Follett C12CI400A Service Manual

12 Series - 220V 60Hz/230V 50Hz

Ice and Water Dispensers

Order parts online

www.follettice.com

Installation, Operation and Service Manual

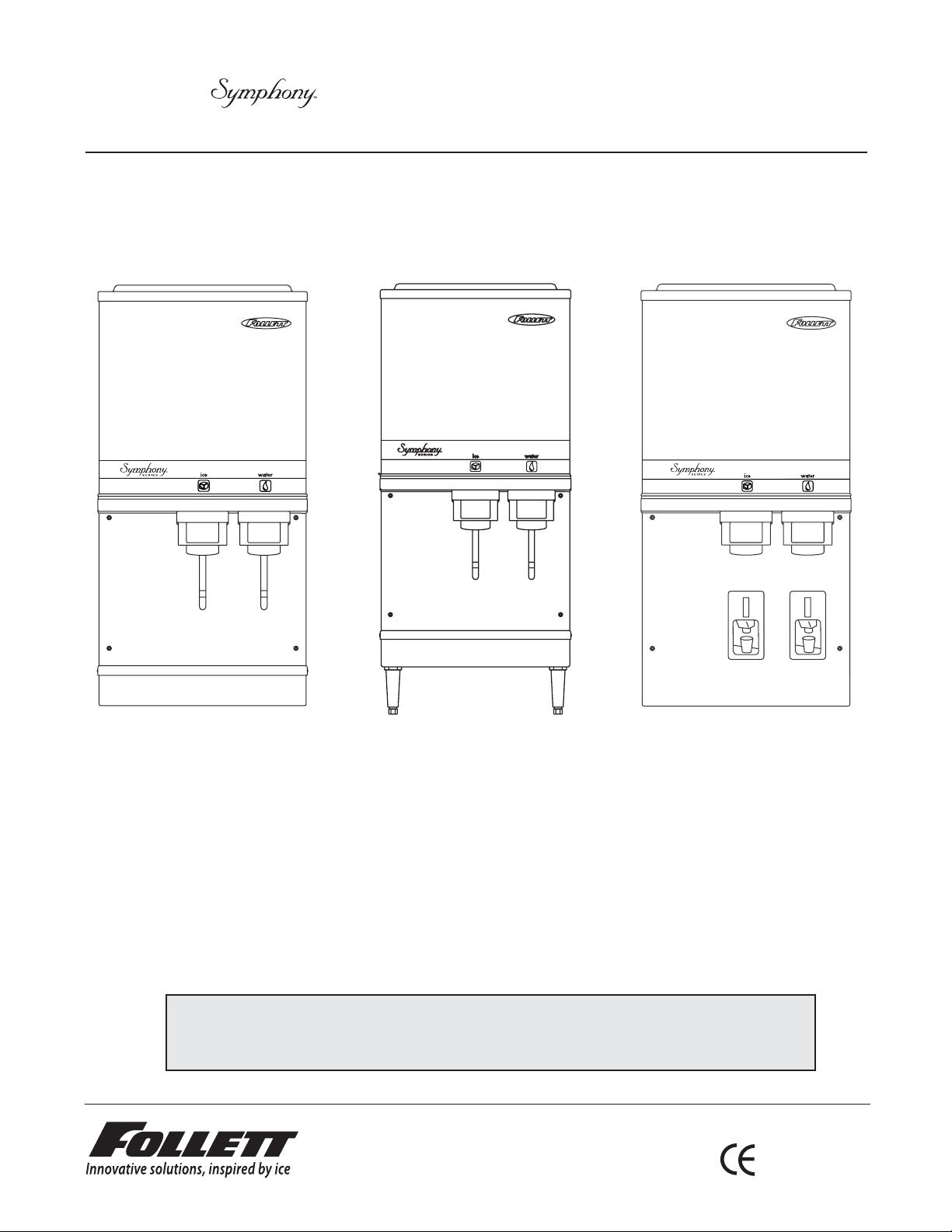

C/E12CI400A

countertop dispenser

Following installation, please forward this manual

C/E12CI400A

countertop dispenser with

SensorSAFE

(shown with legs accessory)

™

actuation

wall mount dispenser (available

with or without drain pan)

to the appropriate operations person.

801 Church Lane • PO Box D, Easton, PA 18044, USA

(610) 252-7301 • Fax (610) 250-0696 • www.follettice.com

C/E12HI400A

00124438R02

Table of contents

Welcome to Follett Corporation

Important cautions

Specifications

Installation

Installing countertop dispensers without legs

Installing countertop dispenser with legs accessory

Installing wall mount dispensers

User information

Cleaning and sanitizing procedures

Dispenser cleaning

Icemaker cleaning and sanitizing

Start-up following cleaning

Service information

Wiring diagram – lever model

Wiring diagram – SensorSAFE model

Icemaker operational and diagnostic sequences

Refrigeration cycle diagram

Icemaker capacity chart

Icemaker data

Refrigeration system data and requirements

Dispenser troubleshooting – lever models

Dispenser troubleshooting – SensorSAFE models

Icemaker troubleshooting

Disassembly and replacement instructions

Replacement parts

3

3

4

5

5

6

7

10

10

10

11

12

13

14

15

16

21

22

22

23

24

25

26

28

32

Follett Corporation

Equipment Return Policy

Follett equipment may be returned for credit under the following conditions:

1. The equipment is new and unused.

2. A return authorization number has been issued by customer service within 30 days after shipment.

3. Follett receives the equipment at the factory in Easton, PA within 30 days after issuance of the return authorization number.

4. The equipment must be returned in Follett packaging. If the packaging has been damaged or discarded, Follett will forward, at the customer’s expense,

new packaging.

Note: Return freight charges are the responsibility of the customer. If equipment is returned and is damaged because of improper packaging, Follett

Corporation will not be held responsible.

Credit will be issued when:

The equipment has been inspected by Follett and deemed suitable to be returned to stock.

Note: A 15% restocking charge will be deducted from the credit. If the cost to return the product to stock exceeds 15%, the actual cost will be deducted.

2

Welcome to Follett

Follett equipment enjoys a well-deserved reputation for excellent performance, long-term reliability and

outstanding after-the-sale support. To ensure that this equipment delivers that same degree of service, we

ask that you review the installation portion of this manual before beginning to install the unit. Our installation

instructions are designed to help you achieve a trouble-free installation. Should you have any questions or

require technical help at any time, please call our technical service group at (610) 252-7301.

Before you begin

After uncrating and removing all packing material, inspect the equipment for concealed shipping damage. If

damage is found, notify your shipper immediately and contact Follett Corporation for help in filing a claim, if

necessary.

Check your paperwork to determine which model dispenser you have. Follett model numbers are designed to

provide information about the type and capacity of Follett ice dispensing equipment. Following is an explanation

of model numbers.

E12CI400A

Condenser type, A = air-cooled

Icemaker capacity in lbs per day

Icemaker location, I = integral

Dispenser configuration, C = countertop, H = wall mount

Approximate storage capacity in lbs

Alternate voltage – C = 220V 60Hz

– E = 230V 50Hz

!

Important cautions

• Do NOT tilt any unit farther than 30° off vertical plane during uncrating or installation.

• Dispenser bin area contains mechanical, moving parts. Keep hands and arms clear of this

area at all times. If access to this area is required, power to unit must be disconnected first.

• Follett recommends installation of an activated carbon filter in icemaker inlet water line.

• Ice is slippery. Maintain counters and floors around dispenser in a clean and ice-free condition.

• Ice is food. Follow recommended cleaning instructions to maintain cleanliness of delivered ice.

• Do not block right side air intake or top air exhaust.

• Keep ventilation openings in the appliance enclosure or in the built-in structure clear of obstruction.

• Do NOT use mechanical devices or other means to accelerate the defrosting process.

• To avoid a hazard due to instability of the appliance it must be fixed according to instructions.

• The appliance must be positioned so the plug is accessible.

• If the cord is damaged it must be replaced by special service agent.

3

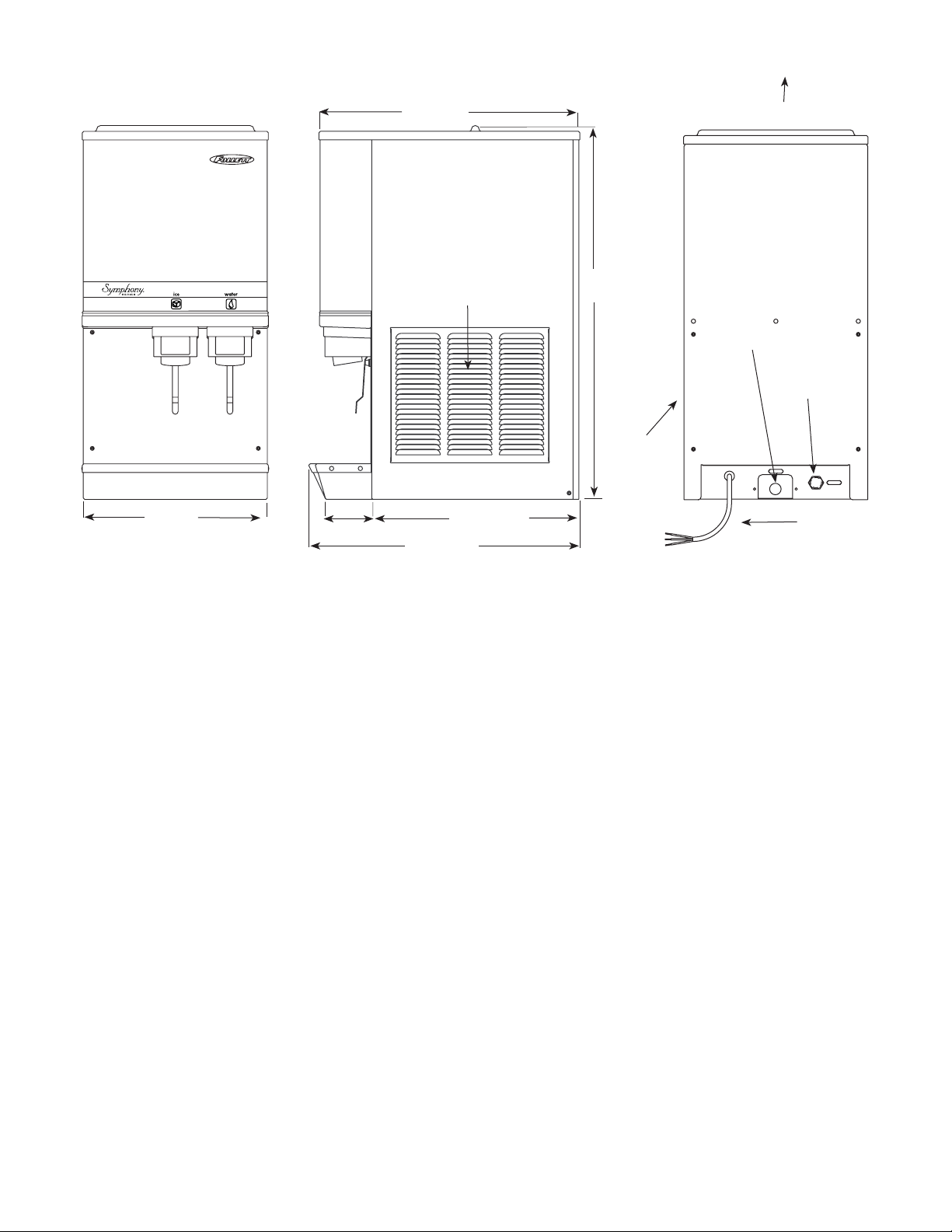

Specifications

407mm

(16")

Dispenser front view

575mm

(22.625")

102mm

(4")

597mm

(23.5")

Dispenser side view

Air

intake

458mm

(18")

826mm

(32.5")

air

intake

air exhaust

3/4" FPT drain

3/8" FPT

water inlet

DRAIN

ICE MACHINE

MAKE-UP WATER

power cord

Dispenser rear view

Electrical

220V 60Hz, 1 phase, 6.5 amps

230V 50Hz, 1 phase, 6.5 amps

Furnished with 1.8m (6 ft) power cord

Ambient

Air temp 38°C/100°F Max. 10°C/50°F Min. (Best performance below 80°F/27°C)

Water temp 32°C/90°F Max. 4°C/40°F Min. (Best performance below 70°F/21°C)

Water pressure 5Bar Max./70 P.S.I. .7 Bar/10 P.S.I. Min.

Plumbing

C/E12CI400A C/E12HI400A

Dispenser drain 3/4" FPT 3/4" FPT

Water inlet 3/8" FPT 3/8" FPT

Note: Water shut-off recommended within 3m (10 ft) of dispenser. Drain to be hard-piped and insulated. Maintain

at least 20mm per 1m run (1/4" per foot) of slope.

Ventilation clearances

6" (153mm) on right side of dispenser, 6" (153mm) at top for ventilation and 12" (305mm) at top recommended for

service.

Note: Do not block right side air intake or top air exhaust

Dry weight

79.4kg (175 lbs)

4

Installation procedures

Before you begin

• All dispensers must be installed level in both directions to ensure proper operation.

• Service and ventilation clearances: 6" (153mm) on right side of dispenser, 6" (153mm) at top for ventilation

and 12" (305mm) at top recommended for service.

• Countertop units installed without legs provide the option of taking utilities out bottom or back of dispenser

(on wall mount units and countertop units with legs, utilities exit from back). See counter cut out drawings for

bottom exiting utilities on units with and without drain pans. For installations where utilities exit through back

of dispenser, refer to back view drawings.

• Wall mount models without drain pan are designed for use above sinks.

• Counter depth must allow front of sink to be a minimum of 23.5 (597mm) from wall.

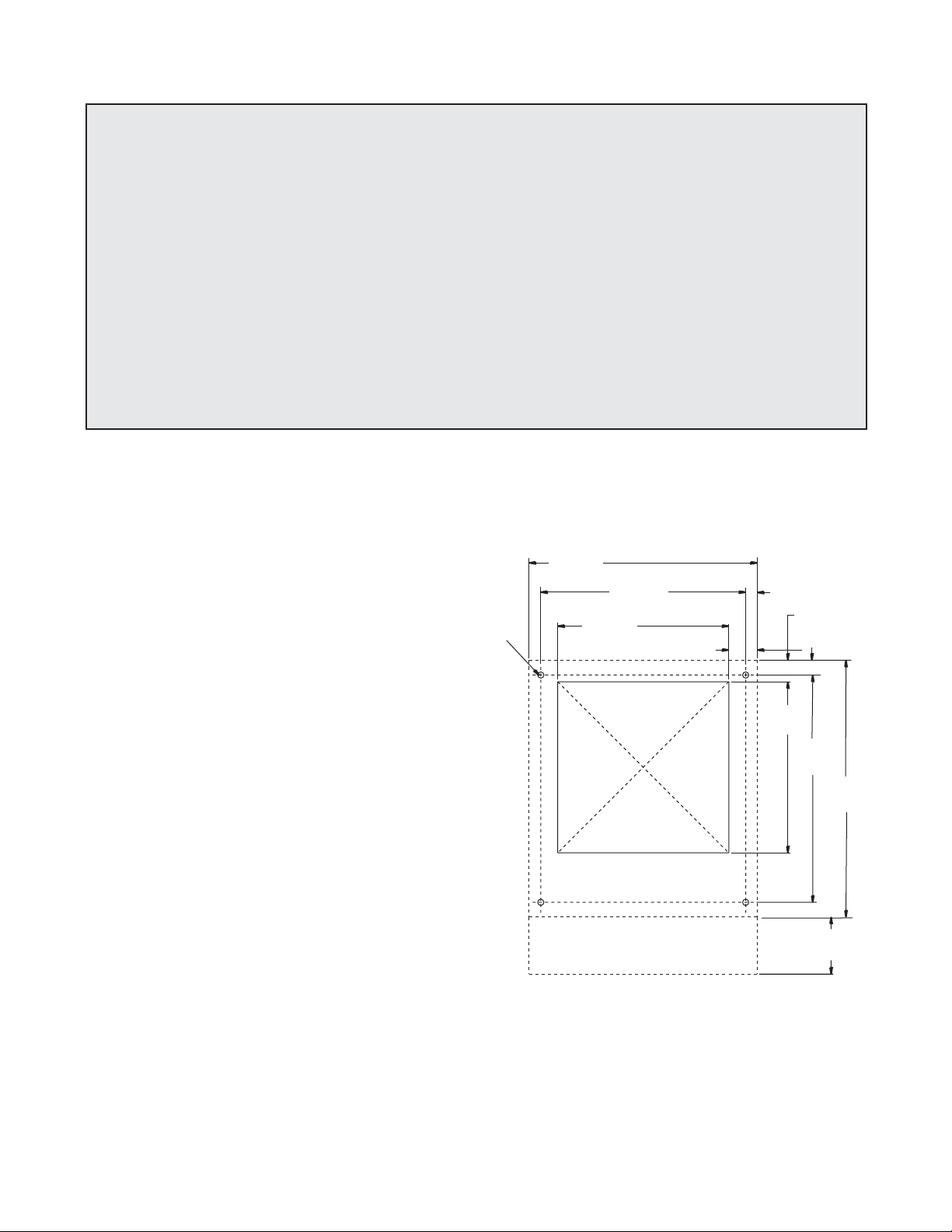

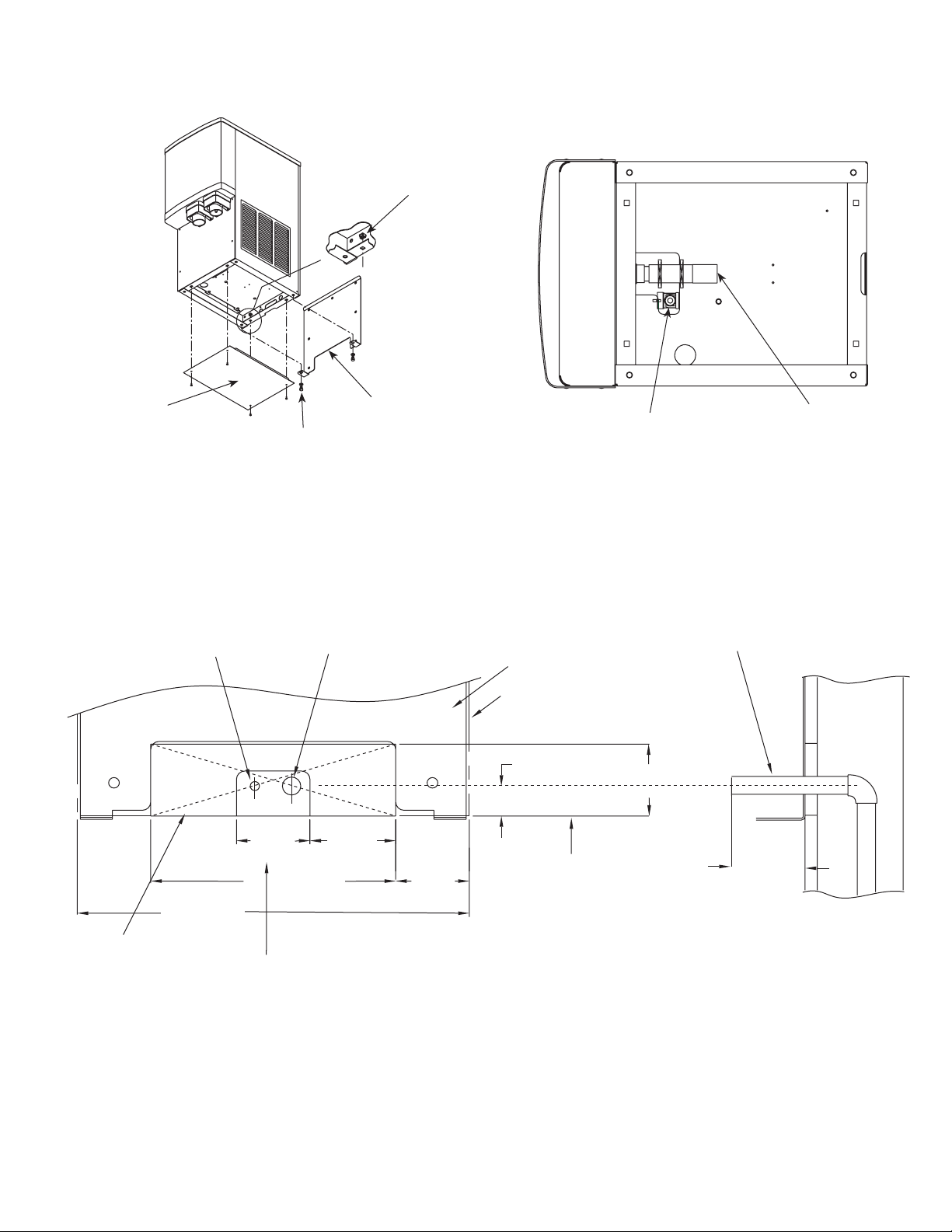

Installing countertop dispensers without legs

1. Position dispenser in desired location,

mark dispenser outline on counter and

remove dispenser.

2. Regardless of whether utilities will exit

through back or bottom of dispenser,

drill four 7/16" holes in counter to

anchor dispenser to counter (Fig. 1)

3. For utilities existing through bottom

only:

(a) Make cut out as shown in

Fig. 1.

(b) Move plug from drain T to

back of unit (Fig. 2).

4. For all units: Apply a thick bead

approximately 6mm (1/4") diameter

of NSF listed silicone sealant

(Dow Corning RTV-732 or equivalent)

6mm (1/4") inside marked outline of

dispenser.

5. Carefully lower dispenser on counter in

proper position and secure to counter

with four (4) 3/8" -16NC bolts.

6. Smooth excess sealant around outside

of dispenser.

12mm (.437")

diameter

Fig. 1 – Counter information

407mm

(16")

366mm

(14.4")

305mm

(12")

51mm (2")

cutout for

connections

through

bottom

21mm (0.8")

39mm (1.5")

26mm (1")

305mm

(12")

404mm

(15.9")

458mm

(18")

102mm

(4")

5

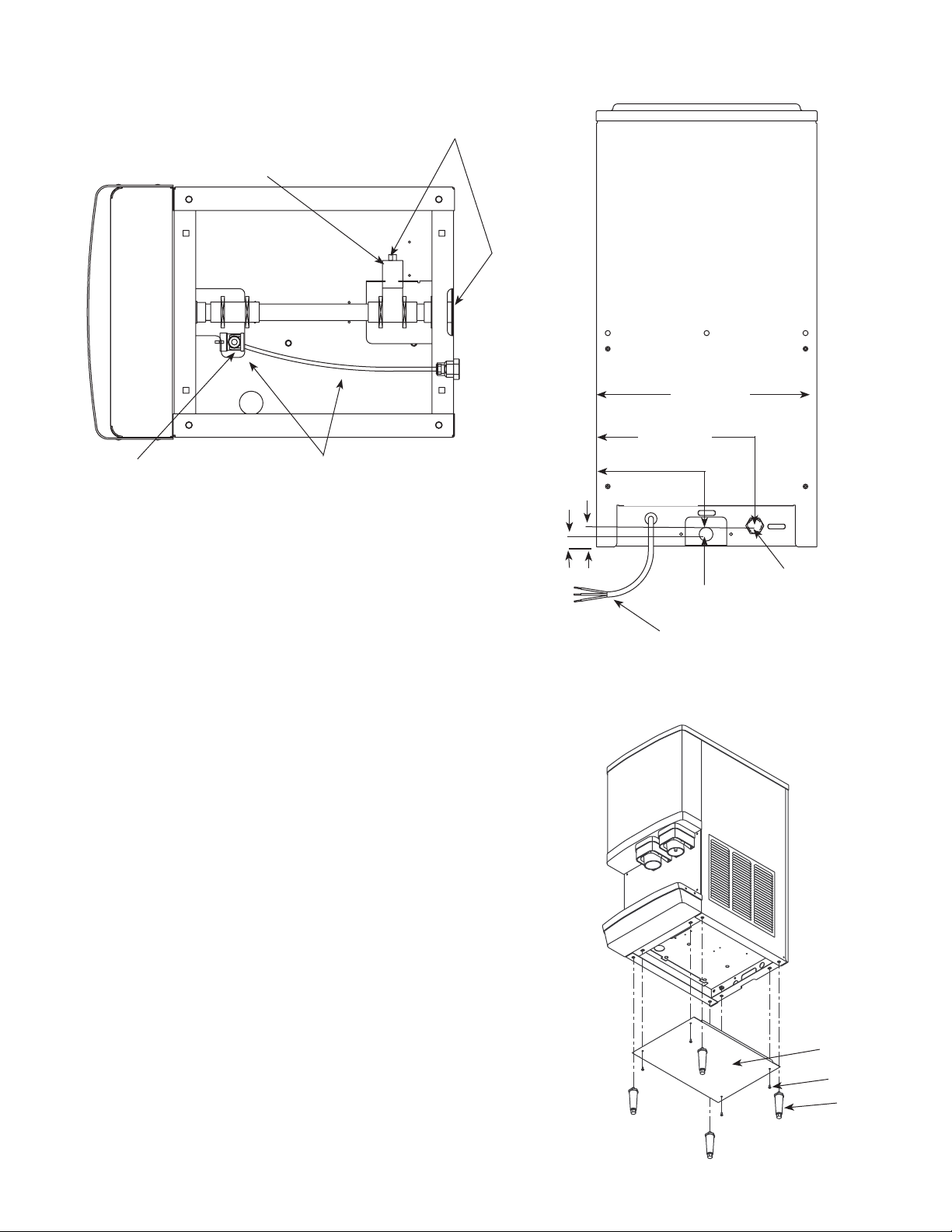

Fig. 2 – Bottom exiting utilities

(countertop units)

19mm (3/4") FPT drain

10mm (3/8") push-in

water inlet elbow

Poly tubing and elbow may be

removed for alternate water inlet

hook up by pushing in on the

locking collar while pulling out on

the tubing.

Pipe plug may be moved to back

of unit for alternate drain hook up

23mm (.9")

Fig. 3 – Rear exiting utilities

(countertop units)

407mm (16")

298mm

(11.7" )

39mm

(1.5")

206mm

(8.1")

DRAIN

MAKE-UP WATER

ICE MACHINE

Installing countertop dispensers

with legs accessory

1. Carefully tip dispenser back to expose underside and

block up in place.

Note: Do NOT tilt unit farther than 30° off vertical plane.

2. Screw legs (shipped taped to drain pan of dispenser)

into dispenser bottom, taking care to seat legs securely

against underside of dispenser.

Note: Countertop dispensers that sit on legs (not bolted

to counter) can be inadvertently moved. Care should be

taken when operating and cleaning to avoid accidents.

3. Attach bottom panel and hardware to bottom of

dispenser with supplied screws (Fig. 4).

4. Position unit in desired location and adjust bullets on

legs to level in both directions.

5. Make final connections.

10mm (3/8") FPT

19mm (3/4")

FPT drain

power cord

water inlet

Fig. 4 – Bottom panel assembly

bottom

panel

screw

leg

6

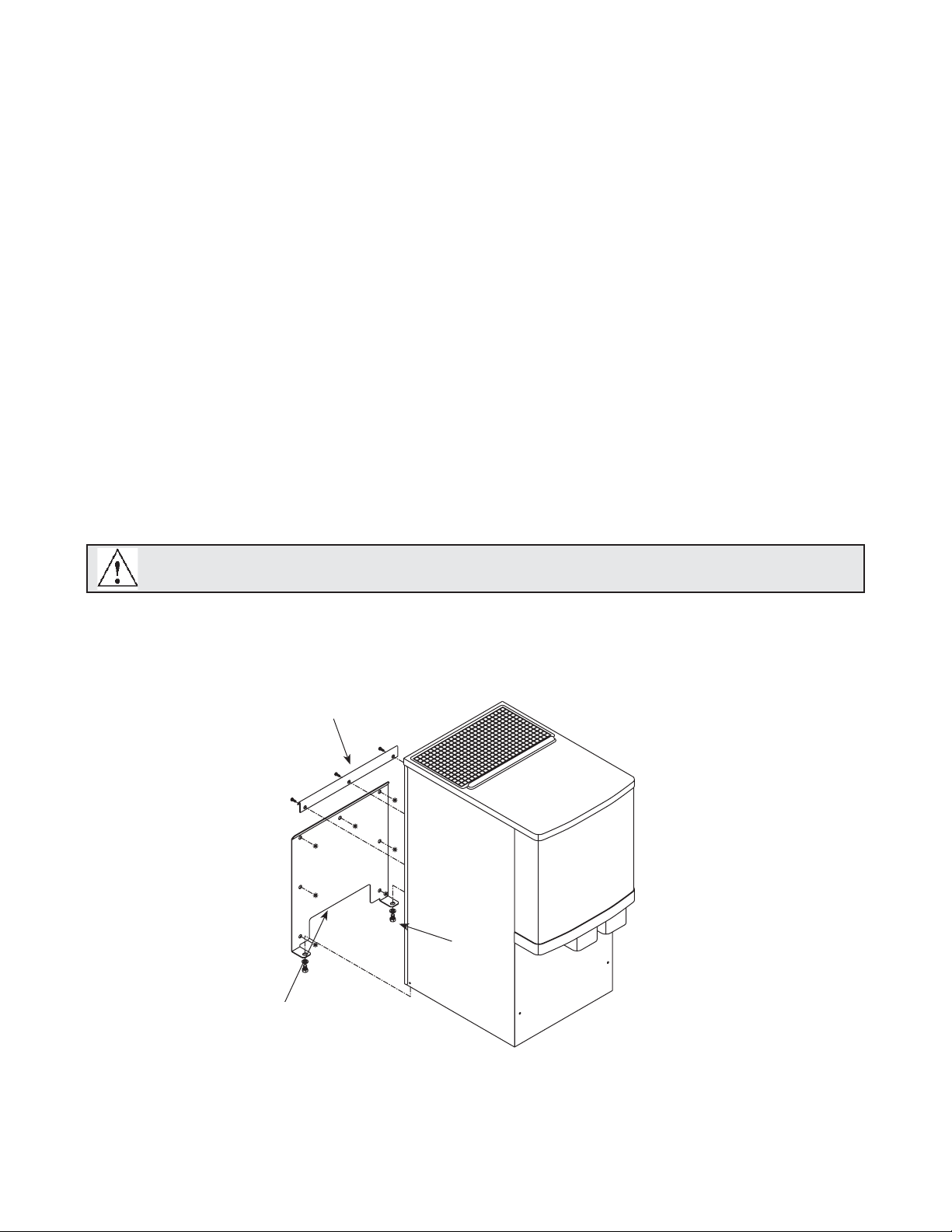

Installing wall mount dispensers

Notes:

No drain pan is provided since the dispenser is intended to be installed above a sink. (Contact Follett if a drain pan is desired.)

SensorSAFE actuation is standard. (Contact Follett if lever actuation is desired. A deeper cabinet will be needed.)

Recommended minimum counter depth and mounting height shown on Fig. 7 ensures that ice will drop into sink.

See Fig. 6 for model dimensions. The dimensions include the 13mm (.5") mounting bracket supplied with the unit.

1. Cut utility hole in wall as shown (Fig. 10).

2. Mount support bracket to wall using fasteners of sufficient strength (fasteners not included, see Fig. 6).

3. Rough in water and drain lines (Fig. 10).

4. Lift dispenser onto support bracket, positioning unit so that hook on back of dispenser is captured by support

bracket angle (Fig. 7).

5. Install two (2) supplied 3/8"-16NC screws through bottom of support bracket into bottom of dispenser (Fig. 5).

6. Make final connections.

7. Attach bottom panel and hardware to bottom of dispenser (Fig. 8).

Fig. 5 – Wall mount bracket and fastener requirements

WALL PREPARATION: Wall and fasteners must be of sufficient strength to carry weight of unit

(185 lbs (83.9kg)). Hardware for this is not included.

wall mounting

bracket

screw

support

bracket

7

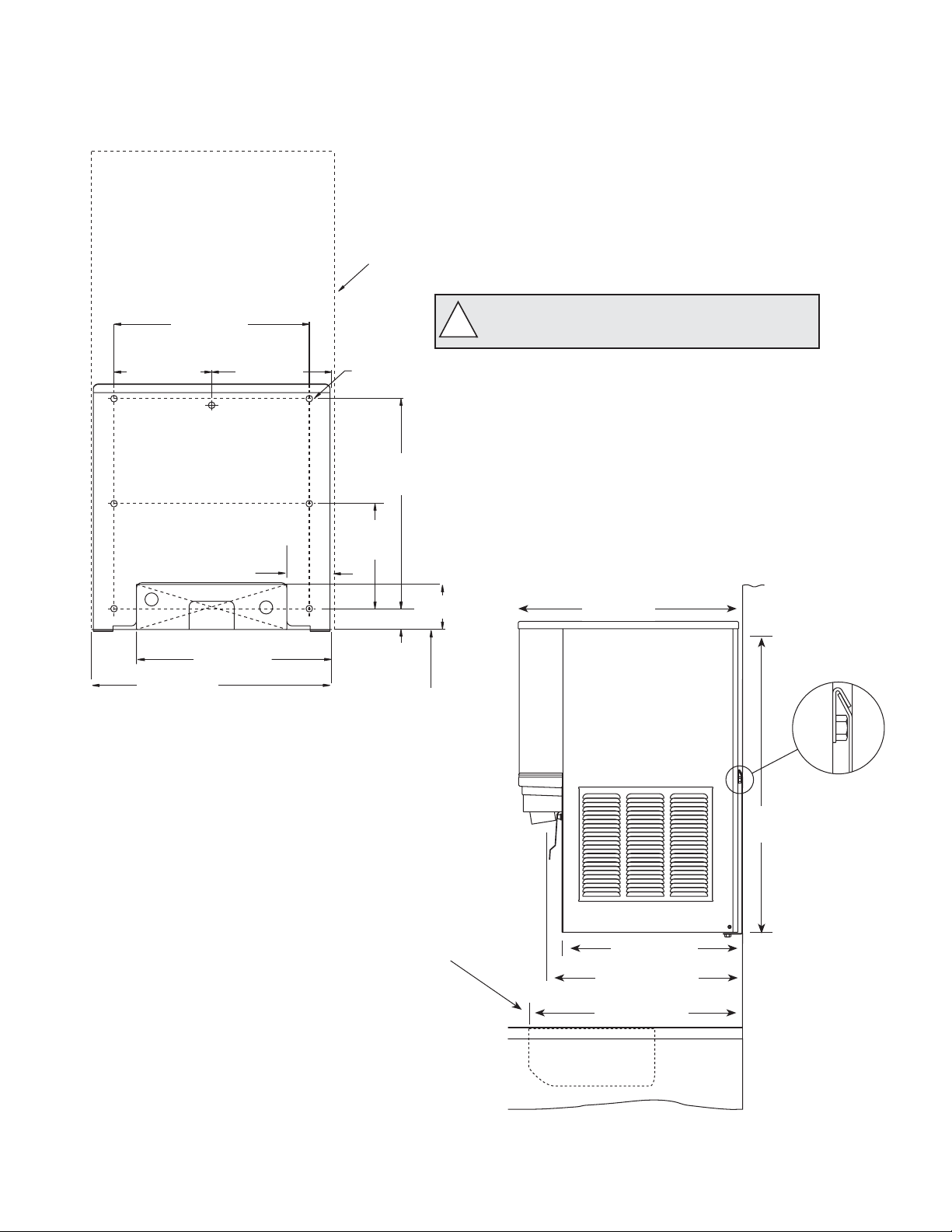

Installing wall mount dispensers

Fig. 6 – Wall mounting dimensions

outline of

dispenser

331mm (13")

166mm (6.5")

407mm (16")

204mm (8")

77mm (3")

254 mm (10")

12mm (.437")

356mm

(14")

178mm

(7")

36mm

(1.4")

bottom of dispenser

!

77mm (3")

Caution: Do NOT rest dispenser weight on

bottom of support bracket.

Fig. 7 – Wall mount side view

572mm

(22.5")

minimum distance to sink front

826mm

(32.5")

470mm (18.5")

493mm (19.375")

597mm (23.5")

8

Fig. 8 – Wall mount unit bottom panel assembly

nut

Fig. 9 – Wall mount bottom view

bottom panel

screw

support bracket

Fig. 10 – Front view of wall mount bracket – utility location

10mm (3/8")

copper water tube

407mm (16")

19mm (3/4")

copper drain tube

77mm

(3") (3.5")

254mm (10")

89mm

32mm (1.25") MAX

23mm (0.88") MIN

77mm

(3")

support bracket

outline of dispenser

bottom of

dispenser

10mm (3/8") push-in

water inlet

Side view of utilities exiting wall

water and

drain tubing

77mm

(3")

19mm (3/4")

FPT drain

wall

77mm

(3")

MIN.

utility cutout

in wall

locate tubing

within dimension shown

9

User information

How the dispenser works

Follett’s 12 series automatic-load ice and water dispensers are equipped with Follett’s 181kg (400 lb)/day

icemaker. In the continuous icemaking process, water freezes to the inside wall of the evaporator. A rotating

stainless steel auger carries the ice to the top of the evaporator where it is compressed and extruded through an

outlet port. The ice is then pushed through a tube to the storage hopper. When the hopper is full, a bin thermostat

opens and shuts the icemaker off. When the dispense mechanism is activated, a dispense motor is turned on,

causing the wheel to turn. This moves ice to the dispense chute where it drops by gravity into the container held

below the chute.

How the SensorSAFE accessory works

Follett’s SensorSAFE accessory maximizes sanitation and minimizes the possibility of cross-contamination by

eliminating physical contact between the cup or container and dispenser. Sensors in the panel use reflected

infrared light to detect the presence of the container and send a signal to a control board which then activates the

appropriate components for ice or water dispensing.

The SensorSAFE package includes a cleaning switch under the left side of the front cover which

temporarily shuts off dispensing to allow cleaning of the panel and lenses. If the switch is not turned back on after

cleaning, the dispenser automatically resets after two minutes for normal operation.

SensorSAFE also includes a time limit safety feature which automatically stops ice dispensing after

one minute of continuous dispensing. Dispensing can be resumed by moving the container away from

the dispenser and returning it to the activation zone.

Cleaning and sanitizing procedures

Solution A: Prepare cleaning solution (200 ppm of available

chlorine content) of Ecolab Mikro-chlor Cleaner or

equal chlorinated detergent. Solution temperature

must be 24°C – 52°C (75°F – 125°F).

Solution B: Prepare sanitizing solution (50 ppm of available

chlorine content) of Ecolab Mikro-chlor Cleaner or

equal chlorinated detergent. Solution temperature must

be 24°C – 52°C (75°F – 125°F).

Follett recommends following the periodic cleaning schedule below to ensure

the quality of ice provided. Use only recommended cleaning solutions. Do not

use solvents, abrasive cleaners, metal scrapers or

sharp objects.

Warning – Always disconnect power before cleaning.

!

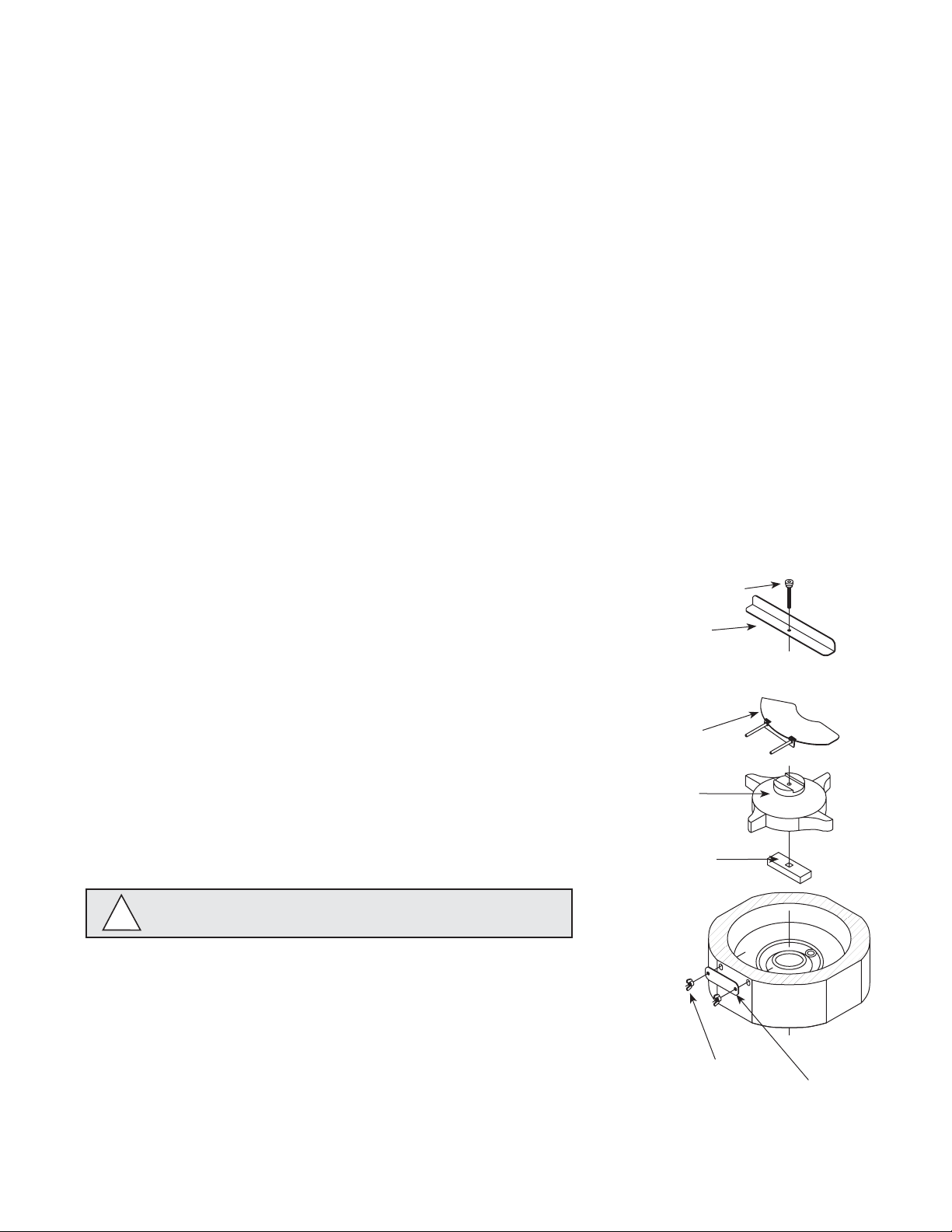

Dispenser cleaning: start-up and quarterly intervals

1. Remove all ice from storage hopper.

2. Remove center thumbscrew, locking plate, two wingnuts and

backing plate from front of storage hopper.

3. Remove stud assembly, agitator, spacer, baffle, wheel and drive

bar in this sequence.

4. Remove dispense chute.

stud assembly

agitator

baffle

wheel

drive bar

wingnut

backing

plate

10

5. Wipe lid, wheel, baffle, inside of storage area and dispense chute with damp cloth wrung out in Solution A.

6. Rinse all above items with damp cloth and wring out in clear water.

Note: To avoid possible damage to motor assembly, use a damp cloth only to clean storage hopper. Do not

allow water to run through center hole in bottom of hopper.

7. Sanitize all above items with damp cloth wrung out in Solution B. Do not rinse.

8. Pour 284ml (1 cup) household bleach into drain pan, followed by 3.8L (1 gallon) hot tap water to flush drains.

9. Reinstall all parts.

Dispenser grille and drain pan – weekly intervals

1. Remove grille and wash with Solution A. Rinse thoroughly.

2. Pour 282ml (1 cup) household bleach into drain pan, followed by 3.8L (1 gallon) of hot tap water to flush

drains.

Splash panel front, SensorSAFE dispensers

1. Deactivate dispensing by pressing and releasing clean switch located on left side of unit under top front

cover.

2. Clean lens using a soft cloth and mild, non-abrasive, non-chlorine based cleaner.

3. Reactivate dispensing by pressing and releasing clean switch again.

Icemaker cleaning & sanitizing

Preventive maintenance

Periodic cleaning of Follett’s icemaker system is required to ensure peak performance and delivery of clean,

sanitary ice. The recommended cleaning procedures which follow should be performed at least as frequently as

recommended below and more often if environmental conditions dictate.

Cleaning of the condenser can usually be performed by facility personnel. Cleaning of the icemaker system

in most cases should be performed by your facility’s maintenance staff or a Follett authorized service agent.

Regardless of who performs the cleaning, it is the operator’s responsibility to see that this cleaning is performed

according to the schedule below. Service problems resulting from lack of preventive maintenance will not be

covered under the Follett warranty.

Cleaning procedures

Recommended monthly cleaning of condenser

1. Use a vacuum cleaner or stiff brush to carefully clean condenser coils of air-cooled icemakers to ensure

optimal performance.

2. When reinstalling counter panels in front of remote icemakers, be sure that ventilation louvers line up with

condenser air duct.

Recommended semi-annual cleaning of icemaking system

Icemaking system can be cleaned in place without disassembling water system. Cleaning should be performed at

least every 6 months, and more often if local water conditions dictate.

1. Disconnect power to icemaker.

2. Remove any icemaker panels required to gain access to water reservoir and electrical control box.

3. Turn compressor switch on electrical box of icemaker to OFF position.

4. Remove water reservoir cover and block up reservoir float or close water supply valve.

5. Drain water from reservoir by releasing evaporator drain line from float reservoir bracket and removing plug

from drain line.

11

6. Following manufacturer’s instructions, prepare one gallon (3.8L) of Follett SafeCLEAN Ice Machine Cleaner

(one 7 oz packet) or equivalent. Solution temperature must be at least 120° F (48.9° C).

Warning: Most ice machine cleaners contain citric or phosphoric acid that can cause skin irritation. Read

caution label on product and follow instructions carefully.

7. Plug drain hose, replace drain line in reservoir bracket and pour part of cleaning solution into reservoir, filling

it almost to overflowing.

8. Remove stainless steel compression nozzle and drain lines. Submerge in a cup of cleaning solution while

cleaning rest of system. (Flake icemakers have no compression nozzle and drain lines.)

Caution: To avoid potential pitting, do not soak parts in SafeCLEAN for more than 45 minutes.

9. Restore power to icemaker (gearmotor will run; compressor and fan will not).

10. After 15 minutes, turn power OFF; drain solution from reservoir and evaporator.

11. Fill reservoir almost to overflowing with clean, 120° F (48.9° C) water, and drain. Repeat three times.

12. Following manufacturer’s instructions, prepare 1 gallon (3.8L) of 200ppm 5.25% Sodium Hypochlorite

solution (mix 1 oz household bleach to 2 gallons water) or equivalent. Solution temperature must be at least

120° F (48.9° C).

13. Rinse compression nozzle in clean water and submerge in a cup of sanitizing solution while following

steps 14-19.

14. Connect ice transport tube directly onto evaporator outlet port without compression nozzle.

Note: If bin will not be cleaned at this time, place a large pan in bin storage area to catch ice or connect a

separate ice transport tube to evaporator and divert ice into separate container.

15. Fill reservoir almost to overflowing with sanitizing solution.

16. Restore power to icemaker (gearmotor will run; compressor and fan will not).

17. After 10 minutes, turn compressor switch to ON position.

18. As unit starts to make ice, continue to pour sanitizing solution into reservoir, maintaining level just below

reservoir overflow.

19. Continue to make ice with sanitizing solution for 20 minutes.

20. Turn power to icemaker OFF.

21. Disconnect transport tube from evaporator outlet port. Rinse compression nozzle in clean water and reinstall

on evaporator outlet. Reconnect transport tube to compression nozzle.

22. Drain any remaining sanitizing solution from evaporator.

23. Fill reservoir almost to overflowing with clean, 120° F (48.9° C) water, and drain. Repeat three times.

24. Unblock float (or open water supply valve) and replace reservoir cover; restore power to icemaker and

ensure compressor switch is in ON position. Make ice for at least 15 minutes to flush any remaining

solution from system (remote icemakers with long ice transport hoses may take longer to flush out). Discard

this and all ice made during sanitizing.

25. Inspect evaporator drain pan and drain line and remove any accumulated scale build up.

26. Replace any panels removed prior to cleaning.

Start-up following cleaning

1. Clean and sanitize ice storage area of dispenser in accordance with instructions above before making ice.

2. Turn icemaker on and begin to make ice (icemaker should start immediately with power and bin signal

supplied).

3. After approximately 30 minutes, test dispenser for proper dispensing.

12

Loading...

Loading...