Page 1

VT MOBILE

Gas Flow Analyzer

February 2006

© 2006 Fluke Corporation. All rights reserved.

All product names are trademarks of their respective companies.

Operators Manual

Page 2

Warranty and Product Support

Fluke Biomedical warrants this instrument against defects in materials and workmanship

for one full year from the date of original purchase. During the warranty period, we will

repair or, at our option, replace at no charge a product that proves to be defective,

provided you return the product, shipping prepaid, to Fluke Biomedical. This warranty

does not apply if the product has been damaged by accident or misuse or as the result of

service or modification by other than Fluke Biomedical. IN NO EVENT SHALL FLUKE

BIOMEDICAL BE LIABLE FOR CONSEQUENTIAL DAMAGES.

Only serialized products and their accessory items (those products and items bearing a

distinct serial number tag) are covered under this one–year warranty. PHYSICAL

DAMAGE CAUSED BY MISUSE OR PHYSICAL ABUSE IS NOT COVERED

UNDER THE WARRANTY. Items such as cables and nonserialized modules are not

covered under this warranty.

Recalibration of instruments is not covered under the warranty.

This warranty gives you specific legal rights, and you may also have other rights which

vary from state to state, province to province, or country to country. This warranty is

limited to repairing the instrument to Fluke Biomedical’s specifications.

Warranty Disclaimer

Should you elect to have your instrument serviced and/or calibrated by someone other

than Fluke Biomedical, please be advised that the original warranty covering your

product becomes void when the tamper-resistant Quality Seal is removed or broken

without proper factory authorization. We strongly recommend, therefore, that you send

your instrument to Fluke Biomedical for factory service and calibration, especially during

the original warranty period.

Page 3

Notices

All Rights Reserved

Copyright 2006, Fluke Biomedical. No part of this publication may be reproduced, transmitted, transcribed, stored in a retrieval

system, or translated into any language without the written permission of Fluke Biomedical.

Copyright Release

Fluke Biomedical agrees to a limited copyright release that allows you to reproduce manuals and other printed materials for use in

service training programs and other technical publications. If you would like other reproductions or distributions, submit a written

request to Fluke Biomedical.

Unpacking and Inspection

Follow standard receiving practices upon receipt of the instrument. Check the shipping carton for damage. If damage is found, stop

unpacking the instrument. Notify the carrier and ask for an agent to be present while the instrument is unpacked. There are no special

unpacking instructions, but be careful not to damage the instrument when unpacking it. Inspect the instrument for physical damage such

as bent or broken parts, dents, or scratches.

Technical Support

For application support or answers to technical questions, either email techservices@flukebiomedical.com or call 1-800-648-7942 or

1-425-446-6945.

Claims

Our routine method of shipment is via common carrier, FOB origin. Upon delivery, if physical damage is found, retain all packing

materials in their original condition and contact the carrier immediately to file a claim. If the instrument is delivered in good physical

condition but does not operate within specifications, or if there are any other problems not caused by shipping damage, please contact

Fluke Biomedical or your local sales representative.

Standard Terms and Conditions

Refunds and Credits

Please note that only serialized products and their accessory items (i.e., products and items bearing a distinct serial number

tag) are eligible for partial refund and/or credit. Nonserialized parts and accessory items (e.g., cables, carrying cases,

auxiliary modules, etc.) are not eligible for return or refund. Only products returned within 90 days from the date of original

purchase are eligible for refund/credit. In order to receive a partial refund/credit of a product purchase price on a serialized product, the

product must not have been damaged by the customer or by the carrier chosen by the customer to return the goods, and the product

must be returned complete (meaning with all manuals, cables, accessories, etc.) and in “as new” and resalable condition. Products not

returned within 90 days of purchase, or products which are not in “as new” and resalable condition, are not eligible for credit return and

will be returned to the customer. The Return Procedure (see below) must be followed to assure prompt refund/credit.

Restocking Charges

Products returned within 30 days of original purchase are subject to a minimum restocking fee of 15 %. Products returned in

excess of 30 days after purchase, but prior to 90 days, are subject to a minimum restocking fee of 20 %. Additional charges for

damage and/or missing parts and accessories will be applied to all returns.

Page 4

Return Procedure

All items being returned (including all warranty-claim shipments) must be sent freight-prepaid to our factory location. When you return

an instrument to Fluke Biomedical, we recommend using United Parcel Service, Federal Express, or Air Parcel Post. We also

recommend that you insure your shipment for its actual replacement cost. Fluke Biomedical will not be responsible for lost shipments

or instruments that are received in damaged condition due to improper packaging or handling.

Use the original carton and packaging material for shipment. If they are not available, we recommend the following guide for

repackaging:

Use a double–walled carton of sufficient strength for the weight being shipped.

Use heavy paper or cardboard to protect all instrument surfaces. Use nonabrasive material around all projecting parts.

Use at least four inches of tightly packed, industry-approved, shock-absorbent material around the instrument.

Returns for partial refund/credit:

Every product returned for refund/credit must be accompanied by a Return Material Authorization (RMA) number, obtained from our

Order Entry Group at 1-800-648-7952 or 1-425-446-6945.

Repair and calibration:

To find the nearest service center, goto www.flukebiomedical.com/service

In the U.S.A.:

Cleveland Calibration Lab

Tel: 1-800-850-4606

Email: globalcal@flukebiomedical.com

Everett Calibration Lab

Tel: 1-800-850-4606

Email: service.status@fluke.com

In Europe, Middle East, and Africa:

Eindhoven Calibration Lab

Tel: +31-402-675300

Email: ServiceDesk@fluke.com

In Asia:

Everett Calibration Lab

Tel: +425-446-6945

Email: service.international@fluke.com

or

Certification

This instrument was thoroughly tested and inspected. It was found to meet Fluke Biomedical’s manufacturing specifications when it

was shipped from the factory. Calibration measurements are traceable to the National Institute of Standards and Technology (NIST).

Devices for which there are no NIST calibration standards are measured against in-house performance standards using accepted test

procedures.

WARNING

Unauthorized user modifications or application beyond the published specifications may result in electrical shock hazards or improper

operation. Fluke Biomedical will not be responsible for any injuries sustained due to unauthorized equipment modifications.

Restrictions and Liabilities

Information in this document is subject to change and does not represent a commitment by Fluke Biomedical. Changes made

to the information in this document will be incorporated in new editions of the publication. No responsibility is assumed by

Fluke Biomedical for the use or reliability of software or equipment that is not supplied by Fluke Biomedical, or by its

affiliated dealers.

Manufacturing Location

The VT MOBILE is manufactured in Everett, WA, U.S.A.

Page 5

Symbols

Symbol Description

W

P

)

"

12V DC F

~

M 9V NEDA 1604A

6F22 006P

‚

f

"

'

See Operators Manual.

Manufacturer’s declaration of product compliance with applicable

EU directives

CSA Listing mark

Battery Eliminator input

Do not mix with solid waste stream. Dispose of using a qualified

recycler or hazardous material handler.

9-volt battery

Flow Port

Pressure Port

Temperature and Relative Humidity Port

Oxygen Sensor Port

Battery Eliminator Port

Miniature RS232 Port

Page 6

WXWarning. Read before using Analyzer.

To avoid personal injury, follow these guidelines:

Do not use the VT MOBILE in any manner not specified in the Operator’s

Manual. Otherwise, the protection provided by this product may be impaired.

When measuring oxygen, always keep all components of test setup well away

from open flame or other combustion-starting devices.

Use in well-ventilated space. Be aware that a gas defined with VT for Windows

software as ‘User’ may be unknown while using the VT MOBILE.

For high pressure measurements, always turn off gas source before

connection or disconnection of VT MOBILE. Be aware that there is no pressure

indication on the VT MOBILE screen when VT for Windows software is in

control.

• Always press power off on the VT MOBILE and unplug the battery eliminator

before cleaning the outer surface.

• Inspect the product, if the instrument appears damaged or appears to operate

in a manner not specified in the manual, DO NOT CONTINUE USE. Return the

product for service.

• Avoid spilling liquids on the analyzer; fluid seepage into internal components

creates corrosion and a potential shock hazard. Do not operate the instrument

if internal components are exposed to fluid.

• Do not open this product. There are no user replaceable parts.

WCaution

The VT MOBILE should be calibrated annually. Only qualified technical personnel

should perform troubleshooting and service procedures on the VT MOBILE.

Do not expose the system to temperature extremes. Ambient operating

temperatures should remain between 10 and 40 °C. System performance may be

adversely affected if temperatures fluctuate above or below this range.

Clean only with a damp, lint-free cloth, using a mild detergent, and wipe

down gently.

Page 7

Table of Contents

Chapter Title Page

1 Introducing the VT MOBILE................................................................ 1-1

Introduction........................................................................................................ 1-1

Operation, Storage, and Maintenance................................................................ 1-1

Features.............................................................................................................. 1-2

About This Manual ............................................................................................ 1-2

2 Preparing for Operation...................................................................... 2-1

Unpacking the VT MOBILE ............................................................................. 2-1

Powering Up ...................................................................................................... 2-3

Using the Tilt Bail.............................................................................................. 2-3

Using the Keys................................................................................................... 2-4

Selecting the Operating Mode ........................................................................... 2-4

Setting Up .......................................................................................................... 2-5

Selecting the Gas Type.................................................................................. 2-5

Gas Temperature and Relative Humidity ...................................................... 2-5

Selecting the Correction Mode...................................................................... 2-5

Setting the Breath Detect Threshold.............................................................. 2-6

Setting Zero Warn ON or OFF...................................................................... 2-6

Setting the Time ............................................................................................ 2-7

Setting the Date ............................................................................................. 2-7

Selecting the Date Format ............................................................................. 2-8

Setting the Contrast ....................................................................................... 2-8

Checking Version and Serial Numbers ......................................................... 2-8

Connecting the Analyzer ................................................................................... 2-8

High-Flow Connection .................................................................................. 2-9

Low-Flow Connection................................................................................... 2-9

High-Pressure Connection............................................................................. 2-9

Low-Pressure Connection ............................................................................. 2-9

Ventilator Test Connections .......................................................................... 2-10

3 Using the VT MOBILE.......................................................................... 3-1

Understanding the Controls and Indicators........................................................ 3-1

Screens............................................................................................................... 3-4

Ventilator Parameters Screens....................................................................... 3-4

i

Page 8

VT MOBILE

Operators Manual

Waveform Screens......................................................................................... 3-6

Other Measurements Screens ........................................................................ 3-9

Special Functions Screens ............................................................................. 3-10

Using Trend Test ............................................................................................... 3-12

Making Measurements....................................................................................... 3-14

Working with Memory ...................................................................................... 3-14

Printing .............................................................................................................. 3-14

Making a Measurement More Accurate ............................................................ 3-14

Warm-up and Zeroing ................................................................................... 3-14

Oxygen Sensor............................................................................................... 3-16

Verifying Oxygen Sensor Calibration ........................................................... 3-16

Calibrating the Oxygen Sensor...................................................................... 3-16

Using the Temperature and Relative Humidity Sensor ................................. 3-17

Checking Barometric Pressure ...................................................................... 3-18

Changing Barometric Pressure Units ............................................................ 3-19

Viewing Demo Data .......................................................................................... 3-19

Accessing Help .................................................................................................. 3-19

4 Checking Ventilator Parameters ........................................................ 4-1

Introduction........................................................................................................ 4-1

Checking Ventilator Parameters ........................................................................ 4-1

Understanding the Parameters ........................................................................... 4-3

5 Measuring Pressure ............................................................................ 5-1

Introduction........................................................................................................ 5-1

Measuring Low Pressure ................................................................................... 5-2

Measuring High Pressure................................................................................... 5-3

Measuring Airway Pressure............................................................................... 5-5

6 Measuring Flow and Volume.............................................................. 6-1

Introduction........................................................................................................ 6-1

Gas Settings................................................................................................... 6-1

Balance Gas Settings ..................................................................................... 6-1

Correction Modes .......................................................................................... 6-2

Flow Zeroing ................................................................................................. 6-2

Measuring Low Flow......................................................................................... 6-3

Measuring High Flow ........................................................................................ 6-4

Measuring Volume ............................................................................................ 6-5

7 Maintaining and Troubleshooting the VT MOBILE........................... 7-1

Introduction........................................................................................................ 7-1

Calibration and Service...................................................................................... 7-1

Battery................................................................................................................ 7-1

Cleaning............................................................................................................. 7-2

Verifying Oxygen Sensor Calibration ............................................................... 7-2

Replacing the Oxygen Sensor............................................................................ 7-3

Calibrating the Oxygen Sensor .......................................................................... 7-3

Troubleshooting................................................................................................. 7-4

Appendices

A VT for Windows.......................................................................................... A-1

B Specifications .............................................................................................. B-1

ii

Page 9

List of Tables

Table Title Page

1-1. VT MOBILE Versions........................................................................................... 1-1

2-1. Standard Accessories ............................................................................................. 2-2

2-2. Optional Accessories.............................................................................................. 2-2

2-3. Gas Types............................................................................................................... 2-5

2-4. Correction Modes................................................................................................... 2-6

3-1. Controls and Indicators .......................................................................................... 3-2

3-2. Ventilator Parameters............................................................................................. 3-4

4-1. Ventilator Parameters............................................................................................. 4-3

7-1. Troubleshooting the Analyzer................................................................................ 7-4

iii

Page 10

VT MOBILE

Operators Manual

iv

Page 11

List of Figures

Figure Title Page

2-1. Key Available Accessories..................................................................................... 2-3

2-2. VT MOBILE Tilt Bail............................................................................................ 2-4

2-3. Low-Pressure/High-Flow/Low-Flow Connection.................................................. 2-8

2-4. High-Pressure Connection...................................................................................... 2-9

2-5. Ventilator Test Connections................................................................................... 2-10

3-1. Controls and Indicators .......................................................................................... 3-1

3-2. Flow Sensors and Pressure Adapters Disconnected............................................... 3-15

3-3. Flow Sensors and Pressure Adapters Connected ................................................... 3-15

3-4. Oxygen Sensor Calibration .................................................................................... 3-17

3-5. Measuring Temperature and Relative Humidity .................................................... 3-18

4-1. Ventilator Connections........................................................................................... 4-2

4-2. Accessing Calculated Parameters........................................................................... 4-4

4-3. Accessing Other Parameters................................................................................... 4-4

5-1. Measuring Low Pressure........................................................................................ 5-2

5-2. Accessing Low-Pressure Measurements ................................................................ 5-3

5-3. Measuring High Pressure ....................................................................................... 5-4

5-4. Accessing High-Pressure Measurements ............................................................... 5-4

5-5. Accessing Airway Pressure Measurements............................................................ 5-5

6-1. Measuring Low Flow ............................................................................................. 6-3

6-2. Accessing Low-Flow Measurements ..................................................................... 6-4

6-3. Measuring High Flow ............................................................................................ 6-5

6-4. Accessing High-Flow Measurements..................................................................... 6-5

7-1. Changing the Battery.............................................................................................. 7-2

7-2. Oxygen Sensor Calibration .................................................................................... 7-3

v

Page 12

VT MOBILE

Operators Manual

vi

Page 13

Introduction

This Operators Manual provides complete operating instructions for the Fluke

Biomedical VT MOBILE Gas Flow Analyzer (hereafter referred to as the Analyzer.)

Seven language options support the available factory-set versions of the Analyzer. The

overlay language identifies these.

The Analyzer is a general-purpose, portable gas flow analyzer with special modes

designed specifically for testing mechanical patient ventilators. The Analyzer measures

bi-directional flow in both high and low ranges as well as high- and low-pressure ranges.

The Analyzer is not for use in the patient environment. Table 1-1 identifies Analyzer

language versions.

The Analyzer measures the basic signals of pressure, flow, and oxygen. From these basic

signals, the Analyzer computes other parameters. The Analyzer obtains volume from the

integration, or summation, of the flow signal over a period of time.

Chapter 1

Introducing the VT MOBILE

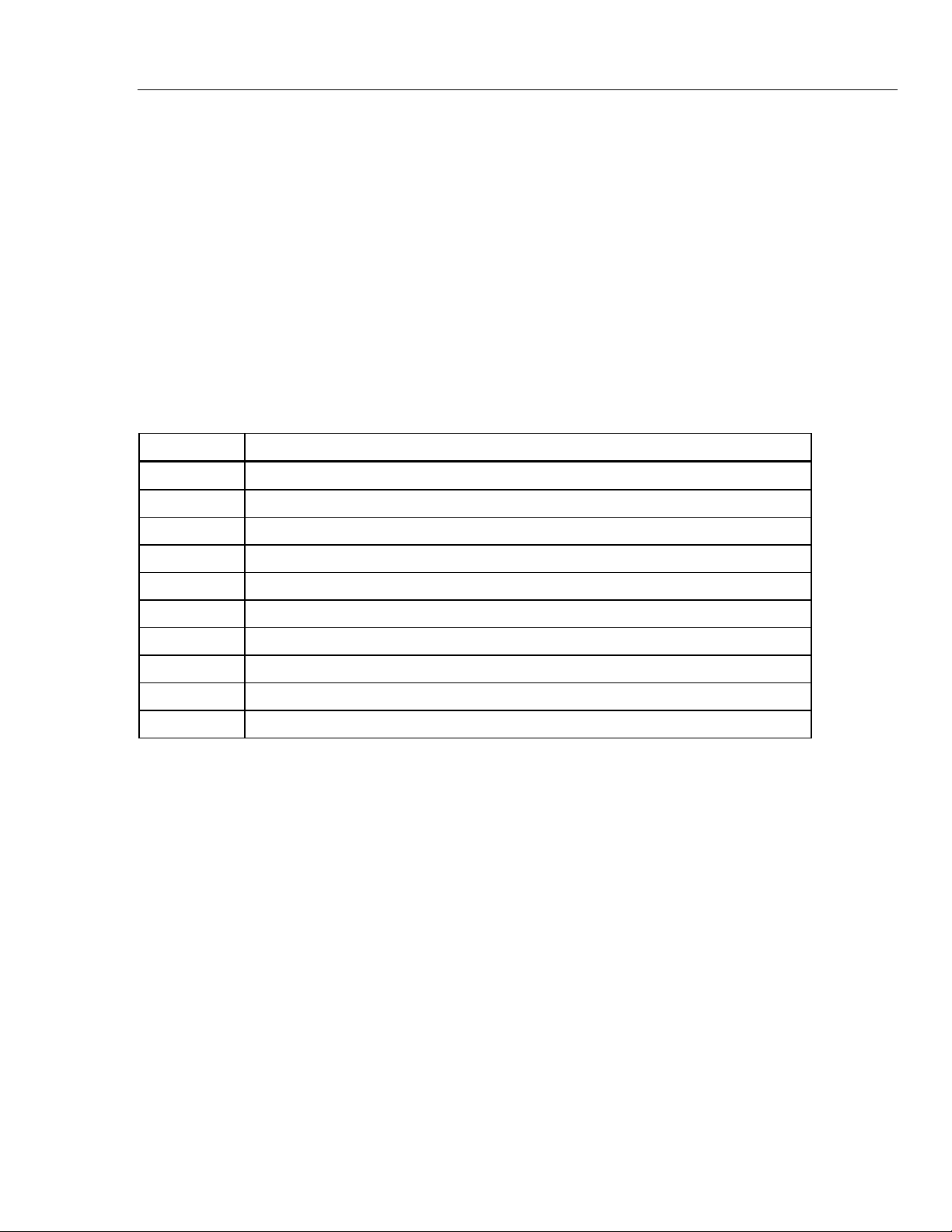

Table 1-1. VT MOBILE Versions

Version Language Overlay

VT MOBILE US English

VT MOBILE FRA French

VT MOBILE DEU German

VT MOBILE ITAL Italian

VT MOBILE SPAN Spanish

VT MOBILE JPN Japanese

VT MOBILE CHI Chinese

Operation, Storage, and Maintenance

Operate the Analyzer in a dry area within temperature limits of 10 °C to 40 °C. The

maximum operating relative humidity at temperatures up to 31 °C is 80 % noncondensing, decreasing linearly to 50 % non-condensing at 40 °C.

Store the Analyzer at a temperature of -25 °C to 50 °C and at a non-condensing relative

humidity of 0 to 95 %.

The battery is the only user-serviceable part in the Analyzer. For safety reasons, only an

experienced technician should perform maintenance requiring other internal access.

1-1

Page 14

VT MOBILE

Operators Manual

Features

Features include:

• Percent Oxygen Measurement. An oxygen sensor measures the oxygen percent of the

gas in series with the high- or low-flow channel of the Analyzer. Maxtec oxygen

sensor distributed by Fluke Biomedical.

• Breath Parameters. The Analyzer measures 16 parameters on each detected breath.

These parameters include tidal volume, minute volume, inspiratory and expiratory

pressures, etc.

• Selectable Units. The Analyzer allows you to select the desired units for each of the

measured signals. For example, pressures can be displayed in mmHg, kPa, bar, mbar,

atm, inH2O, inHg, cmH2O or mmHg.

• Gas Type. Select the gas type from a pre-defined list, or, using the VT for Windows

software, specify a user-defined gas.

• Trend Testing. The Analyzer provides an automated test to see if a predetermined

parameter deviates from limits you set.

• Evaluations/Troubleshooting. Use the Analyzer for pre-purchase evaluations of

ventilators, incoming and routine performance verification, and troubleshooting

clinical problems, as well as teaching principles of mechanical ventilation.

• Computer Control, Data Logging, and Printing. A miniature RS232 serial port allows

connection to a personal computer for external Analyzer control, data logging of test

results, and printing. The Analyzer is compatible with Fluke Biomedical’s VT for

Windows PC software (version 2.01.00 or higher.)

•

Lung Simulator. The Analyzer operates with or without a test lung attached. Use the

optional Fluke Biomedical ACCU LUNG as a test lung with integrated airway

restrictors that assist you in evaluating intermittent errors.

About This Manual

This manual provides a complete description of the Analyzer and its applications. The

manual contains information for beginners as well as experts in mechanical ventilator

evaluation and separate measurement of pressure, flow, and volume.

Chapters are as follows:

• Chapter 1: Introducing the VT MOBILE. An introduction to the Analyzer

• Chapter 2: Preparing for Operation. Unpacking and setting up the Analyzer

• Chapter 3: Using the VT MOBILE. How to use the keys and interpret the screens

• Chapter 4: Checking Ventilator Parameters. How to access and interpret the 16

ventilator parameters

• Chapter 5: Measuring Pressure. How to measure high and low pressure

• Chapter 6: Measuring Flow and Volume. How to measure high and low flow and

derive volume

• Chapter 7: Maintaining and Troubleshooting the VT MOBILE. How to perform

maintenance and routine troubleshooting

• Appendix A: VT for Windows PC Software

• Appendix B: Specifications

1-2

Page 15

Preparing for Operation

Unpacking the VT MOBILE

Before unpacking the Analyzer, visually inspect the shipping box for damage. If no

damage is evident, unpack the Analyzer and its accessories from the shipping carton.

Table 2-1 lists the standard accessories included in the box. Save the foam inserts and

shipping box. You must use the original packing materials when shipping the Analyzer

for service or re-calibration. If the original shipping carton and packing materials are not

available, call a Fluke Biomedical service representative for assistance.

Identify accessories for your Analyzer with the aid of Tables 2-1, 2-2 and Figure 2-1.

Check for missing parts. Carefully inspect the unit for damage such as cracks, dents, or

bent parts. If items are missing or any physical damage is apparent, call Fluke Biomedical

for assistance. For information on ways to contact Fluke Biomedical, see the section in

this manual called “Support.” Also, notify the carrier if the damage appears to be the

result of a shipping mishap.

Chapter 2

2-1

Page 16

VT MOBILE

Operators Manual

Accessory Kit 2548405

High-Flow Sensor 2438334

High-Pressure Adapter (Luer to Male Nut/Nipple D.I.S.S. Oxygen) 2548303

Low-Pressure Adapter 2454175

Oxygen Sensor 2448801

Oxygen Sensor Cable 6 ‘ 2448051

‘T’, 15 mm ID, 22 mm ID, 15 mm ID end 2457028

VT MOBILE RS232 Cable, 6’ 2075257

9 VDC Battery (Alkaline) 614487

Battery Eliminator 2547455

Soft Carrying Case 2523995

Information Packet: Getting Started Manual; Quick Reference Card; CD

with Quick Reference Card, Getting Started Manual, Operators Manual, VT

for Windows (V2.01.00 +)

Table 2-1. Standard Accessories

Item Part Number

2544926

Table 2-2. Optional Accessories

Item Part No.

Low-Flow Sensor 2438352

High-Pressure Adapter (Luer to Female D.I.S.S. Oxygen) 2548315

Temperature and RH Sensor Assembly 2541622

Serial Communications Cable (RS232) DB9F to miniature RS232, 6’ 2075257

Power Adapter, Universal (USA and International) 2118212

ACCU LUNG Portable, Precision Test Lung 2387318

2-2

Page 17

Preparing for Operation

Powering Up

2

High-Flow

Sensor

Low-Pressure

Adapter

Powering Up

RS232

Cable

Low-Flow

Sensor

High-Pressure

Adapters

Figure 2-1. Key Available Accessories

Oxygen

Sensor

Temperature/RH

Sensor

ACCU LUNG

ede03f.eps

1. Press the Power key (H) to power on the Analyzer. The Analyzer displays the power up

screen for several seconds.

2. The Analyzer then prompts you for the zeroing procedure. Place the Analyzer on a flat

surface, and, if necessary, disconnect flow and pressure sensors.

W

Warning

Make sure pressure is set to zero before disconnecting the

High-Pressure Adapter. Exposure to high pressure could cause

personal injury.

3. Press G (Ok). The Analyzer now performs the zeroing procedure. After several seconds,

the Tidal Volume screen appears and the Analyzer is ready for use. If you have pressed R

to initiate the zero procedure, the Analyzer returns to the previous screen displayed.

Note

If the Analyzer encounters a power problem (such as a backwards battery),

thermal overload devices interrupt normal operation. Repair the problem,

wait several seconds, and resume normal operation.

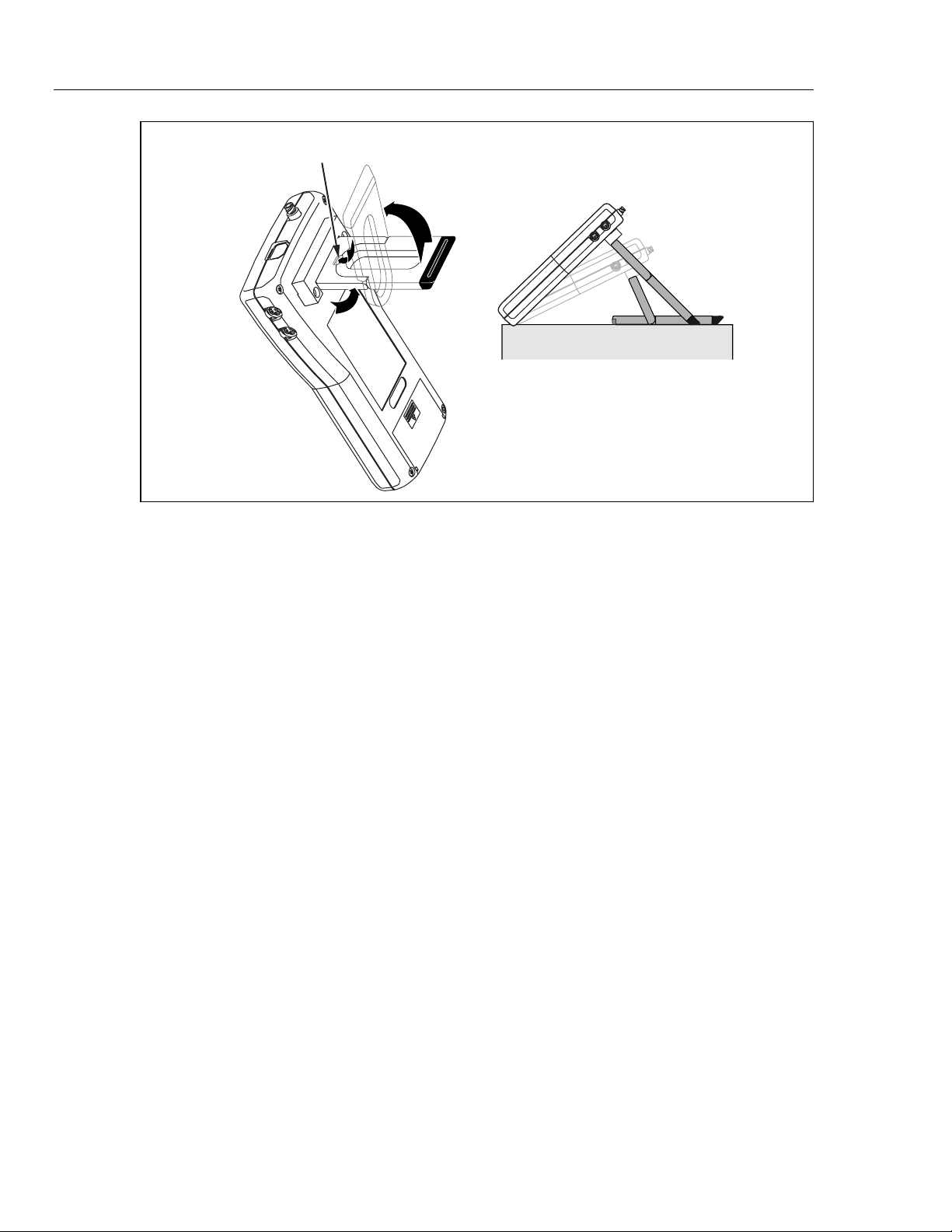

Using the Tilt Bail

As shown in Figure 2-2, you can use the Analyzer in flat or elevated positions. Do not

use the Analyzer by hand or during transport.

2-3

Page 18

VT MOBILE

Operators Manual

RELEASE

HERE

Figure 2-2. VT MOBILE Tilt Bail

edg21f.eps

Using the Keys

Press each key firmly; the Analyzer responds to a recognized key press with a beep.

Generally, you can exit one function by selecting another function. Press the B and

C navigation keys to cycle through multiple functions accessed from one key.

Relevant functions for the two softkeys (F and G) appear in the display

immediately above these keys. When text entry is necessary, quickly press a key to cycle

through the characters it accesses. Pause to accept the present character and move to the

next entry. Think of text entry as text messaging, as you would encounter on a cell phone.

Note

If the Zero warning screen appears at any time, follow on-screen directions

G

and then press

; the interrupted function will continue automatically

after the zeroing procedure.

Selecting the Operating Mode

Local Mode is the default setting upon powering up the Analyzer. In Local Mode, select

functions by pressing keys on the front panel.

To change modes from Local to Remote, first connect the serial cable to both the PC and

the miniature RS-232 serial port on the Analyzer. Launch VT for Windows software

(version 2.01.00 or higher) to activate Remote Mode.

If VT for Windows has remote control, the following appears on the Analyzer display

screen:

2-4

No Graphics Available, While Communications Are Active

Normal local key presses have no effect. Press G (Cancel) to regain local control.

Page 19

Preparing for Operation

Setting Up

Setting Up

Press D to access Analyzer settings. (Press G to return to the measurement screen.)

Selecting the Gas Type

Ensure that you have selected the gas or gas mixture you will be using, as the gas density

will be different for each gas type and mixture. The Analyzer uses this information to

improve the accuracy of the flow calculations. Failure to enter the correct value will

cause the flow and volume calculations to be in error.

2

Select the gas type by pressing

D Æ E Æ E Æ B or C Æ E.

Available selections are: Air, O2, Heliox, CO2, N2, N2O, N2O/O2 (N2O balance O2),

He/O2 (He balance O2), N2/O2 (N2 balance O2), and User. Refer to Table 2-3 for

descriptions of gas types. Only the VT for Windows software can identify a ‘User’ gas.

Table 2-3. Gas Types

Gas Description

Air Standard room air

O2 100% Oxygen

Heliox 30% Oxygen and 70% Helium blend

CO2 100% Carbon Dioxide

N2 100% Nitrogen

N2O 100% Nitrous Oxide

N20 bal O2 Measured Oxygen balance Nitrous Oxide

He bal O2 Measured Oxygen balance Helium

N2 bal O2 Measured Oxygen balance Nitrogen

User User selects custom gas mixture. This option requires the VT for Windows PC software.

Gas Temperature and Relative Humidity

These parameters are not really settings, but are available when the optional Temperature

and Relative Humidity Sensor is connected. The Analyzer measures the gas flowing

through the sensor and uses this information to improve the accuracy of the flow

measurements. All temperatures are in degrees Celsius.

Selecting the Correction Mode

This setting calculates the flow volume of the air flowing through the high or low-flow

ports. Ensure that the correction mode setting matches the one used by the ventilator or

anesthesia machine manufacturer for their display of flow and volume measurements. If

the correction mode is unknown, select “ATP” (Ambient Temperature and Pressure).

Refer to Table 2-4 for descriptions of the correction modes.

The Analyzer can operate with a correction mode of ATP, STPD

, BTPS, or STPD0.

21

Select the mode as follows:

1. Press

D Æ E Æ C (to ‘Corr Mode’)

2. Press E Æ C (to select mode)

3. Press E to activate your selection.

2-5

Page 20

VT MOBILE

Operators Manual

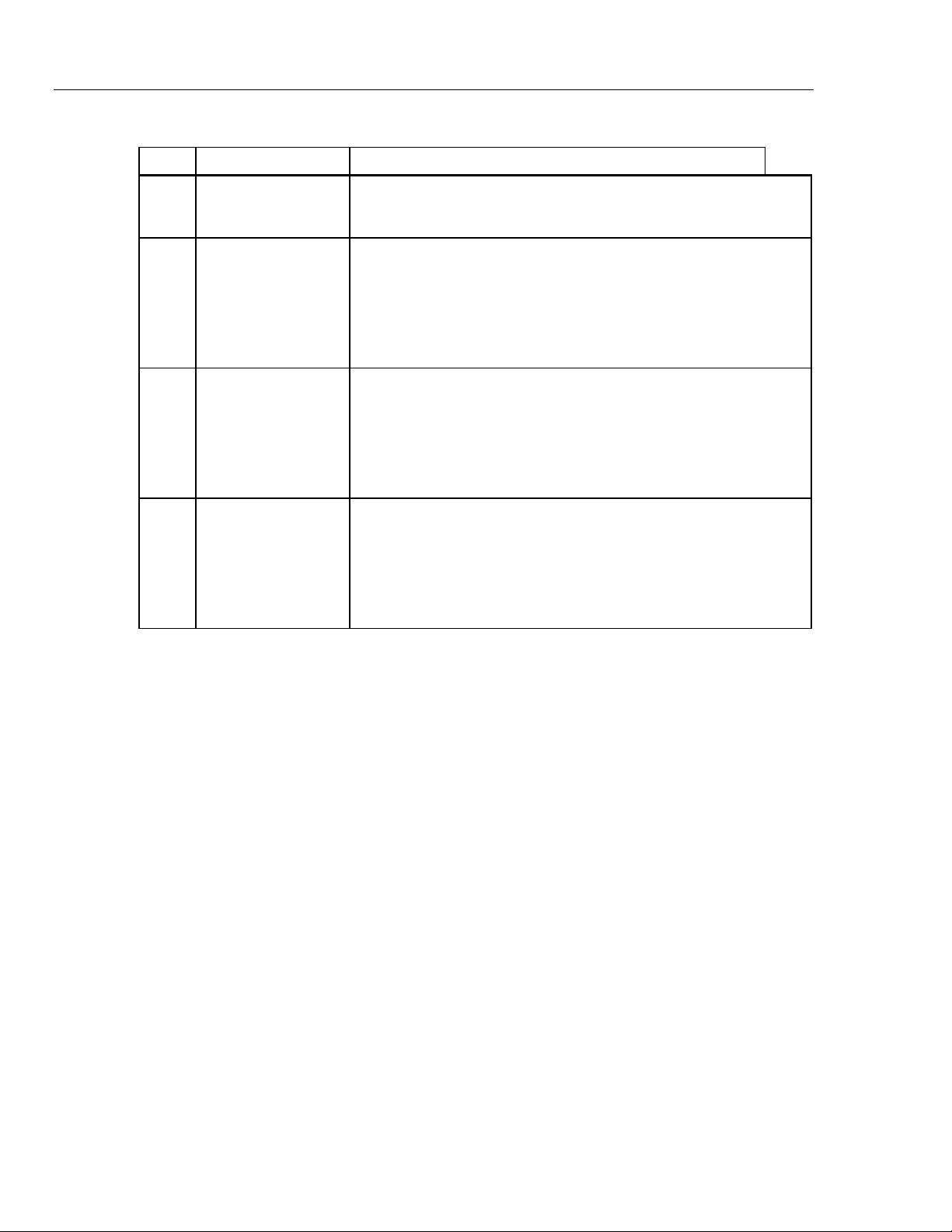

Mode Name Description

Table 2-4. Correction Modes

ATP Ambient Temperature

and Pressure

BTPS Body Temperature and

Pressure Saturated

with water vapor

STPD0 Standard Temperature

and Pressure Dry,

0 °C

STPD21 Standard Temperature

and Pressure Dry,

21 °C

The Analyzer corrects the flow rate (and therefore, volume) such that the

reported flow equals the flow if the gas temperature and pressure are at

ambient (room) temperature and pressure.

The Analyzer corrects the flow rate (and therefore, volume) such that the

reported flow equals the flow if the gas temperature and pressure were

changed to body conditions (37 °C and ambient pressure). Further, the

Analyzer compensates the flow to add the amount of water vapor as if to

make the gas fully saturated (i.e. 100% relative humidity). In this

correction, the Analyzer uses the relative humidity reading to determine

the amount of water vapor that would need to be added.

The Analyzer corrects the flow rate (and therefore, volume) such that the

reported flow equals the flow if the gas temperature and pressure were

changed to standard conditions (0 °C and 760 mmHg). Further, the

Analyzer compensates the flow to subtract the amount of water vapor as

if the gas was dry (i.e. 0% relative humidity). In this correction, the

Analyzer uses the relative humidity reading to determine the amount of

water vapor that would need to be subtracted.

The Analyzer corrects the flow rate (and therefore, volume) such that the

reported flow equals the flow if the gas temperature and pressure were

changed to standard conditions (21°C and 760 mmHg). Further, the

Analyzer compensates the flow to subtract the amount of water vapor as

if the gas was dry (i.e. 0% relative humidity). In this correction, the

Analyzer uses the relative humidity reading to determine the amount of

water vapor that would need to be subtracted.

Setting the Breath Detect Threshold

The Analyzer breath detection algorithm uses a flow rate threshold that the inspiratory

flow must cross to trigger a change in the breath phase. Higher flow rate thresholds yield

less sensitive breath detection. Lower thresholds yield more sensitive breath detection.

The default setting of 2.00 lpm is usually appropriate for the ventilators and anesthesia

machines being tested. This setting tells the Analyzer how to divide the delivered flow

into breaths. If necessary, adjust the Breath Detect Threshold up or down until the breath

rate reported on the Analyzer Timing display matches the ventilator breath rate.

Set the threshold as follows:

1. Press

D Æ E Æ C (to ‘BD Thresh’).

2. Press E Æ C or B (to change threshold in increments of 0.25). You can

also use text entry to enter a new value directly.

3. Press E to activate your selection.

Setting Zero Warn ON or OFF

You need to "zero" (or calibrate) the pressure and differential pressure (flow) sensors in

the Analyzer to a zero reference. This “zero” reminder function can be set to occur

automatically at pre-determined intervals or only when you request the function by

pressing R. The Zero Warn is helpful in reminding you to stop and zero the

transducers from time-to-time during operation. This is especially important during the

40-minute warm-up to full stability. The Analyzer does not calculate breath parameters

for any breath in which a zero occurs. For this reason, it may be desirable to turn off

automatic zeroing for a short while during a critical test.

2-6

Page 21

Preparing for Operation

Setting Up

The Analyzer Zero Warn is set to ON at the factory to remind you to zero out any offset

in the Flow measurements. The Zero Warn screen reminds you at power on, after the first

five minutes, and then after each 30-minute period. After the power-on zero warning, you

can choose to Zero or Cancel when the reminder appears; either action returns the

Analyzer to the same function.

W Caution

Setting Zero Warn to OFF may result in introduction of offset

into the Flow and Volume measurements and cause errors in

the assessment of those measurements against the medical

device under test specification. Fluke Biomedical strongly

recommends that you leave Zero Warn ON.

Turn this warning on or off using the following procedure:

2

1. Press

2. Press E Æ C (to select ON or OFF).

3. Press E to activate your selection.

Setting the Time

You can set hours and minutes. Enter the time in the HHMM or HMM format, where HH

or H is the hours in 12-hour format and MM is the minutes (00 through 59).

To set the time, follow these steps:

1. Press

2. Enter the hour (HH or H) with the text entry keys.

3. Press G.

3. Enter the minutes (MM) with the text entry keys.

4. Press F to select P (PM) or A (AM).

5. Press E.

Setting the Date

To set the date, follow these steps:

1. Press

D Æ C Æ E Æ C Æ E to access the time setting screen.

D Æ CÆEÆ E to access the date setting screen.

D Æ E Æ C (to ‘Zero Warn’).

2. Enter the month (MM) or day (DD), depending on the date format, with the text entry

keys.

3. Press G.

4. Enter the day (DD) or month (MM) with the text entry keys.

5. Press G.

6. Enter the year (YYYY) with the text entry keys.

7. Press E.

The Analyzer displays the date with the following information:

• MM is the number between 1 and 12 corresponding to the month.

• DD is the number between 1 and 31 corresponding to the day of the month.

• YYYY is the year.

2-7

Page 22

VT MOBILE

Operators Manual

Selecting the Date Format

The Analyzer uses either of the following date formats:

• M/D/Y

• D/M/Y

To change the format, follow these steps:

1. Press

2. Press C or C to select ‘M/D/Y’ or ‘D/M/Y’.

3. Press E to activate your choice.

4. Press G to return to the active display screen.

Setting the Contrast

Use the following procedure to change the screen contrast:

1. Press

2. Highlight Contrast by scrolling down with C.

3. Press E and adjust the contrast in either of the following ways:

Checking Version and Serial Numbers

Press

D Æ C Æ E Æ C Æ C Æ E

A Æ C Æ E.

• Press B or C to increment or decrement the contrast in steps of 10.

• Enter any contrast value directly using the text entry keys.

D Æ C Æ C Æ E to check the version and serial numbers.

Connecting the Analyzer

Connect the Analyzer for flow and pressure measurements as shown in Figures 2-3 and

2-4.

2-8

Figure 2-3. Low-Pressure/High-Flow/Low-Flow Connection

edg23f.eps

Page 23

Preparing for Operation

Connecting the Analyzer

Figure 2-4. High-Pressure Connection

High-Flow Connection

The High-Flow Sensor connects to the flow/low-pressure port on the top of the Analyzer.

Connect the High-Flow Sensor in line using adapters from the Accessory Kit.

W Caution

Do not exceed a flow of 200 lpm through the high-flow port.

Damage to the Analyzer could otherwise result.

2

edg22f.eps

Measure only dry gases using the high-flow port. Do not use

this port to measure exhaled or artificially humidified gases.

Low-Flow Connection

The Low-Flow Sensor connects to the flow/low-pressure port on the top of the Analyzer.

Connect the Low-Flow Sensor in line using adapters from the Accessory Kit.

Do not exceed a flow of 35 lpm through the low-flow port.

Damage to the Analyzer could otherwise result.

Measure only dry gases using the low-flow port. Do not use this

port to measure exhaled or artificially humidified gases.

High-Pressure Connection

The High-Pressure Adapter connects to the high-pressure port on the top of the Analyzer.

The connector mates to standard oxygen DISS fittings as used on oxygen supply hoses.

Connectors are available with male or female fittings. Do not apply fluid to the highpressure port.

Do not exceed a pressure of 125 psi at the high-pressure port.

Damage to the Analyzer could otherwise result.

W Caution

W Caution

Low-Pressure Connection

The Low-Pressure Adapter connects to the flow/low-pressure port on the top of the

Analyzer. Do not apply fluid to the low-pressure port.

2-9

Page 24

VT MOBILE

Operators Manual

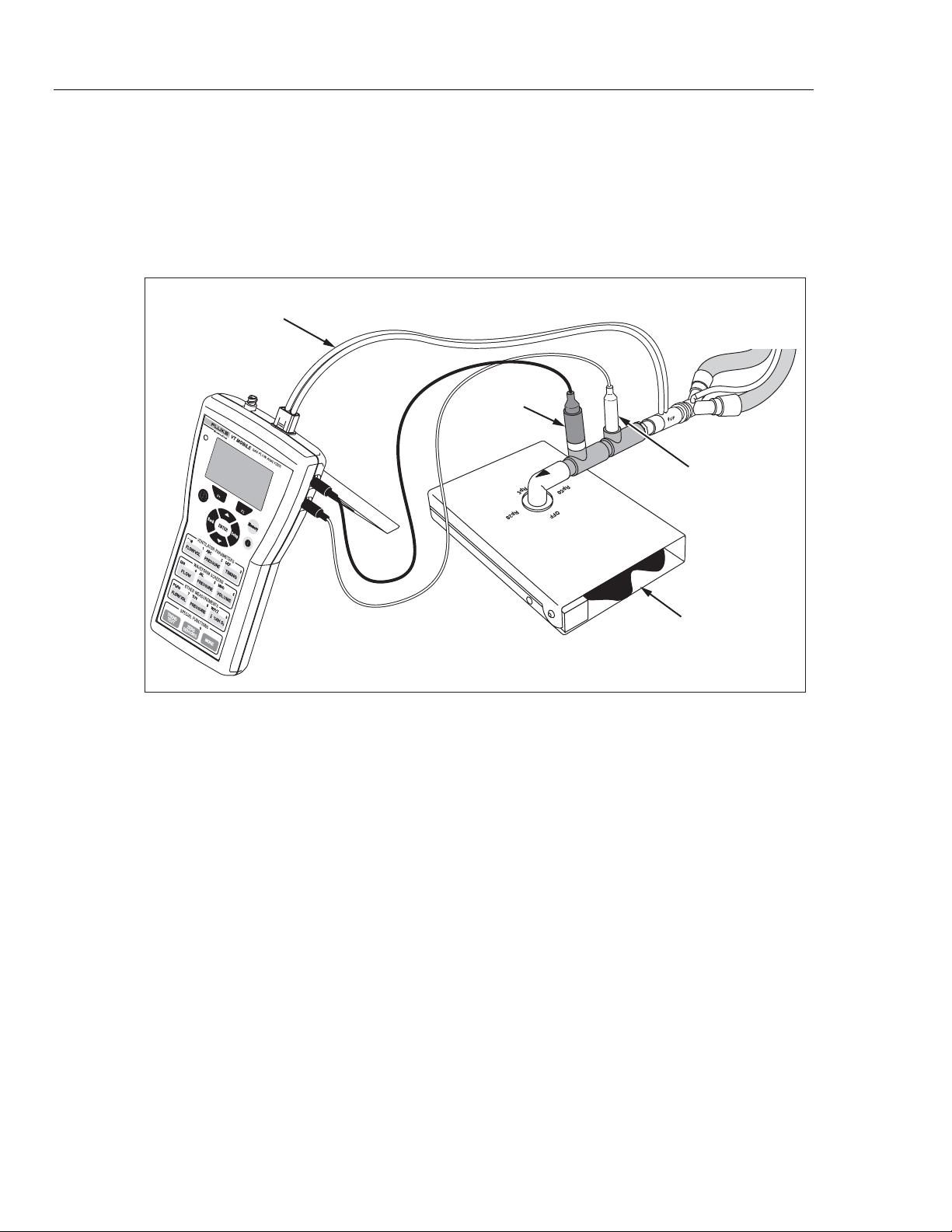

Ventilator Test Connections

W Caution

Do not exceed a pressure of 5 psi at the low-pressure port.

Damage to the Analyzer could otherwise result.

Ventilator testing involves multiple connections as shown in Figure 2-5.

High Flow Sensor

Oxygen

Sensor

Figure 2-5. Ventilator Test Connections

To

Ventilator

Temp./RH Sensor

Fluke Biomedical

ACCU LUNG

ede06f.eps

2-10

Page 25

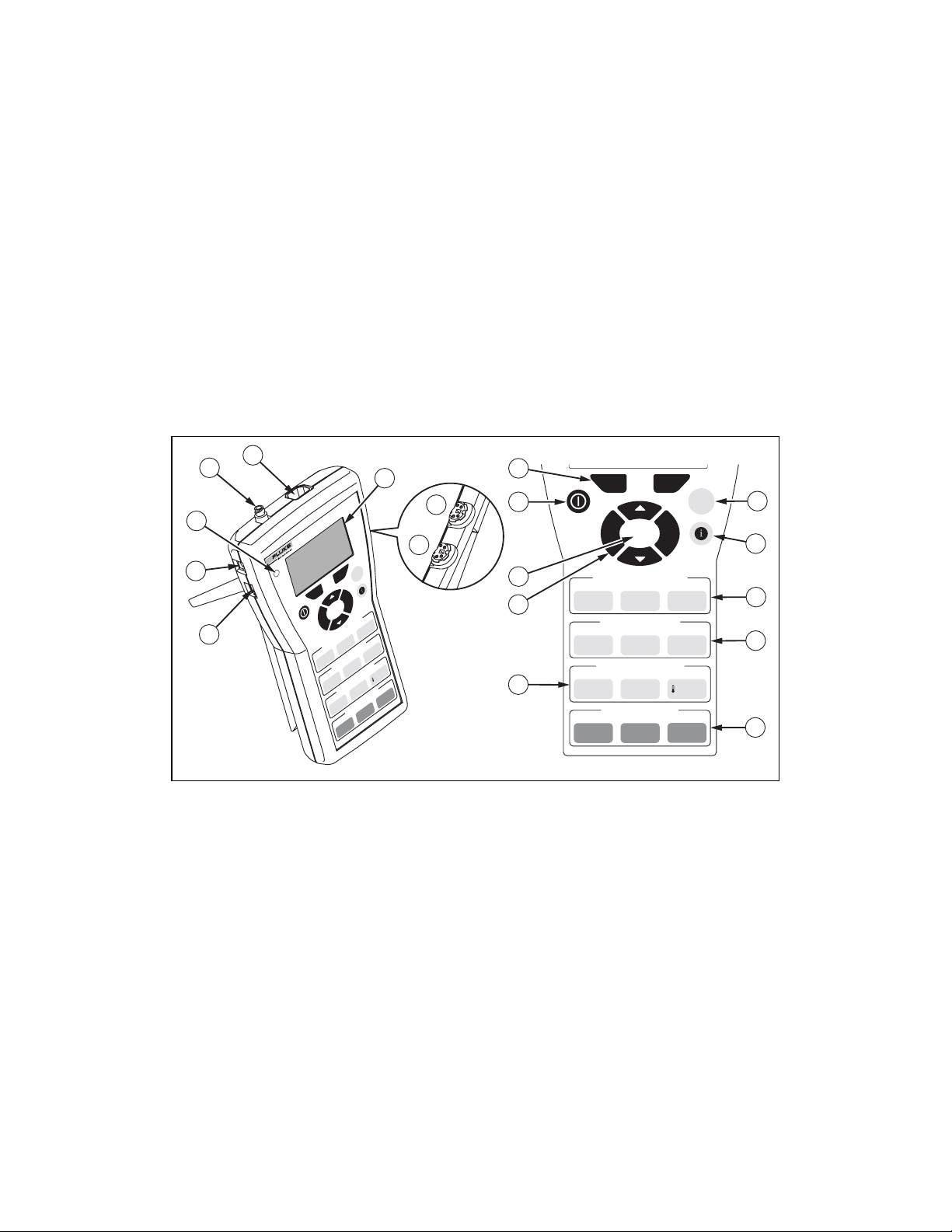

Using the VT MOBILE

Understanding the Controls and Indicators

Figure 3-1 and Table 3-1 describe the controls and indicators.

5

4

6

7

3

2

1

VT MOBILEVT MOBILE

GAS FLOW ANALYZERGAS FLOW ANALYZER

F1 F2

ENTER

Back

1122ABCABC

VENTILATOR PARAMETERS

PRESSURE

,

,

_

_

@

@

/VOL

FLOW

WAVEFORM SCREENS

44

GHIGHI

FLOW

OTHER MEASUREMENTS

PQRSPQRS

FLOW/VOL

TREND

MemoryMemory

Setup

DEFDEF

TIMING

MNOMNO

55

JKLJKL

PRESSURE

TUVTUV

77

PRESSURE

SPECIAL FUNCTIONS

ZERO

SENSORS

TEST

VOLUME

WXYZWXYZ

88

8

33

66

99

2

O

RH

%

00

MORE

18

17

16

15

9

F1 F2

Back

VENTILATOR PARAMETERS

_

, @_ , @ 1122ABCABC

FLOW/VOL

WAVEFORM SCREENS

OTHER MEASUREMENTS

FLOW/VOL

SPECIAL FUNCTIONS

TREND

TEST

Setup

ENTER

PRESSURE

PRESSURE

TUVTUV77PQRSPQRS 99WXYZWXYZ

TIMING

55JKLJKL44GHIGHI 66MNOMNO

VOLUMEFLOW

88

PRESSURE

00

ZERO

SENSORS

MORE

Chapter 3

MemoryMemory

%RH O

33DEFDEF

2

10

11

12

13

14

ede01f.eps

Figure 3-1. Controls and Indicators

3-1

Page 26

VT MOBILE

Operators Manual

No. Name Description/Use

Table 3-1. Controls and Indicators

A

B

C

D

E

F

G

H

I

Miniature RS-232 Serial

Port

Battery Eliminator

Connector

Battery Eliminator

Indicator

High-Pressure Connector Connect the High-Pressure Adapter here. The Analyzer makes

Flow and Low-Pressure

Connector

Display Screen Shows measurement parameters and statistics (Min, Avg, and

Oxygen Sensor Connector Connect the Oxygen Sensor here. The Analyzer makes O2

Temperature, RH Sensor

Connector

Softkeys

F G

Connect the RS-232 cable here (for use with VT for Windows

software.)

Connect the battery eliminator here. Use the battery eliminator

whenever possible.

Glows green when the battery eliminator is supplying power to the

Analyzer. Note that this power source cannot recharge the

battery.

high-pressure measurements from -2 to 100 psi.

Insert one of three coded modular connectors here; the Analyzer

automatically detects the connector type. The Analyzer use the

High-Flow Sensor to measure up to ± 150 lpm, the Low-Flow

Sensor to measure up to ± 25 lpm, or the Low-Pressure Adapter

to measure from -20 to 120 cmH2O.

Max), waveforms, and setup selections. English only.

measurements from 0 to 100%.

Connect the optional Temperature and Relative Humidity Sensor

here.

Use F and G to access selections identified on the screen

immediately above these keys.

J

K

L

Memory Key

J

Help Key

I

Ventilator Parameters

Keys

K L M

Press J to save, view, or delete memory files. A memory file

contains data to reconstruct all aspects of a stored screen

(reading, statistics, waveform, parameters, etc.)

Press I to access context-sensitive help. If necessary, press

B or C to scroll through additional text. Press

the previous screen.

Press K

parameters. When text entry is required, press K successively

to cycle through 1 Æ - Æ @. Press L to cycle through A Æ B

Æ C Æ 2, and press M to cycle through D Æ E Æ F Æ 3.

, L, or M to display ventilator measurement

A to return to

3-2

Page 27

Using the VT MOBILE

Understanding the Controls and Indicators

Table 3-1. Controls and Indicators (cont.)

No. Name Description/Use

3

M

N

O

P

Q

R

Waveform Screens Keys

N L O

Other Measurements Keys

K L P

Special Functions Keys

Q R S

Navigation Keys

A B C D

Enter Key

E

Power Key

H

Press N, L

For any waveform, press F (Rescale) to optimize the

display or press G (Units) to select new units of

measurement. When text entry is required, press N

successively to cycle through G Æ H Æ I Æ 4. Press L to

cycle through J Æ K Æ L Æ 5, and press O to cycle

through M Æ N Æ O Æ 6.

Press K to access direct readings and statistics of flow

and volume. Press L for readings and statistics of high or

low pressure. Repeated presses of P yield readings of

O2 %, temperature, and relative humidity. When text entry is

required, press K successively to cycle through P Æ Q Æ

R Æ S Æ 7. Press L to cycle through T Æ U Æ V Æ 8,

and press P to cycle through W Æ X Æ Y Æ Z Æ 9.

Press Q to start new or review old trending data. Press

R at any time to initiate the zeroing procedure or, when

keypad entry is required, to enter 0. Press S to access

barometric pressure and battery readings.

Press

A to exit specific screens (Setup, Memory, Help,

More, etc.)

Press B or C to cycle through specific screen

selections (Setup, Memory, More, etc.) or to scroll through

help text. Press

Correction Mode, Breath Detect Threshold, Zero Warning,

Date, Time, and version numbers.)

Press E to activate a menu selection.

Press and briefly hold this key to power on or power off the

Analyzer.

, or O to display specific waveforms.

D to access system settings (Gas Type,

3-3

Page 28

VT MOBILE

Operators Manual

Screens

Ventilator Parameters Screens

The Analyzer calculates 16 parameters for every breath. You can display all parameters

individually or most parameters in groups of four. Parameters update following every

breath. Units of measure for breath parameters are fixed. Table 3-2 shows parameters and

groupings, along with abbreviations and units of measurement.

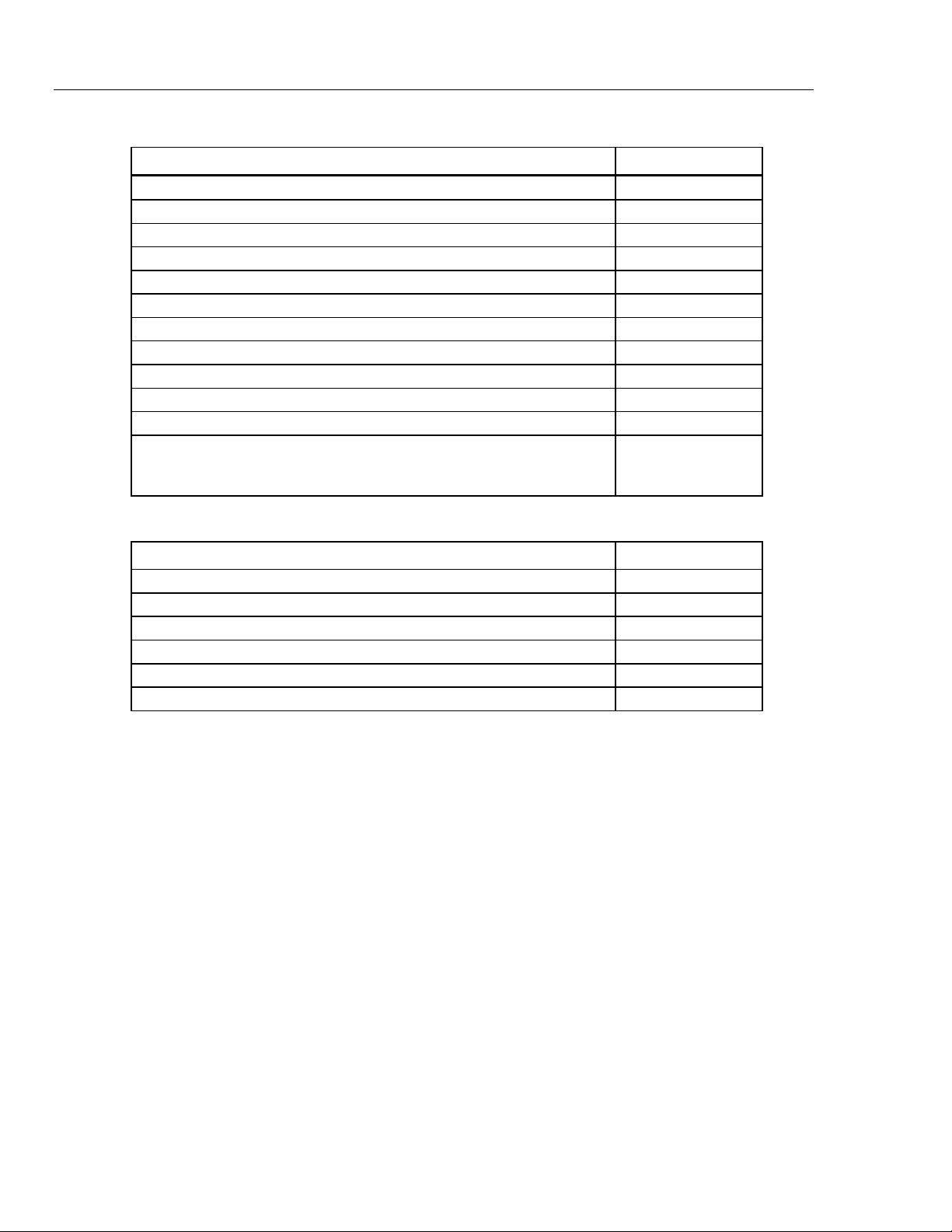

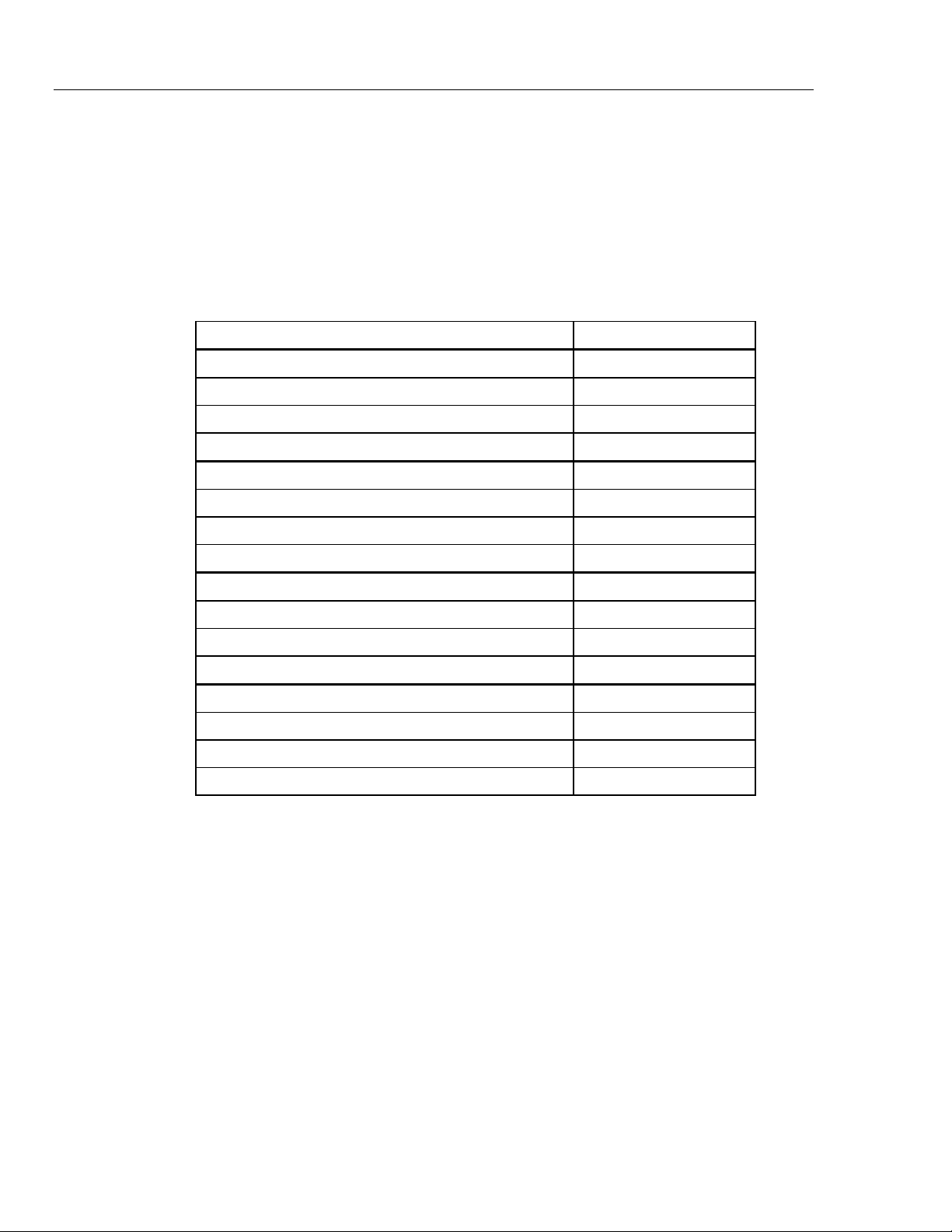

Table 3-2. Ventilator Parameters

Parameter Units

Inspiratory and Expiratory Tidal Volume (VT) ml

Expiratory Minute Volume (MV) lpm

Peak Inspiratory Flow (PIF) lpm

Peak Expiratory Flow (PEF) lpm

Peak Inspiratory Pressure (PIP) cmH2O

Positive-End Expiratory Pressure (PEEP) cmH2O

Mean Airway Pressure (MAP) cmH2O

Inspiratory Pause Pressure (IPP) cmH2O

Breath Rate (Rate) bpm

Inspiratory Time (Ti) s

Expiratory Time (Te) s

Inspiratory, Expiratory Time (I:E) Ratio s:s

Oxygen Concentration % O2

Temperature (optional) °C (selectable)

Relative Humidity (optional) % RH

Barometric Pressure mmHg (selectable)

3-4

Page 29

Using the VT MOBILE

Screens

Viewing a Single Parameter

To view single parameters, press K, L, or M repeatedly. If you are already

viewing a multi-parameter screen, press G (Single). The following is an example of

the PIP single parameter screen:

3

Viewing a Group of Parameters

From an individual parameter screen, press G (All) to display the related screen of

four parameters. The groups are Pressures, Vol/Flow, and Timing. The following is an

example of the Pressures multi-parameter screen:

Viewing All Parameters

You can view all 16 parameters on one screen when using the Analyzer connected to a

PC running the VT for Windows software.

Oxygen Screen

Press P to access the Oxygen Screen. The sample oxygen screen shown below

displays the signal and statistics for the oxygen sensor.

ede26s.bmp

ede27s.bmp

ede28s.bmp

Press F (Clear) to reset the statistics and start a new reading.

Press G (Calibrate) to begin the calibration routine for the oxygen sensor; you will

find complete instructions later in this chapter.

3-5

Page 30

VT MOBILE

Operators Manual

Temperature Screen

Press P as required to access the Temperature Screen (available when the optional

Temperature and Relative Humidity Sensor is connected.) The sample temperature screen

shown below represents the gas temperature as measured in series with the High-Flow or

Low-Flow Sensor.

Relative Humidity Screen

Press P as required to access the Relative Humidity Screen (available when the

optional Temperature and Relative Humidity Sensor is connected.) The sample relative

humidity screen shown below represents the gas relative humidity as measured in series

with the High-Flow or Low-Flow Sensor.

Barometric Pressure Screen

Press S Æ E to access the Barometric Pressure Screen. The Analyzer

continuously measures the barometric pressure using an internal sensor. A sample

barometric pressure screen follows:

ede29s.bmp

ede30s.bmp

ede31s.bmp

3-6

Waveform Screens

You can access waveform representations of the reading by pressing keys in the

WAVEFORM SCREENS section of the keypad. The Analyzer provides Flow, Pressure

(high, low, and airway), and Volume waveform screens.

Page 31

Using the VT MOBILE

Screens

Flow Screen

Press N to access the Flow Waveform Screen, which displays the reading and

waveform for flow in the flow/low-pressure port of the Analyzer. The Analyzer

automatically detects whether the High- or Low-Flow Sensor is connected. A sample

flow waveform screen appears below:

3

Press G to change the units of measure for the flow screen. Possible units of measure

for this screen include:

• LPM: Liters per minute

• CFM: Cubic feet per minute

• LPS: Liters per second

• mL/min: Milliliters per minute

• mL/sec: Milliliters per second

Press F to change the scale on the plot of data to a more appropriate window of

values.

Rescale uses the current Min/Max values to determine plot limits.

Pressure Screen

Press L as required to access the Pressure Screen, which displays the reading and

waveform for the pressure signal from the high-pressure or low-pressure/flow port. In

order, sample high-pressure and low-pressure screens appear below:

Note

ede32s.bmp

ede33s.bmp

ede34s.bmp

3-7

Page 32

VT MOBILE

Operators Manual

Press G to change the units of measure for the pressure screen. Possible units of

measure for this screen include:

• mbar: millibar = .001 Bar

• bar: 14.7 PSIG (Barometric)

• mmHg: millimeters of mercury

• inHg: inches of mercury

• cmH

• inH

O: centimeters of water

2

O: inches of water

2

• PSIG: pounds per square inch

• atm: atmospheres

• kPa: kilopascals

Press F (Rescale) to change the scale on the plot of data to a more appropriate

window of values.

Note

Rescale uses the current Min/Max values to determine plot limits.

Airway Pressure Screen

Press L as required to access the Airway Pressure Screen (Paw), which displays the

reading and waveform measured in the high- or low-flow port with the Analyzer

connected between a ventilator and a test lung. The following is a sample Airway

Pressure Screen:

Volume Screen

Press O to access the Volume Screen. The volume screen displays the reading and

waveform for the volume signal. The volume signal is the integral of the flow signal. A

sample volume screen appears below:

Press G (Units) to change the units of measure for the volume screen. Possible units

of measure for this screen include:

ede35s.bmp

ede36s.bmp

3-8

• Liters Liters

• mL Milliliters

• CF Cubic Feet

Page 33

Using the VT MOBILE

Screens

Press F (Rescale) to change the scale on the plot of data to a more appropriate

window of values.

Note

Rescale uses the current Min/Max values to determine plot limits.

Other Measurements Screens

The Flow, Volume, and Pressure screens display the reading at the top of the screen and

the minimum, maximum, and average of the readings at the bottom of the screen. The

Analyzer calculates these statistics continually until you select a new screen or press

F (Clear).

Flow Screen

Press K as required to access the Flow Screen, which displays the reading and

statistics for flow in the flow/low-pressure port of the Analyzer. The Analyzer

automatically detects whether the high- or low-flow sensor is connected. A sample flow

screen appears below:

3

Press G (Units) to change the units of measure for the flow screen. Possible units of

measure for this screen include:

• LPM – Liters per minute

• CFM – Cubic feet per minute

• LPS – Liters per second

• mL/min – Milliliters per minute

• mL/sec – Milliliters per second

Press F (Clear) to reset the statistics and start a new reading.

Volume Screen

Press K as required to access the Volume Screen, which displays the reading and

statistics for the volume signal. The volume signal is the integral of the flow signal. A

sample Volume Screen appears below:

ede37s.bmp

ede38s.bmp

3-9

Page 34

VT MOBILE

Operators Manual

Pressure Screen

Press G (Units) to change the units of measure for the Volume Screen. Possible units

of measure for this screen include:

• Liters Liters

• mL Milliliters

• CF Cubic Feet

Press F (Clear) to reset the statistics and start a new reading.

Press L to access the Pressure Screen, which displays the reading and statistics for the

pressure signal from the high-pressure or low-pressure/flow port. A sample Pressure

Screen appears below:

Press G (Units) to change the units of measure for the Pressure Screen. Possible units

of measure for this screen include:

• PSIG – Pounds per square inch gauge

• kPa – Kilopascals

• bar – 14.7 PSIG

• mbar – millibar = .001 Bar

• atm – Atmosphere

• inH

0 – Inches of water

2

• inHg – Inches of mercury

• cmH

0 – Centimeters of water

2

• mmHg – Millimeters of mercury

Special Functions Screens

Access the Trend Test, Zero Sensors, Barometric Pressure, and Battery screens with the

keys at the bottom of the keypad.

ede39s.bmp

3-10

Page 35

Using the VT MOBILE

Screens

Trend Test Screens

Press Q to access the Trend Test screens, which allow you to record instances (or

events) of a selected ventilator parameter falling outside limits that you establish. The

opening screen in the trend test setup sequence appears below:

3

Zero Sensors Screens

Press R to access the Zero Sensors screens, which allow you to clear the offset

resulting from drift inherent in the differential pressure transducer. The opening screen in

the zero sensors sequence appears below:

This screen also appears automatically at a set interval to remind you to zero the sensors

if Zero Warn is set to ON in the setup procedure.

More Key Screens

Barometric Pressure Screen

Press S Æ E to access the opening Barometric Pressure Screen, which allows

you to view or change the barometric pressure that is automatically measured by an

internal sensor. Under normal operating conditions, barometric pressure should not need

adjustment. The following is a sample of the opening Barometric Pressure Screen:

ede40s.bmp

ede41s.bmp

Battery Screen

ede31s.bmp

Press S Æ C Æ E to access the Battery Screen, which allows you to view the

battery level. A sample of the 9-volt battery reading (when the battery eliminator is not

connected) appears below:

ede43s.bmp

If the battery eliminator is connected, this screen shows approximately 12 volts.

3-11

Page 36

VT MOBILE

Operators Manual

Using Trend Test

Use Trend Test to examine a single breath parameter over an extended period. The

Analyzer checks the parameter for deviations beyond the limits that you set. Set the limits

in the units you are measuring.

Fluke Biomedical recommends that you disable the Zero Warn feature for the duration of

your trend test. Zero warnings would otherwise interrupt the collection of events. Disable

Zero Warn by pressing

A Æ E Æ C Æ C Æ C Æ E Æ C (to Off)

Æ E Æ G.

Use the following steps to advance through the trend test procedure:

1. Press Q to begin the Trend Test setup.

ede45s.bmp

2. Press F (New) to begin a new trend test.

ede44s.bmp

3. Press B or C to select the trend parameter for the test (VT, MV, PIF, PEF, Rate,

Ti, Te, PIP, PEEP, MAP, or IPP.)

4. Press E to activate the parameter selection.

ede40s.bmp

5. Press F (Low) and then set the low limit by either:

3-12

a. Pressing B or C to increment or decrement the displayed value 0.1 units at

a time, or

b. Using the text entry keys to enter a new value directly.

6. Press E to accept this value.

7. Press G to enter the High limit, and repeat the entry procedure.

Page 37

Using the VT MOBILE

Using Trend Test

8. When both Low and High limit values are correct, press E again to advance to

the Start Trend Test screen.

3

ede46s.bmp

9. Before starting the test, ensure that the ventilator is on, has reached steady-state

conditions, and that the displayed breath parameter is as expected. Press G (Start)

to begin the test.

10. The Analyzer displays the Trend Test screen while the trend test is in progress. The

trend test screen shows the parameter being tested, the current value, the upper and

lower limits, and the number of events (readings falling outside the limits.)

ede47s.bmp

11. To terminate the test, press G (Stop). The Trend Summary screen appears. If there

are no events, the Trend Summary screen is not available.

ede48s.bmp

ede49s.bmp

12. Alternatively, press G (More) to display related parameters.

ede50s.bmp

3-13

Page 38

VT MOBILE

Operators Manual

Making Measurements

Working with Memory

This Operators Manual covers specific measurement procedures in the following

chapters:

• Chapter 4: Checking Ventilator Parameters. Learn how to set up and take

measurements for the 16 ventilator parameters.

• Chapter 5: Measuring Pressure. Learn how to set up and take pressure measurements

using the High- and Low-Pressure adapters.

• Chapter 6: Measuring Flow and Volume. Learn how to set up and take flow and

volume measurements using the High- and Low-Flow sensors.

Access Analyzer memory by pressing J. The following screen appears:

Press C or B to highlight an item, and then press E to make the selection.

Store all existing readings by selecting Save New File. The Analyzer prompts you for a

file name to Save As; use the text entry keys to enter a name. Then press E and wait

for a moment while the Analyzer stores the readings to this file.

Retrieve an existing file by selecting View File, scrolling to the file name, and then

pressing E. You can view the DEMO file in this fashion; it provides sample data for

all possible measurements.

Delete a single file by selecting Delete File, scrolling to the file to delete, and pressing

E.

Delete all files by pressing Delete All and then pressing E.

Printing

Print data from the Analyzer using a PC running VT for Windows. This software also

allows you to view all 16 ventilator parameters on one screen and manipulate and graph

data.

Making a Measurement More Accurate

Warm-up and Zeroing

The Analyzer requires a warm-up period. A five-minute warm-up followed by a zero and

immediate measurement is adequate for most applications. A 40-minute warm-up ensures

maximum accuracy and stability.

ede51s.bmp

3-14

The Zero Warn feature reminds you to zero the transducers at predefined intervals. Fluke

Biomedical strongly recommends that you leave Zero Warn ON and, after removing

pressure and flow sources, zero the transducers whenever the Zero Warn message

appears.

Page 39

Using the VT MOBILE

Making a Measurement More Accurate

The Analyzer requires you to zero immediately after power on. If Zero Warn is ON, the

Analyzer prompts you for an optional zero after the first five minutes and then after each

subsequent 30-minute interval. To zero at the prompt, follow these steps:

1. Place the Analyzer on a flat surface with sensors/adapters disconnected at the

Analyzer (Figure 3-2.)

3

Figure 3-2. Flow Sensors and Pressure Adapters Disconnected

edg17f.eps

2. Press G. Press R at any time to initiate an unprompted zero. Generally, it is

appropriate to zero before any pressure or flow measurement.

3. Reconnect the sensors/adapters (Figure 3-3.)

edg18f.eps

Figure 3-3. Flow Sensors and Pressure Adapters Connected

3-15

Page 40

VT MOBILE

Operators Manual

Oxygen Sensor

Verifying Oxygen Sensor Calibration

The Analyzer calculates the oxygen percentage as the fraction of the partial pressure of

oxygen relative to the total pressure. Note that changes in the total pressure (i.e. airway

pressure) result in a change in the partial pressure of the measured oxygen even though

the percentage of oxygen is the same. Since the pressure can change much faster than the

response time of the oxygen sensor, a small transient (1 to 2% of full-scale) error can

occur in the oxygen measurement when there is a fast change in the pressure at the

oxygen sensor.

Whenever you make an oxygen measurement, or when you calibrate or zero the oxygen

sensor, make sure there is sufficient gas flow past the oxygen sensor. The Analyzer needs

only a small flow of gas (e.g., 10 lpm) to ensure that the oxygen concentration at the

oxygen sensor is measured accurately. A small amount of flow must be present to ensure

gas mixing.

Verify the oxygen sensor calibration at the beginning of any day during which you expect

to measure oxygen concentrations. Note that you must calibrate the Oxygen Sensor

before initial verification; the sensor is not calibrated as shipped. The Oxygen Sensor

requires subsequent weekly recalibration at a minimum.

Use the following verification procedure:

1. Connect the Oxygen Sensor as shown in Figure 3-4.

2. Introduce a 10 lpm or greater flow of 100% oxygen through the Oxygen Sensor “T”.

3. Press P to access the O2 display.

4. Ensure that the O2 screen oxygen concentration is 100 % ± 2 % of full scale. If the

concentration is less than 98 %, perform the oxygen sensor calibration as described

below.

5. Replace the oxygen sensor after one year (or longer if no replacement message

appears during calibration.)

The Oxygen Sensor is not calibrated at the factory.

Calibrating the Oxygen Sensor

Calibrating the Oxygen Sensor improves pressure compensation for barometric and

airway pressure changes. Figure 3-4 portrays Oxygen Sensor connections.

Note

3-16

Page 41

Using the VT MOBILE

Making a Measurement More Accurate

Oxygen Sensor

Source

Figure 3-4. Oxygen Sensor Calibration

edg20f.eps

3

1. Press P to display the Oxygen measurement screen.

2. Press G to access the Oxygen calibration screen.

3. Connect the High-Flow Sensor and then apply dry air (20.9 % oxygen) at 10 lpm to

either side of the sensor.

4. Press F twice to access the Calibration screen. Wait for the two-minute timer to

count down.

5. Apply 100 % oxygen at 10 lpm.

6. Press G twice and then press F once to access the Calibration screen.

7. After the two-minute interval, the Oxygen measurement screen appears and the

calibration is complete.

Using the Temperature and Relative Humidity Sensor

Use the optional Temperature and Relative Humidity Sensor to compensate for the

conditions of the gas flowing through the High- or Low-Flow Sensor. The Analyzer uses

the gas temperature to improve the accuracy of the flow measurements. Relative

humidity readings provide a reference point for some correction factors. Connect this

sensor to the Analyzer as shown in Figure 3-5.

ede28s.bmp

3-17

Page 42

VT MOBILE

Operators Manual

Temp/RH Sensor

Source

Figure 3-5. Measuring Temperature and Relative Humidity

ede19f.eps

Press P as required to access the temperature and relative humidity screens shown

below:

Checking Barometric Pressure

Other pressures displayed on the Analyzer (e.g., Airway Pressure, differential pressures

as a basis for Flow, etc.) are relative to the internally-measured barometric pressure

(gauge pressure).

An internal sensor constantly measures barometric pressure. Other pressures displayed on

the Analyzer (e.g., airway pressure or differential pressure as a basis for flow) are relative

to the internally-measured barometric pressure (gauge pressure). You can fine-tune the

barometric pressure measurement by entering your own value. The Analyzer then factors

in the difference between the original measurement and your value as an offset correction

for subsequent measurements. The Analyzer stores the correction factor in non-volatile

memory to be remembered when you turn it off and then back on.

ede29s.bmp

ede30s.bmp

3-18

To enter a barometric pressure value, follow these steps:

1. Disconnect the High-Pressure Adapter at the High-Pressure Port.

2. Press S Æ E to access the barometric pressure screen, shown below.

Page 43

Using the VT MOBILE

Viewing Demo Data

3

3. Press F to access the calibration screen. This screen always appears in mmHg

units even though you may have selected other units.

4. Use the text entry keys to enter the barometric pressure in mmHg.

5. Press E to return to the barometric pressure screen.

Note that the Analyzer accepts barometric pressure values between 0.0 and 999.9 mmHg.

Exercise caution in changing barometric pressure readings; correct

barometric pressure yields more accurate pressure, flow, and volume

readings. Under normal operating conditions, barometric pressure should

not need adjustment.

The Analyzer relies on ambient barometric pressure. Do not set for airport

barometric pressure, which is corrected for altitude.

Changing Barometric Pressure Units

To change the barometric pressure units, follow these steps:

1. Press S Æ E.

2. Press G successively to select a barometric pressure unit. Units available are:

mmHg, PSI, kPa, Bar, mBar, ATM, inH2O, InHg, and cmH2O.

Note

ede31s.bmp

3. Press

A to return to the active display.

Viewing Demo Data

This function allows you to show recorded data on screen without needing to hook up to

a ventilator or do any measurements. The recorded data is for "demonstration" purposes.

To select this function, follow these steps:

1. Press J to access the Files screen.

2. Press C as necessary to highlight ‘View File’.

3. Press E and then press C as necessary to highlight ‘DEMO’.

4. Press E to activate your selection. After a pause, the Analyzer returns to a

measurement screen displaying data from the demo file.

5. To stop the demo data display, press J to access the Files screen, highlight ‘Stop

Playback’, and then press E to exit the demo file. Press any measurement key to

continue with live measurements.

Accessing Help

Use the I key to access context-sensitive help. If additional text is available off screen, a

vertical bar appears on the right side of the help screen. Use B or C to scroll

through the complete text. Press G to exit help.

3-19

Page 44

VT MOBILE

Operators Manual

3-20

Page 45

Introduction

To monitor ventilator parameters, the Analyzer must first determine when a breath occurs

and delineate the various phases of the breath. For example, the breath detection

algorithm determines the beginning and ending of the integration periods for calculating

tidal volumes.

The breath detection algorithm is a state machine. The flow waveform is the input to the

state machine. The Analyzer bases state changes on flow waveform crossings of

predefined thresholds. The breath detection threshold can be set to a high flow rate to

reject noise near zero flow.

You can use the High-Flow or Low-Flow Sensor to sample ventilator parameters.

Generally, the Low-Flow Sensor provides better accuracy at low flow rates (less than 25

lpm). Also, review “Making a Measurement More Accurate” in Chapter 3 for a

discussion of the uses of the Oxygen Sensor, Temperature and Relative Humidity Sensor,

and barometric pressure readings in enhancing measurement accuracy. Chapter 3 also

discusses proper warm-up and zeroing procedures to compensate for sensor drift.

Chapter 4

Checking Ventilator Parameters

Checking Ventilator Parameters

Refer to Figure 4-1 when you are connecting the Analyzer to a ventilator and test lung.

1. Press R and follow on-screen instructions.

2. At the Analyzer, connect the High-Flow Sensor to the Flow/Low-Pressure Port.

3. Connect the Oxygen Sensor to the upper port on the right side of the Analyzer.

4. If available, connect the optional Temperature/RH Sensor to the lower port on the

right side of the Analyzer.

4-1

Page 46

VT MOBILE

Operators Manual

5. Using parts from the Accessory Kit and the connectors provided with the sensors,

make connections between the ventilator and the ACCU LUNG as shown in Figure

4-1. Use the sequence: ventilator Y connector Æ High-Flow Sensor (blue stripe

toward the ACCU LUNG) Æ Temperature/RH Sensor Æ Oxygen Sensor Æ ACCU

LUNG. Vertically align all sensors.

6. Set up the ventilator for a characteristic breath pattern. For example, you could set 10

BPM at 7.5 lpm.

7. Set the ACCU LUNG for C20 compliance (both outer springs engaged) and Rp50

resistance (positioned as shown in Figure 4-1.)

High Flow Sensor

Ventilator

Oxygen

Sensor

Temp./RH Sensor

Fluke Biomedical

ACCU LUNG

Figure 4-1. Ventilator Connections

8. Apply power to all elements of the test setup. For the Analyzer, press H on, wait for

the Zeroing screen, and then press

G. The Analyzer is ready to use once the Tidal

Volume screen appears.

To

ede06f.eps

4-2

9. Press the access keys shown in Table 4-1 to display the various ventilator parameters.

Once you have pressed the first key, you can continue pressing that key to view other

parameters or press

G to view all the parameters.

10. As described in Table 4-1, the Analyzer calculates 16 breath parameters in Local

Mode. Note that you can view all 16 parameters and other information on one screen

in Remote mode when using the VT for Windows software.

11. Figure 4-2 shows the ventilator parameter screens.

12. Figure 4-3 shows additional oxygen, temperature, relative humidity, and barometric