Page 1

REF 20/25 – LB

REF 20/25 – PH

REF 20/25 – BB

Order parts online

www.follettice.com

Installation, Operation and Service Manual

Following installation, please forward this manual

totheappropriate operations person.

801 Church Lane • Easton, PA 18040, USA

Toll free (877) 612-5086 • +1 (610) 252-7301

www.follettice.com

00926170R09

Page 2

Contents

Welcome to Follett. . . . . . . . . . . . . . . . . . . . . 3

Before you begin ........................... 3

Ambients ................................. 4

Clearances ............................... 4

Electrical specications ..................... 4

Refrigeration specications .................. 4

Detail drawing ............................. 4

Installation ...........................5

Adjust self-closing door (if necessary) .......... 5

Install shelves (if equipped) and power up ....... 5

Fill product bottle. . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Remote alarm connections (if desired) ......... 7

Dry contacts ........................... 7

RS-485 port ........................... 7

Operation ...........................8

Quick setup checklist ....................... 8

Interior LED lights .......................... 8

Set time & date ............................ 8

Change temperature display to show degrees

Fahrenheit (if desired) ....................... 9

High and low alarm setup ....................10

Alarms .................................. 12

Alarm muting ............................ 12

Alarm volume selection .................... 13

Alarm silence ............................ 13

Password PIN security (default is 3843) ....... 14

To turn password on/off .................... 14

To make a new password PIN ............... 15

Min/max temperature logging ................ 16

Probe calibration .......................... 17

Chart recorder set up (if so equipped) ......... 18

Chart recorder calibration ................... 18

Changing the chart paper ................... 18

Replacing the pen ......................... 18

Removing drawers ........................ 19

Removing slides .......................... 19

Cleaning ............................20

Interior cleaning .......................... 20

Exterior cleaning .......................... 20

Annual cleaning .......................... 21

Service .............................22

Refrigeration system ....................... 22

Defrosting .............................. 22

Controller operation ....................... 23

Temperature sensor readings ................ 23

Heated door (option) – changing cycle ........ 24

Controller hot key ......................... 27

Hot key upload ........................... 27

Hot key download ......................... 28

Troubleshooting .....................34

Before calling for service ................... 34

Appendix ...........................35

Control key functions ...................... 35

Menu Navigation table ..................... 35

Replacement parts ...................36

Unit cooler ............................... 36

Cabinet ................................. 37

Facade ................................. 38

Door assembly ........................... 39

2 00926170 – REF20/25 LB, PH, BB

Page 3

Welcome to Follett

Follett equipment enjoys a well-deserved reputation for excellent performance, long-term reliability and outstanding

after-the-sale support. To ensure that this product delivers that same degree of service, we ask that you take a

moment to review this manual before beginning the installation. Should you have any questions or require technical

help at any point, please call our technical service group at (877) 612-5086 or +1 (610) 252-7301.

Before you begin

After uncrating and removing all packing material, inspect the equipment for concealed shipping damage. If damage

is found, notify the shipper immediately and contact Follett Corporation so that we can help in the ling of a claim, if

necessary.

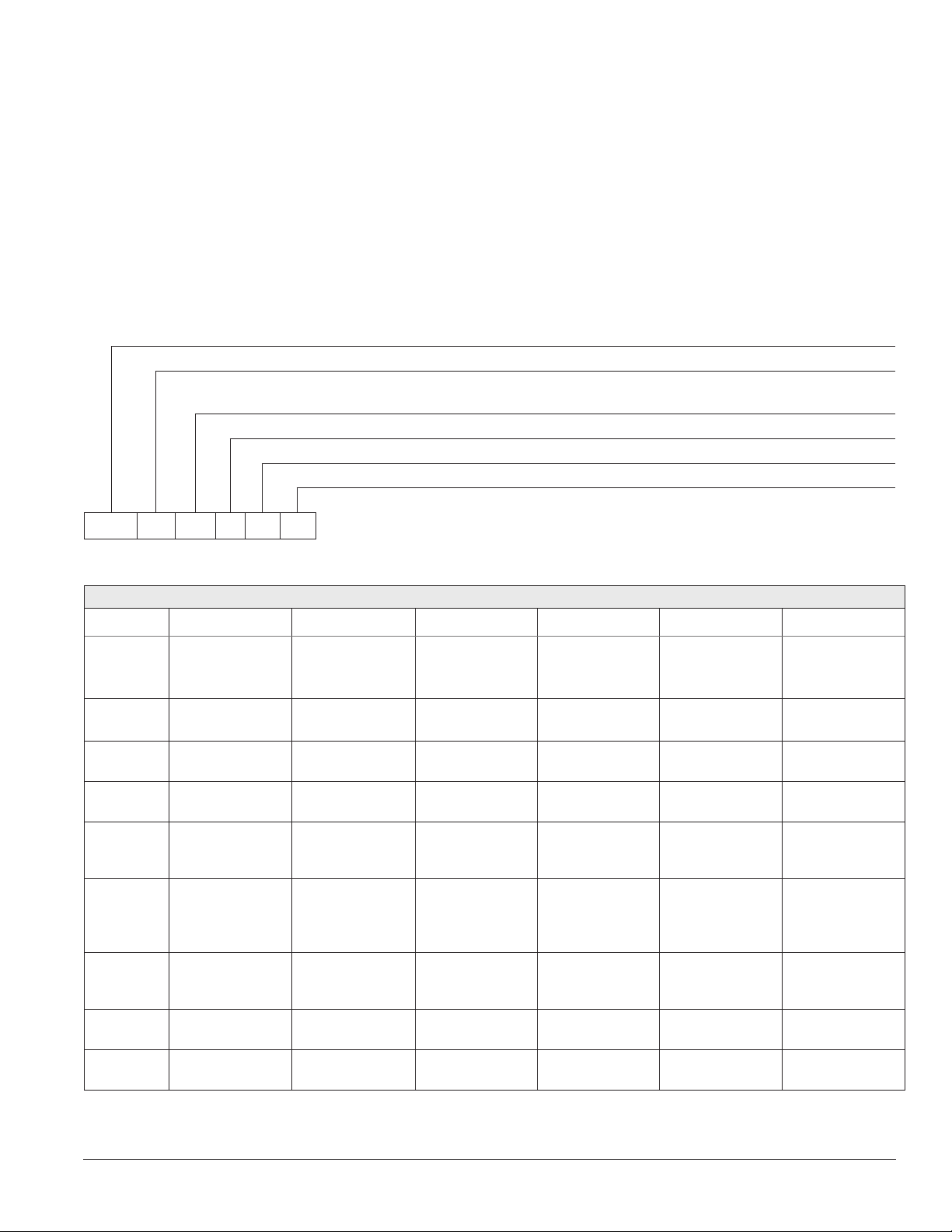

Check your paperwork to determine which conguration you have. Follett conguration numbers are designed to

provide information about the type of refrigerator you are receiving. Following is an explanation of the different item

numbers.

Model

Cubic foot capacity – 20, 25

Conguration – LB (Laboratory - shelves), PH (Pharmacy - baskets),

BB(Bloodbank - drawers)

Door hinge – R (Right hand), L (Left hand)

Door heater option – 00 (No door heater), HT (door heater)

Chart recorder option – 00 (No chart recorder), CR (Chart recorder)

REF 20 LB R 00 00

REF20-LB REF25-LB REF20-PH REF25-PH REF20-BB REF25-BB

Capacity

Storage

system

Exterior

width

Exterior

depth

Exterior

depth with

handles

Exterior

height with

casters

Interior

dimensions

(w x h x d)

Crated

weight

Max. heat

rejection

19.7 cu ft

(558L)

(4) epoxy-

coated shelves

29.75" (76 cm) 29.75" (76 cm) 29.75" (76 cm) 29.75" (76 cm) 29.75" (76 cm) 29.75" (76 cm)

29" (74 cm) 35" (89 cm) 29" (74 cm) 35" (89 cm) 29" (74 cm) 35" (89 cm)

30.5" (78 cm) 36.5" (93 cm) 30.5" (78 cm) 36.5" (93 cm) 30.5" (78 cm) 36.5" (93 cm)

79.5" (202 cm) 79.5" (202 cm) 79.5" (202 cm) 79.5" (202 cm) 79.5" (202 cm) 79.5" (202 cm)

24" x 22.5" x 56"

(61 cmx 58 cm x 143 cm)

395 (180 kg) 430 (196 kg) 450 (205 kg) 485 (220 kg) 475 (216 kg) 525 (239 kg)

950 BTU/hr 1050 BTU/hr 950 BTU/hr 1050 BTU/hr 950 BTU/hr 1050 BTU/hr

24.6 cu ft

(697L)

(4) epoxy-

coated shelves

24" x 28.5" x 56"

(61 cmx73 cm x 143 cm)

Specications

19.7 cu ft

(558L)

(6) epoxycoated baskets

24" x 22.5" x 56"

(61 cmx 58 cm x 143 cm)

24.6 cu ft

(697L)

(6) epoxycoated baskets

24" x 28.5" x 56"

(61 cmx 73 cm x 143 cm)

19.7 cu ft

(558L)/ 280

bags (450ml)

(6) stainless

steel drawers

24" x 22.5" x 56"

(61 cmx 58 cm x 143 cm)

24.6 cu ft

(697L)/ 360

bags (450ml)

(6) stainless

steel drawers

24" x 28.5" x 56"

(61 cmx 73 cm x 143 cm)

00926170 – REF20/25 LB, PH, BB Welcome to Follett 3

Page 4

Standard features – all models

Door Dual pane, low-E glass, condensation free to 80 F (27 C) air/60% RH

Door handle ADA-compliant, full length handle with integral lock

Interior/exteriormaterial Heavy-duty, corrosion resistant stainless steel

Casters (4) dual-wheel swiveling casters with toe locks

Insulation 2.75" (7 cm) thick, CFC-free foam insulation throughout

Lighting (2) full length side LED lights

Air circulation system Ducted air through 12 back plenum openings with front face return

Temperature probe Stainless steel RTD (resistance temperature detectors) top, bottom probe standard

on - BB models, available as option on -LB, -PH models, immersible with panel quick-

disconnect

Ambients

Intended for indoor use where ambient temperature typically does not exceed 80 F (27 C) and ambient relative

humidity does not exceed 60% RH. A heated door is recommended for higher humidity ambients.

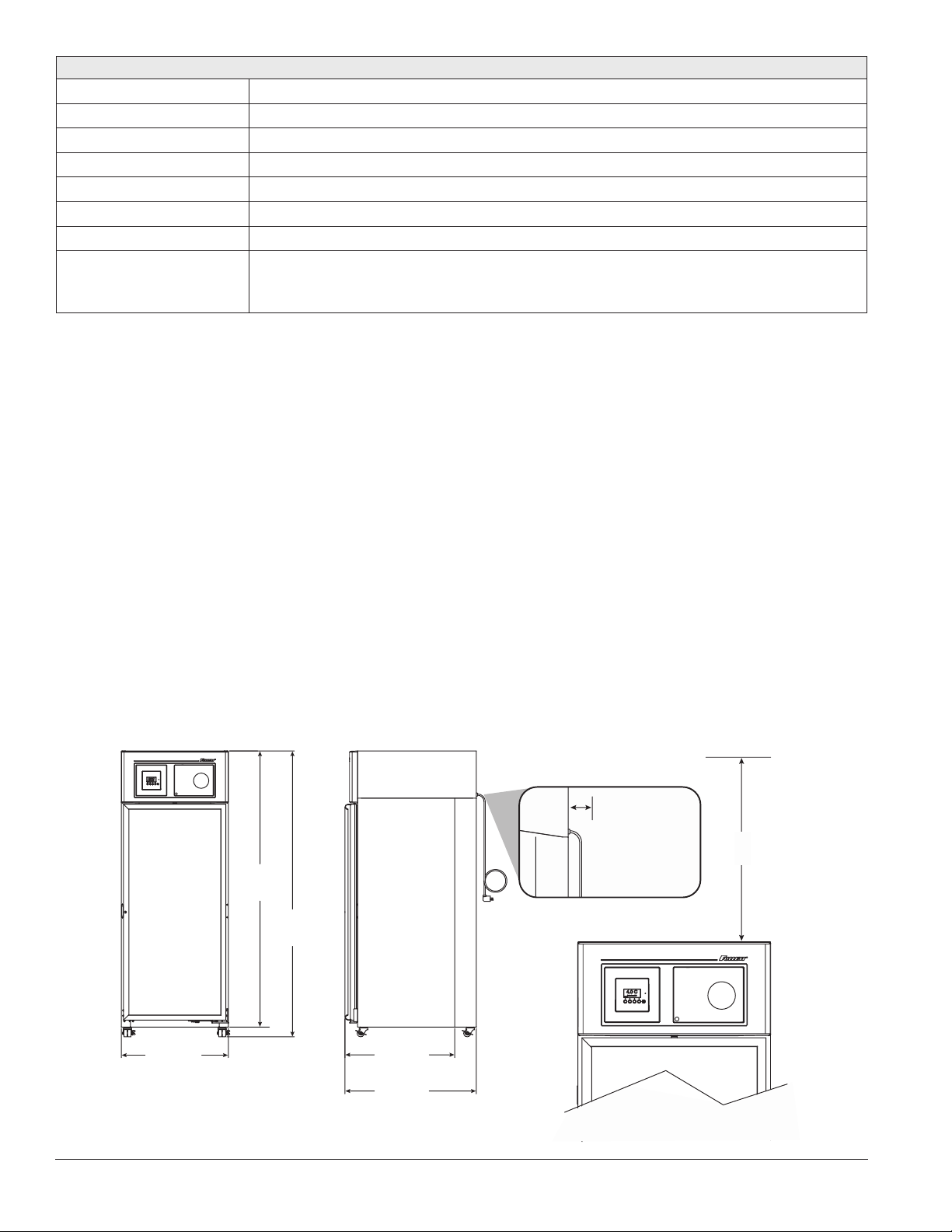

Clearances

The top of the refrigerator must have 10 inches (25.4 cm) of clear space above the refrigerator to ensure proper

ventilation of the refrigeration system.

The back of the refrigerator should have 1 inch (2.5 cm) of clearance to allow for power cord clearance on unit and

an additional 1 inch (2.5 cm) if the unit is to be plugged in directly behind the refrigerator.

Electrical specications

115V, 60Hz, 1 phase

Running load amps: 8.4 amps without heated door; max 9.7 amps with door heater energized 100% (adjustable).

Full load amps (90% maximum continuous current per UL 471 at 40 C): 10.5 amps

Minimum circuit ampacity: 15 amp dedicated circuit

Maximum size of branch circuit overcurrent device: 15 amp dedicated circuit

Refrigeration specications

Refrigerant R134a, 11.4 oz (322g)

Detail drawing

Required Clearances

1.0" (2.5 cm)

for power cord;

76.75"

(195cm)

(202cm)

2.0" (2.5 cm) if

outlet directly

behind unit

79.5"

10.0"

(25.4cm)

29.75"

(76cm)

4 Welcome to Follett 00926170 – REF20/25 LB, PH, BB

REF20

30.5" (78cm)

REF25

36.5" (93cm)

Page 5

Installation

DANGER

• Donottiltanyunitfurtherthan30°offverticalduring

uncrating or installation

• Refrigerationmoduleareacontainsmechanical,moving

parts. Keep hands and arms clear of this area at all

times. If access to this area is required, power to unit

must be disconnected rst.

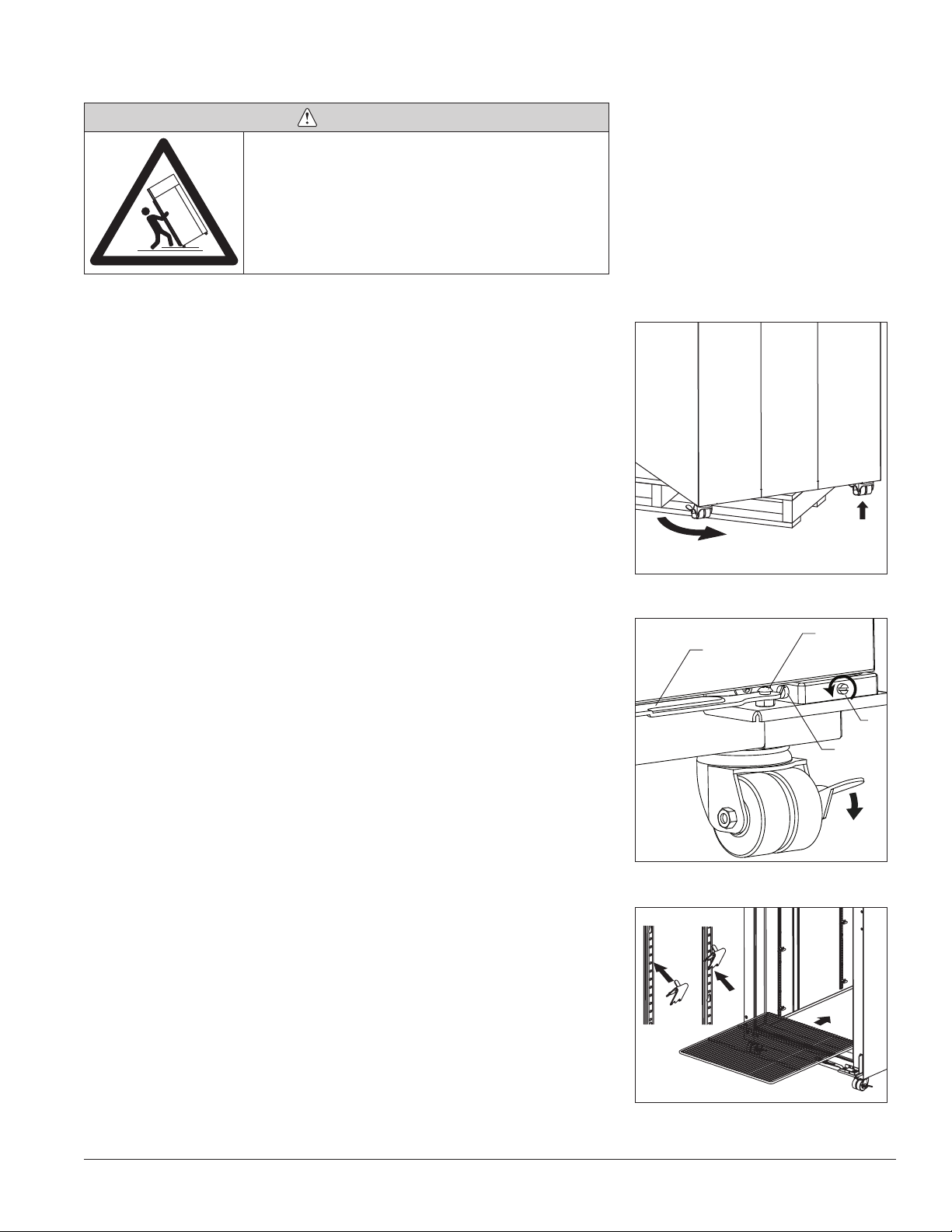

1. Remove key taped to side of refrigerator cabinet and unlock door.

2. Remove casters from box packed inside refrigerator.

Note: California facilities requiring wall and oor anchors – refer to wall anchor

kit instructions (#00938241) packed with seismic kit before proceeding with

caster installation.

3. Unbolt refrigerator from pallet.

4. Rotate refrigerator on pallet to install casters (Fig. 1.1).

5. Install casters by hand one at a time using channel locks to tighten, until

caster meets against the bottom of cabinet (Fig. 1.2).

6. Peel protective lm from exterior walls of stainless cabinet.

Fig. 1

2

1

Adjust self-closing door

1. Roll refrigerator to desired location and lock as many casters as

possible (Fig 2.1).

2. If the door appears to be sagging, remove the philips screw (Fig. 2.2)

holding the Hold Open Bracket to the Hinge Bracket to gain access to

the Sag Adjustment Screw (Fig. 2.3). Turn the Sag Adjustment Screw to

align the door squarely with the freezer cabinet. When nished, reinstall

the Hold Open Bracket.

3. Check door for closing tension and adjust if necessary. To check closing

tension, open door 1” and turn screw (Fig. 2.4) counterclockwise until

you achieve positive close. (Light will go out) Then, turn another half

turn counterclockwise.

Install shelves (if equipped) and power up

1. If refrigerator is equipped with shelves, remove bag containing shelf

supports and position them in desired locations on each pilaster and

insert shelves (Fig. 3).

2. Plug refrigerator into a 115V 60Hz 15 amp dedicated outlet.

Fig. 2

Fig. 3

1

2

Hold Open

Bracket

4

3

1

2

3

00926170 – REF20/25 LB, PH, BB Installation 5

Page 6

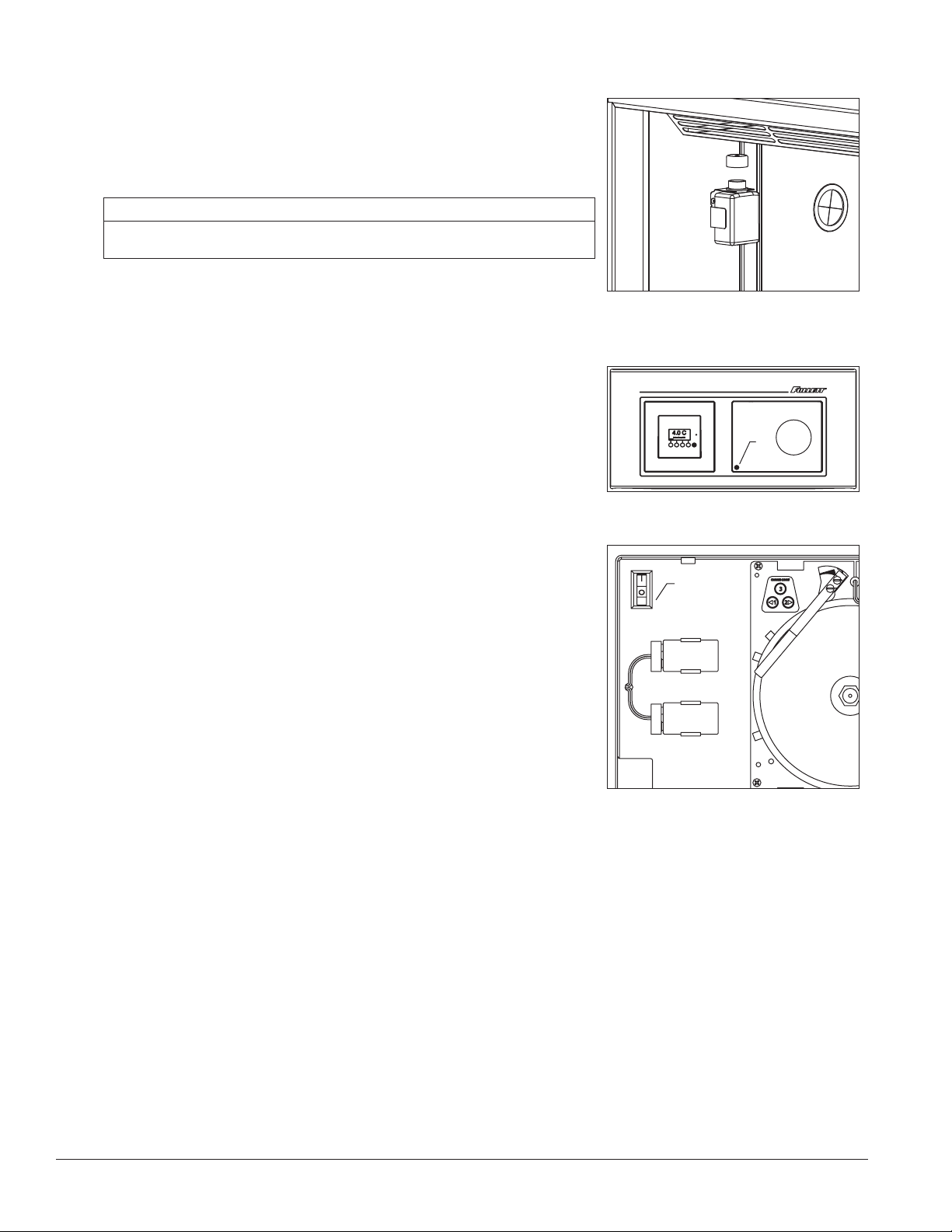

Fill product bottle

1. Remove probe and cap from the top bottle and ll with solution used at

your facility (e.g., 50% glycerine and 50% water) (Fig. 4). Replace cap

and reinsert probe sensor.

2. If equipped with a bottom probe, perform same procedure for bottom

bottle.

ATTENTION INSTALLER

Itisimperativethatthetopprobebottlebelledwithasolutionthatyour

facilityusestoensureproperoperationofunit.

3. Adhere supplied probe wire clips (x4, packaged with manual) to inside

wall leading to the probe bottle.

4. Route probe wire into clips and close the clips.

5. Press lower left corner of front facade door to access power switch

inside (Fig. 5.1).

Fig. 4

Fig. 5

1

Fig. 6

6. Press power switch to turn unit on (Fig. 6.1).

7. Install (2) 9V back-up interface batteries (Fig. 6.2) and (1) 9V chart

recorder back-up battery (if equipped.)

1

2

6 Installation 00926170 – REF20/25 LB, PH, BB

Page 7

Remote alarm connections (if desired)

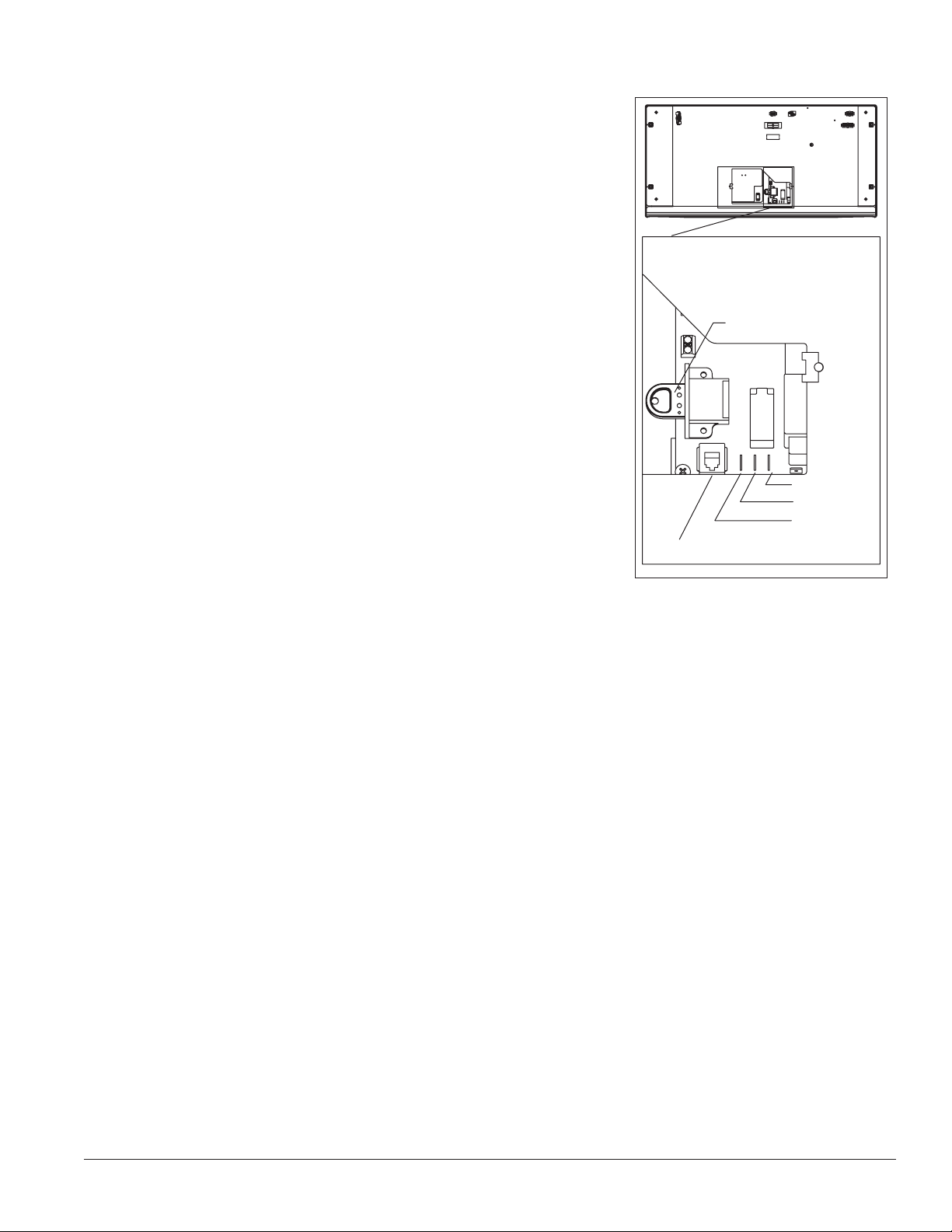

Remote communication connections are located on back side of top facade

(Fig.7).

Drycontacts

• Connection to NO or NC contacts provides remote alarming capability

• No temperature data is communicated

RS-485 port

• Connection provides real-time data streaming

– Temperature

– Alarms

– Refrigeration operation

• MODBUS protocol

• Uses 6 pin, 4 conductor RJ11 jack (not supplied)

Fig. 7

Hotkey

Common

N/O

N/C

Alarm Contacts

RS485 Port

00926170 – REF20/25 LB, PH, BB Installation 7

Page 8

Operation

4.0C

Quick setup checklist

• Set time/date

• Change temperature display from factory default Celsius to Fahrenheit (if desired)

• Set high/low temperature alarms

• Select password access (if required)

• Setup chart recorder (if equipped)

• Verify solution is in bottle

DANGER

• Donotextendallofthedrawersorbasketswhen

fullyloadedtoavoidthepossibilityoftherefrigerator

tipping forward

• Refrigerationmoduleareacontainsmechanical,moving

parts. Keep hands and arms clear of this area at all

times. If access to this area is required, power to unit

must be disconnected rst.

Fig. 8

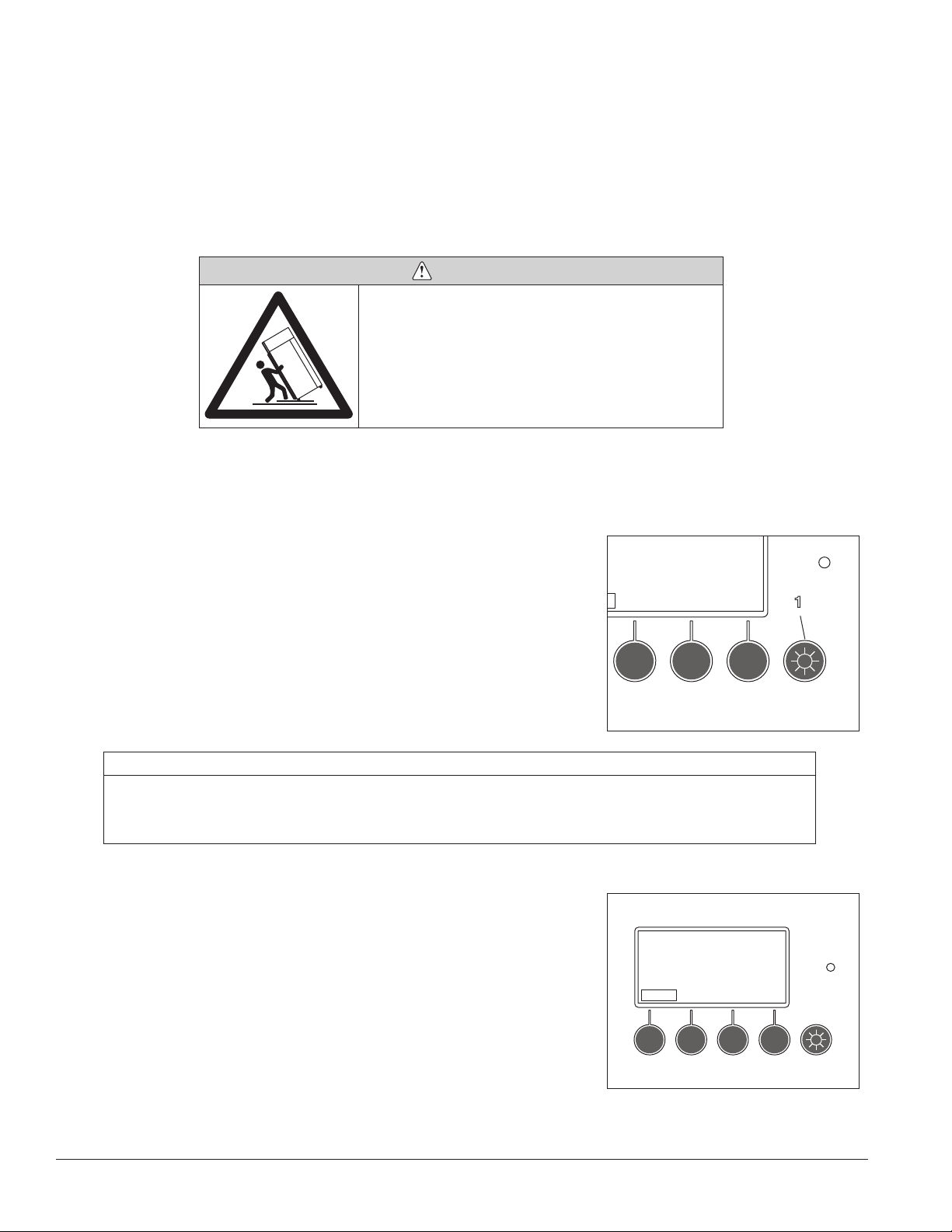

Interior LED lights

Interior lighting of refrigerator with door closed is controlled by light switch

(Fig 8.1) on interface.

Lights will be on whenever door is open regardless of light switch selection.

ATTENTION

• Thetime/datearenotretainedintheeventofapowerinterruptionorifthebatteriesaredead.

• Changebatterieswiththeunitpoweredup.Changeonebatteryatatimetoretaintime/date.Failuretofollowthis

procedure will result in loss of time & date and will not provide accurate time and date stamping for high or low

temperature alarms.

Temp 3.5C

Fig. 9

Set time & date

Set time and date for stamping of minimum and maximum temperatures.

1. Press Menu button (Fig. 9).

4.0C

B ottom Temp 3.5C

Menu

1

8 Operation 00926170 – REF20/25 LB, PH, BB

Page 9

Fig. 10

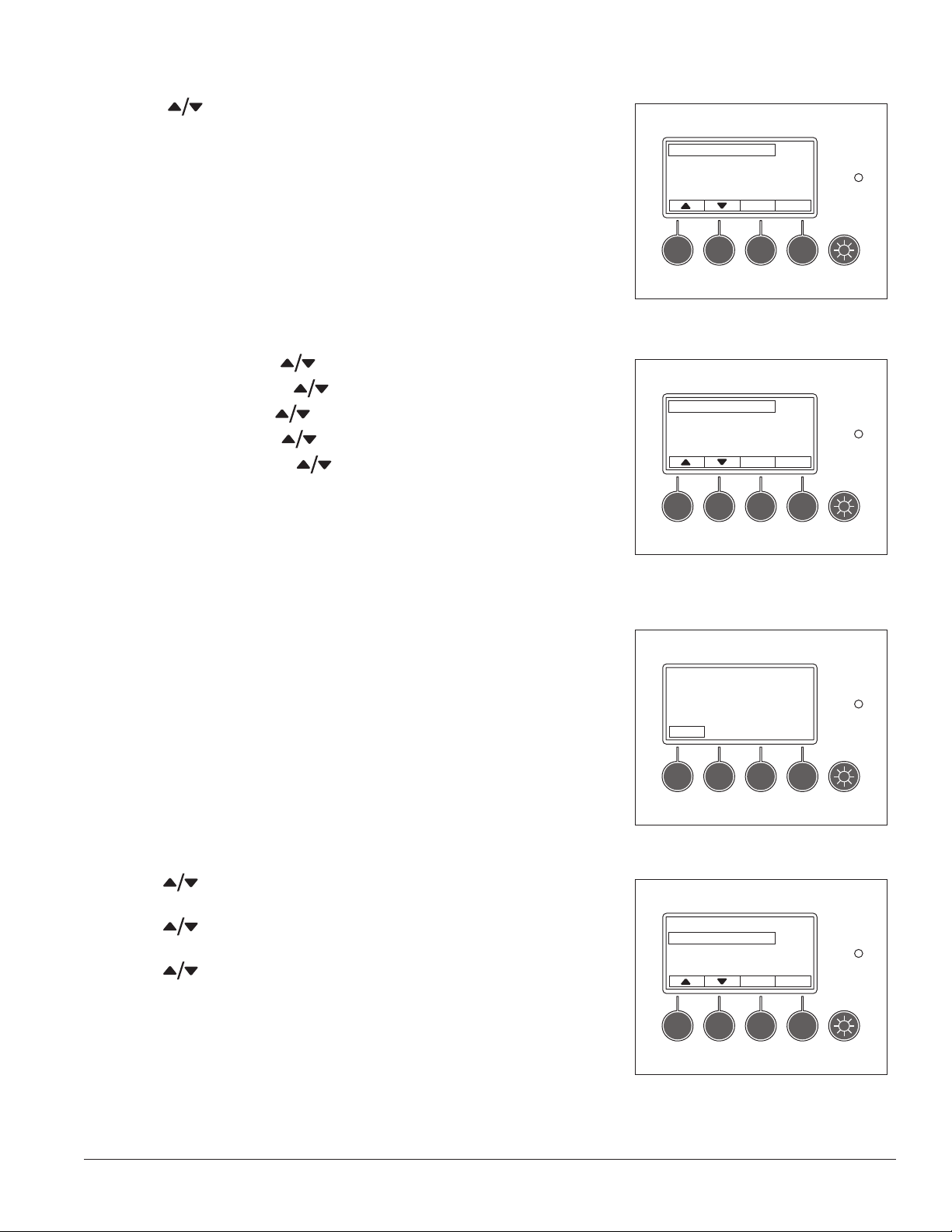

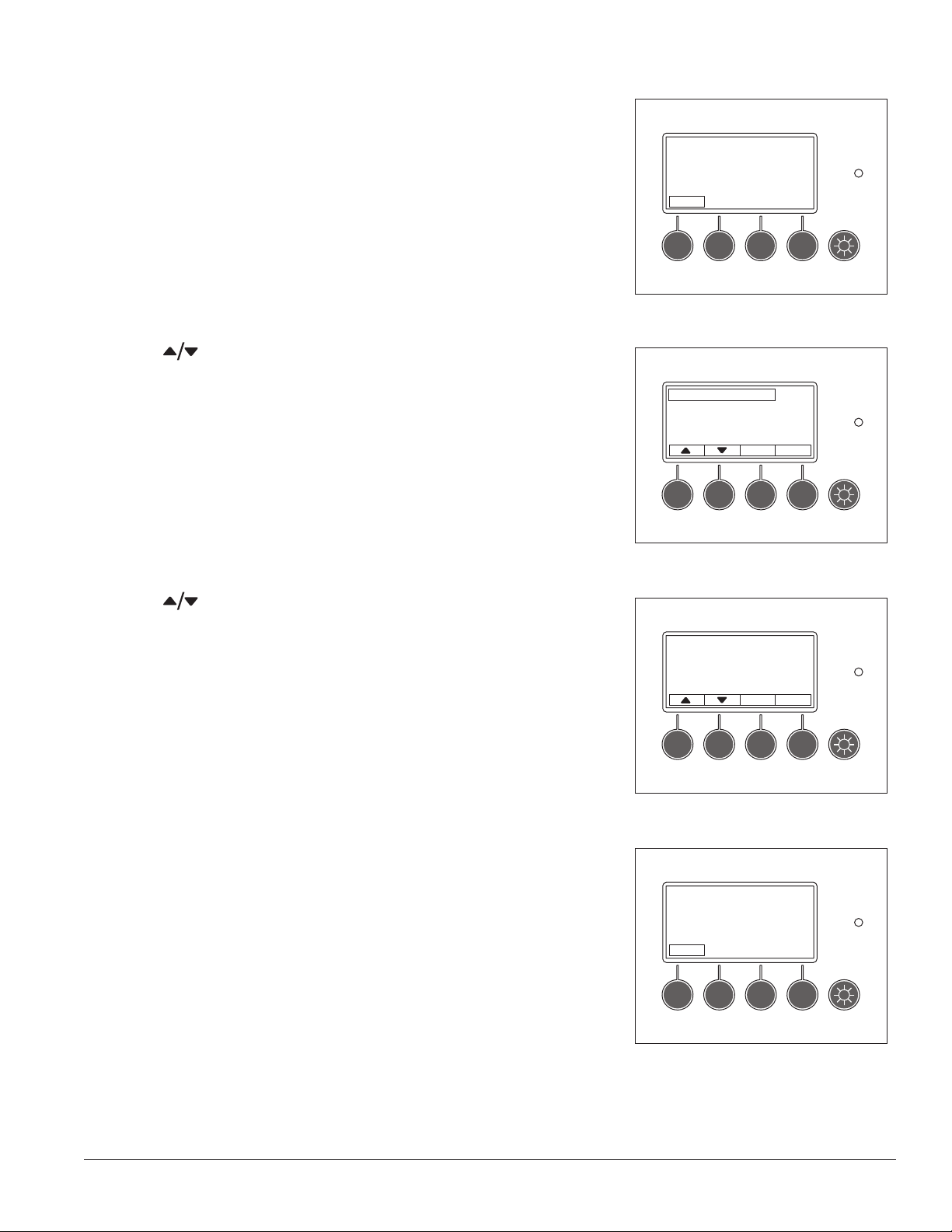

2. Use

to scroll and highlight Set time/date and press Enter to

select (Fig. 10).

3. Adjust the year using

and press NEXT.

4. Adjust the month using and press NEXT.

5. Adjust the day using and press NEXT.

6. Adjust the hour using

and press NEXT. (24 HR Clock)

7. Adjust the minute using .

8. Press Enter to select values.

9. Press Back until the main temperature display screen is displayed.

S et time/date

S et Alarm V olume

Alarm Silence

Fig. 11

S et year: 2009

2009 10/19 16:13

4.0C

Back Enter

3.4C

Next Enter

Change temperature display to show degrees

Fahrenheit (if desired)

Follett has pre-set the temperature display to read in degrees Celsius. If

degrees Fahrenheit display is preferred:

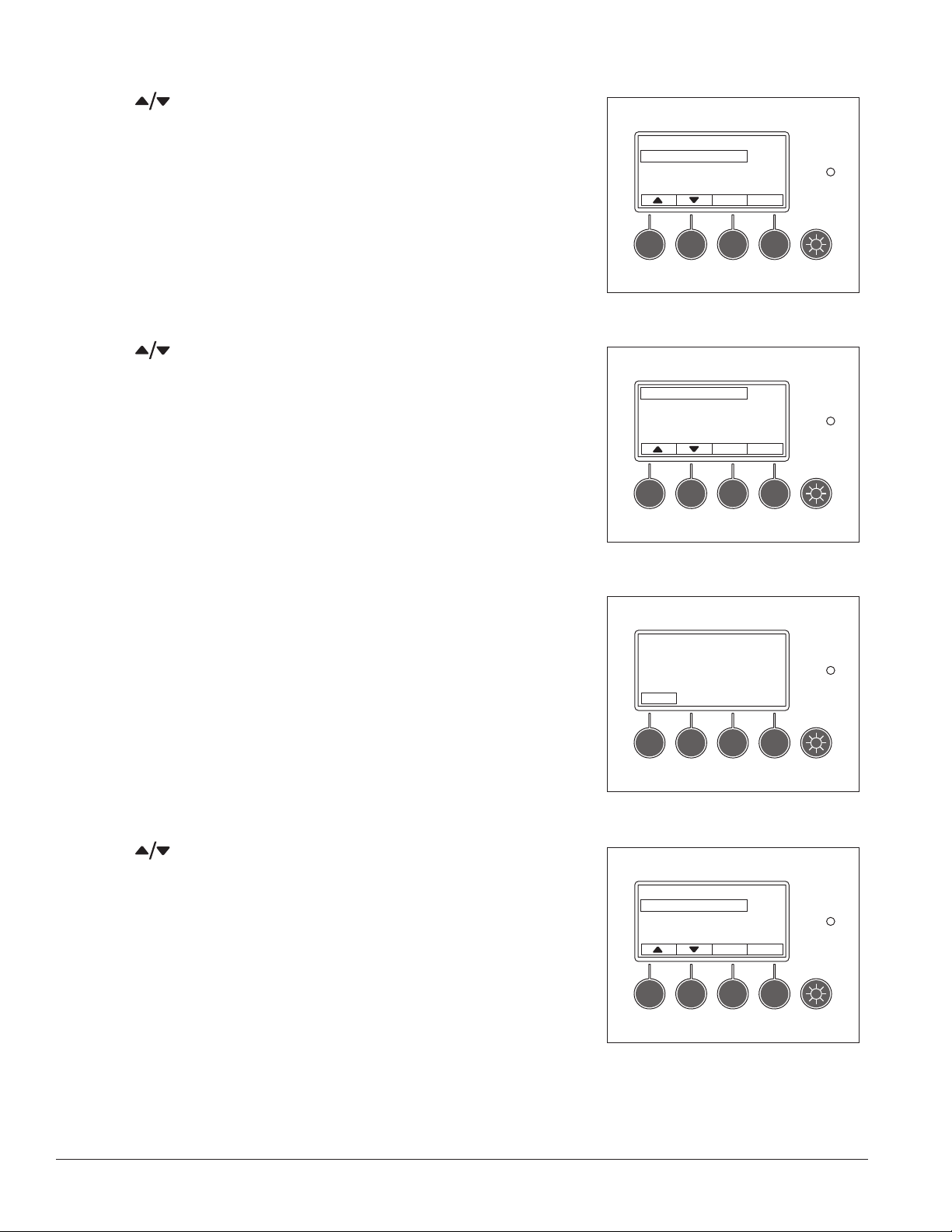

1. Press Menu button (Fig. 12).

2. Use

select (Fig. 13).

3. Use to scroll and highlight Degrees F/C and press Enter to

select.

4. Use

5. PressBack button until the main temperature display screen is

displayed. Temperature is displayed in degrees F.

to scroll and highlight DisplaySettings and press Enter to

to scroll and highlight F and press Enter to select.

Fig. 12

Menu

Fig. 13

Alarm Settings

Display Settings

M in/Max Te mperatures

Batt = 8.5V OK

4.0C

B ottom Temp 3.5C

4.0C

B ack Enter

00926170 – REF20/25 LB, PH, BB Operation 9

Page 10

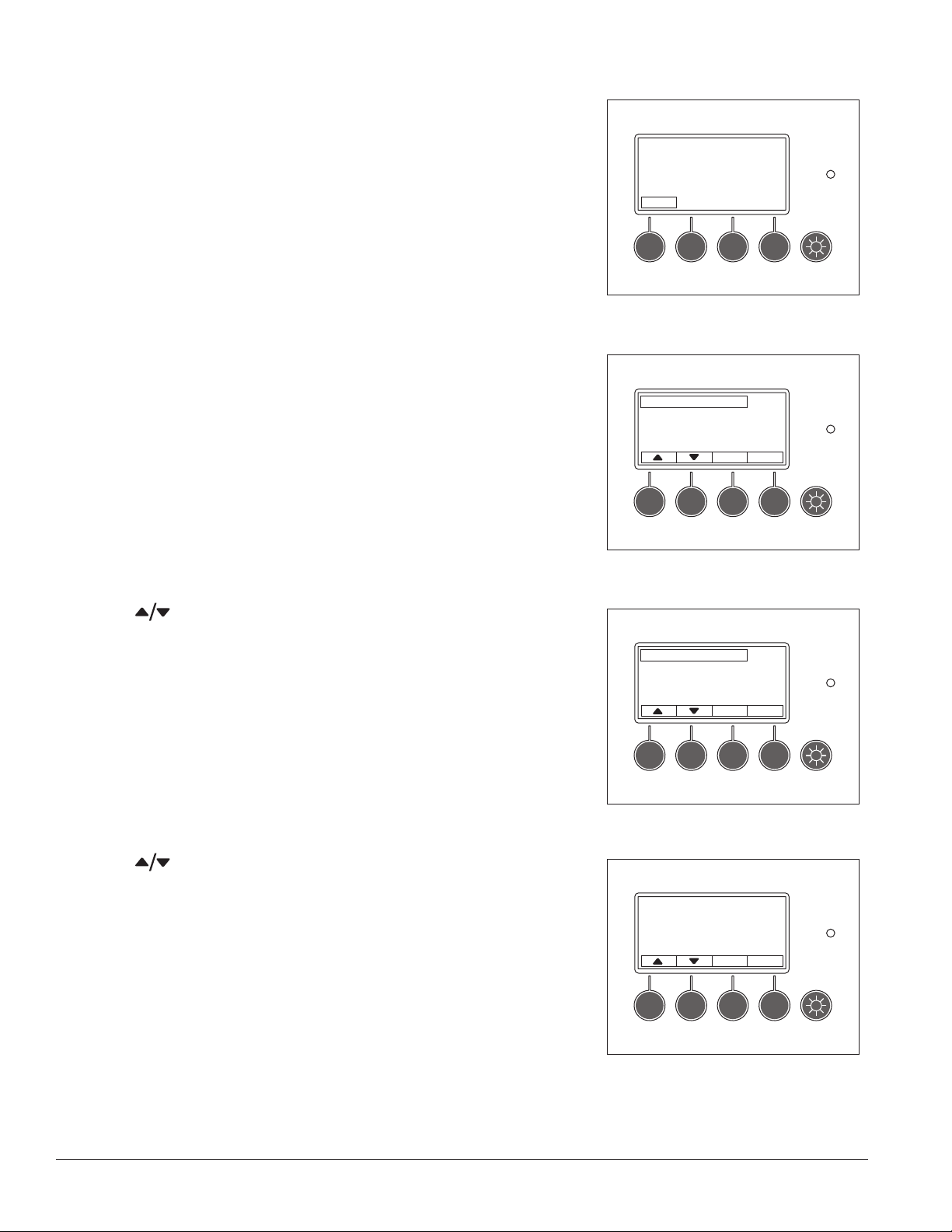

High and low alarm setup

The high alarm is set to a default of 40 C (104 F) from the factory. This

default setting is used so that the alarm will not sound while the unit is

pulling down to temperature. The low alarm default setting is 1.0 C (33.8 F).

After the unit has been installed and the system has stabilized

(approximately 1 hr), the high and low alarm set points should be adjusted

to desired settings.

1. Press Menu button (Fig. 14).

2. Alarm Settings will be highlighted. Press Enter to select (Fig. 15).

Fig. 14

4.0C

B ottom Temp 3.5C

Menu

Fig. 15

3. Use

select (Fig. 16).

to scroll and highlight High Alarm Set and press Enter to

Alarm Settings

Display Settings

M in/Max Te mperatures

Batt = 8.5V OK

Fig. 16

High Alarm Set

Low Alarm Set

Fig. 17

4.0C

Back Enter

4.0C

Back Enter

4. Use to change set point and press Enter to accept (Fig. 17).

High Alarm Setpoint 4.0C

40.0C

BackEnter

10 Operation 00926170 – REF20/25 LB, PH, BB

Page 11

Fig. 18

5. Use

to scroll and highlight Low Alarm Set and press Enter to

select (Fig. 18).

6. Use to change set point and press Enter to accept (Fig. 19).

7. Press Back until the main temperature display screen is displayed.

High Alarm Set

Low Alarm Set

Fig. 19

Low Alarm Setpoint 4.0C

1.0C

4.0C

BackEnter

BackEnter

00926170 – REF20/25 LB, PH, BB Operation 11

Page 12

Alarms

The refrigerator has several alarms that will sound an audible and visual alarm. Alarm type is shown on the top

line of the alarm display and multiple alarms will show progressively on the display. A red LED, to the right of the

display, accompanies all alarms.

All active alarms are conveyed to remote alarm relays. Remote alarm relay provides a choice of either a normally

closed (NC) or normally open (NO) contact. It is recommended for use at 24V 1A (relay is rated for 250V 10A).

Alarmdisplayed

Temp Alarm Only top product temperature probe activates this alarm. Bottom product temperature probe,

if installed, is for display reference only.

Top Probe Error Activates with loss of signal from top probe (open or short circuit).

Bottom Probe Error Activates with loss of signal from bottom probe (open or short circuit).

Door Ajar Alarm Activates with door open longer than 1 minute.

AC Power Alarm Activates after 2 min delay with loss of AC power.

Display backlight will turn off to conserve battery life, but pressing any button will brighten

display for 30 seconds.

Low Battery Alarms Display activates when (2) 9V controller back-up batteries decrease to 7.5V (maximum 4 hr

back-up time remaining.) This alarm will audibly chirp every 5 minutes.

Chart recorder – LED ashes green.

All batteries should be changed at same time. Replace batteries one at a time with AC

powerontokeepcorrecttime/date.

Evap Probe Error Activates with loss of signal from refrigeration control evaporator probe (open or short circuit).

Refrigerator goes into a xed on/off cycle until corrected. Default settings are 4 minutes

compressor on time and 8 minutes compressor off time. Cycle on time and off time are

adjustable in faulty probe cycle sub-menu of refrigeration controls menu.

Alarm muting

All audible alarms can be muted for up to 60 minutes in 5 minute

increments by pressing the MUTE button. The desired mute period will

display, and count down, in the window adjacent the MUTE label (Fig.20).

Conditions

Fig. 20

Door Ajar Alarm

4.0C

MENUMUTE

12 Operation 00926170 – REF20/25 LB, PH, BB

15 min

Page 13

Alarm volume selection

Factory default setting is “high”. To change volume of the alarm:

1. Press Menu button (Fig.21).

Fig. 21

4.0C

B ottom Temp 3.5C

Menu

Fig. 22

2. Use

select (Fig.22).

3. Use

select (Fig.23).

4. Press Back until the main temperature display screen is displayed.

to scroll and highlight Set Alarm Volume and press Enter to

to select the volume (high/medium/low) and press Enter to

Set Alarm Volume

Alarm Silence

Fig. 23

B uzzer Volume 4.0C

HIGH

4.0C

Back Enter

BackEnter

Alarm silence

Audible alarming can be turned off through the menu interface:

1. Press Menu button (Fig. 24).

Fig. 24

4.0C

B ottom Temp 3.5C

Menu

00926170 – REF20/25 LB, PH, BB Operation 13

Page 14

Fig. 25

2. Use

to scroll and highlight Alarm Silence and press Enter to

select (Fig. 25).

3. Use

to select ON or OFF and press Enter to select (Fig. 26).

4. Press Back until main temperature display screen is displayed.

Set Alarm Volume

Alarm Silence

Fig. 26

Audible Alarm 4.0C

ON

4.0C

Back Enter

Back Enter

Password PIN security (default is 3843)

If desired, access to the user selectable features and settings can be

controlled by a password PIN. The refrigerator ships with the password

option turned off. The default password PIN, if the password is turned on, is

3843. This password pin number will always work.

To turn password on/off

1. Press Menu button (Fig.27).

2. Use

Enter to select (Fig.28).

to scroll and highlight Password on/off option and press

Fig. 27

Menu

Fig. 28

Refrigeration Controls

Password on/off

PIN

Set time/date

4.0C

B ottom Temp 3.5C

4.0C

Back Enter

14 Operation 00926170 – REF20/25 LB, PH, BB

Page 15

Fig. 29

3. Use

to choose ON or OFF and press Enter to select (Fig.29).

4. Press Back until the main temperature display screen is displayed.

To make a new password PIN

1. Press Menu button (Fig.30).

Passw ord 4.0C

OFF

Back Enter

Fig. 30

4.0C

B ottom Temp 3.5C

Menu

2. Use

to scroll and highlight PIN and press Enter to select

(Fig.31).

3. Use

to select the rst number of the 4 digit pin. Use the Next

button to move to the next digit, adjust with and repeat for the last

2 digits. Press Enter to select (Fig.32).

4. Press Back until the main temperature display screen is displayed.

Fig. 31

Refrigeration Controls

Password on/off

PIN

Set time/date

Fig. 32

E nter 4 Digit Pin

Digit 1

3843

4.0C

Back Enter

3.3C

Next Enter

00926170 – REF20/25 LB, PH, BB Operation 15

Page 16

Min/max temperature logging

The controller retains maximum and minimum temperatures since last reset

and provides a date and time stamp of when they occurred.

1. Press Menu button (Fig.33).

Fig. 33

4.0C

B ottom Temp 3.5C

Menu

Fig. 34

2. Use

to scroll and highlight Min/Max Temperatures and press

Enter to select (Fig.34).

3. Use

to select the min or max logged temperature (Fig. 35). Press

Enter to reset log.

4. Press Back until the main temperature display screen is displayed.

Alarm Settings

Display Settings

M in/Max Te mperatures

Batt = 8.5V OK

Fig. 35

Min = 2.7C

2009 10/19 12:10

P ress Enter to Reset

4.0C

Back Enter

4.0C

Back Enter

16 Operation 00926170 – REF20/25 LB, PH, BB

Page 17

Probe calibration

Follett refrigerator probes are calibrated to a known standard prior to leaving

the factory. Recalibration can be easily accomplished at any time, if desired:

1. Remove upper temperature probe from probe bottle and completely

submerge into an ice bath.

Note: Ice bath should be densely compacted ice (ake, crushed, nugget, or

cracked) and a little water.

2. Place ice bath with probe in refrigerator and close door.

3. Press Menu button (Fig. 36).

Fig. 36

4.0C

B ottom Temp 3.5C

Menu

Fig. 37

4. Use

hold Enter and

to scroll and highlight Refrigeration Controls, press and

together for 3 seconds (Fig.37).

5. Calibration should be highlighted, press Enter to select (Fig.38).

Refrigeration Controls

Password on/off

PIN

Set time/date

Fig. 38

Calibration

Refrig Setpoint

Differential

H igh Setpoint Limit

4.0C

B ack Enter

4.0C

Back Enter

Fig. 39

6. Cal Top Probe should be highlighted, press Enter to select (Fig.39).

CAL Top Probe

CAL Bottom Probe

4.0C

Back Enter

00926170 – REF20/25 LB, PH, BB Operation 17

Page 18

7. When probe temp stabilizes press Enter button calibrating it to 0.0C

(32 F) (Fig. 40). Wait one minute and press Enter button again to

conrm calibration.

8. Remove probe from ice bath and return to solution-lled probe bottle.

9. Press Back until main temperature display screen is displayed.

10. Repeat steps for bottom probe, if equipped.

ATTENTION

• Bottomtemperatureprobeisonlystandardonbloodbankmodels

• Ifunithasthechartrecorderoption,referto“Chartrecordercalibration”on

page 18.

Fig. 40

S et CAL TEMP W ^/

When Top Probe Stable

P ress Enter

Cal 0.0C i Probe 0.1C

^

4.0C

Back Enter

Chart recorder set up (if so equipped)

The chart recorder is mounted in the front right of the facade behind the

door (Fig. 41). A package of 50 charts that record in C is included with your

refrigerator. If you have changed your display to show temperatures in F,

you will need different charts. Please call Follett at (877) 612-5086 or

+1 (610) 523-9361 to order part number 00967729.

The chart recorder is powered by the controller and has its own battery

back up. An LED provides battery status info: Steady green = battery okay,

Flashing green = low battery or no power to the controller.

Chart recorder calibration

If desired, calibration should be done at the same time as probe calibration

(page 17) by pressing either the left or right arrow keys to correspond with

the calibrated product display temperature.

1. Press Left #1 or Right #2 arrow button (Fig. 41) for 5 seconds until pen

begins to move.

2. Continue to press #1 or #2 button to move pen to record same

temperature as probe.

Changing the chart paper

1. Press and hold #3 button until pen begins to move off chart.

2. Once the pen moves completely off chart, unscrew knob (counter-

clockwise) at center of chart.

3. Remove old chart and place new chart in position so that correct time

coincides with time line groove on recorder.

4. Reinstall knob.

5. Press and hold #3 button for approximately (1) one second until pen

begins to move back onto chart.

6. Make sure pen is marking paper. If not, carefully adjust arm so that

pen makes contact with paper.

Fig. 41

Replacing the pen

1. To replace pen, press and hold the #3 button until pen starts to move

off chart.

2. Once pen has moved completely off chart, carefully lift pen up and

unsnap the “U” clip part to remove pen from metal pen arm.

3. Position new pen on metal pen arm and snap “U” clip underneath pen

around arm to secure.

4. Press and hold #3 button for approximately (1) second until pen begins

to move back onto chart.

5. Make sure pen is marking. If not, carefully adjust arm so that pen

makes contact with paper.

18 Operation 00926170 – REF20/25 LB, PH, BB

Page 19

Removing drawers

1. Pull drawer forward to stop (Fig. 42.1).

2. Lift drawer front to free front rollers from slides (Fig.42.2).

3. Still lifted, pull drawer forward to free back rollers from slides.

Removing slides

1. Push slides all the way back.

2. Swing bottom of slide away from refrigerator wall and lift slide off rollers.

Fig. 42

1

2

00926170 – REF20/25 LB, PH, BB Operation 19

Page 20

Cleaning

Use non chlorine-based cleaners. Cleaners containing chlorine can cause

staining and pitting of the stainless steel.

Disconnect power to unit by turning the power switch off, located on the

upper front facade panel, and removing the power cord from the receptacle.

Interior cleaning

Using a sponge or soft cloth, clean unit with a non-abrasive, nonchlorinated, all-purpose detergent. Note: The left and right air plenums

should be removed to clean them, as well as behind them (Fig.43, 44).

In addition the shelves, baskets, drawers and slides should be cleaned

aswell.

Exterior cleaning

Wipe stainless steel exterior with a soft cloth in the direction of grain as

needed. Stainless steel polish may be used to enhance the nish of the

unit. The glass door and exterior parts may be cleaned with a soft cloth,

window cleaner or other non-abrasive cleaner.

Fig. 43

Fig. 44

20 Cleaning 00926170 – REF20/25 LB, PH, BB

Page 21

Annual cleaning

Removal of dust and other particulates from air intake areas and the

condenser is important for proper operation. Environments with large

amounts of dust may require more frequent cleaning.

1. Disconnect power to unit by turning power switch off (located on upper

front facade panel) and removing power cord from receptacle.

2. The condenser can be accessed from top for cleaning. The side panel

in front of condenser may be completely removed for easier cleaning

by disconnecting facade and removing upper side panel. See “Facade

removal” on page 27 for facade removal instructions.

3. Inspect drain pan for any debris or obstruction in condensate pan

(Fig.45.1).

4. Use a vacuum cleaner with brush attachment to clean condenser,

compressor and related parts.

5. Reinstall upper side panel and facade if removed.

Fig. 45

6. Door maintenance: Place a dab of white lithium grease on top of hold

open arm and keeper on lower hinge assembly of door (Fig.46.1).

1

Fig. 46

1

00926170 – REF20/25 LB, PH, BB Cleaning 21

Page 22

Service

R

The temperature controller and evaporator probe indicate when the refrigeration system is required to turn on

andoff.

The refrigeration system removes heat from the cabinet interior and rejects it to the surrounding room air. When

the evaporator probe temperature reaches 5.0 C (9.0 F) above the controller set point, the probe signals the

controller to turn the refrigeration system on. The normally open controller contacts close and energize the

condenser fan motor and compressor. The compressor uses a current-style starting relay and a starting capacitor

to start the compressor motor.

When the evaporator temperature falls to 5.0 C (9.0 F) below the set point, the probe signals the controller to turn

the refrigeration system off. The controller contacts reopen, which de-energizes the condenser fan motor and the

compressor. The evaporator fan motor runs continuously.

Any accumulated frost on the evaporator coils melts during the off cycle. The condensate drains to a drain

pan mounted in the base of the refrigeration unit. The pan is located under the compressor. The heat from the

compressor, condenser and fan evaporates any condensate in the drain pan as well as providing preliminary

cooling of the high pressure vapor prior to entering the condenser.

Refrigeration system

The REF20/25 series refrigeration system is designed to give many years of trouble-free service. Except for

routine cleaning of the air-cooled condenser and related parts, the refrigeration system requires no service or

maintenance. The system uses a capillary tube metering device and is critically charged. Access ttings are not

provided. Temporary piercing valves are required to work on the refrigeration system. Follett recommends that if

hoses are ever connected to the refrigeration system for service, the refrigerant should be recovered, permanent

access valves should be installed and the system evacuated, and recharged by weighing in the correct refrigerant

charge (refrigerant R134a, 11.4 oz (322g).

Note: Do not charge the system by pressures.

CAPILLARY TUBE

FILTER-DRIER

COMPRESSOR

EVAPORATOR

CONDENSER

HIGH PRESSURE VAPO

HIGH PRESSURE LIQUID

LOW PRESSURE LIQUID

LOW PRESSURE VAPOR

Defrosting

REF20/25 series upright refrigerators do not require manual defrosting. The evaporator defrosts automatically

when the refrigeration unit is in the OFF cycle. The evaporator fan will run continuously.

22 Service 00926170 – REF20/25 LB, PH, BB

Page 23

Controller operation

ATTENTION

BEFORE MAKING ANY CHANGES TO FACTORY-DEFAULT REFRIGERATION

SETTINGS, CONTACT FACTORY.

The controller displays product temperatures in degrees C or F (C is factory default) to 1 decimal point.

The controller is pre-programmed with a 0.5 C (32.9 F) set point which provides a compressor cut-in at 5.5 C

(41.9 F) evaporator coil temperature and cut-out at -4.5 C (23.9 F) evaporator coil temperature. This will correlate

to a product temperature of approximately 4.0 C (39.2 F).

All set points have a 5 C (9.0 F) differential. The 5.0 C (9.0 F) differential means that with a 0.5 C (32.9 F) set

point, for example, the compressor will turn off at -4.5 C (23.9 F) evaporator temperature and turn on when the

evaporator temperature reaches 5.5C (41.9 F).

Product temperature will be displayed on the digital temperature display and chart recorder (if equipped).

Temperature sensor readings

To view temp sensor probe readings:

1. Press Menu button (Fig. 47).

2. Use

to scroll and highlight Refrigeration Controls (Fig.48).

Fig. 47

Menu

Fig. 48

Refrigeration Controls

Password on/off

PIN

Set time/date

4.0C

B ottom Temp 3.5C

4.0C

Back Enter

Fig. 49

3. Press and hold Enter and

together for 3 seconds (Fig.49).

Calibration

Refrig Setpoint

Differential

H igh Setpoint Limit

Back Enter

4.0C

00926170 – REF20/25 LB, PH, BB Service 23

Page 24

Fig. 50

4. Use

to scroll and highlight Temp sensors and press Enter to

select (Fig. 50).

5. The following will be displayed (Fig. 51).

RTD1= Top probe sensor reading

RTD2= Bottom probe sensor reading

(if equipped, otherwise displays default 25 C (77 F))

NTC1= Evaporator Probe reading

NTC2= Displays a default value and is not used

6. Press Back until main temperature display screen is displayed.

FAULTY PROB TIME

T EMP SENSORS

Fig. 51

RTD1= 3.2C

RTD2 = 2.4C

NTC 1 = 3.3C

NTC 2 = -26.8C

4.0C

B ack Enter

Back

Heated door (option) – changing cycle

Factory default for the heated door and fascia heater cycle is set to 50%,

based on a 20 minute cycle (e.g. 50% = 10 minutes off, 10 minutes on).

1. Press Menu button (Fig. 52).

2. Use

to scroll and highlight Refrigeration Controls (Fig.53).

Fig. 52

Menu

Fig. 53

B att = 8.5V OK

Refrigeration Controls

Passw ord on/off

PIN

4.0C

B ottom Temp 3.5C

4.0C

Back Enter

24 Service 00926170 – REF20/25 LB, PH, BB

Page 25

Fig. 54

3. Press and hold Enter and

4. Use

to scroll and highlight DoorHeaterCycle and press Enter

to select (Fig.55).

together for 3 seconds (Fig.54).

Calibration

Refrig Setpoint

Differential

H igh Setpoint Limit

Fig. 55

L ow Setpoint Limit

Door Heater Cycle

Upload To Hotkey

Download from Hotkey

4.0C

Back Enter

4.0C

Back Enter

5. Heater ON cycle is shown as a percentage of 10 minute cycle (Fig. 56).

6. Use

to adjust heater ON cycle percentage and press Enter to

select.

7. Press Back until the main temperature display screen is displayed.

Fig. 56

Heater On Percent 4.0C

50

Back Enter

00926170 – REF20/25 LB, PH, BB Service 25

Page 26

Changing temperature set point

ATTENTION

BEFORE MAKING ANY CHANGES TO FACTORY-DEFAULT REFRIGERATION

SETTINGS, CONTACT FACTORY. FACTORY DEFAULT IS IN DEGREES C. IF USER

HAS CHANGED DISPLAY TO SHOW TEMPERATURE IN DEGREES F, ALL OTHER

TEMPERATURES WILL DISPLAY IN DEGREES F.

The temperature control system is preset by the factory to provide a product

temperature of approximately 4.0 C (39.2 F). If desired, the evaporator

set point temperature can be changed to achieve a different product

temperature. The factory preset 5.0 C (9 F) differential will be maintained

regardless of the controller set point.

EXAMPLE:

If the product temperature is 4.0 C (39.2 F) and the product temperature

needs to be 3.0C (37.3 F). Adjust the refrigeration set point down 1.0 C to

-0.5 C (1.8 F to 31.1 F) from default setting of 0.5C (32.9 F).

Changing the temperature set point:

1. Press Menu button (Fig. 57).

2. Use

to scroll and highlight Refrigeration Controls (Fig. 58).

Fig. 57

Menu

Fig. 58

Refrigeration Controls

Password on/off

PIN

Set time/date

4.0C

B ottom Temp 3.5C

4.0C

Back Enter

3. Press and hold Enter and then

together for 3 seconds.

4. Scroll to Refrig Setpoint, press Enter to select (Fig. 59).

Fig. 59

Calibration

Refrig Setpoint

Differential

H igh Setpoint Limit

4.0C

Back Enter

26 Service 00926170 – REF20/25 LB, PH, BB

Page 27

Fig. 60

5. Use

select (Fig. 60).

6. Press Back until the main temperature display screen is displayed.

to increase or decrease the set point and press Enter to

Facade removal

The facade is removed by loosening the top left and right Phillips screws

on the back of the facade to allow the securing clips to rotate away from

the side panels. The facade can simply pull off of the front by pulling it

out of the bayonet mounts that secure it to the upper left and right panels.

If the facade will be completely removed, the electrical plugs should be

disconnected. The ground wire should be removed from the top right

grounding screw on the cabinet box, not from the facade (Fig.61.1).

CNTRL SETPOINT 4.0C

0.5C

Back Enter

Fig. 61

1

00926170 – REF20/25 LB, PH, BB Service 27

Page 28

Controller replacement

2

CAUTION

• Controllerboardissusceptibletoelectrostaticdischarge.

Extremecareshouldbeexercisedbyusingagrounding

strap when handling and installing control board.

1. Turn off power to unit and unplug.

2. Remove facade and disconnect electrical plugs.

3. Remove screw securing ground screw to refrigerator cabinet

(Fig.62.1). Do not remove ground wire from facade.

4. Place facade face down on at clean surface with bottom of facade

facing you, and remove four screws attaching back panel to facade.

5. Lift and rotate back panel toward you.

6. Take precautions for proper grounding to reduce risk of electrostatic

discharge (ESD) to the controller board.

7. Remove 5 screws securing board to facade (Fig. 62.2).

8. Reposition board away from mounting location and install newboard.

9. Using wiring schematic (attached to inside of removed back panel) as

a guide, remove wires one at a time from back of existing controller

and connect to corresponding terminals on replacement controller.

10. If ribbon cable from the display is not connected, carefully connect to

corresponding location on board (Fig. 62.3).

11. Make sure wiring is secured at same factory locations, so that cover

will not pinch any wires when reinstalled.

12. Flip facade cover back into position on facade and reinstall 4 screws.

13. Place facade on top of refrigerator above compressor.

14. Reconnect electrical plugs and reinstall screw for grounding wire to

grounding location on cabinet.

15. Remount facade to bayonet mounts.

Fig. 62

1

2

3

2

2

2

Reversing the door swing (requires a new door)

REF20/25 units ship standard with a non heated right hinged door. To

change to a left hinged conguration requires a new door. For heated door

options other parts may be required. If the unit has a heated door option

consult technical service by calling (877) 612-5086 or +1 (610) 252-7301.

Heated doors

Heated doors are factory installed. An unheated door cannot be retrotted to

a heated door in the eld.

28 Service 00926170 – REF20/25 LB, PH, BB

Page 29

Door gasket replacement

1. Remove existing gasket from mounting track (Fig. 63).

2. Verify mounting track is free of any remaining gasket material.

3. Align new gasket with mounting track and press rmly in place.

4. Open and close door, checking for proper gasket seal without pinching

against refrigerator.

Fig. 63

Slide-out unit cooler

Follett’s slide-out refrigeration system allows technicians to remove the

entire unit from the refrigerator top.

1. If necessary remove facade and upper side panels.

2. Remove four bolts securing unit cooler to refrigerator top (Fig.64).

3. Gently lift off cooler.

Fig. 64

00926170 – REF20/25 LB, PH, BB Service 29

Page 30

Wiring diagram (After Serial Number E15526)

115 VAC

L1

1φ, 60 Hz

BLK

010203

K8

ON/OFF

20A

16

K6

07

BACKUP

9 V

DOOR SW

PROBE

BOTTOM

PROBE

(RTD2)

EVAP

PROBE

(NTC1)

04

17

K7

09

+

MAGNET

TOP

(RTD1)

BLK

BLK

BLK

+

RED

RED

WHT

RED

RED

WHT

COMPRESSOR

O/L

RED

K8

J30

+

RED

-

BLK

WHT

WHT

+

GND

+

GND

21

J28

22

J23

J20

(CSIR)

J26

J27

C

12 VDC

PCB

+

COND FAN

R

S

EVAP FAN

T1

12 VDC

K6

K2

K2

START RELAY

J36

0-5 VDC

J24

OUT

TXD +

J19

TXD -

GND

J1

K1

-

K7

K5

K1

SR

N/C

N/C

GND

N

WHT

GRN/YEL

SR

RED

WHT

216-259 μF

220 VAC

05

06

18

32

INTERIOR

LINER

39

38

37

+

19

TO CHART

RECORDER

RJ11

6P/4C

REMOTE

ALARM

1 A 24 V

LCD

23

RED

RS485

HOT KEY

I/O PORT

24

-

5V

42

30

K5

08

801 Church Lane

Easton, PA 18040 USA

For service call:

Toll free (877) 612-5086 or

10

25

+

24VDC

POWER

26

SUPPLY

L

DOOR/FASCIA

11

60

12

63

BLK

HEATERS

70

41

62

+

BACKUP

9 V

WHT

20

_

27

N

36

61

64

CHART RECORDER

1+4

+

RED

BLK

12 VDC

-

BLK

76

14

15

2+5

0-5 VDC

31

13

73

+

RED

-

IN

BLK

FROM

PCB

30 Service 00926170 – REF20/25 LB, PH, BB

Page 31

Wiring diagram (After Serial Number E15526)

COND FAN

SR

COMP

R

S

EVAP FAN

COOLER UNIT 00918151

DOOR

HEATER

FASCIA

HEATER

100w45w

CABINETCABINET

BOTTOMTOP

(RTD2)

PROBE

EVAPORATOR

t°

PROBE

(NTC1)

t°

1 2

21

22

G + -G + -

RED

RED

WHT

WHT

RED

RED

RED

J26 J27 J29 J28 J20 J24

(NTC2)

Control PC Board

PROBE

32

04

2 4

K8

1 3

01

09

O/L

C

NEMANEMA

60

ML-2RML-2P

62

61

63

64

24

23

30

04

1

40

2

3

4

5

11

1

41

2

14

3

12

4

15

5

19

1

20

2

02

06

17

18

09

07

10

13

17

16

10

08

19

25

BAT2 9V

BAT1 9V

42

BACKING

PLATE

J19

J6

NC

J42

NO

J4

C

J18

J17

J15

J12

J8

J5

J10

J13

J14

J11

J7

J9

(RTD1)

+

+

J1

REMOTE

K1

K7

EVAP FAN

K6

DOOR HTR

K5

LEDS

K2

t°

J23

COOLER

SWITCH

BAT3 9V

Recorder

+-GG+-

DOOR

NC

Chart

Signal

+

J3

+

5-15P

31

INTERIOR LIGHTING

24 VDC 1 A

15Amp

-V +V

24 VDC

POWER

36 W

SUPPLY

CL II

N L

120Vac

L1

1

01

GND

2

39

N

3

05

02

J40

07

ON/OFF SWITCH

J31J32J33J34

J30

32

26

08

03

16

27

J35

J37J38J39J41

J36

18

05 & 06

13

J21 J22

70

73

72

75

74

5 4 2 1

Chart

Recorder

Transformer

71

76

Component Details

Compressor amperage

RLA - 7.6A, LRA - 44.5A

Compressor winding resistances

C-S (5.2Ω - 5.9Ω), C-R (1.2Ω - 1.3Ω)

Evaporator fan motor amperage

FLA - 0.22A

Condenser fan motor amperage

FLA - 0.46A

00926170 – REF20/25 LB, PH, BB Component Details 31

Page 32

Wiring diagram (Serial Numbers D61742— E15526)

115 VAC

L1

1φ, 60 Hz

BLK

010203

K8

ON/OFF

20A

16

K6

07

BACKUP

9 V

DOOR SW

PROBE

BOTTOM

PROBE

(RTD2)

EVAP

PROBE

(NTC1)

04

17

K7

09

+

MAGNET

TOP

(RTD1)

BLK

+

BLK

BLK

RED

RED

WHT

RED

RED

WHT

COMPRESSOR

O/L

RED

K8

J30

+

RED

-

BLK

WHT

J20

WHT

+

GND

+

GND

21

J28

22

J23

(CSIR)

J26

J27

COND FAN

C

12 VDC

PCB

+

R

S

EVAP FAN

T1

12 VDC

K6

K2

K2

START RELAY

J36

0-5 VDC

J24

OUT

TXD +

J19

TXD -

GND

J1

K1

-

K7

K5

K1

SR

N/C

N/C

GND

N

WHT

GRN/YEL

SR

RED

WHT

216-259 μF

220 VAC

05

06

18

32

INTERIOR

LINER

39

38

37

+

19

TO CHART

RECORDER

RJ11

6P/4C

REMOTE

ALARM

1 A 24 V

LCD

23

RED

RS485

HOT KEY

I/O PORT

24

-

5V

42

20

25

+

24VDC

POWER

26

SUPPLY

L

K5

11

08

10

60

12

63

DOOR/FASCIA

HEATERS

BLK

70

41

62

+

BACKUP

9 V

WHT

RED

BLK

30

_

BLK

27

N

36

61

64

CHART RECORDER

1+4

+

12 VDC

-

76

14

15

2+5

0-5 VDC

31

13

73

+

RED

-

IN

BLK

FROM

PCB

32 Component Details 00926170 – REF20/25 LB, PH, BB

Page 33

Wiring diagram (Serial Numbers D61742— E15526)

COND FAN

COMP

SR

R

C

S

EVAP FAN

COOLER UNIT 00918151

DOOR

HEATER

FASCIA

HEATER

100w45w

CABINETCABINET

BOTTOMTOP

(RTD2)

PROBE

t°

EVAPORATOR

PROBE

(NTC1)

t°

1 2

21

22

G + -G + -

RED

RED

WHT

WHT

RED

RED

RED

J26 J27 J29 J28 J20 J24

(NTC2)

Control PC Board

NEUTRAL

PROBE

32

04

2 4

K8

1 3

01

09

O/L

04

1

40

2

3

4

5

NEMANEMA

60

ML-2RML-2P

62

61

63

64

24

23

30

11

1

41

2

14

3

12

4

15

5

19

1

20

2

02

06

17

18

09

07

10

13

17

16

10

08

19

25

BAT2 9V

BAT1 9V

42

BACKING

PLATE

J19

J6

NC

J42

NO

J4

C

J18

J17

J15

J12

J8

J5

J10

J13

J14

J11

J7

J9

(RTD1)

+

+

J1

REMOTE

K1

K7

EVAP FAN

K6

DOOR HTR

K5

LEDS

K2

HOT

t°

J23

COOLER

SWITCH

BAT3 9V

Recorder

+-GG+-

DOOR

NC

Chart

Signal

J3

+

+

5-15P

31

INTERIOR LIGHTING

24 VDC 1 A

120Vac

15Amp

24 VDC

36 W

CL II

-V +V

POWER

SUPPLY

N L

L1

1

01

GND

2

39

N

3

05

02

J40

ON/OFF SWITCH

J31J32J33J34

J30

32

26

08

07

03

16

27

J35

J37J38J39J41

J36

18

05 & 06

13

J21 J22

70

73

72

75

74

5 4 2 1

Chart

Recorder

Transformer

71

76

Component Details

Compressor amperage

RLA - 7.6A, LRA - 44.5A

Compressor winding resistances

C-S (5.2Ω - 5.9Ω), C-R (1.2Ω - 1.3Ω)

Evaporator fan motor amperage

FLA - 0.22A

Condenser fan motor amperage

FLA - 0.46A

00926170 – REF20/25 LB, PH, BB Component Details 33

Page 34

Wiring diagram (Before Serial Number D61742)

115 VAC

L1

1 , 60 Hz

BLK

010203

K7

ON/OFF

20A

16

K6

BACKUP

9 V

MAGNET

DOOR SW

PROBE

BOTTOM

PROBE

EVAP

PROBE

(NTC)

4

17

TOP

(RTD)

(RTD)

GND

N

COND FAN

WHT

GRN/YEL

05

39

3837

BLK

COMPRESSOR

(CSIR)

O/L

START RELAY

R

C

SR

SR

WHT

216-259

220 VAC

07

µF

S

EVAP FAN

0-5 VDC

OUT

TXD +

TXD -

J1

K1

J36

N/C

GND

N/C

-

RED

+

TO CHART

RECORDER

-

5V

RJ11

REMOTE

ALARM

1 A 24 V

LCD

RS485

HOT KEY

I/O PORT

6P/4C

RED

J26

J27

T1

12 VDC

PCB

12 VDC

J24

J19

J30

+

BLK

BLK

+

RED

RED

WHT

RED

RED

WHT

RED

BLK

WHT

WHT

J23

-

J20

+

GND

+

GND

21

J28

22

+

+

K7

18

INTERIOR

LINER

K6

K5

K1

K2

24

K2

23

19

RED

42

20

25

+

24VDC

POWER

26

SUPPLY

L

K5

11

08

10

60

63

12

DOOR/FASCIA

HEATERS

BLK

70

WHT

41

62

RED

+

BLK

CHART RECORDER

BACKUP

30

_

BLK

27

N

36

61

64

1+4

+

12 VDC

-

76

14

15

2+5

0-5 VDC

31

13

73

+

RED

-

IN

BLK

FROM

PCB

34 Component Details 00926170 – REF20/25 LB, PH, BB

Page 35

Wiring diagram (Before Serial Number D61742)

COND FAN

COMP

SR

R

O/L

S

EVAP FAN

C

1

40

2

3

4

5

04

07

17

18

42

BAT2 9V

BAT1 9V

BACKING

+

+

PLATE

(RTD1)

PROBE

t°

(RTD2)

RED

WHT

RED

RED

CABINETCABINET

BOTTOMTOP

PROBE

G+ -G+ -

G+ -G+ -

WHT

t°

RED

RED

(NTC2)

EVAPORATOR

PROBE

(NTC1)

t°

21

21

22

DOOR

SWITCH

NC

BAT3 9V

Chart

Recorder

Signal

J3

+

+

DOOR

HEATER

FASCIA

HEATER

5-15P

100w

45w

24

31

INTERIOR LIGHTING

(+24VDC 35W)

J40

K1

K7

K6

K3

K4

K5

K2

J1

08

REMOTE

COOLER

EVAP FAN

PAN HTR

DEFROST HTR

DOOR HTR

LEDS

J31J32J33J34

16

0302

J23

J26J27 J29J28 J20J24

Control PC Board

J37J38J39J41

J30

26

27

18

J36

07

05

J35

13

J19

J6

NC

J42

NO

J4

04

NEMANEMA

60

ML-2RML-2P

62

61

63

64

23

30

120Vac

15Amp

11

1

2

3

4

5

1

20

2

36

L1

1

GND

2

N

3

41

14

12

15

19

-V +V

POWER

SUPPLY

NL

01

39

05

10

13

25

13

01

02

17

16

10

18

07

C

J18

J17

J15

J12

J8

J5

J13

J10

J14

J11

J7

J9

ON/OFF SWITCH

+-GG+-

J21J22

70

73

72

75

74

54 21

Chart

Recorder

Transformer

71

76

Component Details

Compressor amperage

RLA - 7.6A, LRA - 44.5A

Compressor winding resistances

C-S (5.2Ω - 5.9Ω), C-R (1.2Ω - 1.3Ω)

Evaporator fan motor amperage

FLA - 0.22A

Condenser fan motor amperage

FLA - 0.46A

00926170 – REF20/25 LB, PH, BB Component Details 35

Page 36

Troubleshooting

Before calling for service

1. Check that unit is plugged in.

2. Test outlet with another appliance to verify power.

Problem Indicators Corrective Action

1. Power switch faulty or in OFF position;

loose connection.

Refrigerator does

not operate (no

components run).

Compressor does not

run.

Evaporator fan motor

does not run.

Refrigerator does not

shutoff.

Refrigerator does not

maintain temperature

(all components run).

2. Refrigerator not plugged in. 2. Connect plug.

3. No power at outlet. 3. Restore power.

4. Temp controller not energizing

components.

5. Probe not sensing cut-in temperature. 5. Replace controller and/or probe.

1. Thermal overload open or defective. 1. Allow to cool or replace.

2. Capacitor and/or relay defective. 2. Replace as required.

3. Compressor defective. 3. Replace compressor.

1. Defective fan motor. 1. Replace fan motor

1. Controller not sensing cut of

temperature.

2. Controller keeping refrigeration system

energized.

1. Condenser or evaporator coil needs

cleaning.

2. Door not closing. 2. Adjust door closure per page 5.

3. Excessively high ambient. 3. Maximum recommended ambient is 100 F.

4. Refrigerant leak. 4. Locate and repair leak.

5. Incorrect refrigerant charge. 5. Recover, evacuate and weigh in correct

6. Plugged capillary tube. 6. Replace capillary tube.

7. Inefficient compressor. 7. Consult technical service.

8. Faulty door gasket. 8. Replace door gasket

1. Turn power switch to ON position; check

switch and connections.

4. Check controller contact terminals for

power. Replace controller if needed.

1. Replace controller and/or evaporator

(NTC1) probe.

2. Replace controller.

1. Clean coils as needed.

charge.

If problems persist after following this basic troubleshooting guide, call Follett’s technical service group at

(877) 612-5086 or +1 (610) 252-7301.

36 Troubleshooting 00926170 – REF20/25 LB, PH, BB

Page 37

Appendix

Control key functions

MENU

Enter main menu

Back

Return to prior

Buttons to select

screen options

Scroll up

Scroll down

ENTER

MUTE

Select

Mutes alarm

C abinet light ON/OFF

Alarm light

Menu Navigation table

Main Menu Sub menu Default setting Range Notes

If password is ON,

enter 4 digit pin

Alarm settings High alarm set 40 C (104 F) 40 to -40 C

Low alarm set 1.0 C (33.8 F) 40 to -40 C

Display settings Show bottom temp NO YES/NO

Display inverse YES YES/NO Reverse light lettering with dark background

Degrees F/C C F or C Displays temperatures in F or C

Min/Max temp Records min/max temperature and time of top probe. Up/

Batt = _V OK Shows status of (2) 9V batteries.

Refrigeration

controls (press

and hold down-

arrow and ENTER

for 3 seconds)

Password ON/OFF OFF ON/OFF

PIN 3843 0000-9999 Any four digit PIN can be stored beside the permanent

Set Time/Date Adjust with up/down arrow, next moves to next digit, press

Set alarm volume High High/Med/Low Buzzer volume

Alarm silence ON ON/OFF Audible alarm

Calibration Cal top probe Adjust with up/down arrow, press enter to set

Refrig. setpoint 0.5 C (32.9 F) 40 to -40 C

Differential 5.0 C (9.0 F) 3.0 to 6 C

High setpoint limit 5.0 C (41.0 F) 40 to -40 C

Low setpoint limit -1.5 C (29.3 F) 40 to -40 C

Door heater cycle 0% 0 to 100% Heater on percent (50% for heated door option)

On time 4 min 2-14 min Compressor on time

Off time 8 min 2-14 min Compressor off time

Temp sensors Displays probe temperatures

3843 0000-9999 Adjust with up/down arrow, next moves to next digit, press

enter to set

Default is set high to not alarm on initial cool down

(104 to -40F)

(104 to -40F)

down arrow displays min/max. Enter to reset.

Cal bottom probe Adjust with up/down arrow, press enter to set

(104 to -40F)

(5.4 to 10.8 F)

(104 to -40F)

(104 to -40F)

factory default. Adjust with up/down arrow, next moves to

next digit, press enter to set.

enter to set

00926170 – REF20/25 LB, PH, BB Appendix 37

Page 38

Replacement parts

Unit cooler

6

1

7

8

3

4

5

2

Reference Description Part #

Not shown Gasket, unit cooler 00912980

Not shown Probe, evap, NTC 00940148

1 Unit cooler with mounting bolts and gasket 00939785

2 Evaporator fan motor with blade 00945311

3 Condenser fan motor with blade 01179704

Not shown Cap tube and drier 00945378

4 Compressor with start capacitor, relay and overload 01096015

5 Start capacitor 01077734

Not shown Start relay 00945360

Not shown Compressor overload 00945386

6 Evaporator 00945766

7 Condenser 00945774

8 Fan guard, condenser 00945782

Not shown Cord and plug kit 00939900

38 Replacement parts 00926170 – REF20/25 LB, PH, BB

Page 39

Cabinet

7

8

6

2

3

9

5

9

1

4

Reference Description Part #

1 Caster, swivel with brake 00187674

2 Bracket, bottle, 125ML 00171132

3 Drawer, assembly, REF25 00939652

3 Drawer, assembly, REF20 00939660

4 Slide, drawer, REF25 (set of 2) 00193045

4 Slide, drawer, REF20 (set of 2) 00188367

5 Bottle with gasket 01015 8 17

Not shown Basket, assembly, REF25 00939710

Not shown Basket, assembly, REF20 00939728

6 Shelf, REF25 (with supports) 01015841

6 Shelf, REF20 (with supports) 01015858

7 Pilaster 00901173

Not shown Pilaster, screws 00902213

8 Support, shelf 00156240

Not shown Air panel 00901561

Not shown Probe, RTD, top 00918839

Not shown Probe, RTD, NIST calibrated, top 01101096

Not shown Probe, RTD, bottom 00988055

Not shown Probe, RTD, NIST calibrated, bottom 0110110 4

Not shown Plug, RTD probe 00919274

Not shown Panel jack, female 00918847

9 Cover, thermal break (4 pieces) 00922997

Not shown Channel, probe 01004159

Not shown Bushing, probe channel (LB and PH require 2, BB requires 3) 001111 0 4

Not shown LED, light strip 00980912

Not shown Wire clip, probe 00919910

Not shown Glycerine (1 pint) 00959296

Not shown LEDs (2), MOV and instructions 01049709

00926170 – REF20/25 LB, PH, BB Replacement parts 39

Page 40

Facade

1

13

6

12

11

2

5

3

9

8

10

4

7

Reference Description Part #

1 Chart recorder 00906198

2 LED power supply 00939801

3 Controller (for serial numbers above D61742) 00918169

3 Controller (for serial numbers below D61742) 01009729

Not shown Kit, door switch 00939959

4 Male, bayonet (strike, snap) 00179549

5 Facade, locking clip 00931501

6 Complete facade assembly with chart recorder 01007293

6 Complete facade assembly without chart recorder 01007301

7 Facade, cover, with chart recorder 00940130

Not shown Facade, cover, without chart recorder 00940155

8 Pens, chart recorder, red (box of 6) 00918813

Not shown Charts (box of 50) in degrees C 00918821

Not shown Charts (box of 50) in degrees F 00967729

9 Battery, 9V 00112177

10 Latch, touch 00901165

11 Shell, upper side REF25 00940098

11 Shell, upper side REF20 00925933

Not shown Top ventilated cover 00991760

12 Control relay, compressor (for serial numbers above D61742) 00980482

Not shown Bottom probe, resistor 01041342

Not shown MOV assembly 01042258

Not shown Back support 00991695

13 Female, fastener 00179556

40 Replacement parts 00926170 – REF20/25 LB, PH, BB

Page 41

Door assembly

13

2

Reference Description Part #

Not shown Door gasket 00945345

Not shown Left-hand, non-heated door 00939876

1 Right-hand, non-heated door 00939884

2 Right-hand hinges and hardware with black colored hold open bracket 00996579

Not shown Left-hand hinges and hardware with black colored hold open bracket 00996587

Not shown Left-hand hinges and hardware with steel colored hold open bracket 00939918

Not shown Right-hand hinges and hardware with steel colored hold open bracket 00939926

Not shown Door magnet kit 00939967

Not shown Bracket, strike 00939983

Not shown Left-hand heated door 00939991

Not shown Right-hand heated door 00940007

Not shown Key, door 00945436

3 Lock, door 00945444

Not shown Soft port kit 00940122

Not shown Wall bracket kit, seismic anchoring 00927194

Not shown Kit, Pyxis bracket 00927202

Not shown Kit, Omnicell 00966432

00926170 – REF20/25 LB, PH, BB Replacement parts 41

Page 42

42 Replacement parts 00926170 – REF20/25 LB, PH, BB

Page 43

00926170 – REF20/25 LB, PH, BB Replacement parts 43

Page 44

801 Church Lane • Easton, PA 18040, USA

Toll free (877) 612-5086 • +1 (610) 252-7301

www.follettice.com

00926170R09

© Follett LLC 6/17

Loading...

Loading...