Page 1

VR101S

Voltage Event Recorder

System

Users Manual

®

December 1997, Rev. 4, 06/02

© 1997, 1999, 2002 Fluke Corporation. All rights reserved.

All product names are trademarks of their respective companies.

Page 2

Page 3

LIMITED WARRANTY & LIMITATION OF LIABILITY

Each Fluke product is warranted to be free from defects in material and

workmanship under normal use and service. The warranty period is one

year and begins on the date of shipment. Parts, product repairs and

services are warranted for 90 days. This warranty extends only to the

original buyer or end-user customer of a Fluke authorized reseller, and

does not apply to fuses, disposable batteries or to any product which, in

Fluke’s opinion, has been misused, altered, neglected or damaged by

accident or abnormal conditions of operation or handling. Fluke warrants

that software will operate substantially in accordance with its functional

specifications for 90 days and that it has been properly recorded on nondefective media. Fluke does not warrant that software will be error free or

operate without interruption.

Fluke authorized resellers shall extend this warranty on new and unused

products to end-user customers only but have no authority to extend a

greater or different warranty on behalf of Fluke. Warranty support is

available if product is purchased through a Fluke authorized sales outlet

or Buyer has paid the applicable international price. Fluke reserves the

right to invoice Buyer for importation costs of repair/replacement parts

when product purchased in one country is submitted for repair in another

country.

Fluke’s warranty obligation is limited, at Fluke’s option, to refund of the

purchase price, free of charge repair, or replacement of a defective

product which is returned to a Fluke authorized service center within the

warranty period.

To obtain warranty service, contact your nearest Fluke authorized service

center or send the product, with a description of the difficulty, postage

and insurance prepaid (FOB Destination), to the nearest Fluke authorized

service center. Fluke assumes no risk for damage in transit. Following

warranty repair, the product will be returned to Buyer, transportation

prepaid (FOB Destination). If Fluke determines that the failure was

caused by misuse, alteration, accident or abnormal condition of operation

or handling, Fluke will provide an estimate of repair costs and obtain

authorization before commencing the work. Following repair, the product

will be returned to the Buyer transportation prepaid and the Buyer will be

billed for the repair and return transportation charges (FOB Shipping

Point).

THIS WARRANTY IS BUYER’S SOLE AND EXCLUSIVE REMEDY AND

IS IN LIEU OF ALL OTHER WARRANTI ES, EXPRESS OR IMPLIED,

INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTY OF

i

Page 4

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

FLUKE SHALL NOT BE LIABLE FOR ANY SPECIAL, INDIRECT,

INCIDENTAL OR CONSEQUENTIAL DAMAGES O R LOSSES,

INCLUDING LOSS OF DATA, WHETHER ARISING FROM BREACH

OF WARRANTY OR BASED ON CONTRACT, TORT, RELIANCE OR

ANY OTHER THEORY.

Since some countries or states do not allow limitation of the term of an

implied warranty, or exclusion or limitation of incidental or consequential

damages, the limitations and exclusions of this warranty may not apply to

every buyer. If any provision of this Warranty is held invalid or

unenforceable by a court of competent jurisdiction, such holding will not

affect the validity or enforceability of any other provision.

Fluke Corporation, P.O. Box 9090, Everett, WA 98206-9090 USA, or

Fluke Industrial B.V., P.O. Box 680, 7600 AR, Almelo, The Netherlands

SERVICE CENTERS

To locate an authorized service center, visit us on the

World Wide Web:

http://www.fluke.com

or call Fluke using any of the phone numbers listed

below:

+1-888-993-5853 in U.S.A. and Canada

+31-402-678-200 in Europe

+1-425-356-5500 from other countries

ii

Page 5

Table of Contents

Chapter 1

Getting Started...............................................................1

Introduction.................................................................1

Features of the Voltage Event Recorder System....1

Safety......................................................................3

Plugging in a recorder.............................................3

Electrical Immunity..................................................4

Safety Inspection ....................................................5

Battery Care............................................................5

Maintenance ...........................................................6

Product Service.......................................................6

What You Need to Run Fluke EventView Software....7

What’s in the VR101S Package..................................7

Installing EventView software.....................................8

Setting the Time and Date ........................................10

Chapter 2

Setting Up the VR101 ..................................................11

Introduction...............................................................11

Connecting the Optical Interface Cable....................11

Starting EventView...................................................11

Selecting a COM Port...........................................12

Opening the Site Report Window..........................12

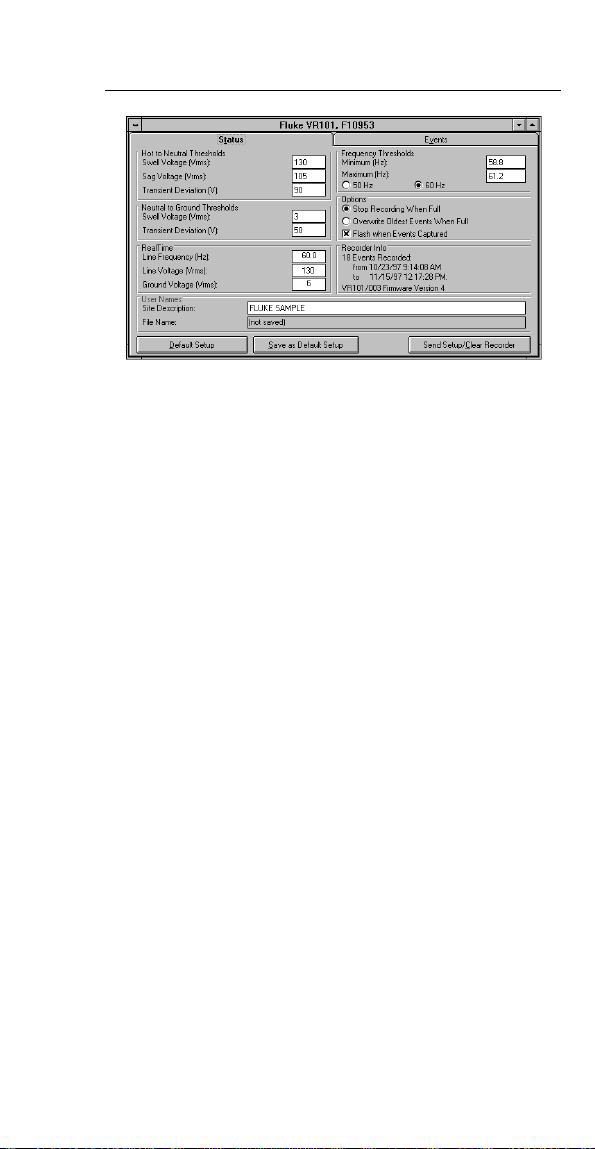

Setting Thresholds on the Status Tab...................13

Viewing the Default Threshold Settings................15

Choosing and Saving New Default Threshold

Settings.................................................................15

Choosing Operating Options.................................15

Describing the Site ................................................16

Viewing Realtime Readings of the Recorder........16

Viewing Recorder Information...............................16

Sending the Setup to the Recorder.......................17

iii

Page 6

VR101S

Users Manual

Chapter 3

Retrieving and Saving Events......................................19

Retrieving Events from a Recorder...........................19

Saving Events...........................................................20

Opening an Already Saved File.............................21

Chapter 4

Displaying and Printing Events.....................................23

Displaying Events.....................................................23

Viewing the Events Tab.........................................23

Viewing Events as a Bar Graph ............................29

(Quick Summary)...................................................29

Viewing a Single Transient as a Graph.................30

Viewing Events as an Event Distribution Graph....31

Changing Graph Styles.........................................33

Printing Events.......................................................... 34

Chapter 5

Troubleshooting............................................................35

Optical Interface Cable.............................................35

Printers .....................................................................37

Voltage Event Recorder............................................37

Technical Support.....................................................38

Chapter 6

Power Quality Issues....................................................39

Power Quality Background .......................................39

Why Is It Such a Concern?....................................39

Common Questions about Power Quality.............40

Power Quality Definitions and Standards .................41

Power Line Disturbance Definitions ......................41

How Bad is Bad?...................................................42

The CBEMA Curve................................................42

Causes and Effects of Poor Power Quality...............43

Causes of Poor Power Quality..............................43

How Power Line Disturbances Affect Your

Equipment.............................................................44

Performing a Power Quality Study............................45

Developing a Power Quality Monitoring Program..45

Now That I Have This Information, What Do I Do

with It?...................................................................48

iv

Page 7

Chapter 7

VR101 Specifications...................................................51

Equipment Ratings...................................................51

Sag, Swell & Outage Measurement..........................54

Transient Measurement............................................55

Frequency Measurement..........................................55

Time Measurement...................................................56

Approvals..................................................................57

v

Page 8

VR101S

Users Manual

vi

Page 9

Chapter 1

Getting Started

Introduction

Features of the Voltage Event Recorder System

The VR101 Voltage Event Recorder, hereafter referred

to as the recorder, records sags, swells, transients,

outages, and frequency variations on the power line. It

is self powered and easy to use—parameters can be set

by a few easy keyst rokes from your PC equipped with

EventView Software

The recorder can retain 4,000 events. The existence of

recorded events is indicated by the recorder’s flashing

light.

Communication between a PC and the recorder is

carried via the Optical Interface Cable. By using this

optical data transfer, the PC remains electrically

isolated.

TM

.

1

Page 10

VR101S

Users Manual

A Quick Overview

The following steps are discussed in detail throughout

this manual:

1. Read the next five pages on safety and battery

care.

2. Install EventView Software on your PC.

3. Plug the VR101 into the closest wall socket.

4. Connect your computer to the VR101 with the

optical cable.

5. Use EventView to adjust the settings on your

VR101.

6. Disconnect the optical cable and move the VR101

to the receptacle you want to monitor.

7. After monitoring, use EventView to download the

results.

2

Page 11

Getting Started

Introduction

Safety

Attention

Carefully read the following safety

information before using the recorder.

Safety Precautions

Specific warning and caution statements, where they

apply, will be found throughout the manual.

A Caution identifies conditions and actions that

may damage the recorder.

A Warning identifies conditions and actions that

pose hazard(s) to the user.

Symbols used on the VR101 and in this manual are

explained in the next table.

1

See explanation in

manual

Recycling

information

Disposal

information

Double Insulation

(Protection Class)

Warning

The recorder is designed and certified to

work only on single-phase systems.

Attempting to modify the recorder or

operating it improperly may cause circuit

damage which can ultimately result in

property damage, personal injury, or death.

Plugging in a recorder

The recorder is designed to plug into a standard

convenience outlet. As a safety precaution, the unit

should be in a place where it can be easily unplugged.

This will also make it accessible for data retrieval. The

recorder does not require a protective earth connection

for safety since there are no exposed metal parts. The

earth conductor is used to measure neutral to ground

3

Page 12

VR101S

Users Manual

(N-G) events and to measure the recorder’s polarity,

indicated by the LED. Also see below under “Using an

Ungrounded Outlet”. The ground prong may be

electrically disconnected (as long as it is not exposed).

The recorder does not need special ventilation,

however, its ambient temperature should not be allowed

to rise above the operating limit. (See Chapter 7 “VR101

Specifications”.

Using an Ungrounded Outlet

Plugging the recorder into an ungrounded outlet has the

following consequences:

1. Polarity indication by the LED is not valid.

2. Neutral to ground events captured are not valid.

3. If the recorder is plugged in improperly (improper

polarity), hot to neutral events captured are shifted

180 degrees and indicated with the opposite

polarity.

Polarity Indication

In some countries outlets are not polarized. This means

that the recorder can be plugged in improperly (hot and

neutral swapped). Improper polarity connection will not

cause damage to the recorder but events will not be

correctly recorded and the results may cause

misinterpretation.

Note 1:

When plugging in the recorder improperly

(improper polarity connection), the LED will

blink quickly during 8 to 16 seconds (also see

Note 2). When plugging in correctly, the LED

lights steadily during 8 to 16 seconds. Polarity

indication starts from 0 to 8 seconds after

plugging in.

Note 2:

The LED on the recorder also blinks when an

event is captured, but then it blinks slowly.

4

Page 13

Getting Started

Introduction

1

Electrical Immunity

The recorder’s internal circuitry is solid-state with built-in

EMI and RFI protection to ensure reliable readings. The

recorder will withstand exposure to a 3,400V transient

for a duration of 20 ms.

Safety Inspection

We recommend that you inspect the recorder

periodically for visible damage. To ensure that it

operates safely, inspect for missing labels, cracks in the

case, or bent and/or broken blades.

Battery Care

The recorder contains a lithium battery which will, under

normal circumstances, allow it to operate for 7 years.

Exposing the recorder to extreme temperatures for

extended periods of time may reduce battery life by as

much as 50%. The recorder is designed for INDOOR

USE. It should not be exposed to direct sunlight.

Do not store the recorder with the event indicator

flashing. This consumes battery power and reduces

battery life. (See page 17 for information on how to

clear the recorder’s events from memory.)

To extend battery life, keep the recorder plugged into a

standard convenience outlet (even when not in use).

This conserves battery power especially when

frequently downloading stored events.

Warning

Battery poses fire, explosion and severe

burn hazard. Do not recharge, disassemble,

heat above 212 °F (100 °C), incinerate, or

expose contents to water

5

Page 14

VR101S

Users Manual

Note:

The VR101 contains a lithium battery. Do not

dispose of the VR101 with other solid waste.

The VR101 should be disposed of by a

qualified recycler or hazardous materials

handler. Contact your authorized FLUKE

Service Center for recycling information.

Maintenance

The recorder is a maintenance-free product. However, it

is recommended that it be kept clean to allow for easy

visual inspections. To clean the recorder, unplug it from

the outlet and wipe it with a dry, clean cloth.

Product Service

The recorder has no user-serviceable parts inside. The

fuse and battery inside the recorder are NOT

REPLACEABLE. Opening the case, or attempting to do

so, will void the warranty and safety certification.

The Optical Interface Cable is the only replacement part

in the VR101S package.

If you require service, please contact your local dealer

or an authorized Fluke service center. (See under

“Service Centers” in the front of this manual.)

6

Page 15

Getting Started

What You Need to Run Fluke EventView Software

What You Need to Run Fluke

EventView Software

In order to run Fluke EventViewTM software, your

computer system must include:

• IBM PC or 100% compatible, with Windows 3.1 or

Windows 95/98/NT installed and operating

• At least one free serial port, 9-pin

• A pointing device (recommended)

• 2 MB hard drive space

• 4 MB RAM (8 MB for Windows 95/98/NT)

Optional Equipment:

• A printer port with a printer supported by Microsoft

Windows

What’s in the VR101S Package

The VR101S package contains the following items:

• VR101/xxx Voltage Event Recorder unit.

• EventViewTM software and Users Manual, located

on CD

• Optical Interface Cable

• Product Registration Card + return envelope

EventView software enables you to set up the recorder,

download all the stored events and display the stored

information.

1

7

Page 16

VR101S

Users Manual

Installing EventView software

1. Before installing EventView software, close other

applications, or restart Windows.

2. For Windows 3.1, open Program Manager, select

File from the menu bar and choose Run...

Windows 95/98/NT users select Start from the

Taskbar on the desktop and choose Run...

3. Insert EventView Disk 1 of 2 in your computer’s

disk drive. In the Run dialog box, type a:setup for

drive A and press Enter (the Return key on some

keyboards). If you are using drive B, type b:setup.

4. EventView supports several languages. If one of

these languages has been specified in the

Windows control panel, EventView uses the same

language. If any other language is specified in

Windows, the EventView setup procedure displays

a language selection menu. Select the desired

language.

During the following steps, change diskette as

indicated.

“Welcome!”

5. A

click Next if you want to start installing the

EventView Software on your hard drive.

6. An information screen appears to inform you about

some important items for installation and use of

EventView Software. Read this carefully. Click

Next.

7. Select the Destination Directory for the EventView

Software. If you want to install the software in the

default directory, click Next. If you prefer another

directory, click Browse to select this directory, then

click Next.

8. A dialog box appears asking if you would like to

back up replaced files. It is a good idea to do so

(select “Yes”.) Click Next.

8

dialog box will appear asking you to

Page 17

Getting Started

Installing EventView software

9. Specify a backup directory or just click Next to

select the default directory. (Note: The backup

directory will be empty if no files are replaced.)

10. Windows 95/98/NT users click Next to begin

installation.

For Windows 3.1 users a dialog box appears to

select or to create the Windows Program Group to

add the EventView Software to. Click Next to

create the Fluke PQ Tools program group. (PQ

stands for Power Quality.)

Click Next to begin installation.

11. Finally click Finish to exit EventView Software

installation.

1

9

Page 18

VR101S

Users Manual

Setting the Time and Date

It is very important th at your PC system’s time and date

are correct before running the EventView program.

When retrieving data from the recorder, the EventView

program uses the PC’s internal clock for time and date

reference. (See the following note.)

• With Windows running, set the time from the

Control Panel in Program Manager.

• Windows 95/98/NT users open the Control Panel

from the Taskbar by choosing Start, Settings, and

Control Panel.

Information about setting the time can be found in the

Windows User’s Guide.

Note

If your PC’s internal clock switched from

summer time to winter time or vice versa

during the period that the VR101 is capturing

events, you should correct the Start Time and

the End time (if date and time indicated) of the

events that occurred up to the time change by

adding or subtracting one hour. (See “Viewing

the Events Tab on page 23.

10

Page 19

Chapter 2

Setting Up the VR101

Introduction

This chapter explains how to use EventView

to program the internal settings of the recorder.

Connecting the Optical Interface Cable

The EventView program communicates with the

recorder via the Optical Interface Cable.

• Plug this cable into an available 9-pin COM port in

your computer.

If your computer has only a 25-pin COM port, plug a

9- to 25-pin adapter (not included with your interface

package) into your computer, and plug the interface

cable into the adapter.

TM

software

Starting EventView

• Windows 3.1 users double-click the Fluke

EventView program icon EV101 in the Fluke PQ

Tools group window.

(Double-click the Update Readme i con to read the latest

information about the VR101S. )

11

Page 20

VR101S

Users Manual

• Windows 95/98/NT users click Start on the

Taskbar, and choose Programs, Fluke PQ Tools

and then EventView.

(Select Update Readme to read the latest information

about the VR101S.)

The main FLUKE EVENTVIEW window will open.

Selecting a COM Port

• With the main FLUKE EVENTVIEW window open,

from the Communicate menu choose the COM port

that the Optical Interface Cable is connected to.

The Communicate menu displays the available COM

ports on your computer.

When you have chosen the correct port, the optical

wand and the red scanning button on the ToolBar will

start to flash. When the wand is flashing it is ready to

communicate with the recorder. If the wand doesn’t

flash, please refer to Chapter 5 “Troubleshooting”.

Opening the Site Report Window

1. With the main VR101 window open, the Optical

Interface Cable connected to a COM port, and the

red scan button flashing, point the optical wand at

the optical port of the recorder (from 0.25” away or

closer) or plug the wand directly into the recorder’s

recessed optical port.

The Site Report Window will open.

12

Page 21

Setting Up the VR101

Starting EventView

2

The Site Report window displays the recorder’s

settings and its recorded events.

If the VR101 is not plugged into a power source, an

information box will appear saying “No voltage

detected on recorder. Realtime halted to conserve

power.” Click OK to continue.

2. Remove the optical wand from the recorder.

Setting Thresholds on the Status Tab

The thresholds are in three categories on the Status

tab: Hot to Neutral, Neutral to Ground, and Frequency.

To change any threshold setting, double-click the

setting and then type in the new value.

Voltage Transients

Transients are fast voltage fluctuations (sometimes

called spikes). They can be positive or negative and can

occur on the hot-neutral line or on the neutral-ground

line. The voltage potential of a transient can be quite

large; hundreds of volts is not uncommon. Transients

typically have a duration far below one cycle and can be

detected down to 1 µs.

The recorder will record as a transient any voltage

deviation of less than one cycle that exceeds the

transient threshold for more than 1 µs.

Voltage Swells

Swells are increases in voltage that last at least ½

cycle. Swells can occur on the hot- neutral lines or on

the neutral-ground lines. Typically, swells are in the

order of tens of volts and last from several cycles to

several seconds.

13

Page 22

VR101S

Users Manual

If the voltage exceeds the swell voltage threshold for

longer than one cycle, a swell e vent will be recorded.

Voltage Sags

Sags are decreases in line voltage lasting for at least ½

cycle. Sags are only measured on the hot-neutral lines.

Typically, a sag will be a few volts or tens of volts below

normal.

If the voltage drops below the sag threshold a sag event

will be recorded. If it drops to below 70Vrms the event

will be recorded as an outage.

Line Frequency Variations

Frequency variations are changes in frequency above

or below the nominal frequency (60Hz in North America,

50Hz in Europe, for example). Variations in frequency

are typical ly a few cycles and can be from seconds to

minutes in duration.

If the frequency drops below the minimum threshold a

low frequency event will be recorded; if it exceeds the

maximum threshold a high frequency event will be

recorded.

For a 120V recorder version the frequency will default to

60Hz.

14

Page 23

Setting Up the VR101

Starting EventView

2

Viewing the Default Threshold Settings

The EventView program has factory-installed default

threshold settings. These settings are adequate for

most applications.

• To see the default threshold settings on the Status

tab, click the Default Setup button.

If you are concerned that some of your electronic

equipment may have particular power quality

requirements, we suggest that you call the equipment

manufacturer for that information. You may discover

that you should alter some of the recorder’s threshold

settings in order to monitor power quality more closely.

Choosing and Saving New Default Threshold Settings

If the factory-installed default threshold settings of the

recorder do not suit your application you may choose

new settings and designate them as the default settings.

1. Make your changes to the settings.

2. Click the Save as Default Setup button.

3. In the dialog box that appears, click OK to confirm

that the default settings will be changed.

These settings are now saved in your computer and

can be sent to any recorder that you communicate

with by clicking Send Setup/Clear Recorder.

Choosing Operating Options

Stop Recording When Full or Overwrite Oldest Events When Full

A recorder can store 4,000 events. You can program it

to either stop recording events or to continue recording

when it is full and record over the oldest events in its

memory.

• Choose either Stop Recording When Full or

Overwrite Oldest Events When Full.

Flash When Data Available

• Check Flash When Data Available if you want the

recorder to blink when it has stored one or more

events (default condition).

15

Page 24

VR101S

Users Manual

Describing the Site

Site Description

the location of the recorder, for instance, if you need to

distinguish between the locations of three recorders in

one office. You may describe the site in your own words

using up to 30 characters. The site description will also

appear as the title of a Quick Summary, a Transient

Graph, and an Event Distribution Graph.

Viewing Realtime Readings of the Recorder

gives you the opportunity of specifying

After establishing communication, leave the wand in the

optical port while the recorder is plugged into an outlet

to see, in real time:

• Line voltage readings (the voltage between the hot

and neutral lines)

• Ground voltage readings (the voltage between the

neutral and ground lines),

• Line frequency readings (the frequency between

the hot and neutral lines)

These readings appear under the

You can turn realtime reading off and on by clicking on

the red Scan button.

RealTime

heading.

Note:

The recorder can NOT record events during

realtime reading. Click the red scan button to

stop realtime reading and to resume event

recording.

Note that if the recorder is not plugged into an outlet

while the wand is in the optical port, real time reading

will stop after a few seconds to conserve power.

Viewing Recorder Information

Under the heading,

see the number of events saved in the recorder and the

time span over which the data was collected.

If no events have been gathered, the words

Stored

will be displayed.

16

Recorder Info

, you will be able to

No Events

Page 25

Setting Up the VR101

Starting EventView

2

Sending the Setup to the Recorder

and as a consequence,

Clearing all events from the recorder

1. Place the wand into the optical port of the recorder.

2. If you have changed threshold settings or you are

leaving the settings the way they are, click Send

Setup/Clear Recorder button.

If you are changing the recorder’s settings to the

default settings, click Default Setup and then click

Send Setup/Clear Logger button.

3. In the dialog box that appears, click Yes to confirm

that all previous events will be cleared from the

recorder.

The new settings will be saved in the recorder.

4. Remove the optical wand from the recorder.

The recorder will begin monitoring as soon as it is

plugged into a standard convenience outlet.

Note:

Plugging in and unplugging the recorder can

cause invalid events being captured.

Starting Event Recording

The VR101 does not start recording until the wand has

been removed from the recorder’s optical port. After

approximately 16 seconds, the VR101 will begin to

record voltage events. Recording can also be initiated

by deactivating the red Scan button on the EventView

toolbar. You may then leave the wand in the recorder’s

optical port.

17

Page 26

VR101S

Users Manual

18

Page 27

Chapter 3

Retrieving and

Saving Events

Retrieving Events from a Recorder

1. With the Main VR101 window open, and with the

Optical Interface Cable connected to your

computer, ensure that the wand is blinking. If it is

not, choose Scan from the Communicate menu

(or, on the ToolBar, click the red scan button so

that it flashes).

2. Place the wand into the recorder’s optical port. The

Site Report window will open at the Status tab.

3. To download the recorder’s stored events to your

computer, click the Events tab.

Downloading will start. During download the Cancel

Download button (to the right of the Scan button)

will become activated enabling you to stop the

download.

4. When all events have been copied to your

computer, you may remove the wand from the

recorder.

19

Page 28

VR101S

Users Manual

Saving Events

1. To save the events that you have downloaded

choose Save from the File menu or click the Save

button on the ToolBar.

The Save As dialog box will appear with the current

file name highlighted in the File Name box.

2. You have two save options:

• Save the file with the existing name—this

means that you will overwrite the previous

file of the same name along with all its

data. To do this, click OK and then click

Yes to replace the previous file.

• Save the file with a new name—this

means that you will type a new name for

the file so that the previous file, along with

its name and its data, will still exist. To do

this:

1. Go to "Save File as Type:"

2. Click the scroll bar and select the

desired file type.

3. Once you have selected the file type,

go back up to "File Name:"

4. Change the file extension to match

that of the file type selected in step 2.

20

Page 29

Retrieving and Saving Events

Saving Events

Opening an Already Saved File

1. From the File menu choose Open Site File.

The Open dialog box will appear.

2. Scroll through the list of site files until you find the

file you want.

3. Double-click the selected file (or click it and then

click OK) to open the Site Report window.

The Site report window will open at the Status tab.

3

On the Status tab you will notice that the items that

cannot be changed are displayed dimmed. Only the site

description and the file name can be changed.

21

Page 30

VR101S

Users Manual

22

Page 31

Chapter 4

Displaying and Printing

Events

Displaying Events

EventView software enables you to view events in

different forms:

• The Events tab in the Site Report window lists all

events that the recorder has gathered.

• Sags, swells and transients can be displayed in a

Quick Summary bar graph.

• A single transient can be displayed as a graph.

• An Event Distribution Graph can be displayed.

Viewing the Events Tab

Having downloaded events from the recorder, and with

the Events tab still open, you can view and analyze the

data that the recorder has gathered since it was last

cleared. The recorder can store up to 4,000 events.

Events are displayed in the order of closing (end time).

An event that is closed (ended) most recently is

displayed at the top of the list.

Note

As events can occur simultaneously while their

duration differ, the display order can differ from

the order of their start times. For example,

during a sag event transients can occur.

Though the start time of the sag is earlier than

that of the transients, the sag event will be

displayed later in the list because its end time

is later.

23

Page 32

VR101S

Users Manual

Event # column

The Event # column displays the number of each event.

The most recent events are displayed first. You may

have to scroll down (use the scroll bar on the right of the

window) to view all the events that the recorder has

recorded. The number 0 is given to an

event that is still in progress at the time that the events

were downloaded from the recorder.

Start Time column

open

event—an

The Start Time column displays the time that an event

started. The resolution of the time stamp in a recorder is

eight seconds. Therefore, if a transient occurred once

every second starting at 12:00:00, the first eight

transients would all be reported to have the same time

of 12:00:00. The next eight transients would be reported

as having the same time of 12:00:08. Also, if identical

information was downloaded twice from a recorder, the

two “identical” site reports could show a time difference

of eight seconds.

Event column

The Event column displays the types of events that

occurred.

24

Page 33

Displaying and Printing Events

Displaying Events

4

Transient Events The recorder can detect both

positive and negative transients down to one 1 µs in

duration on either the H-N and N-G circuits. If the

voltage exceeds the transient deviation threshold for

any given half cycle, a transient event will be recorded.

A transient event can include one or more transients

occurring within the same half cycle. The event column

will display the number of transients that the recorder

was able to count.

An example of a transient event can be seen in the

Event tab shown. Event #8 shows a single transient on

the N-G circuit. The polarity for this transient was

positive, the voltage was 414 volts. The transient was

detected at a phase angle of 330 degrees.

Multiple transients can sometimes occur within a ½

cycle. For example, a large single transient followed b y

several cycle s of high frequency ringing.

Since there are an infinite variety of wave shapes that

can be classified as multiple transients, it is impossible

to determine the accuracy of the reported information

under these conditions.

Event #18 shows an example of a multiple transient

event. This event indicates 9 transients that were

detected starting at a phase angle of 271 degrees. The

detected polarity was negative and the voltages of the

transients were measured as 469 volts.

An important point to note about a multiple transient

event such as #18 above, is that the voltage reading in

the Extreme column will be the maximum voltage

(positive or negative) of any transients that occur more

than 100 µs apart. The degree (in the fourth column) will

be the po sition in the cycle of the first transient. The

angle of neutral-ground transients is referenced to the

start of the hot-neutral sine wave.

If a transient is less than 1 µs in length, the recorder will

indicate the magnitude of the transient but will be

unable to determine the polarity. In this case, the

recorder will show the sign of the transient as “+”.

Sag and Swell Events Sag and swell events are

decreases and increases in line voltage that exceed the

thresholds for at least ½ cycle. Swells can o ccur on the

25

Page 34

VR101S

Users Manual

hot-neutral lines or on the neutral-ground lines. Sags

are only measured on the hot-neutral lines.

Outage Events Outage events less than one second

duration are recorded with half cycle resolut ion. Longer

outages are recorded with 8 second resolution.

Sags and outages are events that are closely related as

far as a VER is concerned. If the sag voltage falls below

the minimum operating voltage for longer than one

second, the event will be recorded as an outage. The

VER will go into a low power mode in order to conserve

battery life under these conditions.

During the low power mode operation, the VER will only

check for adequate line voltage every eight seconds.

When the line voltage is restored, normal logging

operation is resumed. This mode switching can present

confusing event data, especially when sags and

outages occur in a sequence.

The following table shows some examples for a 120V

VER. The minimum operating voltage for a 120V VER is

70Vrms and the settings are as follows:

Hot to Neutral Thresholds

Swell Voltage (Vrms): 128

Sag Voltage (Vrms): 105

Transient Deviation (V): 200

Neutral to Ground Thresholds

Swell Voltage (Vrms): 10

Transient Deviation (Vrms): 100

Frequency Thresholds

Maximum (Hz): 61.2

Minimum (Hz): 58.8

Examples 1 to 6 represent events that are recorded due

to line voltage sags of varying voltages and duration.

Examples 7 to 12 show events that are recorded when

sags and outages occur in sequence.

26

Page 35

Displaying and Printing Events

Displaying Events

4

Hot -

Neutral

Voltage Duration

#

1 100V2 cycles 120V

2 40V

3 100V

4 40V

50V

60V

70V

80V

90V

10 100V

11 100V

12 100V

cycles 120V

seconds 120V

seconds 120V

cycles 120V

seconds 120V

seconds 100V

seconds 100V

cycles 100V

seconds 0V

cycles 0V

cycles 40V

Hot Neutral

Voltage Duration VER Data

Outage, 2 cycles

Outage, 2 cycles and

Sag, 2 seconds

Example #10: Since the VER reports the extreme

value of a sag, the event is recorded as an outage

(extreme value of 0V).

High and Low Frequency Events Frequency events

are recorded when the frequency exceeds the

frequency thresholds.

Extreme Column

The Extreme column displays the maximum value

measured during the event.

End Time/Duration/Degree Column

This column displays the duration of an event, or the

time that the event ended, or (in the case of a single

transient) the event’s position on the sine wave (in

degrees).

The way the information is displayed depends on the

length of the event.

• Events of less than one second are displayed in

numbers of cycles.

• Events of one to 119 seconds are displayed in

seconds.

• Events of between two minutes and 24 hours are

displayed in hours, minutes and seconds (for

example, 07:51:24, which means 7 hours, 51

minutes, and 24 seconds).

27

Page 36

VR101S

Users Manual

• Events that last longer than 24 hours display the

end time (date and time).

If an event was still in progress when data was

downloaded from the recorder, the event will be

designated as an

events are assigned the number zero in the Event #

column.

open event

in this column. Open

28

Page 37

Displaying and Printing Events

Displaying Events

Viewing Events as a Bar Graph

(Quick Summary)

Quick Summary displays the number of sag, swell,

transient, outages, and frequency events as bars on a

graph.

1. With the Site Report window open at the Events

tab, choose Quick Summary from the View menu

(or click the Quick Summary button on the

ToolBar).

2. Make your choices from the following options:

All Data or Selected Data To display all sag,

swell, transient, and frequency events, click All

Data. To display a block of events from the Events

tab, select those events by dragging the pointer

through them to highlight them.

Show Hot to Neutral Events Check this box to

display all hot to neutral events.

Show Neutral to Ground Events Check this box

to display all neutral to ground events.

Sort by Date or Sort into Equal Periods If you

want the horizontal axis divided into 24-hour

periods, click Sort by Date. If you want to divide

the horizontal axis into shorter or longer periods,

click Sort into Equal Periods and type the number

of periods you want to display.

3. When you have finished choosing your options,

click OK to close this dialog box and to open the

Quick Summary.

4

29

Page 38

VR101S

Users Manual

The horizontal axis displays time; the vertical axis

displays the number of events that occurred in each

time period. In the bar graph above, the time periods

are sorted by date.

Note that the thickness of a bar and its position in a time

period is irrelevant—the bar only displays the number of

events and the time period they occurred in.

Viewing a Single Transient as a Graph

A single transient event between hot and neutral or

neutral and ground can be displayed as a graph

enabling you to see if the transient is causing zero

crossings. A transient graph is produced using the

amplitude, direction and position (in degrees) of the

event. The graphical representation is not intended to

show what the wave form looks like nor does it show the

duration of the transient.

To graph a transient you must choose an event that

contains only one transient—it is not possible to graph

an event consisting of multiple transients.

1. With the Site Report window open at the Events

tab, double-click the single-transient event you

want to graph.

(There are two other ways of opening a transient

graph: select the single-transient event you want to

graph by clicking it, and then, either choose Single

Transient... from the View menu, or click the View

Single Transient button on the ToolBar.)

30

Page 39

Displaying and Printing Events

Displaying Events

4

2. To open a dialog box of display options, right-click

the mouse with the pointer in the graph. Also see

under Changing Graph Styles” on page 33.

Viewing Events as an Event Distribution Graph

The Event Distribution Graph plots the magnitude of an

event against duration on a logarithmic scale in order to

determine the importance of the data. For example, a

single random event may not be as significant as a

cluster of recurring events. This information can be

interpreted using the CBEMA Curve found in Chapter 6,

Power Quality Issues,

• With the Site Report window open at the Events

tab, choose Event Distribution Graph from the

View menu (or click the Event Distribution button

on the ToolBar).

in this manual.

The Graph Setup dialog box will appear enabling you to

make your display choices. An explanation of these

choices is given under “Viewing Events as a Bar Graph”

on page 29.

31

Page 40

VR101S

Users Manual

• Click OK to close this dialog box and to display the

Event Distribution Graph.

Since the transients have a duration that is unknown,

they are represented as having a width of 10 µs.

32

Page 41

Displaying and Printing Events

Displaying Events

Changing Graph Styles

The Graph Control dialog box contains a number of edit

features that enable you to change the way a graph

appears. These features include naming and placing

titles, using 3D effects, and saving a graph in different

formats.

• Open the Graph Control dialog box by right clicking

anywhere in a graph. For explanations of the

various features click the Help button.

4

33

Page 42

VR101S

Users Manual

Printing Events

Printing Events from the Events Tab

1. With the Events tab displayed, choose Print from

the File menu (or click the print button on the

ToolBar).

2. Choose the option you want from the Print dialog

box (printing all events, printing one or more pages,

or printing a number of events that you selected).

3. Click OK.

Printing a Graph

1. With a Quick Summary, a Transient Graph, or an

Event Distribution Graph open, choose Print from

the File menu (or click the print button on the

ToolBar).

2. Click Setup from the Print dialog box.

3. If you want the horizontal axis longer than the

vertical axis, choose Landscape orientation from

the Print Setup dialog box.

4. Click OK.

5. Choose the options you want from the Print dialog

box and click OK.

If you are printing a Quick Summary or an Event

Distribution Graph with a color printer, EventView

software gives event types different colors so that you

can distinguish between them. If you do not have a

color printer, the software assigns patterns instead of

colors to different event types.

34

Page 43

Chapter 5

Troubleshooting

Optical Interface Cable

Many manufactures of PC software and hardware use

the COM (serial) port(s). It is difficult to predict potential

COM port conflicts. If the Optical Interface Cable’s wand

tip is not flashing, there are a few steps that can be

taken in order to find the source of the problem.

• Make sure that the Optical Interface Cable is

securely plugged in. The Optical Interface Cable

may appear to be properly connected but only be

partially plugged in.

• Try a different serial port. If the PC has more than

one serial port, try another port to see if the Optical

interface flashes.

• Determine if you have any other Windows

programs using the serial port. PC faxing

programs or other programs that use the COM port

can cause conflicts during data transmission. To

verify that no other programs are running and

causing communication problems, shut down your

computer and restart it before you run EventView

software.

• Verify that your serial port settings are correct.

In Windows 3.1 you can use the Microsoft

Diagnostics program,

number of installed serial ports in your PC, and

their settings. These settings should be the same

as those displayed in the advanced section of

“Ports” in the Windows 3.1 Control Panel. Exit

Windows or restart the computer in MS-DOS mode

before running

MSD.EXE

MSD

. If you have an internal

, to find out the

35

Page 44

VR101S

Users Manual

modem, MSD may detect the modem’s serial port.

This serial port cannot be directly used with the

Optical Interface Cable.

Windows 95/98/NT users verify port settings in

Device Manager. Device Manager is found on the

TaskBar by choosing Start, Settings, Control

Panel, System, and Device Manager.

Common Serial Port Settings:

Port I/O Address IRQ

COM1 3F8h 4

COM2 2F8h 3

COM3 3E8h 4

COM4 2E8h 3

• Verify that your serial port is functioning

properly. You can use any standard Windows

communications program to ensure the port is

functioning. Examples of these are

Windows 3.1

HyperTerminal

Terminal

.

or Windows 95/98/NT

ProComm

Exit all programs (including the EventView

program) and connect the Optical Interface Cable

to the port. Run the communications software and

set the local echo to “off” and hardware flow control

to “none”. If you are using HyperTerminal, choose a

direct connection to the port. Open the port with the

communications software. Any alphanumeric

character you type on the keyboard should cause

the optical interface to flash, and the character to

appear on the screen.

If the optical interface does not flash when you

type, disconnect it and use a piece of wire to

connect serial port pins 2 and 3 together. Any

alphanumeric character you type on the keyboard

should appear on the screen. If no characters

appear, the port may be broken or incorrectly

configured. If characters appear, your Optical

Interface Cable may be broken.

If the optical interface flashes when you type, it

should also work with EventView software. Exit the

communications program, and re-start the

,

36

Page 45

Troubleshooting

Printers

EventView program. If you are unable to make the

optical interface flash when running the program,

re-install EventView software.

• Check your mouse driver. Certain older or inferior

drivers for mice, trackballs and laptop “pointing

sticks” are know n to interfere with serial port

operation. If, after disabling your mouse driver, the

optical interface functions normally, try using a

different mouse driver such as Logitech or

Microsoft.

• Try another computer if you have one. An

alternative to serial port troubleshooting is to use a

different computer. Another computer with its serial

ports set up correctly will confirm that there is an

incorrect setup or software/hardware conflict with

the original PC.

Printers

• Verify that the printer is plugged in, turned on, and

has paper.

• Verify that Windows is set up correctly. Windows

uses its own printer drivers. Setup is done through

the Windows Control Panel. If you need help, follow

the instructions in the Windows 3.1 Guide under

Printers/Setup; in Windows 95/98/NT click Help

and choose Troubleshooting Printers.

• Try printing from another program to eliminate the

possibility of a hardware conflict.

5

Voltage Event Recorder

• The voltage readings of the recorder differ on

different meters. A recorder reads voltage in

average RMS. Some manufacturers’ meters may

have a True RMS display.

• Date and/or time are not correct. The recorder

uses the PC’s internal clock to reference the time of

downloaded data. Set the PC’s internal clock to the

current time. The Windows 3.1 User’s Guide, under

System Time and Date, will explain this procedure;

in Windows 95/98/NT click Help, time, and

changing your computer’s time. Make sure that

the time format is either 24-hour or AM/PM, not

both.

37

Page 46

VR101S

Users Manual

• Two recorders have different transient readings

on the same circuit. Locally generated transients

can carry relatively little power. One recorder can

absorb some of the energy leaving less for the next

one to read.

• VER Records long periods of large NG swell.

The VER is plugged into a convenience outlet that

has been wired with the hot and neutral lines

reversed.

• VER does not record any data. The VER does

not record events while communicating. Make sure

that you stop the realtime display. The VER will be

ready to record events in 8-16 seconds.

Technical Support

If you are experiencing problems with your recorder

system, plea se contact your local dealer or an

authorized Fluke service center. (See under “Service

Centers” in the front of this manual.)

38

Page 47

Chapter 6

Power Quality Issues

Power Quality Background

Why Is It Such a Concern?

Many people blame the power utility for degrading

power when, in most cases, the problem is caused by

poor power distribution within a facility. Equipment such

as computers, TVs, phone systems, alarm systems,

process controls and even the heating, ventilation and

air conditioning system in your building use

microprocessor technology to function. As a result, you

must ensure that your electrical environment has good

power to e nsure reliable system operation.

Studies have found that most power line disturbances

are caused by the equipment being operated inside a

building and that few are utility generated. Lightning,

wildlife, and human contact with transmission lines are

the major contributors to power line disturbances on the

distribution grid.

Major causes of power line disturbances in a building

are:

• Overloaded circuits

• Power factor correction capacitors

• Fast switching of large loads

• Incorrect or poor wiring connections

The Effects of Poor Power Quality within Your Organization

Power line disturbances can cause far more trouble

than just equipment damage. By looking at it from a cost

perspective, one can see that there is a far larger loss

from poor power quality.

39

Page 48

VR101S

Users Manual

For example, more than likely your business uses

microprocessor-based systems. If these devices are

continually affected by voltage disturbances, they can

be damaged and cause a shutdown. The downtime will

result in financial losses.

Power quality monitoring should be considered an

integral part of any maintenance program. Continual

monitoring is an easy way to determine whether your

power quality is adequate. It can also help predict your

future power quality requirements.

Common Questions about Power Quality

Why Not Use a Meter and Check?

Determining whether a power quality problem exists is

very difficult with traditional meters and scopes. The

difficulty is that they cannot tell you what has happened

in the past. In addition, power quality problems occur

faster than the blink of an eye. Many power quality

problems result from various types of incompatible

equipment operating simultaneously. Equipment such

as air conditioning units, heavy machinery and office

equipment are the major culprits. Because buildings are

wired with numerous circuits, traditional methods of

pinpointing the source of power conflicts are almost

useless. Data logging can tell you where your problems

occur, at what time, and how often.

Why Not Buy a Protection Device?

Protection devices such as constant voltage

transformers, UPS’s and transient protection devices

may not provide the correct protection for the types of

problems that are occurring on your power line. The

only way to know what type of protection device is

required is to analyze the nature of the power line

disturbances.

For instance, there are many UPS’s at different price

ranges, each claiming to offer some protection. But

some UPS’s cause more problems than they solve.

Outfitting your entire electrical environment with power

quality enhancing devices could cost a large amount of

money not to mention extended downtime. Data logging

your electrical environment before and after choosing a

correction method is the only way to find out whether

you have chosen the best method.

40

Page 49

Power Quality Issues

Power Quality Definitions and Standards

Power Quality Definitions and

6

Standards

Power Line Disturbance Definitions

Disturbance-Free Voltage

Common Power Line Disturbances

Many terms are used to describe power line

disturbances. Below are some graphic examples of

power line disturbances recorded by a recorder followed

by definitions of the terms.

41

Page 50

VR101S

Users Manual

Sag An operating voltage of 90% of nominal volts or

less

Swell More than one cycle above 10% of nominal

Dropout Power loss of 1 ms to 1 s

Outage More than 1 s of power loss

Positive Transient A momentary overvoltage of 4 ms

or less

Negative Transient A momentary undervoltage of 4

ms or less

Frequency Variation ± 1Hz of the fundamental

frequency (50 or 60Hz)

How Bad is Bad?

Manufacturers of electrical equipment may specify

requirements for power quality. The tolerances below

are general and do not apply to all manufacturers of

sensitive electronic equipment. Generally, sensitive

equipment (computers) can operate within the following

voltage tolerances:

Swells

• Up to 10% above nominal continuously

• Up to 30% above nominal for less than 0.5 seconds

Sags

• Down to 10% below nominal continuously

• Down to 30% below nominal for less than 0.5

seconds

• Down to 0 volts for 4 ms (acceptable but not

recommended)

Transients

• Not to exceed ± 150% of sine voltage for more than

0.2 ms

Frequency Variation

• ± 1Hz

The CBEMA Curve

The Computer Business Equipment Manufacturers

Association (CBEMA) has published a susceptibility

graph detailing how various types of power line

disturbances affect sensitive electronic equipment (see

below).

42

Page 51

Power Quality Issues

Causes and Effects of Poor Power Quality

Although this graph does not apply to all equipment, it

does apply to a vast amount of equipment in the

marketplace.

Causes and Effects of Poor Power

Quality

Causes of Poor Power Quality

Swells

• Shutdown of heavily loaded equipment

• Abrupt power restoration

• Utility switching

Sags

• Abrupt increase in load

• Dropouts/Outages

• Lightning

• Outdoor contact with transmission lines

• Ground Faults

• Equipment failures

• Acts of nature

Transients

• Switching loads on and off

• Utility switching

• Lightning

• Normal computer operation

• Fault clearing

• Power factor correction capacitors

6

43

Page 52

VR101S

Users Manual

Frequency Variation

• Major load increases

• Utility switching

How Power Line Disturbances Affect Your

Equipment

Depending on their degree and frequency, power line

disturbances can cause corrupted data or permanent

damage in sensitive electronic equipment. The following

list shows the effects that power line disturbances can

have on various types of sensitive electronic equipment.

Swells

• Discomfort from flickering lights

• Computer damage

• Degradation of power protection equipment

Sags

• Equipment shutdown

• Power-down circuitry in power supply operates

incorrectly

• Computer lock-ups

• Diminished speed of disk drives (data errors)

Dropouts/Outages

• Data loss

• Equipment downtime

• Computer lock-ups

• Clock timing errors

Transients

• Electronics damage (through bypassing protection

circuitry)

• Insulation breakdown in transformers and motors

• Data errors, data loss

Frequency Variation

• Incorrect clock timing

• Writing errors in any electronic writing device

(magnetic tapes, disk drives)

44

Page 53

Power Quality Issues

Performing a Power Quality Study

Performing a Power Quality Study

Developing a Power Quality Monitoring

6

Program

A power quality monitoring program is a simple, useful

process that helps determine the best method for

assessing an electrical environment’s power quality.

Before you monitor power quality, develop a monitoring

plan. the plan should define the duration and location of

your power quality studies. Here are a few basic steps

to developing a power quality study.

Developing a Power

Quality Monitoring Program

Define Location

Network

Server

Tolerance

Setpoint

Oct.Jan. May Dec.Mar. July Nov.Feb. June

Administration

Area

Tolerance

Setpoint

Sample Power Quality Monitoring Program

Production

Area

Tolerance

Setpoint

DurationDurationDuration

45

Page 54

VR101S

Users Manual

Developing a Location Plan

Depending on the size of the organization, number of

departments, and importance of certain locations, note

the priority locations. The location plan may change

throughout the power quality study as clues may direct

you to a possible problem location.

Developing a Tolerance Plan

Thresholds should reflect the equipment being used.

Even a heavy piece of machinery such as a CNC

machine may be considered sensitive since it has

electronic circuits.

The default settings function in EventView software is

adequate for most sensitive loads. Some equipment

may require tighter tolerances. If so, use the tolerances

provided by the manufacturer of the equipment.

Developing the Study Duration Strategy

In order to determine how long to monitor the site,

determine the organization’s workload cycle. A workload

cycle is the duration of production, whether it is a

product or service. A site should be monitored over the

entire workload cycle.

Another consideration is the workload cycle vs. the time

of day, month or season. At 10:00 AM the organization

may be using all of its equipment at once. Air

conditioners tend to operate more often in the summer

months and space heaters tend to operate in the winter

months. This, in conjunction with your organization’s

workload cycle, can cause equipment conflicts

throughout the year. To determine a workload cycle,

answer the questions that are appropriate for your

study.

Manufacturing How long does it take to produce a run

of your product?

Services How often do you provide your service (daily,

seasonally)?

Administration How does your staffing or workload

vary (monthly, seasonally)?

Finalizing the Power Quality Monitoring Plan

The key to finalizing the power quality monitoring plan is

to publish and assign responsibility for it. The power

46

Page 55

Power Quality Issues

Performing a Power Quality Study

quality monitoring program will help make the

organization more productive and will possibly save

money.

Final Note

This is only one strategy that can verify power quality.

Different situations may call for different strategies in

order to investigate and solve power quality concerns.

6

47

Page 56

VR101S

Users Manual

Now That I Have This Information, What Do I

Do with It?

There are two ways to solve most power line

disturbances: either rewire the electrical system to

separate the sensitive loads from the problem

branches, or place a number of UPS’s or other

protection devices in mission critical areas. The problem

with using a UPS is it may introduce more disturbances

downstrea m of the electrical system as it may use a

switch mode power supply. A UPS is only a temporary

solution. The real problem is probably located

somewhere in your electrical distri bution system. Poor

wiring, poor connections, poor load distribution or

improper grounding may be the problem.

When trying to solve power line disturbances, consider

the following:

• The power requirements of the sensitive electronic

equipment

• The severity of the problem

• The effectiveness of each possible type of power

conditioner

• the performance/price relationship

Repetitive / Cycling Events

These types of events are usually caused by

incompatible loads on a circuit. HVAC systems, laser

printers, and large motors may cause conflicts when

they cycle. These types of conflicts occur because the

building’s electrical demand has increased, and there is

no one responsible for monitoring the load on the

system until there is a problem. Moving sensi tive loads

to a separate circuit may solve this problem.

Unrepetitive / Isolated Events

These types of disturbances are usually caused by the

location of the organization. If you are in an area where

there is lightning, high winds, or if the equipment is

being used only occasionally, simple power line

conditioners and filters may help to protect most of the

equipment. Many power line disturbances are easy and

inexpensive to prevent (depending on their frequency

and magnitude).

48

Page 57

Power Quality Issues

Performing a Power Quality Study

The following power conditioning suggestion chart is

useful for choosing an adequate protection device for

unrepetitive power line disturbances.

6

Transient/

Swell

Protector

Transients X* X X

Swells X* X X

Sags X

Outages X

* Used only when transients and s wel l s are moderate in

quantity or else damage may occur to the power protection

device.

When considering a protection device, make sure that it

covers the entire operating range. It is a waste of money

buying a protection device rated to remove transients of

up to 1000 volts if you have recorded transients of more

than this.

The difference between power line filters and protectors

is that filters can catch fast transients of high

magnitudes. Filters tend to be more expensive than

protectors.

The information you receive from your recorder will

enable you to make an informed decisions about

protection devices.

Please note that this appendix is not a comprehensive

study of power quality, nor does it attempt to provide all

solutions to power quality problems.

Power Line

Filter

Uninterruptible

Power Supply

Power quality is a complex issue. It may be necessary

to make additional measurements such as: line current

levels, harmonic content, and distortion using other

power quality diagnostic equipment.

49

Page 58

VR101S

Users Manual

50

Page 59

Chapter 7

VR101 Specifications

The following specifications are valid only when the

Voltage Event Recorder is plugged into a grounded

standard convenience outlet and when the LED

indicates correct polarity.

Specifications subject to change without notice.

Equipment Ratings

Model number VR101/xx3

Nominal Supply:

Operating Range:

Operating Frequency:

120V

70 to 140V

50/60Hz

Power:

Model numbers VR101/xx1, /xx4, /xx5, and /xx7

Nominal Supply:

Operating Range:

Operating Frequency:

Power:

2W

240V

140 to 270V

50/60Hz

3W

51

Page 60

VR101S

Users Manual

Plug Configurations

Back view of country versions

52

L = LINE

N = NEUTRAL

E = EARTH

Page 61

VR101 Specifications

Equipment Ratings

7

Memory Size:

Storage Method:

Sampling Method:

Alarm Type:

Polarity Detection

Polarity Indication:

Size:

Weight:

Operating Limits:

Battery:

Expected Battery Life:

Fuse:

: Within 8 s after plugging in.

Red LED lights steadily during 8

32kB, 4000 events

First-in First-out, or Fill-then-

stop

Continuous (half cycle

integrated)

Optical; red LED slowly blinks

when there are events stored in

memory.

to 16 seconds if polarity is OK.

Red LED quickly blinks during 8

to 16 seconds if improper

polarity.

85mm x 68mm x 35mm

(3.35 in x 2.65 in x 1.35 in)

120g (4 oz)

-40 to 160 °F (-40 to 70 °C)

(excluding Optical Interface

Cable)

0 to 95% RH (non-condensing)

15,000 feet (4.57 km) altitude.

3.6V Lithium (non-replaceable)

7 years (provided that maximum

battery care is taken, see under

“Battery Care” on page 5)

1/16A Fast-blow (non-

replaceable)

53

Page 62

VR101S

Users Manual

Sag, Swell & Outage Measurement

Hot to Neutral

Model number VR101/xx3

Range:

Accuracy:

Resolution:

Model numbers VR101/xx1, /xx4, /xx5, and /xx7

Range:

Accuracy:

Resolution:

Neutral to ground

Model number VR101/xx3

Range:

0 to 200Vrms

±2Vrms*

1Vrms

0 to 270Vrms

±4Vrms**

2Vrms

3 to 150Vrms

Accuracy:

Resolution:

Model numbers VR101/xx1, /xx4, /xx5, and /xx7

Range:

Accuracy:

Resolution:

* sags less than 70V for > 1s will be report ed as 0V

** sags less than 140V for > 1s will be reported as 0V

±2Vrms

1Vrms

3 to 150Vrms

±2Vrms

1Vrms

54

Page 63

VR101 Specifications

Transient Measurement

Transient Measurement

Range

Hot to Neutral:

100 to 2500Vpeak

7

Neutral to Ground:

Accuracy:

Resolution:

Width Detection:

Phase Angle

Range: 20° to 180°, 200° to 360°

Accuracy: ±1°

Resolution: 1°

50 to 2500Vpeak

±10% of reading + 10V

10V

1 µs minimum

Frequency Measurement

Range: 45 to 65Hz

Accuracy: ±0.1Hz (3 cycles minimum)

Resolution: 0.1Hz

55

Page 64

VR101S

Users Manual

Time Measurement

Events <1 s(econd)

Accuracy

Hot to Neutral:

±0.5 cycle*

Neutral to Ground:

±1 cycle**

Resolution

Hot to Neutral:

Neutral to Ground:

0.5 cycle

1 cycle

Clock accuracy: ±2 s/day

Timer counter capacity 4.25 year (24 bit counter,

resolution 8 seconds)

* Outages are reported with ½ cycle resolution until the

VER goes into low power mode. A VER will go into the

low power mode after approximately one second of an

outage condition. In low power mode, the resolution

becomes 8 seconds.

Swell, sag, and frequency events have ½ cycle

resolution up to approximatel y 10 minutes after which

the resolution becomes 8 s ec onds.

** Neutral to Ground swells have 1 cycle resolution up to

approximately 10 minutes after which the resolution

becomes 8 seconds.

56

Page 65

Approvals

Safety:

VR101 Specifications

Approvals

This device is safety approved by CSA

and CSA(NRTL/C) for measurements on

300V CAT III, Pollution Degree 2, double

insulation, per:

UL3111-1 (1994)

IEC1010-1 (1990)

CSA C22.2 No. 1010.1 (1992)

EN61010-1 (1993)

7

Environmental:

EMC:

MIL-T-28800E, Type III, Class 3

FCC rules part 15.

89/336/EEC

Emission: EN50081.1

Immunity: EN50082.2

(IEC1000-4-2, -3, -4, -5)

57

Page 66

VR101S

Users Manual

Declaration of Conformity

for

Fluke VR101

Voltage Event Recorder

Manufacturer

Fluke Industrial B.V.

Lelyweg 1

7602 EA Almelo

The Netherlands

Statement of Conformity

Based on test results using appropriate standards,

the product is in conformity with

Electromagnetic Compatibility Directive 89/336/EEC

Low Voltage Directive 73/23/EEC

Sample tests

Standards used:

EN 61010.1 (1993)

Safety Requirements for Electrical Equipment for

Measurement, Control, and Laboratory Use

EN 50081-1 (1992)

Electromagnetic Compatibility.

Generic Emission Standard:

EN55022 and EN60555-2

EN 50082-2 (1992)

Electromagnetic Compatibility.

Generic Immunity Standard:

IEC1000-4 -2, -3, -4, -5

The tests have been performed in a

typical configuration.

This Conformity is indicated by the symbol

i.e. “Conformité européenne”.

58

,

Page 67

-A-

Approvals, 57

-B-

Bar graph, 29

Battery care, 5

-C-

CBEMA Curve, 42

Changing graph styles, 33

COM port

selecting, 12

Index

-D-

Date and Time, setting, 10

Declaration of Conformity, 58

Default threshold settings

changing, 15

viewing, 15

Displaying events, 23

-E-

Electromagnetic Compatibility, 58

Equipment Ratings, 51

Event Distribution Graph, 31

Events

displaying, 23

printing, 34

retrieving, 19

saving, 20

59

Page 68

VR101S

Users Manual

Events tab

End Time/Duration/Degree Column, 27

Event column, 24

Events # column, 24

Extreme column, 27

Start Time column, 24

-F-

Flash When Data Available, 15

Frequency Measurement, 55

Frequency variations, 14, 27

-G-

Graph Control dialog box, 33

-L-

Logger Information, viewing, 16

-O-

Opening a saved file, 21

Optical Interface Cable, connecting, 11

Options, choosing operating .., 15

Outages, 26

Overwrite Oldest Events When Full, 15

-P-

Polarity Indication, 4

Power quality, 39

common questions, 40

definitions and standards, 41

performing a study, 45

Printing events, 34

-Q-

Quick Summary, 29

-R-

Realtime Readings, viewing, 16

Retrieving events from a Voltage Event Recorder, 19

-S-

Safety inspection, 5

Safety Precautions, 3

Safety Requirements, 58

Sags, 14, 25

Saving events, 20

60

Page 69

Index (continued)

Scan button, 12, 19

Sending setup to a Voltage Event Recorder, 17

Single Transient Graph, 30

Site Description, 16

Site Report Window, opening, 12

Software

equipment required, 7

installing, 8

setting the time and date, 10

starting the program, 11

Specifications, 51

Stop Recording When Full, 15

Swell, Sag & Outage Measurement, 54

Swells, 13, 25

-T-

Thresholds, setting, 13

Time and Date, setting, 10

Time Measurement, 56

Transient Measurement, 55

Transients, 13, 25

Troubleshooting

Optical Interface Cable, 35

printers, 37