Page 1

Electrosurgical Analyzer

PN 2202027

April 2007

© 2007 Fluke Corporation, All rights reserved. Printed in USA

All product names are trademarks of their respective companies.

RF303

Operators Manual

Page 2

Warranty and Product Support

Fluke Biomedical warrants this instrument against defects in materials and workmanship for one full year from the date of original purchase. During the warranty

period, we will repair or, at our option, replace at no charge a product that proves

to be defective, provided you return the product, shipping prepaid, to Fluke Biomedical. This warranty does not apply if the product has been damaged by accident or misuse or as the result of service or modification by other than Fluke Biomedical. IN NO EVENT SHALL FLUKE BIOMEDICAL BE LIABLE FOR

CONSEQUENTIAL DAMAGES.

Only serialized products and their accessory items (those products and items bearing a distinct serial number tag) are covered under this one-year warranty.

PHYSICAL DAMAGE CAUSED BY MISUSE OR PHYSICAL ABUSE IS NOT

COVERED UNDER THE WARRANTY. Items such as cables and nonserialized

modules are not covered under this warranty.

Recalibration of instruments is not covered under the warranty.

This warranty gives you specific legal rights, and you may also have other rights

which vary from state to state, province to province, or country to country. This

warranty is limited to repairing the instrument to Fluke Biomedical’s specifications.

Warranty Disclaimer

Should you elect to have your instrument serviced and/or calibrated by someone

other than Fluke Biomedical, please be advised that the original warranty covering

your product becomes void when the tamper-resistant Quality Seal is removed or

broken without proper factory authorization. We strongly recommend, therefore,

that you send your instrument to Fluke Biomedical for factory service and calibration, especially during the original warranty period.

Notices

All Rights Reserved

© Copyright 2007, Fluke Biomedical. No part of this publication may be reproduced, transmitted,

transcribed, stored in a retrieval system, or translated into any language without the written permission

of Fluke Biomedical.

Copyright Release

Fluke Biomedical agrees to a limited copyright release that allows you to reproduce manuals and

other printed materials for use in service training programs and other technical publications. If you

would like other reproductions or distributions, submit a written request to Fluke Biomedical.

Page 3

Unpacking and Inspection

Follow standard receiving practices upon receipt of the instrument. Check the shipping carton for

damage. If damage is found, stop unpacking the instrument. Notify the carrier and ask for an agent to

be present while the instrument is unpacked. There are no special unpacking instructions, but be careful not to damage the instrument when unpacking it. Inspect the instrument for physical damage such

as bent or broken parts, dents, or scratches.

Technical Support

For application support or answers to technical questions, either email techser-

vices@flukebiomedical.com or call 1-800- 648-7952 or 1-425-446-6945.

Claims

Our routine method of shipment is via common carrier, FOB origin. Upon delivery, if physical damage is found, retain all packing materials in their original condition and contact the carrier immediately to file a claim. If the instrument is delivered in good physical condition but does not operate

within specifications, or if there are any other problems not caused by shipping damage, please contact Fluke Biomedical or your local sales representative.

Standard Terms and Conditions

Refunds and Credits

Please note that only serialized products and their accessory items (i.e., products and items

bearing a distinct serial number tag) are eligible for partial refund and/or credit. Nonserialized

parts and accessory items (e.g., cables, carrying cases, auxiliary modules, etc.) are not eligible

for return or refund. Only products returned within 90 days from the date of original purchase are

eligible for refund/credit. In order to receive a partial refund/credit of a product purchase price on a serialized product, the product must not have been damaged by the customer or by the carrier chosen by

the customer to return the goods, and the product must be returned complete (meaning with all manuals, cables, accessories, etc.) and in “as new” and resalable condition. Products not returned within 90

days of purchase, or products which are not in “as new” and resalable condition, are not eligible for

credit return and will be returned to the customer. The Return Procedure (see below) must be followed to assure prompt refund/credit.

Restocking Charges

Products returned within 30 days of original purchase are subject to a minimum restocking fee of 15

%. Products returned in excess of 30 days after purchase, but prior to 90 days, are subject to a minimum restocking fee of 20 %. Additional charges for damage and/or missing parts and accessories will

be applied to all returns.

Return Procedure

All items being returned (including all warranty-claim shipments) must be sent freight-prepaid to our

factory location. When you return an instrument to Fluke Biomedical, we recommend using United

Parcel Service, Federal Express, or Air Parcel Post. We also recommend that you insure your shipment for its actual replacement cost. Fluke Biomedical will not be responsible for lost shipments or

instruments that are received in damaged condition due to improper packaging or handling.

Use the original carton and packaging material for shipment. If they are not available, we recommend

the following guide for repackaging:

Use a double-walled carton of sufficient strength for the weight being shipped.

Use heavy paper or cardboard to protect all instrument surfaces. Use nonabrasive material

around all projecting parts.

Use at least four inches of tightly packed, industry-approved, shock-absorbent ma-

terial around the instrument.

Page 4

Returns for partial refund/credit:

Every product returned for refund/credit must be accompanied by a Return Material Authorization

(RMA) number, obtained from our Order Entry Group at 1-800-648-7952 or 1-425-446-6945.

Repair and calibration:

To find the nearest service center, go to www.flukebiomedical.com/service

In the U.S.A.:

Cleveland Calibration Lab

Tel: 1-800-850-4606

Email: globalcal@flukebiomedical.com

Everett Calibration Lab

Tel: 1-888-99-FLUKE (1-888-993-5853)

Email: service.status@fluke.com

In Europe, Middle East, and Africa:

Eindhoven Calibration Lab

Tel: +31-402-675300

Email: ServiceDesk@fluke.com

In Asia:

Everett Calibration Lab

Tel: +425-446-6945

Email: service.international@fluke.com

, or

Certification

This instrument was thoroughly tested and inspected. It was found to meet Fluke Biomedical’s manufacturing specifications when it was shipped from the factory. Calibration measurements are traceable

to the National Institute of Standards and Technology (NIST). Devices for which there are no NIST

calibration standards are measured against in-house performance standards using accepted test procedures.

WARNING

Unauthorized user modifications or application beyond the published specifications may result in electrical shock hazards or improper operation. Fluke Biomedical will not be responsible for any injuries sustained due to unauthorized equipment modifications.

Restrictions and Liabilities

Information in this document is subject to change and does not represent a commitment by

Fluke Biomedical. Changes made to the information in this document will be incorporated in

new editions of the publication. No responsibility is assumed by Fluke Biomedical for the use

or reliability of software or equipment that is not supplied by Fluke Biomedical, or by its affiliated dealers.

Manufacturing Location

The RF303 Electrosurgical Analyzer is manufactured in Everett, Washington by Fluke Biomedical, 6920 Seaway Blvd., Everett, WA, U.S.A.

Page 5

Table of Contents

1 Introduction and Specifications.............................................. 1-1

Introduction .......................................................................................... 1-3

General Safety Information................................................................... 1-3

Symbols ............................................................................................ 1-4

Warnings and Cautions..................................................................... 1-4

Electromagnetic Interference and Susceptibility............................... 1-5

EC Directive 89/336/EEC EN 50081-1 Emissions....................... 1-6

EC Directive 89/336/EEC EN 50082-1 Immunity........................ 1-6

USA Federal Communications Commission ................................ 1-6

Canadian Department of Communications ................................... 1-6

Control and Interface Panels................................................................. 1-7

Instrument Specifications ..................................................................... 1-9

General Specifications.......................................................................... 1-11

Accessories ........................................................................................... 1-13

2 Installation, Setup, and Maintenance ..................................... 2-1

Installation and Setup............................................................................ 2-3

Power-Up Sequence.......................................................................... 2-3

Operating the Analyzer Using Battery Power................................... 2-5

LED Backlight Display Operation.................................................... 2-7

Ventilation ........................................................................................ 2-7

Connecting Test Leads between the ESU and the Analyzer ............. 2-7

Test Lead Set with Retractable Shrouds ....................................... 2-8

ESU- Dispersive Safety Lead ....................................................... 2-8

ESU Jumper Safety Lead.............................................................. 2-9

ESU CQM Safety Lead................................................................. 2-9

Maintenance.......................................................................................... 2-10

Cleaning............................................................................................ 2-10

Calibration ........................................................................................ 2-10

Replacing Fuses................................................................................ 2-10

3 Operation .................................................................................. 3-1

The Signal Averaging Mode (SAM)..................................................... 3-3

Testing the ESU.................................................................................... 3-3

Key to Panel Diagrams ..................................................................... 3-4

Generator Output Test ...................................................................... 3-4

Basic Contact Quality Monitor (CQM) Test..................................... 3-7

HF Leakage Current Test 1............................................................... 3-10

i

Page 6

RF303

Operators Manual

HF Leakage Current Test 2 .............................................................. 3-13

HF Leakage Current Test 3 .............................................................. 3-16

Connecting an Oscilloscope to the Analyzer........................................ 3-19

Remote Operation via the RS-232 Function......................................... 3-19

Setting Up and Operating the Analyzer in Simplex Mode ............... 3-20

Setting Up and Operating the Analyzer in Duplex Mode................. 3-20

Appendices

A Load Issues................................................................................... A-1

B Interpretation of Fluctuating Readings ......................................... B-1

C Abbreviations ............................................................................... C-1

ii

Page 7

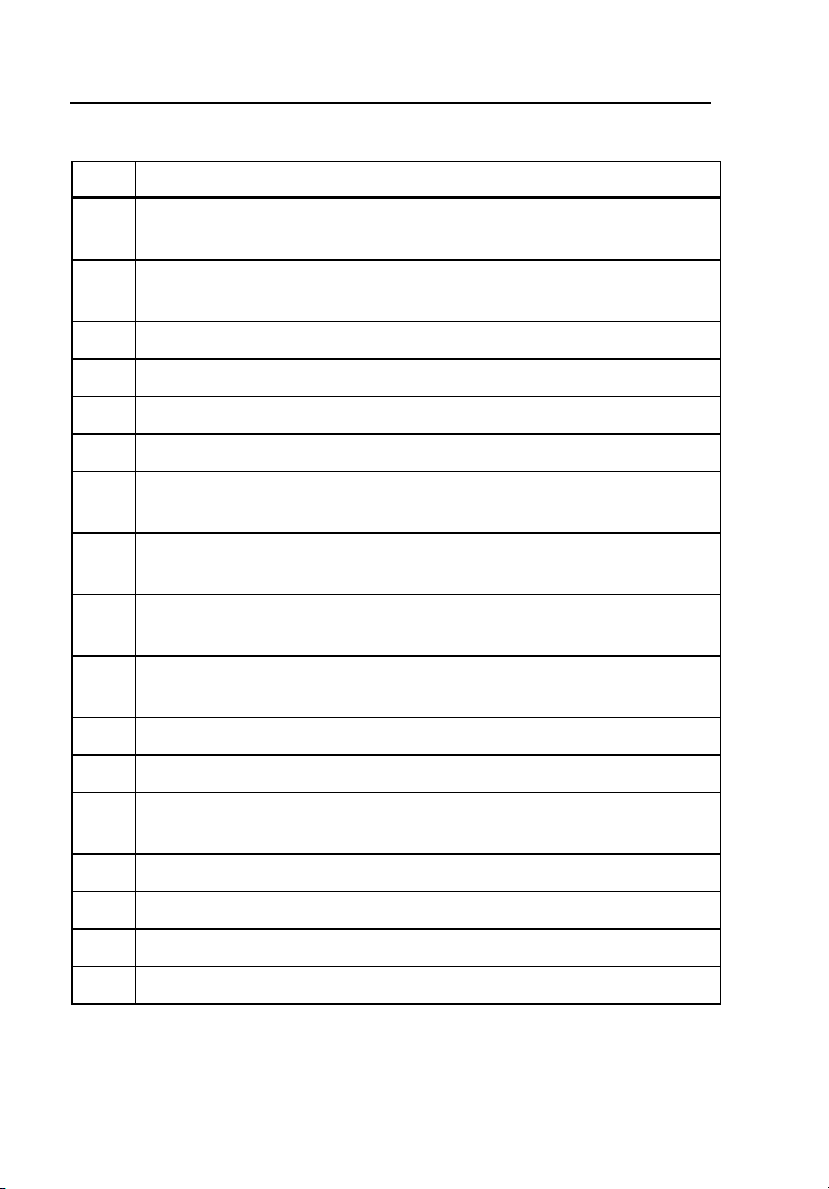

List of Tables

Table Title Page

1-1. Symbols ................................................................................................ 1-4

1-2. Controls and Connections..................................................................... 1-7

1-3. Accessories ........................................................................................... 1-13

1-4. Optional Accessories for the RF303 ..................................................... 1-13

2-1. Power-Up Error Condition Codes......................................................... 2-4

2-2. Battery Operating Status....................................................................... 2-6

2-3. Battery Status Light .............................................................................. 2-6

3-1. Error Responses .................................................................................... 3-22

3-2. Available Duplex Mode Commands..................................................... 3-23

iii

Page 8

RF303

Operators Manual

iv

Page 9

List of Figures

Figure Title Page

1-1. Analyzer Control and Interface Panels ................................................. 1-7

2-1. Fuse Cover............................................................................................ 2-11

3-2. Generator Output Test .......................................................................... 3-7

3-2. Basic CQM Check ................................................................................ 3-9

3-3. HF Leakage Test Number One ............................................................. 3-12

3-4. HF Leakage Test Number Two............................................................. 3-15

3-5. HF Leakage Test Number Three........................................................... 3-18

3-6. Burst Waveform on Oscilloscope Display............................................ 3-19

v

Page 10

RF303

Operators Manual

vi

Page 11

Chapter 1

Introduction and Specifications

Contents Page

Introduction ................................................................................. 1-3

General Safety Information ......................................................... 1-3

Symbols.................................................................................... 1-4

Warnings and Cautions ............................................................ 1-4

Electromagnetic Interference and Susceptibility...................... 1-5

EC Directive 89/336/EEC EN 50081-1 Emissions............... 1-6

EC Directive 89/336/EEC EN 50082-1 Immunity ............... 1-6

USA Federal Communications Commission........................ 1-6

Canadian Department of Communications........................... 1-6

Control and Interface Panels........................................................ 1-7

Instrument Specifications ............................................................ 1-9

General Specifications................................................................. 1-11

Accessories .................................................................................. 1-13

1-1

Page 12

RF303

Operators Manual

1-2

Page 13

Introduction and Specifications

Introduction

1

Introduction

The RF303 Electrosurgical Analyzer, hereafter referred to as the “Analyzer”,

tests electrosurgical units (ESU) for generator output and high frequency (HF)

leakage. It is compatible with both isolated and earth/ground-referenced types

of electrosurgical units. You can test both the high-level monopolar and the

low-level bipolar ESU outputs using this versatile Analyzer.

The Analyzer uses a precision high-voltage capacitive attenuator to sample the

applied ESU signal. You can use this attenuated HF voltage and the selected

test load resistance value to derive the true-rms values of both current and

wattage.

The Analyzer internal test load simulates the range of resistance encountered

during surgical procedures. Additionally, a second, 200 ohm (e) auxiliary test

load resistance is built-in to analyze earth/ground-referenced ESUs as specified

in the International Standard IEC 601-2-2.

The exclusive use of non-conductive, high-impact plastic case material

minimizes extraneous high frequency leakages within the Analyzer.

General Safety Information

This Analyzer complies with safety and technical requirements described in

the following directives:

• UL 3101-1

• CAN/CSA C22.2 No. 1010.1 (1992)

• EC 73/23/EEC EN 61010–1

• ANSI / AAMI HF–18-1986

• IEC 601-2–2

• IEC 1289-1

• IEC 1289-2

A Warning identifies hazardous conditions and actions that could cause

bodily harm or death.

A Caution identifies conditions and actions that could damage the Analyzer,

the equipment under test, or cause permanent loss of data.

1-3

Page 14

RF303

Operators Manual

Symbols

Table 1-1 describes the symbols used in this document.

Table 1-1. Symbols

Symbol Description Symbol Description

W

$

t

Risk of danger. Important

information. See manual.

Conforms to relevant

Canadian and U.S.

standards

Underwriters Laboratories

listed product

Indicates that a terminal is

connected to the chassis

when such a connection is

not apparent.

J Earth ground

X

P

B AC (Alternating Current)

F DC (Direct Current)

~

Hazardous voltage. Risk

of electrical shock.

Conforms to European

Union directives

Do not dispose of this

product as unsorted

municipal waste. Contact

Fluke or a qualified

recycler for disposal.

Warnings and Cautions

When testing electrosurgical units, observe the following to ensure operator

safety and maintain integrity of the high frequency (HF) measurement.

W X Warning

To avoid possible electric shock, burning of the skin, or

personal injury, follow these guidelines:

• Use only test leads supplied with the Analyzer to test the

ESU. These test leads utilize a shrouded 4mm plug to

limit exposure to the high-voltage and high frequency

ESU signal. The retractable ends of these leads are for

use on ESU only.

1-4

Page 15

Introduction and Specifications

General Safety Information

• Do not plug in or remove a test lead from either the ESU

or the Analyzer while the ESU generator is activated (or

keyed). This high frequency ESU signal can be several

thousand volts in amplitude when the output is opencircuited.

• Whenever practical during testing, activate the ESU

generator output using the foot switch supplied with the

ESU.

• No probes or accessories supplied with the analyzer are

intended for handheld use. Set up using the safety test

leads and stand clear when activating the ESU with the

footswitch.

• Place the Analyzer on an insulated, non-conductive work

surface to limit possible HF current paths to earth

ground.

• Routinely inspect test leads for wear and tear. Repair or

replace the test leads to maintain operator safety and

Analyzer performance.

1

Note

To ensure accuracy of measurement, follow these guidelines:

• Whenever practical during testing, place test leads carrying the

ESU signals in parallel, approximately 0.5 meters apart, to limit

capacitive coupling.

• Avoid crossing or tangling test lead cables during use and do not

drape them across conductive, grounded surfaces. Due to their

length, erroneously high HF readings may result.

Electromagnetic Interference and Susceptibility

Like all similar equipment, this equipment generates, uses, and can radiate

radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area could cause interference, in

which case the user will be required to correct the interference and bear any

1-5

Page 16

RF303

Operators Manual

costs. The limits established by the following organizations are designed to

provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment.

The Analyzer has been tested by independent testing laboratories and found to

meet the following requirements:

EC Directive 89/336/EEC EN 50081-1 Emissions

Radiated Emissions and Line Conducted Emissions. Verification was to the

limits and methods of EN 55011. The device is classified as EN 55011, Group

A.

EC Directive 89/336/EEC EN 50082-1 Immunity

Electrostatic Discharge Susceptibility, Radiated Susceptibility, and Electrical

Fast Transient/Burst Susceptibility. Verification of compliance was conducted

to the limits and methods of EN 50082-1:1992, IEC 1000-4-2; EN 61000-4-3;

IEC 1000-4-4; EN 61000-4-5; EN 61000-4-6; EN 61000-4-11.

USA Federal Communications Commission

This equipment has been found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC Rules.

Canadian Department of Communications

This digital apparatus does not exceed Class A limits for radio emissions from

digital apparatus set out in the Radio Interference Regulations of the Canadian

Department of Communications.

Le present appareil numerique n'met pas du bruits radioelectriques depassant

les limites applicables aux appareils numerique de la Class A prescrites dans le

Reglement sur le brouillage radioelectrique edicte par le ministere des

Communications du Canada.

1-6

Page 17

Introduction and Specifications

Control and Interface Panels

1

Control and Interface Panels

Figure 1-1 and Table 1-2 describe the controls and interfaces of the Analyzer.

19

9

20

1

2

3

5

4

6

7

8

10

RF-303

ELECTROSURGICAL ANALYZER

11

12

Figure 1-1. Analyzer Control and Interface Panels

Table 1-2. Controls and Connections

13

18

17

16

1514

exz14.eps

Item Name / Description

1 Display

Backlit, numeric, 4-digit LCD

2 Power Indicator (WATTS) Lamp

Displays reading in watts.

3 Current Indicator (mA) Lamp

Displays readings in milliamperes (mA).

1-7

Page 18

RF303

Operators Manual

Table 1-2 Controls and Connections (cont.)

Item Name / Description

4 Test Load (OHMS) Lamp

Displays resistance in ohms.

5 Mode Selection (MODE SELECT ENT) Pushbutton

Toggles the display between Power (in watts) and Current (in mA).

6 Increase Test Load (OHMS SELECT +) Pushbutton

7 Decrease Test Load (OHMS SELECT -) Pushbutton

8 Carrying Handle

9 Battery Status Lamp

10 Scope Output

BNC connector

11 Measuring Resistance/HF Meter

All measurements made through these inputs.

12 Earth Connections

Provides earth reference for HF Leakage tests.

13 HF Load Resistance

Auxiliary test load for earth/ground-referenced Type BF Tests 2 and 3.

14 Battery Ground / Signal Earth Ground

15 Power Cord Inlet

16 Fuse Cover

Both power mains fuses are located behind this panel.

17 Power On/Off Switch

18 Ventilation Air Outlet

19 Ventilation Air Inlet

20 RS232 Port

1-8

Page 19

Introduction and Specifications

Instrument Specifications

1

Instrument Specifications

Modes of Operation

Line Powered (Battery Charge and Maintenance Charge)

Battery Operation

Offline (Battery Charge and Maintenance Charge)

Displayed Parameters

Power (Watts)

HF Current (milliamperes)

Test Load (ohms)

Test Performed

Generator Output

HF Leakage ........................................................ Performs HF leakage tests to IEC 601

Measurement

Technique ........................................................... Precision high-voltage capacitive

HF Power (watts)

Resolution....................................................... 1 to 400 W / Resolution: 0.1 W

Maximum power input .................................... 400 W rms

Accuracy..................................................... ± 5 % of reading or ± 3 watts,

HF Current

Range ......................................................... 30 to 2500 mA rms, Resolution: 1 mA

Accuracy..................................................... ± 2.5 % of reading or ± 15 mA,

Bandwidth/System Response

Bandwidth of rms converter circuit (1 % accuracy)

Flat response.................................................. 10 kHz to 10 MHz

-3 dB points..................................................... 1 kHz to 20 MHz

System Response (measurement circuitry and selected test load):

-3 dB points..................................................... 1 kHz to 10 MHz @ 300 e

2-2, 1289-2, ANSI/AAMI standards:

Type BF Test 1 – Earth referenced

monopolar output Type CF/Bipolar –

Isolated monopolar or bipolar output

attenuator samples applied ESU

signal. This directly measured HF

voltage and the selected test load

resistance value utilized to derive the

true-rms values of both current and

wattage readings.

whichever is greater

whichever is greater.

1-9

Page 20

RF303

Operators Manual

Test Load Section

Main Test Load

Selections........................................................15

Selection range ...............................................50 to 750 e

Step size..........................................................50 e

Duty Cycle .......................................................50 % @ 400 W (maximum 30 seconds

Resonance impedance variation ..................... ± 0.5 dB maximum (<10 MHz)

Accuracy (DC to 500 kHz)...................................± 4 % of selected value measured at

Auxiliary Leakage Test Load Fixed:

200 e

Accuracy..........................................................± 4 %

Power rating ....................................................225 W

Input Capacitance (nominal)

Active to dispersive .........................................30 pF

Active or Dispersive to Earth ground...............40 pF

Battery

Type: Sealed lead-acid

Voltage ................................................................12 volts nominal

Capacity ..............................................................2.2 A H

Field serviceable .................................................No

Typical time between recharges..........................2-hour minimum

Battery cycles ......................................................200

Recharging ..........................................................Instrument has internal, automatic

Auxiliary Contact Quality Monitor

Testing Feature ...................................................The main test load section is used to

Display

Type ....................................................................LCD, 7-segment

Display size .........................................................Four full digits

Overall display size .............................................2.0” x 0.75”

ON during any one-minute period)

calibration to: ± 1 % (across the entire

operating temperature range)

charger that is activated when unit is

plugged into wall with power cord. No

external charger required.

perform a simple Auxiliary Contact

Quality Monitor Testing Feature

(CQM) operational check.

1-10

Page 21

Introduction and Specifications

General Specifications

Front-Panel Controls / Pushbuttons

Measurement Select (1)

Load Select:

Increment test load (+) one step

Decrement test load (-) one step

Designations:

Generator output-active (1)

Generator output-dispersive (2)

Auxiliary HF leakage load (2)

Connector type ................................................... 4-mm (0.160”) diameter safety sockets

Input voltage limit................................................ 10,000 V peak

Input current limit ................................................ 3 amperes rms

Installation category............................................ II

Side Input connection

Designation......................................................... Signal reference

Oscilloscope Output

Transformer coupled output

Scale Factor........................................................ uncalibrated

Connector type ................................................... BNC

Calibration Period

Calibration recommended every 12 months.

1

General Specifications

Temperature Range

Operating: ........................................................... 15 to 35 °C

Storage ............................................................... 0 to 50 °C

Humidity Range

90 % non-condensing

Altitude

To 2,000 meters

Ventilation

Internal fan with variable speed control

Over temperature detector

Magnetic tachometer sensor to detect blocked fan motor

1-11

Page 22

RF303

Operators Manual

Power Requirements

Universal input switching supply (12 V dc output)

Operating Voltages:

Specified..........................................................115 V ac/230 V ac

Maximum range...............................................83 to 264 V ac

Operating frequencies:

Specified..........................................................50 Hz/60 Hz

Maximum range...............................................47 to 63 Hz

Maximum input requirement............................60 VA

Fusing

External (user-replaceable)

Quantity ...........................................................2

250 V, 3.15 A, Type F, L1 and L2

Case construction

High-impact plastic, UL94-V0

Weight

5.6 kg (14.15 lb)

Dimensions

15.24 cm H x 34.24 cm W x 30.48 cm D (6.00 in. H x 13.48 in. W x 12.00 in. D)

Intended Use

Indoor

Installation category II

Pollution degree 2

Portable equipment

Sound levels less than 65 db A

1-12

Page 23

Introduction and Specifications

Accessories

1

Accessories

Table 1-3 lists the accessories provided with the Analyzer and their

corresponding Fluke part numbers. Table 1-4 lists optional accessories and

their part numbers.

Table 1-3. Accessories Provided with the Analyzer

Accessory Fluke Part #

Analyzer Operaters Manual 2202027

Analyzer Accessory Kit

Includes: (quantity)

Fuse: type F, 3.15 A, 250 V (2) 2183792

Suregrip large alligator clip set (2/set) 1610159

Test lead set with retractable sheaths (2/set) 1903307

ESU – Dispersive safety lead (1) 2772171

ESU – CQM safety lead (1) 2772180

ESU – Jumper safety lead (2) 2772209

Ground pin adapter (1) 2242165

Table 1-4. Optional Accessories for the Analyzer

Accessory Fluke Part #

Watertight protective carrying case 2248587

Serial cable 2204472

2202009

1-13

Page 24

RF303

Operators Manual

1-14 2-1

Page 25

Chapter 2

Installation, Setup, and Maintenance

Contents Page

Installation and Setup .................................................................. 2-3

Power-Up Sequence................................................................. 2-3

Operating the Analyzer Using Battery Power.......................... 2-5

LED Backlight Display Operation ........................................... 2-7

Ventilation................................................................................ 2-7

Connecting Test Leads between the ESU and the Analyzer .... 2-7

Test Lead Set with Retractable Shrouds............................... 2-8

ESU- Dispersive Safety Lead............................................... 2-8

ESU Jumper Safety Lead...................................................... 2-9

ESU CQM Safety Lead ........................................................ 2-9

Maintenance................................................................................. 2-10

Cleaning ................................................................................... 2-10

Calibration................................................................................ 2-10

Replacing Fuses ....................................................................... 2-10

Page 26

RF303

Operators Manual

2-2

Page 27

Installation, Setup, and Maintenance

Installation and Setup

2

Installation and Setup

The Analyzer has a universal power supply and automatically operates with

applied main voltages having a maximum range of 83-264 V ac. You do not

need to adjust voltage via jumpers or programming tabs to operate the

Analyzer.

Set up the Analyzer for operation by attaching the supplied power cord to the

power cord inlet located on the right panel of the Analyzer case. If necessary,

please refer to “Instrument Familiarity” to help you identify the power cord

inlet.

Power-Up Sequence

After plugging the Analyzer into a correctly rated earth-ground outlet, locate

the power switch on the right panel. Move the switch to the ON position

(marked with the

sequence:

1. The three front LED indicator lamps illuminate, and you see this

information momentarily appear in the display:

– symbol). Next, you should observe the following power-up

2. Next the installed version of the Analyzer’s firmware briefly appears in

the display. Here’s an example:

2-3

exz01.eps

Page 28

RF303

Operators Manual

Note

The letter E, followed by a number indicates an error condition; the

Analyzer has encountered a problem during its internal self-test. See

“Power-Up Error Condition Codes”, below.

3. The instrument will briefly display several random numbers that are

associated with the rms output offset during initialization.

4. The display then reverts to a Power Save Mode, where the display is

blanked out, and the backlight is dim. The battery and mode LEDs remain

ON. The Analyzer advances to its default test load condition of 300 ohms,

ready to measure ESU power in watts.

Power-Up Error Condition Codes

Table 2-1 shows all error condition code numbers that can appear in the

display at power-up and the condition indicated by the code.

Table 2-1. Power-Up Error Condition Codes

Code Number Error Condition Indicated

E 03 EPROM checksum wrong

exz02.eps

2-4

E 04 RAM bad

E 05 EEPROM checksum wrong

E 06 ac-to-dc power converter bad

E 07 RMS converter bad

E 08 Peak detectors bad

E 09 Temperature sensors bad

Page 29

Installation, Setup, and Maintenance

Installation and Setup

2

Operating the Analyzer Using Battery Power

You can operate the Analyzer using either ac power or dc power. When you

power on the Analyzer with the supplied ac power cord installed and

connected to an appropriate ac power source, the Analyzer operates on ac

power. When you power on the Analyzer with the ac power cord disconnected,

the Analyzer automatically operates on battery (dc) power.

Note

The battery is a sealed lead-acid type. Do not attempt to replace the

battery. Return the Analyzer to a service center for replacement of the

battery.

The Analyzer contains an internal ac/dc converter. During ac power operation,

this converter assists in charging the battery, if it is not already fully charged.

If the battery is fully charged, it is held in a maintenance float mode.

If you remove the ac power cord while the Analyzer is powered on, the

Analyzer automatically resets in a battery-powered mode. The Analyzer can

operate on a fully-charged battery for approximately two hours. Battery age,

previous battery cycles, and Analyzer operating conditions all affect the actual

length of time that the Analyzer operates on battery power.

When the battery nears the end of its discharge cycle, the unit automatically

turns off to protect the battery from damage. This action is preceded by a

warning interval of about 5 minutes, indicated by a flashing red light of the

battery status indicator.

When the ac power cord is connected between the Analyzer and an ac power

source, and the Analyzer is not powered on, the battery charger is active.

However, instrument controls and measurement circuits do not receive power.

See Table 2-2, below for a summary of battery operating status under various

conditions.

2-5

Page 30

RF303

Operators Manual

Table 2-2. Battery Operating Status

Power Source to

Analyzer

Connected to ac

Power Source?

No On Battery Discharging

No Off No power Open circuit,

Yes Off No power Charging

Yes On AC Charging

On/Off Switch

Setting

Analyzer

Instrument

Controls and

Measurement

Circuits

Battery Status

minimal leakage

Battery Status Light

The battery status indicator light is labeled BATTERY STATUS. Table 2-3

shows status light displays and their corresponding conditions.

Table 2-3. Battery Status Light

Light Battery Condition

Flashing green Battery is being qualified (checked) with medium

charge or receiving full charge. Voltage is OK.

Steady green Maintenance charge voltage OK or battery

operation with voltage OK.

Flashing red and green Automatic shut-down is pending, battery is nearly

exhausted.

Flashing red Automatic shut-down is imminent.

Steady red When plugged in; indicates that the battery is not

charging and needs replacement by the Fluke

Biomedical Service Center.

Note

The Analyzer should be charged overnight, when the battery is fully

drained.

2-6

Page 31

Installation, Setup, and Maintenance

Installation and Setup

2

LED Backlight Display Operation

The Analyzer’s display lights when you select a load or when a test

measurement is received by the instrument.

Ventilation

The Analyzer requires proper ventilation so that it does not overheat during

operation. Always ensure that the two ventilation ports, located on each side of

the Analyzer, are not blocked during use. Maintain at least four inches (10.2

centimeters) of clear space around each of these ports.

An internal fan located immediately behind the grille on the left side port

supplies forced-air ventilation. Sensors measure the temperature of the load

resistors, and the fan accelerates as the load temperature increases. Fan rotation

is monitored also. If the load temperature is excessive or if the fan is not

functioning, an error condition is indicated on the display, and the audio

transducer emits a beeping sound. The error display codes are:

E 01: Temperature too high.

E 02: Fan not operating.

W Caution

Permanent damage to the Analyzer can occur if you

continue to apply a high-level ESU signal after the alert

has been activated.

Connecting Test Leads between the ESU and the Analyzer

A complete set of test leads is supplied with the Analyzer. Use these test leads

to connect the ESU generator output to the Analyzer and to configure the

Analyzer to conduct a specific ESU test. Safe connection to the Analyzer is

facilitated by shrouded safety plugs.

2-7

Page 32

RF303

Operators Manual

W X Warning

To avoid possible electric shock, burning of the skin, or

personal injury, follow these guidelines: Retractable end of

test leads are for use on ESU only. No probes or

accessories supplied with the Analyzer are intended for

handheld use. Set up using the safety test leads and stand

clear when activating the ESU with the footswitch.

The following is a description of the supplied test leads.

Test Lead Set with Retractable Shrouds

Part # 1903307

Color: One red and one black

Quantity: Two/set

One end of each test lead has a fixed shroud 4mm banana plug to connect with

the Analyzer. The other end has a retractable shroud 4mm banana plug

compatible with the active electrode/bipolar jacks on most ESU panels. A red

safety alligator clip is included for direct connection to an actual active

electrode element if preferred.

A removable black clamp facilitates firm attachment to a ground reference

point. This lead is important for making leakage measurements in the battery

mode of operation.

ESU- Dispersive Safety Lead

Part # 2772171

Color: Clear with blue connectors

Quantity: One

One end of the test lead has a single fixed-shroud 4mm banana plug to connect

with the Analyzer. The other end has a CQM style two-pin connector that

plugs directly into the neutral (or dispersive) electrode jack on most ESU

panels.

2-8

Page 33

Installation, Setup, and Maintenance

Installation and Setup

Note

The mechanical pin is removed from the CQM connector to disable

CQM during ESU generator output tests.

ESU Jumper Safety Lead

Part # 2772209

Color: Black

Quantity: Two

Both ends of these two short jumpers have fixed shroud 4mm banana plugs

and are used to configure the Analyzer for the IEC Type BF Tests 1 and 2,

which utilize the auxiliary HF load resistance (200e). Both jumpers are

required to conduct these tests.

ESU CQM Safety Lead

Part # 2772180

Color: Clear with blue and yellow connectors

2

Quantity: One

One end of the test lead has two fixed shroud 4mm banana plugs to connect

across the Analyzer test load. The other end has a CQM style 2PIN connector

that plugs directly into the neutral (or dispersive) electrode jack on most ESU

panels.

Note

The mechanical pin is intact to enable the CQM function during CQM

testing. Do not use this lead for output testing.

2-9

Page 34

RF303

Operators Manual

Maintenance

Follow the recommendations below to keep the Analyzer in good working

condition.

Cleaning

Moisten a clean cloth with a mild solution of detergent and water only and

wipe the Analyzer clean.

W Caution

To avoid damaging the Analyzer, use only dilute, mild

detergent for cleaning.

Calibration

Calibrate the Analyzer every 12 months.

Replacing Fuses

The Analyzer contains two operator-replaceable fuses, rated as Type F, 3.15 A,

and 250 V. These fuses are in the two main supply lines.

You can replace one or both of these fuses by opening the fuse cover located

on the right panel. Refer to Figure 2-1 for a diagram of the fuse cover

assembly. If necessary, see “Instrument Familiarity”, to identify the fuse cover.

2-10

Page 35

Installation, Setup, and Maintenance

Maintenance

Figure 2-1. Fuse Cover

2

exz16.eps

W X Warning

To avoid severe electrical shock, disconnect the power

source before replacing fuses.

1. Make sure that the power switch is in the OFF position (O) and disconnect

the power cord. The Analyzer is now safely powered down.

2. Pry the left side of the fuse cover up from the power inlet assembly, using

a small flat-blade screwdriver. The fuse cover latches on the right side and

remains attached to the Analyzer.

3. Remove a fuse carrier with your fingers, lifting it from the power inlet

housing.

Note

To avoid damage to the Analyzer, do not use any sharp instrument to

lift a fuse carrier.

4. Replace the fuse in the carrier with one of the same amperage and voltage

ratings.

2-11

Page 36

RF303

Operators Manual

5. Reinstall the fuse carrier into the power inlet module, ensuring that the

arrows on the ends of the fuse carriers point up.

6. Close the fuse cover until it snaps into place.

7. Reconnect the power cord, and power-up the Analyzer, if desired.

If you have replaced these fuses and the Analyzer still does not work properly,

contact the Fluke Biomedical Technical Assistance Center at 800-648-7952.

2-12

Page 37

Chapter 3

Operation

Contents Page

The Signal Averaging Mode (SAM)............................................ 3-3

Testing the ESU........................................................................... 3-3

Key to Panel Diagrams............................................................. 3-4

Generator Output Test.............................................................. 3-4

Basic Contact Quality Monitor (CQM) Test............................ 3-7

HF Leakage Current Test 1 ...................................................... 3-10

HF Leakage Current Test 2 ...................................................... 3-13

HF Leakage Current Test 3 ...................................................... 3-16

Connecting an Oscilloscope to the Analyzer ............................... 3-19

Remote Operation via the RS-232 Function................................ 3-19

Setting Up and Operating the Analyzer in Simplex Mode....... 3-20

Setting Up and Operating the Analyzer in Duplex Mode ........ 3-20

3-1

Page 38

RF303

Operators Manual

3-2

Page 39

Operation

The Signal Averaging Mode (SAM)

3

The Signal Averaging Mode (SAM)

Upon power-up, the Analyzer defaults to the instantaneous algorithm for

power output measurement, which shows fluctuating ESU output if it exists.

You can select the desired SAM by depressing the MODE SELECT and OHM SELECT keys simultaneously. Each time you initiate this key

sequence, the Analyzer increments to the next mode. Starting at the default

mode (“F 0”), the next mode entered is the one-second signal-averaging mode

(“F 1” appears on the display). Initiating the key sequence again selects the

two-second signal averaging mode (“F 2” appears on the display). Initiating

the key sequence again brings the unit back to the default instantaneous mode

(“F 0” appears on the display), and so on.

Testing the ESU

The sections that follow describe the specific ESU tests you can perform using

the Analyzer. Test procedures prompt you to manually connect test leads in the

required configuration.

W X Warning

To avoid possible electric shock, burning of the skin, or

personal injury, follow these guidelines: Retractable end

of test leads are for use on ESU only. No probes or

accessories supplied with the analyzer are intended for

handheld use. Set up using the safety test leads and stand

clear when activating the ESU with the footswitch.

The Analyzer does not internally configure the test leads. You can view

functional-block diagrams for each test at the end of each test procedure

section in this chapter. Additional information about test leads is given in

“Installation.”

3-3

Page 40

RF303

Operators Manual

Note

The Analyzer can test a wide range of electrosurgical units for basic

operation and performance. It is compatible with both isolated and

earth–ground referenced outputs, and with both monopolar and

bipolar outputs. If you have any questions about testing an ESU, you

can review “Specifications” and the technical service manual for the

ESU you want to test. In addition, you can contact our technical

assistance center at 800-648-7952.

Key to Panel Diagrams

The Analyzer uses lights to indicate whether the value displayed in the

window represents watts, mA, or ohms. The diagrams in this section resemble

the Analyzer panel. The key is as follows:

○ Analyzer panel light is off

● Analyzer panel light is on

Generator Output Test

The Analyzer provides an effective method of attaching a resistive load to the

ESU under test and displays the output directly in either watts or HF current of

the applied ESU signal. See Figure 3-1 for a diagram of the generator output

test.

Test Procedures

This test involves:

• connecting the ESU you want to test to the Analyzer

• selecting a test load resistance

• measuring the ESU’s power output

• measuring the ESU’s current output

• ending the test

To connect the ESU to the Analyzer for a monopolar output test:

1. Connect the ESU Active electrode to the yellow jack (marked) active,

using one of the test leads from the set, Part # 1903307.

3-4

Page 41

Operation

Testing the ESU

3

2. Connect the ESU Neutral/Dispersive electrode to the left blue jack

dispersive, using the test lead, Part # 2772171.

3. Continue to load selection.

To connect the ESU to the Analyzer for a bipolar output test:

1. Connect the ESU Bipolar-1 electrode to the yellow jack (marked) active,

using one of the test leads from the set, Part # 1903307.

2. Connect the ESU Bipolar-2 electrode to the left blue jack dispersive, using

the other test lead from the set, Part # 1903307.

3. Continue to load selection.

To select the desired test load resistance:

1. Press the OHMS SELECT increase (+) or decrease (-) buttons until the

test load value you want appears in the display. After approximately one

second, the display returns to a blank screen. Below is an example of a test

load value as it appears in the display.

WATTS

mA

OHMS

ENT

MODE SELECT

OHMS SELECT

exz03.eps

Note

The default (or initial power-up) test load selection is 300 ohms.

3-5

Page 42

RF303

Operators Manual

To measure the ESU’s power output:

1. Activate the ESU.

2. If the WATTS indicator lamp on the panel is lit, go to Step 3. If it is not

lit, press the MODE SELECT (ENT) button to select WATTS and go to

Step 3.

3. View the power measurement on the display. Here is an example:

WATTS

mA

OHMS

ENT

MODE SELECT

OHMS SELECT

exz04.eps

To measure the ESU’s current output:

1. While the ESU is still activated, press the MODE SELECT (ENT) button

until the milliamperes (mA) indicator lamp lights.

2. View the ESU’s current output (in mA). Below is an example.

WATTS

mA

OHMS

ENT

MODE SELECT

OHMS SELECT

To end the generator output test:

Deactivate the ESU.

W Caution

To avoid damage to the Analyzer and the ESU under test,

do not exceed the Analyzer’s duty cycle, which is 30

seconds ON during any continuous one-minute period.

3-6

exz05.eps

Page 43

Operation

M

3

exz06.eps

Testing the ESU

ESU RF303

YEL

BLU

BLU

HF

Meter

Supply

Mains

Earth

ESU Active

Active

Dispersive

CQM

Figure 3-1. Generator Output Test

ESU Dispersive

Main

Test

Load

Basic Contact Quality Monitor (CQM) Test

This test of the contact quality monitor uses the Analyzer’s test load to

simulate a patient’s skin resistance in contact with the dual element

neutral/dispersive electrode pad.

Note

Perform this test on electrosurgical units without energizing the

generator output. Do not connect the ESU active electrode to the

Analyzer during this test.

The CQM (REM) test is intended for the neutral/dispersive electrode of

monopolar ESUs equipped with a contact quality monitor. The

neutral/dispersive electrode is actually two separate pads attached to the

patient’s skin. The CQM (REM) circuit issues an alarm only if the patient

loses contact with one or both of the two pads. See Figure 3-2 for a diagram at

the end of this section.

3-7

Page 44

RF303

Operators Manual

Test Procedures

The procedures involved with this test include:

• connecting the ESU neutral/dispersive electrode to the Analyzer

• selecting a 50-ohm test load resistance

• increasing load resistance on the Analyzer to observe the ESU’s

visual or audio alarm

To connect the ESU’s neutral/dispersive electrode to the Analyzer:

1. Connect one of the two color-coded banana plugs (test lead Part #

2772180) to the Analyzer’s yellow jack active.

2. Connect the other banana plug to the Analyzer’s left blue jack dispersive.

3. Connect the 2PIN CQM (REM) connector on the other end of the test lead

to the neutral/dispersive electrode of the ESU.

To select a 50-ohm test load resistance setting:

1. Press the OHMS SELECT increase (+) or decrease (-) buttons as needed

until the test load value 50 appears in the display. After approximately one

(1) second, the display returns to a blank screen. Below is an example of a

test load value as it appears in the display.

3-8

ENT

MODE SELECT

WATTS

mA

OHMS

OHMS SELECT

exz12.eps

Page 45

Operation

Testing the ESU

3

To observe the ESU’s visual or audible alarm:

1. With the 50-ohm test load attached to the ESU CQM (REM) input, it

should sense this level of resistance in the "pass zone." Depending upon

the ESU device manufacturer, this pass zone can extend from 135 to 250

ohms. Test load settings over the pass zone activate the CQM alarm.

Note

Refer to the technical support/service manual of the ESU you are

testing for the recommended check-out procedure for the ESU CQM

feature.

2. Increase the test load from 50 ohms until the CQM alarm sounds. The

value at that point is the CQM alarm resistance.

Supply

Mains

Earth

ESU

ACTIVE

DISPERSIVE

CQM

Figure 3-2. Basic CQM Check

X No connection

ESU CQM

Basic CQM Check

(Contact Quality Monitor)

RF303

BLU

Main

Test

Load

YEL

exz13.eps

3-9

Page 46

RF303

Operators Manual

HF Leakage Current Test 1

The HF leakage current test number one is an IEC isolated output/bipolar, CFtype leakage current test. It shows you the amount of open-circuit high

frequency current leakage from a single isolated electrode to earth/ground

through a 200-ohm resistive test load. See Figure 3-3 for a diagram of this test

at the end of this section.

Note

This high frequency leakage current test is intended only for isolated

output electrosurgical units. If you test the active electrode of an

earth-referenced Type BF ESU in the manner described in this

section, you will be measuring the full output of the generator, not a

high frequency leakage current. While conducting this test

inappropriately will not damage the Analyzer, the resulting high

frequency leakage current measurement will not be valid for an

earth/ground referenced ESU.

Test Procedures

The procedures involved with this test include:

• connecting the ESU electrode you want to test to the Analyzer

• selecting a 200-ohm test load resistance

• measuring the ESU’s HF leakage current

• ending the test

To connect the ESU electrode to the Analyzer:

1. If you are testing the ESU’s active or single bipolar electrode, connect the

electrode to the yellow jack active, using one of the test leads from the set,

Part # 1903307, or

If you are testing the ESU’s neutral/dispersive electrode, connect that

electrode to the yellow jack active, using the test lead Part # 2772171.

2. Connect the jumper between the right blue jack dispersive and the left

green jack ground earth reference, using test lead Part # 2772209.

3-10

Page 47

Operation

Testing the ESU

3

3. If operating under battery power, attach a test lead from the set (Part #

1903307) from the battery ground on the side panel to the ground earth

reference.

To select a 200-ohm test load resistance setting:

1. Press the OHMS SELECT increase (+) or decrease (-) buttons as needed

until the test load value 200 appears in the display. After approximately

one second, the display returns to a blank screen. Below is an example of

a test load value as it appears in the display.

WATTS

mA

OHMS

ENT

MODE SELECT

OHMS SELECT

exz07.eps

To measure the ESU’s signal HF leakage:

1. If the mA indicator lamp on the panel is lit, go to Step 2. If it is not lit,

press the MODE SELECT (ENT) button to select mA and go to Step 2.

2. Activate the ESU and view the signal HF leakage measurement in

milliamperes on the display. Here is an example.

WATTS

mA

OHMS

ENT

MODE SELECT

OHMS SELECT

exz18.eps

To end HF leakage test number one:

Deactivate the ESU to end the HF leakage test.

3-11

Page 48

RF303

Operators Manual

W Caution

To avoid damage to the Analyzer and the ESU under test,

do not exceed the Analyzer’s duty cycle, which is 30

seconds ON during any continuous one-minute period.

HF Leakage Test 1

OPEN CIRCUIT TEST

CONNECT ONE HF LEAD ONLY

ESU RF303

ESU

Active

SUPPLY

MAINS

EARTH

ACTIVE

DISPERSIVE

CQM

F

TYPE CF

WHILE IN BATTERY OPERATION MODE:

Use Lead from side battery ground banana

jack to earth reference point.

OR

ESU

Dispersive

Jumper

YEL

MAIN

TEST

LOAD

BLU

GRN

GROUND EARTH

REFERENCE

Figure 3-3. HF Leakage Test Number One

METER

M

HF

exz11.eps

3-12

Page 49

Operation

Testing the ESU

3

HF Leakage Current Test 2

The HF leakage test number two is an IEC earth-referenced, BF-type leakage

current test. You perform the test by connecting a 200-ohm resistive test load

from the ESU’s active electrode to earth/ground on the Analyzer. High

frequency leakage current is then measured through a second 200-ohm

resistive load. You can view the resulting measurement on the Analyzer’s

display. See Figure 3-4 for a diagram of this test at the end of this section.

Test Procedures

The procedures involved with this test include:

• connecting the ESU you want to test to the Analyzer

• selecting a 200-ohm test load resistance

• measuring the ESU’s HF leakage current

• ending the test

To connect the ESU to the Analyzer:

1. Connect the ESU Active electrode to the right gray jack aux HF leakage,

using one of the test leads from the set, Part # 1903307.

2. Connect the ESU Neutral/Dispersive electrode to the left blue jack

dispersive, using test lead Part # 2772171.

3. Connect a jumper between the yellow jack active and the left green jack

ground earth reference, using test lead Part # 2772209.

4. Connect a jumper between the right blue jack dispersive and the left gray

jack aux HF leakage, using test lead Part # 2772209.

5. If operating under battery power, attach a test lead from the set (Part #

1903307) from the battery ground on the side panel to the ground earth

reference.

To select a 200-ohm test load resistance setting:

1. Press the OHMS SELECT increase (+) or decrease (-) buttons repeatedly

until the test load value 200 appears in the display. After approximately

one second, the display returns to a blank screen. Below is an example of

a test load value as it appears in the display.

3-13

Page 50

RF303

Operators Manual

WATTS

mA

OHMS

ENT

MODE SELECT

OHMS SELECT

exz07.eps

To measure the ESU’s signal HF leakage:

1. If the mA indicator lamp on the panel is lit, go to Step 2. If it is not lit,

press the MODE SELECT (ENT) button to select mA and go to Step 2.

2. Activate the ESU and view the signal HF leakage measurement in

milliamperes on the display. Here is an example.

WATTS

mA

OHMS

ENT

MODE SELECT

OHMS SELECT

exz18.eps

To end HF leakage test number two:

Deactivate the ESU to end the HF leakage test.

W Caution

To avoid damage to the Analyzer and the ESU under test,

do not exceed the Analyzer’s duty cycle, which is 30

seconds ON during any continuous one-minute period.

3-14

Page 51

Operation

Testing the ESU

Earth Reference Leakage Type BF Test 2

(Load between electrodes)

ESU

RF303

3

SUPPLY

MAINS

EARTH

Active Lead

ACTIVE

Jumper

DISPERSIVE

CQM

ESU

Dispersive

Jumper

TYPE BF

WHILE IN BATTERY OPERATION MODE:

Use Lead from side battery ground banana

jack to earth reference point.

Figure 3-4. HF Leakage Test Number Two

GRA

GRA

BLU

BLU

MAIN

TEST

LOAD

YEL

GRN

HF

METER

M

GROUND

EARTH

REFERENCE

exz08.eps

3-15

Page 52

RF303

Operators Manual

HF Leakage Current Test 3

The HF leakage test number three is an IEC earth-referenced, BF-type leakage

current test. You perform the test by connecting a 200-ohm resistive test load

from the ESU’s active electrode to earth/ground on the Analyzer. Then you

connect a second 200-ohm resistive load from the ESU’s neutral/dispersive

electrode to earth/ground on the Analyzer. The Analyzer then displays the high

frequency current leakage from the ESU you’re testing. See Figure 3-5 for a

diagram of this test at the end of this section.

Test Procedures

The procedures involved with this test include:

• connecting the ESU you want to test to the Analyzer

• selecting a 200-ohm test load resistance

• measuring the ESU’s HF leakage current

• ending the test

To connect the ESU to the Analyzer:

1. Connect the ESU Active electrode to the right gray jack aux HF leakage,

using one of the test leads from the set, Part # 1903307.

2. Connect the ESU Neutral/Dispersive electrode to yellow jack active, using

test lead Part # 2772171.

3. Connect a jumper between the right blue jack dispersive and the left green

jack ground earth reference, using test lead Part # 2772209.

4. Connect a jumper between the right green jack ground earth reference and

the left gray jack aux HF leakage, using test lead Part # 2772209.

5. If operating under battery power, attach a test lead from the set (Part #

1903307) from the battery ground on the side panel to the ground earth

reference.

To select a 200-ohm test load resistance setting:

1. Press the OHMS SELECT increase (+) or decrease (-) buttons as needed

until the test load value 200 appears in the display. After approximately

one second, the display returns to a blank screen. Below is an example of

a test load value as it appears in the display.

3-16

Page 53

Operation

Testing the ESU

WATTS

mA

OHMS

ENT

MODE SELECT

OHMS SELECT

3

exz07.eps

To measure the ESU’s signal HF leakage:

1. If the mA indicator lamp on the panel is lit, go to Step 2. If it is not lit,

press the MODE SELECT (ENT) button to select mA and go to Step 2.

2. Activate the ESU and view the signal HF leakage measurement on the

display. The measurement will be in milliamperes. Here is an example.

WATTS

mA

OHMS

ENT

MODE SELECT

OHMS SELECT

exz18.eps

To end HF leakage test number three:

Deactivate the ESU to end the HF leakage test.

W Caution

To avoid damage to the Analyzer and the ESU under test,

do not exceed the Analyzer’s duty cycle, which is 30

seconds ON during any continuous one-minute period.

3-17

Page 54

RF303

Operators Manual

Earth Reference Leakage Type BF Test 3

(Load from active electrode to earth)

ESU

RF303

SUPPLY

MAINS

EARTH

ESU Active

ACTIVE

Jumper

DISPERSIVE

CQM

ESU

Dispersive

Jumper

TYPE BF

WHILE IN BATTERY OPERATION MODE:

Use Lead from side battery ground banana

jack to earth reference point.

Figure 3-5. HF Leakage Test Number Three

GRA

GRA

GRN

YEL

MAIN

TEST

LOAD

BLU

GRN

HF

METER

M

GROUND

EARTH

REFERENCE

exz10.eps

3-18

Page 55

Operation

Connecting an Oscilloscope to the Analyzer

3

Connecting an Oscilloscope to the Analyzer

You can connect an oscilloscope to the Analyzer. Connect a standard coaxial

cable to the scope out BNC connector located on the top left of the panel.

Adjust your oscilloscope to view the applied waveform. Refer to Figure 3-6 to

see a typical burst waveform.

Figure 3-6. Burst Waveform on Oscilloscope Display

exz17.bmp

Remote Operation via the RS-232 Function

You can operate the Analyzer locally or remotely. Local mode is the default;

you manually control the Analyzer by pressing the buttons on the panel. Set

the desired test load and indicate whether to measure in watts or milliamperes.

All test load and measurement values appear on the display.

Two remote modes are also available: Simplex Mode (unidirectional

communication) and Duplex Mode (bi-directional communication).

3-19

Page 56

RF303

Operators Manual

Setting Up and Operating the Analyzer in Simplex Mode

In Simplex Mode, you control operation of the Analyzer from the panel. By

pressing the MODE SELECT (ENT) key, you can transmit a fixed data string

to a host device that includes the ESU readings (in watts), HF current (in

milliamps), and test load value (in ohms). The Analyzer sends data to a host

device at a fixed baud rate. The Analyzer cannot receive commands from a

remote terminal or computer in Simplex Mode.

To set up and operate in Simplex Mode, follow these steps:

1. Connect the Analyzer to the computer with a serial interface cable, Part #

2238659.

2. Set the computer to receive data at a baud rate of 2400 with 8 data bits, no

parity, and 1 stop bit.

3. With the Analyzer power turned off, press and hold both the + and -

OHMS SELECT keys located on the panel.

4. Power-up the Analyzer, and then release both keys when the double beep

is heard.

5. Set up the Analyzer to conduct the desired ESU measurement.

6. Press and release the MODE SELECT key to transmit the data while a

measurement is displayed.

7. Data transfers in the format:

Watts =XXXX, I=YYYY, Load =ZZZ.

8. To exit Simplex Mode, power down the Analyzer.

Setting Up and Operating the Analyzer in Duplex Mode

In Duplex Mode, you control operation of the Analyzer from a remote terminal

or computer by issuing specific remote commands that control all features of

the Analyzer. You can view test data received as a result of sending a remote

command on the host controller's display. In Duplex Mode, all panel keys are

"locked out" to allow all functions to be under full direction of the host

controller.

To set up and operate in Duplex Mode, follow these steps:

1. Connect the Analyzer to the computer with a serial interface cable, Part #

2238659.

3-20

Page 57

Operation

Remote Operation via the RS-232 Function

2. Set the computer to communicate with a baud rate of 2400 with 8 data

bits, no parity, and 1 stop bit.

Note

Serial port flow control uses neither XON/XOFF signals nor

hardware flow control (RTS/CTS).

3. Power-up the Analyzer without pressing any keys.

4. To set the Analyzer in Remote Mode, send the GOTOREMOTE

command. After the command is received by the Analyzer, four horizontal

bars appear on the display. Since the controlling computer always receives

a return value, a response, the asterisk will be displayed on the monitor.

5. Control the Analyzer with the desired commands.

6. To exit Remote Mode and return to Local Mode, send the GOTOLOCAL

command.

Observe the following while operating in Duplex Mode:

• Commands must be terminated by a carriage return/ line feed (CR)

(LF).

3

• Setup commands always end with the colon character and a

parameter: (plus the parameter) For example, the setup command

SETLOAD requires the colon followed by the load value (in ohms):

SETLOAD: 50

• Multiple commands (or parameters) are separated by commas. All

possible command (parameter) choices are shown. Unless otherwise

stated, the default parameters are listed first.

• As mentioned earlier, every command returns a value as a response.

The return value may be a string of alphanumeric characters.

Commands that do not require any special return value will show the

star character * simply to indicate that the command has been

executed.

• After the Analyzer receives a command, it will ignore all other

commands until after it has responded to the first command.

• If you do not enter a command and just press the Enter key (carriage

return) on the computer keyboard, the Analyzer will return the ?

(question mark) character.

3-21

Page 58

RF303

Operators Manual

• All responses are uppercase, followed by CR and LF.

• Measurement readings from the Analyzer are returned identically as

they would appear on the Analyzer's display; that is, as numbers, with

or without a decimal point, and followed by any appropriate unit of

measurement.

• Errors always return a response beginning with: ?ERR=XX (plus the

description). Table 3-1 lists each of the error responses.

Table 3-1. Error Responses

Error Response Explanation

?ERR=01,BAD OR MISSING

PARAMETERS

?ERR=02,ILLEGAL NUMBER OF

PARAMETERS

?ERR=03,PARAMETER OUT OF

RANGE OR SYNTAX ERROR

?ERR=04,COMMAND NOT

AVAILABLE FROM THIS MODE

?ERR=05, DEACTIVATE ESU

BEFORE ADJUSTING

?ERR=06,ACCESS DENIED The command is a calibration

The received command requires

parameters, and there were none, or

they were not recognized.

The command did not include the

correct number of parameters.

One or more of the parameters were

out of the correct range, or there was

an error in the syntax of the

command.

The Model Analyzer is not in the

special sub mode within the remote

that is required for the command.

There is an ESU signal present at the

meter inputs that is not allowed for

the command to be executed.

command and the calibration jumper

is not connected

Table 3-2 describes various commands available in Duplex Mode.

3-22

Page 59

Operation

Remote Operation via the RS-232 Function

Table 3-2. Available Duplex Mode Commands

3

Command Description Parameters

Required

GOTOREMOTE

GOTOLOCAL

IDENT

VER

SETMODE:{parm}

Places the Analyzer in

the duplex remote

mode.

Returns the Analyzer to

normal (local mode)

operation / exits duplex

remote mode.

Identifies the Analyzer

model and firmware

version number.

Identifies the firmware

version number.

Changes the format of

the Analyzer response

to the RDMETER

command. Separate the

command from the

desired mode

(parameter) using a

colon. Refer to

RDMETER below.

Example:

SETMODE:OUTPUT

None *

None

None

None

OUTPUT (for

measuring

generator

output).

RFLKG (for

measuring

HF leakage).

RARF (for

conducting

CQM test).

Return Value

(Response)

*

Model Analyzer name

and the version of the

firmware.

Example: MODEL

Analyzer VERSION

X.XX

Where X.XX is the

version number.

Firmware version

number.

Example: VERSION

X.XX

Where: X.XX is the

version number.

*

3-23

Page 60

RF303

Operators Manual

Table 3-2. Available Duplex Mode Commands (cont.)

Command Description Parameters

Required

RDMODE Prompts the Analyzer to

transmit the currently

selected mode.

EXITMODE Prompts the Analyzer to

exit the currently

selected mode.

Note: You must exit the

current mode before

entering another.

SETLOAD:{parm} Sets the measurement

test load resistance from

50-750 ohms in 50 ohm

increments. Not

available in RFLKG

mode.

RDLOAD Resistance value of the

selected test load

appears in the display.

None NONE

None *

Values of 50750 in

increments of

50

None RRRR (ohms)

Return Value

(Response)

OUTPUT

RFLKG

RARF

*

Where RRRR is the

load value in ohms.

Formatted to four

digits with leading

spaces as required.

RDPOWER Prompts an Analyzer

power measurement in

watts. Not available in

RFLKG and RARF

modes.

None PPP.P (w)

3-24

Page 61

Operation

Remote Operation via the RS-232 Function

Table 3-2. Available Duplex Mode Commands (cont.)

3

Command Description Parameters

Required

RDCURRENT Prompts an Analyzer

current measurement in

milliamperes. Not

available in RARF

mode.

RDMETER Prompts the Analyzer to

measure the applied

signal of the ESU.

Prompts the Analyzer to

return all measurements

of the applied signal of

the ESU.

{MODE=NONE}

None AAAA (mA)

None

None I=AAAA(mA),

Return Value

(Response)

Where AAAA is

current in

milliamperes.

CF=XX.X,

KVPP=XXX,

PWR=PPP.P(w)

Where AAAA is the

Current reading in

milliamps, XX.X is the

Crest Factor, XXX is

the peak-to-peak

voltage in kVolts and

PPP.P is the power in

watts.

3-25

Page 62

RF303

Operators Manual

Table 3-2. Available Duplex Mode Commands (cont.)

Command Description Parameters

Required

Prompts the Analyzer to

return all measurements

of the applied signal of

the ESU.

{MODE=OUTPUT}

Prompts the Analyzer to

measure the applied

signal current of the

ESU.

{MODE=RFLKG}

Prompts the Analyzer to

return the current test

load.

{MODE=RARF}

None I=AAAA(mA),

None I=AAAA(mA)

None REM RESISTANCE=

Return Value

(Response)

CF=XX.X,

KVPP=XXX,

PWR=PPP.P(w)

Where AAAA is the

Current reading in

milliamps, XX.X is the