Page 1

Horizon Elite™ Ice Machine Installation Instructions

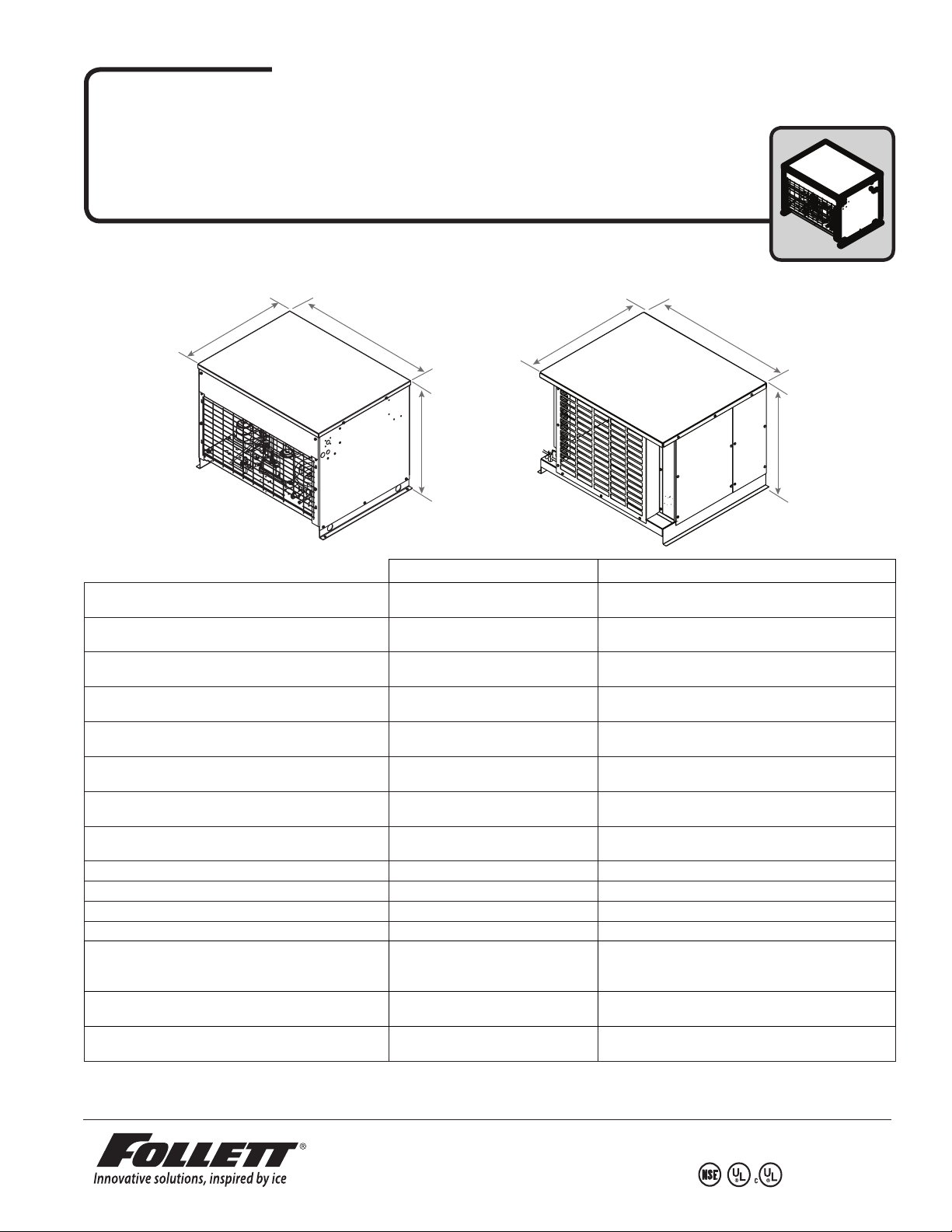

HCD/HMD/HCF/HMF1010R _ _

HCD/HMD/HCF/HMF1410R _ _

for Remote Condensing Unit

1010/1410 single phase (Tecumseh)

1010 three phase (Tecumseh)

D1

W1 Width 36.25" (91.4 cm) – all models 36.25" (90.1 cm) – single phase (Tecumseh)

D1 Depth 25.50" (64.8 cm) – all models 25.50" (64.8 cm) – single phase (Tecumseh)

H1 Height 26.10" (66.3 cm) – all models 26.10" (66.3 cm) – single phase

Electrical single phase – 208-230/60/1

Operating power single phase – 2.4 kW

Minimum circuit ampacity single phase – 10.7 A

Maximum overcurrent protection single phase – 15 A

Outdoor condensing unit operating limits

(air temperature)

Maximum refrigerant line run length 100' (30.5 m) 100' (30.5 m)

Maximum line rise above evaporator 35' (10.7 m) 35' (10.7 m)

Evaporator mounting above condenser 15' (4.6 m) 15' (4.6 m)

Maximum refrigeration line drop without oil trap 15' (4.6 m) 15' (4.6 m)

Refrigerant charge 12.5 lb required at installation 12.5 lb – single phase (Tecumseh)

Approximate ship weight 260 lb (118 kg) 270 lb (122 kg) – single phase (Tecumseh)

Approximate net weight 250 lb (114 kg) 260 lb (118 kg) – single phase (Tecumseh)

W1

H1

Horizon Elite 1010 series Horizon Elite 1410 series

three phase – 208-230/60/3

three phase – 2.2 kW

three phase – 9.9 A

three phase – 15 A

min -20 F (-29 C)

max 120 F (49 C)

1410 three phase (Larkin)

D1

37.75" (95.9 cm) – three phase (Larkin)

28.25" (71.6 cm) – three phase (Larkin)

19.75" (50.2 cm) – three phase (Larkin)

single phase – 208-230/60/1 (Tecumseh)

three phase – 208-230/60/3 (Larkin)

single phase – 4.2 kW (Tecumseh)

three phase – 3.0 kW (Larkin)

single phase – 19.3 A (Tecumseh)

three phase – 15 A (Larkin)

single phase – 30 A (Tecumseh)

three phase – 15 A (Larkin)

min -20 F (-29 C)

max 120 F (49 C)

8.5 lb – three phase (Larkin)

required at installation

230 lb (104 kg) – three phase (Larkin)

210 lb (95 kg) – three phase (Larkin)

W1

H1

801 Church Lane • Easton, PA 18040, USA

Toll free (877) 612-5086 • +1 (610) 252-7301

www.follettice.com

01113356R02

Page 2

Prior to installation, carefully unpack and inspect the

contents of your condensing unit!

Site preparation

To ensure proper performance, ease of service and warranty coverage, it is critical that you follow

the requirements detailed in this manual. If you cannot meet these requirements or have questions,

call our technical service group at 877.612.5086 for installation support.

1

2.1

1. 1

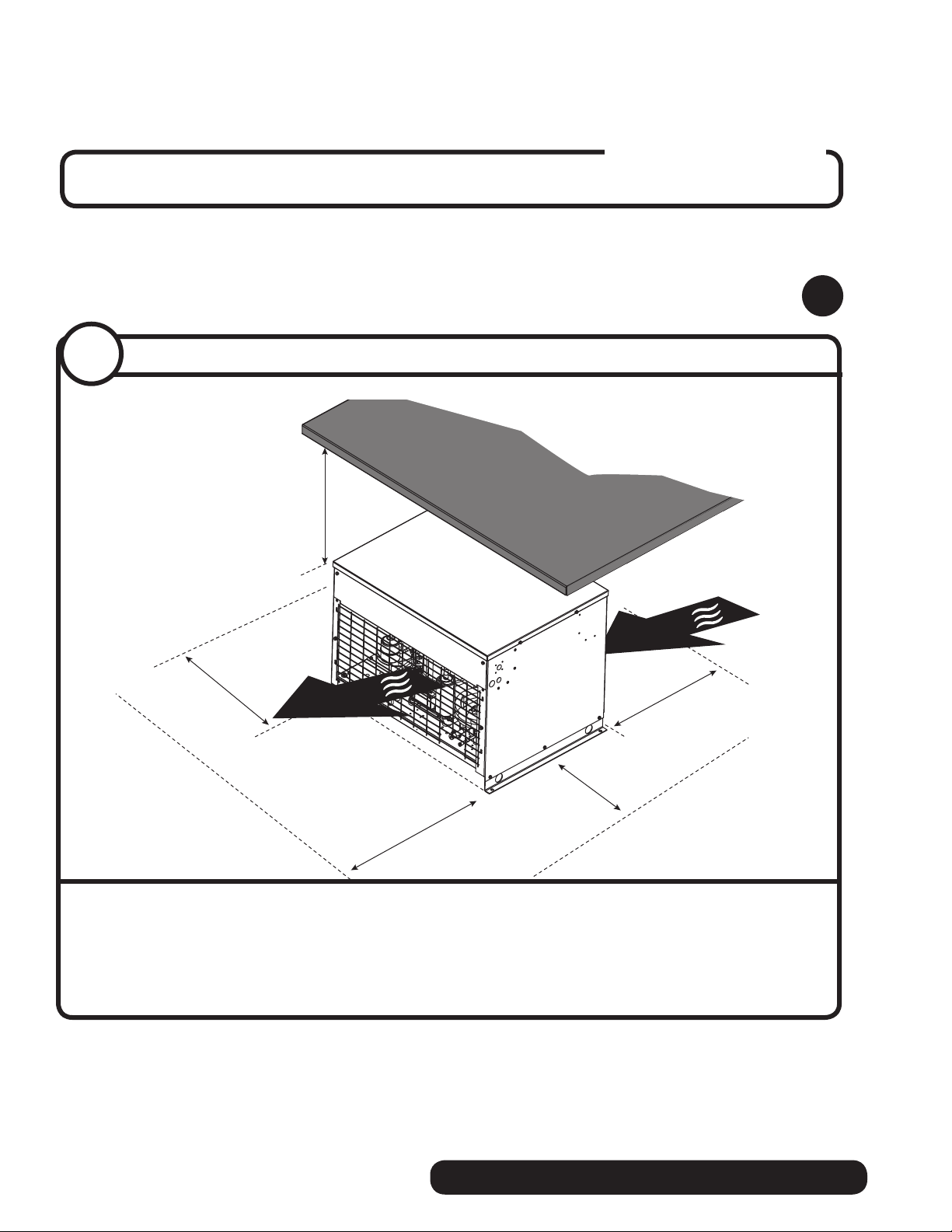

Condenser Unit Clearances

min. 36.00"

(91.4 cm)

exhaust

24.00"

(61.0 cm)

air in

48.00"

(121.9 cm)

24.00"

(61.0 cm)

• Position condenser unit as shown.

Required clearances:

§ Mininum 48” (121.9 cm) front and back

§ Minimum 24” (61.0 cm) left and right

§ Minimum 36” (91.4 cm) above

2

48.00"

(121.9 cm)

REMOTE CONDENSING UNIT

Page 3

2.1

1. 2

Condenser installation specications

S-trap

required

Easton Pennsylvania

CORPORATION

PART NO

SERIAL NO

MODEL

SINGLE

FULL LOAD AMPS

HZ

VOLTS

PHASE

MOTOR COMPRESSOR THERMALLY PROTECTED

OZ

CHARGE

REFRIGERANT

PSIG

DESIGN PRESSURE HIGH SIDE

LOW SIDE

208264

MIN. BRANCH CIRCUIT AMPACITY

AMPS

Stock Module Identification Plate

MADE IN

ULU

NSF

THE USA

L

RR

Module No.

MAX. BRANCH CIRCUIT FUSE SIZE

AMPS

C

Product

Service No.

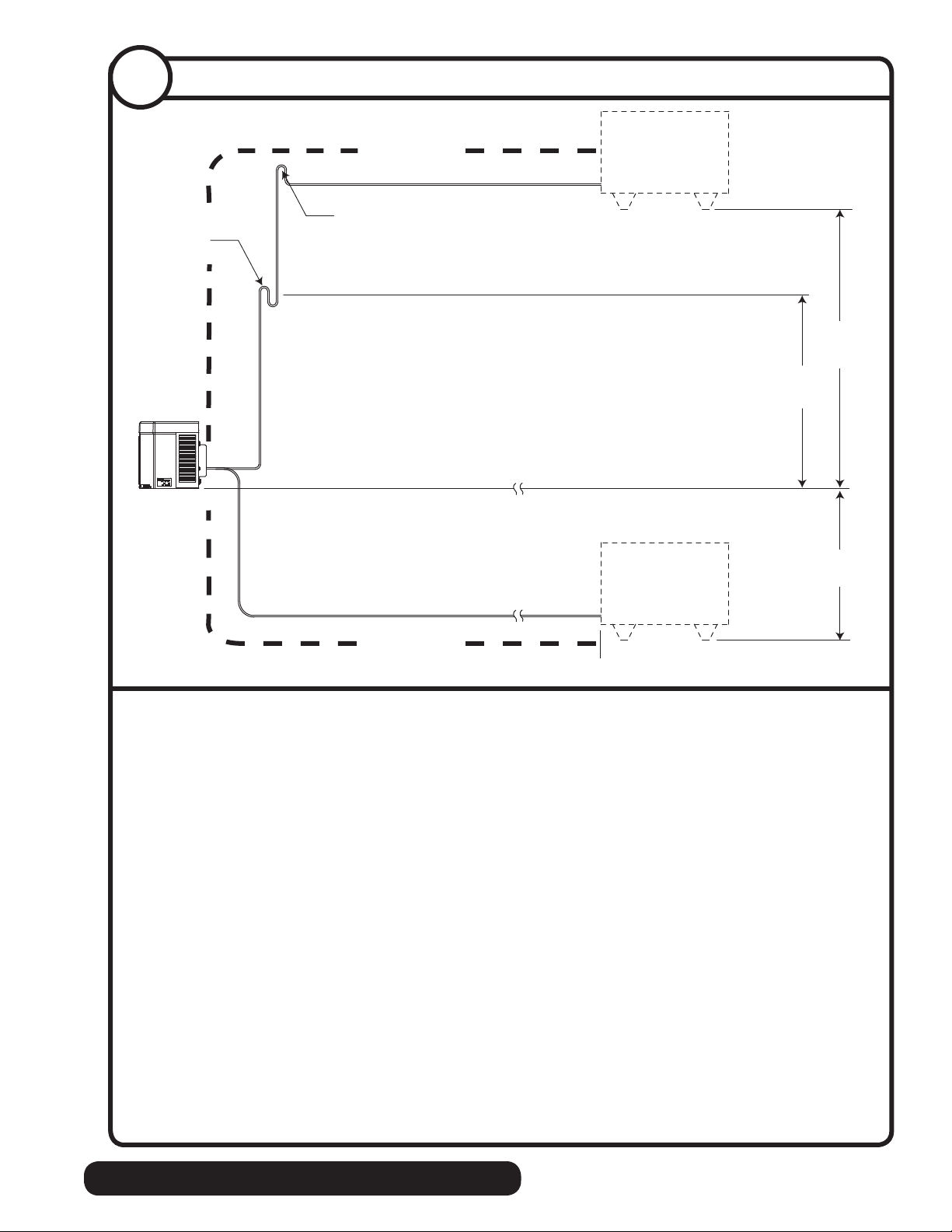

EVAPORATOR

UNIT

➊

100' max.

(30.5 m)

➍

➊

P-trap

required

EVAPORATOR UNIT LEVEL

CONDENSER UNIT

maximum

line rise

CONDENSER UNIT

maximum

line drop

➋

+35'

(+10.7 m)

+20'

(+6.1 m)

–15'

(–4.6 m)

100' max.

(30.5 m)

➌

➍

Site layout:

• Outdoor ambient temperature range: –20 F to 120 F (–29 C to 49 C)

• Installation with condenser unit elevations above 20' (6.1 m) require an S-trap at the midpoint

of the rise and a P-trap at the top of the rise

➊

• Maximum line rise must not exceed 35' (10.7 m) ➋

• Maximum line set length must not exceed 100' (30.5 m)

• Maximum line drop must not exceed 15' (4.6 m)

➍

➌

REMOTE CONDENSING UNIT

3

Page 4

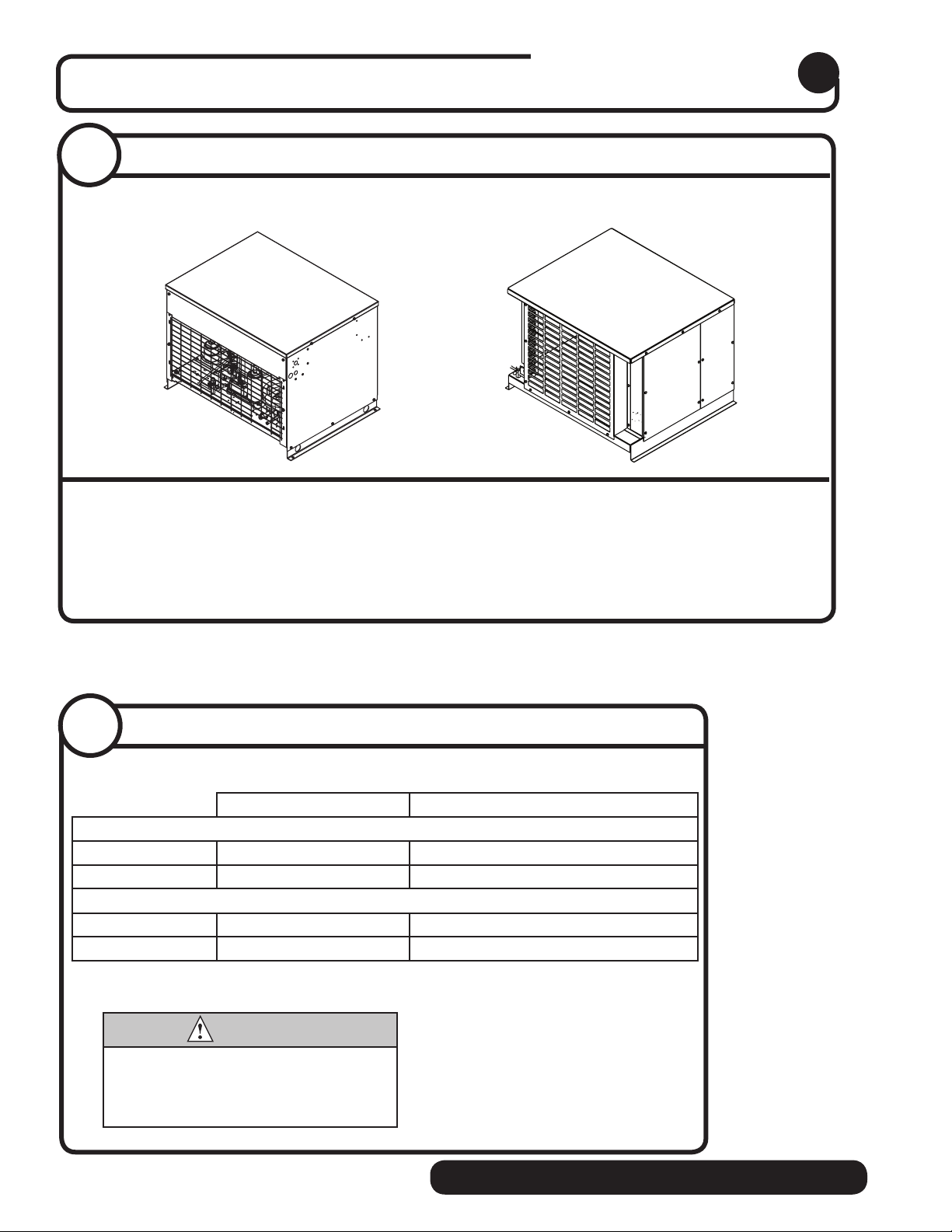

Condenser installation

2

2.1

• Level unit

• Securely attach base of unit using holes found in base plate

• Required rack system capacity at 0 F (-18C) evaporator (EPR supplied by installer).

1010N: 7,700 Btu/hr (1940 kcal/hr)

1410N: 10,000 Btu/hr (2519 kcal/hr)

Install condensing unit

1010/1410 single phase

1010 three phase

1410 three phase (Larkin)

2.2

Horizon Remote Single-Phase 208-230/60/1)

Horizon Remote Single Phase (208-230/60/1)

1010 10.7A 15A

1410 19.3A 30A

Horizon Remote 3 Phase (208-230/60/1)

1010 (Tecumseh) 9.94A 15A

1410 (Larkin) 15A 15A

• Refer to wiring schematic located in condenser unit electrical box

Electrical requirements

Min Circuit Ampacity Max Overcurrent Protection (MOP)

CAUTION

• Electrical disconnects required within

10' (3 m) for all hard wired connections

• Install in accordance with NEC and local

electrical codes

4

REMOTE CONDENSING UNIT

Page 5

2.3

Electrical connections at contactor

Single Phase

POWER SUPPLY

230-60-1

Three Phase

POWER SUPPLY

230-60-3

ELECTRICAL

DISCONNECT

L3

L2

L1

GRD

CRANK CASE

HEATER

ELECTRICAL

DISCONNECT

L3

L2

L1 T1

GRD

• Electrical disconnects required within 10' (3 m) for all hard wired

connections.

• Install in accordance with NEC and local electrical codes.

T3

T2

T1

COMPRESSOR CONTACTOR

NC AUXILIARY SWITCH

L1

T1

COMPRESSOR

CONTACTOR

• Electrical disconnects required within 10' (3 m) for all hard wired

connections.

• Install in accordance with NEC and local electrical codes.

T3

T2

L2

T2

L3

T3

2.4

COMPRESSOR

CONTACTOR NC

CRANK CASE

HEATER

AUXILIARY SWITCH

Condensing unit refrigeration line-set connection point

(Tecumseh unit shown, but location is same for all units)

L1

T1

L2

T2

1010/1410:

5/8" suction

3/8" liquid

L3

T3

REMOTE CONDENSING UNIT

5

Page 6

Refrigeration line installation

3

3.1

Refrigeration line installation: 5/8" suction / 3/8" liquid line (1010, 1410)

CAUTION

• The installer of the refrigeration line set must be USA Government Environmental Protection Agency (EPA)

certied in proper refrigeration handling and service procedures

• A qualied person must perform all roof or wall penetration

• Do not form unwanted traps in refrigeration lines. A service loop is not considered an oil trap.

• Never coil excess refrigeration tubing

• The compressor oil rapidly absorbs moisture. Minimize the exposure of the refrigeration system by not releasing

the condenser unit or evaporator unit holding charge until all line connections are nished and the system is

ready for evacuation.

WARNING

• This unit contains an R404A holding charge

1. Make and connect line set run from the condensing unit to the evaporator unit with all

specications found in the installation specications section. Do not overheat shut off valves on

the condenser unit or evaporator unit.

Note: Insulate entire suction line (not the liquid line) including shut off valves to prevent

condensation.

2. Leak check eld joints via the evaporator unit service valves.

3. Evacuate line set via the evaporator unit service valves.

R404A Ice Machine Charge Specications

Line Run Total Charge 1010/1410 single phase,

1010 three phase (Tecumseh)

0 - 100' (0 - 30.5 m) 12.5 lb (5.7 kg) 8.5 lb (3.9 kg)

100’ + (30.5 m+) not recommended – consult factory

Note: Condensing unit shipped with 0.5 lb R404A charge.

Total Charge 1410R three phase (Larkin)

5. Open the liquid line service valve and suction line service valve on the evaporator unit and

condenser unit.

6. Open the liquid line valve on the receiver, then the suction line valve on the compressor unit.

7. Liquid charge unit through liquid line shut off valve on the evaporator unit or receiver valve on

the condensing unit.

8. Isolate the refrigerant tank from high pressure side on the system.

9. Turn on power to condensing unit and evaporator unit.

10. Complete system charge through low pressure side.

6

REMOTE CONDENSING UNIT

Page 7

Pressure adjustment

4

4.1

Set low-pressure switch - if applicable

DIFFERENTIAL

ADJUSTMENT

SCREW

CUT-IN

ADJUSTMENT

SCREW

1) Adjust the top LEFT screw

2) Adjust the top RIGHT

until the pointer is set to 10

(the dierential).

screw until the pointer

is set to 20 (the cut-in).

Dierential

EXAMPLE

Cut In

20 - 10 = 10

10

Dierential

3.0

2.0

1.0

LBS.

KG.

CUT OUT IS

DIFFERENTIAL

40

30

20

10

CUT IN

MINUS

10

20

40

60

80

100

LBS.

Hail hood

1.0

4.0

5.5

7.0

KG.

0

Cut Out

Cut In

20

5

5.1

Install hail hood (Tecumseh units only)

Please remove the condenser enclosure

top to access the following parts:

• Left and right brackets (not

interchangeable)

• Hail hood

• 1/4 x 20 x 1/2 hex head screw (10)

1

2

1. Locate the left bracket (1)

and install using two supplied

screws (2).

2. Locate the right bracket (3)

and install using two supplied

2

3

4

screws (4).

4

REMOTE CONDENSING UNIT

7

Page 8

3. Install hail hood (5) to brackets using the

remaining six screws (6).

Note: The bottom hole in the bracket is not

used when mounting the hail hood (7).

5.1

1. Hail hood comes factory

Install hail hood (Larkin units only)

mounted. To remove hood for

condenser cleaning, please

remove the four (4) hex head

screws. Reinstall after cleaning

using the same four screws.

Hex Head

Screws

6

7

NOT USED

5

8

REMOTE CONDENSING UNIT

Page 9

Start up and test

NOTICE

Ice machine MUST be cleaned and sanitized prior to operation!

Consult Operation and Service Manual provided with ice machine for cleaning and sanitizing instructions.

6

6.1

Verify operation

• Turn dispenser power ON if applicable

• Check current draw of compressor to verify correct electrical operation

• Put a piece of ice on bin thermostat or hold a cup under the shuttle actuator on the bin/

dispenser to verify that the evaporator unit shuts OFF; condensing unit pumps down and

shuts off.

• After shut off, restart the ice machine

Horizon Condenser Unit Compressor Amperage

Single Phase

Model Number Condensing Unit Running amps (+/- 10%)

1010R

01075365

1410R

01075373

Three Phase

Model Number Condensing Unit Running amps (+/- 10%)

1010R

01113 125

1410R

01113 133

1410R

01278373

AJA7490ZXDPN (Tecumseh) 7. 4

AWA9513ZXDPN (Tecumseh) 13.7

AWA9490ZXTPN (Tecumseh) 6.7

AWA9517ZXTPN (Tecumseh) 9.9

LZT015M6CFIM (Larkin) 10.7

REMOTE CONDENSING UNIT

9

Page 10

10

REMOTE CONDENSING UNIT

Page 11

REMOTE CONDENSING UNIT

11

Page 12

Harmony, Horizon, Horizon Elite, Ice Manager, and Vision are trademarks of Follett LLC.

Chewblet, RIDE and Follett are registered trademarks of Follett LLC, registered in US.

801 Church Lane • Easton, PA 18040, USA

Toll free (877) 612-5086 • +1 (610) 252-7301

www.follettice.com

01113356R02

© Follett LLC 7/19

Loading...

Loading...