLLETT or ( 610) 252-7301.

• Follett recommends use of an activated carbon filter for units equipped with icemakers.

• Ice is slippery. Maintain counters and floors around dispenser in a clean and ice-free condition.

• Ice is food. Follow cleaning instructions to maintain cleanliness of delivered ice.

!

2

3

Electrical Specifications – 115V, 60Hz, 1 phase

Single-sided models

U300 – dispenser 6.0 amps

U300B – dispenser 7.0 amps

U300R400A/W – dispenser 6.0 amps, icemaker 11.0 amps

U300BR400A/W – dispenser 7.0 amps, icemaker 11.0 amps

U300R800A/W – dispenser 6.0 amps, icemakers 11.0 amps each

U300BR800A/W – dispenser 7.0 amps, icemakers 11.0 amps each

Dual-sided models

UD300 – dispenser 8.0 amps

UD300R400A/W – dispenser 8.0 amps, icemaker 11.0 amps

UD300R800A/W – dispenser 8.0 amps, icemakers 11.0 amps each

Note: Each icemaker and dispenser require separate circuit with electrical disconnect within

10 feet (6m). Equipment ground required. Standard electrical – 115V, 60 Hz, 1 phase. Max. fuse

dispenser – 15 amps; each icemaker – 20 amps.

Plumbing

Dispenser – all models

3/4" PVC slip fit bin drain

1" PVC slip fit drain pan drain(s)

1" PVC slip fit beverage bath drain (units with beverage cooling only)

Note: Drains must be hard piped and insulated. Maintain 1/4" per foot (6mm per 304mm) min. slope

Icemaker – automatic load models only

1/4" FPT water in

1/2" MPT drain

3/8" FPT condenser inlet (water-cooled condenser only)

1/2" FPT condenser drain (water-cooled condenser only)

Note: Water disconnect within 10 feet (3m) of icemaker(s) is required for automatic load units

U300 series dispensers with remote icemaker(s) require separate circuit and

disconnect for each icemaker and dispenser.

!

On all models with remote icemaker(s), black wire on icemaker control board

LINE VAC terminal must be moved to 24V terminal.

!

Do not reduce size of drain lines or tie drains together.

!

4

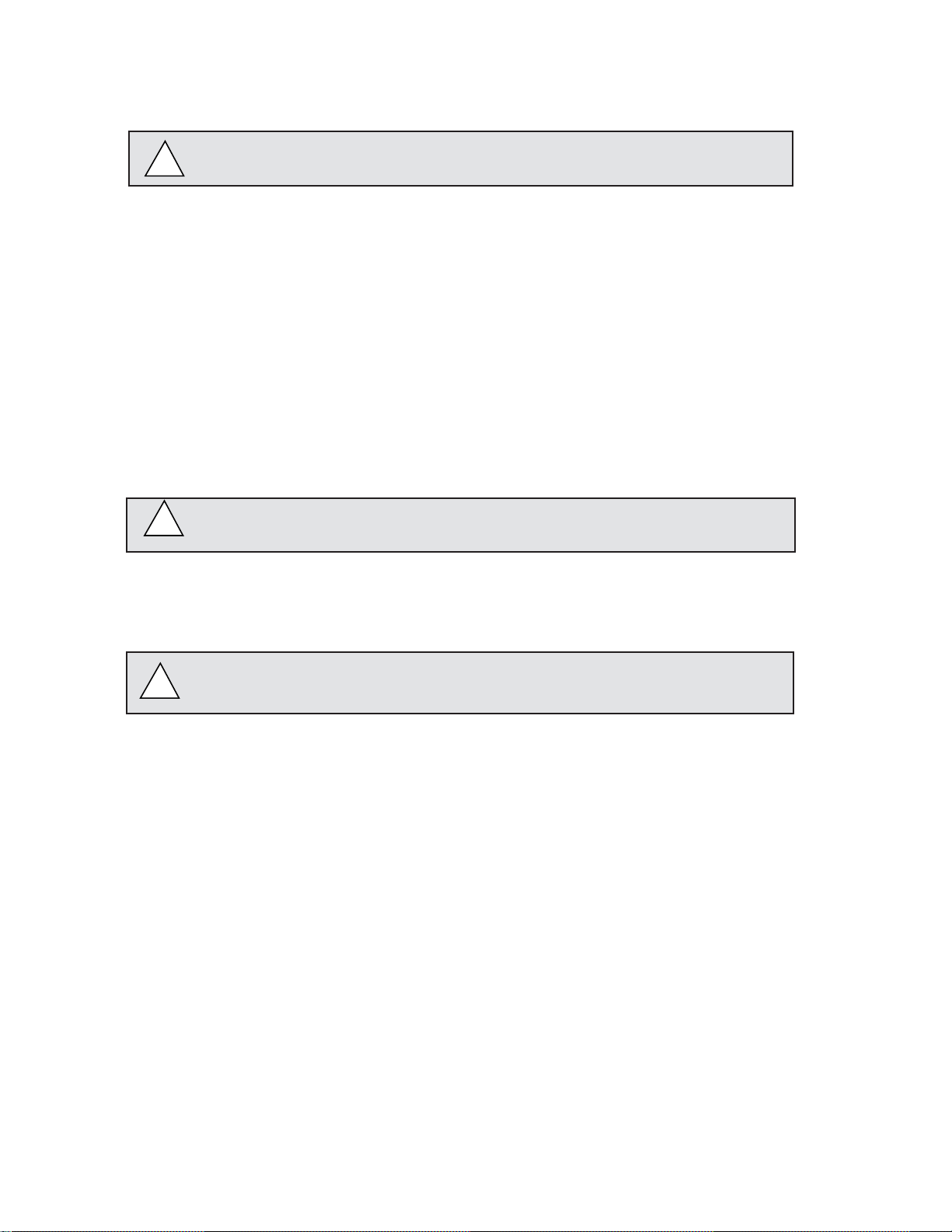

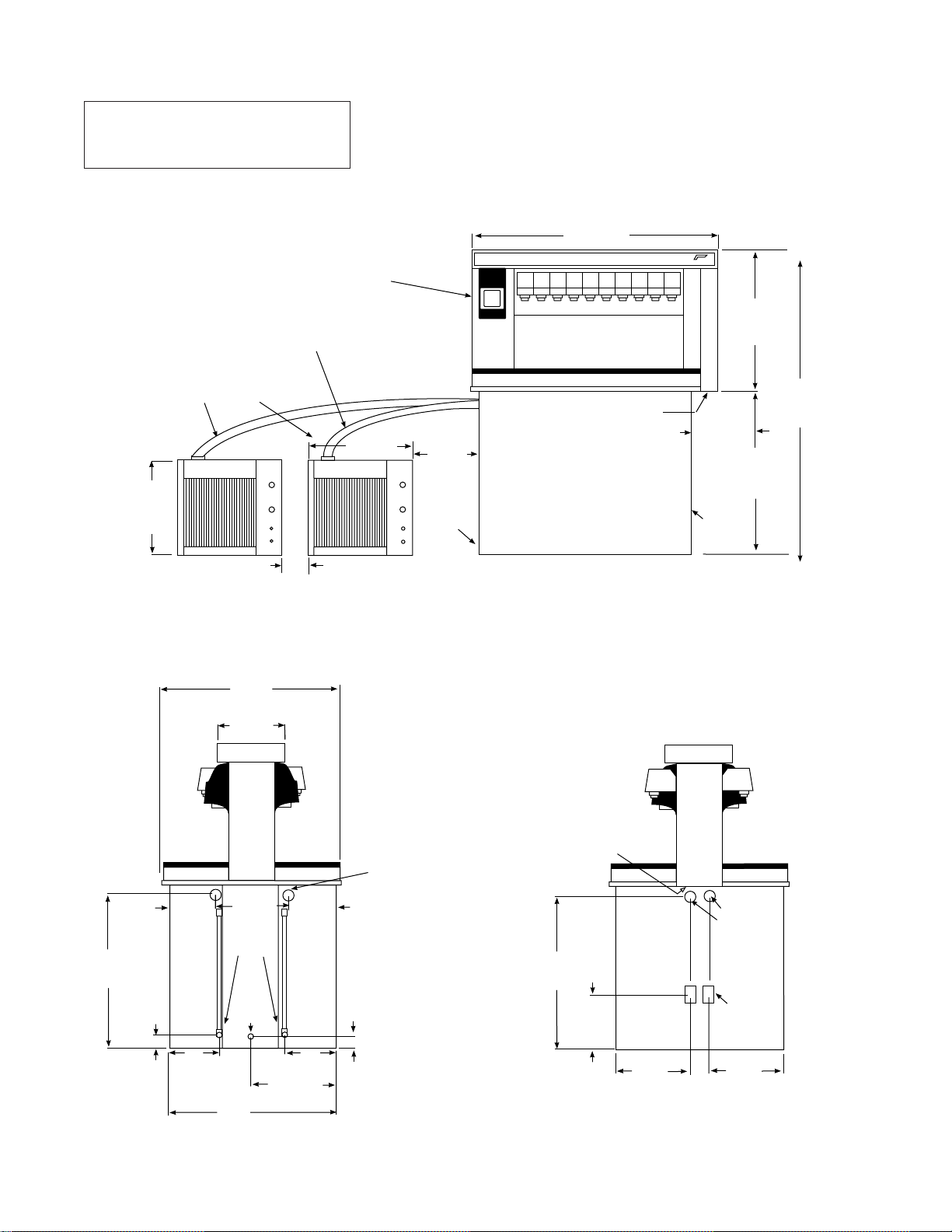

U300 series single-sided dispensers

Front view

Side view – ice dispense chute

Required clearances:

• 60" (1524mm) for installation

• 49" (1245mm) for auger removal

dispenser only

with no icemaker

model U300/U300B

one icemaker –

models U300R400A/W

U300BR400A/W

two icemakers –

models U300R800A/W

U300BR800A/W

18.875"

(480mm)

17"

(432mm)

6" min

(153mm)

entrance

beverage

lines

12" min

(305mm)

electric

conn.

disp.

drains

ICE

40.875

(1039mm)

25.25"

(642mm)

54.875"

(1394mm)

29.625"

(753mm)

ice waterbath

(U300BR400A/W,

U300BR800A/W,

U300B

only)

beverage

lines enter

through

bottom

junction

boxes

7" (178mm)

3" (77mm)

10"

(254mm)

2.5"

(64mm)

22"

(559mm)

9"

(229mm)

30"

(762mm)

32.375"

(823mm)

1"

drains

3/4"

drain

15"

(381mm)

ice

transport

tube entry

8.5"

(216mm)

27.5"

(699mm)

2"

(51mm)

9"

(229mm)

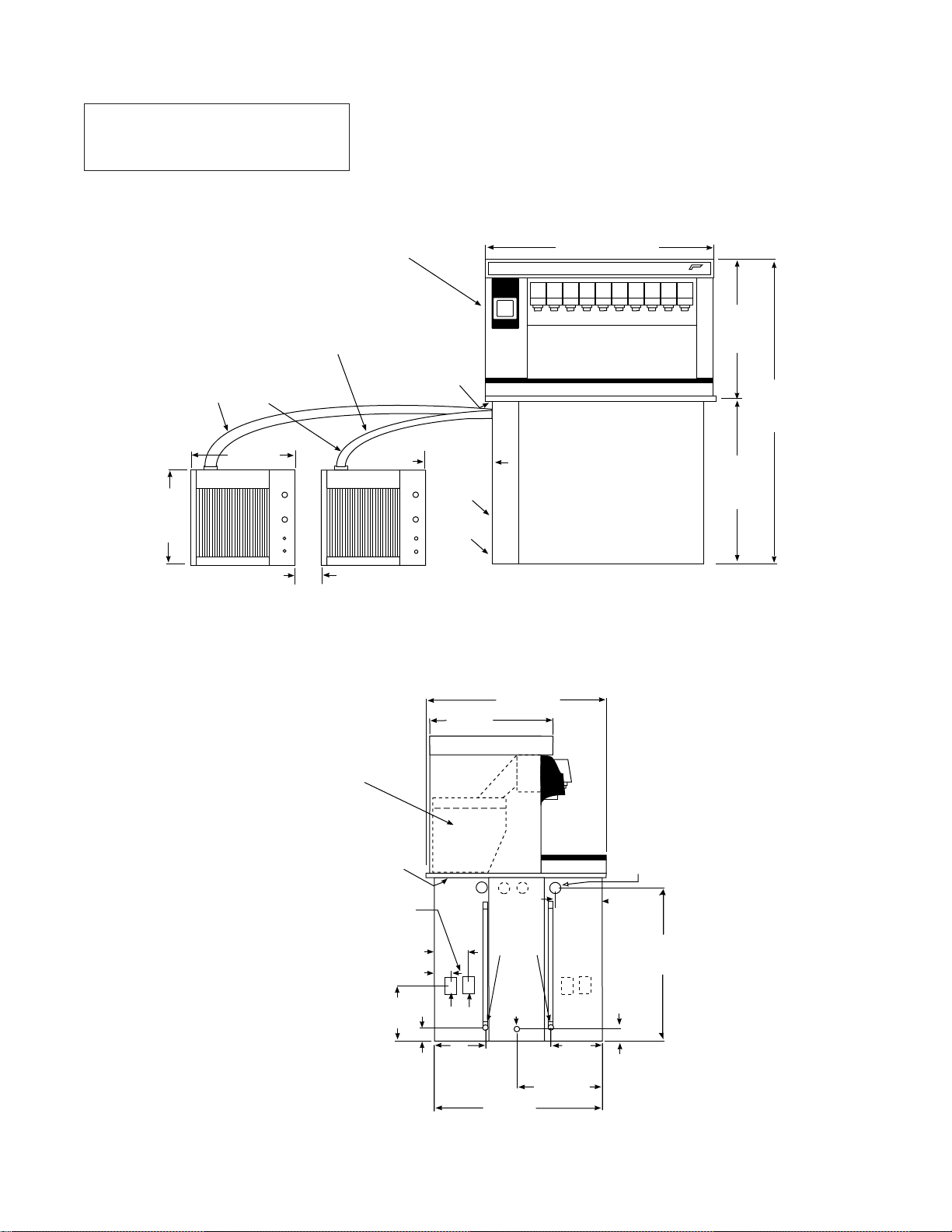

UD300 series dual-sided dispensers

Side view - ice dispense chute

Front view

Side view opposite ice dispense chute

Required clearances:

• 60" (1524mm) for installation

• 49" (1245mm) for auger removal

5

dispenser only with no

icemaker

model UD300

dispenser with one icemaker

models UD300R400A/W

dispenser with two icemakers

Models UD300R800A/Wm

18.875"

(480mm)

17"

(432mm)

12" min.

(305mm)

disp.

drains

ICE

43.875

(1115mm)

beverage

lines exit

through

bottom of

chase

25.25"

(642mm)

54.875"

(1394mm)

12" min.

(305mm)

29.625"

(753mm)

electric

conn.

32.375"

(823mm)

12.125"

(308mm)

8.5"

(216mm)

27.5"

(699mm)

2.5"

(64mm)

1"

drains

3/4"

drain

6" min.

(153mm)

ice

tube

entry

8.5"

(216mm)

2"

(51mm)

beverage

lines exit

through

bottom of

chase

alt. ice

transport

tube entry

27.5"

(699mm)

10"

(254mm)

electric

conn.

9"

(229mm)

30"

(762mm)

9"

(229mm)

15"

(381mm)

13.25"

(337mm)

13.25"

(337mm)

To start up and operate dispenser

1. Follow all cleaning and start-up instructions in U300 Installation Manual packed with dispenser before operating

dispenser.

2. Turn power switches located under dispenser top to ON position.

3. For manual load models, remove drain pan and fill storage area with compatible ice. (See caution on page 2 of

this manual concerning ices which may be used in this dispenser.)

4. For automatic fill models, turn icemaker (bin signal) switch(es) located inside dispenser top to ON position and begin

to make ice.

5. When dispenser has at least 6" (153mm) of ice in storage area, press lever or button to ensure that dispenser is

operating properly.

How dispenser works

Follett’s single-sided U300 series and dual-sided UD300 series ice dispensers are available in manual load

configurations (using ice from another source) or automatic load configurations (fed from one or two Follett 400 lb/day

remote icemakers). An ice water bath beverage cooling system located directly behind valves is available for single-sided

U300 series dispensers. Dual-sided units must use a separate mechanical cooling system to cool beverage lines.

In all models, ice is stored below counter in dispenser storage area. When dispense lever or button is pushed, dispense

motor is activated. This causes wheel assembly in storage area to rotate counterclockwise, moving ice to vertical auger

assembly. Vertical auger carries ice up to dispense chute where it drops by gravity into container.

In automatic load models, ice is manufactured in either one or two Follett remote icemakers. These icemakers may be

located up to 20 ft (3m) away from dispenser. As water freezes to inside walls of icemaker evaporator, a rotating stainless

steel auger removes ice and carries it to top of evaporator assembly where it is compressed and extruded through an

outlet port. The extruded ice is then pushed through tube to storage compartment of dispenser. A bin thermostat shuts off

icemaker when storage compartment is full.

Periodic cleaning of dispenser

Solution A: Prepare cleaning solution (200 ppm available chlorine content) of Ecolab Mikro-chlor Cleaner or

equal chlorinated detergent. Solution temperature must be at 75˚ – 125˚F (23˚ – 52˚C).

Solution B: Prepare sanitizing solution (50 ppm available chlorine content) of Ecolab Mikro-chlor Cleaner or

equal chlorinated detergent. Solution temperature must be at 75˚ – 125˚F (23˚ – 52˚C).

Recommended daily cleaning of drain pan

1. Remove all debris from drain pan.

2. Pour 1 gallon (4L) hot water into drain pan to keep drain lines clear.

Recommended weekly cleaning

1. Remove drain pan(s) and grille(s) and wash with Solution A above. Rinse thoroughly.

2. On units with beverage valves, remove nozzles and diffusers from valves, soak for at least 10 minutes in cleaning

Solution A, rinse, sanitize with Solution B and reinstall.

3. Pour a solution of one cup (8 oz/237ml) household bleach mixed with one gallon (3.8L) hot water into drain pan(s) to

help prevent algae growth in drain lines.

Recommended quarterly cleaning (every 3 months)

1. Empty all ice from dispenser.

2. Remove dispenser top and turn bin signal switch(es) and dispenser power switch to OFF position.

3. Remove dispenser drain pan(s) and grille(s).

4. Remove thumbscrews from splash panel, lift up and out at bottom of panel and remove.

5. Remove chute cover(s), dispense chute(s), auger tube and auger (see disassembly instructions).

6. Remove yoke rods, drive shaft and dispense wheel (see disassembly instructions).

7. Clean all components and bin storage area with Solution A, rinse thoroughly with clear water and sanitize with

Solution B. Caution: To avoid damage to switch, do not immerse chute cover in solution. Wipe only with

cleaning cloth.

6

Do NOT run plastic parts (drain pan, dispense chute cover, dispense wheel) through

a dishwasher.

!

Loading...

Loading...