Page 1

VT Plus HF

Gas Flow Analyzer

Operators Manual

PN 2137275

May 2008, Rev. 2, 4/09

© 2008, 2009 Fluke Corporation, All rights reserved. Printed in USA. Specifications are subject to change without notice.

All product names are trademarks of their respective companies.

Page 2

Warranty and Product Support

Fluke Biomedical warrants this instrument against defects in materials and workmanship

for one year from the date of original purchase. During the warranty period, we will

repair or at our option replace, at no charge, a product that proves to be defective,

provided you return the product, shipping prepaid, to Fluke Biomedical. This warranty

covers the original purchaser only and is not transferable. The warranty does not apply if

the product has been damaged by accident or misuse or has been serviced or modified by

anyone other than an authorized Fluke Biomedical service facility. NO OTHER

WARRANTIES, SUCH AS FITNESS FOR A PARTICULAR PURPOSE, ARE

EXPRESSED OR IMPLIED. FLUKE SHALL NOT BE LIABLE FOR ANY SPECIAL,

INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES OR LOSSES,

INCLUDING LOSS OF DATA, ARISING FROM ANY CAUSE OR THEORY.

This warranty covers only serialized products and their accessory items that bear a

distinct serial number tag. Recalibration of instruments is not covered under the warranty

This warranty gives you specific legal rights and you may also have other rights that vary

in different jurisdictions. Since some jurisdictions do not allow the exclusion or limitation

of an implied warranty or of incidental or consequential damages, this limitation of

liability may not apply to you. If any provision of this warranty is held invalid or

unenforceable by a court or other decision-maker of competent jurisdiction, such holding

will not affect the validity or enforceability of any other provision.

07/07

Page 3

Notices

All Rights Reserved

© Copyright 2008, Fluke Biomedical. No part of this publication may be reproduced, transmitted, transcribed, stored in a retrieval

system, or translated into any language without the written permission of Fluke Biomedical.

Copyright Release

Fluke Biomedical agrees to a limited copyright release that allows you to reproduce manuals and other printed materials for use in

service training programs and other technical publications. If you would like other reproductions or distributions, submit a written

request to Fluke Biomedical.

Unpacking and Inspection

Follow standard receiving practices upon receipt of the instrument. Check the shipping carton for damage. If damage is found, stop

unpacking the instrument. Notify the carrier and ask for an agent to be present while the instrument is unpacked. There are no special

unpacking instructions, but be careful not to damage the instrument when unpacking it. Inspect the instrument for physical damage such

as bent or broken parts, dents, or scratches.

Technical Support

For application support or answers to technical questions, either email techservices@flukebiomedical.com or call 1-800- 850-4608 ext

2560 or 1-440-498-2560.

Claims

Our routine method of shipment is via common carrier, FOB origin. Upon delivery, if physical damage is found, retain all packing

materials in their original condition and contact the carrier immediately to file a claim. If the instrument is delivered in good physical

condition but does not operate within specifications, or if there are any other problems not caused by shipping damage, please contact

Fluke Biomedical or your local sales representative.

Standard Terms and Conditions

Refunds and Credits

Please note that only serialized products and their accessory items (i.e., products and items bearing a distinct serial number

tag) are eligible for partial refund and/or credit. Nonserialized parts and accessory items (e.g., cables, carrying cases,

auxiliary modules, etc.) are not eligible for return or refund. Only products returned within 90 days from the date of original

purchase are eligible for refund/credit. In order to receive a partial refund/credit of a product purchase price on a serialized product, the

product must not have been damaged by the customer or by the carrier chosen by the customer to return the goods, and the product

must be returned complete (meaning with all manuals, cables, accessories, etc.) and in “as new” and resalable condition. Products not

returned within 90 days of purchase, or products which are not in “as new” and resalable condition, are not eligible for credit return and

will be returned to the customer. The Return Procedure (see below) must be followed to assure prompt refund/credit.

Restocking Charges

Products returned within 30 days of original purchase are subject to a minimum restocking fee of 15 %. Products returned in excess of

30 days after purchase, but prior to 90 days, are subject to a minimum restocking fee of 20 %. Additional charges for damage and/or

missing parts and accessories will be applied to all returns.

Return Procedure

All items being returned (including all warranty-claim shipments) must be sent freight-prepaid to our factory location. When you return

an instrument to Fluke Biomedical, we recommend using United Parcel Service, Federal Express, or Air Parcel Post. We also

recommend that you insure your shipment for its actual replacement cost. Fluke Biomedical will not be responsible for lost shipments

or instruments that are received in damaged condition due to improper packaging or handling.

Use the original carton and packaging material for shipment. If they are not available, we recommend the following guide for

repackaging:

Use a double-walled carton of sufficient strength for the weight being shipped.

Use heavy paper or cardboard to protect all instrument surfaces. Use nonabrasive material around all projecting parts.

Use at least four inches of tightly packed, industry-approved, shock-absorbent material around the instrument.

Returns for partial refund/credit:

Every product returned for refund/credit must be accompanied by a Return Material Authorization (RMA) number, obtained from our

Order Entry Group at 1-800- 850-4608 ext 2560 or 1-440-498-2560.

Page 4

Repair and calibration:

To find the nearest service center, go to www.flukebiomedical.com/service

In the U.S.A.:

Cleveland Calibration Lab

Tel: 1-800-850-4606

Email: globalcal@flukebiomedical.com

Everett Calibration Lab

Tel: 1-888-993-5853

Email: service.status@fluke.com

In Europe, Middle East, and Africa:

Eindhoven Calibration Lab

Tel: +31-402-675300

Email: ServiceDesk@fluke.com

In Asia:

Everett Calibration Lab

Tel: +425-446-6945

Email: mailto:service.international@fluke.com

, or

Certification

This instrument was thoroughly tested and inspected. It was found to meet Fluke Biomedical’s manufacturing specifications when it

was shipped from the factory. Calibration measurements are traceable to the National Institute of Standards and Technology (NIST).

Devices for which there are no NIST calibration standards are measured against in-house performance standards using accepted test

procedures.

WARNING

Unauthorized user modifications or application beyond the published specifications may result in electrical shock hazards or

improper operation. Fluke Biomedical will not be responsible for any injuries sustained due to unauthorized equipment

modifications.

Restrictions and Liabilities

Information in this document is subject to change and does not represent a commitment by Fluke Biomedical. Changes made

to the information in this document will be incorporated in new editions of the publication. No responsibility is assumed by

Fluke Biomedical for the use or reliability of software or equipment that is not supplied by Fluke Biomedical, or by its

affiliated dealers.

Manufacturing Location

The VT PLUS HF Gas Flow Analyzer is manufactured in Everett, Washington by Fluke Biomedical, 6920 Seaway Blvd.,

Everett, WA, U.S

Page 5

Table of Contents

Chapter Title Page

1 Introduction and Specifications......................................................... 1-1

Introduction........................................................................................................ 1-3

Key Features ...................................................................................................... 1-3

Unpacking and Inspection.................................................................................. 1-3

General Safety Considerations........................................................................... 1-4

Symbols ......................................................................................................... 1-4

Warnings and Cautions.................................................................................. 1-4

Instrument Familiarity ....................................................................................... 1-5

Front Panel..................................................................................................... 1-6

Right Panel .................................................................................................... 1-6

Rear Panel...................................................................................................... 1-7

Left Panel....................................................................................................... 1-7

Front Panel Details ........................................................................................ 1-8

Specifications..................................................................................................... 1-10

General Specifications................................................................................... 1-10

Performance Specifications ........................................................................... 1-11

Breath Parameter Accuracy Specifications ................................................... 1-12

Accessories ........................................................................................................ 1-14

2 Connection and Setup ........................................................................ 2-1

Connecting the Analyzer ................................................................................... 2-3

Pneumatic Connections ................................................................................. 2-3

High Flow (Inlet and Exhaust).................................................................. 2-3

Low Flow (Inlet and Exhaust)................................................................... 2-3

High Pressure (+ and -) ............................................................................. 2-3

Low Pressure (+ and -).............................................................................. 2-4

Test System Setup ......................................................................................... 2-4

Bi-directional Flow Mode ......................................................................... 2-4

Unidirectional Flow Mode ........................................................................ 2-5

Printer Cable Attachment .............................................................................. 2-6

Using the Setup Screen ...................................................................................... 2-7

Setting Testing Parameters ................................................................................ 2-7

Gas Settings................................................................................................... 2-8

Gas Type ................................................................................................... 2-8

i

Page 6

VT Plus HF

Operators Manual

Gas Temperature ....................................................................................... 2-9

Ambient Temperature ............................................................................... 2-9

Relative Humidity ..................................................................................... 2-9

Correction Mode............................................................................................ 2-10

Barometric Pressure....................................................................................... 2-10

Breath Detection............................................................................................ 2-11

Inspiratory/Expiratory Tidal Volumes........................................................... 2-12

Zero Mode ..................................................................................................... 2-12

Setting Analyzer Operating Parameters............................................................. 2-13

Time............................................................................................................... 2-13

Date ............................................................................................................... 2-14

Date Format ................................................................................................... 2-14

Demo Data..................................................................................................... 2-14

Filtering ......................................................................................................... 2-15

Display Calibration Date on Startup Screen.................................................. 2-15

Serial Mode ................................................................................................... 2-15

Printer Options............................................................................................... 2-16

Printer Type............................................................................................... 2-16

Graphics .................................................................................................... 2-17

Audio Levels ................................................................................................. 2-17

General ...................................................................................................... 2-17

Keypad ...................................................................................................... 2-17

Errors......................................................................................................... 2-18

Restore Defaults ............................................................................................ 2-18

Utilities .............................................................................................................. 2-20

Oxygen Sensor Calibration............................................................................ 2-20

System Diagnostics ....................................................................................... 2-21

Linearization.................................................................................................. 2-21

Unlock Calibration ........................................................................................ 2-22

Information ........................................................................................................ 2-22

3 Operation ............................................................................................. 3-1

Measured Signals............................................................................................... 3-3

High Flow...................................................................................................... 3-3

Low Flow ...................................................................................................... 3-3

Airway Pressure............................................................................................. 3-3

Low Pressure ................................................................................................. 3-3

Barometric Pressure....................................................................................... 3-4

High-Pressure Measurement.......................................................................... 3-4

Oxygen Concentration................................................................................... 3-4

Calculated Breath Parameters........................................................................ 3-4

Screen Objects ................................................................................................... 3-6

Title Bar......................................................................................................... 3-7

Data Plots ...................................................................................................... 3-7

Breath Parameters.......................................................................................... 3-7

Breath Detection Icons .................................................................................. 3-8

Instantaneous Numeric Data.......................................................................... 3-9

Statistics......................................................................................................... 3-9

Selecting Breath Parameters .............................................................................. 3-10

Flow Screens...................................................................................................... 3-11

High-Flow Screen.......................................................................................... 3-11

Low-Flow Screen .......................................................................................... 3-12

Pressure Screens ................................................................................................ 3-13

High-Pressure Screen .................................................................................... 3-13

ii

Page 7

Contents (continued)

Low Pressure Screen ..................................................................................... 3-14

Airway Pressure Screen................................................................................. 3-15

Volume Screen................................................................................................... 3-16

Oxygen Screen................................................................................................... 3-17

Full Breath Parameters Test Screen................................................................... 3-18

Monitor Screen .................................................................................................. 3-19

Units of Measure................................................................................................ 3-20

Special Functions............................................................................................... 3-21

Trend Test...................................................................................................... 3-21

Leak Test ....................................................................................................... 3-24

Stacked Volume Test..................................................................................... 3-27

RT200 Emulation Mode ................................................................................ 3-28

Assist Test ..................................................................................................... 3-31

High Frequency Oscillator Mode .................................................................. 3-32

4 Remote Operation ............................................................................... 4-1

Getting Started ................................................................................................... 4-3

System Requirements .................................................................................... 4-3

Connecting to the Analyzer ........................................................................... 4-3

Installing the Software................................................................................... 4-3

Starting the Software ..................................................................................... 4-4

Overview of VT for Windows PC Software...................................................... 4-5

Menu Bar ........................................................................................................... 4-6

Toolbar............................................................................................................... 4-8

Main Screens and Tests ..................................................................................... 4-9

Monitor Screen .............................................................................................. 4-9

Single Plot Screen.......................................................................................... 4-10

Loop Screen................................................................................................... 4-11

Full Test Screen............................................................................................. 4-12

Trend Test...................................................................................................... 4-12

Leak-Test....................................................................................................... 4-16

Stacked Volume Test Screen......................................................................... 4-18

Serial Communications...................................................................................... 4-20

Selecting COM Port ...................................................................................... 4-20

Selecting the Serial Communications Mode ................................................. 4-20

Data and File Handling ...................................................................................... 4-21

Events ............................................................................................................ 4-21

Opening and Closing Data Files.................................................................... 4-22

File Control Interface .................................................................................... 4-23

Playback Controls ..................................................................................... 4-24

Event Markers ........................................................................................... 4-25

File Information Panel............................................................................... 4-26

Event Panel ............................................................................................... 4-26

Generating Signal (.sig) Files ........................................................................ 4-26

Generating Parameter (.par) Files.................................................................. 4-26

Report Printing................................................................................................... 4-27

Operating System Loading ................................................................................ 4-27

Plots ................................................................................................................... 4-28

Automatically Re-scaling Plots ..................................................................... 4-28

Manually Re-scaling Plots............................................................................. 4-28

Signal Selection ............................................................................................. 4-29

Zeroing............................................................................................................... 4-30

Manual Zeroing ............................................................................................. 4-30

Automatic Zeroing......................................................................................... 4-30

iii

Page 8

VT Plus HF

Operators Manual

Other Setup Functions ....................................................................................... 4-31

Breath Detect ................................................................................................. 4-31

Breath Detect Threshold................................................................................ 4-31

Gas Settings................................................................................................... 4-31

Barometric Pressure....................................................................................... 4-34

5 Maintenance, Service, and Calibration.............................................. 5-1

Maintenance....................................................................................................... 5-3

Avoiding Damage.......................................................................................... 5-3

Cleaning......................................................................................................... 5-3

Oxygen Sensor Replacement ............................................................................. 5-3

Fuse Replacement .............................................................................................. 5-4

Service and Calibration...................................................................................... 5-5

Appendices

A Gas Analyzer Tutorial ................................................................................. A-1

B Error Messages............................................................................................ B-1

C Troubleshooting .......................................................................................... C-1

iv

Page 9

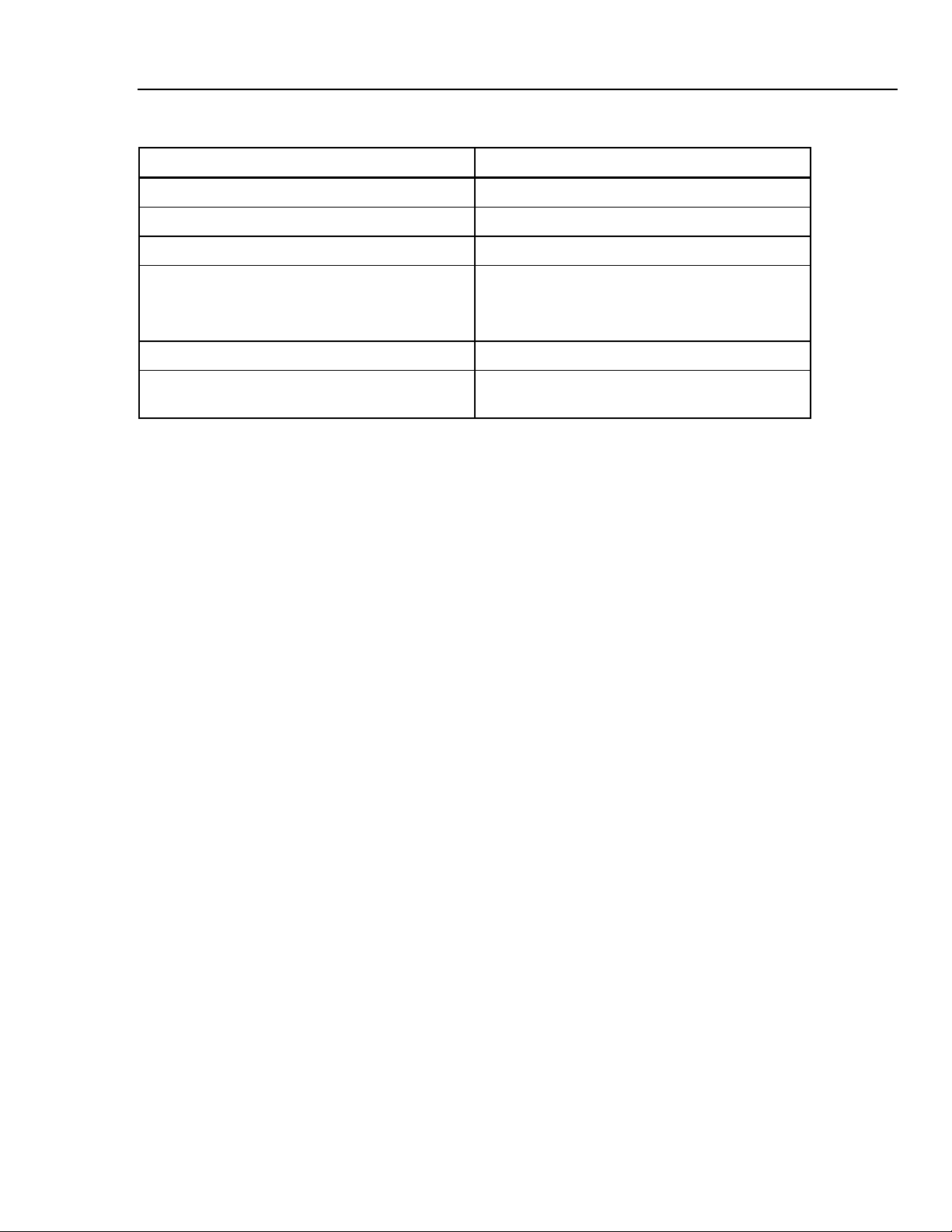

List of Tables

Table Title Page

1-1. Symbols.................................................................................................................. 1-4

1-2. Front Panel Components ........................................................................................ 1-6

1-3. Right Panel Components........................................................................................ 1-6

1-4. Back Panel Components ........................................................................................ 1-7

1-5. Left Panel Components .......................................................................................... 1-7

1-6. Front Panel Functions ............................................................................................ 1-8

1-7. Breath Parameter Accuracy Specifications ............................................................ 1-13

1-8. Standard Accessories ............................................................................................. 1-14

1-9. Optional Accessories.............................................................................................. 1-15

2-1. Gas Type Values .................................................................................................... 2-8

2-2. Breath Detection Options....................................................................................... 2-11

2-3. Serial Port Options ................................................................................................. 2-15

2-4. Factory Defaults ..................................................................................................... 2-18

3-1. Parameters Calculated by the Analyzer ................................................................. 3-5

3-2. Display Components .............................................................................................. 3-6

3-3. Breath Detection Icons........................................................................................... 3-8

3-4. Available Units of Measure.................................................................................... 3-20

3-5. Available Conversion Factors ................................................................................ 3-21

3-6. Supported RT200 Functions................................................................................... 3-29

4-1. Elements of the VT for Windows Interface ........................................................... 4-6

4-2. Menu Bar Options .................................................................................................. 4-7

4-3. Setup Submenu Options......................................................................................... 4-7

4-4. Toolbar Buttons...................................................................................................... 4-8

4-5. Data Types ............................................................................................................. 4-21

4-6. Generated File Types ............................................................................................. 4-21

4-7. Playback Controls .................................................................................................. 4-24

B-1. Error Messages....................................................................................................... B-1

C-1. Troubleshooting ..................................................................................................... C-1

v

Page 10

VT Plus HF

Operators Manual

vi

Page 11

List of Figures

Figure Title Page

1-1. Front and Right Analyzer Panels ........................................................................... 1-5

1-2. Rear and Left Analyzer Panels............................................................................... 1-7

1-3. Analyzer Front Panel.............................................................................................. 1-8

2-1. Connecting the Analyzer in a Bi-Directional Flow Mode ..................................... 2-4

2-2. Connecting the Analyzer to the Inspiratory Limb of the Breathing Circuit........... 2-5

2-3. Connecting the Analyzer to the Expiratory Limb of the Breathing Circuit ........... 2-5

3-1. Information Shown on Analyzer Display............................................................... 3-6

3-2. The Assist Test....................................................................................................... 3-31

3-3. Ventilator Breathing Circuit Setup for Bi-Directional Measurements................... 3-31

4-1. VT for Windows PC software Interface................................................................. 4-5

4-2. VT for Windows Menu Bar ................................................................................... 4-6

4-3. VT for Windows Toolbar....................................................................................... 4-8

4-4. Monitor Screen....................................................................................................... 4-9

4-5. Single Plot Screen .................................................................................................. 4-10

4-6. Loop Screen ........................................................................................................... 4-11

4-7. Full Test Screen...................................................................................................... 4-12

4-8. Trend Test: Setup Screen ....................................................................................... 4-13

4-9. Trend Test Screen: Testing Underway................................................................... 4-14

4-10. Trend Test Screen: Final Values Displayed ........................................................... 4-15

4-11. Leak Test: Setup Screen......................................................................................... 4-16

4-12. Leak Test Screen: Testing Underway .................................................................... 4-17

4-13. Stacked Volume Test: Setup Screen ...................................................................... 4-18

4-14. Stacked Volume Screen: Testing Underway.......................................................... 4-19

4-15. File Menu ............................................................................................................... 4-22

4-16. File Control Interface ............................................................................................. 4-23

4-17. File Information Panel............................................................................................ 4-26

5-1. Fuse Compartment ................................................................................................. 5-4

A-1. Circuit Connection for the Analyzer in Bi-directional Mode................................. A-6

vii

Page 12

VT Plus HF

Operators Manual

viii

Page 13

Chapter 1

Introduction and Specifications

Title Page

Introduction........................................................................................................ 1-3

Key Features ...................................................................................................... 1-3

Unpacking and Inspection.................................................................................. 1-3

General Safety Considerations........................................................................... 1-4

Symbols ......................................................................................................... 1-4

Warnings and Cautions.................................................................................. 1-4

Instrument Familiarity ....................................................................................... 1-5

Front Panel..................................................................................................... 1-6

Right Panel .................................................................................................... 1-6

Rear Panel...................................................................................................... 1-7

Left Panel....................................................................................................... 1-7

Front Panel Details ........................................................................................ 1-8

Specifications..................................................................................................... 1-10

General Specifications................................................................................... 1-10

Performance Specifications ........................................................................... 1-11

Breath Parameter Accuracy Specifications ................................................... 1-12

Accessories ........................................................................................................ 1-14

1-1

Page 14

VT Plus HF

Operators Manual

1-2

Page 15

Introduction and Specifications

Introduction 1

Introduction

The VT Plus HF Gas Flow Analyzer, referred to hereafter as the Analyzer, is a generalpurpose, gas flow analyzer with special modes for testing mechanical patient ventilators.

The Analyzer measures bidirectional flow in both high and low ranges, as well as highand low-pressure ranges. Users control the unit using the command system or a special

control mode that uses RT200-style commands. Multiple special-function tests allow

efficient troubleshooting.

The Analyzer can measure either high- or low-flow and pressure, eliminating the need for

gauges and flow meters. It measures 21 ventilator parameters and can display all of them

on one screen. Results can be printed directly from the unit or from Windows-compatible

software on a PC. The Analyzer also has onboard graphing capability and shows the

minimum, maximum, average, and absolute measurement for all parameters.

This manual provides a description of the Analyzer and its applications. It should be used

as a guide when using the instrument to analyze a ventilator and test lung.

Key Features

• Bi-directional flow, low- and high-pressure, volume, and oxygen concentration, and

pressure measurements

• Very high-frequency measurement capability – up to 900 BPM (15 Hz)

• RS232 and printer ports

• Included Windows-compatible graphics software

• Minimum, maximum, average, absolute, and graph for all parameters

• All 21ventilator parameters displayed on one screen simultaneously

• Operation by user-friendly command mode or RT200 command mode

• Operation with a variety of precision test lungs available from Fluke Biomedical to

complete a fully NIST-traceable ventilator test

• Tests the leak rate of a sealed vessel or test lung

• Tests whether a predetermined parameter deviates from limits set by the user

• Useful for pre-purchase evaluations of ventilators, incoming and routine performance

verification, troubleshooting clinical problems, and teaching principles of mechanical

ventilation

Unpacking and Inspection

Use the following checklist when unpacking the Analyzer. There are no special

unpacking instructions, but be careful not to damage the instrument when unpacking it.

• Inspect the shipping carton for damage. If the shipping carton is damaged, carefully

continue unpacking the instrument and note any dents and scratches on the Analyzer.

Save the damaged shipping carton and packing material for the carrier’s inspection.

• If there is no shipping damage, continue removing the Analyzer from the shipping

case. Save the box and packing materials.

Note

This box contains specifically designed inserts to ensure safe shipment of

the Analyzer. Please save these for return of the unit for service or

calibration.

1-3

Page 16

VT Plus HF

Operators Manual

General Safety Considerations

Symbols

• Perform a visual inspection to ensure that the Analyzer is intact and if there is any

physical damage, such as bent or broken parts, dents, or scratches. If the Analyzer

has been damaged, call the Fluke Biomedical Service Center immediately. If the

Analyzer be returned to Fluke for service, follow the procedure given under

Maintenance, Service, and Calibration: Packing Instructions.

• After unpacking the Analyzer, check to see if all of the standard accessories listed

under Accessories have been included with the Analyzer. If anything is missing,

contact the Fluke Biomedical Service Center.

Read the Users Manual before operating the Analyzer.

Table 1-1 describes the symbols associated with the Analyzer.

Table 1-1. Symbols

Symbol Description

X Hazardous voltage

W Important information; refer to manual

ΠConforms to UL Std 3101-1; certified to Can/USA Std C22.2 No. 1010.1

P Conforms to European Union directives

~

Do not dispose of this product as unsorted municipal waste. Go to Fluke’s

website for recycling information.

Hg Contains mercury. Dispose properly.

Warnings and Cautions

A Warning identifies hazardous conditions and actions that could cause bodily harm or

death.

A Caution identifies conditions and actions that could damage the Analyzer, the

equipment under test, or cause permanent loss of data.

To avoid possible electrical shock or personal injury, follow

these guidelines:

• Use this Analyzer only in the manner specified by the

manufacturer.

• Do not use the product if it operates abnormally.

XW Warning

1-4

• Plug the main power cord only into a power outlet that has a

protective earth contact to connect the chassis of the Analyzer to

ground.

• Do not use extension cords without earth ground, or a hazardous

condition may result.

• Turn off the Analyzer and disconnect its power cord before

opening the case or performing any service procedures.

Page 17

Introduction and Specifications

Instrument Familiarity 1

W Caution

To avoid damage to the Analyzer or adverse affects on its

performance, follow these guidelines:

• Do not expose the system to temperature extremes.

Ambient temperatures should remain between 10 °C and

40 °C. System performance may be adversely affected if

temperatures fluctuate above or below this range.

• Clean the Analyzer only by wiping it down with a clean, lint-

free cloth dampened with a mild detergent solution. A

solution of 70 % isopropyl alcohol may be used to remove

stains and clean the system. No other solvents are

recommended. Do not spray liquid directly on or immerse

the unit.

Instrument Familiarity

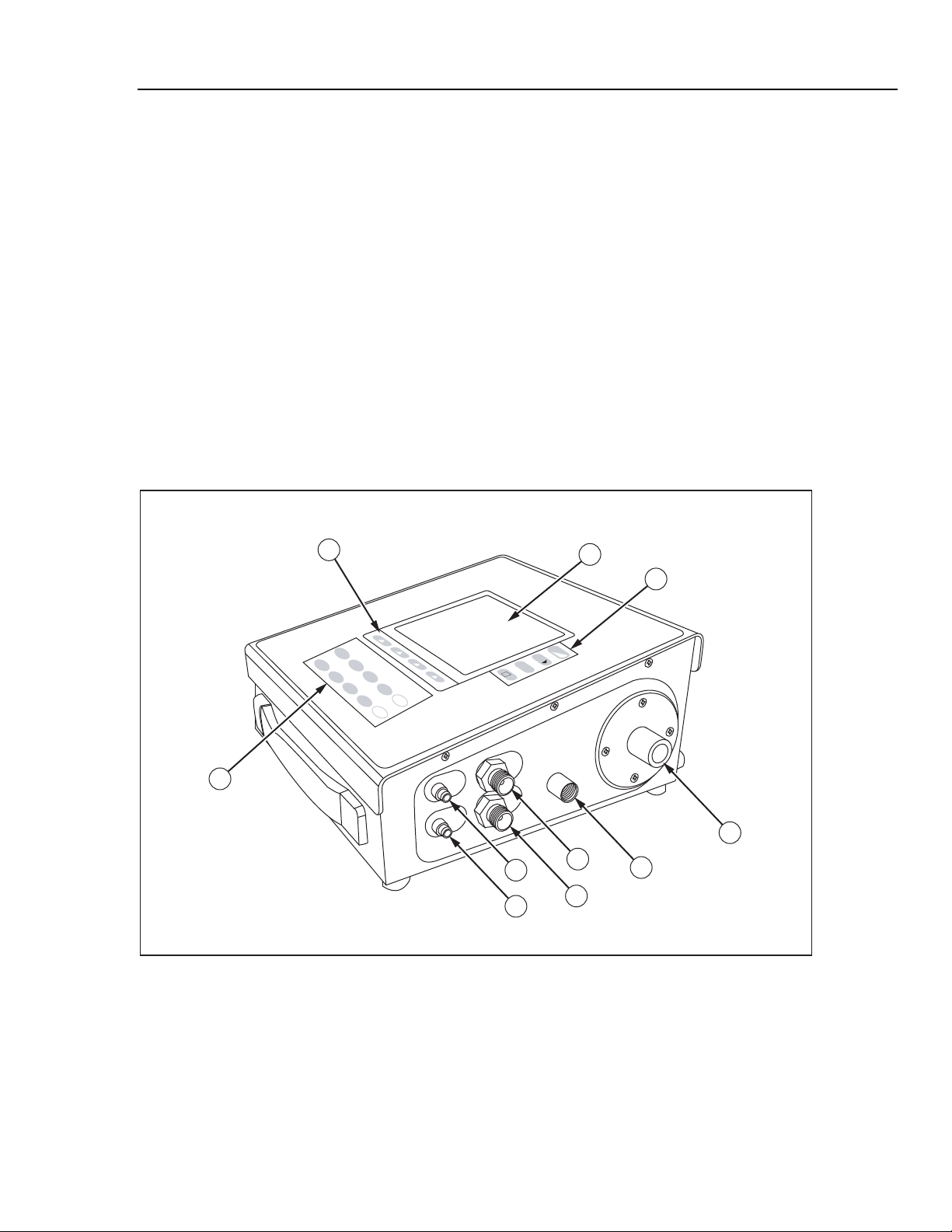

Figure 1-1 shows the top and right panels of the Analyzer.

3

1

2

F

L

O

W

0

P

R

F

U

E

L

S

L

S

U

TEST M

R

E

5

1

M

V

O

6

4

ODES

O

N

L

IT

U

O

M

R

E

2

Z

E

O

RO

2

7

3

M

S

O

E

R

T

E

U

P

4

8

P

A

R

A

M

E

T

E

9

R

S

+

gas or

d

flui

-

dry gas

only

ssure

±67kPa)

low pre

g (

range ±500mmH

II /

?

high flow &

inlet

gen

oxy

ge ± 300 lpm

ran

d.

gasses only

bele

dry

use

ual for

ept where la

s

ation

c

cifi

pe

W

exc

+

or

refer to users man

gas

complete inlet s

uid

fl

gas

dry

only

low flow

10

5

6

7

8

9

fec120.eps

Figure 1-1. Front and Right Analyzer Panels

1-5

Page 18

VT Plus HF

Operators Manual

Front Panel

Right Panel

The components of the front panel are listed in Table 1-2. See Front Panel Details for

detailed descriptions of front panel components.

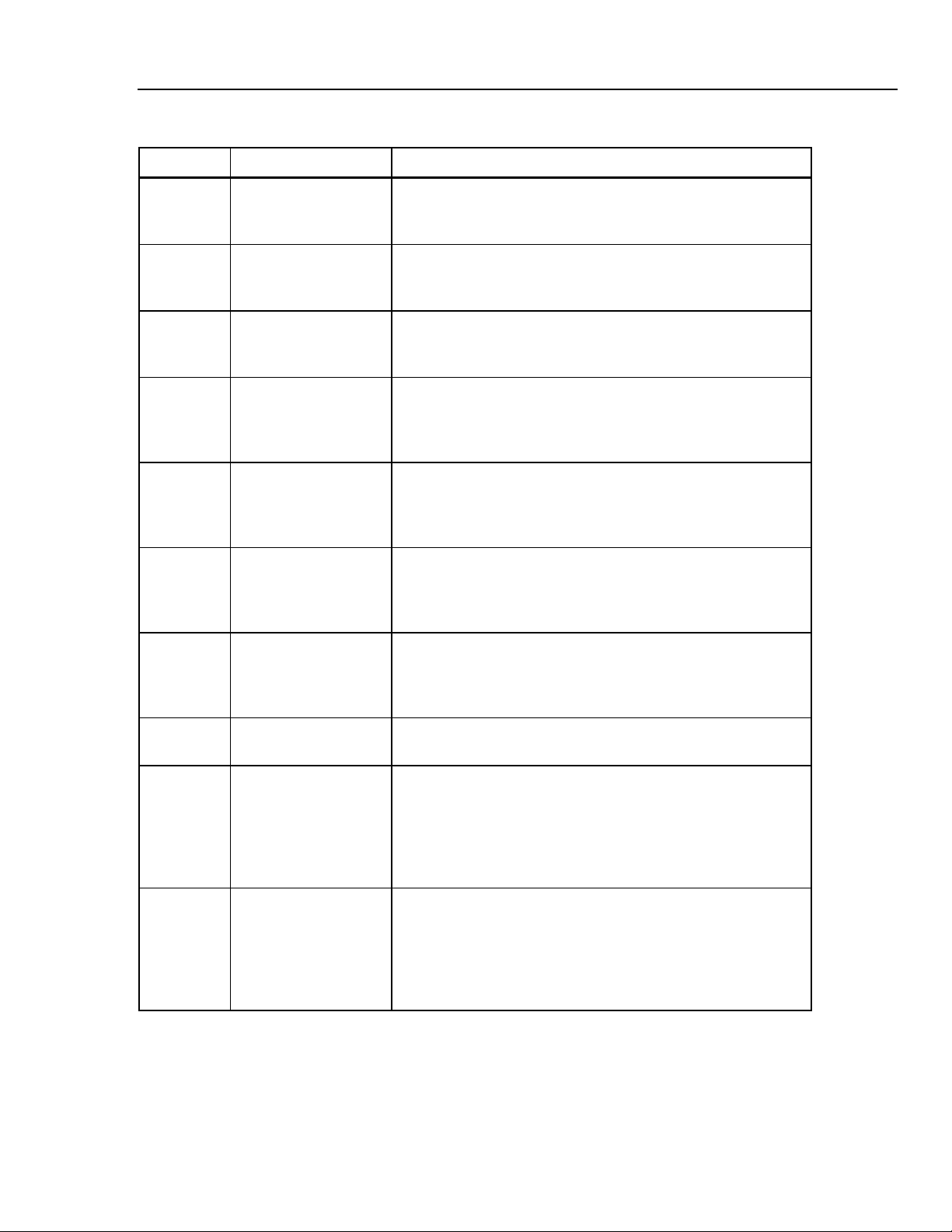

Table 1-2. Front Panel Components

Label Description

A LCD Display with CFL backlight

B Contrast, Pause/resume, print, and help keys

C Soft keys

D Test Mode keys

The components of the right panel of the Analyzer are described in Table 1-3.

Table 1-3. Right Panel Components

Label Description

E Low Pressure (+) Gas Or Fluid Port

F Low Pressure (-) Dry Gas Only Port

G High Pressure (+) Gas Or Fluid Port

H High Pressure (-) Dry Gas Only Port

I Low Flow Inlet

J High Flow And Oxygen Inlet

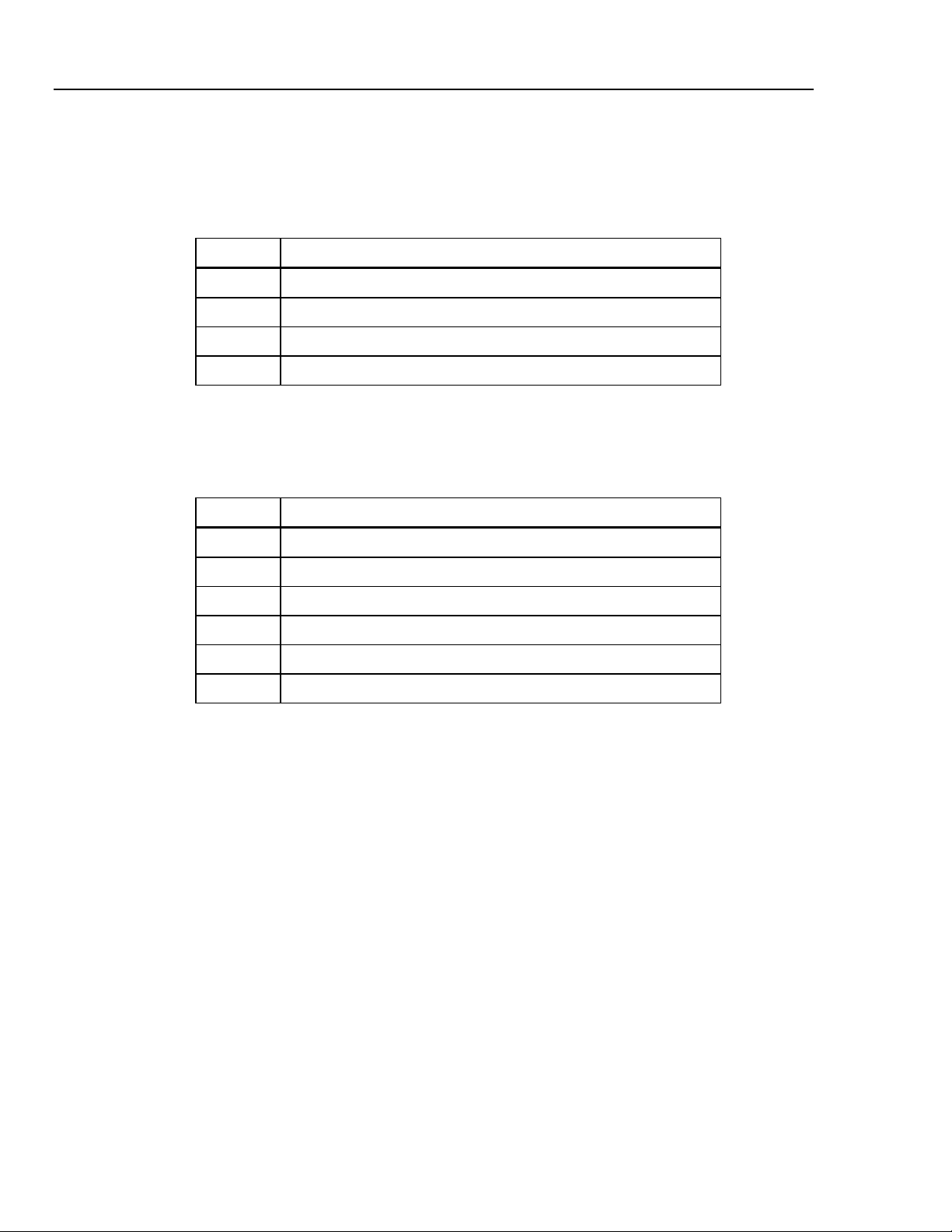

Figure 1-2 shows the rear and left panels of the Analyzer.

1-6

Page 19

Introduction and Specifications

1

Instrument Familiarity 1

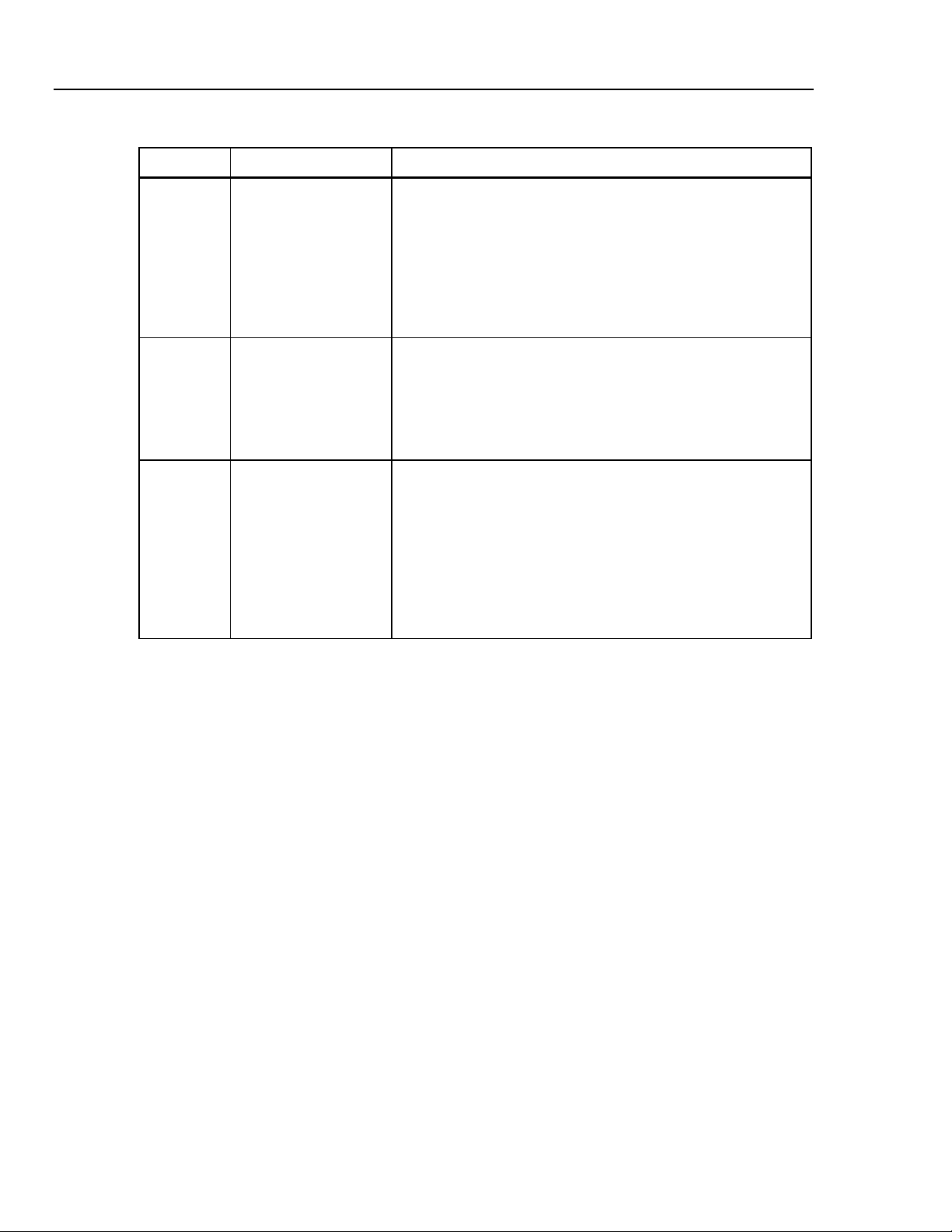

Rear Panel

The components of the back panel are listed in Table 1-4.

Label Description

2

3

4

5

Figure 1-2. Rear and Left Analyzer Panels

Table 1-4. Back Panel Components

A RS232 Serial Port

B Parallel Printer Port

C Power Switch

D Power Cord Input

E Oxygen Sensor Access

7

6

fec121.eps

Left Panel

The components of the left panel are listed in Table 1-5.

Table 1-5. Left Panel Components

Label Description

F High-Flow Exhaust Port

G Low-Flow Exhaust Port

1-7

Page 20

VT Plus HF

Operators Manual

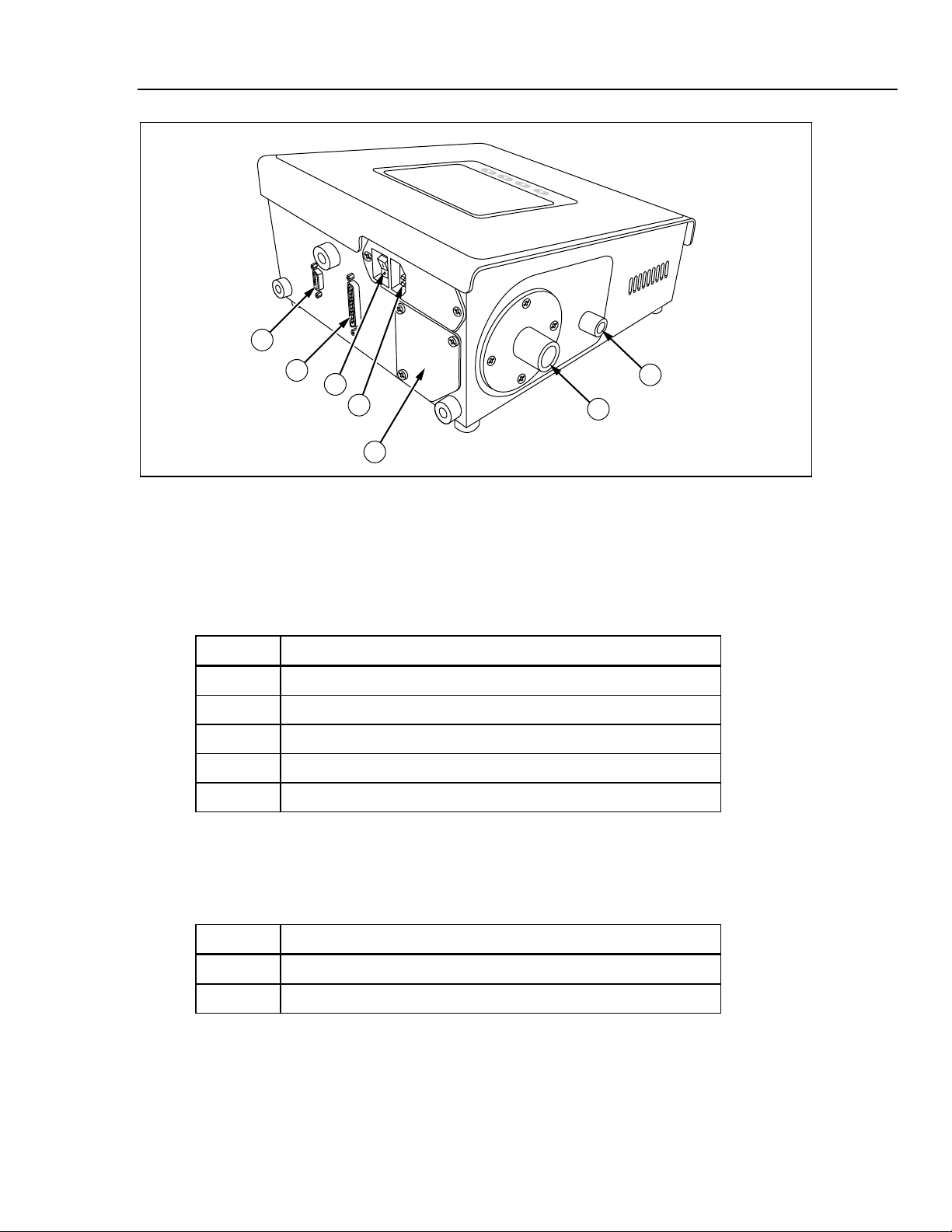

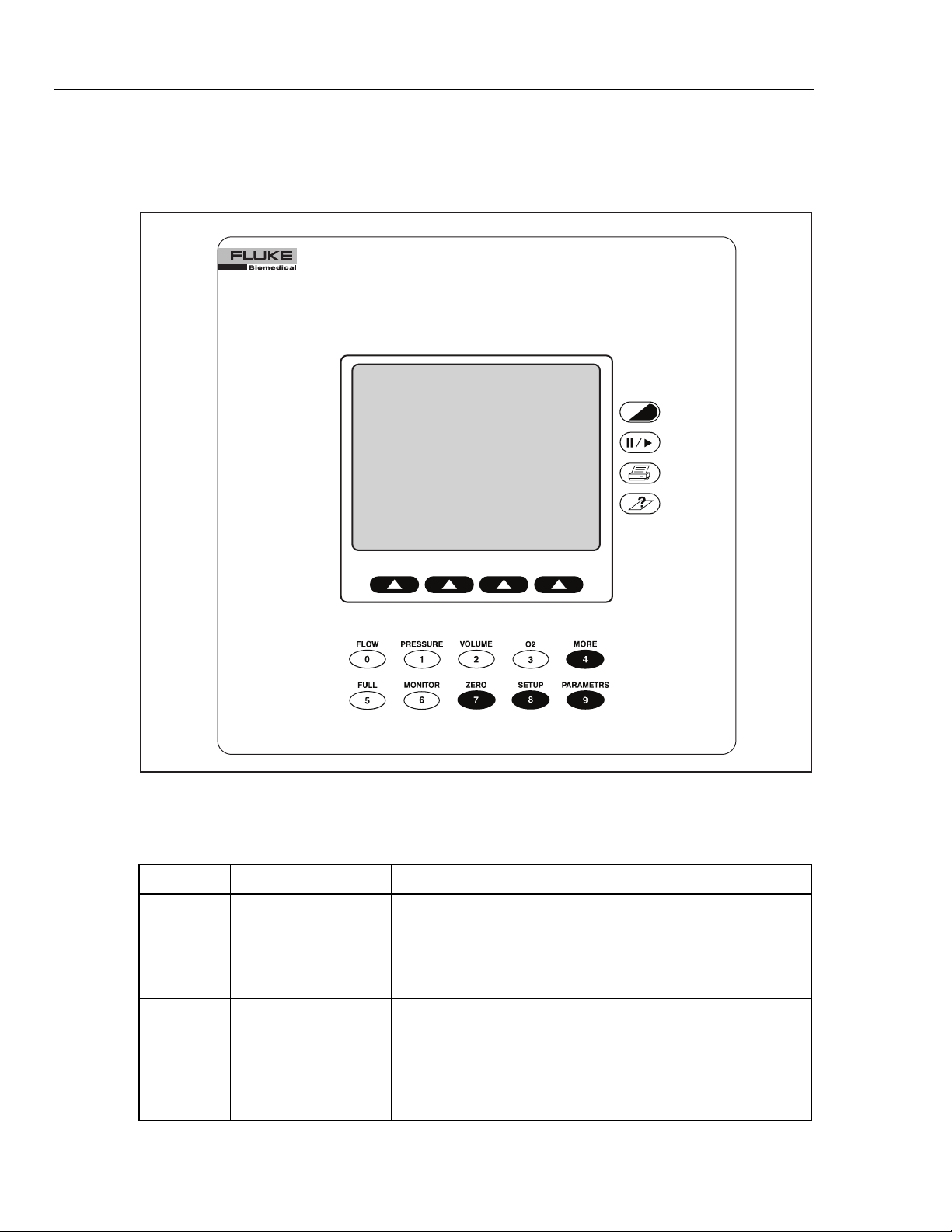

Front Panel Details

Figure 1-3 shows details of the Analyzer front panel, and Table 1-6 describes the various

keys, their icons, and functions.

VT PLUS HF

GAS FLOW ANALYZER

TEST MODES

1-8

Figure 1-3. Analyzer Front Panel

Table 1-6. Front Panel Functions

Icon Name Function

E

F

Contrast Adjustment This key adjusts the screen contrast to match the user’s

preference. Each time the key is pressed, the screen becomes

lighter. When the minimum contrast is reached, the screen is set

to the maximum contrast and the screen can be made lighter

until the preferred setting is achieved.

Pause/Resume This key pauses the plots and numeric data on the screen to

allow further examination of the data, or for transcription of the

data by the user. After the screen has been paused, a second

press of the Pause/Resume key resumes the plot. Note: The

Analyzer stops sampling the transducers while in the Pause

mode.

fec011.eps

Page 21

Introduction and Specifications

Table 1-6. Functions (cont.)

Icon Name Function

Instrument Familiarity 1

G

H

D

:

;

<

Print This key prints the current data to the printer. The mode and

format of the printout is set using the printer options function

selected under the setup menu.

Help This key displays help for any screen. A brief description of the

screen and of the options available from that screen is provided

when help is pressed.

Soft Keys These are four programmable keys located directly below the

display. Each display mode has unique options assigned to its

soft keys.

FLOW/0 Key This key selects the flow mode on the Analyzer. The flow mode

displays signal, instantaneous numeric value and statistical data

for the high or low flow signal. This key is also the 0 key for

numeric data entry.

PRESSURE/1 Key This key selects the pressure mode. The pressure mode

displays the signal, instantaneous numeric value, and statistical

data for the high, low, or airway pressure signal. This key is also

the 1 key for numeric data entry.

VOLUME/2 Key This key selects the volume mode. The volume mode displays

the signal, instantaneous numeric value, and statistical data for

the volume signal. This key is also the 2 key for numeric data

entry.

=

>

?

@

O2/3 Key This key selects the oxygen mode. The oxygen mode displays

the signal, instantaneous numeric value and statistical data for

the oxygen signal. This key is also the 3 key for numeric data

entry.

MORE/4 Key This key selects other tests such as the Leak test and the Trend

test. This key is also the 4 key for numeric data entry.

FULL/5 Key This key selects the full breath parameters mode. The full mode

displays all of the breath parameters calculated by the Analyzer

following every breath. Note that one of the breath-detect

settings must be enabled to observe volume signals or data.

Refer to System Setup for breath detection settings. This key is

also the 5 key for numeric data entry.

MONITOR/6 Key This key selects the monitor mode. The monitor mode displays

the signal and instantaneous value for three of the signals

measured by the Analyzer. Alternatively, the lower of the three

plots may be replaced by selected breath parameters. The user

can select the signals and/or parameters that are displayed. This

key is also the 6 key for numeric data entry.

1-9

Page 22

VT Plus HF

Operators Manual

Table 1-6. Functions (cont.)

Icon Name Function

A

B

C

ZERO/7 Key This key initiates the zero function in the Analyzer. All of the

pressure and differential pressure (flow) sensors in the Analyzer

must be periodically zeroed or calibrated to a zero reference.

When zero is selected, the device measures the zero value of

the selected signal for flow measuring. The Analyzer can be set

to periodically call of the zero function. Refer to System Setup

for Zero Mode Descriptions. This key is also the 7 key for

numeric data entry.

SETUP/8 Key This key accesses the Analyzer configuration and setup

screens. When this key is pressed, a menu is displayed. The

soft keys are used to navigate the menu. From this menu, other

sub-menus are accessible to adjust the various configuration

settings. The details of this menu and its sub-menus are

described later. This key is also the 8 key for numeric data entry.

PARAMETERS/9 Key This key selects which of the breath parameters are displayed in

the various modes. Each mode screen has space to display 4 of

the breath parameters. Using the parameters function, the four

breath parameters can be selected. Note that if 4 parameters

are already selected, then no more can be selected until one of

the previously selected parameters is cleared. Also note that the

parameters that are selected only apply to the screen that the

Analyzer was in when the parameters key was pressed. This

key is also the 9 key for numeric data entry.

Specifications

The following are general, performance, breath parameter accuracy specifications for the

Analyzer.

General Specifications

Display ................................................... 320 x 240 LCD with CFL backlight

Viewing Area ......................................... 3 in x 4 in (10.1 cm x 8.2 cm) Blue on white background

Operational Modes ............................... Manual mode for simple tests or troubleshooting; computer-control

Output Ports.......................................... RS232 serial port and parallel-printer port

Operating Environmental Conditions

Temperature Range........ ................ 10 °C to 40 °C

Ambient Humidity................... ......... 0 - 80 % non-condensing to 31 °C, decreasing to 50 % at 40 °C

Barometric Pressure......................... 8 to 18 psia

Vibration .......................................... Devices intended to be used on tabletop or other stable surface.

Storage Environmental Conditions

Temperature Range ........................-25 to 50 °C

Humidity........................................... 0 to 95 % non-condensing °C

Power Requirements

Maximum Over-voltage ...................264 V ac

Input Voltage Range .......................100 to 240 V ac

Input Frequency Range ................. 50/60 Hz

mode, using RS232 serial port for special applications; use of Analyzer

with VT for Windows PC software for recording graphs and logging

data to a computer

1-10

Page 23

Introduction and Specifications

Power Consumption ....................... <132 VA

Fuse Rating .................................... 0.5 A, Slo-Blo

Specifications 1

Performance Specifications

Low-Pressure Port

Maximum Applied Pressure............. 60 psi

Operating Pressure ......................... (Differential) ±500 mmHg (±10 psi)

Span Accuracy ................................ ±0.80 % of reading or ±1.5 mmHg, whichever is greater

Frequency Response ...................... >10 Hz

Resolution........................................ 0.1 mmHg

Sample Rate ...................................100 Hz

(Common-mode) 30 psi

Note

Fluid pressure may be applied to the positive port; however, fluids should

be kept from entering the pressure port by using a suitable length of

connection tubing.

High-Pressure Port

Maximum Applied Pressure............ 150 psi

Operating Pressure ........................ ±100 psi

Span Accuracy ............................... ±1 % of reading or ±0.3 psig, whichever is greater

Frequency Response ..................... >10 Hz

Resolution....................................... 0.1 psi

Sample Rate................................... 100 Hz

Fluid pressure may be applied to the positive port; however, fluids should

be kept from entering the pressure port by using a suitable length of

connection tubing.

Airway Pressure

Maximum Applied Pressure............. 20 psi

Operating Pressure ........................ ±120 cmH

Span Accuracy ............................... ±0.75 % of reading or r 0.5 cmH

Frequency Response ..................... >25 Hz or t10-90 <40 ms, whichever is greater

Resolution....................................... 0.1 cmH

Sample rate .................................... 100 Hz

Airway pressure is internally tapped off the proximal flow sensor port,

which is the port closest to the exhaust port on the Analyzer.

Continuous Flow

Low Flow ............................................... ±(2 % of reading and 1 % of range)

High Flow............................................... ±(2 % of reading and 1 % of range)

Volumetric Flow

High-Flow Port

Maximum Flow Rate........................ (absolute value) 500 lpm

Operating Flow Range.................... ±300 lpm

Accuracy......................................... ±2.0 % of range

Resolution....................................... 0.01 lpm

Note

2

O

2

Note

O

O, whichever is greater

2

1-11

Page 24

VT Plus HF

Operators Manual

Frequency Response. .................... >25 Hz or t10-90 <40 ms, whichever is greater

Sample Rate................................... 100 Hz

Dynamic Resistance....................... <2.00 cmH

Low-flow Dropout............................ 25 lpm

Breath Detect Threshold................. (user settable) 2.0 lpm

Volume Range................................ >±60 l

O @ 60 lpm

2

Notes

• Tidal Volume Accuracy ±3 % of reading or ±10 ml, whichever is

greater

• Volume Accuracy tested to 7 liters.

• Flow accuracy is specified for dry air or oxygen.

• Do not use with humidified gases.

Low Flow Port

Maximum Flow Rate........................(absolute value) 50 lpm

Operating Flow Range.................... ±25 lpm

Accuracy......................................... ±1.0 % of range

Resolution....................................... 0.01 lpm flow >1 lpm; 0.001 lpm flow <1 lpm

Frequency Response ...................... >25 Hz or t10-90 <40 ms, whichever is greater

Sample Rate................................... 100 Hz

Dynamic Resistance....................... <2.5 cmH

Low-flow Dropout............................ 0.01 lpm

Breath Detect Threshold................. (user settable) 0.50 lpm

Volume Range ............................... >±60 l

O @ 5 lpm

2

Note

• Tidal Volume Accuracy ± 3 % of reading or ±5 ml, whichever is

greater

• Volume Accuracy tested to 1 liter

• Flow accuracy is specified for dry air or oxygen.

• Do not use with humidified gases.

• Below 0.25 lpm, measurement accuracy is obtained by allowing the

Analyzer to fully warm up, and manually zeroing before reading or

documenting a measurement.

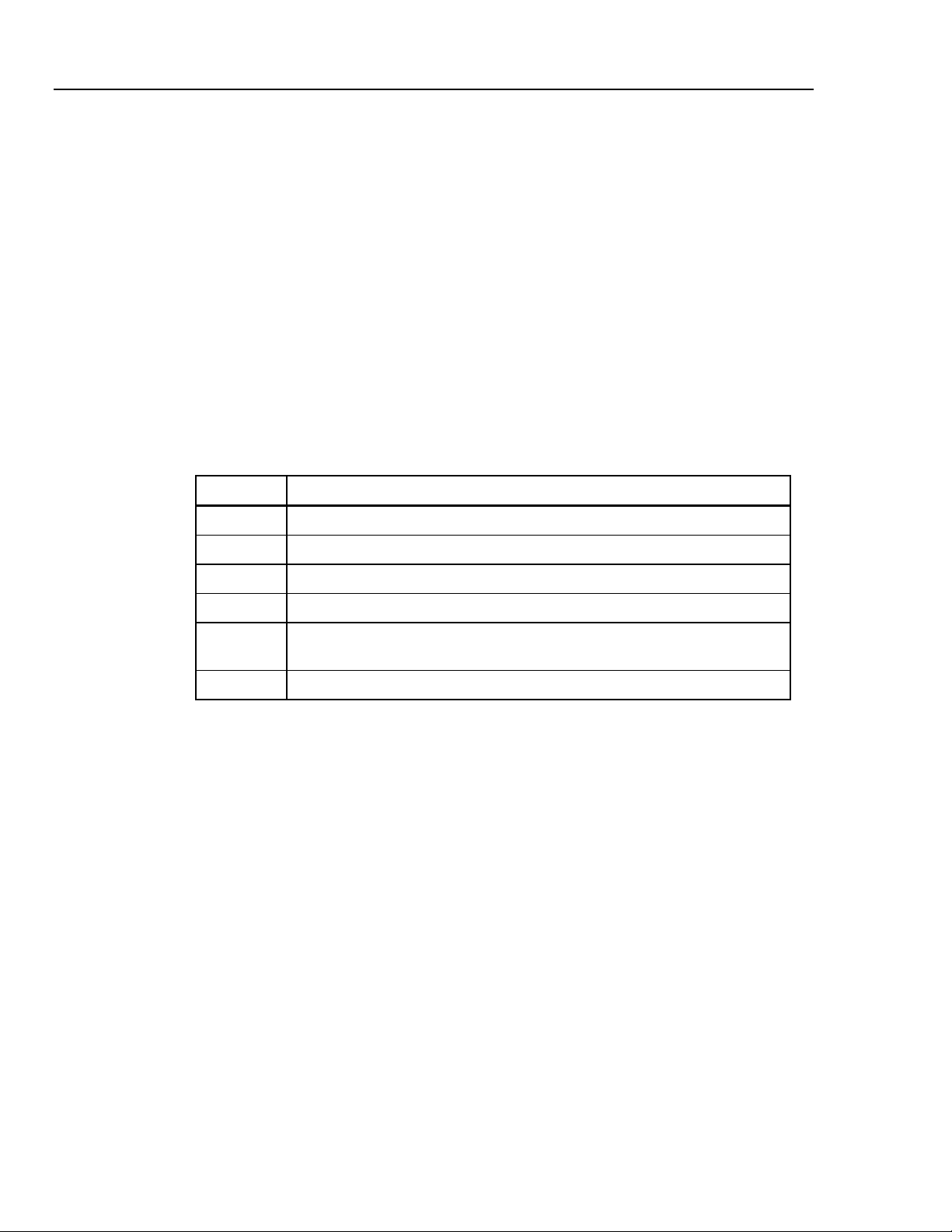

Breath Parameter Accuracy Specifications

Breath parameter accuracy specifications are listed in Table 1-7.

Note

If a choice of readings is indicated by an “or”, choose whichever is

greater; for example, 3 % or 250 ml.

1-12

Page 25

Introduction and Specifications

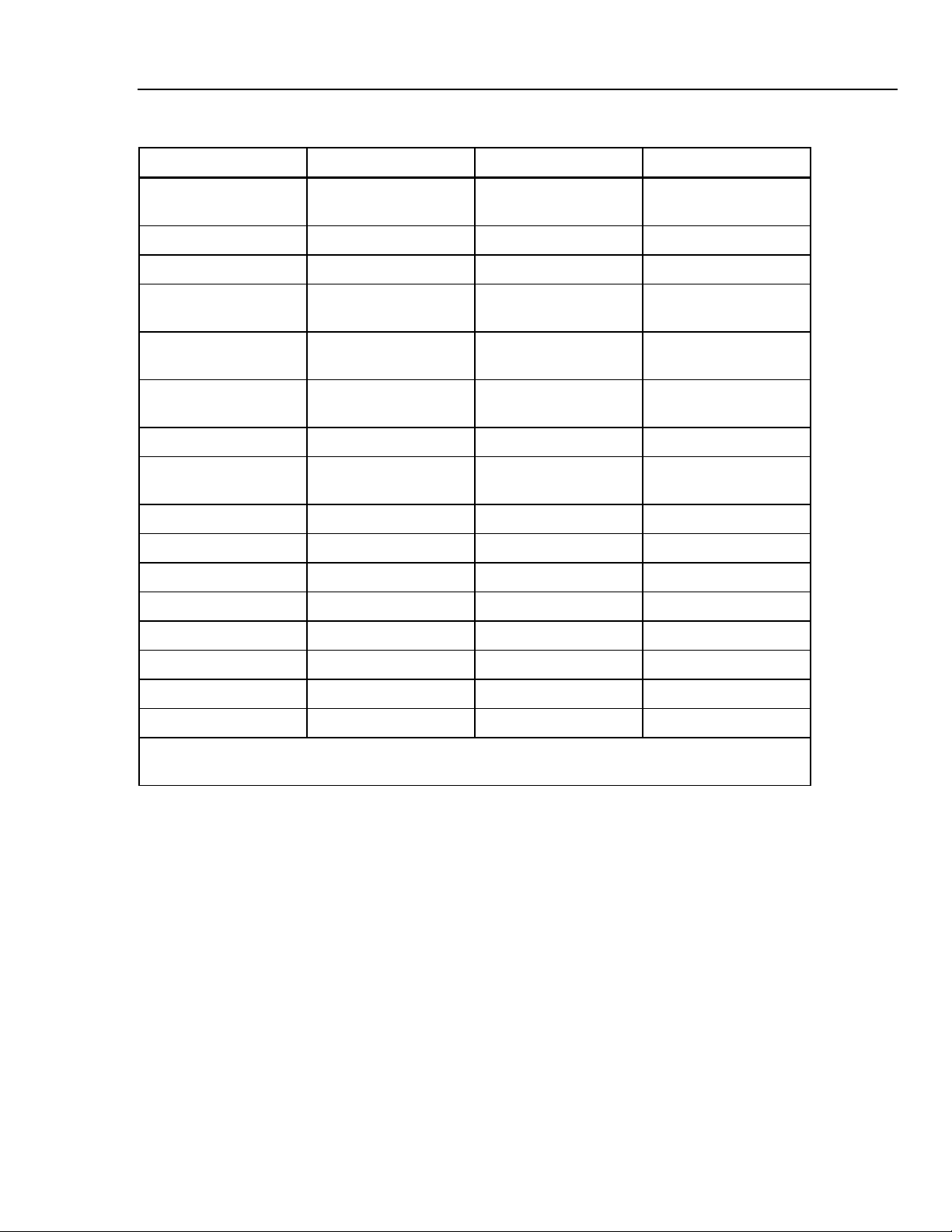

Table 1-7. Breath Parameter Accuracy Specifications

Parameter Resolution Range Accuracy

Specifications 1

Inspiratory and

Expiratory Tidal Volume

0.1 ml As specified in

high/low-flow spec

As specified in

high/low-flow spec

Minute Volume 0.001 lpm 0-60 l 3 %

Breath Rate 0.1 bpm 0.5 – 150 bpm 1 %

Inspiratory to Expiratory

0.01 1:200 to 200:1 2 % or .1

Time Ratio (I:E Ratio)

Peak Inspiratory

0.1 cmH2O ±120 cmH2O ±3 % or 1 cmH2O

Pressure

Inspiratory Pause

0.1 cmH2O ±120 cmH2O ±3 % or 1 cmH2O

Pressure

Mean Airway Pressure 0.1 cmH2O ±80 cmH2O ±3 % or 0.5 cmH2O

Positive End-expiratory

0.1 cmH2O -5 to 40 cmH2O ±3 % or 0.5 cmH2O

Pressure (PEEP)

Lung Compliance1 0.1 ml/cmH2O 0 - 150 ml/cmH2O ±5 % or 5 ml/cmH2O

Inspiratory Time 0.01 sec 0 - 60 sec 0.5 % or 0.02 sec

Inspiratory Hold Time 0.01 sec 0 - 60 sec 1 % or 0.1 sec

Expiratory Time 0.01 sec 0 - 90 sec 0.5 % or 0.01 sec

Expiratory Hold Time 0.01 sec 0 - 90 sec 1 % or 0.1 sec

Peak Expiratory Flow 0.01 lpm 0 - 300 lpm 3 % or 2 lpm

Peak Inspiratory Flow 0.01 lpm 0 - 300 lpm 3 % or 2 lpm

Flow Bias2 0.01 lpm 0 - 30 lpm 2 % or 0.5 lpm

1

Inspiratory pause time >0.5 sec

2

Expiratory pause time >0.5 sec

1-13

Page 26

VT Plus HF

Operators Manual

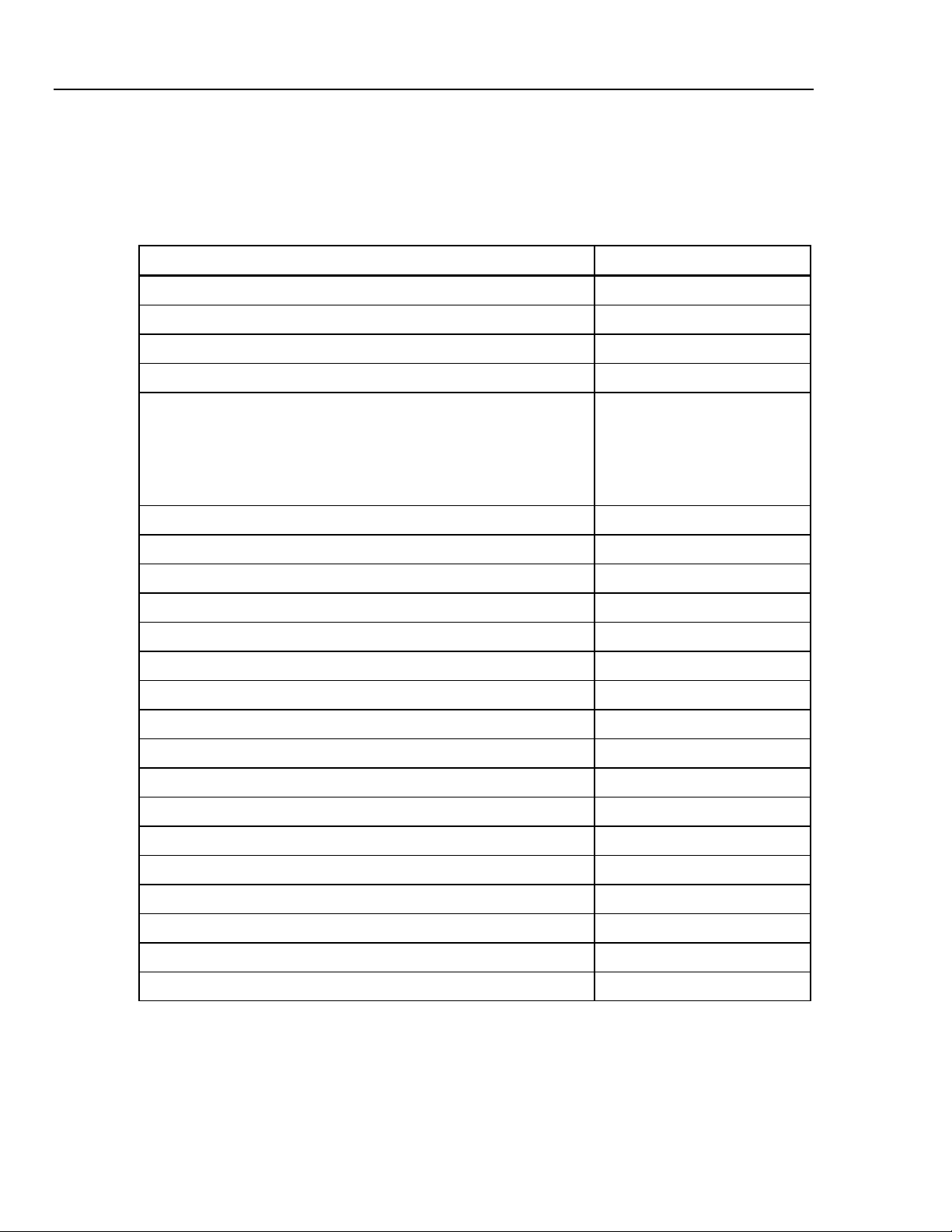

Accessories

Operators manual 2137275

VT for Windows PC software 2392054

Standard bi-directional RS232 serial cable 2238659

Tilt stand 2133387

Table 1-8 lists standard accessories provided with the Analyzer. Table 1-9 lists optional

accessories.

Table 1-8. Standard Accessories

Item Part Number

Power cable

US

Schuko

UK

Australia

Accessory kit containing the following items: 2131367

One bacterial filter for external connection to the flow ports 2133712

One adapter, DISS O2 nut and nipple with ¼ in ID hose barb 2391777

4’ Tubing 1/8” ID clear w/blue stripe 2391848

Two 22 mm ID x 22 mm ID tubing adapters 2133305

Two 22 mm OD x 22 mm OD tubing adapters 2133291

Two tapered 15 mm OD x 22 mm OD tubing adapters 2133269

Two tapered 15 mm OD x 15 mm OD tubing adapters 2133278

Two tapered 15 mm ID x 15 mm ID tubing adapters 2133284

Two narrow bore tubing adapters 2133322

Two flexible 15 mm ID x 22 mm ID tubing adapters 2133310

Two 1/4" NPT male to 1/8" ID tubing barb fitting (Nylon) 2133240

2238562

769422

2238570

658641

1-14

Two 1/4" NPT male to 1/16" ID to bulkhead connection 2133202

Two luer to barb fittings 2213679

Two replacement fuses 0.5 A slow-blow 2133932

One DISS Handtight Nut/Nipple to 1/4” ID hose barb adapter 2216329

Certificate of Calibration – Data Sheet NA

Page 27

Introduction and Specifications

Table 1-9. Optional Accessories

Item Part Number

Soft vinyl carrying case 2222822

Hard-sided protective carrying case 2248587

Soft-sided carrying case for ACCU-LUNG 2397628

Accessories 1

Graphics Printer

110 V Citizen IDP3110

220 V Citizen IDP3110

D25 male to Centronics parallel cable 2238072

ACCU-LUNG Lung Simulator with Soft-sided

carrying case (2397628)

2248762

2719653

2387318

1-15

Page 28

VT Plus HF

Operators Manual

1-16 2-1

Page 29

Chapter 2

Connection and Setup

Title Page

Connecting the Analyzer ................................................................................... 2-3

Pneumatic Connections ................................................................................. 2-3

High Flow (Inlet and Exhaust).................................................................. 2-3

Low Flow (Inlet and Exhaust)................................................................... 2-3

High Pressure (+ and -) ............................................................................. 2-3

Low Pressure (+ and -).............................................................................. 2-4

Test System Setup ......................................................................................... 2-4

Bi-directional Flow Mode ......................................................................... 2-4

Unidirectional Flow Mode ........................................................................ 2-5

Printer Cable Attachment .............................................................................. 2-6

Using the Setup Screen ...................................................................................... 2-7

Setting Testing Parameters ................................................................................ 2-7

Gas Settings................................................................................................... 2-8

Gas Type ................................................................................................... 2-8

Gas Temperature ....................................................................................... 2-9

Ambient Temperature ............................................................................... 2-9

Relative Humidity ..................................................................................... 2-9

Correction Mode............................................................................................ 2-10

Barometric Pressure....................................................................................... 2-10

Breath Detection............................................................................................ 2-11

Inspiratory/Expiratory Tidal Volumes........................................................... 2-12

Zero Mode ..................................................................................................... 2-12

Setting Analyzer Operating Parameters............................................................. 2-13

Time............................................................................................................... 2-13

Date ............................................................................................................... 2-14

Date Format ................................................................................................... 2-14

Demo Data..................................................................................................... 2-14

Filtering ......................................................................................................... 2-15

Display Calibration Date on Startup Screen.................................................. 2-15

Serial Mode ................................................................................................... 2-15

Printer Options............................................................................................... 2-16

Printer Type............................................................................................... 2-16

Graphics .................................................................................................... 2-17

Audio Levels ................................................................................................. 2-17

General ...................................................................................................... 2-17

Page 30

VT Plus HF

Operators Manual

Keypad ...................................................................................................... 2-17

Errors......................................................................................................... 2-18

Restore Defaults ............................................................................................ 2-18

Utilities .............................................................................................................. 2-20

Oxygen Sensor Calibration............................................................................ 2-20

System Diagnostics ....................................................................................... 2-21

Linearization.................................................................................................. 2-21

Unlock Calibration ........................................................................................ 2-22

Information ........................................................................................................ 2-22

2-2

Page 31

Connection and Setup

Connecting the Analyzer 2

Connecting the Analyzer

The Analyzer can be connected to a ventilator and a test load in either a bidirectional or

unidirectional flow configuration.

Pneumatic Connections

The following is a description of various pneumatic connections on the Analyzer.

High Flow (Inlet and Exhaust)

The outer diameter of the high flow ports is a standard 22 mm fitting to allow connection

using patient hoses. The inner diameter of the high flow ports is designed to accept a 15

mm male respiratory fitting such as endotracheal tubes, gas sampling adapters, etc.

W Caution

To avoid damage to the Analyzer or adverse affects on its

performance, follow these guidelines:

• Pressure inside the high flow port should not exceed ±120

cmH

O.

2

• Measure only dry gases with the high flow port. Do not use

this port to measure exhaled or artificially humidified

gases.

Low Flow (Inlet and Exhaust)

The outer diameter of the low-flow ports is a standard 15 mm to allow connection with

standard respiratory fittings such as gas sampling Y-pieces and gas sampling adapters.

The inner lumen of the low-flow ports are threaded to accept a standard ¼ in NPT fitting.

To avoid damage to the Analyzer or adverse affects on its

performance, follow these guidelines:

• Pressure inside the low flow port should not exceed ±120

cmH

O.

2

• Measure only dry gases with the low flow port. Do not use

this port to measure exhaled or artificially humidified

gases.

High Pressure (+ and -)

The high-pressure ports are primarily designed for testing wall and tank pressurized gas

sources. The connector mates to standard oxygen DISS fittings as used on oxygen supply

hoses. Note that only the + side can be used to measure fluid pressure.

To avoid damage to the Analyzer or adverse affects on its

performance, follow these guidelines:

W Caution

W Caution

• Applied differential pressure to either side of the high-

pressure port should not exceed 100 psi.

• The negative (-) side of the high-pressure port cannot be

used to measure fluid pressure.

2-3

Page 32

VT Plus HF

Operators Manual

Low Pressure (+ and -)

Test System Setup

The low-pressure ports connect using standard luer fittings. Note that only the + side can

be used to measure fluid pressure.

W Caution

To avoid damage to the Analyzer or adverse affects on its

performance, follow these guidelines:

• Pressures applied to either side of the low-pressure port

should not exceed ±500 mmHg.

• Negative (-) side of the low-pressure port cannot be used to

measure fluid pressure.

High- or low-flow ranges can be used for ventilator testing. One test setup is measuring

ventilator parameters using a test lung. Either a bi-directional flow mode, as shown in

Figure 2-1 or a unidirectional flow mode, as shown in Figures 2-2 and 2-3, below can be

chosen; however, the bi-directional mode is preferred.

Bi-directional Flow Mode

1. Connect the ventilator, using a Y-piece adapter, to the flow inlet port on the right of

the Analyzer.

2. Connect the flow exhaust port on the left to the test lung using standard breathing

hoses.

Ventilator

Figure 2-1. Connecting the Analyzer in a Bi-Directional Flow Mode

3. Ensure that the breath detection mode is set to bi-directional.

a. Go into Setup.

Inspiratory Hose

Expiratory Hose

Analyzer

TEST

LUNG

OutletInlet

fec002.eps

2-4

b. Choose Settings

c. Choose Breath Detect and modify as needed

Page 33

Connection and Setup

Connecting the Analyzer 2

Unidirectional Flow Mode

Alternatively, the Analyzer can be used to measure only inspiratory or expiratory gas

flow, as described below.

Inspiratory Testing

1. Connect the inspiratory hose to the flow port on the right of the Analyzer.

2. Connect the flow exhaust port on the left to the test lung using standard breathing

hoses.

Ventilator

Figure 2-2. Connecting the Analyzer to the Inspiratory Limb of the Breathing Circuit

3. Ensure that the breath detection mode is set to Unidirectional Inspiratory.

a. Go into Setup

b. Choose Settings

c. Choose Breath Detect and modify as needed

Expiratory Testing

1. Connect the expiratory hose to the flow port on the right side of the Analyzer.

Inlet

VT PLUS HF

Expiratory Hose

Outlet

Inspiratory Hose

TEST

LUNG

fec008.eps

2. Connect the flow exhaust port on the left to the ventilator using standard breathing

hoses.

Inspiratory Hose

Ventilator

VT PLUS HF

Expiratory Hose

Outlet

Figure 2-3. Connecting the Analyzer to the Expiratory Limb of the Breathing Circuit

Inlet

2-5

TEST

LUNG

fec009.eps

Page 34

VT Plus HF

Operators Manual

3. Ensure that the breath detection mode is set to Unidirectional Expiratory.

a. Go into Setup

b. Choose Settings

c. Choose Breath Detect and modify as needed

The Analyzer displays a screen showing the flow of gas delivered by the ventilator:

The instantaneous flow rate displays in large numbers in the upper right portion of the

screen. The flow statistics (min., max and average) are shown below in the center right

portion of the screen. A subset of the breath parameters is shown below the flow plot.

The following adjustments can be made to the screen:

• Switch between the high- and low-flow ports – Press the RANGE soft key.

• Change the measurement units (LPM, CFM, LPS) – Press the UNITS soft key.

• Change the plot scaling – Press the RESCALE soft key. The new scaling is based on

the minimum and maximum values shown in the statistics area.

• Erase the plot and re-initialize the statistics and breath parameters – Press the

CLEAR soft key.

• See more information in any screen – Press the HELP key.

• Pause and resume the plot screen, respectfully – Press the PAUSE/RESUME key.

Printer Cable Attachment

The printer uses a D25 male to Centronics parallel cable for parallel printing. This cable

is available from Fluke (part #2238072) or from most electronic supply outlets.

To attach the parallel cable:

fec049.bmp

2-6

1. Connect the 36-pin end for the Centronics type parallel cable to the printer’s parallel

input connector.

2. Attach the 25-pin male end of the parallel cable to the 25-pin connector on the back

of the Analyzer.

Page 35

Connection and Setup

Using the Setup Screen 2

Using the Setup Screen

To use the Setup screen:

1. Press the SETUP/8 key. The Setup screen displays:

The options are:

• Settings – a menu for choosing options that affect flow and measurement on the

Analyzer

• System – a menu for choosing options that affect how information on the

Analyzer is set up such as time and date

• Utility – used for system service and calibration only

• Information – product information about the Analyzer, such as serial number

and copyright

2. Use the S and T soft keys to highlight an option.

3. Press the ENTER soft key to select the option.

4. Press the BACK soft key to return to the previous menu.

Setting Testing Parameters

To adjust the settings:

1. From the Setup screen, highlight Settings and press the ENTER soft key. The

Settings menu displays.

2. Change settings to pre-selected options or to numeric values by highlighting the

option and pressing the MODIFY soft key.

fec027.bmp

For example, if one selects Correction Mode then presses MODIFY, he can scroll

through the available Correction Mode options. If one selects an option that requires

a numeric entry, such as BD Threshold and press MODIFY, the entered data is

cleared, and the field can accept numeric input from the keypad until the ENTER key

is pressed.

2-7

Page 36

VT Plus HF

Operators Manual

Gas Settings

Note

The option displayed when exiting the settings screen is saved and used for

future measurements.

The following is a description of each setting.

This setting tells the Analyzer what type of gas is flowing through the high- and low-flow

ports. The Analyzer uses this information to improve the accuracy of the flow

calculations.

Note

Failure to enter the correct value causes the flow and volume calculations

to be in error.

To modify the gas settings:

1. From the Setup menu, highlight Settings and press the ENTER soft key.

2. Highlight Gas Settings and press the MODIFY soft key.

Depending on the option, a value can be pre-selected or input from the keypad. The

following is a description of each of the options.

Gas Type

The possible values for Gas Type are shown in Table 2-1.

User Defined User selects custom gas mixture. This option requires the VT for Wondows

Table 2-1. Gas Type Values

Value Description

Air Standard room air

N2 100 % Nitrogen

N2O 100 % Nitrous Oxide

CO2 100 % Carbon Dioxide

O2 100 % Oxygen

Heliox 30 % Oxygen and 70 % Helium blend

N2O bal O2 Measured Oxygen balance Nitrous Oxide

He bal O2 Measured Oxygen balance Oxygen Helium

N2 bal O2 Measured Oxygen balance Nitrogen

PC software.

Note

For balance gas settings, the oxygen concentration is measured using the

Analyzer oxygen sensor located on the high-flow port. If the low-flow port

is to be used, allow gas to flow through both high- and low-flow ports so

that the oxygen can be measured.

2-8

To modify the gas type:

Page 37

Connection and Setup

Setting Testing Parameters 2

1. From the Gas Settings menu, highlight Gas Type.

2. Press the MODIFY soft key until the desired value displays.

3. Press the BACK soft key to return to the Settings menu.

Gas Temperature

This setting is the temperature of the gas flowing through the high- or low-flow port. The

Analyzer uses this information to improve the accuracy of the flow measurements. All

temperatures are in °C.

To enter a gas temperature:

1. From the Gas Settings menu, highlight Gas Temperature.

2. Press the MODIFY soft key to display the value field.

3. Input the desired value from the keypad.

Note

The Analyzer accepts temperatures between 0 and 99 °C. No decimal

values or fractions are allowed.

4. Press the ENTER soft key to save the change or the ESCAPE soft key to cancel the

change.

5. Press the BACK soft key to return to the Settings menu.

Ambient Temperature

This setting is the room temperature air flowing through the high-or low-flow ports.

To change ambient temperature:

1. From the Gas Settings menu, highlight Ambient Temp.

2. Press the MODIFY soft key to display the value field.

3. Input the desired value from the keypad.

The Analyzer accepts temperatures between 0 and 99 °C. No decimal

values or fractions are allowed.

4. Press the ENTER soft key to save the change or the ESCAPE soft key to cancel the

change.

5. Press the BACK soft key to return to the Settings menu.

Relative Humidity

This setting is the relative humidity in the air flowing through the high- and low-flow

ports and is used only for STPD and BTPS corrections. The relative humidity is not used

in calculating the effective viscosity on the Analyzer; however, the gas calculator in the

VT Plus PC software does use relative humidity in determining the effective viscosity of

user-defined gases.

Note

To change relative humidity:

1. From the Gas Settings menu, highlight Rel. Humidity.

2. Press the MODIFY soft key to display the value field.

2-9

Page 38

VT Plus HF

Operators Manual

Correction Mode

3. Input the desired value from the keypad.

4. Press the ENTER soft key to save the change or the ESCAPE soft key to cancel the

change.

5. Press the BACK soft key to return to the Settings menu.

Note

Use only dry gases with the Analyzer. Do not use with heated humidified gases; using

humidified gases at room temperature may cause flow measurement errors of up to 1 %

of reading for near-saturated, non-condensing gases.

This setting calculates the flow volume of the air flowing through the high- or low-flow

ports. This value should match the correction mode of the device under test (DUT).

To change correction mode:

1. From the Gas Settings menu, highlight Correction Mode.

2. Press the MODIFY soft key to toggle to the desired value.