Follett HCD1650NHS User Manual

Features

Horizon Chewblet ice machine with up to 1580lb

(717 kg) dailyproduction of customer preferred

Chewblet ice

- automatically transport ice through a tube with

RIDE® technology from up to 75' (22.8 m) away

- chewable, compressed nugget ice is preferred

over cubes

1

- Chewblet ice dispenses reliably from ice and

beveragedispensers

- available with approximately 1.00" (2.54 cm) long

standard Chewblet ice or optional 3/8" (0.95 cm)

long MicroChewblet

™

ice

- environmentally responsible R404a refrigerant with

zero ozonedepletion potential

- water and energy ecient

- quiet production without noisy harvest cycles

Durable, attractive ice machine

- regular bearing inspection or replacement is

not required

- easy-to-read LED operating status and

diagnostic display

- smooth contours for aesthetically

appealing appearance

Designed with sanitation in mind

- Agion® silver-based antimicrobial product protection

of key iceand water contact components

- aluminum-bronze evaporator has

antimicrobial properties

- automatic self-flushing reduces water scale buildup

- floatless, sealed design inhibits formation of biofilms

- semi-automatic cleaning and sanitizing system

Certifications

Warranty

- 3 years parts and labor, 5 years compressor parts

Horizon

remote 1650 series Chewblet® ice machine

Short form specification:

Ice machine to be a Follett® Horizon Chewblet ice machine model

________________ [Insert size/series,condenser type and installation/mounting,

from model number guide] capable of producing compressed nugget ice using

an ecient, sanitary horizontal evaporator/auger system and delivering ice by

a flexible wire reinforced transport tube to ice storage bin, iceand water

dispenser, ice and beverage dispenser, drop-in dispenser or Ice Manager ™

diverter valve system and provided with a stainless steel frame and exterior,

slide-out evaporator unit with utility docking station, front-mounted unit

status display, automatic self-flush, and semi-automatic cleaning and sanitizing

system, plusall the featureslisted below and mounting/performance-enhancing

accessories checked:

Horizon remote 1650 series ice machine

For use with

ice storage bin

Follett Vision™

dispenser

ice and beverage

dispenser (by others)

drop-in dispenser

(byothers)

Ice Manager diverter

valve system

All models ENERGY STAR® certified

1

Ordered separately

2

Requires Harmony™ top kit (see page 5 for part number)

NOTE: For Micro Chewblet ice, replace second character (C) with an M

e.g. HMD1650ABT

For three phase remote condensing unit, replace third character (D) with F

e.g. HCF1650RBT

1

Install/mount Condenser V/Hz/Ph Item number

top mount

RIDE

RIDE

top mount

RIDE

RIDE

RIDE

with 115/60/1 HCD1650RBT

without 115/60/1 HCD1650NBT

with 115/60/1 HCD1650RBS

without 115/60/1 HCD1650NBS

with 115/60/1 HCD1650RVS

without 115/60/1 HCD1650NVS

with 115/60/1 HCD1650RHT

2

without 115/60/1 HCD1650NHT

with 115/60/1 HCD1650RHS

without 115/60/1 HCD1650NHS

with 115/60/1 HCD1650RJS

without 115/60/1 HCD1650NJS

with 115/60/1 HCD1650RMS

without 115/60/1 HCD1650NMS

™

1 Independent third party studies. Contact Follett for details.

2 Disclaimer: Antimicrobial protection is limited to the treated components and does not treat water or ice.

Job

Item

801 Church Lane | Easton, PA 18040, USA

1.800.523.9361 | 1.610.252.7301 | follettice.com

Accessories

Harmony conversion top kit for ice and beverage

dispensers (listed on page 5)

Water filter kit (item# 00978957 – see form# 9905

fordetails)

___ ea. extra primary water filter cartridge

___ ea. extra pre-filter cartridge

Carbonless water filter kit (item# 01050442 – see form#

6380 fordetails)

Wall mount bracket (item# 00997098)

Ice machine stand, height-adjustable (item# 00128561)

Longer ice transport tube, specify length: ___ ft/m in

5'/1.5 m increments (10'/3 m is standard)

(item# 00174896)

35' (10.7 m) refrigeration lines (item# 00977785 –

not pre-charged) for 1650R

Timer to control one or two Horizon ice machines

(see accessory form# 3311)

Nu-Calgon® IMS-III sanitizer, 16 oz bottle

(item# 00979674)

SafeCLEAN™ environmentally responsible ice machine

cleaner (item#00132001)

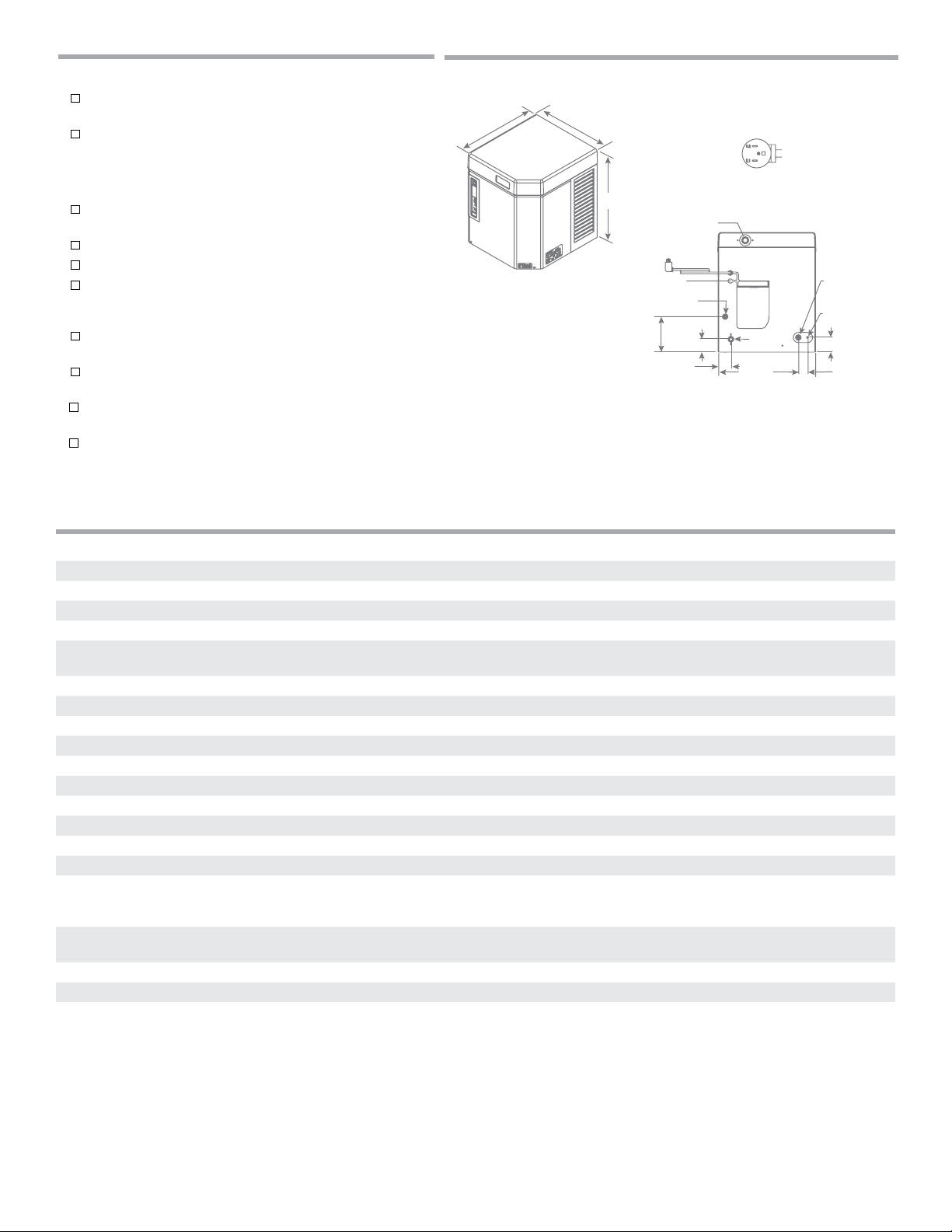

Dimensional drawing

D1

W1

H1

6.95"

(17. 65 cm)

C5

C3

2.53"

(6.43 cm)

2.50"

(6.35 cm)

C2

C1

Back View

C4

15.69"

(39.85 cm)

C7

C6

2.87

(7.29 cm)

1. 81

(4.60 cm)

Specification

W1 Width 19.30" (49.0 cm)

D1 Depth 23.77" (60.4 cm)

H1 Height 23.50" (59.7 cm)

Clearance 1.00" (2.54 cm) top, right and left

Electrical

115 V/60/1

C2 Ice transport tube see page 6 for details

C3 Water inlet 3/8" OD push-in water inlet

C4 Drain 3/4" MPT - vented T required

C5 Ice bin signal cord connection for Vision applications only

C6 Liquid line 3/8"

C7 Suction line 7/8"

Air temperature 50 -100 F (10 - 38 C)

Water temperature 45 - 90 F (7 - 32 C)

Potable water pressure 10 - 70 psi (69 - 483 kPa)

Ice production see ice production charts on page 8

Energy consumption

90 F (32 C) air,

70 F (21C) water

Water consumption 12.5 gal (47 L) of potable water per 100lb (45.4kg) of ice

Approximate ship weight 190 lb (86 kg)

NOTE: For indoor use only

C1 6 amps, requires dedicated 15 amp circuit,

7' (2 m) cord, NEMA 5-15 plug.

single phase – 4.8 kWh

three phase – 3.7 kWh

per 100lb(45.4 kg) ice

(per AHRI test standards) 13.2 gal (50 L) including periodic flushing

2

Form# 7040

Remote 1650 series ice machine

W1

D1

H1

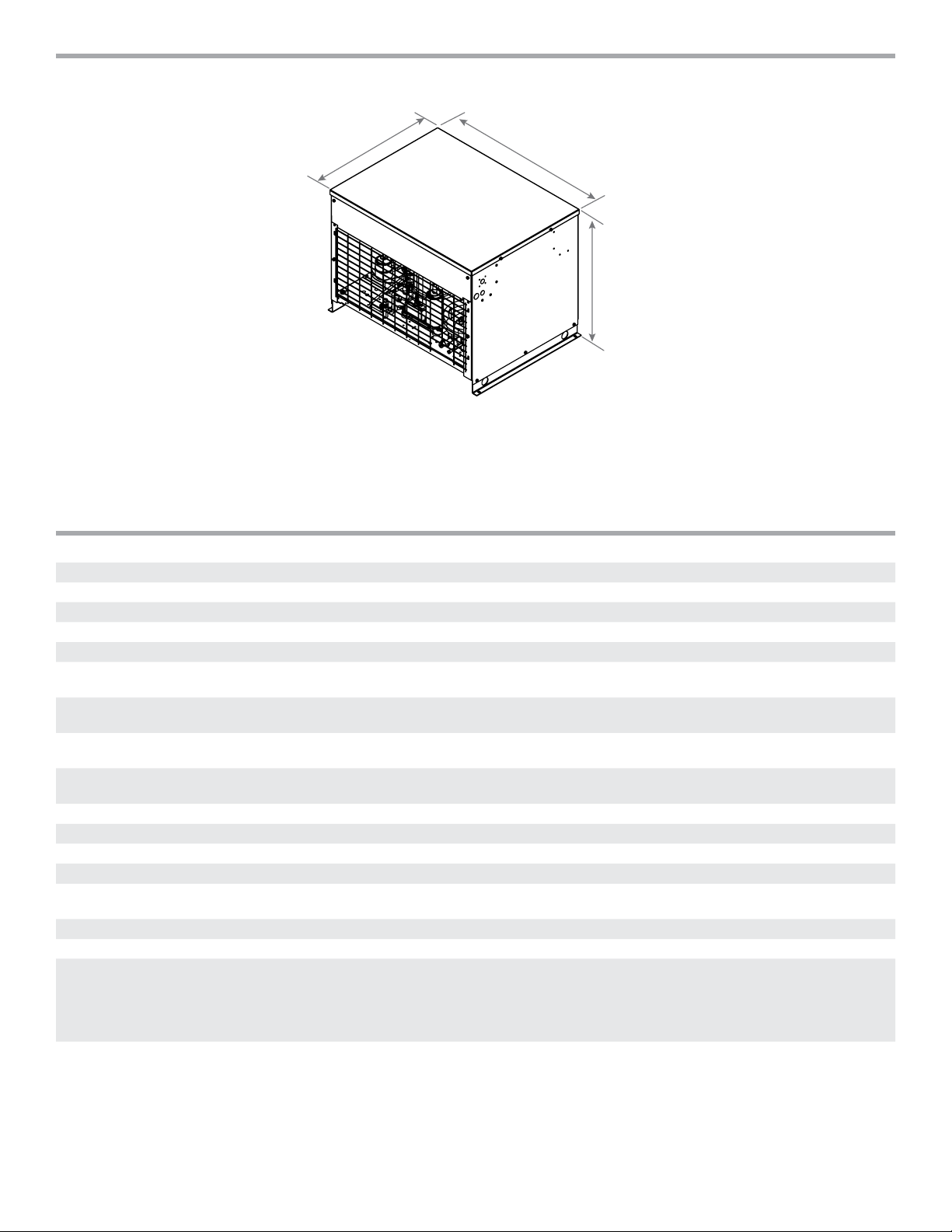

Dimensional drawing

Specification

W1 Width 36.25" (92.0 cm) - all models

D1 Depth 25.50" (64.8 cm) - all models

H1 Height 26.10" (66.3 cm) - all models

Electrical single phase 208-230/60/1

Electrical three phase 208-230/60/3

Minimum circuit ampacity single phase 29.90 A

three phase 21.24 A

Minimum overcurrent protection single phase 50 A

three phase 35 A

Electrical

208-230 V/60/3 - three phase

Cooling unit operating limits

(air temperature)

Maximum refrigerant line run length 100' (30.5 m)

Maximum line rise above evaporator 35' (10.7 m)

Evaporator mounting above condenser 15' (4.6 m)

Maximum refrigeration line drop 15' (4.6 m)

BTU/hr (Kcal/hr) at

0 F (-18 C) evaporator, 90 F (32C) ambient air, 1650N units only)

Rack systems * EPR valve - set to 0 F (-18 C)

Approximate ship weight 340 lb (154 kg)

NOTE:

1. 1650 model condensing units have a liquid suction line heat exchanger. The entire liquid line should be insulated separately from

the suction line.

2. Outdoor installation of low side is not recommended and will void warranty.

* EPR valve to be supplied by installer.

35 amps, requires dedicated

amp circuit, internal connection

min -20 F (-29 C)

max 120 F (49 C)

13,000 (3,276)

Remote 1650 series ice machine

Form# 7040

3

Loading...

Loading...