Page 1

VLI™

Visible Level Interface

Operation & Maintenance Manual

© 1998 - 2007 DH Instruments, a Fluke Company

Page 2

© 1998 - 2007 DH Instruments, a Fluke Company All rights reserved.

Information in this document is subject to change without notice. No part of this document may be reproduced or transmitted in any

form or by any means, electronic or mechanical, for any purpose, without the express written permission of DH Instruments, a

Fluke Company 4765 East Beautiful Lane Phoenix AZ 85044-5318 USA.

DH Instruments makes sincere efforts to the ensure accuracy and quality of its’ published materials; however, no warranty,

expressed or implied, is provided. DH Instruments disclaims any responsibility or liability for any direct or indirect damages

resulting from the use of the information in this manual or products described in it. Mention of any product does not constitute an

endorsement by DH Instruments of that product. This manual was originally composed in English and subsequently translated into

other languages. The fidelity of the translations cannot be guaranteed. In case of conflict between the English version and other

language versions, the English version takes precedence.

DH Instruments, DH, DHI, DH400 and VLI are trademarks, registered and otherwise, of DH Instruments, a Fluke Company.

Windows is a registered trademark of Microsoft Corporation.

070712

550039a

Printed in the USA.

© 1998 - 2007 DH Instruments, a Fluke Company

Page 3

TABLE OF CONTENTS

T

AABBLLEE OOFF

T

TABLE OF CONTENTS ...............................................................I

1. INTRODUCTION ................................................................. 1

1.1 PRODUCT OVERVIEW ...........................................................................................................................1

1.2 OPERATING PRINCIPLE........................................................................................................................1

1.3 COMPONENT LOCATION ......................................................................................................................1

2. INSTALLATION .................................................................. 3

2.1 UNPACKING AND INSPECTION............................................................................................................3

2.2 INITIAL SETUP........................................................................................................................................3

2.3 OPERATION............................................................................................................................................4

2.3.1 INTERFACING TWO LIQUIDS (OIL, WATER, ETC.) ...................................................................................4

2.3.2 INTERFACING A GAS WITH A LIQUID .......................................................................................................4

3. MAINTENANCE .................................................................. 5

ANNEX.................................................................................... 7

C

OONNTTEENNTTS

C

S

Page I © 1998 - 2007 DH Instruments, a Fluke Company

Page 4

VLI™ OPERATION & MAINTENANCE MANUAL

N

N

OOTTEES

S

© 1998 - 2007 DH Instruments, a Fluke Company Page II

Page 5

1. INTRODUCTION

.

11.

I

NNTTRROODDUUCCTTIIOON

I

N

1.1 PRODUCT OVERVIEW

The purpose of the DH Instruments (DHI) Visible level Interface (VLI) P/N 100693 is to interface two

pressure media directly; for example, gas and oil or oil and water. A VLI is often used when the medium

used by a piston gauge is not the same as the medium used by the test. Max working pressure of VLI P/N

100693 is 100 MPa (15 000 psi)

1.2 OPERATING PRINCIPLE

This component interfaces two pressure media in a high pressure chamber. Using two media of different

densities allows a natural separation between the two fluids that can be referenced to an indicating

pointer in the VLI and viewed through a transparent lens.

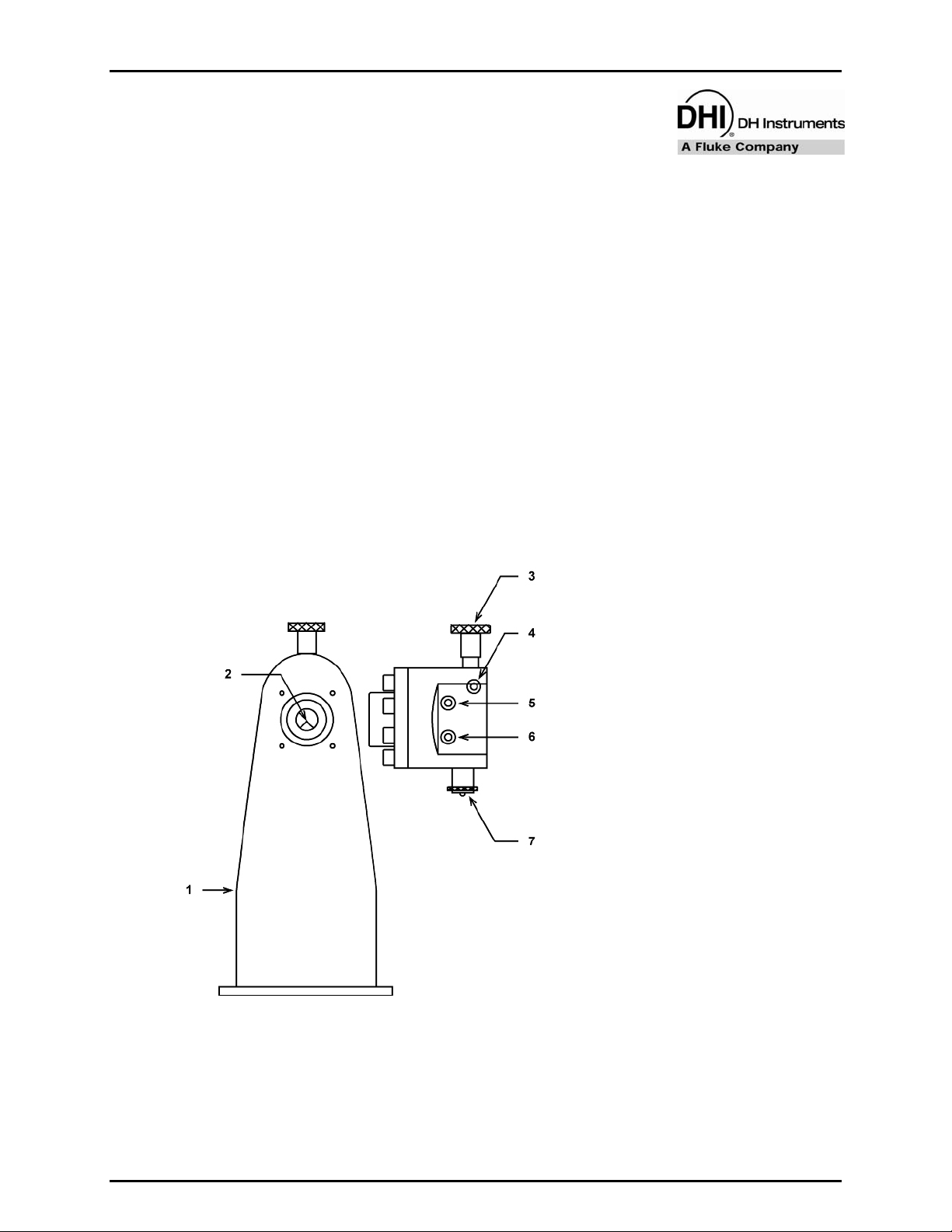

1.3 COMPONENT LOCATION

1. Stand

2. Reference Pointer

3. Upper Pet-cock

4. Overflow Port

5. Upper Pressure Interface

Port

6. Lower Interface Port

7. Drain Cock

Figure 1. VLI Components

Page 1 © 1998 - 2007 DH Instruments, a Fluke Company

Page 6

VLI™ OPERATION & MAINTENANCE MANUAL

N

N

OOTTEES

S

© 1998 - 2007 DH Instruments, a Fluke Company Page 2

Page 7

.

22.

I

NNSSTTAALLLLAATTIIOON

I

N

2.1 UNPACKING AND INSPECTION

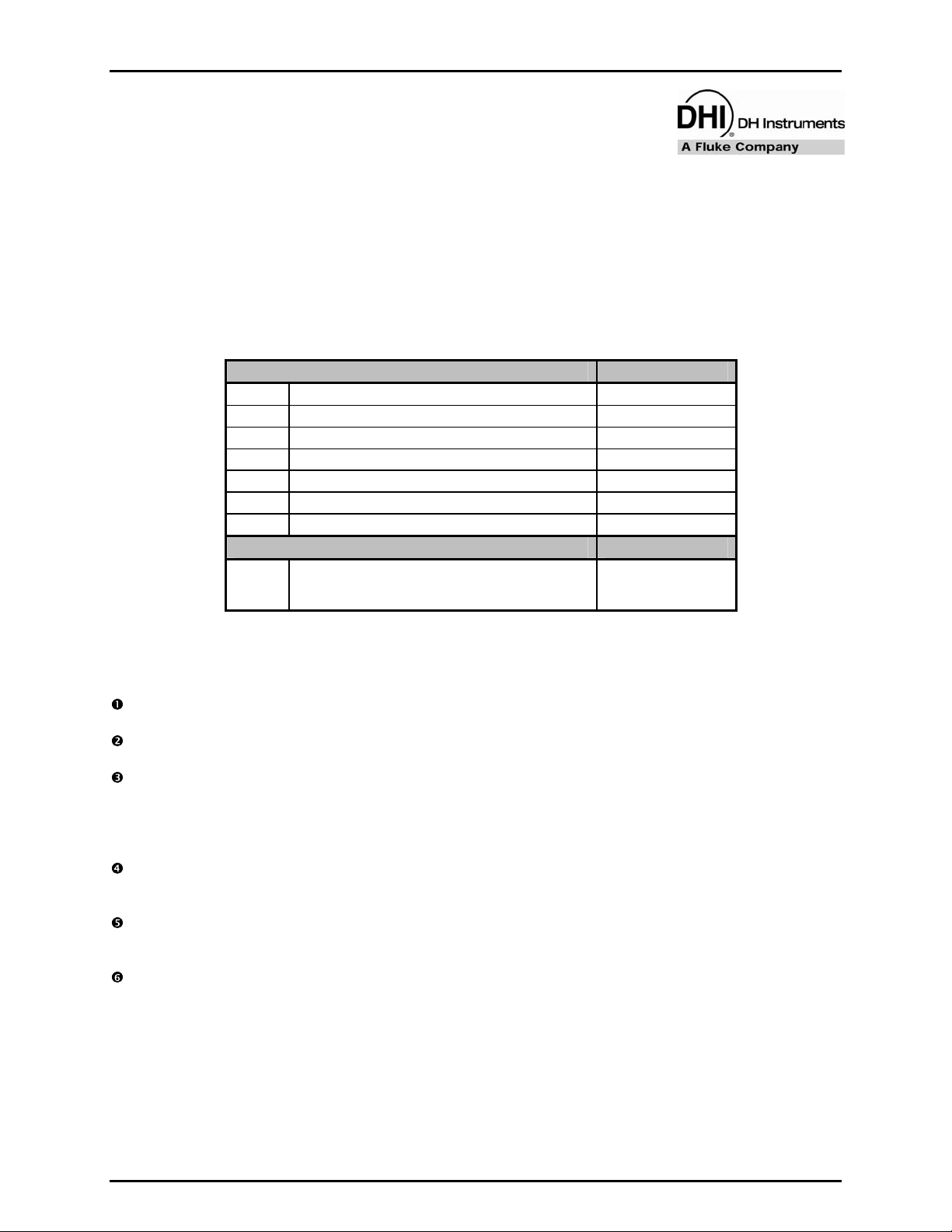

The VLI consists of the following items:

Table 1. VLI Parts List

DESCRIPTION PART #

1 ea. Visible Level Interface (VLI) 100693

6 ea. DH 1500 Gland (1500 bar, metric thread) 100265

4 ea. DH 1500 Collar (1500 bar) 100278

2 ea. DH 1500 Plug (1500 bar) 102053

1 ea O-Ring (spare) 101063

4 ea 4x12 mm Button Head Screw NPN

1 ea. Operation and Maintenance Manual 550039

OPTIONAL PART #

1 ea.

1 ea.

VLI Stand, High

OR

VLI Stand, Low

2. INSTALLATION

100703

100702

2.2 INITIAL SETUP

Place the VLI on the same surface as the piston gauge or other reference to which it is to be connected.

Ensure the VLI and the connecting hardware are clean and free of contamination.

Connect the VLI to the standard using the connecting hardware supplied.

If the piston gauge medium has the greater density, the connection should be made at the lower port

of the VLI. If this is not true, then the connection should be made at the middle port.

Fill the VLI through the connecting hardware to the tip of the interface level indicator with the fluid that

has the highest density.

Remove the upper pet-cock on the VLI. Carefully fill the rest of the VLI with the lighter medium until

the air is completely displaced form the VLI. Install the upper pet-cock and tighten hand tight.

When interfacing a gas medium with a liquid medium the control of pressure must be performed on

the gas side. A variable volume in the hydraulic side is necessary to adjust the change in the

interface level as pressures and temperatures change.

Page 3 © 1998 - 2007 DH Instruments, a Fluke Company

Page 8

2.3 OPERATION

2.3.1 INTERFACING TWO LIQUIDS (OIL, WATER, ETC.)

Pressures can be generated from either side, or on both sides. The interface reference level

can then be changed by adjusting the volume on either side. When interfacing two liquids it

is preferable if they are easily identifiable. If both liquids are the same color, identification of

the interface level may be difficult.

2.3.2 INTERFACING A GAS WITH A LIQUID

It would not be possible to generate pressure by decreasing the volume in the hydraulic

pressure circuit. Pressure is increased through the gas pressure circuit. The hydraulic circuit

volume can be adjusted to fine tune the interface reference level. Again, unless the fluid

temperature or the volumes change, the level will stay the same.

Decreasing pressure is achieved by releasing gas pressure through the gas pressure circuit.

Never open a hydraulic exhaust to release pressure when using a VLI with gas. Equipment

failure and personal injury may occur.

VLI™ OPERATION & MAINTENANCE MANUAL

An additional caution must be observed when interfacing a gas with a liquid in the VLI. This

is due to the fact that once a pressure is reached, there exists a possibility that some of the

gas will be dissolved into the liquid. This condition could lead to outgassing (rapid boiling)

when returning to zero.

To prevent boiling liquid into the gas or gas into the liquid, decrease pressures slowly to

approximately 200 psi (1.4 MPa). Hold that pressure until outgassing has apparently stopped

and then decrease to zero.

© 1998 - 2007 DH Instruments, a Fluke Company Page 4

Page 9

3. MAINTENANCE

.

33.

No special maintenance requirements are necessary for the VLI. Attention to cleanliness in the system is

the only caution.

M

AAIINNTTEENNAANNCCE

M

E

Page 5 © 1998 - 2007 DH Instruments, a Fluke Company

Page 10

VLI™ OPERATION & MAINTENANCE MANUAL

N

N

OOTTEES

S

© 1998 - 2007 DH Instruments, a Fluke Company Page 6

Page 11

ANNEX

A

NNNNEEX

A

X

Page 7 © 1998 - 2007 DH Instruments, a Fluke Company

Page 12

VLI™ OPERATION & MAINTENANCE MANUAL

© 1998 - 2007 DH Instruments, a Fluke Company Page 8

Loading...

Loading...