Page 1

Tools & Equipment

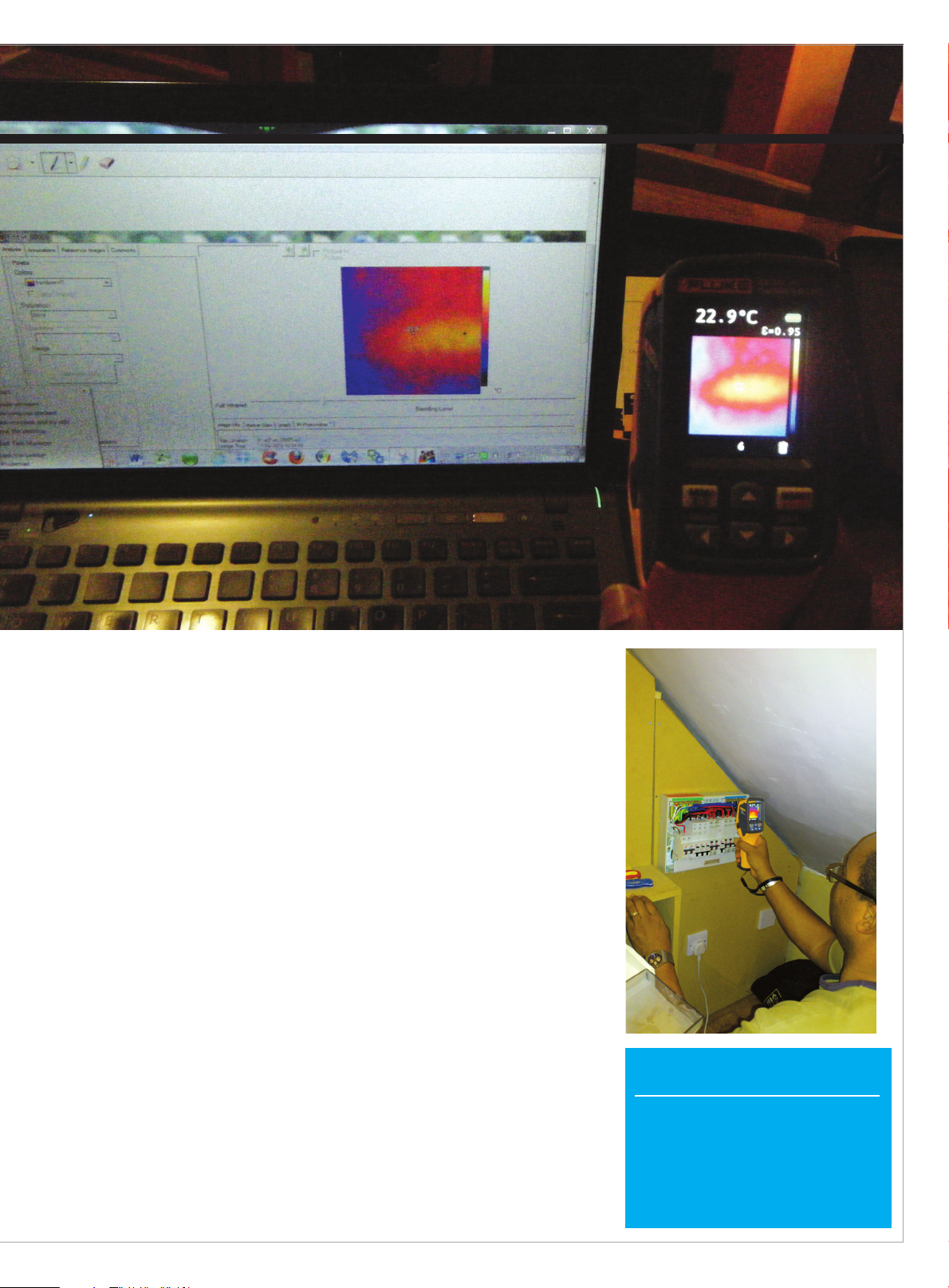

PICTURE

PERFECT

Every picture tells a story, so Norman

Bradshaw gets to grips with the new

Fluke VT02 Visual Thermal Infra-Red

thermometer to see what it can reveal.

hat is the difference between being an Electrical

Contractor, and being a Successful Electrical

W

or not owning Fluke’s new VT02 Visual Thermal IR thermometer. Let

me expand on that.

Growing up in our fast changing industry has brought us many

challenges. For me, one of the greatest challenges and rewards

has been learning to conduct meaningful electrical PIR’s, now

known as EICR’s. To be good at conducting Electrical Installation

Condition Reports-(EICR’s) you need skill, confidence, sound

technical knowledge and tools that inspire confidence.

seems to want a report done for as little as possible. You know as

well as I do that you cannot skimp on quality - so how are you

going to juggle providing a service while at the same time not

working for free? From my experience you need to know what

you are worth and have the tools to back you up. A step in the

right direction is being able to show your client what would be

included in your summary – a thermal IR report – your competitor does

not possess one. What a shame!

Contractor? The difference could simply be owning

This skill is further compounded by the fact that everyone

Back to basics

What is thermal imaging? It is the non-contact detection and measurement of

temperature differences shown pictorially by using different colours, or to put

it in a vernacular - it allows you to see what your eyes can’t. Fluke’s VT02 Visual

IR thermometer blends infrared heat map technology with digital thermal

imagery. Up until now thermal imaging cameras have been wishful thinking for

most electricians, but Fluke have developed the VT02 which falls into a new

category; it fits in between IR spot thermometers and IR thermal imaging

Page 2

Fluke IR Thermometer

cameras, giving you the chance to put that

technology right into the palm of your hand. For

the price of a top spec multifunctional tester

you can now purchase Fluke’s latest addition to

the IR family.

The spec

I was very excited to put this tool through its

paces as I already have an IR spot thermometer

and I wanted to see how this one compared. As

I go through the features see if you could think

of some jobs you have done or going to do

where this technology will make a difference.

Fluke’s new IR thermometer stands a little

over 200mm tall yet it is jam packed with all you

need to do a good job. You can enter the date,

time and hour for starters, which is excellent for

keeping a log of your pictures and jobs. There is

also a slot on the thermometer where the 4 GB

micro SD card is to be inserted so that you can

store all the pictures you have taken.

Later you can then transfer them to your

computer using Fluke’s SmatView software, and

if that is not all you can blend then and add

notes to your photographs – your client is going

to be very impressed! To record any details you

want, it is simply a matter of just pressing the

green trigger on the front of the thermometerjob done!

The menu button also acts as the power off

and on button. There are six buttons in all and

to find out what they do simply requires

pressing the arrows and when you see what you

Images can be transferred to your computer using Fluke’s SmartView software

want then press select. You have for example the

option of having the temperature displayed in

Degrees Celsius or Fahrenheit.

There is a button for taking pictures close up

of further away, depending on what you are

testing. You can get as close as six inches by

selecting the near mode. You can also adjust or

record emissivity (the ability of a material to

radiate heat energy) colour palette, back-ground

temperatures and temperature markers.

Ease of use

The real beauty of this camera is that it is so

easy to use. This machine does not just give you

an average reading like many IR thermometers,

but the exact temperature of the object you are

looking at – so fellow electricians – you can

measure with confidence!

By just pressing one button you can capture

in real time what is going on at the point under

test. You can take several images and later

compare your readings.

Even without reading through the entire

manual you get a very good idea of what it can

do. Thermal Imaging is a growing field as

insurance companies have started to request

these types of surveys particularly where access

to carry out insulation resistance or continuity

tests is virtually impossible. While Thermal

imaging should never replace traditional testing,

it does give you a measure of flexibility and

another string to your bow, so… point & shoot!

The camera can be used as

close as six inches effectively

READE RLINK

Want more info?

Free Text PE416 to 62244

Free Circle on the Enquiry Card

Free Scan the QR Code

PROFESSIONAL ELECTRICIAN APRIL 2013 81

Loading...

Loading...